Mechanism of Particle Agglomeration for Single and Multi-Nozzle Atomization in Spray Drying: A Review

Abstract

:1. Introduction

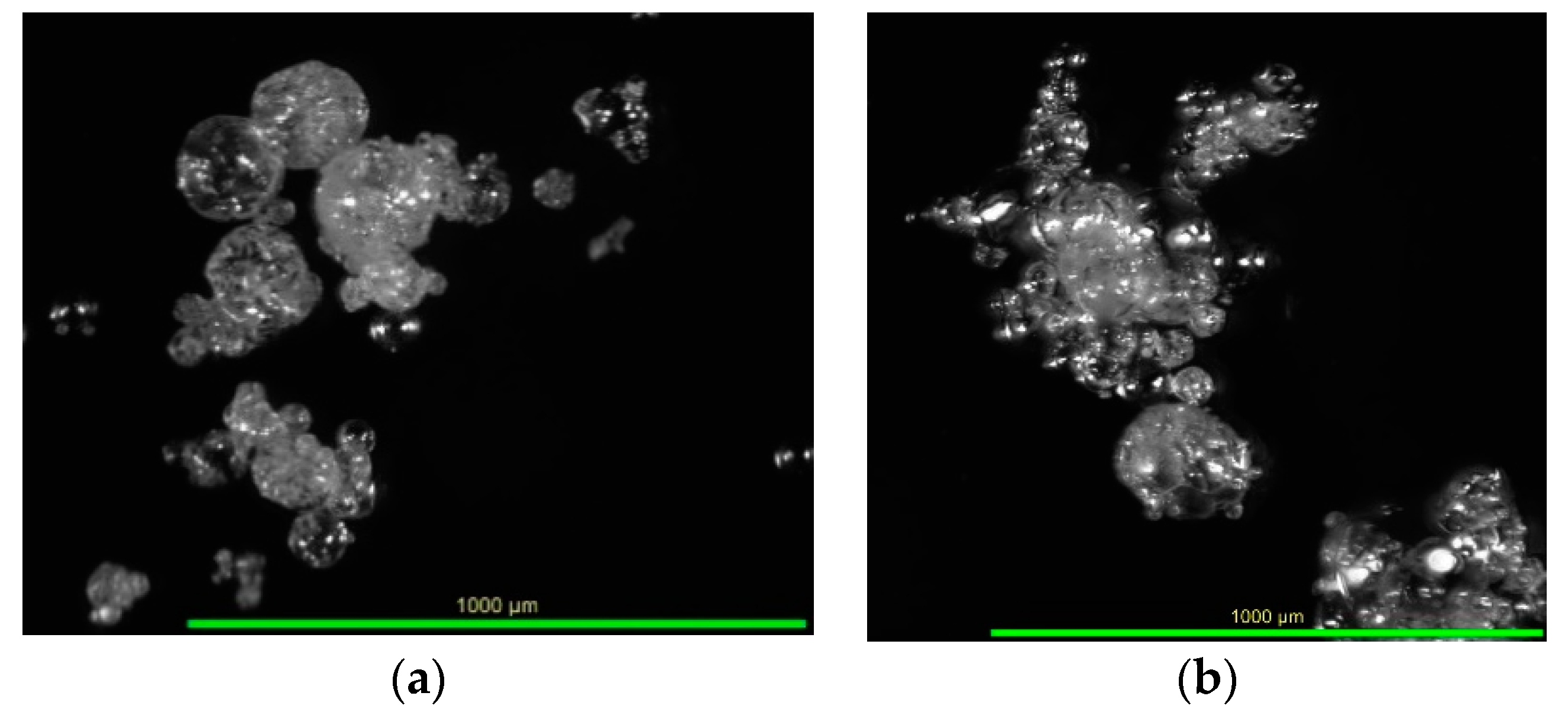

2. Agglomeration in Spray Drying

2.1. Study on Particle Agglomeration Mechanism in Spray Drying

2.2. Particle Agglomeration and Product Quality

3. Effect of Nozzle System Configuration on Particle Agglomeration in Spray Drying

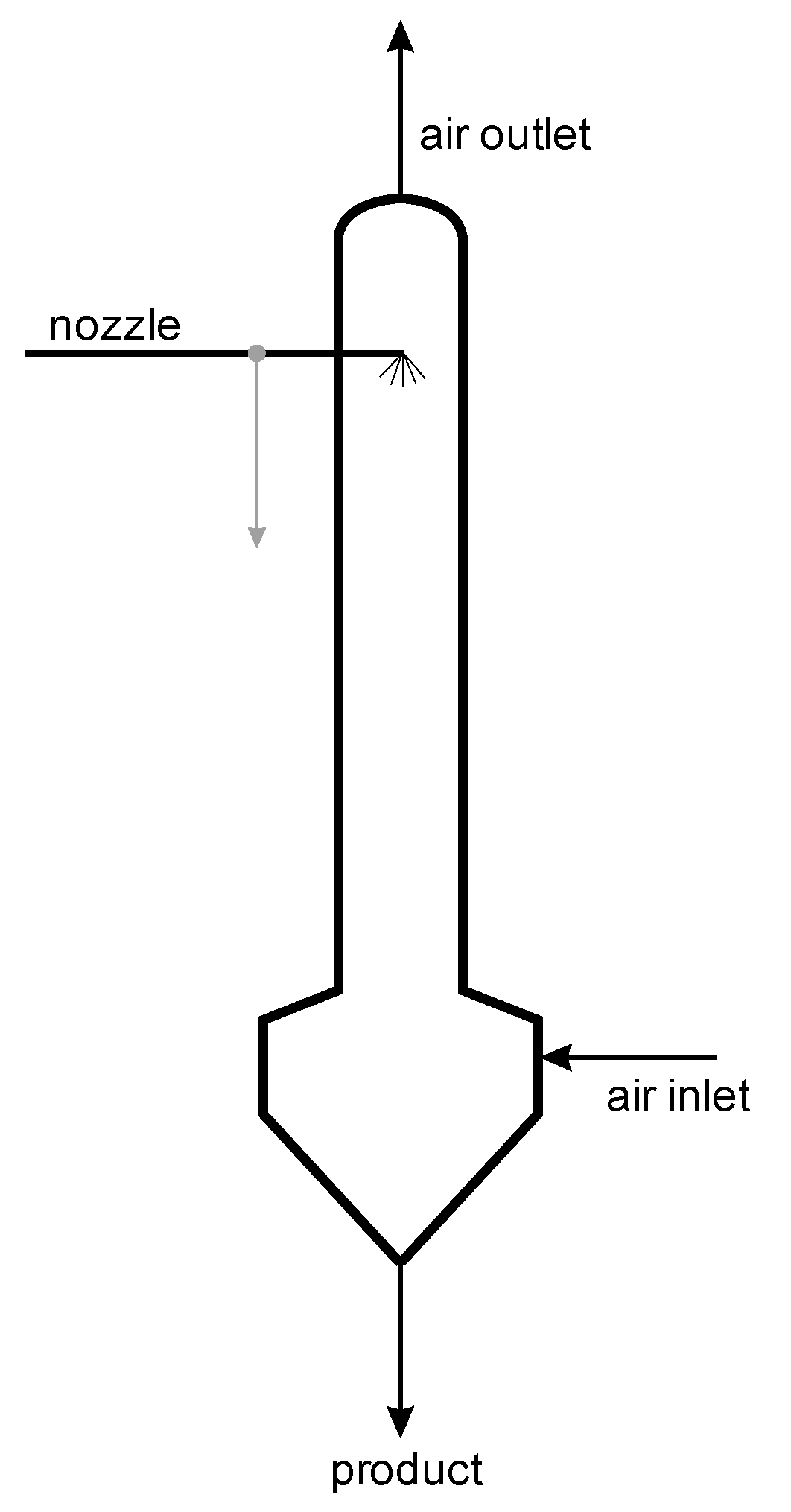

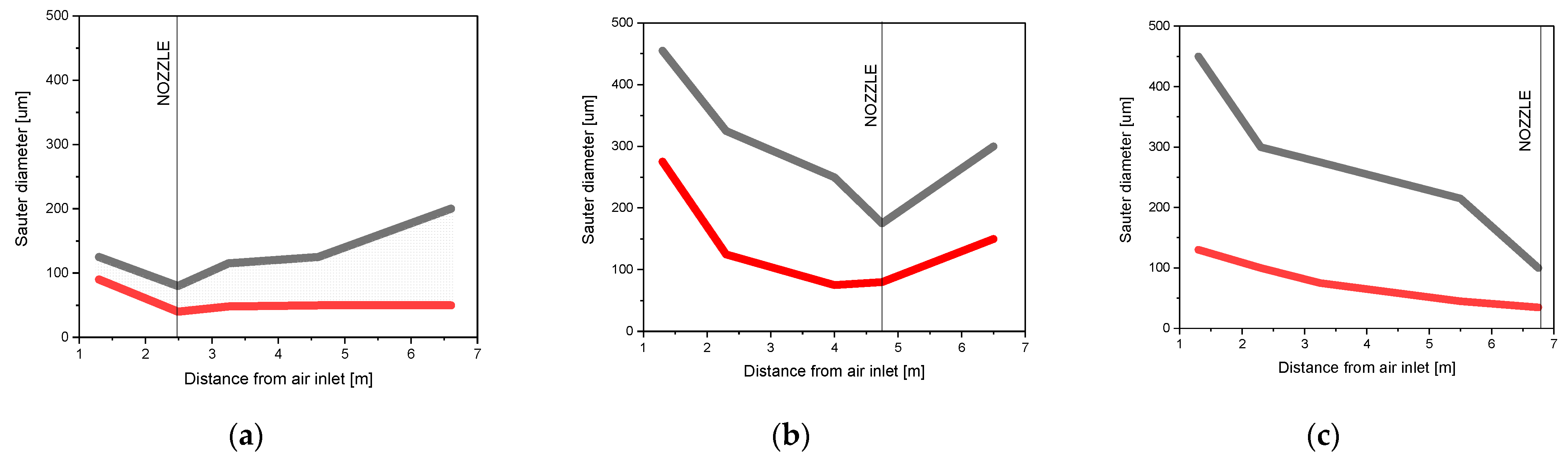

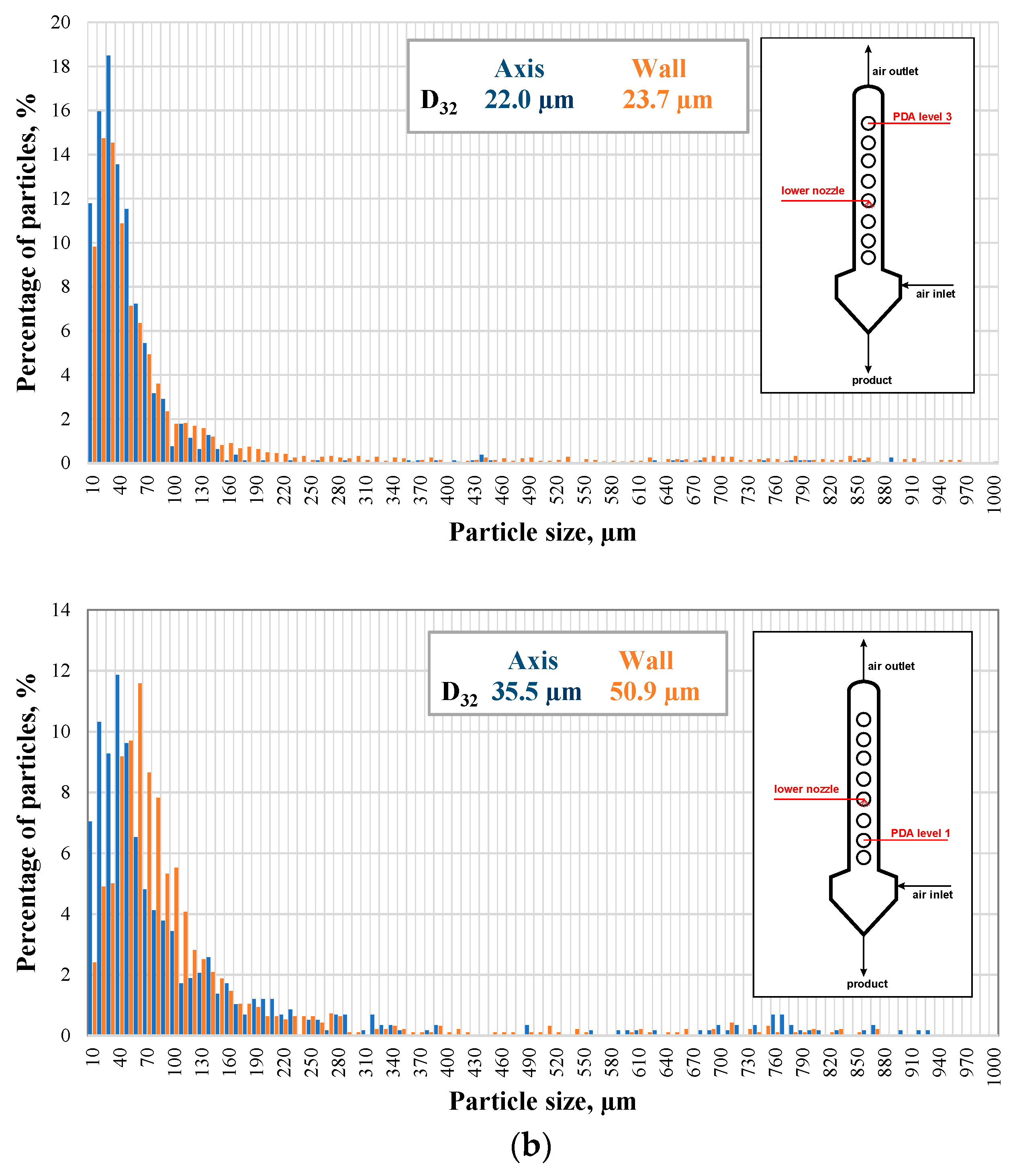

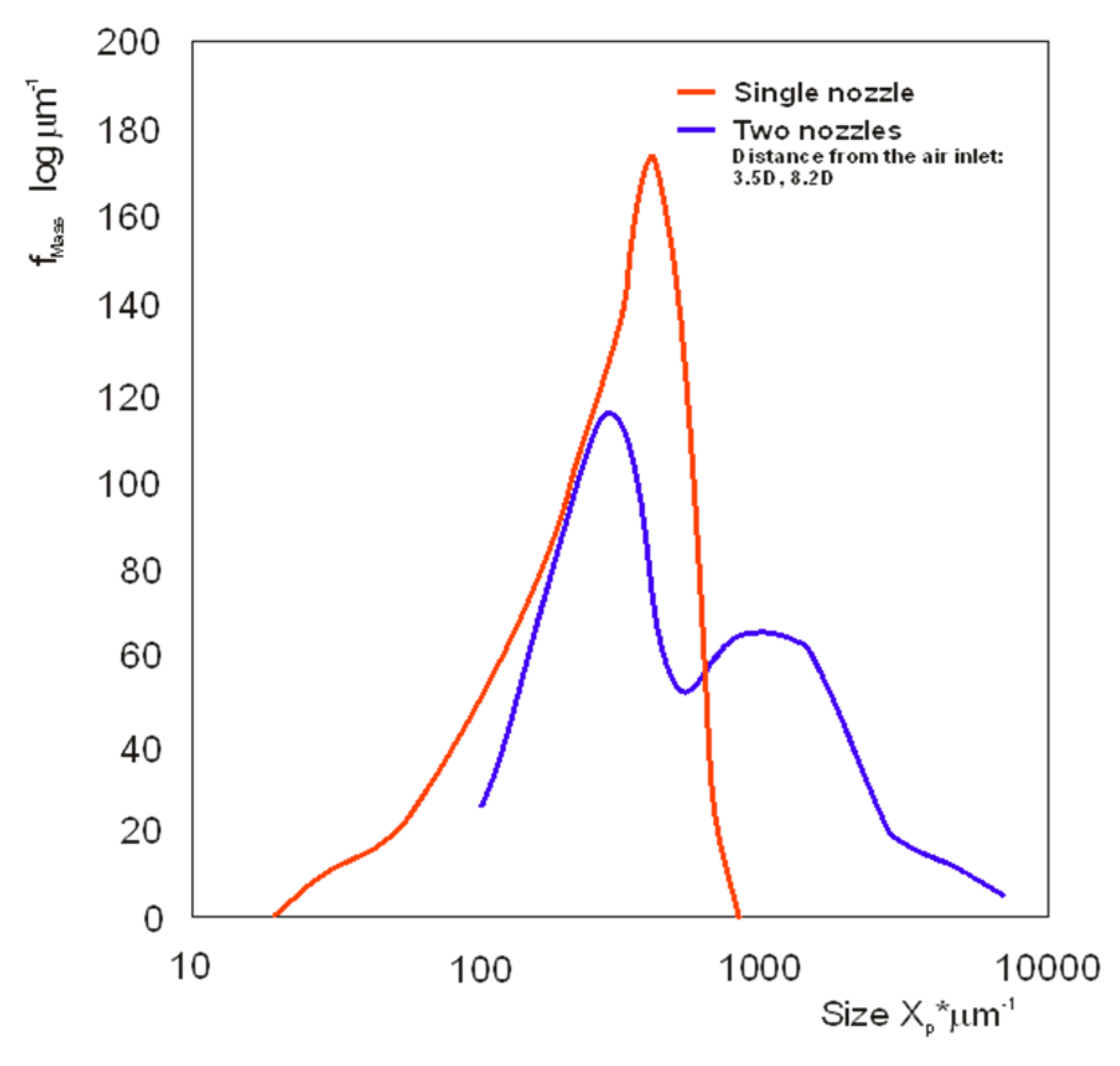

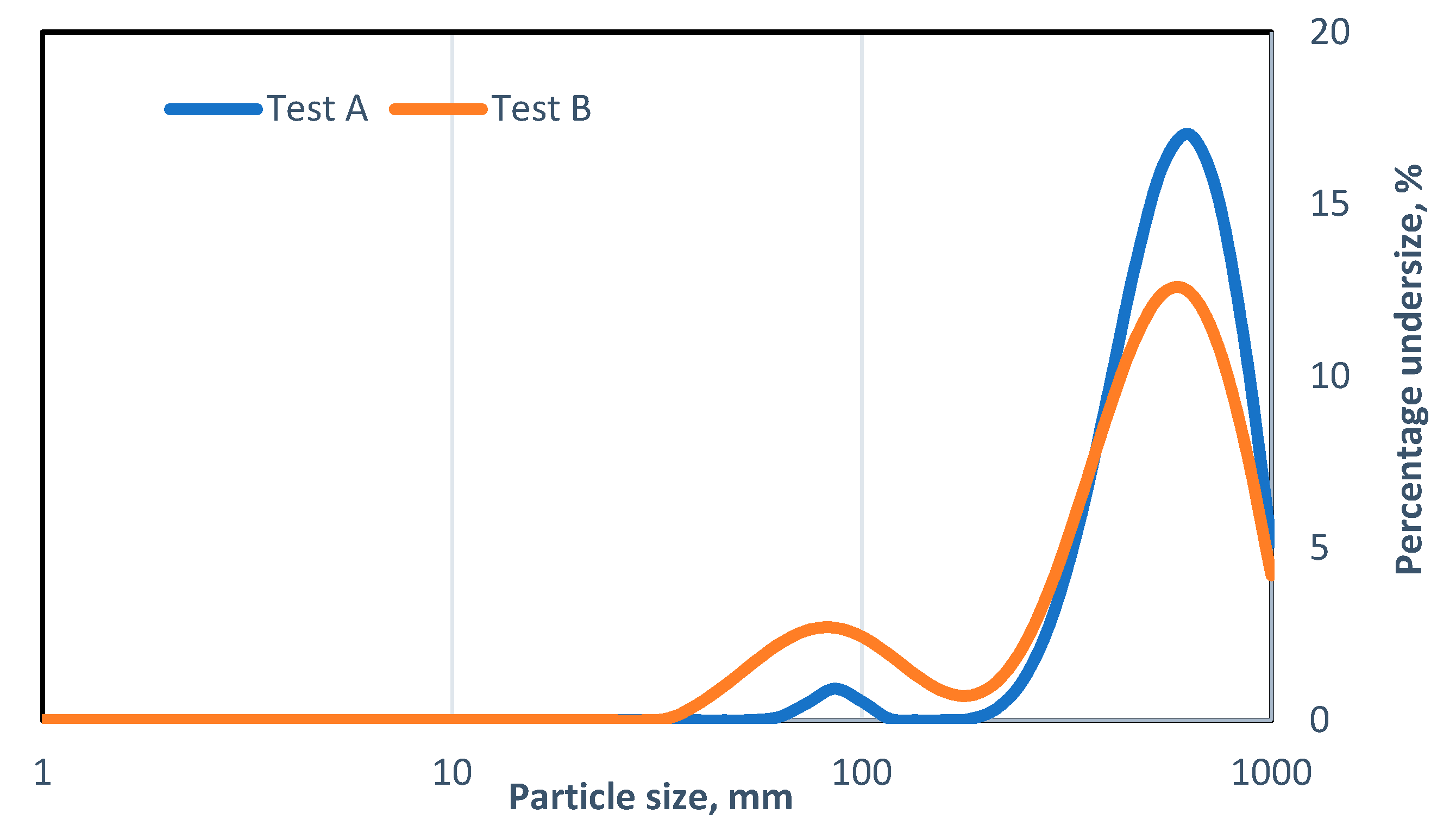

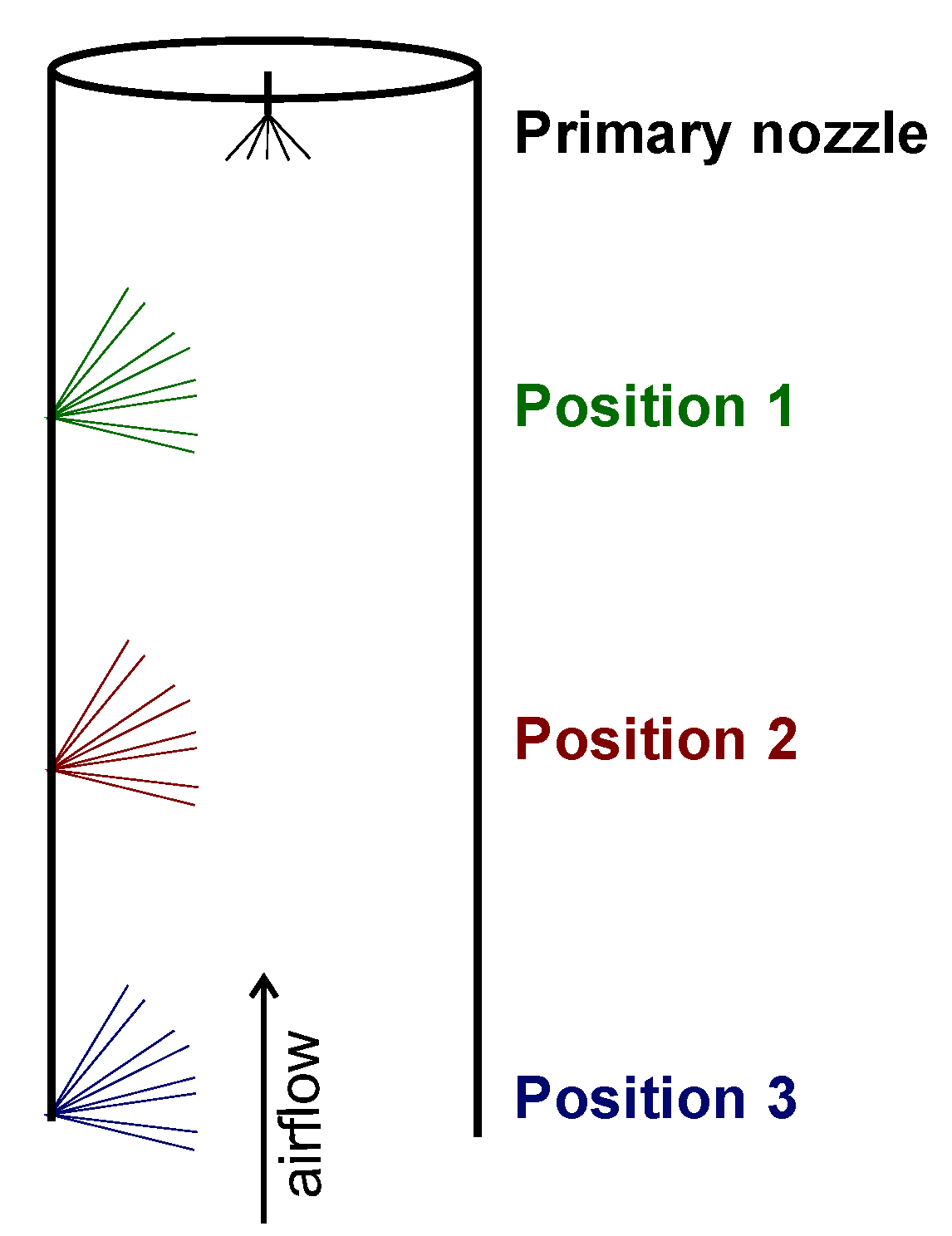

