Abstract

Biosurfactants and bioemulsifiers (BS/BE) are naturally synthesized molecules, which can be used as alternatives to traditional detergents. These molecules are commonly produced by microorganisms isolated from hydrocarbon-rich environments. Gordonia alkanivorans strain 1B was originally found in such an environment, however little was known about its abilities as a BS/BE producer. The goal of this work was to access the potential of strain 1B as a BS/BE producer and perform the initial characterization of the produced compounds. It was demonstrated that strain 1B was able to synthesize lipoglycoprotein compounds with BS/BE properties, both extracellularly and adhered to the cells, without the need for a hydrophobic inducer, producing emulsion in several different hydrophobic phases. Using a crude BS/BE powder, the critical micelle concentration was determined (CMC = 16.94 mg/L), and its capacity to reduce the surface tension to a minimum of 35.63 mN/m was demonstrated, surpassing many commercial surfactants. Moreover, after dialysis, emulsification assays revealed an activity similar to that of Triton X-100 in almond and sunflower oils. In benzene, the E24 value attained was 83.45%, which is 30% greater than that of the commercial alternative. The results obtained highlight for the presence of promising novel BS/BE produced by strain 1B.

1. Introduction

To achieve a more sustainable development, it is necessary to rethink production methods, transforming what was once a model of producing, consuming, and discarding without considering the repercussion into a circular approach based on the transformation of sustainable carbon sources into biodegradable nontoxic products. Like many others, the detergent industry, which represented an estimated market value of EUR 130.34 billion in the year 2020, is also adapting to this paradigm, and as such, there is a high demand for natural alternatives [1]. Biosurfactants/bioemulsifiers (BS/BE) are biologically produced surface-active molecules, which are alternatives to their synthetic counterparts, with lower toxicity and higher degradability, causing reduced impacts on the ecosystems. These molecules facilitate the mixing of two immiscible substances, such as water and oil or water and air, since they have both hydrophobic and hydrophilic properties. Moreover, their scope of applications is wider than simple detergents due to their intrinsic properties: lower skin irritation and reduced allergenic activity; high antioxidant, antimicrobial, antiadhesive, and antiviral properties; and varied temperature, pH, and salt resistance. They can also be used in pharmaceutical, food, cosmetics, textile industries and even in chemical synthesis [2,3].

There are several microorganisms known to produce these molecules, typically those that inhabit environments rich in hydrophobic carbon sources, such as oil contaminated soils or solid waste lixiviates, amongst others. These molecules facilitate the contact between the cells and carbon source, reducing mass transfer difficulties. Moreover, due to their nature, BS/BE can also increase the resistance of the microorganisms to these toxic environments and help scavenge nutrients which would otherwise be inaccessible [4,5].

Depending on the microorganisms, BS/BE production can be induced by culture conditions. In fact, several factors, such as oxygen concentration, agitation, pH, temperature, culture density, and/or concentration of different salts, can have both positive and negative influences [6,7,8]. One of the most influential factors is the carbon source, which, based on its nature and concentration, can change not only the amount of BS/BE produced but also its type and characteristics [9,10,11]. In this context, many BS/BE screening works refer to the use of hydrophobic carbon sources, such as oils and different organic solvents, as well as common sugars, such as sucrose or glucose, to assess/induce production.

The genus Gordonia is known for its plasticity and high adaptability, especially in hydrocarbon rich environments. Amongst the individuals of this genus, there are several examples of species capable of producing compounds with surfactant and/or emulsifying activity, differing in their nature and characteristics [12,13,14,15,16,17,18,19]. In the last decades, G. alkanivorans strain 1B has demonstrated a vast biotechnological potential. Initially, it was mostly studied for its high desulfurization abilities, as well as its fructophilic properties [20,21,22,23,24]; however, more recently, studies have been centered on its capacity to use many different alternative carbon sources [25,26,27,28] and its high production of carotenoids, which are considered high value-added products [29,30,31].

Because it was isolated from oil-contaminated soil and it presents the ability to use hydrophobic compounds as carbon or sulfur sources, it became apparent that this strain could produce surface-active compounds (BS/BE). Thus, based on prior knowledge on this desulfurizing bacterium, the main goal of this study was to perform a screening towards the culture conditions that may influence the production of surface-active compounds (BS/BE), namely, the carbon and sulfur sources (C- and S-sources), to choose the conditions that induce higher yields. Moreover, a process for extracting the BS/BE was developed and the raw characteristics of the crude extract were studied.

2. Materials and Methods

2.1. Chemicals

All chemicals used in this study were of analytical grade. Dibenzothiophene (DBT) (99%) was obtained from Acros Organics, and dimethylformamide (DMF) from Riedel-de-Haen. A DBT stock solution (150 mM) was prepared by dissolving it in DMF to facilitate manipulation, preservation, and reproducibility. Sodium sulfate anhydrous (>99%) was obtained from Merck. n-Hexadecane (99%), absolute ethanol and glycerol (86%) were from Sigma-Aldrich. Triton X-100 from Alfa Aesar and Tween 80 and Sodium dodecyl sulfate (SDS) from Merck, all with a purity > 99%, were used as reference synthetic surfactants. Yeast malt broth (YMB), a complete culture medium, was from Difco.

2.2. Microorganism and Culture Conditions

The microorganism used in this study was the bacterium G. alkanivorans strain 1B isolated from oil contaminated soil samples [20] and kept at a culture collection of microorganisms (CCM at LNEG, Portugal, Lisbon). Unless specifically stated, the basal salts medium used to maintain the culture and perform all assays was a sulfur-free mineral (SFM) medium (1.22 g/L NH4Cl, 2.5 g/L KH2PO4, 2.5 g/L Na2HPO4.2H2O, 0.17 g/L MgCl2.6H2O), supplemented with 0.5mL/L of a trace elements solution without sulfur [23]. For the induction assays, different carbon sources and sulfur sources (C- and S- sources) were added to the culture medium into different formulations, but the initial pH was always adjusted to 7.5. Unless stated otherwise, to avoid deterioration, concentrated solutions of C-source were filter sterilized and added to culture medium prior to inoculation.

In a preliminary set of assays, three different C-sources (fructose, glucose, olive oil) and two different S-sources (Na2SO4, DBT) were tested. Fructose and glucose were added for an initial concentration of 10 g/L, from a 500 g/L filter sterilized stock solution, and olive oil was added at 1% (v/v) after filter sterilization. Sodium sulfate (Na2SO4) and DBT were added for an initial concentration of 300 mg/L and 300 µM, respectively.

Then, 2 more sets of induction assays were performed, where a total of 10 C-sources were tested and compared for their induction potential. Olive oil, used olive oil, used frying oil, glycerol, n-hexadecane, and ethanol were used at 1% (v/v). The three oils were filter sterilized, glycerol was autoclaved due to its viscosity, and ethanol and n-hexadecane were considered sterile by nature. Used olive oil and used frying oil were collected after extensive heating for the confection of different foods. Food particles were also removed prior to filter sterilization. Sucrose, mannose, and citrate (from ammonium ferric citrate) were added at 10 g/L from filter sterilized concentrated solutions. Yeast malt broth (YMB), prepared according to the supplier, was also tested as an alternative complete culture medium. Thus, except for YMB cultivation, Na2SO4 at 300 mg/L was used as a S-source.

All induction cultures were performed in 500 mL shake-flasks, with 100 mL culture medium, at an initial pH of 7.5. The flasks were incubated at 30 °C, and 150 rpm agitation in an orbital incubator, without control of light source. Prior to any induction assay, the bacterial inoculum was first prepared by growing strain 1B with 150 mL of SFM medium, in 500 mL Erlenmeyer flasks, with fructose (5 g/L) as the only C-source and 150 µM DBT as the only S-source, at initial pH 7.5. The cultivation was also carried out in an orbital incubator at 30 °C and 150 rpm for 72 h. Then, 2% (v/v) of this inoculum was used to inoculate each culture medium formulation tested.

2.3. Emulsification Assays

At the end of each growth, cells were separated from the supernatant through centrifugation at 7673× g for 30 min at 4 °C. The cell-free supernatants were placed in tubes to which hydrophobic liquids were added in a 1:1 ratio, unless stated otherwise. These tubes were vigorously vortexed for 60 s and left to rest at room temperature for 24 h. The presence of a layer corresponding to the mixture of both phases, an emulsion, was evaluated. The height of the emulsion layer was measured to calculate the percentage of emulsion in relation to the total height to obtain the emulsification index (E24, %) [32]. Negative controls were performed with ultrapure water and the hydrophobic phase to correctly access emulsification potential. Triplicates were carried out for all E24 determinations.

2.4. Purification Process

2.4.1. BS/BE Extraction/Concentration

Different methods were tested to extract/concentrate the BS/BE produced. Initially, a method based on ethanol precipitation was tested, where ethanol at −20 °C was added drop by drop to the cell-free supernatant of the culture, until it represented three-quarters of the volume. During this process, there was a visible formation of precipitate, which was then washed with ethanol, dried, and resuspended in water. This new solution was then evaluated for emulsification properties through E24 assays [33,34].

Another method based on the extraction with ethyl acetate (or n-heptane) was tested: 750 µL of cell-free supernatant were mixed with 1500 µL of ethyl acetate (or n-heptane) and left overnight for separation. Afterwards, the top translucent ethyl acetate layer was collected and evaporated, resulting in a reddish viscous liquid, which was evaluated for emulsification properties [35].

In addition, two more approaches were used to extract the BS/BE from the cell-free supernatants: ethyl acetate vs. n-heptane extraction. In a first approach, the cell-free supernatants were transferred to separation funnels with ethyl acetate in a 4:1 ratio, mixed vigorously for 5 min and left overnight for phase separation. Three phases were formed: an upper phase containing ethyl acetate, a lower phase containing leftover BS/BE, and a middle phase containing an emulsion of water ethyl acetate and BS/BE. The three phases were collected separately. The lower aqueous phase and the upper phase with ethyl acetate were placed on a new funnel, and the process was repeated 2x to ensure maximum extraction. The combined middle phase was collected and centrifuged at 15,000× g for 15 min to break the emulsion and remove both water and ethyl acetate. The leftover ethyl acetate was evaporated using nitrogen gas (N2), and the BS/BE was resuspended in ultrapure water to obtain a 10-fold concentrated extract (CE). Furthermore, the concentration of each CE was determined through dry weight after freeze-drying (Biobase Vertical Freeze-Dryer, Model nº BK-FD18P).

In a second approach, to expedite the extraction methodology, a modified version of the above protocol was employed in which the organic solvent was changed from ethyl acetate to n-heptane, and the concentration step was carried out by freeze-drying to powder form, instead of using N2 evaporation. This methodology was used for the extraction of BS/BE produced by strain 1B cultivated in SFM medium with fructose and sulfate. The crude BS/BE powder obtained was used for further characterization and partial purification step (dialysis).

2.4.2. Chemical and Biochemical Composition

CHNS elemental analysis was performed following the ISO 16967:2015. The total carbohydrate content was estimated by the phenol-sulfuric acid method described by Dubois et al. [36]. Protein concentration was estimated based on the nitrogen concentration obtained in the elemental analysis [37]. For the lipid content estimation, 20 mg from the freeze dried crude BS/BE was extracted with 600 µL of chloroform:methanol (2:1 v/v). The extraction was repeated three times, and the combined organic extracts were evaporated at 50 °C. The lipid content was determined gravimetrically [38]. All chemical/biochemical composition tests were performed in triplicate.

