Discussion on the Reconstruction of Medium/Low-Permeability Gas Reservoirs Based on Seepage Characteristics

Abstract

:1. Introduction

2. Experimental Methodology

2.1. Experimental Conditions

- (1)

- Temperature and pressure: 20 °C; atmospheric pressure.

- (2)

- Experimental brine: filtered formation brine with a TDS of 5600 mg/L.

- (3)

- Displacement gas: standard methane gas with a purity of 95%; apparent viscosity: 0.0178 mPa·s.

- (4)

- Displacement crude oil: density: 0.83 g/cm3; viscosity: 10.66 mPa·.s.

- (5)

- Experimental core: artificial core samples prepared from quartz minerals.

- (5)

- The other experimental parameters and conditions are shown in Table 1.

- (6)

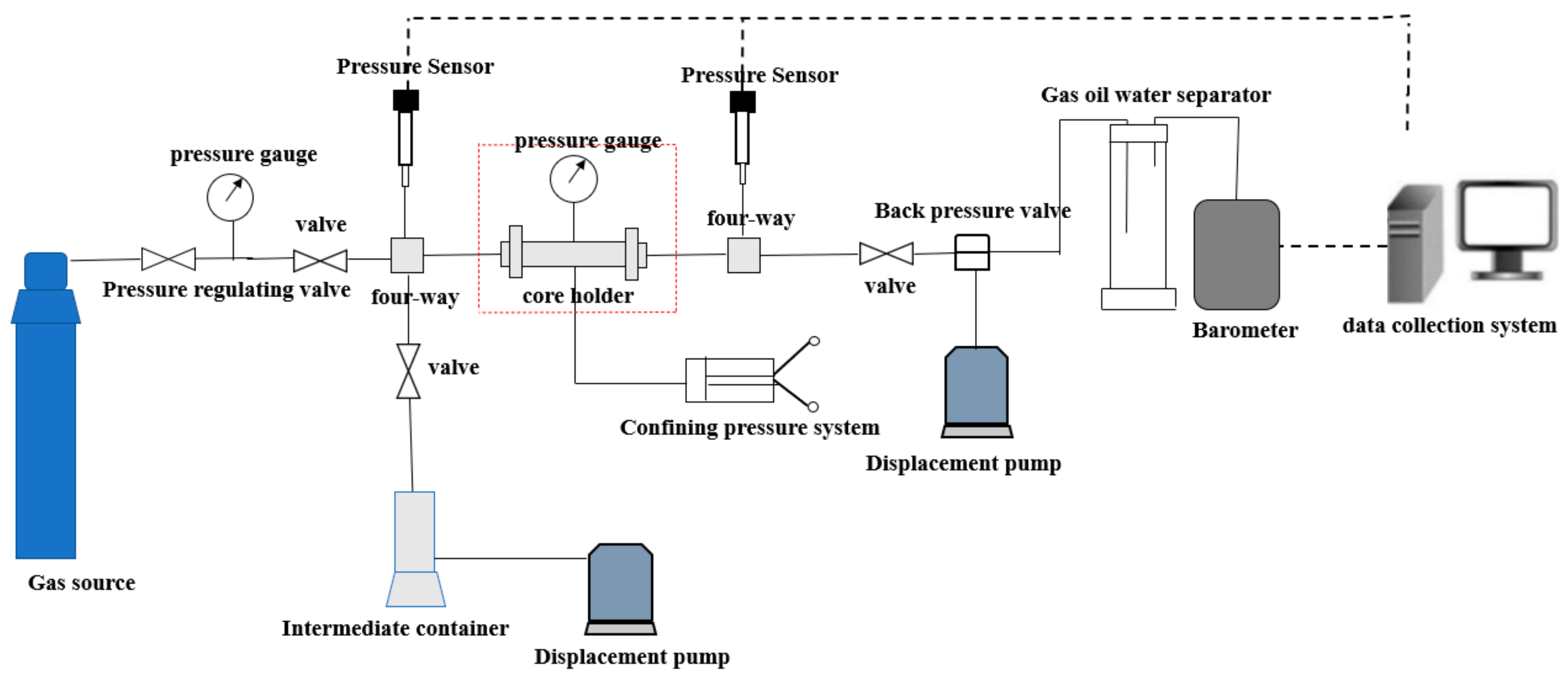

- Components of the experimental set-up: ISCO pump (Teledyne ISCO, Lincoln, NE, USA), core holder (Hai’an core Petroleum Instrument Co., Ltd., Nantong, China), intermediate container (Hai’an Core Petroleum Instrument Co., Ltd., Nantong, China), six-way valve (Hai’an Core Petroleum Instrument Co., Ltd., Nantong, China), oil/water/gas three-phase separator (Hai’an Core Petroleum Instrument Co., Ltd., Nantong, China).

