Abstract

In order to study the gas migration in gas-bearing coal, and reasonably arrange gas drainage boreholes to improve the efficiency of gas drainage, a gas-solid coupling model is established based on the pore-fracture dual medium porous model. The solid deformation of coal body, gas seepage and diffusion, and gas adsorption and desorption are considered in this model. The COMSOL software is used to simulate the gas change in the coal matrix and coal fracture under single borehole extraction. We analyze the effective extraction range and study the migration mechanism of gas between coal fracture and borehole, coal matrix and coal fracture, and coal matrix. The effective extraction area of multi-borehole negative pressure gas extraction varies with extraction time and borehole spacing. At 140 d, the effective extraction radius is r = 1.3 m, and the spacing of boreholes is , respectively. The influence of the equilateral triangle shape of three boreholes on the gas extraction effect is studied. The simulation results show that when three boreholes are extracted for 140 days under different borehole spacing, different gas extraction effects will be affected by a superposition effect. Considering the change in gas pressure, the effect of gas extraction in the effective extraction area, and the safety and cost performance of gas extraction, it is concluded that the optimal hole spacing is 5 m around 140 d. This study aims to provide reference for underground gas drilling layout and reasonable hole spacing.

1. Introduction

Coal is the dominant energy source in China. With the depletion of shallow coal resources, a large number of mines in China entered deep mining, and the threat of gas disasters is extremely serious [1,2,3]. The hidden danger of coal and gas outburst increases, which seriously threatens the personal safety of underground workers and affects the mining efficiency of coal resources in China [4,5,6]. Pre-drainage of coal seam gas can effectively prevent coal and gas outburst. Efficient gas extraction plays an important role in reducing coal seam gas pressure and gas emission, as well as preventing coal–gas outburst [7,8,9]. Drilling negative pressure extraction is the most common method of gas extraction. Drilling spacing and extraction time are significant factors affecting the extraction effect.

With the deepening of the research on the seepage law of coal seam gas, it is realized that the migration mode of coal seam gas in coal body is not single, and there are many flow modes among coal pores, fractures, and matrix [10,11,12,13]. According to the various characteristics of coal mechanics and the migration of gas in coal, the establishment of a gas-solid coupling model is the theoretical basis for the analysis of gas extraction by negative pressure drilling. Zhu et al. determined the dynamic change model of permeability and porosity considering coal deformation and the Klinkenberg effect, and deduced the low permeability gas-solid coupling model [14,15,16]. Based on the innovative gas-solid coupling model, Cheng et al. used COMSOL Multiphysics to numerically solve the model. The migration of gas in coal under the influence of diffusion and seepage is analyzed, and the influence of negative pressure on gas migration is studied [17,18,19]. Li et al. simulated the gas extraction effect under different hole spacing by analyzing the mechanism of gas flow around the borehole and the superposition effect of extraction. He obtained the reasonable hole spacing of bedding gas extraction: 2r ≤ L ≤ R [20]. Zhang et al. established a coal seam gas seepage model considering the assumption of double-hole medium and the influence of stress redistribution on the seepage characteristics of coal seam gas. They studied the influence of coal seam pressure change on gas adsorption and seepage, and the improvement of gas extraction effect by overlapping the arrangement of two boreholes [21]. Chen made a more detailed study on the optimization of borehole extraction spacing and effective extraction area [22].

The study of gas migration and the effect of different borehole spacing on gas extraction have great reference value for practical engineering. The optimal design of extraction boreholes affects the safety of coal mining and the sustainable development of coal resources. [23]. In the existing research, the research results of coal permeability, porosity change, and single row multi-borehole extraction effect of negative pressure extraction gas are quite abundant, but most of them are based on a two-dimensional case. However, based on pore-fracture dual porous media, there are few studies on understanding and analyzing gas migration in coal from the perspective of a three-dimensional simulation. There are also few studies on the gas migration and extraction effect in the coal body during drilling negative pressure extraction through the three-dimensional visualization model. In order to better reveal the migration of gas in coal during the extraction process of three boreholes and the influence of different borehole spacing on effective extraction area, an innovative gas-solid coupling model was proposed based on previous studies. The model takes into account the Klinkenberg effect, coal matrix, and skeleton deformation of coal fracture outward seepage and matrix diffusion gas influx, coal matrix adsorption gas, and the desorption diffusion gas dynamic process. In order to provide a theoretical basis for further understanding of gas migration law and studying the extraction effect under the influence of the multi-hole extraction superposition effect, this research takes a coal mine as the background and uses COMSOL simulation software for three-dimensional simulation. The research intends to provide reference value for practical engineering.

2. Establishment of Coalbed Gas-Solid Coupling Model

2.1. Coal Deformation Equation

Coal deformation mainly refers to the effective stress acting on the coal skeleton to deform the coal skeleton. In this paper, the double medium model is cited [24]. The stress effect is also affected by gas adsorption and desorption. The effective stress expression is:

In the formula, is the effective stress, MPa; is the total stress, MPa; are the effective stress coefficients of coal pore and fracture, respectively; are gas pressure in the coal matrix and fracture, respectively, MPa; is a Kronecker tensor; is the volumetric strain coefficient caused by gas adsorption and desorption in coal, ; and is adsorption–desorption strain of coal under isothermal condition. Among them, . K is the bulk modulus of coal, MPa; are the bulk modulus of the coal matrix and skeleton, respectively, MPa.

Equilibrium equation, geometric equation, and constitutive equation constitute the volumetric deformation equation of coal containing gas.

The force balance of each surface of the unit body is analyzed. According to the conservation of momentum, the equilibrium equation is:

The coal skeleton undergoes slight deformation, and the geometric equation is:

Assuming that the coal is a linear elastic body, according to Hooke’s law, the constitutive equation is:

In the formula, G is the shear modulus, MPa; v is Poisson’s ratio; and is the volume strain. Among them, , E is elastic modulus of coal, MPa.

The change in gas pressure will induce the deformation of the coal matrix and coal skeleton. Gas adsorption and desorption in the coal matrix will also affect the deformation of the coal matrix. Combining the three Equations (1)–(3), based on the dual pore medium model, the governing equation of coal deformation can be obtained:

2.2. Gas Migration Equation in Coal

Based on surface physical chemistry, considering the influence of effective stress, gas pressure, coal matrix adsorption, and desorption gas, the porosity equation is [25]:

In the formula, is the initial fracture porosity; is the adsorption deformation of coal; and is Langmuir pressure constant, MPa.

There is a cubic relationship between permeability and porosity [26]:

Considering the influence of the Klinkenberg effect in gas-bearing double porous media, the permeability calculation formula is obtained:

In the formula, is the initial permeability of coal, mD; and c is the Kirsch coefficient.

Coal is regarded as a porous medium composed of pores and fracture. The gas content in coal includes the gas content in coal matrix pores and coal fractures. The mass of gas in the unit volume coal matrix is composed of adsorbed gas and free gas in coal matrix pores and and free gas in coal fractures.

The gas adsorption in the coal matrix follows the Langmuir equation:

The free gas in coal matrix pores and coal fractures can be calculated by gas state equation.

The free gas quality in coal matrix pores:

The free gas quality in coal fracture:

Gas quantity in unit volume coal pore:

In the formula, is the density of gas under standard conditions, ; is coal density, ; a is the maximum adsorption capacity per unit volume of coal, ; b is the adsorption constant of coal, ; A is coal ash; B is coal moisture; is the porosity of the coal matrix, %; is the molar mass of gas, kg/mol; R is the ideal gas constant, J/(mol·K); T is the temperature in coal, K; m1 is the amount of gas adsorbed per unit volume of coal matrix, ; m2 is the amount of free gas per unit volume of coal matrix, ; mf is the amount of free gas per unit volume of coal fracture, ; and mm is the gas content per unit volume of coal matrix, .

In the original state, without mining disturbance, coal pore pressure is equal to coal fracture pressure. When the gas is extracted by a negative pressure borehole, the borehole breaks the dynamic balance of coal structure and gas pressure in the original state. As a result, the pressure difference between coal pore and gas pressure in coal fracture is produced. The migration of gas in coal pores conforms to Fick’s diffusion law, and the migration in fractures conforms to Darcy’s linear seepage law. The change in gas in coal matrix pores of unit coal body per unit of time follows the law of conservation of mass. The amount of gas change is equal to the amount of desorption gas of coal body outside the absorption unit minus the amount of diffusion gas of unit body:

In the formula, is the external mass source of the unit, ; is the unit mass source, ; D is the gas diffusion coefficient, ; is desorption time of adsorbed gas, d; and is a Hamiltonian operator.

The change in gas in the coal fracture of unit time follows the law of conservation of mass. The amount of gas change is equal to the amount of fracture seepage plus the amount of coal matrix pore diffusion source:

In the formula, V is the velocity of gas seepage in coal fracture, m/s; ; and is the gas dynamic viscosity, .

