Modelling Method and Application of Anti-Corrosion Pill Particles in Oil and Gas Field Wellbore Casing Annulus Based on the Discrete Element Method

Abstract

:1. Introduction

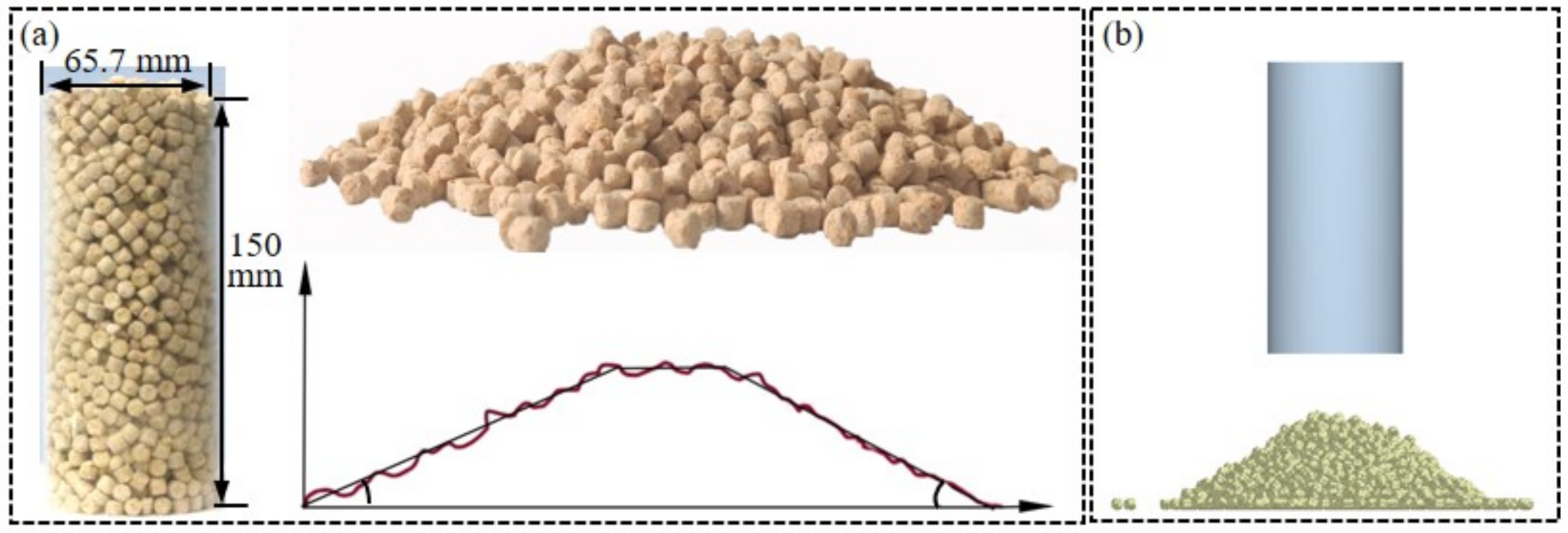

2. Materials and Modelling

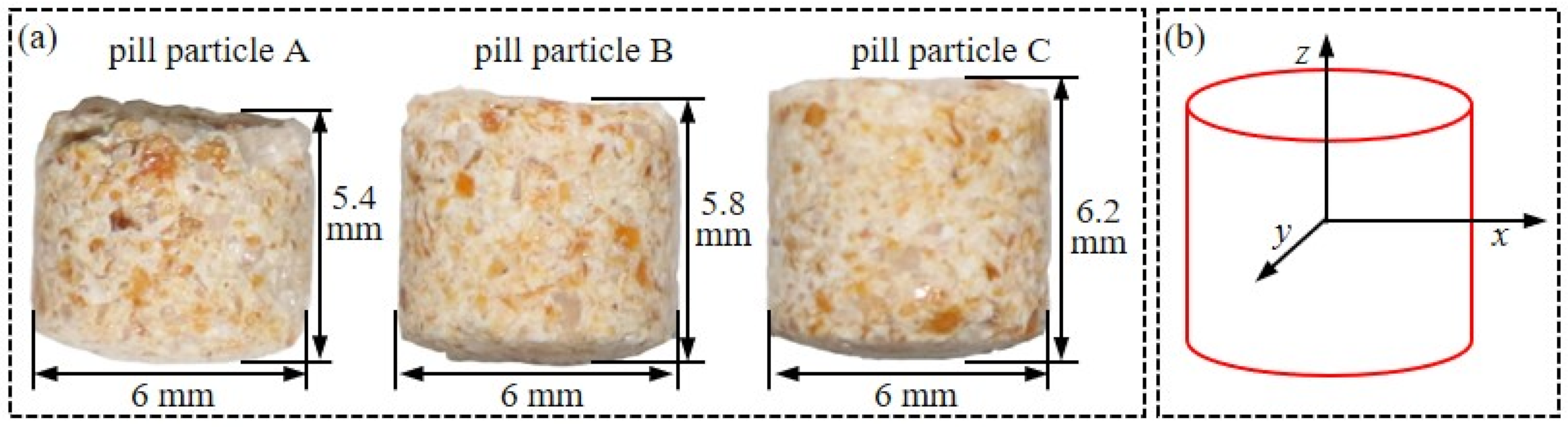

2.1. Shape and Size Analysis

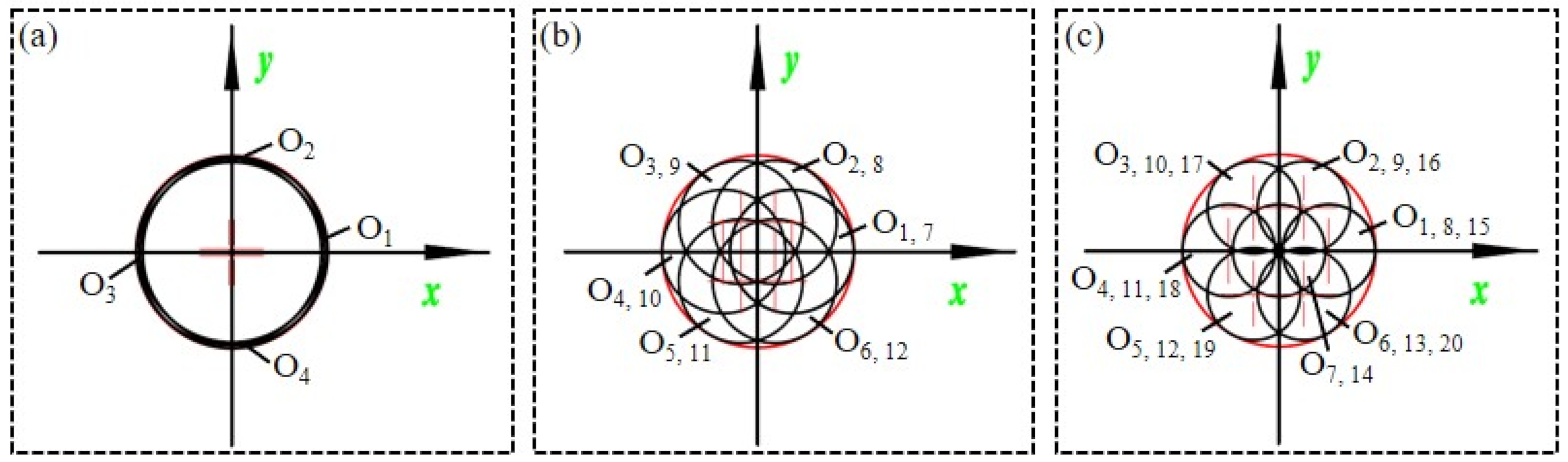

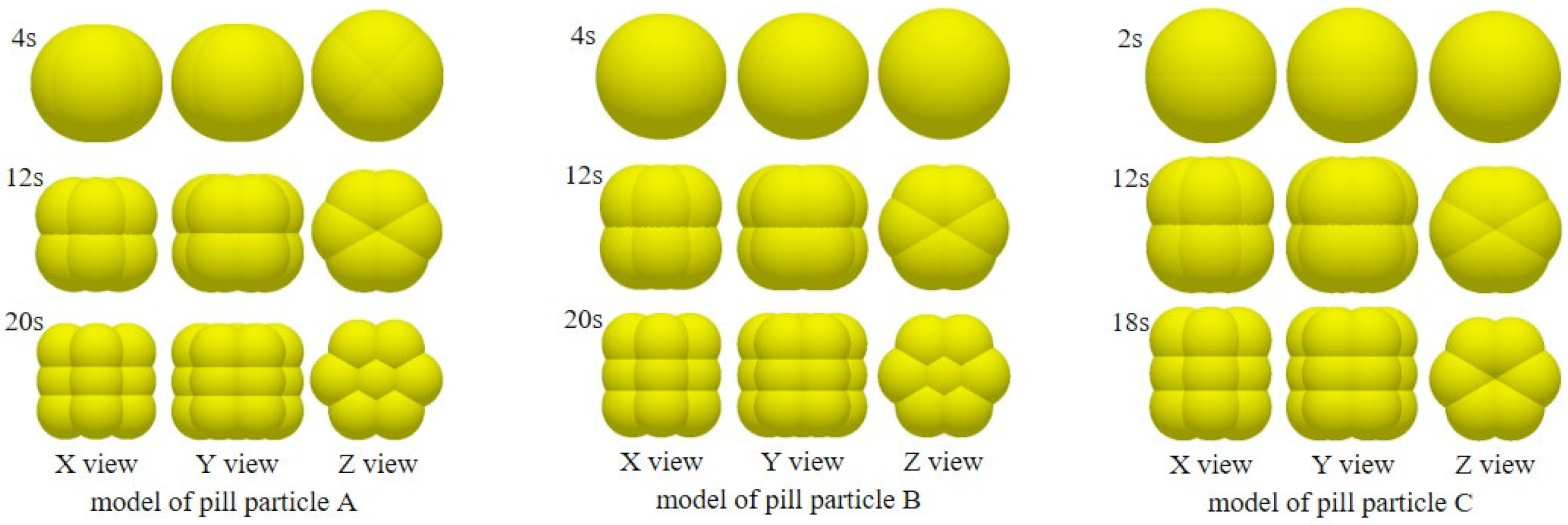

2.2. Modelling Methods of Pill Particles