- (7)

- The experimental set-up is shown in Figure 1 below.

2.2. Experimental Methods and Procedures

2.2.1. Experimental Steps for Multicycle Oil and Water Seepage Simulation

- (1)

- The relative permeability measurement is performed as follows [22,23]: A. Vacuum-saturate the core sample with water first. Record the saturated water volume and thereby calculate the pore volume. Establish initial oil saturation by injection of oil at a flow rate of 0.1 mL/min. B. Adjust the crude oil injection rate to 1 mL/min, to eliminate the capillary end effect, and measure the oil phase permeability. C. Inject water to displace oil at the rate of 1 mL/min. (Note: accurately record the accumulative oil production, accumulative liquid production, and displacement pressure difference across the rock sample). Determine the water phase permeability at residual oil saturation. Stop the water–oil displacement experiment and measure the water saturation of the rock sample. D. Re-install the rock sample by reversing its direction into the core holder. Select the same speed (1 mL/min) to displace water with oil. E. Reverse the rock sample and place into the core holder again. Repeat the above steps until the difference in the oil phase relative permeability at residual water saturation between the last two measurements is less than 3%.

- (2)

- Calculation of the relative permeability curve: By ignoring the capillary force in the process of displacement, the improved “J·B·N” data processing method is used. In detail, the differential method instead of the derivative method is used. In other words, the oil and water volumes are measured after being static for a period of time, which can greatly improve the measurement accuracy. Sort the data recorded in the experiment, calculate the relative permeabilities one-by-one according to formulas (1)–(5), and establish a relationship chart for relative permeability and saturation.

2.2.2. Experimental Steps for Multicycle Air and Water Seepage Simulation

- (1)

- The relative permeability measurement steps are as follows: A. Dry the core sample [24,25]. The gas permeability is determined by injecting gas at a rate of 7 mL/min. B. Vacuum-saturate the core sample with formation water and determine the porosity via the weight difference between the dry and wet core sample. C. Inject formation water at a constant rate of 1 mL/min to determine the absolute permeability. D. Gas displaces water at a rate of 7 mL/min. E. Record the pressure difference, cumulative produced fluids volume, cumulative produced water volume, gas breakthrough time and gas permeability at residual water saturation. F. Reverse the core sample, then re-install it into the core holder. Inject water to displace gas at a speed of 1 mL/min. Record the displacement pressure difference, accumulated fluids produced, accumulated water produced and the water permeability at the residual gas saturation. G. Repeat the above experimental steps.

- (2)

- Calculation procedure: Convert the cumulative produced fluids, measured at atmospheric pressure, to the value at the average rock sample pressure 𝑉l ⇒ = ∆Vωi + ∆(i−1) + [2𝑝𝑎∕(∆𝑝 + 2𝑝𝑎)]∆𝑉𝑔𝑖; Draw curves of cumulative gas produced versus time, cumulative water produced versus time and cumulative injection time. Separate the points evenly on the curve and perform the following calculations, (6)–(11).

2.2.3. Experimental Procedures for Multicycle Gas–Oil Seepage Simulation

- (1)

- Experimental steps for relative permeability measurement of gas and oil:

- A.

- Dry the core sample and determine the absolute permeability by injecting gas at a flow rate of 7 mL/min.

- B.

- Vacuum-saturate the core sample with formation brine and determine the porosity via the weight difference between the dry and wet core sample.

- C.

- Establish the connate water saturation by injecting oil to displace water at a flow rate of 1 mL/min until either no more water is produced, or the oil displacement stops when the injected volume reaches PV. Record the amount of water produced, and calculate the oil saturation and connate water saturation of the rock samples.

- D.

- Inject gas to displace the oil at a rate of 7 mL/min. Record the displacement pressure, oil production volume and gas production at desired time.

- E.

- When the residual oil saturation is reached, stop the displacement experiment and calculate the gas permeability.

- F.

- Inject oil from the other direction at a rate of 1 mL/min. Record the displacement pressure, oil production volume and gas production at desired time, until the residual gas saturation is reached. Determine gas phase effective permeability, and stop the displacement.

- G.

- Repeat the above experimental steps to complete multiple cycles of gas–oil seepage simulation.

- (2)

- The data processing method is similar to the one with gas and water [26].

2.2.4. Experimental Steps and Data Processing for Multicycle Injection and Production Experiments

- A.

- Dry the core sample. Measure the absolute permeability by injecting the gas at 7 mL/min.

- B.

- Vacuum-saturate the core sample with water first. Record the saturated water volume and calculate the pore volume. Establish the initial oil saturation by injecting oil at a rate of 0.1 mL/min until there is no more water produced.

- C.

- imulate the gas injection process: inject natural gas at a constant speed of 10 mL/min and gradually pressurize to 15 MPa.