The formula of pore gas pressure of the coal matrix changing with time can be obtained from the Equation (13):

The formula can be obtained from the Equation (11) and the Equation (14):

The deformation equation of gas-bearing coal is (1)–(5), (6), (8) is the change formula of porosity and permeability of coal, and (9)–(16) is the equation of gas occurrence and migration in coal pores and fractures. In the process of negative pressure drilling, the mechanical structure characteristics of coal body and the balance of gas in the original state of coal body are broken, and the coal body structure is slightly deformed. The coal deformation leads to changes in porosity and permeability, which affects the migration of gas in coal. The gas-solid coupling model is established by combining the deformation control Equation (5) of a gas-bearing coal body with the mass conservation control Equations (13) and (16) of gas migration in coal pores and fractures.

3. Numerical Simulation

3.1. Model Assumptions

- Assuming that the coal body is an isotropic pore-fracture porous medium, the coal body is regarded as a linear elastic body, and the coal body undergoes small deformation.

- Assuming that there is no energy exchange between the coal body and the surrounding environment, the roof and floor of the coal seam are impermeable, and the extracted gas only comes from the coal body.

- It is assumed that the initial fracture gas pressure in the coal body is the same as the initial fracture gas pressure in the coal matrix pore.

- Assuming that the temperature does not change when the gas migrates in the coal body during the extraction process, the gas is an ideal gas, which conforms to the ideal gas state equation. Gas diffusion conforms to Fick diffusion law, gas adsorption conforms to Langmuir adsorption law, and gas seepage conforms to Darcy law.

3.2. Model Introduction

In this paper, a coal mine of No. 4 coal seam gas extraction is taken as the research object. No. 4 coal has an average thickness of 10.75 m, and the coal coefficient is 18.99%. The apparent density of coal is 1.24~1.59 t/m3, with an average of 1.36 t/m3. The true density is 1.41~1.59 t/m3, with an average of 1.49 t/m3. The coal seam has an initial gas pressure between 1.01 MPa and 1.29 MPa. The gas content in the coal seam is 3.91~4.58 m3/t.

Based on the gas-solid coupling model constructed above, with the help of the multi-physics coupling simulation software COMSOL Multiphysics, the physical field coupling calculation is carried out by using the custom partial differential equation module (PDE) and the solid mechanics module in structural mechanics. The transient solver is selected. The migration of gas in coal is described by the PDE module, and the deformation of the coal structure is described by the solid mechanics module. The gas-solid coupling formula derived above is embedded in the formula of the module.

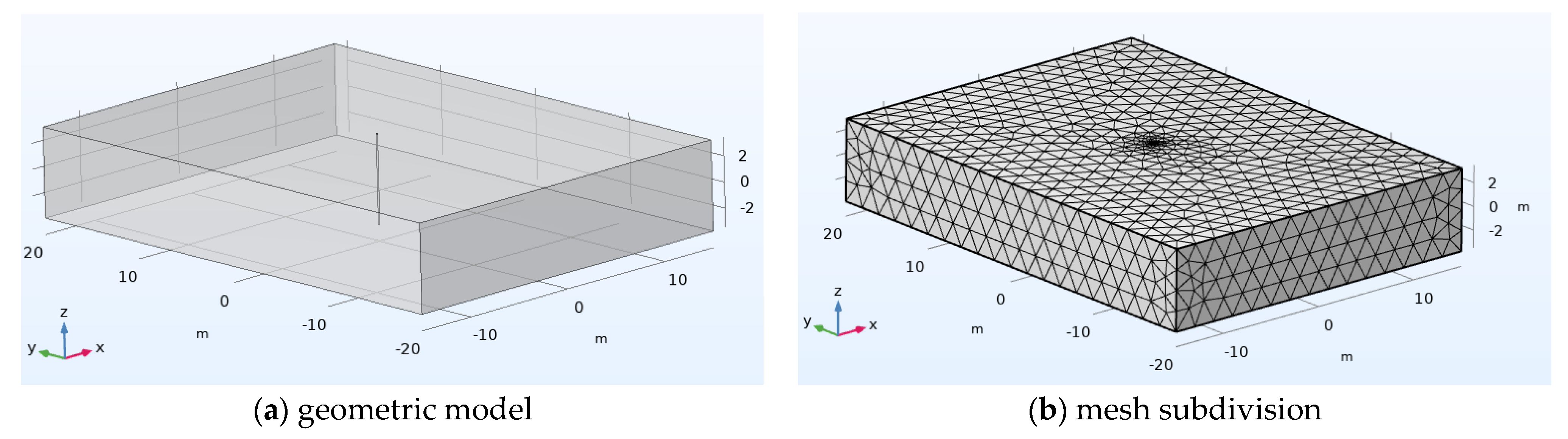

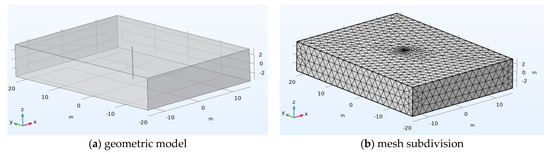

A three-dimensional geometric model of 30 m × 40 m × 7 m is established as shown in Figure 1a. The radius of the central extraction borehole is 75 mm. The coal seam has the overlying strata load of 12 MPa, and the direction extends the Z-axis vertically downward. The coal body is set not to produce energy exchange with the outside, so the outer boundary of coal is set to zero flux. It is assumed that there is no displacement around the coal seam in its normal direction and the bottom surface is fixed. The borehole extraction gas negative pressure is set to 20 kPa. The initial gas pressure of coal matrix pores and coal fractures is 1.01 MPa. When meshing, as shown in Figure 1b below, it is set to user-controlled meshing. The mesh is divided into a free subdivision tetrahedron with a curvature factor of 0.6. The maximum element size is 2 m and the minimum element size is 0.5 m. The parameters used for numerical simulation are shown in Table 1.

Figure 1.

Geometric model and meshing.

Table 1.

Table of parameters required for simulation.

4. Simulation Results and Analysis

4.1. Influence of Negative Pressure Extraction on Gas Migration

The method of predicting whether it is an outburst danger zone stipulated in the “Coal and Gas Outburst Prevention Rules” is based on the coal seam gas pressure of 0.74 MPa and the content of 8 as the critical value. Reducing the gas pressure of coal seam to 0.74 MPa during the extraction process is an important discriminant index. In the two-dimensional plane, the radius of the area where the gas pressure is lower than 0.74 MPa is the effective extraction radius. The area where gas pressure is less than 0.74 MPa is regarded as an effective extraction area. In the three-dimensional model, the area where the gas pressure in coal is less than 0.74 MPa is regarded as an effective extraction area.