2.2.1. Modelling Methods for Pill Particle A and B

2.2.2. Modelling Methods for Pill Particle C

3. Experimental Verification and Simulation Analysis

3.1. Simulation Model

3.2. Measurement and Calibration of Physical and Mechanical Parameters

3.3. Bulk Density Test and Simulation

3.3.1. Bulk Density Test Setup

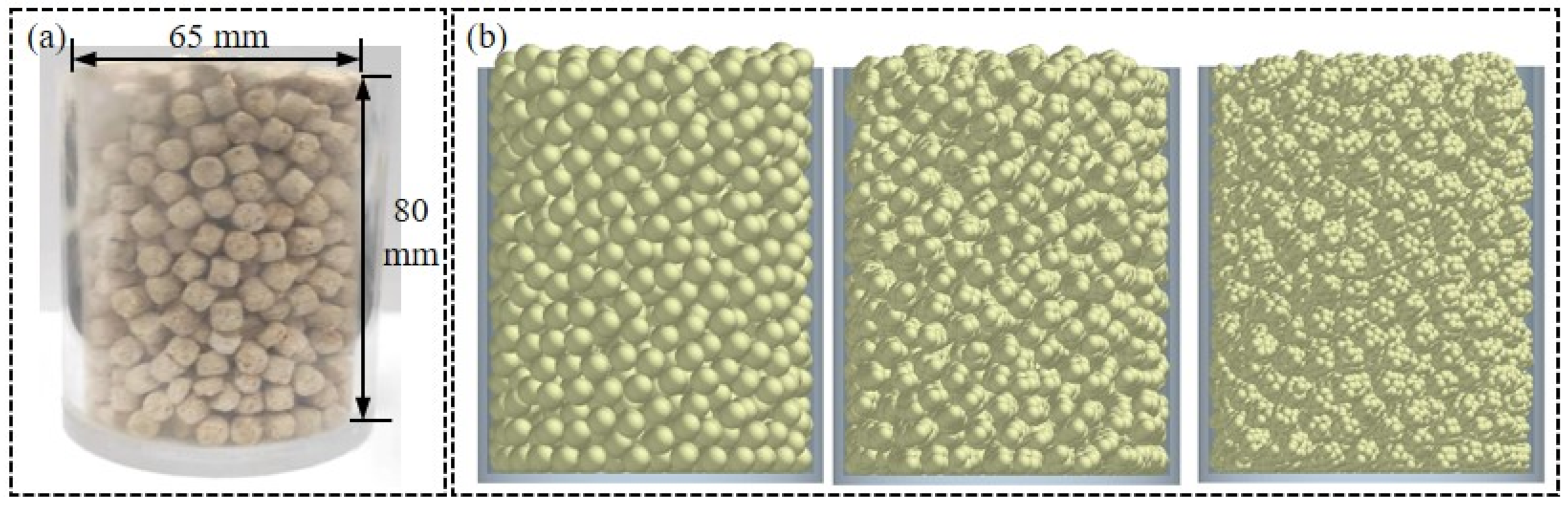

3.3.2. Bulk Density Simulation Setup

3.4. Angle of Repose Test and Simulation