- D.

- Simulate the soaking process: close the outlet valve for 2 h.

- E.

- Simulate the oil production process: open the valve and gradually discharge the liquid. Control the liquid production time as half of the gas injection time, and depressurize to atmospheric pressure.

- F.

- Gradually increase the pressure until it rises to 15 MPa again, and repeat the process for 8 cycles. (Note: the amount of oil produced during multiple injection processes cannot be directly measured; it can only be determined by a weighing method. Therefore, the oil and water volume in the rock-heart can only be expressed by liquid saturation. Moreover, the liquid saturation is obtained by the average density of oil and water).

- G.

- Finally, measure the core weight and determine the oil and water volumes by the distillation method.

3. Results and Discussion

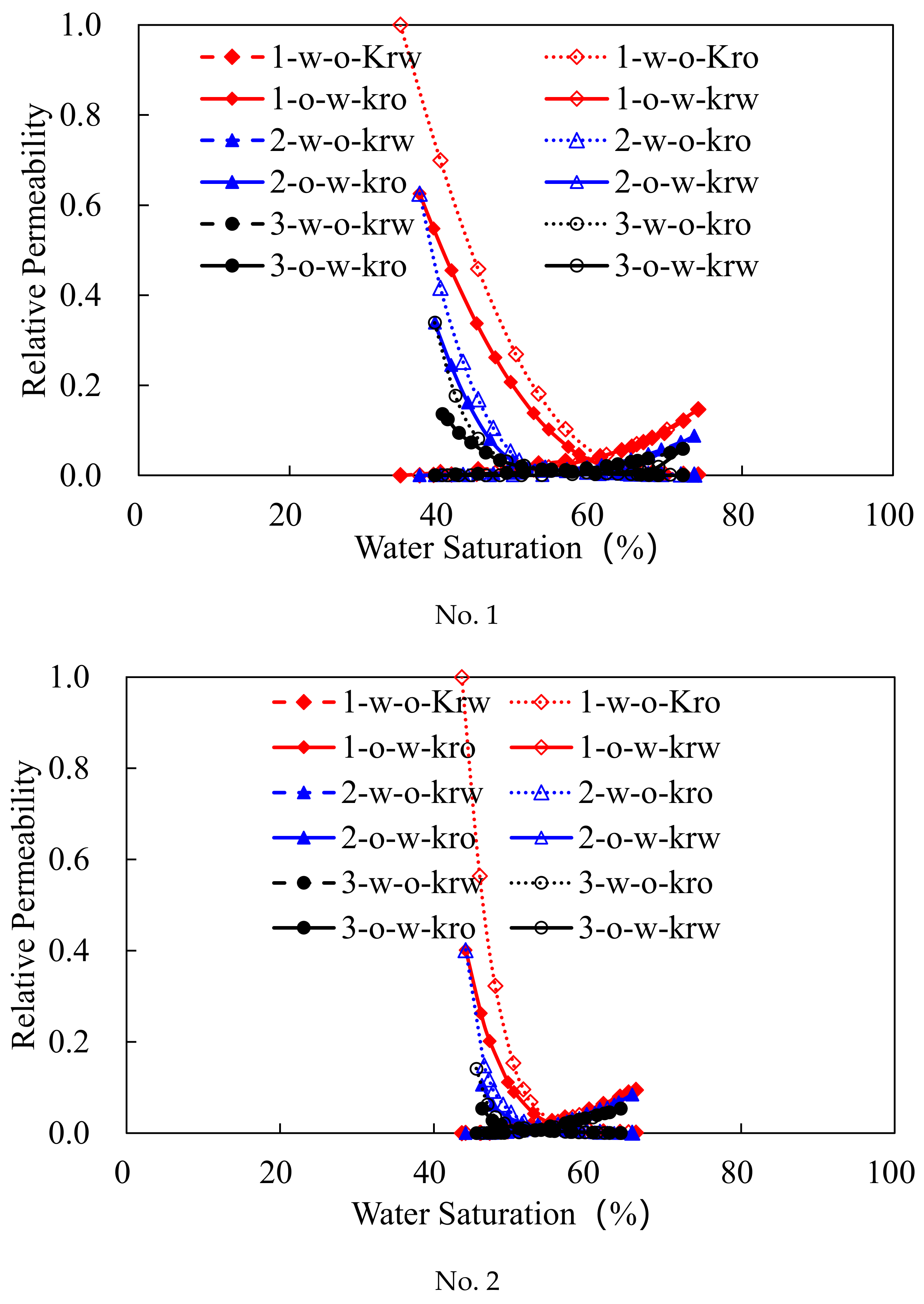

3.1. Oil–Water Relative Permeability Characteristics during Multicycle Displacements

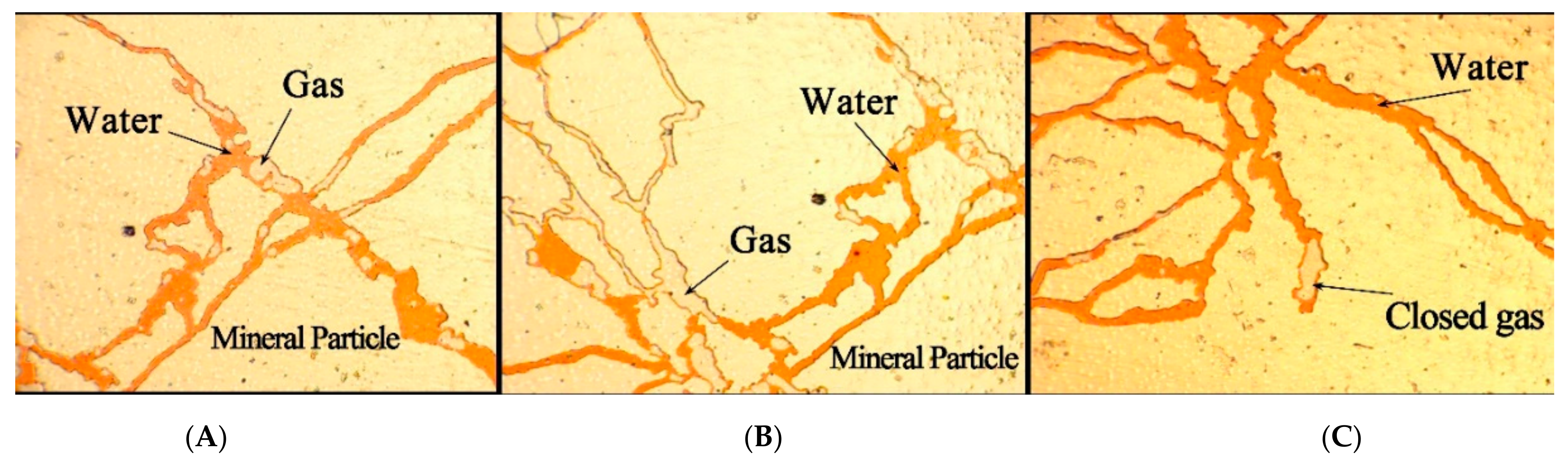

3.2. Gas–Water Relative Permeability Characteristics during Multicycle Displacements

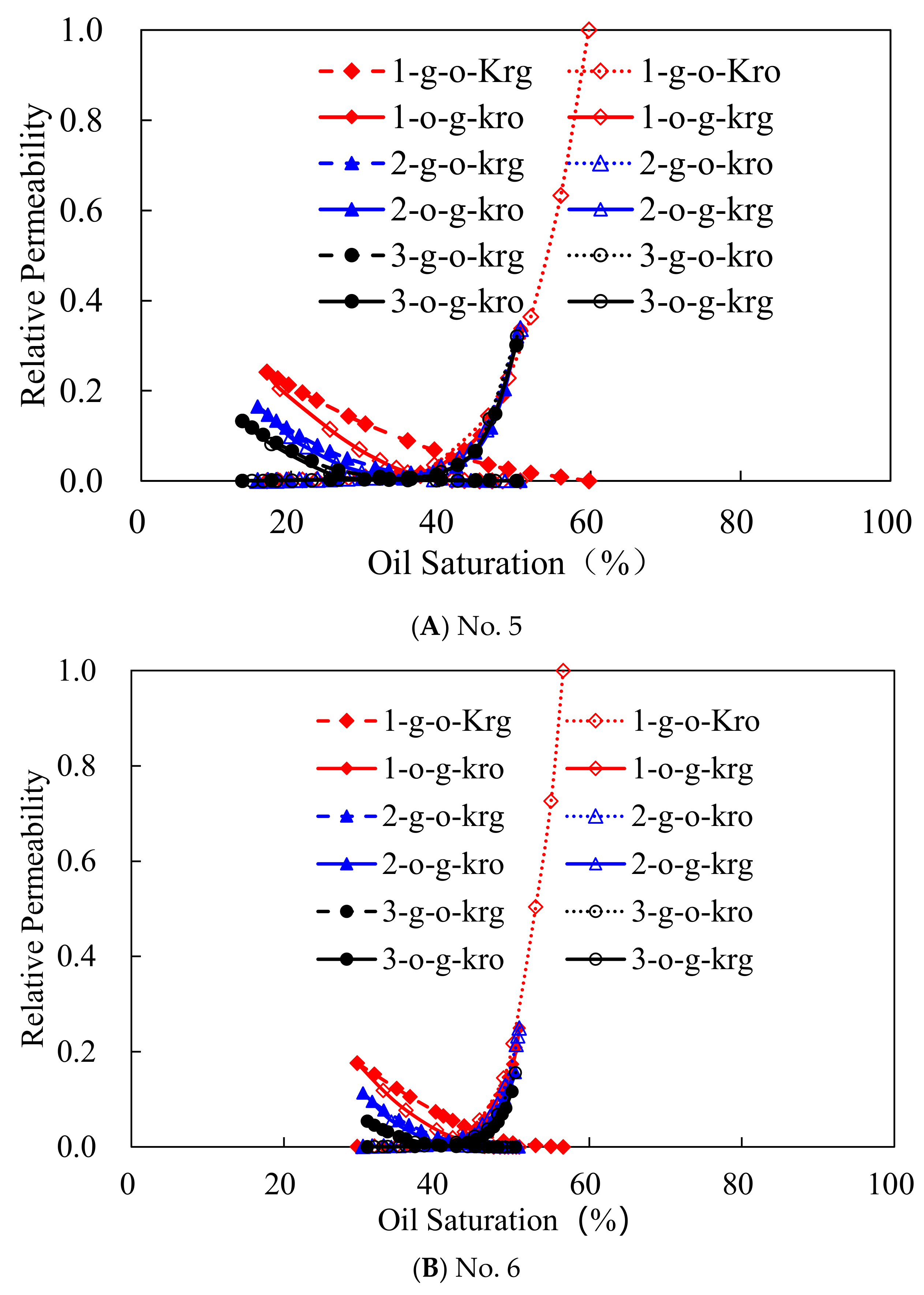