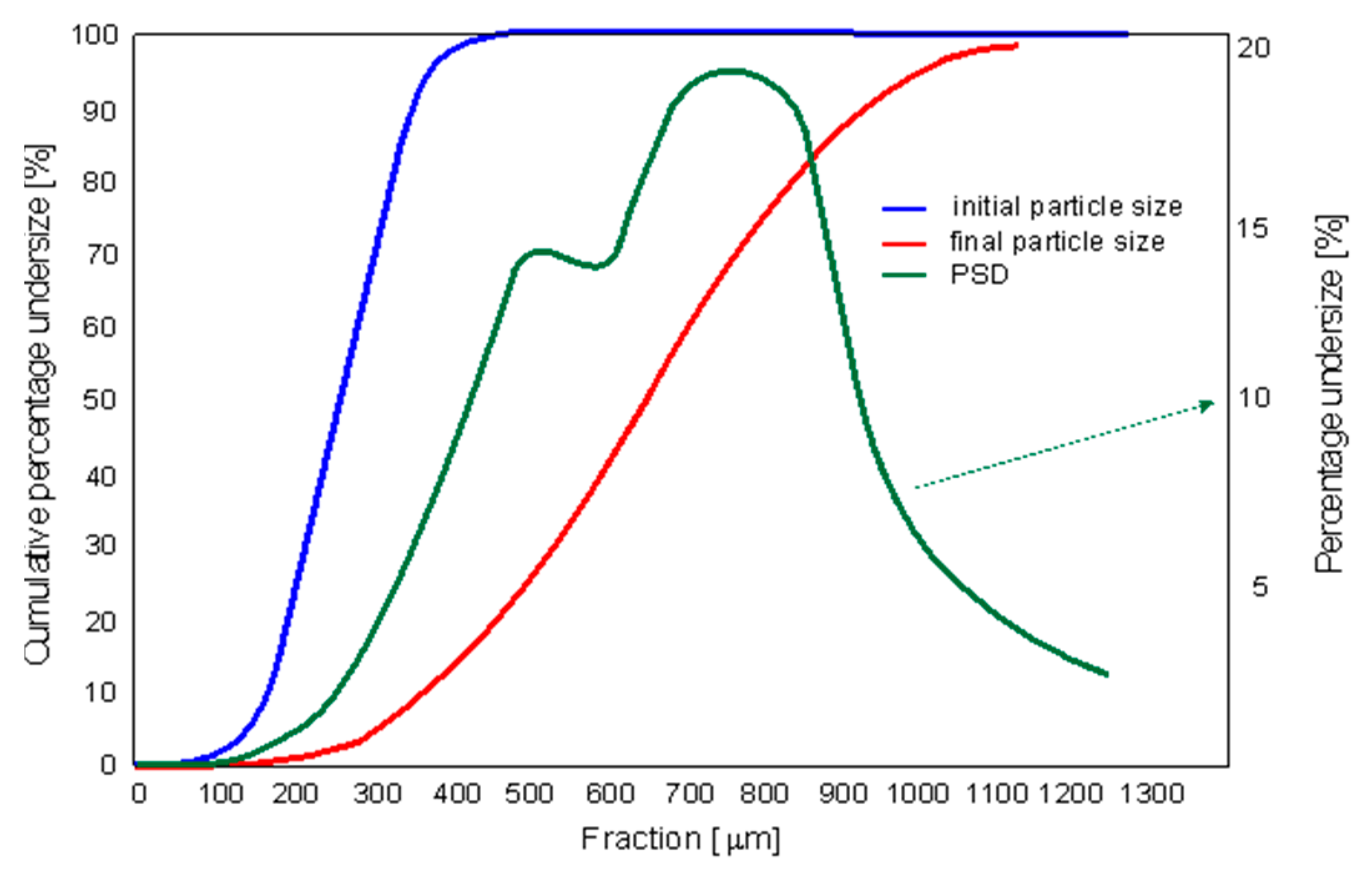

3.1. The Effect of a Single Nozzle Position on Particle Agglomeration in Spray Drying

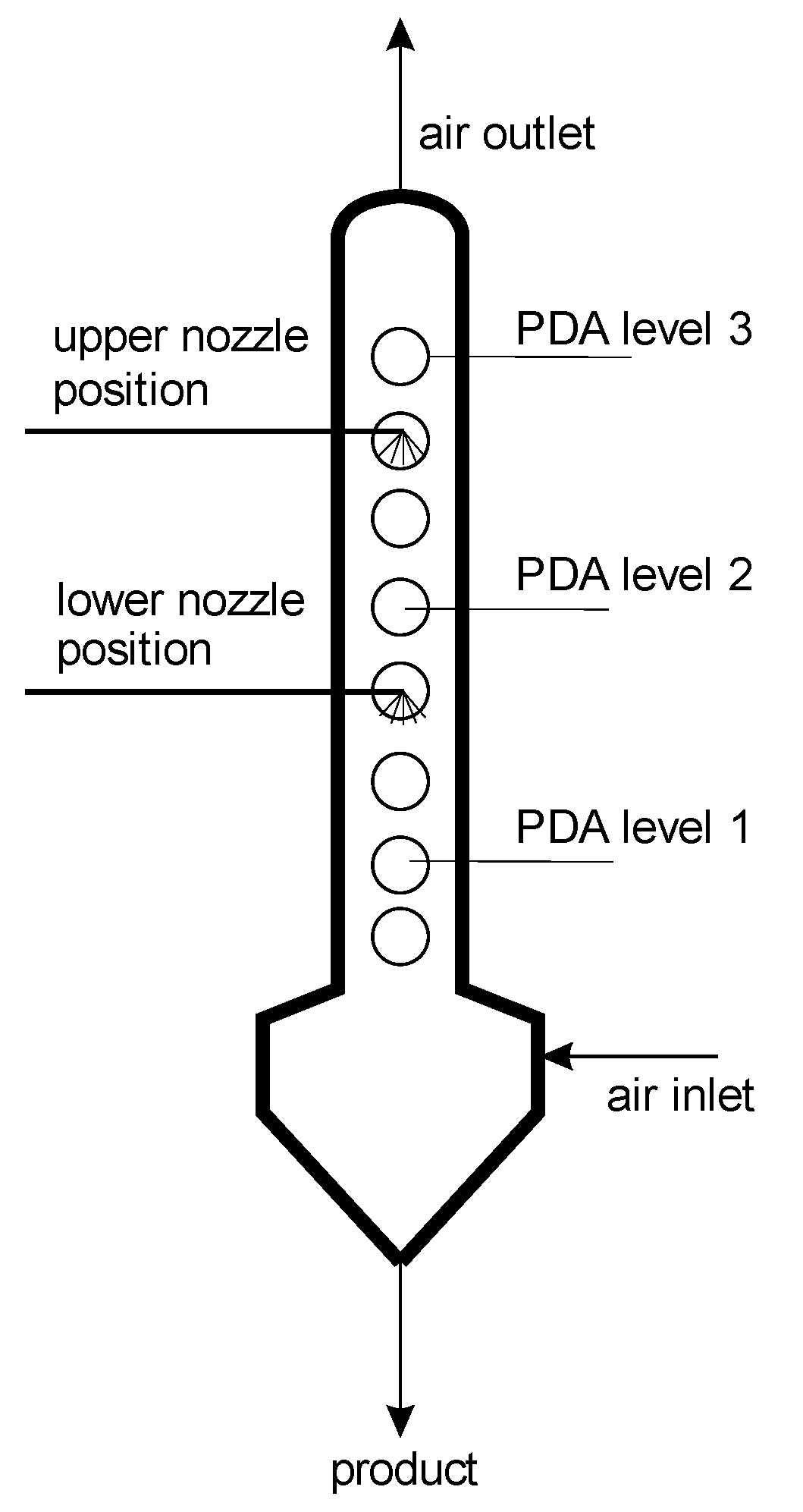

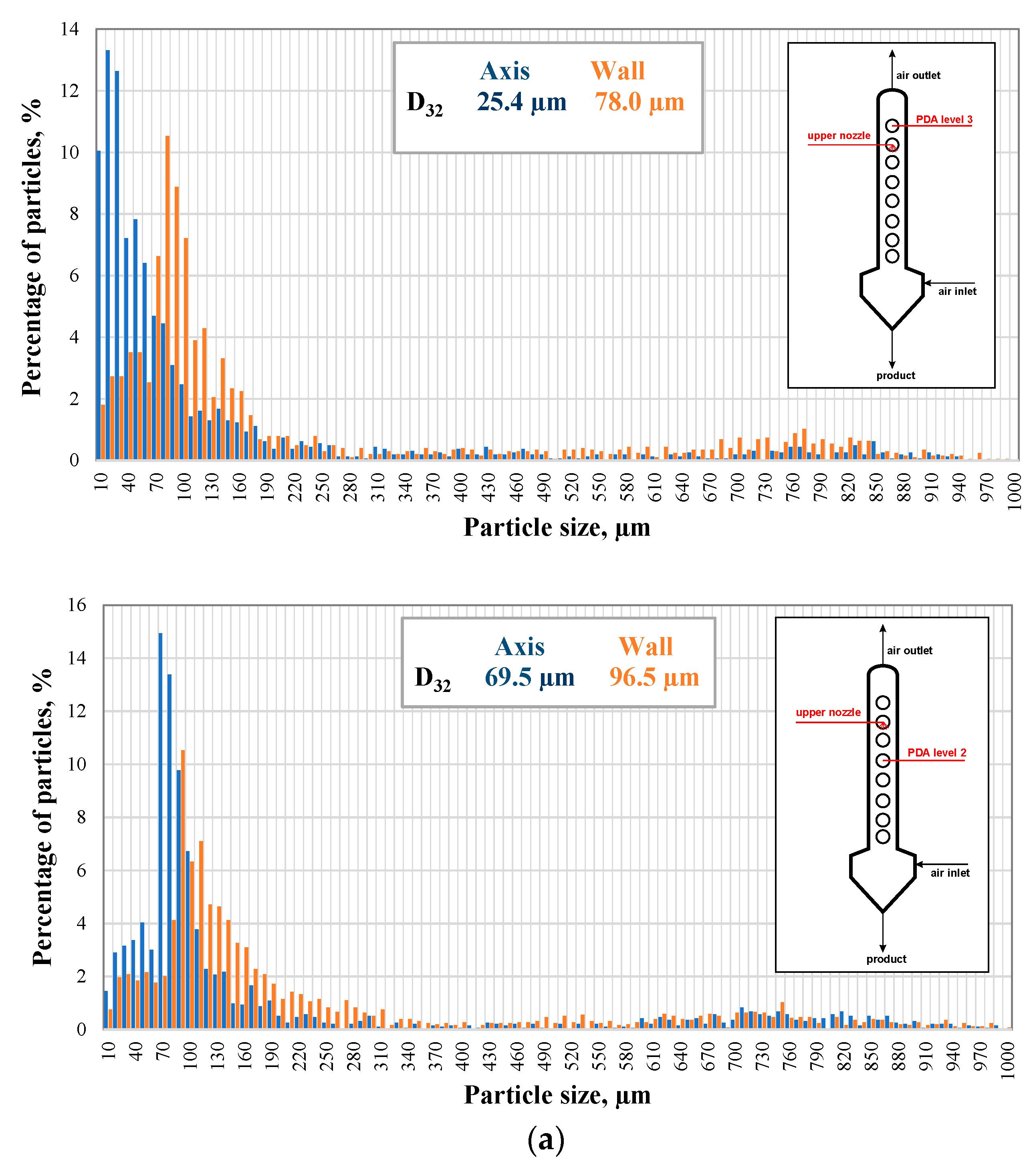

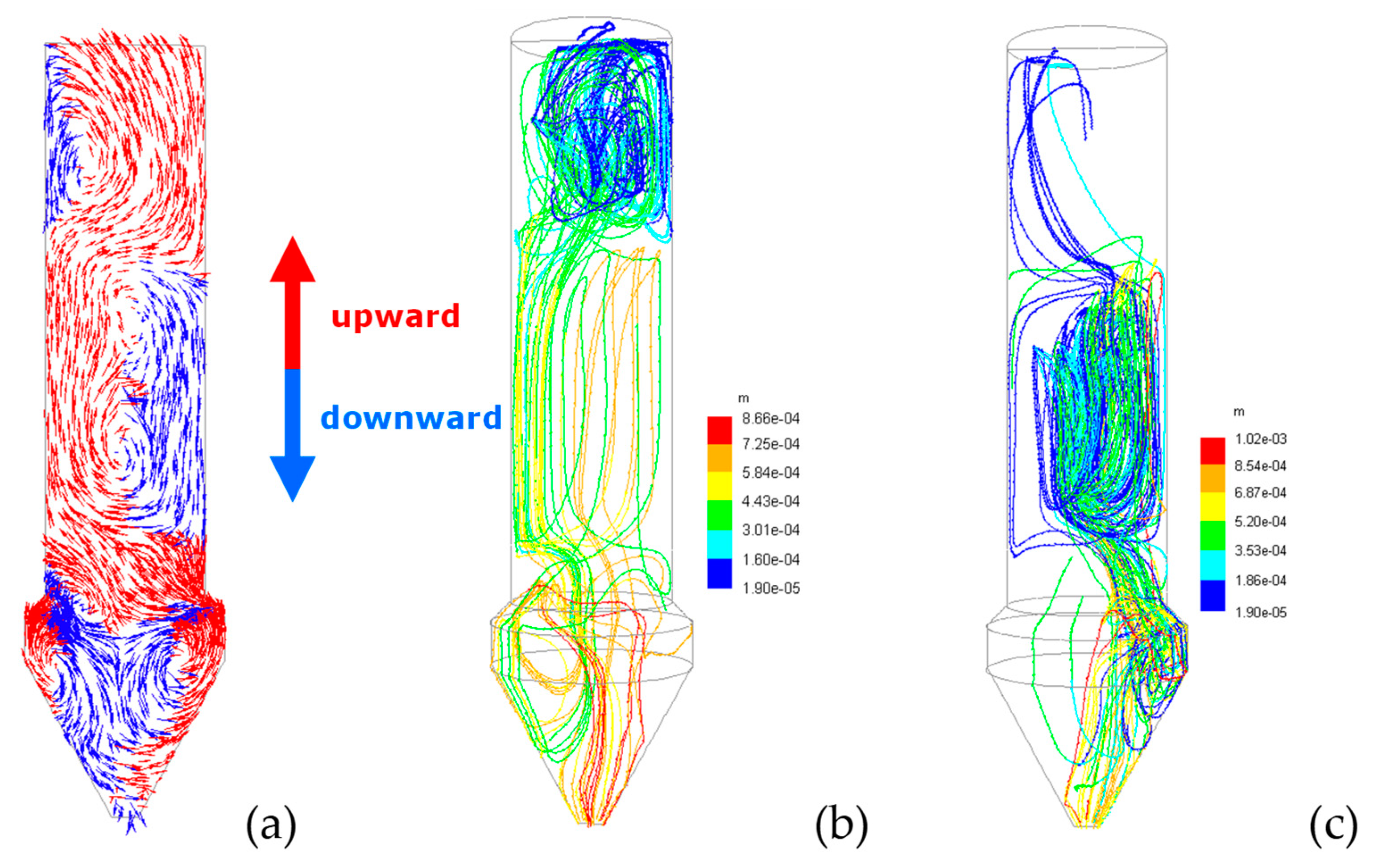

3.2. Particle Agglomeration in Multiple-Nozzle System Atomization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gianfrancesco, A.; Turchiuli, C.; Dumoulin, E.; Palzer, S. Prediction of Powder Stickiness along Spray Drying Process in Relation to Agglomeration. Part. Sci. Technol. 2009, 27, 415–427. [Google Scholar] [CrossRef]