3.4.1. Angle of Repose Test Setup

3.4.2. Angle of Repose Simulation Setup

4. Results Analysis and Discussion

4.1. Results Analysis and Discussion of Bulk Density Test

4.1.1. Bulk Density Test Results Analysis

4.1.2. Bulk Density Test Discussion

4.2. Results Analysis and Discussion of Angle of Repose

4.2.1. Angle of Repose Test Results Analysis

4.2.2. Angle of Repose Test Discussion

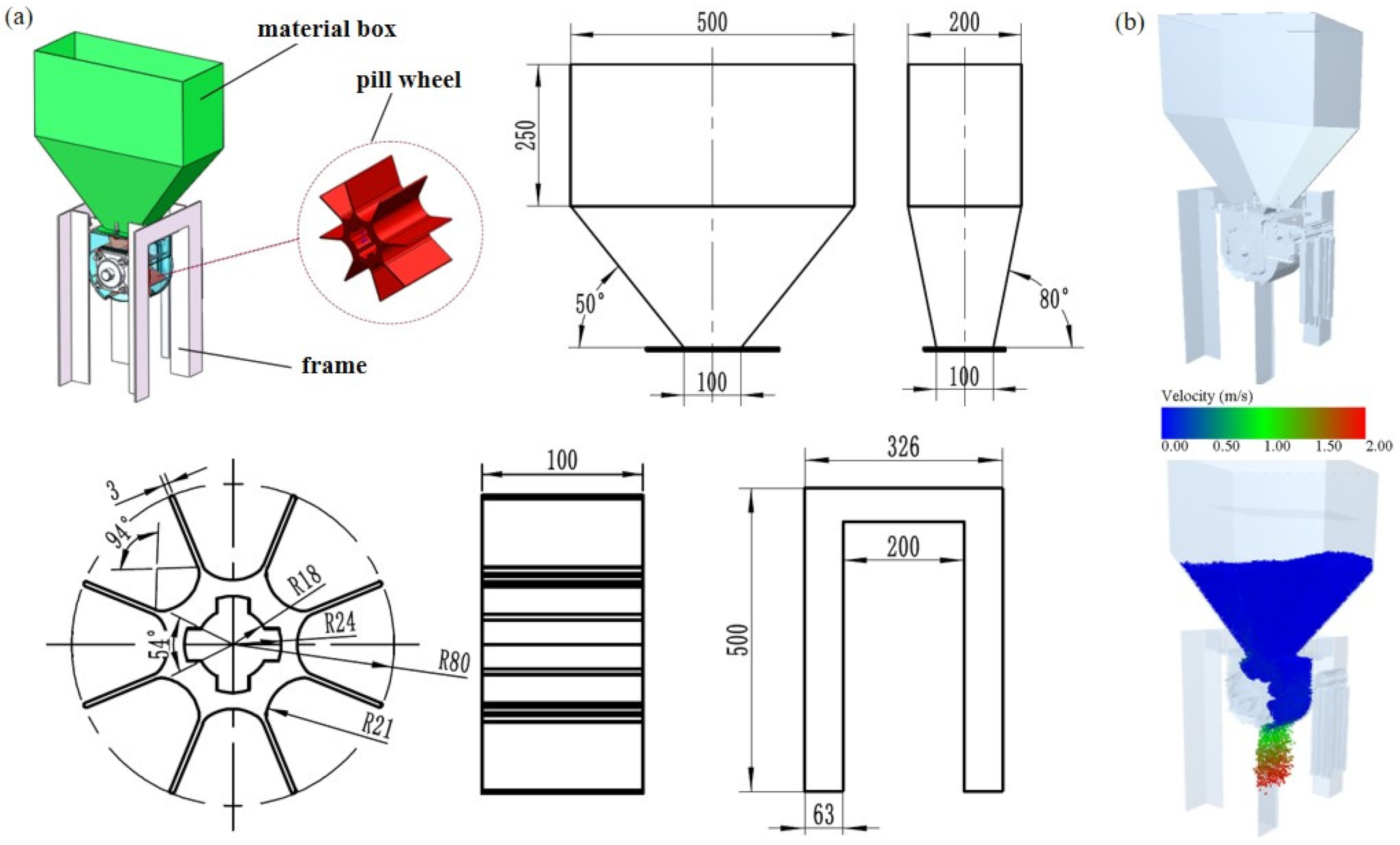

5. Example Applications