3.3. Gas–Oil Relative Permeability Characteristics during Multicycle Displacements

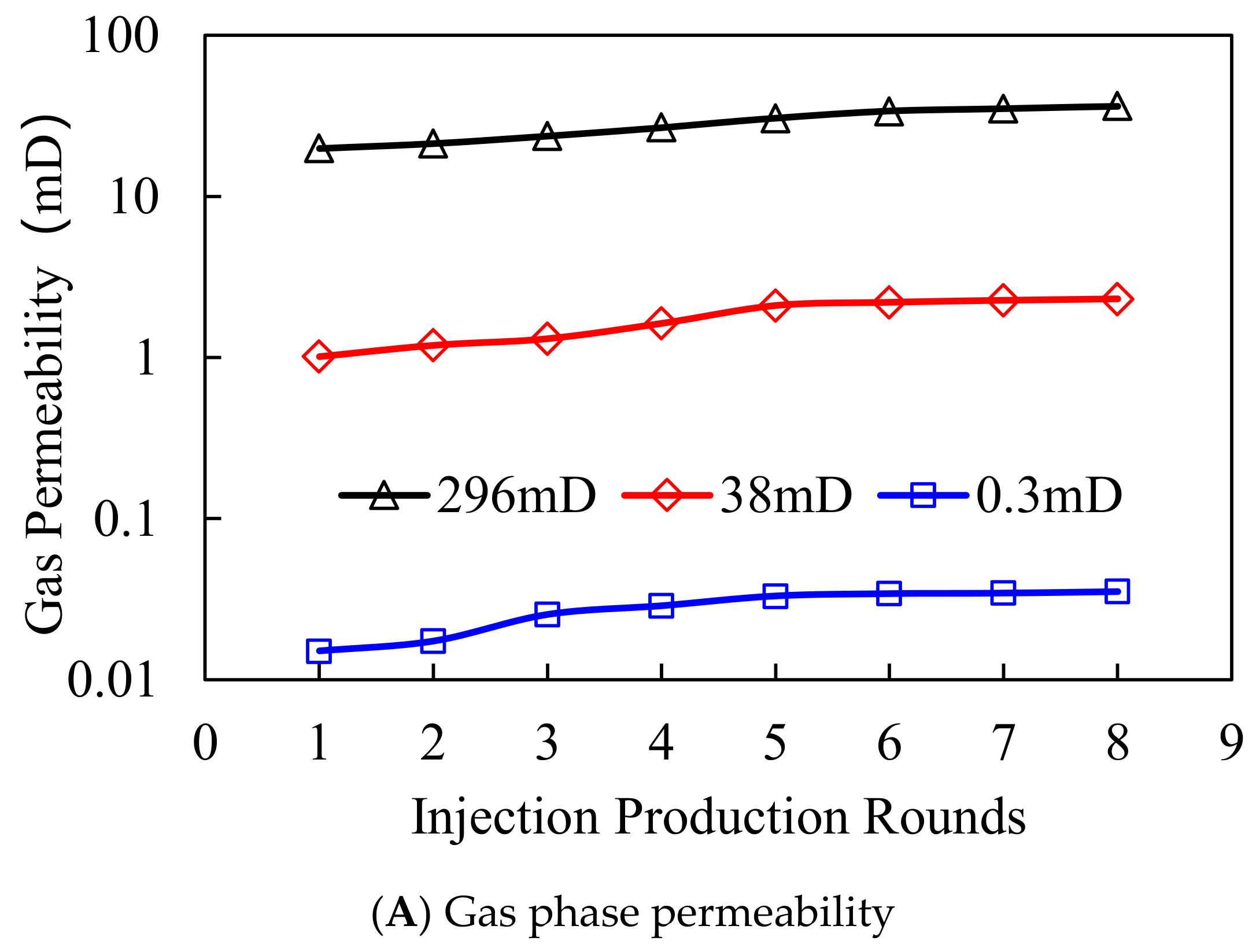

3.4. Results of the Multicycle Injection and Production of Different Permeability Cores

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| fo(Sw) | oil phase fractional flow rate; |

| and | have no secondary cumulative oil production or liquid extraction volume, expressed by the fraction of the pore volume; |

| the value of the relative injection capacity, also known as the flow capacity ratio; | |

| Δp0 | initial drive pressure, MPa; |

| Δp(t) | displacement pressure difference at t moment, MPa; |

| Swe | value of water saturation of rock sample outlet end surface; |

| Sw | bound water saturation, decimal; |

| Sg:av | average gas saturation, %; |

| Vw | accumulated export water volume, mL; |

| qgi | gas flow during two-phase flow, mL/s; |

| qg | gas flow during single-phase flow, mL/s; |

| fg | gas content (decimal number); |

| fw | water content (decimal number); |

| μg | injection gas viscosity, mPa·s; |

| μw | viscosity of simulated formation water in saturated rock samples, mPa·s; |

| C | antihypertensive volume factor (decimal number); |