- Selvamuthukumaran, M.; Tranchant, C.; Shi, J. Spraying DryingConcept, Application and Its Recent Advances in Food Processing. In Handbook on Spray Drying Applications for Food Industries; CRC Press: Boca Raton, FL, USA, 2019; ISBN 978-0-429-05513-3. [Google Scholar]

- Palzer, S. Agglomeration of Pharmaceutical, Detergent, Chemical and Food Powders—Similarities and Differences of Materials and Processes. Powder Technol. 2011, 206, 2–17. [Google Scholar] [CrossRef]

- Izonin, I.; Tkachenko, R.; Gregus, M.; Duriagina, Z.; Shakhovska, N. PNN-SVM Approach of Ti-Based Powder’s Properties Evaluation for Biomedical Implants Production. Comput. Mater. Contin. 2022, 71, 5934–5947. [Google Scholar] [CrossRef]

- Patel, R.P.; Patel, M.P.; Suthar, A.M. Spray Drying Technology: An Overview. Indian J. Sci. Technol. 2009, 2, 44–47. [Google Scholar] [CrossRef]

- Rahse, W.; Dicoi, O. Spray Drying in the Detergent Industry; Conference Proceedings: Dotmund, Germany, 2001; pp. 83–87. [Google Scholar]

- Francia, V.; Martín, L.; Bayly, A.E.; Simmons, M.J.H. Particle Aggregation in Large Counter-Current Spray Drying Towers: Nozzle Configuration, Vortex Momentum and Temperature. Procedia Eng. 2015, 102, 668–675. [Google Scholar] [CrossRef] [Green Version]

