1. Introduction

The frequency range and intensity of fluid fluctuations in aircraft hydraulic systems are widened and aggravated due to high-velocity and -pressure conditions, and the vibration modes of aircraft hydraulic pipes are diverse, on account of the complex pipe structures or multiple structural supports, as well as a wide range of external excitations. The resulting fluid–structure interaction (FSI) vibration can easily cause pipe rupture and leakage failure, thus threatening the reliability of the hydraulic systems and safety of the aircraft. Therefore, it is a significant research work to investigate the frequency domain FSI vibration characteristics of aircraft hydraulic pipes.

Considerable research regarding the FSI nonlinear dynamics characteristics of aircraft hydraulic pipes has been reported in the past years [

1,

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12]. The precondition for analyzing these dynamic behaviors was to establish an accurate mathematical model. Many researchers deduced the dynamics model for pipes conveying fluid, and linear partial differential equations were used for the relevant study in this paper. The typical existing research results and status are summarized. Skalak [

13] defined the fundamental four-equation model as describing the axial vibration of pipes conveying fluid, where the water hammer model was coupled to two equations regarding the axial force model for the pipe; the friction and damping effects were disregarded. Then, by considering Poisson coupling and factors for the pipe wall thickness, the four-equation model was further modified and extended by Wiggert et al. and Tijsseling [

14,

15] to have smaller correction terms, and it achieved good predictions of a straight single pipe in a pipe system [

16]. Based on the theory of inviscid compressible fluid pressure pulses in a thin-walled pipe, Walker and Phillips [

17] developed the six-equation model, and it was applied to the numerical solution of a water-filled copper pipe with a cap under an axial impulsive force. The eight-equation model, used to describe plane elbow, was first proposed by Davidson and Smith [

18] and includes four axial vibration equations and four transverse vibration equations. Gale and Tiselj [

19] improved Skalak’s four-equation model by adding four Timoshenko’s beam equations and presented the eight-equation model for the description of the two-way fluid–structure interaction of both one-dimensional pipes and two-dimensional planar pipes with arbitrary shape; this model was successfully applied to the numerical simulation of the tank–pipe–valve system. Wilkinson [

20] proposed the fourteen-equation model based on the Bernoulli–Euler beam model, and transfer matrices and equations representing boundary various conditions were derived. Then, the fourteen-equation model was extended and widely used by many scholars [

21,

22,

23,

24] for modelling fluid pulsation, Poisson coupling, friction coupling, junction coupling, deformation of the pipe in various directions, extra mass, springs, and various complex boundary conditions. Moreover, the fourteen-equation model has been applied to the analysis of some complex engineering environments [

1,

4,

10,

23,

25], and it has become the most systemic model at present. Notably, Tan et al. [

26] found that Timoshenko beam theory is more suitable for studying the vibration characteristics of pipes conveying high-speed fluid. Therefore, the engineering application and verification of the fourteen-equation model based on Timoshenko beam theory in high-speed fluid transmission pipes deserve further study.

In the above-mentioned models, only semi-analytical or numerical methods can be used for solving; the representative methods are as follows: method of characteristics (MOC) [

14,

27,

28,

29,

30], finite element method (FEM) [

31,

32,

33], MOC–FEM [

34,

35], and transfer matrix method (TMM) [

1,

4,

10,

21,

23,

24,

25,

36,

37,

38,

39]. MOC and MOC–FEM are especially used for fluid transient response analysis in the time domain, while FEM and TMM are widely used for forced vibration response in the frequency domain [

1]. FEM is the most common method for analyzing complex pipe structures; however, FEM requires a better quality mesh to ensure solution precision at high frequencies [

3], which will consume a lot of computing time and memory resources [

36]. Compared with FEM, the TMM can not only construct the governing equation more easily, but it can also lessen the amount of calculation; therefore, the TMM is easily adaptable to industrial applications. The typical existing research works are summarized. Considering straight and uniformly curved tubing segments as a one-dimensional distributed parameter system, Tentarelli [

21] proposed an appropriate set of dynamic models and analytical methods that were applicable to simple sections and complex pipe systems, and they were based on the TMM. Lesmez et al. [

39] deduced the overall transfer matrix of the pipe system conveying fluid; the corresponding state vectors of the pipe and fluid were provided, and the modal analysis of pipe was carried out and verified. By comparing the difference between the direct numerical analysis in frequency domain and frequency domain results obtained from the time domain via Laplace transform, Zhang and Tijsseling et al. [

38] proposed a frequency domain solution method based on the Laplace transform transfer matrix method (LTTMM) and verified by the typical tests designed by Dundee University and Delft Hydraulic Research Institute. Xu et al. [

24] used the fourteen-equation model to describe the FSI in liquid-filled complex pipelines and proposed a general solution method to predict the frequency response of multi-branch pipes based on the transfer matrix method. A series of theoretical research was carried out by the Harbin Engineering University research team [