| P3 | rock sample inlet pressure (absolute), MPa; |

| P4 | rock sample outlet pressure (absolute), MPa. |

| Kro(Swi) | relative permeability of the oil phase in the bound water state, mD |

| Krw(Sor) | value of relative permeability of water phase in residual oil, mD; |

| Sor | residual oil saturation, decimal number; |

| m: n | constant; |

| 1-g-o-Kro | 1 represents turn; g-o represents gas flooding; Kro represents relative permeability of oil phase. |

References

- Jza, B.; Yta, B.; Tza, B.; Kya, B.; Xwa, B.; Qi, Z. Natural gas market and underground gas storage development in China. J. Energy Storage 2020, 29, 101338. [Google Scholar]

- Nils, L.; David, W. Gas storage valuation in incomplete markets. Eur. J. Oper. Res. 2021, 288, 318–330. [Google Scholar]

- Tang, Y.; Long, K.; Wang, J.; Xu, H.; Wang, Y.; He, Y.; Shi, L.; Zhu, H. Change of phase state duringMulti-wheel injection and production process of condensate gas reservoir based underground gas storage. Pet. Explor. Dev. 2021, 48, 395–406. [Google Scholar] [CrossRef]

- Toosheh, E.K.; Jafri, A.; Teymouri, A. Gas-water-rock interactions and factors affecting gas storage capacity during natural gas storage in a low permeability aquifer. Pet. Explor. Dev. 2018, 45, 1123–1128. [Google Scholar] [CrossRef]