- Francia, V.; Martín, L.; Bayly, A.E.; Simmons, M.J.H. Agglomeration during Spray Drying: Airborne Clusters or Breakage at the Walls? Chem. Eng. Sci. 2017, 162, 284–299. [Google Scholar] [CrossRef]

- Jubaer, H.; Xiao, J.; Chen, X.D.; Selomulya, C.; Woo, M.W. Identification of Regions in a Spray Dryer Susceptible to Forced Agglomeration by CFD Simulations. Powder Technol. 2019, 346, 23–37. [Google Scholar] [CrossRef]

- Yuksel, H.; Dirim, S.N. Application of the Agglomeration Process on Spinach Juice Powders Obtained Using Spray Drying Method. Dry. Technol. 2020, 39, 19–34. [Google Scholar] [CrossRef]

- Hirt, C.W.; Nichols, B.D. Volume of Fluid (VOF) Method for the Dynamics of Free Boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Mezhericher, M.; Levy, A.; Borde, I. Theoretical Drying Model of Single Droplets Containing Insoluble or Dissolved Solids. Dry. Technol. 2007, 25, 1025–1032. [Google Scholar] [CrossRef]

- Li, M.X. Analysis and Modeling of Droplet-Droplet Interaction and Particle-Droplet Interaction in Dispersions; Particles and Process Engineering Department, Bremen University: Bremen, Germany, 2012. [Google Scholar]

- Ho, C.; Sommerfeld, M. Modelling of Micro-Particle Agglomeration in Turbulent Flows. Chem. Eng. Sci. 2002, 57, 3073–3084. [Google Scholar] [CrossRef]

- Kim, S.; Lee, D.J.; Lee, C.S. Modeling of Binary Droplet Collisions for Application to Inter-Impingement Sprays. Int. J. Multiph. Flow 2009, 35, 533–549. [Google Scholar] [CrossRef]

- Taskiran, O.O.; Ergeneman, M. Trajectory Based Droplet Collision Model for Spray Modeling. Fuel 2014, 115, 896–900. [Google Scholar] [CrossRef] [Green Version]

- Nijdam, J.J.; Guo, B.; Fletcher, D.F.; Langrish, T.A.G. Challenges of Simulating Droplet Coalescence within a Spray. Dry. Technol. 2004, 22, 1463–1488. [Google Scholar] [CrossRef]

- Tsotsas, E.; Mujumdar, A.S. Modern Drying Technology Vol. 1 Computational Tools at Different Scales. Dry. Technol. 2008, 26, 812–814. [Google Scholar] [CrossRef]