2.4.3. Dialysis of the Extract

A total of 200 mg of the crude BS/BE powder, obtained by freeze-drying after the n-heptane extraction methodology, were solubilized in 40 mL of deionized water. Subsequently, this solution was submitted to dialysis in 12,000 Da MWCO (molecular weight cut-off) membranes (Zellutrans, Roth Carl) against deionized water with sodium azide (50 ppm) for 10 days at room temperature, with constant stirring. The dialyzed solution was then freeze-dried, and the powder obtained (named as dialyzed powder) was stored at 4 °C for further characterization.

2.5. Critical Micelle Concentration (CMC) Determination

Crude BS/BE powder was weighted and dissolved in ultrapure water to prepare solutions with different concentrations, ranging from 1.37 mg/L to 841.2 mg/L. These solutions were used in a Kruss K12 Mk6 tensiometer, at 25 °C, to access how the crude BS/BE affect the surface tension (ST). Starting with ultrapure water as negative control, progressively greater concentrations of crude BS/BE were tested. Each concentration was measured 10 times, and the ST average values obtained (mN/m) were plotted and used to calculate CMC for the crude BS/BE [39]. The same protocol was applied to SDS (0.024–4.723 g/L) and Tween 80 (0.18 and 106.24 mg/L), as worldwide reference surfactants, to access the relative surfactant activity of the BS/BE.

2.6. Oil Spreading Test

The oil spreading assay was performed by adding 30 mL of deionized water into a Petri dish with 8.5 cm in diameter, followed by the addition of 100 μL of gear oil to the surface of the water. Subsequently, using the dialyzed extract powder, different BS/BE solutions were prepared (1–10 g/L) and then 40 μL of each was added to the oil surface. The diameters of clear zones of triplicate assays from the same sample were determined. The diameter of the clear zone indicates the surfactant activity, also called oil displacement activity. A negative control was performed with deionized water, in which no oil displacement or clear zone was observed, and Triton X-100 was used as the positive control.

2.7. Effect of Temperature

The effect of temperature on BS/BE from G. alkanivorans strain 1B was first evaluated on concentrated extracts (CEs extracted with ethyl acetate methodology) obtained from the bacterial growth on fructose and DBT before and after autoclaving. Herein, the effect of autoclaving at 121 °C, 1 bar, for 30 min on emulsification index E24 was determined.

In addition, 1 g/L solution of dialyzed BS/BE, prepared by dissolving the dialyzed powder in deionized water, was also subjected to 80 °C for 20 min. The acclimatized solution was taken to a tensiometer to determine its influence on water surface tension. The same test was performed prior to the thermal treatment to compare its effects.

3. Results and Discussion

3.1. Preliminary Screening

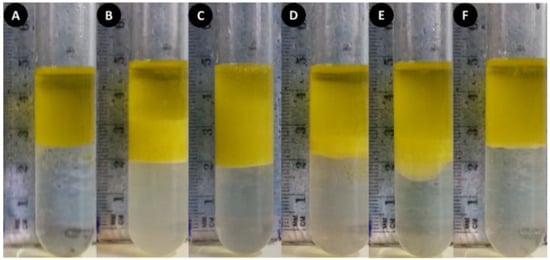

G. alkanivorans strain 1B was first cultivated with three different C-sources and two different S-sources. Fructose and glucose were selected as hydrophilic C-sources typically used to cultivate this bacterium, while olive oil was selected as a known hydrophobic inducer of BS/BE production [40]. In terms of S-sources, sodium sulfate (Na2SO4) was chosen as a common option, and dibenzothiophene (DBT) was selected as an inducer due to its hydrophobic nature and common use for biodesulfurization assays [20]. The different C-sources were adjusted to an initial concentration of 10 g/L, and the bacterial cultures were incubated for 15 days. Afterwards, the cultures were centrifuged and the cell-free supernatants were used in emulsification assays (E24) with olive oil, as illustrated in Figure 1, to screen for BS/BE production.

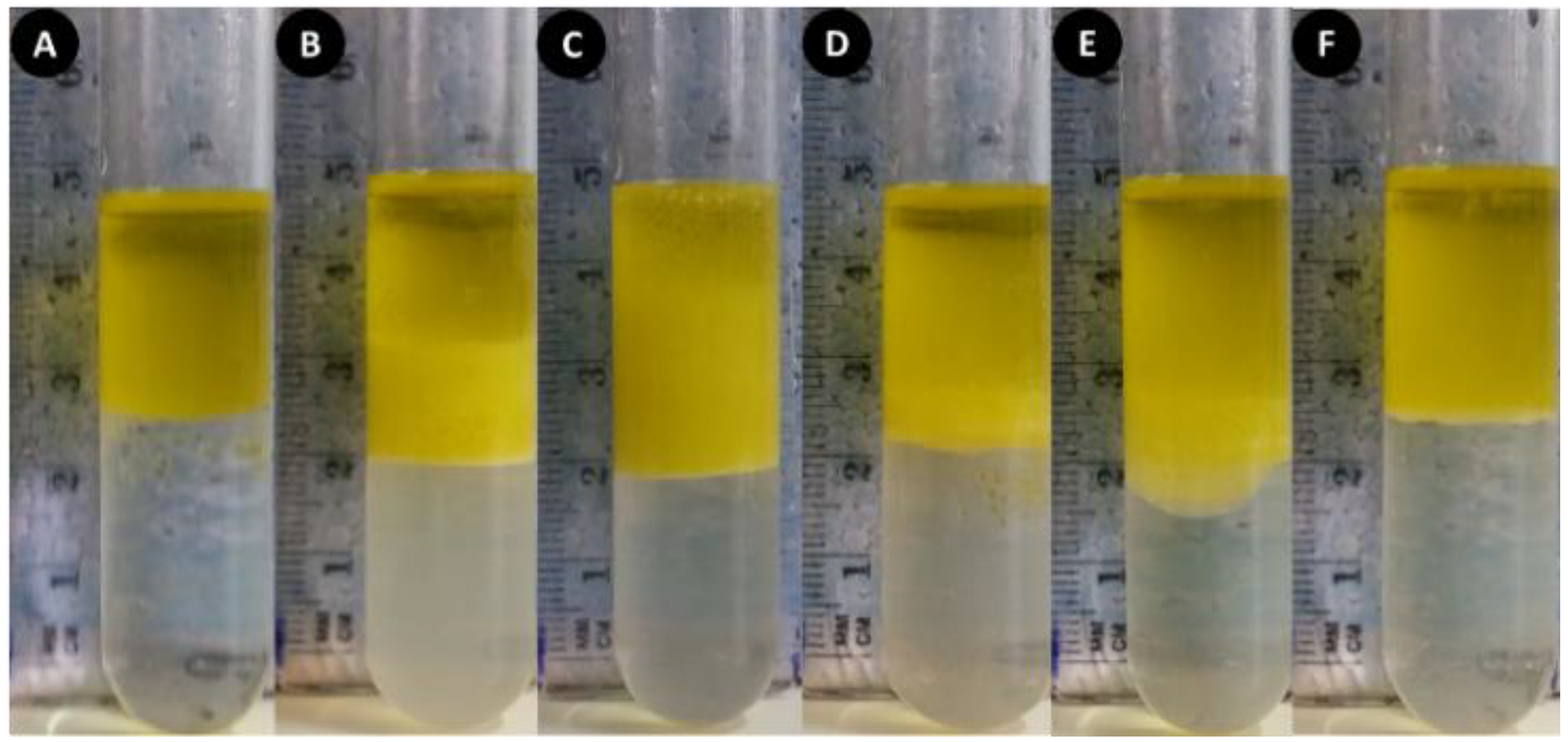

Figure 1.

Emulsification assays (E24 test) resulting from the mixture of olive oil and supernatants from cultures of G. alkanivorans strain 1B cultivated using different carbon and sulfur sources: (B) Olive oil and Na2SO4; (C) Fructose and DBT; (D) Fructose and Na2SO4; (E) Glucose and DBT; and (F) Glucose and Na2SO4. (A) Negative control with water and olive oil.

Comparing the results obtained for each supernatant (Figure 1B–F) with those obtained with water (the negative control—Figure 1A), it becomes evident that in every condition tested there was some emulsifying activity. In most conditions, the emulsion was mostly observed on the upper (hydrophobic) layer, with the exception of tube E, in which emulsification was on the lower layer. The assays with the highest emulsification indices were those with supernatants from cultures with hydrophobic inducers, namely, olive oil (Figure 1B, E24 = 23.2%) and DBT (Figure 1C,E, with E24 = 55.6 and E24 = 21.8%, respectively). In fact, the highest result, with an almost 100% emulsification of the upper layer, was obtained with the supernatant from the growth on fructose and DBT (Figure 1C), while the lowest results were observed for the supernatants from cultures with fructose/glucose and Na2SO4 (Figure 1D,F), with E24 values of 14.8% and 3.6%, respectively.

Furthermore, comparing the two S-sources, the results obtained with DBT were higher, regardless of the C-source used. Comparing the two sugars, independently of the S-source, the results obtained with fructose were higher. This indicates that glucose does not stimulate BS/BE production under these conditions or that it stimulates molecules with different properties. Since cells grown with glucose were shown to produce higher carotenoid concentrations [30], it could be the case that carbon is diverted towards these pigments reducing BS/BE production.

In addition, based on these results, a new set of assays was performed for other types of C-sources to assess their potential for BS/BE induction. Hence, strain 1B was further cultivated with n-hexadecane, ethanol, ammonium ferric citrate, mannose, sucrose, YMB (as a complete alternative culture medium), and olive oil as the positive control. After nine days of growth, cells were removed through centrifugation and the respective supernatants were tested in emulsification assays.

Moreover, to better understand the properties of the BS/BE molecules, 10-fold concentrated extracts (CEs) were also produced from the cell-free supernatants. In this context, different known methods, such as ethanol precipitation and ethyl acetate (or n-heptane) extraction, were tested to extract/concentrate these compounds; however, in all cases, the solutions obtained did not present emulsifying activity. Thus, a protocol was developed in which the supernatants were concentrated through emulsion formation with ethyl acetate. CEs were used in emulsification assays (with olive oil as the hydrophobic phase) and compared with the originals. These extracts were also subjected to freeze-drying to determine rough estimation of BS/BE concentration.

Table 1 describes the results for growth parameters (optical density at 600 nm (OD600), dry cell weight (DCW), and pH), the emulsification index (E24) values for both supernatants and CEs for each condition tested, and also the estimate of the BS/BE concentration (g/L) in CEs.

Table 1.

Analytical parameters for the cultures and supernatants (S)/concentrated extracts (CEs) obtained in the growths with different C-sources.

In terms of bacterial growth, the results confirmed that strain 1B presents a broad range of metabolic pathways, showing different behaviors depending on the C-sources tested. Using sugars such as mannose and sucrose or a complex rich medium, such as YMB, the strain 1B reached biomass and OD600 values within the expected range for 10 g/L of sugars. Using n-hexadecane and olive oil, the bacteria reached the highest values of biomass, which could be the result of the different nature of these C-sources. Using ethanol or citrate as the C-source, the biomass only reached 1.08 g/L and 0.86 g/L, respectively. The culture with ferric citrate presented the lowest results in terms of biomass (DCW) and OD, mostly due to the generation of large aggregates during growth, which made accurate sampling very difficult.