- Shao, J.; You, L.; Kang, Y.; Chen, M.; Zhang, N. Experimental study on stress sensitivity of underground gas storage. J. Pet. Sci. Eng. 2020, 195, 107577. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, Y.; Sheng, Z.; Yan, X. Uncertainty failure risk quantitative assessments for underground gas storage near-wellbore area. J. Energy Storage 2021, 36, 102393. [Google Scholar] [CrossRef]

- Wang, J.K.; Li, Y.H.; Xu, S.J.; Li, C.; Wang, J.M.; He, R.W.; Zhang, J.L. Change mechanism of pore structure and filling efficiency during injection production of sandstone underground gas storage. J. Nat. Gas Sci. Eng. 2022, 97, 104366. [Google Scholar] [CrossRef]

- Al-Khdheeawi, E.; Vialle, S.; Barifcani, A.; Iglauer, S. Impact of reservoir wettability and heterogeneity on CO2 -plume migration and trapping capacity. Int. J. Greenh. Gas Control 2017, 58, 142–158. [Google Scholar] [CrossRef]

- Al-Khdheeawi, E.; Vialle, S.; Barifcani, A.; Iglauer, S. Influence of CO2-wettability on CO2 migration and trapping capacity in deep saline aquifers. Greenh. Gases 2016, 7, 328–338. [Google Scholar] [CrossRef] [Green Version]