- Verdurmen, R.E.M.; Menn, P.; Ritzert, J.; Blei, S.; Nhumaio, G.C.S.; Sonne Sørensen, T.; Gunsing, M.; Straatsma, J.; Verschueren, M.; Sibeijn, M.; et al. Simulation of Agglomeration in Spray Drying Installations: The EDECAD Project. Dry. Technol. 2004, 22, 1403–1461. [Google Scholar] [CrossRef]

- Dhanalakshmi, K.; Ghosal, S.; Bhattacharya, S. Agglomeration of Food Powder and Applications. Crit. Rev. Food Sci. Nutr. 2011, 51, 432–441. [Google Scholar] [CrossRef]

- Turchiuli, C.; Gianfrancesco, A.; Palzer, S.; Dumoulin, E. Evolution of Particle Properties during Spray Drying in Relation with Stickiness and Agglomeration Control. Powder Technol. 2011, 208, 433–440. [Google Scholar] [CrossRef]

- Palzer, S. Influence of Material Properties on the Agglomeration of Water-Soluble Amorphous Particles. Powder Technol. 2009, 189, 318–326. [Google Scholar] [CrossRef]

- Hazlett, R.; Schmidmeier, C.; O’Mahony, J.A. Approaches for Improving the Flowability of High-Protein Dairy Powders Post Spray Drying—A Review. Powder Technol. 2021, 388, 26–40. [Google Scholar] [CrossRef]

- Francia, V.; Martín, L.; Bayly, A.E.; Simmons, M.J.H. Agglomeration in Counter-Current Spray Drying Towers. Part A: Particle Growth and the Effect of Nozzle Height. Powder Technol. 2016, 301, 1330–1343. [Google Scholar] [CrossRef] [Green Version]

- Francia, V.; Martín, L.; Bayly, A.E.; Simmons, M.J.H. Agglomeration in Counter-Current Spray Drying Towers. Part B: Interaction between Multiple Spraying Levels. Powder Technol. 2016, 301, 1344–1358. [Google Scholar] [CrossRef] [Green Version]

- Gianfrancesco, A.; Turchiuli, C.; Dumoulin, E. Powder Agglomeration during the Spray-Drying Process: Measurements of Air Properties. Dairy Sci. Technol. 2008, 88, 53–64. [Google Scholar] [CrossRef] [Green Version]

- Fröhlich, J.A.; Raiber, T.V.; Hinrichs, J.; Kohlus, R. Nozzle Zone Agglomeration in Spray Dryers: Influence of Total Solid Content on Agglomerate Properties. Powder Technol. 2021, 390, 292–302. [Google Scholar] [CrossRef]

- Huntington, D.H. The Influence of the Spray Drying Process on Product Properties. Dry. Technol. 2004, 22, 1261–1287. [Google Scholar] [CrossRef]

- Guo, B.; Fletcher, D.F.; Langrish, T.A.G. Simulation of the Agglomeration in a Spray Using Lagrangian Particle Tracking. Appl. Math. Model. 2004, 28, 273–290. [Google Scholar] [CrossRef] [Green Version]

- Hussain, F.; Jaskulski, M.; Piatkowski, M.; Tsotsas, E. CFD Simulation of Agglomeration and Coalescence in Spray Dryer. Chem. Eng. Sci. 2022, 247, 117064. [Google Scholar] [CrossRef]

- Zbicinski, I.; Piatkowski, M. Continuous and Discrete Phase Behavior in Countercurrent Spray Drying Process. Dry. Technol. 2009, 27, 1353–1362. [Google Scholar] [CrossRef]

- Piatkowski, M. Drying Kinetics of Counter-Current Spray Drying; TUL: Lodz, Poland, 2011. (In Polish) [Google Scholar]

- Piatkowski, M.; Wawrzyniak, P.; Jaskulski, M.; Zbicinski, I.; Zawadzki, D. Experimental Analysis of the Effect of Nozzle Position on Product Properties in Counter-Current Pilot Plant Spray Drying Tower; Conference Proceedings: Worcester, MA, USA, 2022. [Google Scholar]

- Davis, R.P.; Haines, M.S.; Sagel, J.A. Multilevel Spray-Drying Method. U.S. Patent 3,629,951, 28 December 1971. [Google Scholar]

- Jaskulski, M.; Wawrzyniak, P.; Zbicinski, I. CFD Prediction of Powder Particle Size Distribution in the Industrial Scale Spray Drying Process; Conference Proceedings: Gifu, Japan, 2016. [Google Scholar]

- Wawrzyniak, P.; Piatkowski, M.; Jaskulski, M.; Zbicinski, I.; Jubaer, H. Analysis of Product Properties in Counter-Current Spray Drying with Two Nozzles System; Conference Proceedings: Worcester, MA, USA, 2022. [Google Scholar]

- Wawrzyniak, P.; Podyma, M.; Zbicinski, I.; Bartczak, Z.; Rabaeva, J. Modeling of Air Flow in an Industrial Countercurrent Spray-Drying Tower. Dry. Technol. 2012, 30, 217–224. [Google Scholar] [CrossRef]

- Wawrzyniak, P.; Podyma, M.; Zbicinski, I.; Bartczak, Z.; Polanczyk, A.; Rabaeva, J. Model of Heat and Mass Transfer in an Industrial Counter-Current Spray-Drying Tower. Dry. Technol. 2012, 30, 1274–1282. [Google Scholar] [CrossRef]

- Jaskulski, M.; Wawrzyniak, P.; Zbicinski, I. CFD Simulations of Droplet and Particle Agglomeration in an Industrial Counter-Current Spray Dryer. Adv. Powder Technol. 2018, 29, 1724–1733. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zbicinski, I.; Ciesielski, K.; Ge, B. Mechanism of Particle Agglomeration for Single and Multi-Nozzle Atomization in Spray Drying: A Review. Processes 2022, 10, 727. https://doi.org/10.3390/pr10040727

Zbicinski I, Ciesielski K, Ge B. Mechanism of Particle Agglomeration for Single and Multi-Nozzle Atomization in Spray Drying: A Review. Processes. 2022; 10(4):727. https://doi.org/10.3390/pr10040727

Chicago/Turabian StyleZbicinski, Ireneusz, Krzysztof Ciesielski, and Bangguo Ge. 2022. "Mechanism of Particle Agglomeration for Single and Multi-Nozzle Atomization in Spray Drying: A Review" Processes 10, no. 4: 727. https://doi.org/10.3390/pr10040727

APA StyleZbicinski, I., Ciesielski, K., & Ge, B. (2022). Mechanism of Particle Agglomeration for Single and Multi-Nozzle Atomization in Spray Drying: A Review. Processes, 10(4), 727. https://doi.org/10.3390/pr10040727