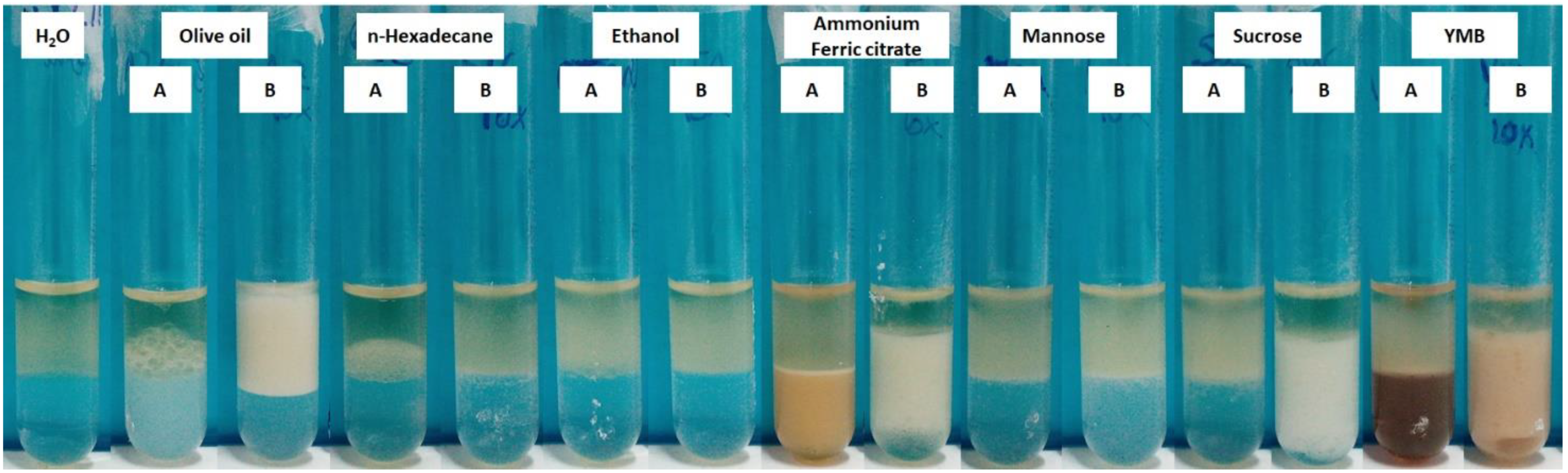

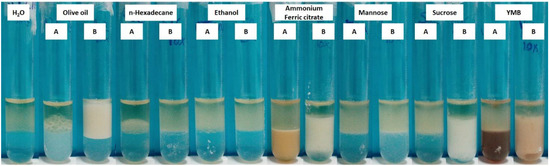

Figure 2 shows the results of the emulsification assays after 24 h, for both supernatants (Figure 2—tubes A) and their respective CEs (Figure 2—tubes B), as well as the negative control (with water). Table 1 and Figure 2 (tubes A) reveal that the direct supernatants from cultures with olive oil, n-hexadecane, sucrose, and YMB were able to form emulsions. These emulsions were mostly in the upper layer and not very strong, never reaching E24 values above 40%. Using the concentrated extracts (CEs), the culture grown on ethanol maintained the negative result, while the cultures grown on mannose and ammonium ferric citrate demonstrated emulsifying activity. The best results were observed for CEs obtained when strain 1B was grown in olive oil (57%), ammonium ferric citrate (65%), sucrose (74%), and YMB (77%), and the corresponding emulsions generated were very strong and stable. In the case of the latter three, emulsion was mostly in the lower layer, while in the case of olive oil, emulsion was mostly in the upper layer.

Figure 2.

Emulsifying activity (E24) against olive oil of the supernatants (tubes A), resulting from growth with different C-sources and respective BS/BE concentrated extracts (tubes B). Ultrapure water was used as a negative control.

It is also important to point out that although the E24 value was lower with olive oil, a complete emulsification of the upper layer was observed. This seems to indicate that different substances are being produced depending on the growth conditions. With olive oil as an inducer, even at a lower concentration there seems to be a water-in-oil emulsion, which is reinforced with the increase in concentration. On the other hand, after concentration, with the remaining C-sources, the emulsion is mostly of oil-in-water (Figure 2). Many factors could be contributing to this result. However, it is likely that the need to access C-sources of different types stimulates the production of different compounds, or slight variations in the same compound, resulting in the responses observed [9].

The emulsifying activity of the culture grown with n-hexadecane was lost during the concentration process. Since the concentration method was based on ethyl acetate precipitation/emulsification, if the BS/BE does not interact with the solvent it will be lost. Furthermore, looking at the weight of the freeze-dried CEs it becomes clear that other substances are being concentrated. CEs with low activity, such as the CE obtained from the growth with mannose, presented high BS/BE concentration (7.78 g/L), while some CEs with higher emulsifying activity, such as that from sucrose, presented lower BS/BE concentration (1.72 g/L). This indicates that there is a need to study other extraction methods and/or apply purification methods to enhance the emulsifying activity evaluation.

Comparing the biomass production and emulsifying activity, it becomes apparent that, while BS/BE production is dependent on cellular growth, there is no direct correlation between higher biomass concentration and higher E24 results. The negative result for BS/BE production obtained for ethanol can be due to the lower growth; however, for the remaining conditions, as demonstrated in the first set of assays, the nature of the C-source seems to have a greater influence. As stated above, the cultures grown with sucrose and mannose present the highest E24 values, but not the highest biomass, while the culture with n-hexadecane, presented the second highest biomass and a lower E24 result. As such, these results seem to confirm that, depending on its growth conditions, G. alkanivorans strain 1B will produce compounds with distinct properties, namely, different degrees of emulsifying activity. This fact has been previously reported in different works, where the C-source can influence not only the biochemical nature of the BS/BE produced but also its properties. For example, Ivanova et al. [41] demonstrated that with some bacteria, the use of hydrophobic C-sources induced the production of surface-active compounds, while the use of hydrophilic C-sources resulted in the production of emulsifiers.

3.2. Alternative Low-Cost Carbon Sources

The costs of large-scale microbial surfactant production are greatly influenced by the carbon source and other nutrients in the culture medium [6,9]. One way to mitigate this problem, aiming to obtain a more sustainable bioprocess, is the use of cheaper C-sources. In this context, since the strain 1B was able to grow and produce BS/BE on olive oil, this opened the possibility to test related low-cost alternative C-sources. Therefore, used olive oil and used frying oil, as model wastes from the restaurant and food industries, and glycerol, as a model for the byproduct obtained from the processing of these used oils in the biodiesel industry, were used to cultivate the bacterium towards BS/BE production. Raw olive oil was used as positive control, and Na2SO4 was used as the S-source on all assays. After the end of each growth, the supernatant and cells were separated through centrifugation, and the supernatants were used on emulsification assays.

Strain 1B was able to use all four C-sources to grow, but it showed a clear preference for the three oils, growing at a much slower rate with glycerol. When cultivated with any oil, the strain 1B grew in large aggregates surrounding the lipidic masses, while, when cultivated with glycerol, it formed smaller, more disperse aggregates. However, in both cases, the irregular cell distribution made it impossible to perform sampling over time in a representative manner.

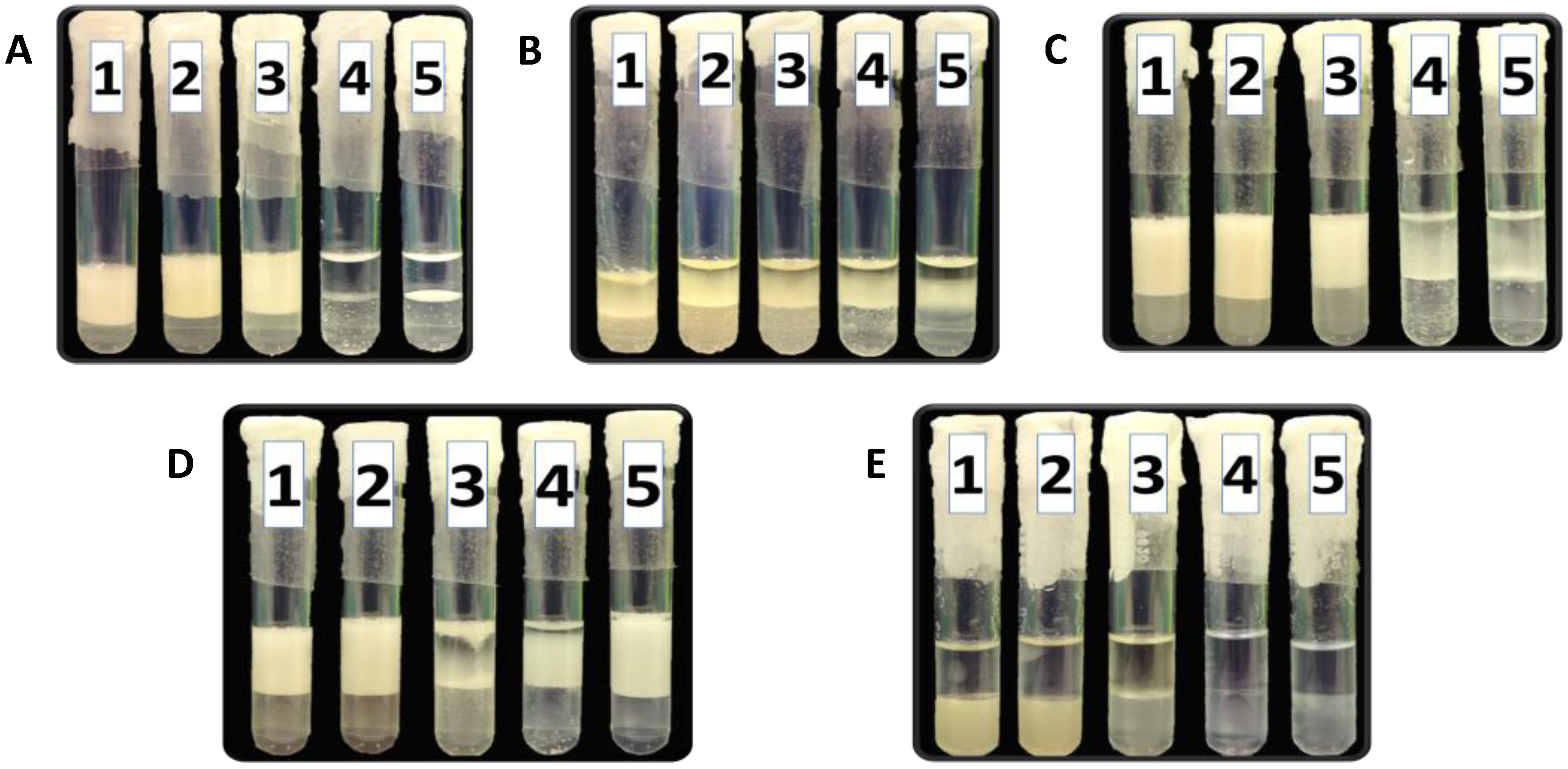

To determine the emulsification index (E24) of the different supernatants obtained, five different hydrophobic liquids were selected to be used in emulsification tests: olive oil, n-heptane, frying oil, machine oil, and ethyl acetate. Each of the four supernatants was mixed with each of the five hydrophobic liquids in a 1:1 ratio, and water was used as the negative control. The different emulsifications after 24 h are represented in Figure 3 and Table 2. The results differed depending on the C-source used for growth and the hydrophobic phase tested. Four of the five hydrophobic phases tested resulted in emulsification only in the upper layer. Ethyl acetate was the exception, with emulsification mostly in the lower aqueous layer. Overall, the supernatants from the cultures with any of the oils presented the strongest emulsions, with the highest emulsification indices being 61% to 70% in n-heptane and 56% to 67% in frying oil. The results with gear oil were the most difficult to evaluate, given that the negative control had a significant emulsification; however, supernatants obtained with olive oil (raw and used) clearly resulted in the highest emulsification indices (Table 1). Furthermore, the culture grown with used frying oil generated a different behavior in terms of emulsification pattern, incorporating air into the upper hydrophobic layer (Figure 3D—tube 3). With olive oil as a hydrophobic layer, the negative control also presented a high emulsification index; however, the oil induced cultures (Figure 3B, tubes 1–3) clearly produced greater E24 values. With ethyl acetate as the hydrophobic phase (Figure 3E), only the cultures grown on olive oil were capable of producing emulsion (approximately 54% to 56%). Overall, the culture grown with glycerol presented the lowest E24 values, only showing a slight improvement in comparison to the control when tested with frying oil (Table 2).