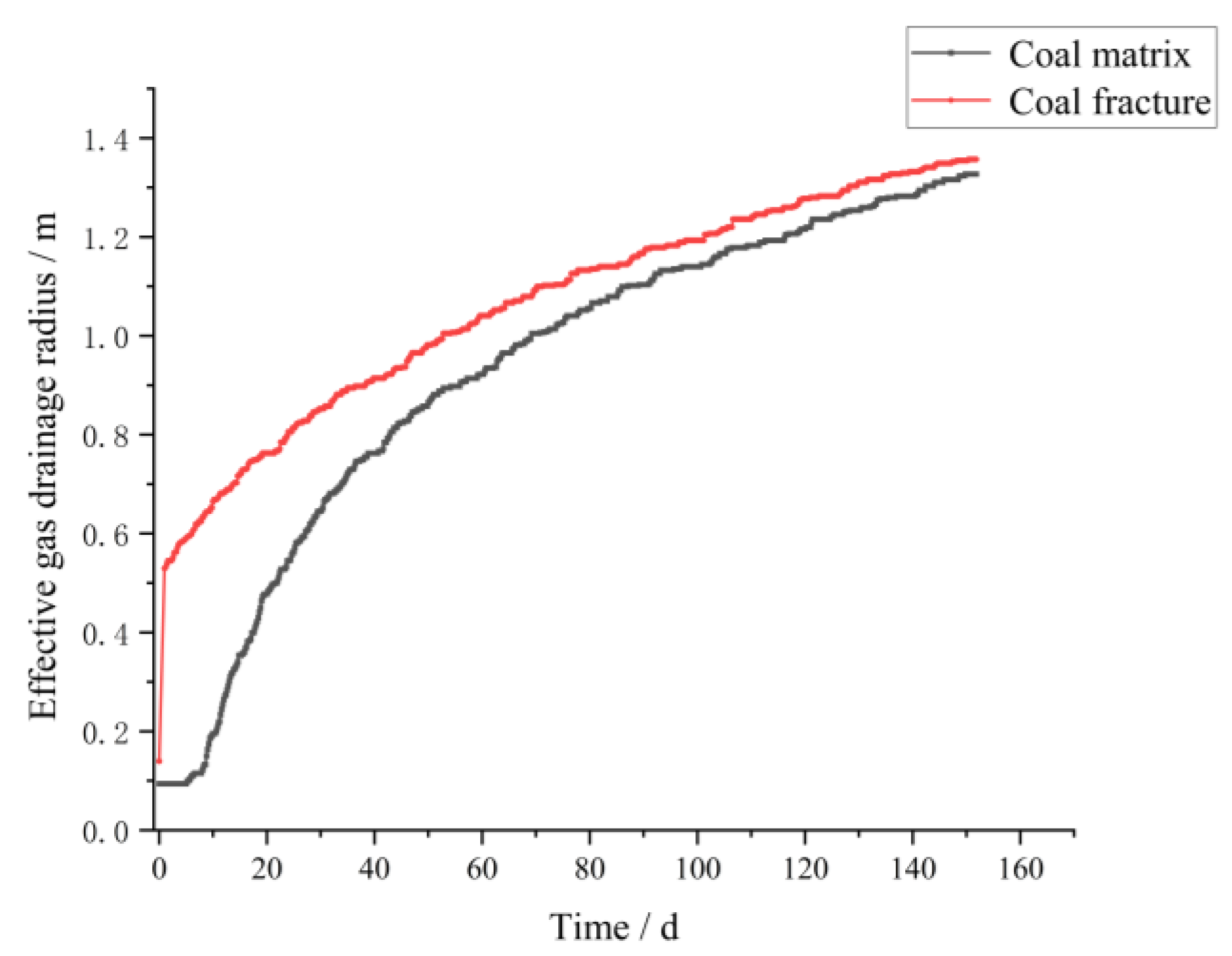

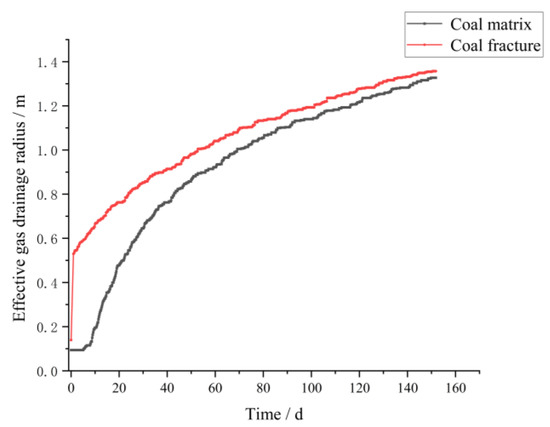

A single borehole is set up to simulate the effective extraction radius considering coal fracture and gas pressure in matrix under different extraction time. As shown in Figure 2, taking the bottom of the coal seam as an example, the effective extraction radius considering gas pressure in the coal matrix is always smaller than that considering gas pressure in coal fracture. However, the difference of effective extraction radius decreases with the extension of extraction time. Combined with the three-dimensional effect diagram of the effective extraction area at different times obtained by simulation, it can also be understood that the effective extraction area with a smaller coal matrix gas pressure less than 0.74 MPa is contained in the effective extraction area where the coal fracture gas pressure is less than 0.74 MPa. Two days before the extraction, the effective extraction radius of coal fracture increased sharply, and then maintained a certain trend of continuous increase, but with the increase in extraction time, the increase gradually decreased. In the first 5 days of extraction, the increase in the effective extraction radius of the coal matrix was very small, and then increased significantly, but with the increase in extraction time, the increase was gradually reduced.

Figure 2.

Change in effective extraction radius under different extraction time.

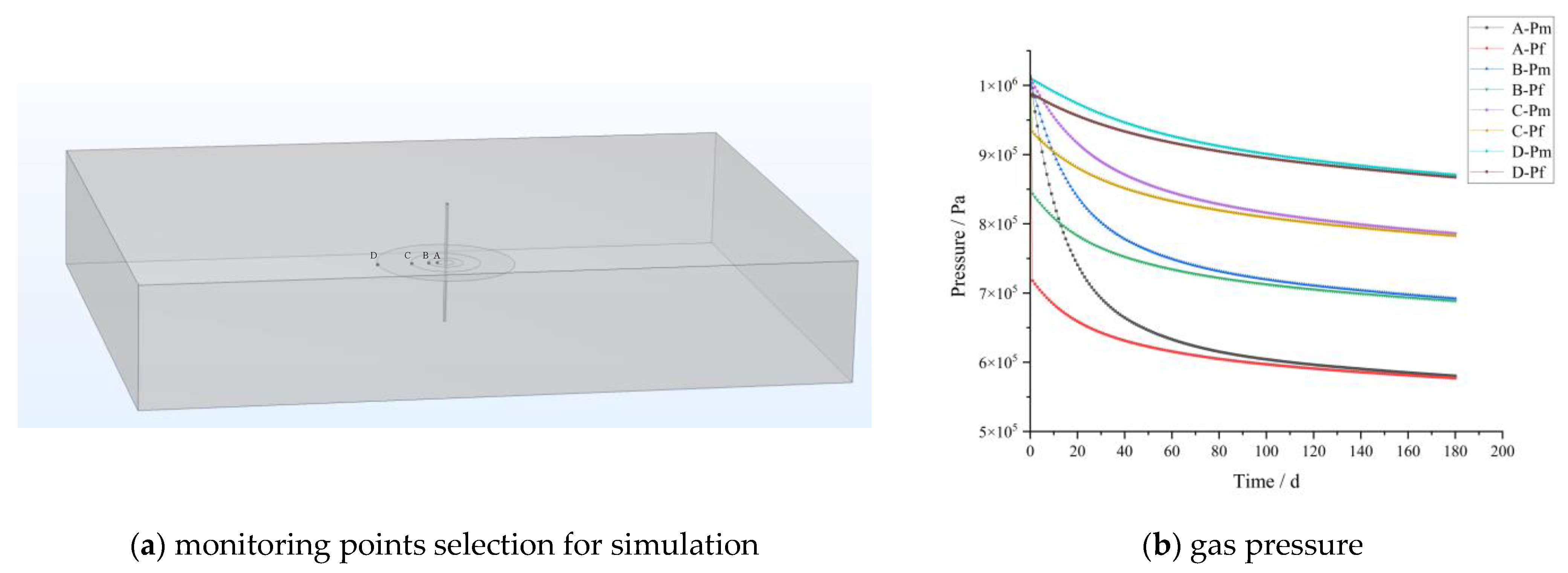

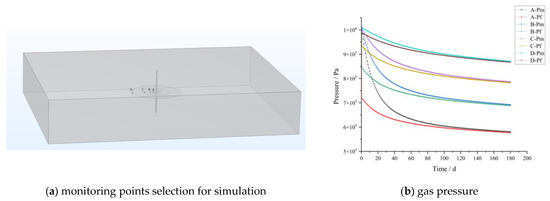

As shown in Figure 3a, points A (0,0.5,0), B (0,1,0), C (0,2,0), and D (0,4,0) are selected as simulation monitoring points to simulate the gas pressure of coal matrix pores and coal fractures under different extraction time monitored in the same plane and different radius. The result is shown in Figure 3b. It can be seen from Figure 3 that at the same extraction time, the gas pressure in coal matrix pores is always larger than that in the coal fractures. At 30 days before drainage, gas pressure in fracture of A and B coal bodies decreases greatly. In contrast, with the four monitoring points farther away from the borehole distance, C and D two-coal seam gas pressure in the fracture decreased slightly. The gas pressure of the coal matrix at the four monitoring points did not decrease significantly as the gas pressure of coal fracture. At the four monitoring points, the gas pressure of coal fracture and the gas pressure of the coal matrix decrease gradually with the continuous extraction and tend to be gentle. The difference between gas pressure in the coal fracture and coal matrix at the four monitoring points decreases gradually.

Figure 3.

Coal matrix and fracture gas pressure under different extraction time.

In the initial stage of drilling drainage, the pressure difference between the gas pressure in the fracture and the negative pressure of the borehole is obvious, and the free gas in the fracture flows to the borehole, so the gas pressure in the coal fracture decreases sharply. The seepage of gas in the fracture to the borehole causes the obvious pressure difference between the coal matrix and the gas in the fracture. The gas in the coal matrix diffuses to the fracture, and the gas adsorbed by the coal matrix desorbs under the influence of the pressure difference, and then participates in the diffusion to the fracture. Gas diffusion and desorption diffusion in coal matrix produce gas pressure difference with surrounding coal matrix, which will also absorb gas diffused by surrounding coal matrix. Under the same extraction time at the same position, the gas pressure in the coal fractures is always smaller than that in a negative pressure borehole, and the gas pressure in coal matrix pores is always larger than that in coal fractures. The influence scope of borehole negative pressure extraction expands gradually with the increase in extraction time. The fracture around borehole and matrix gas pressure decreases gradually with the increase in extraction time. However, the gas content in coal is constant, and there is a pressure difference between the negative pressure borehole and free gas in the fracture. The gas pressure between the fracture and the coal matrix, and the gas pressure between the coal matrix and the surrounding coal matrix gradually decrease with the extraction. The gas pressure in the effective extraction area, the coal matrix around the borehole, and the fracture will tend to be gentle and no longer change significantly after reaching a certain extraction time.