5.1. Pill Discharging Process Device

5.2. Simulation Setup of Pill Discharging Process

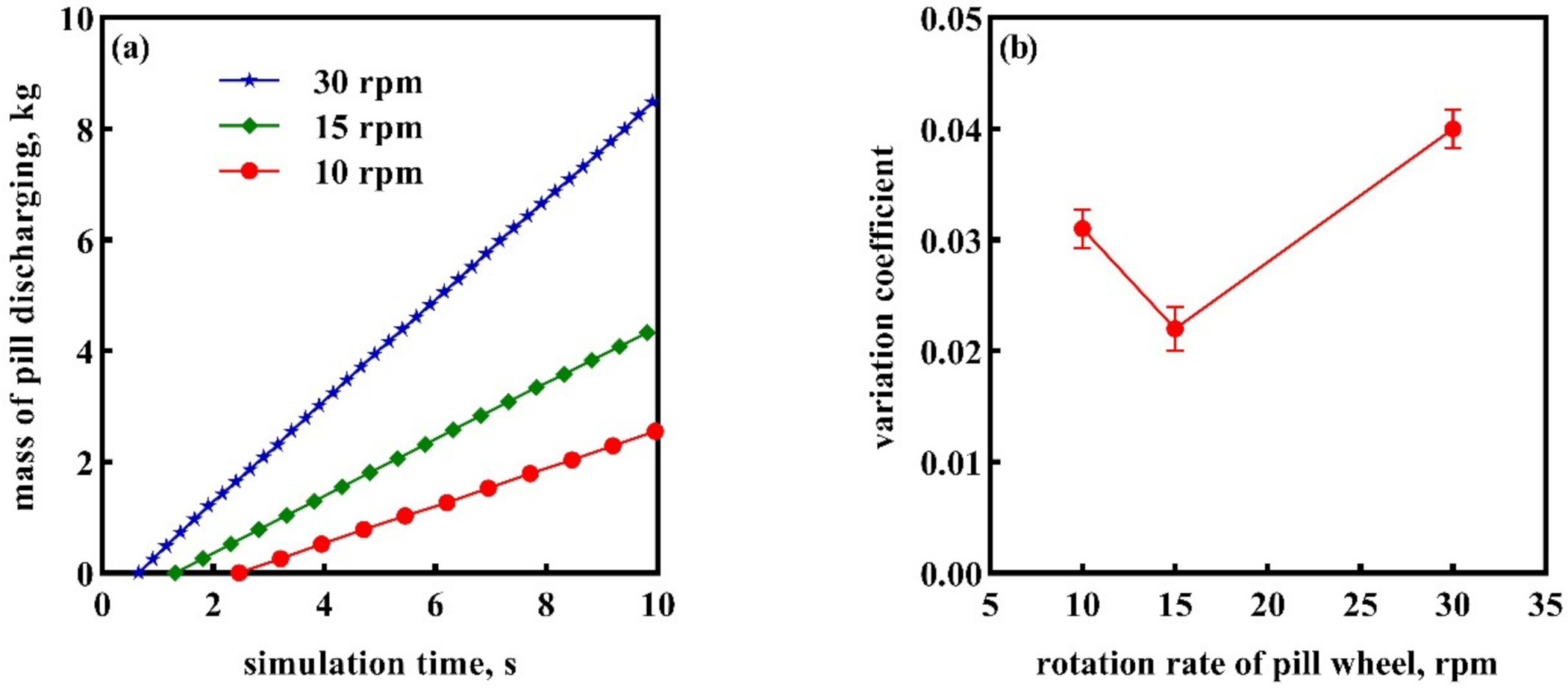

5.3. Results Analysis and Discussion of Discharge Process

6. Conclusions

- (1)

- The particle shape and size parameters were evaluated and analyzed to approximate the cylindrical shape of the pill particles, and the particle population was classified into pill particles A (5.4 mm), B (5.8 mm), and C (6.2 mm) based on their height, with the mass ratio of particles accounting for 35%, 35%, and 30%, respectively.

- (2)

- This work proposes a population modelling approach for pill particles based on DEM. Multi-sphere particle models were created for pill particle A (4, 12, and 20 spheres), pill particle B (4, 12, and 20 spheres), and pill particle C (2, 12, and 18 spheres). It serves as a guide for modeling cylindrical and irregular particles.