Figure 3.

Emulsifying activity (E24) of the supernatants resulting from growth with different C-sources (1. used olive oil; 2. raw olive oil; 3. used frying oil; and 4. glycerol), using different organic phases: (A) n-heptane; (B) olive oil; (C) frying oil; (D) gear oil; and (E) ethyl acetate. Ultrapure water was used as a negative control (5).

Table 2.

Emulsifying activity (E24) of the supernatants resulting from growth with different C-sources (1. used olive oil; 2. raw olive oil; 3. used frying oil and 4. glycerol) against n-heptane, olive oil, Frying oil, Gear oil, and ethyl acetate as organic phase. Ultrapure water was used as a negative control (5).

These results reinforce the concept that the strain 1B produces substances with different properties in response to the C-source. As expected, the use of vegetable oils as hydrophobic C-sources resulted in the highest response. Using olive oil, the BS/BE produced revealed great plasticity in terms of application, demonstrating emulsifying activity for all hydrophobic liquids tested (Figure 3). The results obtained when using glycerol were unexpected, since it has been described as a good alternative C-source to promote BS/BE production with several other bacteria [6,9,42,43]. It could be the case that, as observed with glucose, carbon is being preferentially diverted towards carotenoid production [29,30], as the culture demonstrated intense coloration. Alternatively, BS/BE molecules could be at a low concentration or present other properties, which require further studies to determine. Previous studies have demonstrated that the cultivation of different strains of Lactobacillus spp. in sugarcane molasses or glycerol generated different results in terms of the biochemical composition of the BS/BE [9]. This fact may support that the same can happen with other bacteria with different C-sources.

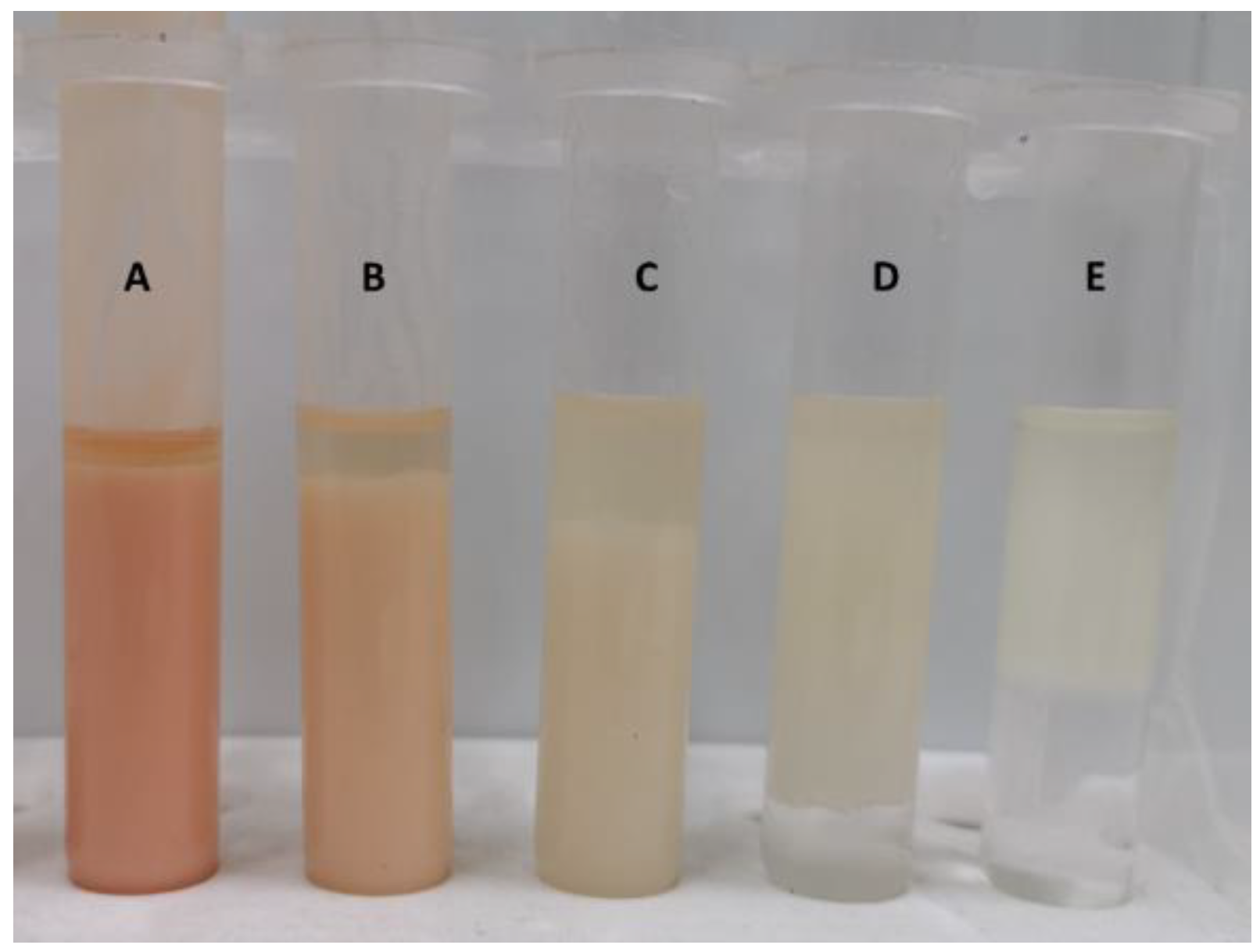

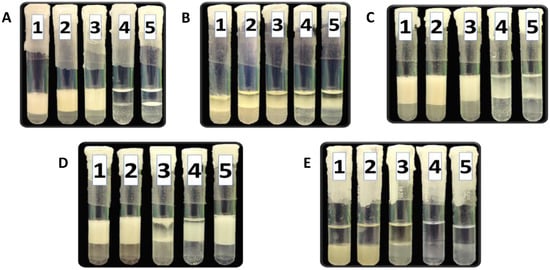

3.3. Cellular Emulsifying Activity

To determine if the cellular biomass itself also presented emulsifying activity, the strain 1B was cultivated with fructose and Na2SO4, conditions shown to induce BS/BE production. Cells were collected after centrifugation and separated from the supernatant. Then, different concentrations of cells (0.1 to 4 g, wet weight) were used in emulsification assays (E24) with olive oil to determine if cells retained some emulsifying properties (Figure 4). When the cells (4 g) were tested directly with olive oil 1:1, there was almost complete emulsification (≈95%) after 24 h (Figure 4A). By diluting the concentrated cells with three parts of water, there was a small reduction in the emulsion to 87% (Figure 4B). Further decreasing cellular concentration by diluting 0.4 g of cells in 3.6 mL generated a visible reduction in the emulsion to 77% (Figure 4C). In all three cases, the lower layer (water), maintained complete emulsion. However, by decreasing the concentration to 0.1 g of cells to 3.9 mL of water, there was a change in behavior. There was a complete emulsification of the upper olive oil layer, and a visible translucent lower phase (Figure 4D). The resulting emulsion was less dense, indicating lower emulsifying activity.

Figure 4.

Emulsifying activity (E24) of different concentrations of cells of G. alkanivorans strain 1B against olive oil in a 1:1 ratio (4 mL of hydrophobic phase:4 mL of hydrophilic phase): (A) 4 g (wet weight); (B) diluted 1:4 in ultrapure water (1 g); (C) diluted 1:10 in ultrapure water (0.4 g); (D) diluted 1:40 in ultrapure water (0.1 g); (E) negative control—ultrapure water without cells.

Looking at the negative control, using water and olive oil (Figure 4E), it becomes clear that even without cells some turbidity still remains in the upper hydrophobic layer, indicating a weak emulsion. Compared with the lowest concentration of cells (Figure 4D), the height and density of the emulsion are lower, and there is a higher percentage of clear lower phase. These results demonstrate that the cells have some emulsifying activity, even at lower concentrations, indicating that not all BS/BE produced is expelled to the culture medium, and a significant concentration is retained by the cells, either as a part of their cellular membrane or strongly attached to it [40,41,44]. As G. alkanivorans strain 1B was isolated from oil contaminated soils, such properties give it a clear evolutionary advantage, since membrane hydrophobicity would allow for easier access to the hydrophobic C-sources (e.g., hydrocarbons) abundant in oil.

3.4. Partial Purification and BS/BE Characterization

To facilitate purification and reduce interference of hydrophobic inducers, such as DBT and olive oil, strain 1B was further cultivated in SFM medium with fructose as C-source, condition shown to induce BS/BE production (Figure 1D). Once again, the supernatant was collected after cells removal by centrifugation, but, this time, it was extracted with n-heptane, instead ethyl acetate, and freeze-dried to obtain a crude BS/BE powder (less contaminated with foreign substances). Indeed, n-heptane proved to be very effective towards the extraction of surface-active substances produced by strain 1B. This crude BS/BE powder was used for chemical/biochemical characterization, CMC determination, and further purified through a dialysis step.

3.4.1. Chemical and Biochemical Composition

Different tests were performed using the crude BS/BE powder to determine its chemical/biochemical composition. Elemental analysis (CHNS) revealed a carbon percentage of 41.5%, followed by 8.3% of hydrogen and 3.4% of nitrogen and only residual sulfur (<0.3%). Biochemical results indicated that the crude powder is mostly constituted by lipids (52.3%) but also presents significant concentrations of proteins (21.25%) and polysaccharides (10.32%). These values are similar to what was described for lipoprotein biosurfactants, in terms of CHN, with a greater percentage of polysaccharides [45,46], indicating that this crude BS/BE can be a lipoglycoprotein.

It is important to highlight that, as reported for other bacteria, there could be multiple compounds present in the crude powder, with different biochemical composition and BS/BE properties. The final unpurified product could represent a mixture of lipids, polysaccharides, and proteins at different proportions depending on culture conditions [9,47]. Furthermore, as indicated above, the extraction/concentration method can drastically change this composition, since it will determine which molecules are concentrated. Nevertheless, this characterization clearly indicates that the crude BS/BE produced by the strain 1B under these conditions is mostly of lipidic nature. Previous works with other members of the Gordonia genus revealed the production of trehalose lipids [47,48,49]; however, the low polysaccharide percentage and high lipid and protein content detected and the low solubility in organic solvents seem to indicate that it is not the case for the strain 1B.