23,

36,

37,

40]. A transfer matrix method in the frequency domain that considered the FSI of the liquid-filled pipes with elastic constraints was proposed by using the point transfer matrix. The fluid pressure and vibrations of branched pipes were analyzed based on an absorbing transfer matrix method in the frequency domain. The application range of various types of models and simulation algorithms of fluid-filled pipe systems that considered the FSI in the frequency domain were compared and discussed. Based on the transfer matrix method, the Yanshan University research team [

1,

4,

10,

25] carried out theoretical research and experimental verification of FSI vibration of aircraft hydraulic pipes, which broadens the application range of the transfer matrix method in engineering practice. From the above review, it can be seen that TMM has been widely used in the vibration problems of pipes conveying fluid, due to its good adaptability, compared with other solution methods.

The aforementioned studies dealt with mathematical models and analysis methods that are sufficient to handle the FSI dynamics of simple fluid-conveying pipe systems, and the constraints are limited only to simple excitation and boundary conditions. More extensive mathematical models for a wide range of fluid pressures, Reynolds numbers, and the wide-range vibration frequencies of the structures (the constraints of which can describe arbitrary excitation and boundary conditions) deserve further investigation. In addition, as a calculation method applicable to cascaded structures, the TMM requires the assembly of multiple matrix cells. The calculation cases of complex pipes for directing practice in the engineering field and problem of overflow in the calculation and calculation result instability in high-frequency ranges need to be further discussed.