4.2. Drilling Engineering Optimization

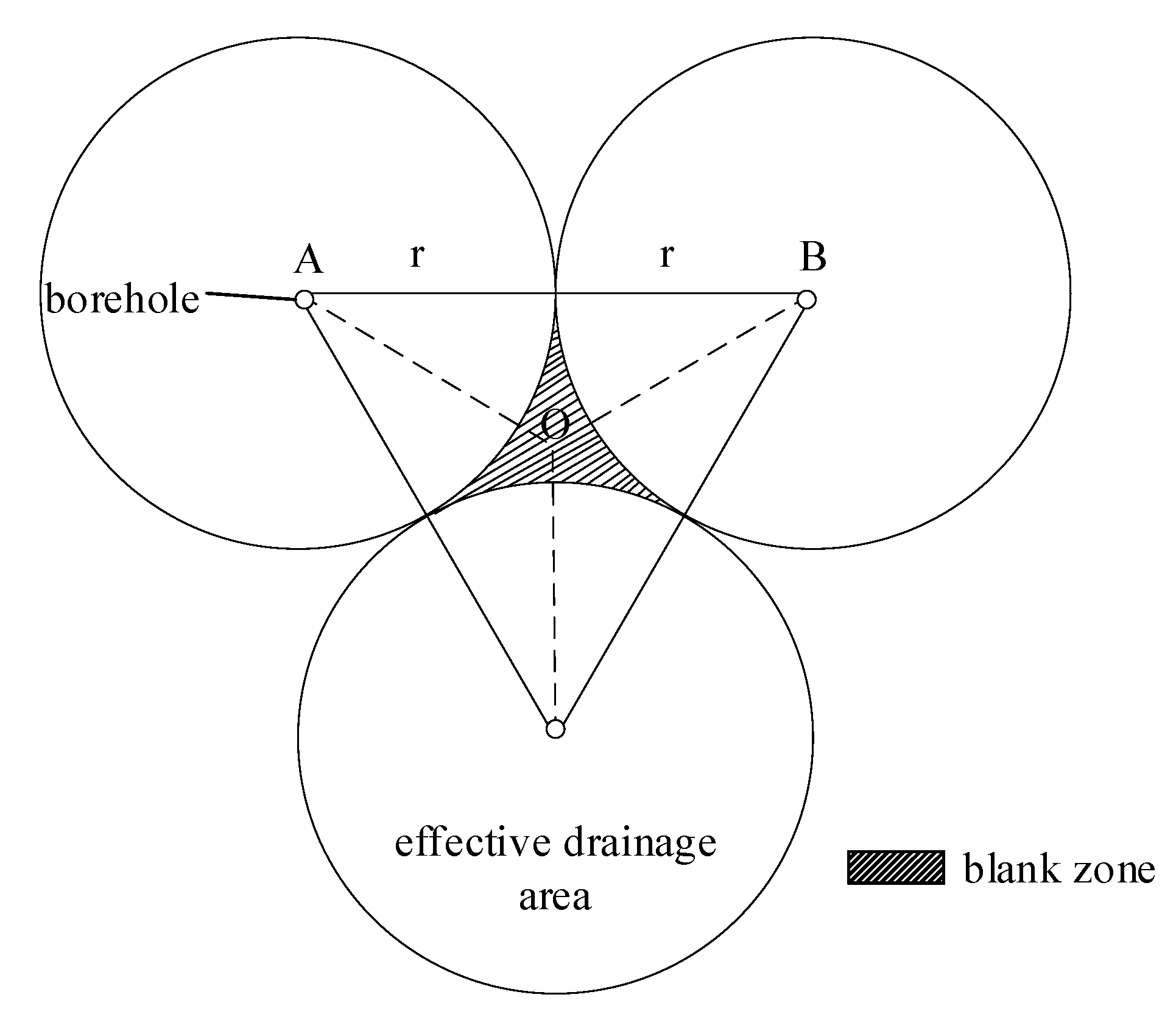

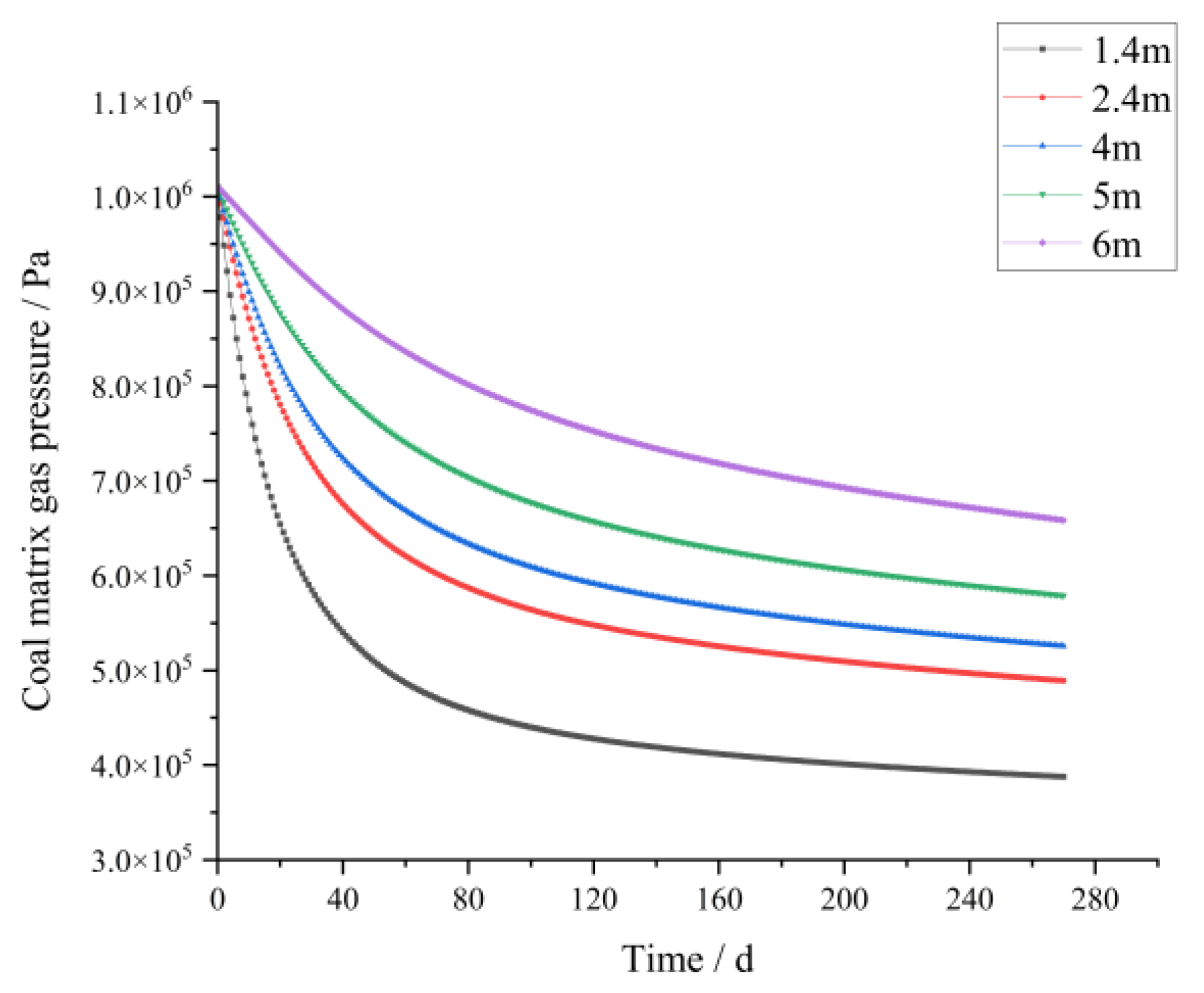

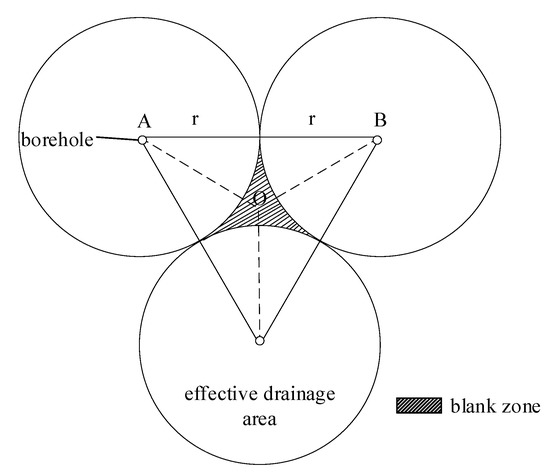

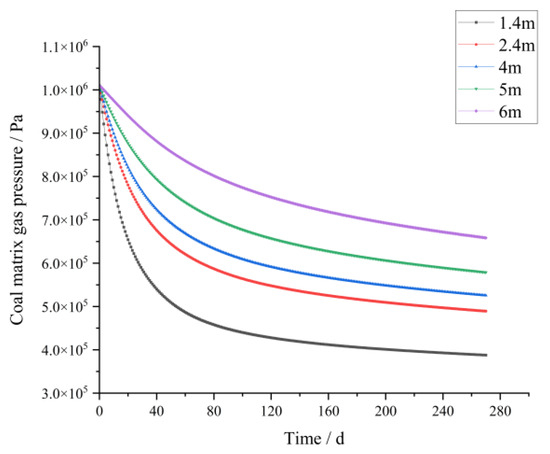

When studying the effective extraction radius, in order to avoid the possible interaction between multiple boreholes, the single borehole extraction used in Section 4.1 is adopted. The effective extraction radius increases with the increase in extraction time, but the increase gradually decreases until it tends to be gentle. With the increase in extraction time, the amount of gas extraction increases. However, more than a certain extraction time, even if the extraction time is longer, it has little effect on the pure amount of gas extraction. Since the adsorbed gas in the coal matrix occupies the vast majority of the total gas in the coal seam, the effective extraction radius r = 1.3 m, considering the gas pressure of the coal matrix, is selected as the reference for the arrangement of borehole spacing when the extraction is 140 d. According to the research of Chen Yuexia et al. [22,27] without considering the influence of superposition effect between boreholes, when four boreholes are used for extraction, through geometric derivation, it is concluded that when the spacing between boreholes is less than or equal to , there will be no blank zone with pressure higher than the specified pressure in the borehole layout area. However, in fact, when multiple boreholes are extracted, due to the interaction between boreholes due to borehole spacing, the superposition effect is generated [28,29]. As shown in Figure 4, when the hole spacing of the three extraction boreholes is set to 2r, the three boreholes are surrounded by an equilateral triangle with a side length of 2r. In theory, if the superposition effect between boreholes is not considered, there will be a blank zone shown in the shadow part, where