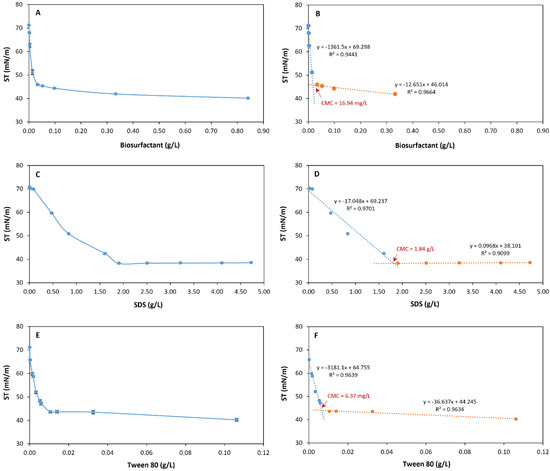

3.4.2. CMC Determination

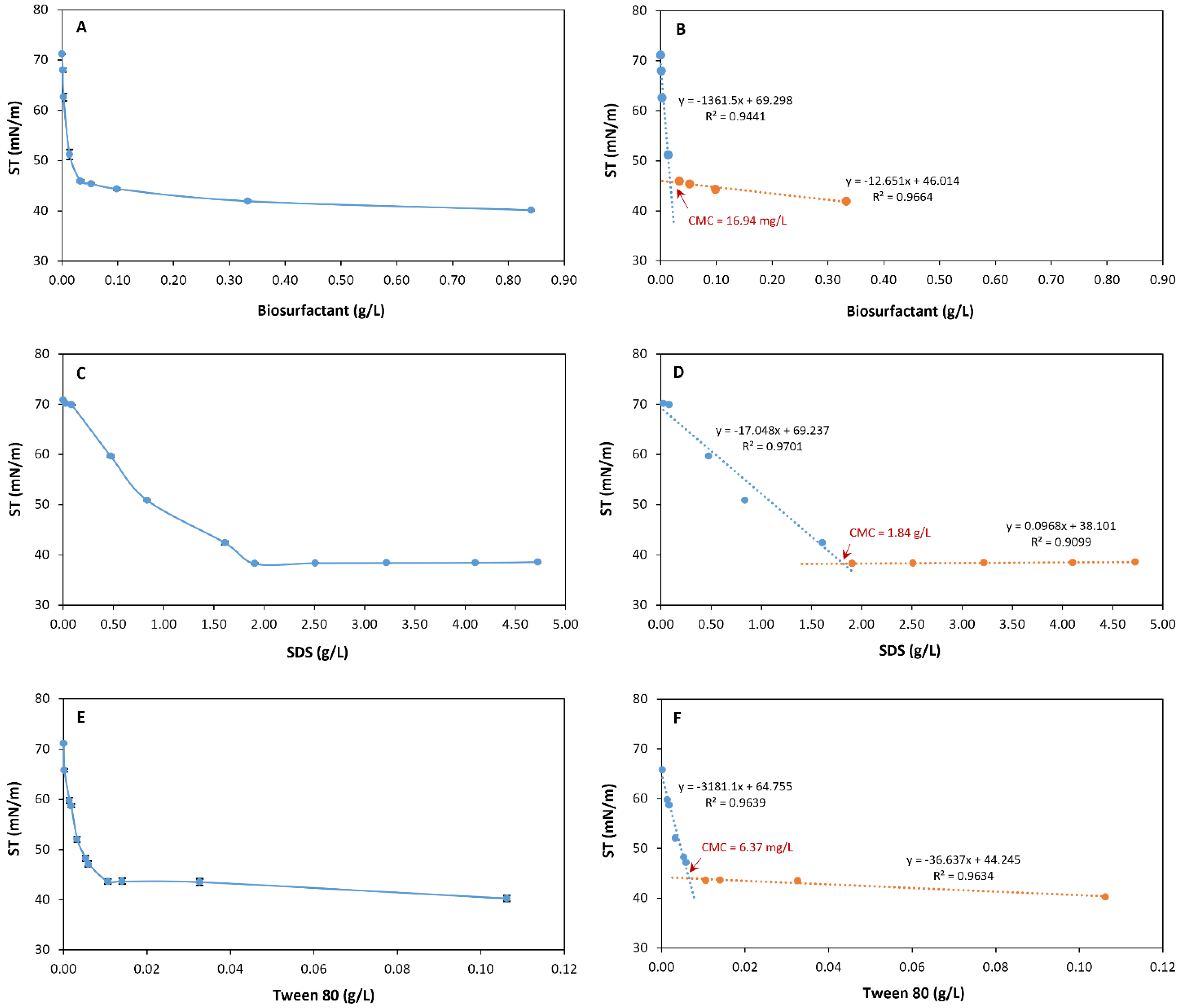

A set of solutions, with concentrations ranging from 1.37 mg/L to 841.2 mg/L, was prepared by dissolving the crude BS/BE powder in ultrapure water and then analyzed for ST (mN/m), using a tensiometer. In addition, for data comparison of surfactant activity, the ST reduction was also evaluated for SDS (0.024–4.723 g/L) and Tween 80 (0.18 and 106.24 mg/L), as worldwide reference surfactants. The results of ST in function of surfactant concentration and the corresponding CMC calculation are presented in Figure 5.

Figure 5.

Evaluation of the surface tension (ST) of different solutions containing increasing surfactant concentrations: (A) Crude BS/BE; (C) SDS and (E) Tween 80, and calculation of the corresponding CMC (B,D,F). In all plots, each data point, for each concentration, is the average value of 10 measurements. Standard deviation (n = 10) is represented as error bars in plots (A,C,E).

Figure 5A shows that for crude BS/BE, when a range of increasing concentrations up to 33.28 mg/L were tested, there was a sharp decrease in ST, from 71.17 mN/m (0 mg/L, water control) to 45.92 mN/m (33.28 mg/L). Further increases in BS/BE concentration resulted in much smaller decreases in ST to a value of 40.11 mN/m for 841.2 mg/L. Based on these results, a CMC of 16.94 mg/L was estimated for the crude BS/BE (Figure 5B), with an ST of 46.23 mN/m. However, when a concentration of about 30 g/L of crude BS/BE was tested in the tensiometer an ST of 35.63 mN/m was observed. Figure 5C,E show the effect of increasing concentrations of SDS and Tween 80, respectively, on ST. The estimated CMC value for SDS was 1836.9 mg/L (Figure 5D), with a ST of 38.28 mN/m, and for Tween 80, it was 6.37 mg/L (Figure 5F), with a ST of 44.01 mN/m.

The CMC of 16.94 mg/L, obtained for the crude BS/BE from G. alkanivorans strain 1B extracted with n-heptane without further purification is comparable to that obtained for Tween 80 (6.4 mg/L) and was significantly lower than the CMC obtained for SDS (1836.9 mg/L). Moreover, a crude BS/BE solution of 841.2 mg/L resulted in a ST reduction of about 31 mN/m (from 71.17 to 40.11 mN/m), clearly surpassing the 20 mN/m that is the threshold level defined by Willumsen & Karlson [39] to evaluate a good biosurfactant.

Other biosurfactants, such as surfactin from Bacillus subtilis AB2.0, present lower ST for similar CMC (24.7 mN/m and 16.23 mg/L) [50]. However, within the Gordonia genus, there are significant differences, and the values obtained for strain 1B are amongst the best, especially with crude extracts, without a hydrophobic inducer. Indeed, the results obtained in this study accentuate such differences, since, contrary to what was described for G. alkanivorans RIPI90A by Mohebali et al. [40], strain 1B is clearly able to produce and release BS/BE to the environment. Conversely, G. amicalis [11] was also reported to produce crude BS/BE extracts, reaching slightly worse results for similar concentrations (ST = 42.9 mN/m with 1 g/L), achieving a minimum of 37 mN/m, with its highest concentration.

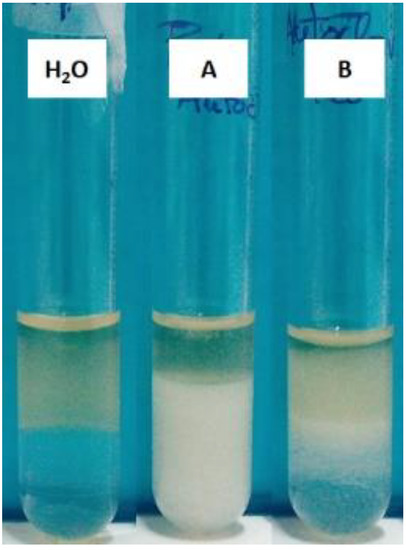

3.4.3. Dialysis and Further Characterization

The crude BS/BE powder has a vivid orange color, which clearly indicates the presence of some impurities, such as carotenoids, sugars, and salts. So, as a first attempt to remove some contamination, 200 mg of this powder was dissolved in deionized water, and the solution was subjected to a dialysis in MWCO membranes (12 kDa). The dialyzed solution was subsequently freeze-dried to be used in further characterization assays. After weighing the dialyzed powder, a reduction of 54.5% in the dry weight was observed. However, this weight loss might not correspond simply to purification. Due to its properties, some BS/BE could have been lost to the dialysis membranes since it easily adheres to surfaces. Furthermore, the dialyzed powder maintained much of its orange coloration, indicating that contaminants were still present.

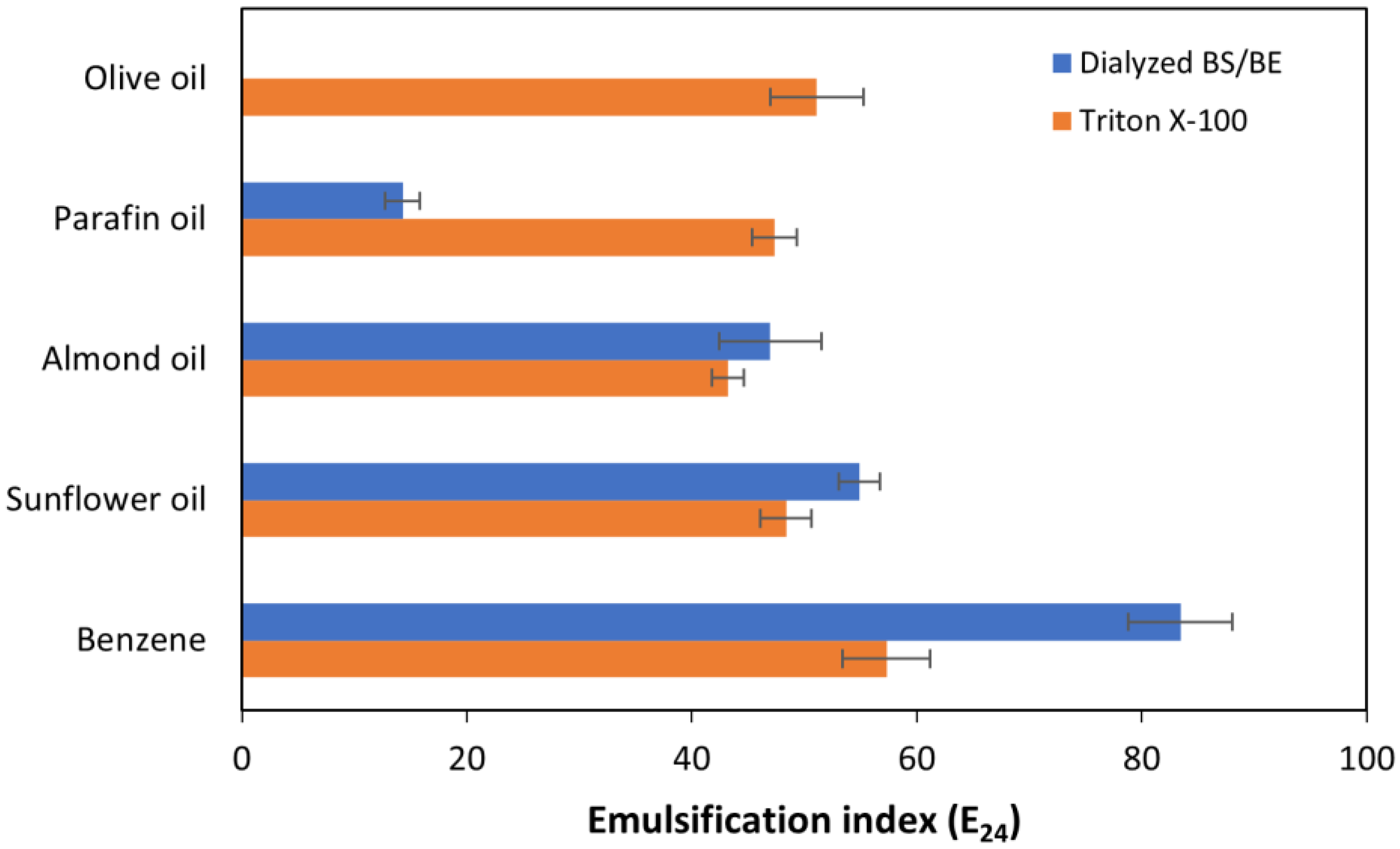

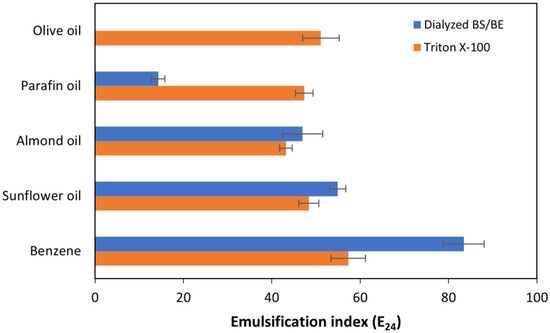

Nevertheless, this dialyzed powder was further evaluated for emulsifying activity (E24) and CMC. For the emulsification assays, the dialyzed powder was dissolved in deionized water to obtain a 1 g/L solution that was tested against different organic hydrophobic phase (benzene, olive oil, almond oil, sunflower oil, and paraffin oil). With benzene as organic phase, a control assay was also carried out with a solution 1 g/L of crude BS/BE, before dialysis, to evaluate the purification step effectiveness. After 24 h, the crude BS/BE presented an E24 of 65.22%, while the dialyzed BS/BE presented an E24 of 83.35%. This increase in the emulsification index seems to confirm that some contaminants were removed with the dialysis process; however, since the reduction in mass was >50%, a greater increase in E24 would be expected. This probably indicates that there was some BS/BE loss along the dialysis protocol.