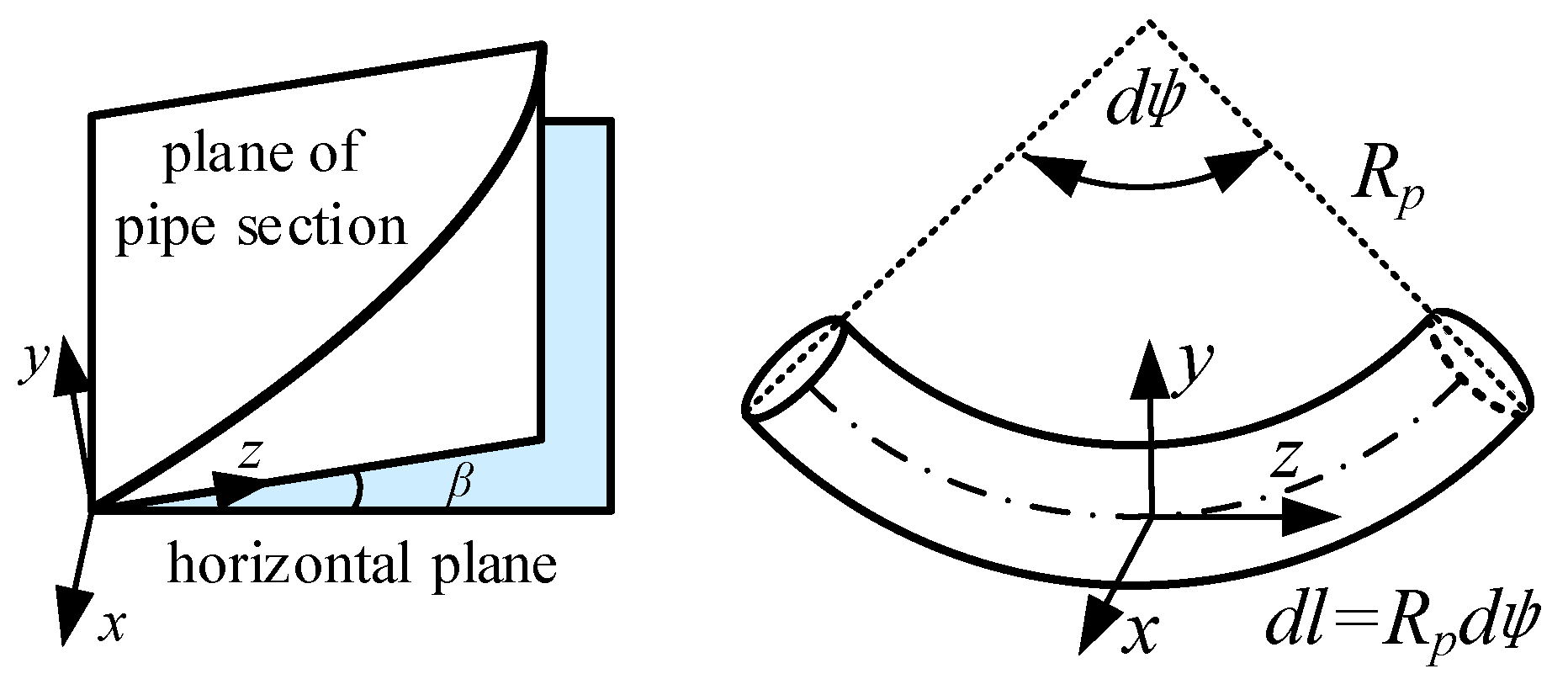

The present work developed a more comprehensive FSI governing the equations of three-dimensional space pipes conveying fluid. The excitation, complex boundary, and middle constraint models were established and added into the global model of the pipe system. Further, the unified expression of the improved Laplace transform transfer matrix method (LTTMM) for solving the FSI governing the equations was derived, forming the frequency methodology to solve for hydraulic pipe systems containing diverse constraints. Then, the frequency domain FSI response of an aircraft hydraulic pipeline containing diverse constraints under various cases was analyzed through numerical and experimental methods, and the results reveal the complex resonant laws regarding aircraft hydraulic pipes with complex constraints in the broad frequency band and prove the accuracy and efficiency of the presented method.

3. Laplace Transform Transfer Matrix Method

The TMM has been comprehensively applied to FSI analysis in piping systems.

Figure 5 shows the state vectors and correlated matrix relations of the single pipe section and cascaded pipe with middle support.

The fourteen-equation model can be accurately solved in the frequency domain, and the LTMM for the fourteen partial differential equations is derived in this section; meanwhile, some improvements and expansions are also performed.

Equation (20) provides the matrix expression of the fourteen equations; then, let

,

. Equation (28) can be obtained via Laplace transform:

where

,

.

,

, Equation (28) can be simplified as:

where

and

are the eigenvalues and eigenvector of

, respectively.

Evidently, the linear ordinary differential Equation (29) can be solved as:

where

Substituting

into Equation (30) provides:

Assuming no spatial distributive excitation is acting on the pipe, that means

,

, and

; substituting these parameters into Equation (32) obtains:

Substituting Equation (33) into Equation (32) obtains:

The solution of the fourteen equations can be written as:

Here, represents the field transfer matrix of the pipe.

For the single pipe section with the length

L, seven dimensional relations of boundary and excitation equations exist at each pipe end and are expressed as:

The relation of the two state vectors of the single pipe section could be expressed as:

For the cascaded pipe, the overall transfer matrix can be expressed by a systematic multiplication of the field and point transfer matrices:

where

is the transfer matrix of each pipe unit, and

is the corresponding length.

Then, the boundary equation of the initial end of the cascaded pipe can be obtained from Equations (35) and (36):

where

It is easy to obtain and from Equations (38) and (39); hence, the variables of any pipe sections mounted in the cascaded pipe system could be calculated.

5. Conclusions

This paper studies the fluid–structure interaction dynamics of aircraft hydraulic pipes with complex constraints and boundary conditions, both numerically and experimentally, in the frequency domain. A partial differential fourteen-equation model accounts for the effects of pipe wall thickness, and high-speed, high-pressure fluid was applied to describe the nonlinear FSI dynamics of aircraft hydraulic pipe. The flow pulsation excitation model, fluid boundary conditions containing the velocity inlet and pressure outlet, and one-dimensional support constraint model considering the equivalent stiffness parameters were used to denote the complex constraints. These resulting equations were solved by the Laplace transform transfer matrix method (LTTMM) in the frequency domain. According to the numerical and experimental results, displayed in the form of the dynamic response characteristics of flow velocity, fluid pressure, and pipe vibration velocity, some important conclusions and interesting features are described as follows.

The developed FSI theoretical model and improved Laplace transform transfer matrix method (LTTMM) realized, from one analysis case to another, a simple modification of the matrix model parameters of the fluid and pipe structure, such as fluid excitations, boundary conditions, and support constraints. The method involves a few unified matrix models and does not require any modification to the solving course to obtain accurate results, which is especially suitable for the FSI dynamics analysis of aircraft hydraulic pipe with complex constraints in the broad frequency range.

The harmonic amplitude of fluid pulsation in pipe systems showed an increasing trend, with increasing flow velocity and fluid pressure, and it gradually decreased with the increasing harmonic order. The change in the fundamental frequency response amplitude fluctuating was the most obvious, and flow pulsation was the main reason for stimulating the pressure pulsation. Flow-induced forced vibration of the pipe showed the characteristics of large-amplitude radial vibration and multi-harmonic points, without considering other excitation sources. The harmonic frequencies of pipe vibration were consistent with the harmonic frequencies of fluid pulsation. The maximum vibration velocity amplitude of the pipe was the first-order harmonic frequency, and the vibration velocity amplitude showed a decreasing trend with increasing harmonic order. The flow rate mainly affects the amplitude of pipe vibration, but that does not change the vibration frequencies, while the pressure has little effect on vibration amplitude and frequencies.

Furthermore, from the view of vibration control, a reasonable arrangement of the clamp in pipe systems can effectively reduce the transverse vibration; thus, increasing the fundamental frequencies of the pipe can avoid low-order high energy vibration in pipe systems, and inhibiting flow rate pulsation is a very effective method for reducing FSI resonance in pipe systems.