- Al-Khdheeawi, E.; Vialle, S.; Barifcani, A.; Iglauer, S. Influence of injection well configuration and rock wettability on CO2 plume behaviour and CO2 trapping capacity in heterogeneous reservoirs. J. Nat. Gas. Sci. Eng. 2017, 43, 190–206. [Google Scholar] [CrossRef]

- Al-Khdheeawi, E.; Vialle, S.; Barifcani, A.; Sarmadivaleh, M.; Zhang, Y.; Iglauer, S. Impact of salinity on CO2 containment security in highly heterogeneous reservoirs. Greenh. Gases 2017, 8, 93–105. [Google Scholar] [CrossRef]

- Niz, V.E. A Numerical and Physical Study of Relative Permeability in High-Pressure Air Injection Process. Ph.D. Thesis, University of Calgary, Calgary, AB, Canada, 2009. [Google Scholar]

- Durucan, S.; Ahsan, M.; Syed, A.; Shi, J.; Korre, A. Two Phase Relative Permeability of Gas and Water in Coal for Enhanced Coalbed Methane Recovery and CO2 Storage. Energy Procedia 2013, 37, 6730–6737. [Google Scholar] [CrossRef] [Green Version]

- Christoforos, B.; Giulia, C.; Carmela, F.; Mantegazzi, A.; Rocca, V.; Tango, G.; Trillo, F. Multidisciplinary Analysis of Ground Movements: An Underground Gas Storage Case Study. Remote Sens. 2020, 12, 3487. [Google Scholar]

- Zhu, S.J.; Ye, Z.B.; Zhang, J.; Xue, X.S.; Chen, Z.H.; Xiang, Z.P. Research on optimal timing range for early polymer injection in sandstone reservoir. Energy Rep. 2020, 6, 3357–3364. [Google Scholar] [CrossRef]

- Niz-Velasquez, E.; Moore, R.G.; van Fraassen, K.C.; Mehta, S.; Ursenbach, M. Experimental and numerical modeling of three-phase flow under high-pressure air injection. SPE Reserv. Eval. Eng. 2010, 13, 782–790. [Google Scholar] [CrossRef]

- Oak, M.J. Three-Phase Relative Permeability of Water-Wet Berea; Paper presented at the SPE/DOE Enhanced Oil Recovery Symposium; SPE: Tulsa, OK, USA, 1990; p. 20183. [Google Scholar]

- Withjack, E.M.; Devier, C.; Michael, G. The Role of X-ray Computed Tomography in Core Analysis; Paper presented at the SPE Western Regional/AAPG Pacific Section Joint Meeting; SPE: Long Beach, CA, USA, 2003; p. 83467. [Google Scholar]

- Lu, W.; Liu, Q.; Zhang, Z. Measurement of three-phase relative permeabilities. Pet. Explor. Dev. 2012, 39, 713–719. [Google Scholar] [CrossRef]

- Maini, B.B.; Nicola, F.; Goldman, J. Measurements and Estimation of Three-Phase Relative Permeability; Petroleum Recovery Institute: Calgary, AB, Canada, 1990. [Google Scholar]

- Ao, X.; Wang, B.B.; Qu, H.; Xiang, Z.P.; Luo, Z. Swelling of Shales with Slickwater in Carbon Dioxide. Energy Fuels 2021, 35, 5122–5129. [Google Scholar] [CrossRef]

- Shi, L.T.; Zhu, S.J.; Zhang, J.; Wang, S.X.; Xue, X.S. Research into polymer injection timing for Bohai heavy oil reservoirs. Pet. Sci. 2015, 12, 129–134. [Google Scholar] [CrossRef] [Green Version]

- Zhao, S.; Pu, W.F. Investigation into the effect of polymer microspheres (PMs) on oil-water relative permeability and oil-in-water emulsion stability for enhanced oil recovery. J. Dispers. Sci. Technol. 2021, 42, 1695–1702. [Google Scholar] [CrossRef]

- Ao, X.; Lu, Y.Y.; Tang, J.R.; Chen, Y.; Li, H. Investigation on the physics structure and chemical properties of the shale treated by supercritical CO2. J. CO2 Util. 2017, 20, 274–281. [Google Scholar] [CrossRef]

- Beltrán, A.; Hernández-Díaz, D.; Chávez, O.; Garcia, A.; Zenit, R. Experimental study of the effect of wettability on the relative permeability for air–water flow through porous media. Int. J. Multiph. Flow 2019, 120, 103091. [Google Scholar] [CrossRef]