the gas pressure of the coal matrix is higher than 0.74 MPa. According to the Pythagorean theorem, the AO length can be obtained as . When the borehole spacing is , the gas extraction simulation is carried out by three boreholes. Figure 5 shows the variation curve of the coal matrix gas pressure with time at the center points (0,0,0) of three boreholes during gas extraction. When the drill hole spacing changes, it is ensured that the point is always located in the center of the equilateral triangle surrounded by three boreholes. It can be seen that when the extraction spacing is 1.4 m and the extraction time is 0 d–70 d, the gas pressure of the coal matrix decreases obviously. After the extraction time was 70 days, the gas pressure in the coal matrix did not decrease significantly and finally stabilized. When the borehole spacing is different, the depressurization effect of the drilling area is less obvious with the increase in borehole spacing. The gas pressure in the coal matrix showed a rapid decrease trend at the initial stage, and then the downward trend slowed down. The gas pressure in the coal matrix decreases not obviously with the extension of extraction time, and gradually tends to be gentle. The decrease rate of coal matrix gas pressure in the area surrounded by boreholes becomes slower with the increase in borehole spacing. This is because the superposition effect between boreholes decreases with the increase in borehole spacing. In addition, with the continuation of the extraction process, the gas pressure gradient between coal fractures and boreholes, between coal fractures and coal matrix pores, and between coal matrix pores, gradually decreases, and the gas migration is not strong at the beginning of extraction.

Figure 4.

Schematic diagram of borehole gas extraction influence area.

Figure 5.

Variation in coal matrix gas pressure with time under different extraction spacing.