- (3)

- Using the bulk density and angle of repose tests as examples, the pill particle population modelling approach was utilized to deduce the mechanism by which the number of pill particle-filled spheres affects the particle accumulation process and flow behavior. By comparing the simulation findings to the test data, the feasibility and efficacy of the pill particle population modelling approach were established.

- (4)

- Using the independently built pill discharging device as an example, the 12-sphere model of pill particles A, B, and C was utilized to deduce the process by which the wheel’s rotation speed affects the pill discharging performance. The method’s applicability and practical use were shown by assessing the simulation results of the pill discharging process and establishing the groundwork for future improvements of the pill discharging device.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, Z.W.; Nguang, S.K.; Kong, D.X. Advances in modelling, monitoring, and control for complex industrial systems. Complexity 2019, 2019, 2975083. [Google Scholar] [CrossRef]

- Gao, Z.W.; Kong, D.X.; Gao, C.H. Modeling and control of complex dynamic systems: Applied mathematical aspects. J. Appl. Math. 2012, 2012, 869792. [Google Scholar] [CrossRef] [Green Version]

- Gao, Z.W.; Saxen, H.; Gao, C.H. Special section on data-driven approaches for complex industrial systems. IEEE Trans. Ind. Inform. 2013, 9, 2210–2212. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. Discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Yu, Y.J.; Fu, H.; Yu, J.Q. DEM-based simulation of the corn threshing process. Adv. Powder Technol. 2015, 26, 1400–1409. [Google Scholar] [CrossRef]

- Yu, Y.J.; Li, L.S.; Zhao, J.L.; Wang, X.G. Discrete element simulation based on elastic-Plastic damping model of corn kernel-cob bonding force for rotation speed optimization of threshing component. Processes 2021, 9, 1410. [Google Scholar] [CrossRef]

- Sun, J.F.; Chen, H.M.; Wang, Z.M.; Ou, Z.W.; Yang, Z.; Liu, Z.; Duan, J.L. Study on plowing performance of EDEM low-resistance animal bionic device based on red soil. Soil Tillage Res. 2020, 196, 104336. [Google Scholar] [CrossRef]

- Li, Y.D.; Xu, H.G.; Jing, C.H.; Jiang, J.H.; Hou, X.Y. A novel heat transfer model of biomass briquettes based on secondary development in EDEM. Renew. Energy 2019, 131, 1247–1254. [Google Scholar] [CrossRef]

- Yu, Y.J.; Li, L.S.; Zhao, J.L.; Wang, X.G.; Fu, J. Optimal design and simulation analysis of spike tooth threshing component based on DEM. Processes 2021, 9, 1163. [Google Scholar] [CrossRef]

- Yang, L.W.; Chen, L.S.; Zhang, J.Y.; Liu, H.J.; Sun, Z.C.; Sun, H.; Li, Y.D.; Zheng, L.H. Fertilizer sowing simulation of a variable-rate fertilizer applicator based on EDEM. IFAC-Pap. 2018, 51, 418–423. [Google Scholar] [CrossRef]

- Neto, A.G.; Hudobivnik, B.; Moherdaui, T.F.; Wriggers, P. Flexible polyhedra modeled by the virtual element method in a discrete element context. Comput. Methods Appl. Mech. Eng. 2021, 387, 114163. [Google Scholar] [CrossRef]

- Yan, B.; Regueiro, R.A.; Sture, S. Three-dimensional ellipsoidal discrete element modeling of granular materials and its coupling with finite element facets. Eng. Comput. 2010, 27, 519–550. [Google Scholar] [CrossRef]

- Kim, K.C.; Jiang, T.; Kim, N.L.; Kwon, C. Effects of ball-to-powder diameter ratio and powder particle shape on EDEM simulation in a planetary ball mill. J. Indian Chem. Soc. 2022, 99, 100300. [Google Scholar] [CrossRef]

- Zhou, H.; Chen, Y.H.; Li, H.S.; Xu, Z.Y.; Dong, H.R.; Wang, W.P. Effect of particles micro characteristics destroyed by ball milling on fly ash electrostatic separation. Adv. Powder Technol. 2022, 33, 103449. [Google Scholar] [CrossRef]

- Tavares, L.M.; Rodriguez, V.A.; Sousani, M.; Padros, C.B.; Ooi, J.Y. An effective sphere-based model for breakage simulation in DEM. Powder Technol. 2021, 392, 473–488. [Google Scholar] [CrossRef]