Figure 6 presents the E24 values obtained for dialyzed BS/BE versus Triton X-100, using different organic phases. A solution of 1 g/L Triton X-100, as reference surfactant, was used as positive control for further comparison of the emulsification potential of dialyzed BS/BE. With the exception of olive oil, the dialyzed BS/BE was able to maintain emulsions for 24 h in all tested compounds, and in 3 out of 5 conditions (benzene, almond oil and sunflower oil, respectively), the E24 values observed were ≥47%, which are values characteristic of stable emulsions [39]. The highest E24 value was obtained with benzene (83.45%, as mentioned above), followed by those with sunflower oil and almond oil (54.90% and 46.97%, respectively), and the lowest E24 was obtained with paraffin oil (14.30%). When compared to Triton X-100 (Figure 6), the dialyzed BS/BE presented lower E24 values on olive and paraffin oils, similar E24 values on almond and sunflower oils and an E24 value about 30% greater on benzene. Once again, these results highlight the emulsifying properties of the BS/BE from G. alkanivorans strain 1B.

Figure 6.

Emulsifying activity (E24) of dialyzed BS/BE (biosurfactant/bioemulsifier) vs. Triton X-100 (positive control), with different organic phases (benzene, olive oil, almond and sunflower oil, and paraffin oil). Standard deviation (n = 3) is represented as error bars.

In addition, a set of increasing concentrations of dialyzed BS/BE powder (0.1–10 g/L) were prepared and further analyzed in the tensiometer for CMC determination. The CMC estimated was 0.53 g/L with a ST of 41.5 mN/m. This indicates that during the dialysis process, significant surfactant activity was lost, since CMC for crude BS/BE was 16.94 mg/L (ST = 46.23 mN/m). Much work still needs to be carried out towards the purification of BS/BE produced by strain 1B, aiming to remove contaminants without loss of surfactant/emulsifier properties.

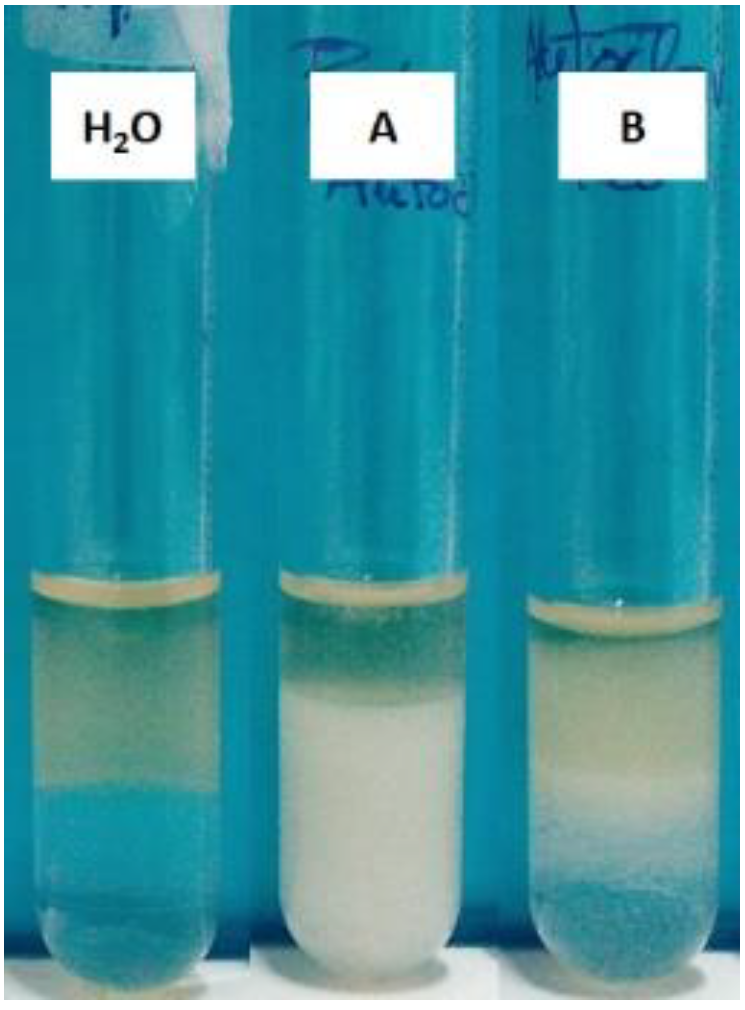

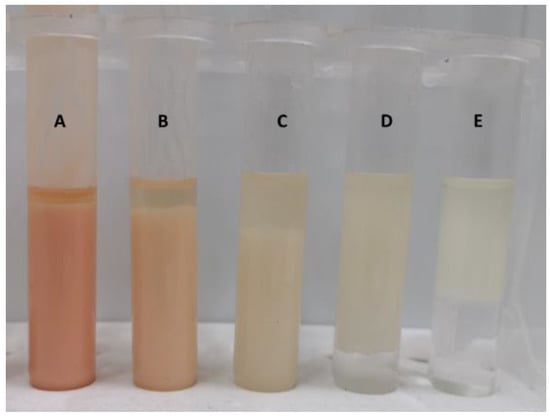

3.5. Effect of Temperature on BS/BE Properties

A first screening of the influence of temperature on the emulsifying activity of BS/BE from G. alkanivorans strain 1B was evaluated on concentrated extracts (CEs) from a bacterial growth on fructose and DBT. At the end of the growth, half of the culture was subjected to a decontamination procedure by autoclaving at 121 °C for 30 min. Both parts were centrifuged to remove cells, extracted with ethyl acetate, and concentrated 10-fold. Then, the CEs were tested in emulsification assays as presented in Figure 7. As expected, CE from non-autoclaved part of the culture presented a high emulsifying activity (Figure 7A), with a complete emulsification of the aqueous phase and a total emulsification of 70% (E24). In contrast, the CE obtained from the autoclaved part of the culture presented a significant reduction in emulsifying activity. The emulsion obtained was much weaker and mostly visible in the organic layer (Figure 7B). This indicates some destruction or modification of the BS/BE during the process of autoclaving. However, when compared with the negative control (water), after 24 h, there was a visible emulsion corresponding to an E24 of about 60%. These results show that the crude BS/BE (CE) was able to maintain emulsifier properties after being exposed to extreme conditions (121 °C for 30 min), reinforcing the potential of the new BS/BE produced by strain 1B.

Figure 7.

Emulsifying activity (E24) of the concentrated extract from a culture with fructose and DBT (A) before and (B) after autoclaving (121 °C) for 30 min. Ultrapure water was used as a negative control.

Furthermore, the effect of high temperature exposure on the surfactant activity of the BS/BE was also evaluated in a simple single-point stability test using a solution with 1 g/L of dialyzed powder. Half of this solution was subjected to 80 °C for 20 min, after which a surface tension reduction test was conducted in parallel with that for the half solution that was maintained at room temperature. The dialyzed BS/BE was able to reduce the ST of water by 38.18% (to 40.69 ± 0.09 mN/m) before the thermal treatment and by 38.54% (to 40.26 ± 0.18 mN/m) after the exposure to 80 °C for 20 min. This clearly indicates some thermal stability of surfactant properties. However, more tests must be carried out after further purification studies on G. alkanivorans strain 1B new BS/BE.