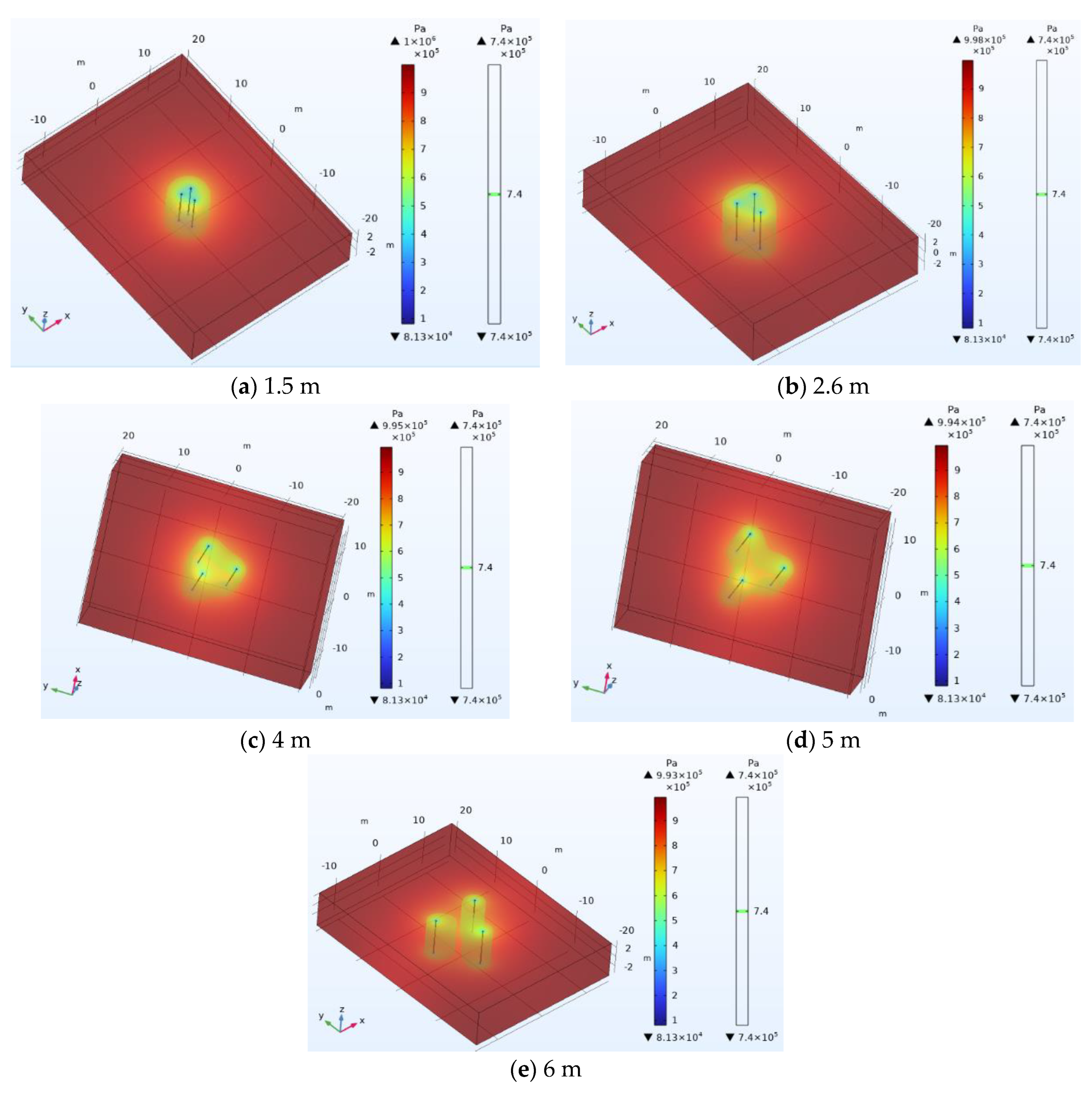

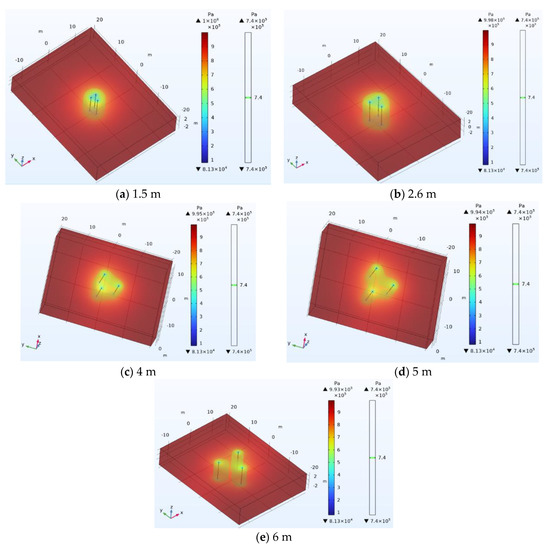

Figure 6 shows the distribution of the coal matrix gas pressure and effective extraction radius when the extraction time is 140 d and the borehole spacing is 1.5 m, 2.6 m, 4 m, 5 m, and 6 m, respectively. The light green surface in the figure is 0.74 MPa isosurface. It can be seen from Figure 6a that when the borehole spacing is 1.5 m, the effective extraction area of the three boreholes is approximately cylindrical, and the gas pressure of the coal matrix in the area surrounded by the three boreholes is obviously low. This is because the borehole spacing is small, the borehole superposition effect is obvious, and the gas extraction effect in the area surrounded by the borehole is obvious. It can be seen from Figure 6b–d that when the borehole spacing is 2.6 m, 4 m, and 5 m, the effective extraction area of the three boreholes is a rounded triangular prism. With the increase in borehole spacing, the higher the gas pressure in the area surrounded by the three boreholes, the more irregular the effective extraction area, and with the internal depression, there is an overall trend of division. This is because the superposition effect of boreholes decreases with the increase in borehole spacing, and the effect of gas extraction in the area surrounded by boreholes is weakened. It can be seen from Figure 6e that when the borehole spacing is 6 m, the effective extraction area of the three boreholes is distributed around the three boreholes in three irregular cylinders, and the blank zone appears in the area surrounded by the three boreholes. This is because the superposition effect weakens with the increase in borehole spacing until a certain distance between boreholes is no longer affected by the superposition effect. The borehole spacing is different. The gas pressure in the area around the borehole decreases continuously with the increase in the extraction time. The smaller the borehole spacing, the greater the gas pressure drop and the faster the gas drop rate. However, the longer the extraction time, the slower the gas pressure decreases. When the borehole spacing increases to a certain distance, a blank zone appears in the area surrounded by boreholes. When the borehole spacing is small, the time required to achieve the expected extraction effect is shorter; but the more boreholes required, the higher the construction cost. When the borehole spacing is large, the extraction rate of gas slows down, and it takes a long time to achieve the expected extraction effect. However, the number of boreholes required is small, and the effective extraction area is large over time within a reasonable project budget.

Figure 6.

Effective extraction area effect diagram under different hole spacing of 140 d extraction.

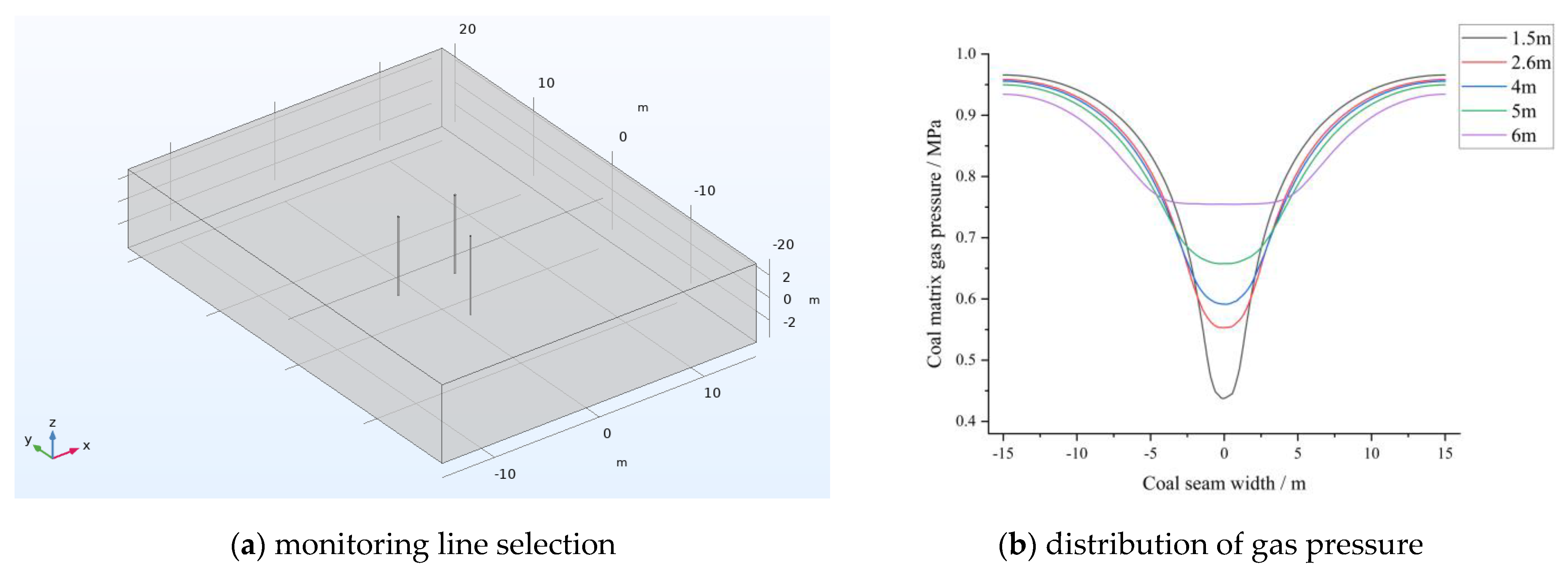

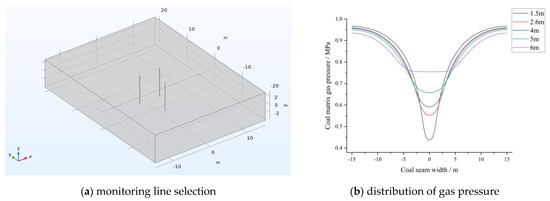

As shown in Figure 7a, (−15,0,0) and (15,0,0) points are selected to make the X-axis direction section. The gas pressure of the coal matrix on the section line is simulated at 140 days of extraction with different hole spacing, and the results are shown in Figure 7b. In the extraction of 140 d, under different borehole spacing: with the increase in borehole spacing, the effect of gas pressure reduction is more obvious. The smaller the borehole spacing is, the greater the gas pressure drop rate in the area around the borehole is, and the more obvious the gas extraction effect is. The gas pressure drop rate around borehole decreases with the increase in borehole spacing, and the effect of gas extraction is worse. It shows that the drilling superposition effect is inversely proportional to the borehole spacing.

Figure 7.

Gas pressure distribution of coal matrix on the cut-off line under different extraction spacing at 140 d.