- Danesh, A.; Mirghasemi, A.A.; Palassi, M. Evaluation of particle shape on direct shear mechanical behavior of ballast assembly using discrete element method (DEM). Transp. Geotech. 2020, 23, 100357. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Way, T.R.; Syed, Z.; Schafer, R.L. Modeling soil-bulldozer blade interaction using the discrete element method (DEM). J. Terramechanics 2020, 88, 41–52. [Google Scholar] [CrossRef]

- Horabik, J.; Wiącek, J.; Parafiniuk, P.; Bańda, M.; Kobyłka, R.; Stasiak, M.; Molenda, M. Calibration of discrete-element-method model parameters of bulk wheat for storage. Biosyst. Eng. 2020, 200, 298–314. [Google Scholar] [CrossRef]

- Zeng, Y.; Mao, B.Q.; Jia, F.G.; Han, Y.L.; Li, G.R. Modelling of grain breakage of in a vertical rice mill based on DEM simulation combining particle replacement model. Biosyst. Eng. 2022, 215, 32–48. [Google Scholar] [CrossRef]

- Wang, T.Z.; Quan, Q.Q.; Li, M.X.; Huang, J.C.; Zhao, Z.J.; Guo, F.; Meng, L.Z.; Wang, G.Q.; Tang, D.W.; Deng, Z.Q. An asteroid anchoring method based on cross-drilling geometric force closure of ultrasonic drill. Acta Astronaut. 2021, 178, 813–823. [Google Scholar] [CrossRef]

- Han, D.D.; Zhang, D.X.; Jing, H.R.; Yang, L.; Cui, T.; Ding, Y.Q.; Wang, Z.D.; Wang, Y.X.; Zhang, T.L. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Stoimenov, N.; Ruzic, J. Analysis of the particle motion during mechanical alloying using EDEM software. IFAC-Pap. 2019, 52, 462–466. [Google Scholar] [CrossRef]

- Zhang, L.; Zhai, Y.B.; Chen, J.N.; Zhang, Z.E.; Huang, S.Z. Optimization design and performance study of a subsoiler underlying the tea garden subsoiling mechanism based on bionics and EDEM. Soil Tillage Res. 2022, 220, 105375. [Google Scholar] [CrossRef]

- Tao, H.; Zhong, W.Q.; Jin, B.S. Comparison of construction method for DEM simulation of ellipsoidal particles. Chin. J. Chem. Eng. 2013, 21, 800–807. [Google Scholar] [CrossRef]

- Zhou, L.; Yu, J.Q.; Wang, Y.; Yan, D.X.; Yu, Y.J. A study on the modelling method of maize-seed particles based on the discrete element method. Powder Technol. 2020, 374, 353–376. [Google Scholar] [CrossRef]

- Sun, K.; Yu, J.Q.; Liang, L.S.; Wang, Y.; Yan, D.X.; Yu, Y.J. A DEM-based general modelling method and experimental verification for wheat seeds. Powder Technol. 2022, 401, 117353. [Google Scholar] [CrossRef]

- Langston, P.A.; Tuzun, U.; Heyes, D.M. Continuous potential discrete particle simulations of stress and velocity-fields in hoppers—transition from fluid to granular flow. Chem. Eng. Sci. 1994, 49, 1259–1275. [Google Scholar] [CrossRef]

- Langston, P.A.; Tuzun, U.; Heyes, D.M. Discrete element simulation of granular flow in 2D and 3D hoppers—dependence of discharge rate and wall stress on particle interactions. Chem. Eng. Sci. 1995, 50, 967–987. [Google Scholar] [CrossRef]

- Langston, P.A.; Tuzun, U.; Heyes, D.M. Discrete element simulation of internal-stress and flow-fields in funnel flow hoppers. Powder Technol. 1995, 85, 153–169. [Google Scholar] [CrossRef]

- Zhu, H.P.; Zhou, Z.Y.; Yang, R.Y.; Yu, A.B. Discrete particle simulation of particulate systems: Theoretical developments. Chem. Eng. Sci. 2007, 62, 3378–3396. [Google Scholar] [CrossRef]

- Iwashita, K.; Oda, M. Rolling resistance at contacts in simulation of shear band development by DEM. J. Eng. Mech. ASCE 1998, 124, 285–292. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Wright, B.D.; Yang, R.Y.; Xu, B.H.; Yu, A.B. Rolling friction in the dynamic simulation of sandpile formation. Phys. A Stat. Mech. Its Appl. 1999, 269, 536–553. [Google Scholar] [CrossRef]