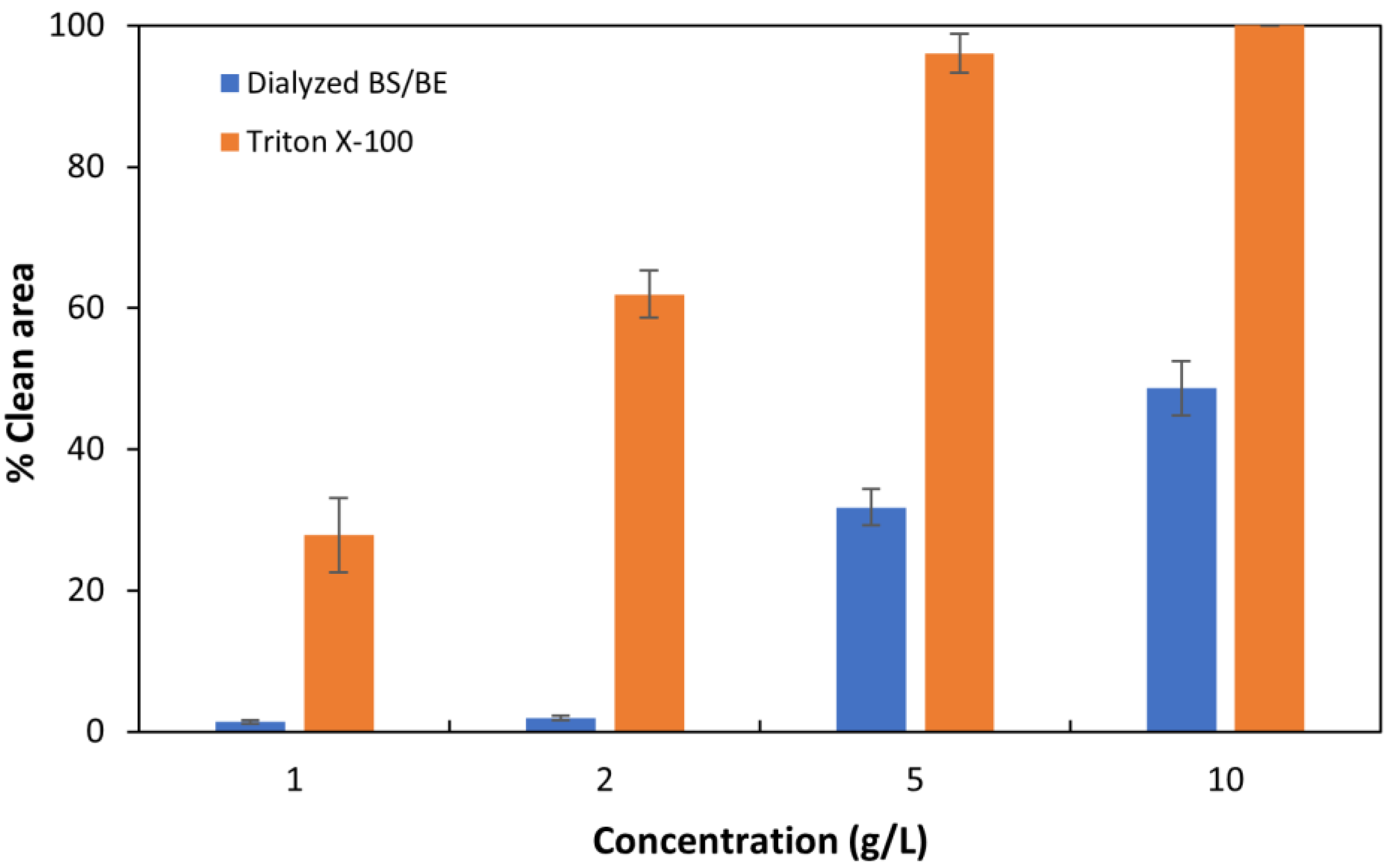

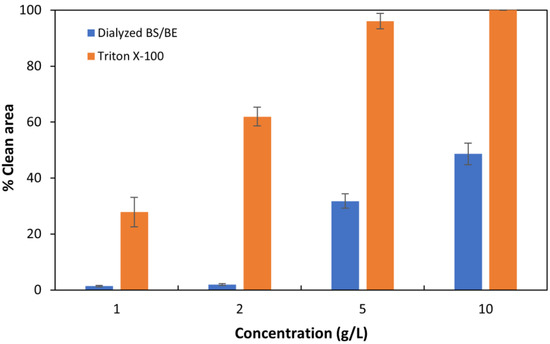

3.6. Oil Spreading Test

Oil spreading tests with gear oil are a known method for the quick relative quantification of surfactant activity [51]. Tests were conducted for both the dialyzed BS/BE and Triton X-100 as a reference surfactant. The results are illustrated in Figure 8. The oil dispersions (clear area, %) were 1.37%, 1.96%, 31.76%, and 48.63% for 1, 2, 5, and 10 g/L dialyzed BS/BE, respectively. Comparing these results to those for Triton X-100, the BS/BE from strain 1B produced significantly lower oil dispersion. However, this difference was mitigated for higher concentrations, and at 10 g/L, the BS/BE solution achieved almost 50% of the oil-dispersing activity demonstrated by Triton X-100 at the same concentration.

Figure 8.

Results from oil dispersion test using both dialyzed BS/BE (biosurfactant/bioemulsifier) and Triton X-100. Standard deviation (n = 3) is represented as error bars.

Initial concentration, using n-heptane, favored compounds with emulsifying activity (Figure 6), which may contributed to a smaller oil-dispersing activity. In fact, as stated above, the dialyzed BS/BE is not a purified extract, and therefore, these results can be greatly improved after adequate purification advances.

4. Conclusions

This screening study demonstrated that G. alkanivorans strain 1B can produce surface-active compounds, denominated as BS/BE since they present both surfactant and emulsifying activities. The diverse growth conditions of strain 1B, with different C- and/or S- sources, have induced BS/BE synthesis with different properties (e.g., distinct emulsifying activity on several different organic hydrophobic phases), which can indicate the presence of different molecules. A crude BS/BE, obtained by n-heptane extraction process from a bacterial culture grown in fructose and sulfate, was characterized in terms of biochemical composition and both surfactant and emulsifying activities. It was identified as a potential lipoglycoprotein, with an E24 of 65.22%, against benzene and a CMC value of 16.94 mg/L (ST = 46.23 mN/m), which is comparable to that obtained for Tween 80 (6.4 mg/L), with close ST values, and it was significantly lower than the CMC obtained for SDS (1836.9 mg/L). Moreover, a crude BS/BE solution of 841.2 mg/L resulted in an ST reduction of about 31 mN/m (from 71.17 to 40.11 mN/m), clearly surpassing the 20 mN/m that is the threshold level to evaluate a good biosurfactant.

Dialysis was assessed as a partial purification process, but the further characterization of dialyzed BS/BE indicated that there was some product loss along the dialysis process, leading to the inherent loss of its emulsifier/surfactant properties. For an accurate characterization of this new BS/BE produced by strain 1B, a rigorous work on its purification must be carried out aiming to identify the type of compound(s).

Overall, this study helps to better understand the behavior of this strain when exposed to different inducements and some of its adaptations to its original hydrocarbon rich environment, while at the same time pointing out a promising novel BS/BS that can be a useful tool towards different industries as its chemical counterpart alternative. One possible application is as a high-value-added product into a fossil fuel biodesulfurization refinery with G. alkanivorans strain 1B.

Author Contributions

Conceptualization, T.P.S.; formal analysis, T.P.S., S.M.P., J.T., C.V.G. and L.A.; funding acquisition, S.M.P., C.A.V.T., F.F. and L.A.; investigation, T.P.S., S.M.P., J.T., C.V.G., C.A.V.T., F.F. and L.A.; methodology, T.P.S., S.M.P., J.T., C.V.G. and L.A.; project administration, S.M.P., C.A.V.T., F.F. and L.A.; supervision, S.M.P., F.F. and L.A.; validation, T.P.S., S.M.P. and L.A.; writing—original draft, T.P.S.; writing—review and editing, S.M.P., J.T., C.V.G., C.A.V.T., F.F. and L.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financed by national funds through FCT (Fundação para a Ciência e a Tecnologia) in the scope of the project GreenFuel (PTDC/EAM-AMB/30975/2017). Elemental analysis was performed in the Laboratory of Biofuels and Biomass (LBB) at LNEG by Amélia Caldeira and Rita Sousa. In addition, biosurfactant dialysis and subsequent characterization was also supported by national funds from FCT in the scope of the project UIDP/04378/2020 and UIDB/04378/2020 of the Research Unit on Applied Molecular Biosciences—UCIBIO and the project LA/P/0140/2020 of the Associate Laboratory Institute for Health and Bioeconomy—i4HB. Tiago P. Silva also acknowledges FCT for his PhD financial support (SFRH/BD/104977/2014).

Data Availability Statement

The authors confirm that the datasets supporting the findings and conclusions of this study are available within the article.

Acknowledgments

This work was financed by national funds through FCT (Fundação para a Ciência e a Tecnologia) in the scope of the project GreenFuel (PTDC/EAM-AMB/30975/2017). Elemental analysis was performed in the Laboratory of Biofuels and Biomass (LBB) at LNEG by Amélia Caldeira and Rita Sousa. In addition, biosurfactant dialysis and subsequent characterization was also supported by national funds from FCT in the scope of the project UIDP/04378/2020 and UIDB/04378/2020 of the Research Unit on Applied Molecular Biosciences—UCIBIO and the project LA/P/0140/2020 of the Associate Laboratory Institute for Health and Bioeconomy—i4HB. Tiago P. Silva also acknowledges FCT for his PhD financial support (SFRH/BD/104977/2014).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Research and Markets Global Laundry Detergents Industry (2020 to 2027)—Key Market Trends and Drivers. Available online: https://www.prnewswire.com/news-releases/global-laundry-detergents-industry-2020-to-2027---key-market-trends-and-drivers-301289066.html (accessed on 3 November 2021).

- Fei, D.; Zhou, G.-W.; Yu, Z.-Q.; Gang, H.-Z.; Liu, J.-F.; Yang, S.-Z.; Ye, R.-Q.; Mu, B.-Z. Low-Toxic and Nonirritant Biosurfactant Surfactin and Its Performances in Detergent Formulations. J. Surfactants Deterg. 2020, 23, 109–118. [Google Scholar] [CrossRef]

- Jahan, R.; Bodratti, A.M.; Tsianou, M.; Alexandridis, P. Biosurfactants, Natural Alternatives to Synthetic Surfactants: Physicochemical Properties and Applications. Adv. Colloid Interface Sci. 2020, 275, 102061. [Google Scholar] [CrossRef]

- Carolin, C.F.; Kumar, P.S.; Ngueagni, P.T. A Review on New Aspects of Lipopeptide Biosurfactant: Types, Production, Properties and Its Application in the Bioremediation Process. J. Hazard. Mater. 2021, 407, 124827. [Google Scholar] [CrossRef] [PubMed]

- Ravindran, A.; Sajayan, A.; Priyadharshini, G.B.; Selvin, J.; Kiran, G.S. Revealing the Efficacy of Thermostable Biosurfactant in Heavy Metal Bioremediation and Surface Treatment in Vegetables. Front. Microbiol. 2020, 11, 222. [Google Scholar] [CrossRef]

- Moshtagh, B.; Hawboldt, K.; Zhang, B. Biosurfactant Production by Native Marine Bacteria (Acinetobacter Calcoaceticus P1-1A) Using Waste Carbon Sources: Impact of Process Conditions. Can. J. Chem. Eng. 2021, 99, 2386–2397. [Google Scholar] [CrossRef]

- Franzetti, A.; Caredda, P.; la Colla, P.; Pintus, M.; Tamburini, E.; Papacchini, M.; Bestetti, G. Cultural Factors Affecting Biosurfactant Production by Gordonia Sp. BS29. Int. Biodeterior. Biodegrad. 2009, 63, 943–947. [Google Scholar] [CrossRef]

- Nazareth, T.C.; Zanutto, C.P.; Maass, D.; Ulson De Souza, A.A.; Ulson De Souza, S.M.D.A.G. Impact of Oxygen Supply on Surfactin Biosynthesis Using Brewery Waste as Substrate. J. Environ. Chem. Eng. 2021, 9, 105372. [Google Scholar] [CrossRef]

- Mouafo, T.H.; Mbawala, A.; Ndjouenkeu, R. Effect of Different Carbon Sources on Biosurfactants’ Production by Three Strains of Lactobacillus spp. BioMed Res. Int. 2018, 2018, 5034783. [Google Scholar] [CrossRef]

- Sowani, H.; Kulkarni, M.; Zinjarde, S. Harnessing the Catabolic Versatility of Gordonia Species for Detoxifying Pollutants. Biotechnol. Adv. 2019, 37, 382–402. [Google Scholar] [CrossRef]

- Jackisch-Matsuura, A.B.; Santos, L.S.; Eberlin, M.N.; de Faria, A.F.; Matsuura, T.; Grossman, M.J.; Durrant, L.R. Production and Characterization of Surface-Active Compounds from Gordonia Amicalis. Braz. Arch. Biol. Technol. 2014, 57, 138–144. [Google Scholar] [CrossRef]

- Arenskötter, M.; Bröker, D.; Steinbüchel, A. Biology of the Metabolically Diverse Genus Gordonia. Appl. Environ. Microbiol. 2004, 70, 3195–3204. [Google Scholar] [CrossRef] [PubMed]

- Franzetti, A.; Bestetti, G.; Caredda, P.; la Colla, P.; Tamburini, E. Surface-Active Compounds and Their Role in the Access to Hydrocarbons in Gordonia Strains. FEMS Microbiol. Ecol. 2008, 63, 238–248. [Google Scholar] [CrossRef] [PubMed]

- Fusconi, R.; Maria Nascimento Assunção, R.; de Moura Guimarães, R.; Rodrigues Filho, G.; Eduardo da Hora Machado, A. Exopolysaccharide Produced by Gordonia Polyisoprenivorans CCT 7137 in GYM Commercial Medium and Sugarcane Molasses Alternative Medium: FT-IR Study and Emulsifying Activity. Carbohydr. Polym. 2010, 79, 403–408. [Google Scholar] [CrossRef]

- Qi, P.; Zhang, G.; Sun, D.; Wu, T.; Li, Y. Enhanced Separation of Emulsified Oil from Alkaline-Surfactant-Polymer Flooding Produced Water by Gordonia Sp. TD-4: From Interactions to Mitigation Strategies and Bio-Demulsifying Mechanisms. J. Clean. Prod. 2022, 337, 130538. [Google Scholar] [CrossRef]