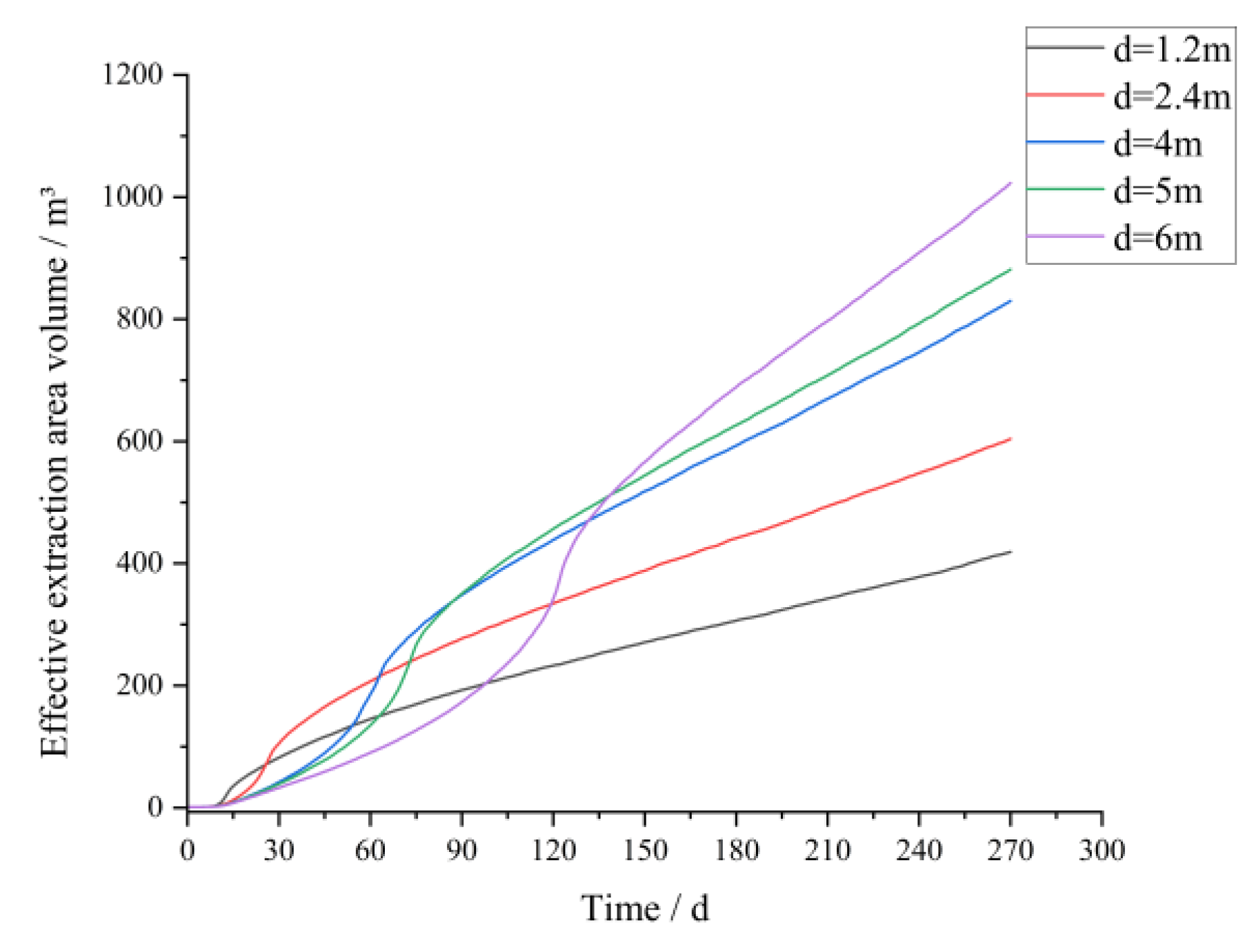

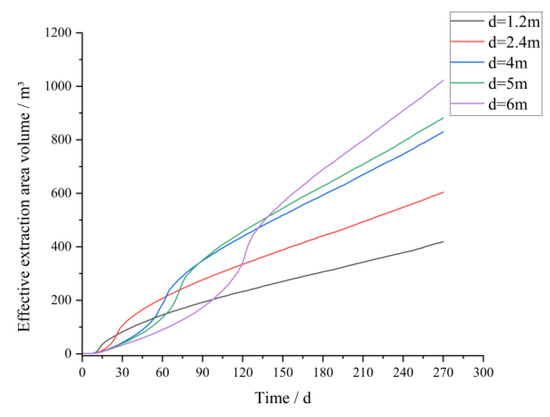

Figure 8 is the volume change curve of the effective extraction area with time and borehole spacing. It can be seen from the diagram that under the condition of five different borehole spacing, the volume of the effective extraction area increases from gentle to sharp and then to a large increase. When the borehole spacing is 1.5 m, 2.6 m, 4 m, 5 m, and 6 m, the effective extraction area volume increases sharply in about 10 d–15 d, 15 d–30 d, 45 d–65 d, 60 d–75 d, and 105 d–120 d, respectively. At the beginning of extraction, the bigger the superposition effect is, the smaller the borehole spacing is, and the bigger the effective extraction area is. Primarily, at about 25 d, the volume of the effective extraction area with a borehole spacing of 2.6 m expands sharply, exceeding the volume of the effective extraction area with a borehole spacing of 1.2 m. Next, with the increase in extraction time, the volume of effective extraction area with borehole spacing of 4 m expands sharply, which exceeds the volume of effective extraction area with borehole spacing of 1.5 m and 2.6 m, successively. Then, the volume of the effective extraction area with a borehole spacing of 5 m continues to expand, exceeding the volume of the effective extraction area with a borehole spacing of 1.5 m, 2.6 m, and 4 m. As the extraction continues, the volume of the effective extraction area with a borehole spacing of 6 m first expands sharply, and then the increase decreases and continues to expand, successively exceeding the effective extraction area with a borehole spacing of 1.5 m, 2.6 m, 4 m, and 5 m. The effective extraction area volume of different borehole spacing changes with the extraction time, as shown in Table 2.

Figure 8.

The volume change in effective extraction area under different extraction spacing at 140 d.

Table 2.

Table of parameters required for simulation.

After the extraction time is 135 d, although the effective extraction area with borehole spacing of 6 m has the largest volume, it can be seen from Figure 7b that when the extraction time is 140 d, there is a blank zone with gas pressure higher than 0.74 MPa in the area surrounded by boreholes, so the extraction effect is not ideal. As the extraction time becomes longer and longer, the internal blank zone is gradually eliminated. Considering that if the gas pressure in the internal area surrounded by the borehole already reached the standard, the long extraction time may lead to safety problems due to pressure imbalance. When the borehole spacing is small, the actual economic problems caused by the increase in the effective extraction area with the extraction time are no longer obvious, and the extraction time is allowed under the actual working conditions. The comprehensive analysis shows that when the extraction time of the mine is about 140 d and the borehole spacing is set to 5 m, the extraction effect is the best.

5. Discussion

In this paper, based on the porous model of pore-fracture dual medium, considering the influence of coal skeleton and coal matrix deformation when coal adsorbs and desorbs gas, considering coal fracture seepage, coal matrix adsorption, desorption and diffusion gas, gas diffusion between coal matrix, and the Klinkenberg effect, a gas-solid coupling model is established. The effective extraction radius is obtained according to the variation law of coal matrix gas content with extraction time. Extending from a two-dimensional plane to a three-dimensional space, the volume change in effective extraction area is studied, so as to more intuitively analyze and verify the migration of gas in borehole coal fracture coal matrix during negative pressure borehole extraction. In the three-dimensional visualization model, it can be clearly seen that under the same extraction time, the effective extraction area, considering the change in gas pressure in coal fracture, is different from the effective extraction area considering the change in gas pressure in the coal matrix. Compared with two-dimensional theoretical analysis, it is more intuitive and more conducive to explain the mechanism of gas migration. Through the three-dimensional visualization model, at a certain distance between boreholes, it can be clearly seen that the gas pressure in the area around the borehole decreases more obviously than that outside the borehole, which indicates that the boreholes are affected by the superposition effect. When multiple boreholes are used for gas extraction, the borehole spacing has a great influence on the extraction effect. The extraction time required to eliminate the blank zone in the area surrounded by the borehole is longer with the increase in the borehole spacing. As long as the spacing of boreholes is within a reasonable range, the blank zone can be eliminated by prolonging the extraction time in theory. If the borehole spacing is too large, in theory, it reduces the number of boreholes and needs to extend the extraction time to eliminate blank area. However, the pressure imbalance may be caused by excessive extraction, and safety accidents may occur. Extending the extraction also requires the consumption of certain economic resources. If the borehole spacing is too small, the superposition effect between boreholes is strong, and the extraction time required to eliminate the blank zone time is short, but the increase in the number of boreholes may cause waste of resources. Therefore, the study of reasonable borehole spacing has a certain guiding significance for practical engineering.

This study has some inspiration and guiding significance for coal energy security and sustainable mining, but there are still deficiencies. According to different geological conditions, there are elastic–plastic changes in the actual coal, and the change in temperature will also affect the deformation of coal structure, so the coal deformation control equation remains to be improved. In the study of the optimal borehole spacing, the layout and spacing of boreholes need to be adjusted according to the actual coal mine conditions and engineering planning, and the selection method of the optimal borehole spacing needs to be improved.

6. Conclusions

(1) The gas-solid coupling model of negative pressure drilling gas extraction was established. The model is based on the coal pore-fracture porous media model, considering the coal deformation, gas diffusion seepage, gas adsorption, and desorption process. The change in gas pressure Pm in the coal matrix and gas pressure Pf in coal fracture is simulated, and the migration mechanism of gas between coal matrix, coal fracture, and borehole is verified.

(2) When gas is extracted by a negative pressure borehole, the gas in a coal fracture seeps into borehole driven by extraction negative pressure. After the gas in the fracture flows out, the coal matrix gas diffuses into the fracture under the pressure difference to participate in the seepage. The gas pressure of the coal matrix decreases, the gas adsorbed in the surrounding coal matrix desorbs, and the free gas contained diffuses to the coal matrix under the action of pressure difference. The gas pressure in the coal body near the borehole decreases obviously, and the farther away from the borehole, the weaker the influence of extraction. The pressure gradient decreases with the increase in extraction time, the effect of gas migration will gradually weaken, and the effective extraction range of the borehole is limited.

(3) During multi-borehole extraction, the gas pressure in the area around the borehole decreases obviously under the influence of the superposition effect. With the increase in borehole spacing, the extraction effect in the area around the borehole decreases. The effective extraction area formed by multi-borehole negative pressure gas extraction is related to extraction time and borehole spacing. When the three boreholes are extracted for 140 days, the effective extraction area is approximately cylindrical when the borehole spacing is 1.5 m. The effective extraction area is approximately a rounded triangular prism when the borehole spacing is 2.6 m, 4 m, and 5 m, but the longer the borehole spacing, the surrounding inward depression is split. The effective extraction area is divided into three near-cylindrical areas when the borehole spacing is 6 m, and a blank zone appears in the area surrounded by the borehole. Considering the shape, volume change, extraction effect, safety, and economic problems of the effective extraction area, the best effect is to select the hole spacing of 5 m when the three boreholes are used as the group extraction for 140 days.