- Zhu, H.P.; Yu, A.B. Averaging method of granular materials. Phys. Rev. E 2002, 66, 021302. [Google Scholar] [CrossRef] [PubMed]

- Coetzee, C.J. Review: Calibration of the discrete element method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Coetzee, C.J. Particle upscaling: Calibration and validation of the discrete element method. Powder Technol. 2019, 344, 487–503. [Google Scholar] [CrossRef]

- American Society of Agricultural Engineers. Compression Test of Food Materials of Convex Shape; ASAE Standards: St. Joseph, MI, USA, 2017; pp. 1–15. [Google Scholar]

- Zhang, X.H. Computer Numerical Simulation of Pellet Feed in Cooling Process. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2004. [Google Scholar]

- Yan, Y.F.; Meng, D.X.; Song, Z.H.; Liu, L.Q.; Li, F.D. Particle kinetic simulation and experiment for flute-wheel feeding machine. Trans. Chin. Soc. Agric. Mach. 2016, 47, 249–253. [Google Scholar]

- González-Montellano, C.; Fuentes, J.M.; Ayuga-Téllez, E.; Ayuga, F. Determination of the mechanical properties of maize grains and olives required for use in DEM simulations. J. Food Eng. 2012, 111, 553–562. [Google Scholar] [CrossRef]

- LoCurto, G.J.; Zhang, X.; Zakirov, V.; Bucklin, R.A.; Vu-Quoc, L.; Hanes, D.M.; Walton, O.R. Soybean impacts: Experiments and dynamic simulations. Trans. ASAE 1999, 40, 789–794. [Google Scholar] [CrossRef]

- Ding, S.P.; Bai, L.; Yao, Y.X.; Yue, B.; Fu, Z.L.; Zheng, Z.Q.; Huang, Y.X. Discrete element modelling (DEM) of fertilizer dual-banding with adjustable rates. Comput. Electron. Agric. 2018, 152, 32–39. [Google Scholar] [CrossRef]

| Parameters | Pill Particle | ABS Plastic | Organic Glass | Galvanized Steel |

|---|---|---|---|---|

| Density ρ, kg/m3 | 1380 | 1050 | 1800 | 7865 |

| Poisson’s ratio υ | 0.350 | 0.394 | 0.350 | 0.300 |

| Elastic modulus E, Pa | 1.100 × 108 | 3.189 × 109 | 1.300 × 109 | 7.900 × 1010 |

| Restitution coefficient e | 0.201 | 0.299 | 0.279 | 0.305 |

| Coefficient of static friction μs | 0.466 | 0.577 | 0.533 | 0.511 |

| Coefficient of rolling friction μr | 0.080 | 0.120 | 0.050 | 0.070 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Qiao, C.; Wan, J.; Lu, Y.; Song, J.; Yao, Z.; Wei, X.; Yu, Y. Modelling Method and Application of Anti-Corrosion Pill Particles in Oil and Gas Field Wellbore Casing Annulus Based on the Discrete Element Method. Processes 2022, 10, 1164. https://doi.org/10.3390/pr10061164

Liu D, Qiao C, Wan J, Lu Y, Song J, Yao Z, Wei X, Yu Y. Modelling Method and Application of Anti-Corrosion Pill Particles in Oil and Gas Field Wellbore Casing Annulus Based on the Discrete Element Method. Processes. 2022; 10(6):1164. https://doi.org/10.3390/pr10061164

Chicago/Turabian StyleLiu, Dongtao, Chunshang Qiao, Jun Wan, Yuliang Lu, Jiming Song, Zhenhe Yao, Xinjie Wei, and Yajun Yu. 2022. "Modelling Method and Application of Anti-Corrosion Pill Particles in Oil and Gas Field Wellbore Casing Annulus Based on the Discrete Element Method" Processes 10, no. 6: 1164. https://doi.org/10.3390/pr10061164

APA StyleLiu, D., Qiao, C., Wan, J., Lu, Y., Song, J., Yao, Z., Wei, X., & Yu, Y. (2022). Modelling Method and Application of Anti-Corrosion Pill Particles in Oil and Gas Field Wellbore Casing Annulus Based on the Discrete Element Method. Processes, 10(6), 1164. https://doi.org/10.3390/pr10061164