- Modaresghazani, J.; Moore, R.G.; Mehta, S.A.; Fraassen, K.C.V. Investigation of the relative permeabilities in two-phase flow of heavy oil/water and three-phase flow of heavy oil/water/gas systems. J. Pet. Sci. Eng. 2019, 172, 681–689. [Google Scholar] [CrossRef]

| Number | Permeability mD | Porosity % | Length cm | Diameter cm | Experiment Type |

|---|---|---|---|---|---|

| 1 | 266.64 | 16.57 | 4.82 | 2.51 | Oil–water seepage |

| 2 | 0.87 | 5.67 | 4.78 | 2.52 | Oil–water seepage |

| 3 | 238.36 | 15.17 | 4.76 | 2.51 | Gas–water seepage |

| 4 | 1.23 | 5.17 | 4.78 | 2.52 | Gas–water seepage |

| 5 | 269.33 | 16.51 | 4.82 | 2.51 | Gas–oil seepage |

| 6 | 35.64 | 9.80 | 4.83 | 2.47 | Gas–oil seepage |

| Core Number | Length cm | Diameter cm | Porosity % | Permeability mD | Water Saturation before Gas Drive, % | Oil Saturation before Gas Drive, % |

|---|---|---|---|---|---|---|

| 1 | 4.82 | 2.51 | 15.44 | 296.58 | 72.14 | 27.86 |

| 2 | 4.89 | 2.53 | 21.71 | 38.03 | 66.51 | 33.49 |

| 3 | 4.82 | 2.52 | 4.33 | 0.33 | 64.35 | 35.65 |

| Interdrive Cycle | Swi, % | Soi, % | Effective Gas Storage Space | Kro(Swi) | Krw(Soi) | Isopoint Permeability |

|---|---|---|---|---|---|---|

| 1 | 34.69 | 25.83 | 39.48 | 0.76 | 0.65 | 0.11 |

| 2 | 37.23 | 26.35 | 36.42 | 0.55 | 0.25 | 0.06 |

| 3 | 39.25 | 27.86 | 32.89 | 0.44 | 0.08 | 0.02 |

| 1 | 43.66 | 33.69 | 22.65 | 0.40 | 0.10 | 0.02 |

| 2 | 44.14 | 34.17 | 21.69 | 0.14 | 0.09 | 0.02 |

| 3 | 45.55 | 35.65 | 18.80 | 0.05 | 0.05 | 0.01 |

| Penetration Rate | Interdrive Wheel | Swi, % | Sgi, % | Effective Gas Storage Space | Krg(Swi) | Krw(Sgi) |

|---|---|---|---|---|---|---|

| 266 mD | 1 | 41.70 | 4.65 | 53.65 | 0.30 | 0.31 |

| 2 | 39.98 | 8.65 | 51.37 | 0.17 | 0.25 | |

| 3 | 39.07 | 11.30 | 49.63 | 0.16 | 0.21 | |

| 0.8 mD | 1 | 63.50 | 10.62 | 25.88 | 0.22 | 0.17 |

| 2 | 61.90 | 14.48 | 23.62 | 0.13 | 0.09 | |

| 3 | 60.52 | 15.65 | 23.83 | 0.11 | 0.07 |

| Penetration Rate | Interdrive Wheel | Soi | Displacement Efficiency | Swi | Sgi | Kro(Sgi) | Krg(Soi) |

|---|---|---|---|---|---|---|---|

| 278 mD | 1 | 16.75 | 33.83 | 39 | 10.42 | 22.33 | 15.94 |

| 2 | 15.55 | 34.59 | 38.75 | 11.11 | 21.16 | 10.91 | |

| 3 | 13.48 | 36.57 | 38.75 | 11.20 | 19.92 | 8.81 | |

| 33 mD | 1 | 29.59 | 27.00 | 43.41 | 6.85 | 0.25 | 0.18 |

| 2 | 30.36 | 20.47 | 42.32 | 7.34 | 0.16 | 0.11 | |

| 3 | 30.95 | 19.39 | 42.32 | 7.79 | 0.12 | 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, G.; Liu, W.; Zhu, S.; He, H.; Wang, Q.; Sun, Y.; Xiao, Q.; Yang, S. Discussion on the Reconstruction of Medium/Low-Permeability Gas Reservoirs Based on Seepage Characteristics. Processes 2022, 10, 756. https://doi.org/10.3390/pr10040756

Gao G, Liu W, Zhu S, He H, Wang Q, Sun Y, Xiao Q, Yang S. Discussion on the Reconstruction of Medium/Low-Permeability Gas Reservoirs Based on Seepage Characteristics. Processes. 2022; 10(4):756. https://doi.org/10.3390/pr10040756

Chicago/Turabian StyleGao, Guangliang, Wei Liu, Shijie Zhu, Haiyan He, Qunyi Wang, Yanchun Sun, Qianhua Xiao, and Shaochun Yang. 2022. "Discussion on the Reconstruction of Medium/Low-Permeability Gas Reservoirs Based on Seepage Characteristics" Processes 10, no. 4: 756. https://doi.org/10.3390/pr10040756