Author Contributions

Investigation, W.C.; methodology, F.D.; supervision, K.W.; writing—original draft, F.D.; writing—review and editing, W.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 52004291 and 52130409.

Data Availability Statement

The data are available from the corresponding author on reasonable request.

Acknowledgments

We also would like to thank the anonymous reviewers for their valuable comments and suggestions that lead to a substantially improved manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yuan, L. Deep coal and gas mining strategic thinking in China. J. China Coal Soc. 2016, 41, 1–6. [Google Scholar]

- Wang, K.; Du, F. Coal-gas compound dynamic disasters in China: A review. Process Saf. Environ. Prot. 2020, 133, 1–17. [Google Scholar] [CrossRef]

- Xue, D.J.; Zhou, J.; Liu, Y.T.; Gao, L. On the excavation-induced stress drop in damaged coal considering a coupled yield and failure criterion. Int. J. Coal Sci. Technol. 2020, 7, 58–67. [Google Scholar] [CrossRef]

- Du, F.; Wang, K. Unstable failure of gas-bearing coal-rock combination bodies: Insights from physical experiments and numerical simulations. Process Saf. Environ. Prot. 2019, 129, 264–279. [Google Scholar] [CrossRef]

- Guo, D.Y.; Lv, P.F.; Zhao, J.C.; Zhang, C. Research progress on permeability improvement mechanisms and technologies of coalbed deep-hole cumulative blasting. Int. J. Coal Sci. Technol. 2020, 7, 329–336. [Google Scholar] [CrossRef]

- Shu, L.Y.; Wang, K.; Liu, Z.S.; Zhao, W.; Zhu, N.N.; Lei, Y. A novel physical model of coal and gas outbursts mechanism: Insights into the process and initiation criterion of outbursts. Fuel 2022, 323, 124305. [Google Scholar] [CrossRef]

- Li, X.Y.; Zheng, J.Y.; Liu, J.P. Numerical Simulation of Borehole Parameters for Coal Seam Gas Pre-Drainage. Int. J. Heat Technol. 2021, 39, 1328–1334. [Google Scholar] [CrossRef]

- Wang, K.; Guo, Y.Y.; Wang, G.; Du, F. Seepage and Mechanical Failure Characteristics of Gas-bearing Composite Coal-Rock Under True Triaxial Path. J. China Coal Soc. 2022, 1–12. [Google Scholar] [CrossRef]

- Tu, Q.Y.; Cheng, Y.P.; Xue, S.; Ren, T.; Cheng, X. Energy-limiting factor for coal and gas outburst occurrence in intact coal seam. Int. J. Min. Sci. Technol. 2021, 31, 729–742. [Google Scholar] [CrossRef]

- Li, W.R.; Wang, D.K.; Wang, J.G. Improved mathematical model of apparent permeability: A focused study on free and multilayer adsorptive phase flow. J. Nat. Gas Sci. Eng. 2022, 101, 104508. [Google Scholar] [CrossRef]

- Pan, Z.J.; Connell, L.D.; Camilleri, M.; Connelly, L. Effects of matrix moisture on gas diffusion and flow in coal. Fuel 2010, 89, 3207–3217. [Google Scholar] [CrossRef]

- Wang, K.; Du, F.; Wang, G. Investigation of gas pressure and temperature effects on the permeability and steady-state time of Chinese anthracite coal: An experimental study. J. Nat. Gas Sci. Eng. 2017, 40, 179–188. [Google Scholar] [CrossRef]

- Hou, W.T.; Wang, H.P.; Yuan, L.; Wang, W.; Xue, Y.; Ma, Z.W. Experimental research into the effect of gas pressure, particle size and nozzle area on initial gas-release energy during gas desorption. Int. J. Min. Sci. Technol. 2021, 31, 253–263. [Google Scholar] [CrossRef]

- Zhu, W.C.; Liu, J.; Sheng, J.C.; Elsworth, D. Analysis of coupled gas flow and deformation process with desorption and Klinkenberg effects in coal seams. Int. J. Rock Mech. Min. Sci. 2006, 44, 971–980. [Google Scholar] [CrossRef]

- Hu, G.Z.; Xu, J.L.; Wang, H.T.; Jin, Z.Y.; Wu, R.L. Research on a dynamically coupled deformation and gas flow model applied to low-permeability coal. J. China Univ. Min. Technol. 2011, 40, 1–6. [Google Scholar]

- Xia, T.-Q.; Gao, F.; Kang, J.-H.; Wang, X.-X. A fully coupling coal-gas model associated with inertia and slip effects for CBM migration. Ecol. Environ. Conserv. 2016, 75, 582. [Google Scholar] [CrossRef]

- Cheng, Y.P.; Dong, J.; Li, W.; Chen, M.Y.; Liu, K.; Zhao, W. Effect of negative pressure on coalbed methane extraction and application in the utilization of methane resource. J. China Coal Soc. 2017, 42, 1466–1474. [Google Scholar]

- Liu, Q.Q.; Cheng, Y.P.; Li, W.; Jin, K.; He, T.; Zhao, W. Mathematical Model of Coupled Gas Flow and Coal Deformation Process in Low-Permeability and First Mined Coal Seam. Chin. J. Rock Mech. Eng. 2015, 34, 2749–2758. [Google Scholar]

- Zhang, Y.Y. Numerical Simulation Study on Effective Radius of Degassing Borehole. Master’s Thesis, Henan Polytechnic University, Jiaozuo, China, 2015. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CMFD201602&filename=1016710989.nh (accessed on 8 January 2023).

- Li, B.; Wei, J.P.; Sun, D.H.; Zhang, L.L.; Borisyukd, Y.A. Research on the Reasonable Spacing of Holes in Gas Drainage along Coal Seams in Consideration of the Superimposed Effect of Drainage. J. Eng. Sci. Technol. Rev. 2016, 9, 102–110. [Google Scholar]

- Zhang, L.; Jing, C.; Li, S.G.; Bao, R.Y.; Zhang, T.J. Seepage Law of Nearly Flat Coal Seam Based on Three-Dimensional Structure of Borehole and the Deep Soft Rock Roadway Intersection. Energies 2022, 15, 5012. [Google Scholar] [CrossRef]

- Chen, Y.X. Parameters Evolution during Gas Drainage and Numerical Simulation of Boreholes Optimization. Ph.D. Disssertation; Chongqing University: Chongqing, China, 2018. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CDFDLAST2019&filename=1018852869.nh (accessed on 8 January 2023).

- Hu, S.X.; Liu, X.; Li, X.Z. Fluid–Solid Coupling Model and Simulation of Gas-Bearing Coal for Energy Security and Sustainability. Processes 2020, 8, 254. [Google Scholar] [CrossRef]

- Wang, D.K.; Tang, J.H.; Wei, J.P.; Wei, L.; Wu, J.; Yuan, M.Y.; Pang, X.F.; Guo, Y.J. A fluid-solid coupling model of coal seam gas considering gas multi-mechanism flow and numerical simulation analysis of gas drainage. J. China Coal Soc. 2022, 1–13. [Google Scholar] [CrossRef]

- Wang, D.K.; Peng, M.; Fu, Q.C.; Qin, H.J.; Xia, Y.L. Evolution and numerical simulation of coal permeability during gas drainage in coal seams. Chin. J. Rock Mech. Eng. 2016, 35, 704–712. [Google Scholar]

- Wu, Y.; Liu, J.S.; Elsworth, D.; Chen, Z.W.; Connell, L.; Pan, Z.J. Dual poroelastic response of a coal seam to CO2 injection. Int. J. Greenh. Gas Control. 2010, 4, 668–678. [Google Scholar] [CrossRef]

- Chen, Y.X.; Chu, T.X.; Chen, P.; Tang, Y. Quantitative study of 3D numerical simulation on optimizing borehole layout spacing of gas drainage. Coal Geol. Explor. 2021, 49, 78–84, 94. [Google Scholar]

- Wei, P.; Huang, C.W.; Li, X.L.; Peng, S.J.; Lu, Y.N. Numerical simulation of boreholes for gas extraction and effective range of gas extraction in soft coal seams. Energy Sci. Eng. 2019, 7, 1632–1648. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, J.; Pan, J.T. Study on gas seepage from coal seams in the distance between boreholes for gas extraction. J. Loss Prev. Process Ind. 2018, 54, 266–272. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).