- Sowani, H.; Kulkarni, M.; Zinjarde, S. Uptake and Detoxification of Diesel Oil by a Tropical Soil Actinomycete Gordonia Amicalis HS-11: Cellular Responses and Degradation Perspectives. Environ. Pollut. 2020, 263, 114538. [Google Scholar] [CrossRef]

- Qi, P.; Sun, D.; Gao, J.; Liu, S.; Wu, T.; Li, Y. Demulsification and Bio-Souring Control of Alkaline-Surfactant-Polymer Flooding Produced Water by Gordonia Sp. TD-4. Sep. Purif. Technol. 2021, 263, 118359. [Google Scholar] [CrossRef]

- Saeki, H.; Sasaki, M.; Komatsu, K.; Miura, A.; Matsuda, H. Oil Spill Remediation by Using the Remediation Agent JE1058BS That Contains a Biosurfactant Produced by Gordonia Sp. Strain JE-1058. Bioresour. Technol. 2009, 100, 572–577. [Google Scholar] [CrossRef]

- Laorrattanasak, S.; Rongsayamanont, W.; Khondee, N.; Paorach, N.; Soonglerdsongpha, S.; Pinyakong, O.; Luepromchai, E. Production and Application of Gordonia Westfalica GY40 Biosurfactant for Remediation of Fuel Oil Spill. Water Air Soil Pollut. 2016, 227, 325. [Google Scholar] [CrossRef]

- Alves, L.; Salgueiro, R.; Rodrigues, C.; Mesquita, E.; Matos, J.; Gírio, F.M. Desulfurization of Dibenzothiophene, Benzothiophene, and Other Thiophene Analogs by a Newly Isolated Bacterium, Gordonia Alkanivorans Strain 1B. Appl. Biochem. Biotechnol.-Part A Enzym. Eng. Biotechnol. 2005, 120, 199–208. [Google Scholar] [CrossRef]

- Alves, L.; Melo, M.; Mendonça, D.; Simões, F.; Matos, J.; Tenreiro, R.; Gírio, F.M. Sequencing, Cloning and Expression of the Dsz Genes Required for Dibenzothiophene Sulfone Desulfurization from Gordonia Alkanivorans Strain 1B. Enzym. Microb. Technol. 2007, 40, 1598–1603. [Google Scholar] [CrossRef]

- Alves, L.; Paixão, S.M. Toxicity Evaluation of 2-Hydroxybiphenyl and Other Compounds Involved in Studies of Fossil Fuels Biodesulphurisation. Bioresour. Technol. 2011, 102, 9162–9166. [Google Scholar] [CrossRef] [PubMed]

- Alves, L.; Paixão, S.M. Fructophilic Behaviour of Gordonia Alkanivorans Strain 1B during Dibenzothiophene Desulfurization Process. New Biotechnol. 2014, 31, 73–79. [Google Scholar] [CrossRef] [PubMed]

- Alves, L.; Paixão, S.M.; Pacheco, R.; Ferreira, A.F.; Silva, C.M. Biodesulphurization of Fossil Fuels: Energy, Emissions and Cost Analysis. RSC Adv. 2015, 5, 34047–34057. [Google Scholar] [CrossRef]

- Alves, L.; Paixão, S.M. Enhancement of Dibenzothiophene Desulfurization by Gordonia Alkanivorans Strain 1B Using Sugar Beet Molasses as Alternative Carbon Source. Appl. Biochem. Biotechnol. 2014, 172, 3297–3305. [Google Scholar] [CrossRef]

- Paixão, S.M.; Silva, T.P.; Arez, B.F.; Alves, L. Advances in the Reduction of the Costs Inherent to Fossil Fuels Biodesulfurization Towards Its Potential Industrial Application. In Nanocomposites for the Desulfurization of Fuels; Saleh, T., Ed.; IGI Global: Hershey, PA, USA, 2020; pp. 235–283. [Google Scholar]

- Silva, T.P.; Paixão, S.M.; Teixeira, A.V.; Roseiro, J.C.; Alves, L. Optimization of Low Sulfur Carob Pulp Liquor as Carbon Source for Fossil Fuels Biodesulfurization. J. Chem. Technol. Biotechnol. 2013, 88, 919–923. [Google Scholar] [CrossRef]

- Silva, T.P.; Paixão, S.M.; Roseiro, J.C.; Alves, L. Jerusalem Artichoke as Low-Cost Fructose-Rich Feedstock for Fossil Fuels Desulphurization by a Fructophilic Bacterium. J. Appl. Microbiol. 2015, 118, 609–618. [Google Scholar] [CrossRef]

- Silva, T.P.; Paixão, S.M.; Alves, L. Ability of Gordonia Alkanivorans Strain 1B for High Added Value Carotenoids Production. RSC Adv. 2016, 6, 58055–58063. [Google Scholar] [CrossRef]

- Fernandes, A.S.; Paixão, S.M.; Silva, T.P.; Roseiro, J.C.; Alves, L. Influence of Culture Conditions towards Optimal Carotenoid Production by Gordonia Alkanivorans Strain 1B. Bioprocess Biosyst. Eng. 2018, 41, 143–155. [Google Scholar] [CrossRef]

- Silva, T.P.; Alves, L.; Paixão, S.M. Effect of Dibenzothiophene and Its Alkylated Derivatives on Coupled Desulfurization and Carotenoid Production by Gordonia Alkanivorans Strain 1B. J. Environ. Manag. 2020, 270, 110825. [Google Scholar] [CrossRef]

- Dubey, K.V.; Charde, P.N.; Meshram, S.U.; Shendre, L.P.; Dubey, V.S.; Juwarkar, A.A. Surface-Active Potential of Biosurfactants Produced in Curd Whey by Pseudomonas Aeruginosa Strain-PP2 and Kocuria Turfanesis Strain-J at Extreme Environmental Conditions. Bioresour. Technol. 2012, 126, 368–374. [Google Scholar] [CrossRef]

- Squillaci, G.; Finamore, R.; Diana, P.; Restaino, O.F.; Schiraldi, C.; Arbucci, S.; Ionata, E.; la Cara, F.; Morana, A. Production and Properties of an Exopolysaccharide Synthesized by the Extreme Halophilic Archaeon Haloterrigena Turkmenica. Appl. Microbiol. Biotechnol. 2016, 100, 613–623. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, A.S.; Coutinho, J.O.P.A.; Júnior, A.C.; Rosa, C.A.; Siqueira, E.P.; Santos, V.L. Characterization of New Biosurfactant Produced by Trichosporon Montevideense CLOA 72 Isolated from Dairy Industry Effluents. J. Basic Microbiol. 2009, 49, 553–563. [Google Scholar] [CrossRef] [PubMed]

- Loiseau, C.; Portier, E.; Corre, M.H.; Schlusselhuber, M.; Depayras, S.; Berjeaud, J.M.; Verdon, J. Highlighting the Potency of Biosurfactants Produced by Pseudomonas Strains as Anti-Legionella Agents. BioMed Res. Int. 2018, 2018, 8194368. [Google Scholar] [CrossRef] [PubMed]

- Dubois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric Method for Determination of Sugars and Related Substances. Anal. Chem. 2002, 28, 350–356. [Google Scholar] [CrossRef]

- Krul, E.S. Calculation of Nitrogen-to-Protein Conversion Factors: A Review with a Focus on Soy Protein. J. Am. Oil Chem. Soc. 2019, 96, 339–364. [Google Scholar] [CrossRef]

- Lewis, T.; Nichols, P.D.; McMeekin, T.A. Evaluation of Extraction Methods for Recovery of Fatty Acids from Lipid-Producing Microheterotrophs. J. Microbiol. Methods 2000, 43, 107–116. [Google Scholar] [CrossRef]

- Willumsen, P.A.; Karlson, U. Screening of Bacteria, Isolated from PAH-Contaminated Soils, for Production of Biosurfactants and Bioemulsifiers. Biodegradation 1996, 7, 415–423. [Google Scholar] [CrossRef]

- Mohebali, G.; Ball, A.; Kaytash, A.; Rasekh, B. Stabilization of Water/Gas Oil Emulsions by Desulfurizing Cells of Gordonia Alkanivorans RIPI90A. Microbiology 2007, 153, 1573–1581. [Google Scholar] [CrossRef][Green Version]

- Ivanova, A.E.; Borzenkov, I.A.; Sokolova, D.S. Catabolic Potential and Surfactant Activity of Halotolerant Hydrocarbon-Oxidizing Bacteria. Microbiology 2021, 90, 405–415. [Google Scholar] [CrossRef]

- Putri, M.; Hertadi, R. Effect of Glycerol as Carbon Source for Biosurfactant Production by Halophilic Bacteria Pseudomonas Stutzeri BK-AB12. Procedia Chem. 2015, 16, 321–327. [Google Scholar] [CrossRef]

- Bezerra, K.G.O.; Gomes, U.V.R.; Silva, R.O.; Sarubbo, L.A.; Ribeiro, E. The Potential Application of Biosurfactant Produced by Pseudomonas Aeruginosa TGC01 Using Crude Glycerol on the Enzymatic Hydrolysis of Lignocellulosic Material. Biodegradation 2019, 30, 351–361. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wu, J.; Liu, Y.; Wu, X. Biological Process of Alkane Degradation by Gordonia Sihwaniensis. ACS Omega 2022, 7, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Saranya, P.; Bhavani, P.; Swarnalatha, S.; Sekaran, G. Biosequestration of Chromium(III) in an Aqueous Solution Using Cationic and Anionic Biosurfactants Produced from Two Different Bacillus Sp.—A Comparative Study. RSC Adv. 2015, 5, 80596–80611. [Google Scholar] [CrossRef]

- Rodríguez-López, L.; López-Prieto, A.; Lopez-Álvarez, M.; Pérez-Davila, S.; Serra, J.; González, P.; Cruz, J.M.; Moldes, A.B. Characterization and Cytotoxic Effect of Biosurfactants Obtained from Different Sources. ACS Omega 2020, 5, 31381–31390. [Google Scholar] [CrossRef] [PubMed]

- Franzetti, A.; Caredda, P.; Ruggeri, C.; la Colla, P.; Tamburini, E.; Papacchini, M.; Bestetti, G. Potential Applications of Surface Active Compounds by Gordonia Sp. Strain BS29 in Soil Remediation Technologies. Chemosphere 2009, 75, 801–807. [Google Scholar] [CrossRef]

- Delegan, Y.; Sargsyan, A.; Hovhannisyan, N.; Babayan, B.; Petrikov, K.; Vainstein, M. Analysis of Genome Sequence and Trehalose Lipid Production Peculiarities of the Thermotolerant Gordonia Strain. J. Basic Microbiol. 2020, 60, 14–21. [Google Scholar] [CrossRef]

- Iwahori, K.; Tokutomi, T.; Miyata, N.; Fujita, M. Formation of Stable Foam by the Cells and Culture Supernatant of Gordonia (Nocardia) Amarae. J. Biosci. Bioeng. 2001, 92, 77–79. [Google Scholar] [CrossRef]

- Alvarez, V.M.; Guimarães, C.R.; Jurelevicius, D.; de Castilho, L.V.A.; de Sousa, J.S.; da Mota, F.F.; Freire, D.M.G.; Seldin, L. Microbial Enhanced Oil Recovery Potential of Surfactin-Producing Bacillus Subtilis AB2.0. Fuel 2020, 272, 117730. [Google Scholar] [CrossRef]

- Youssef, N.H.; Duncan, K.E.; Nagle, D.P.; Savage, K.N.; Knapp, R.M.; McInerney, M.J. Comparison of Methods to Detect Biosurfactant Production by Diverse Microorganisms. J. Microbiol. Methods 2004, 56, 339–347. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).