The Relationship between Penetration, Tension, and Torsion for the Fracture of Surimi Gels: Application of Digital Image Correlation (DIC)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Surimi Gel Preparation

2.3. Texture Analysis

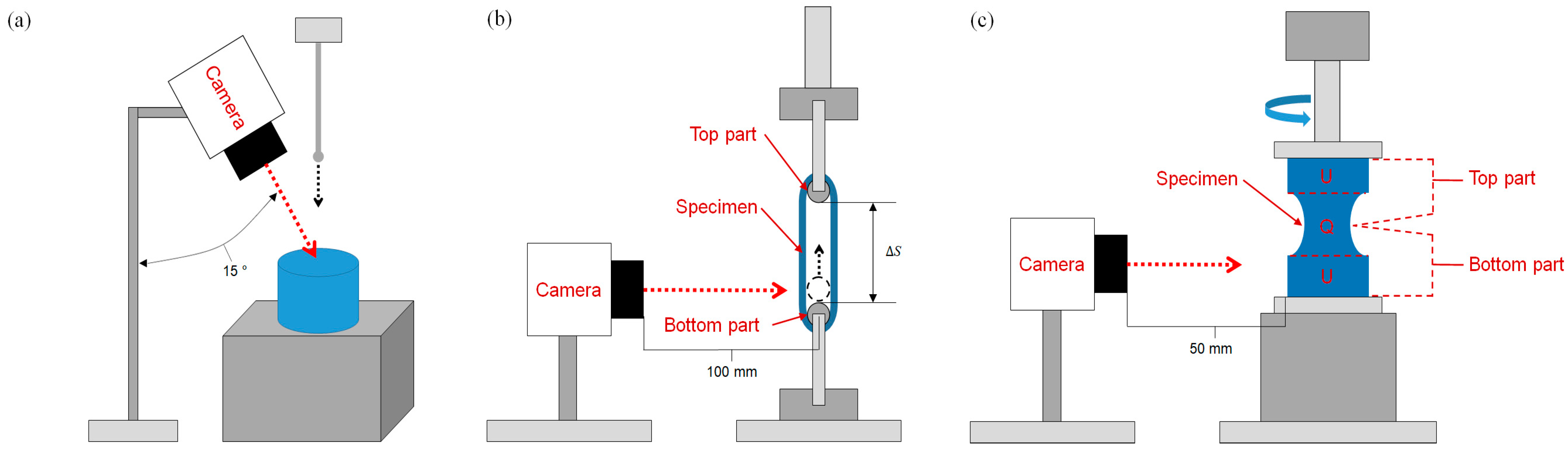

2.3.1. Penetration Test

2.3.2. Ring Tensile Test

2.3.3. Torsion Test

2.4. Digital Image Correlation (DIC)

2.4.1. Image Acquisition

2.4.2. Calculation of Local Strain

2.5. Statistical Analysis

3. Results and Discussion

3.1. Textural Properties Related to the Hardness of Surimi Gel

3.2. Textural Properties Related to Hardness of Surimi Gels

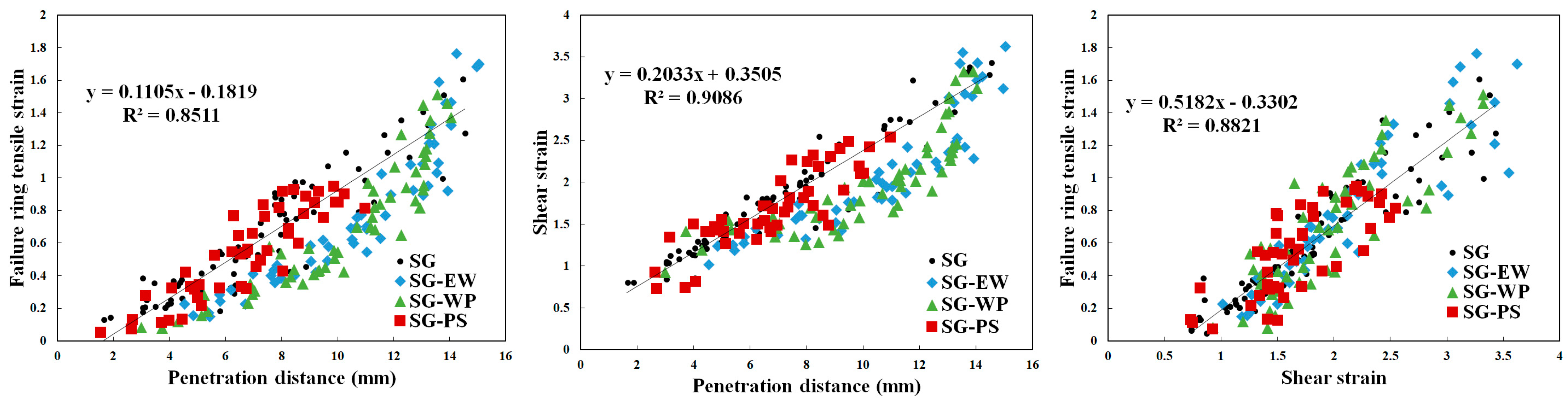

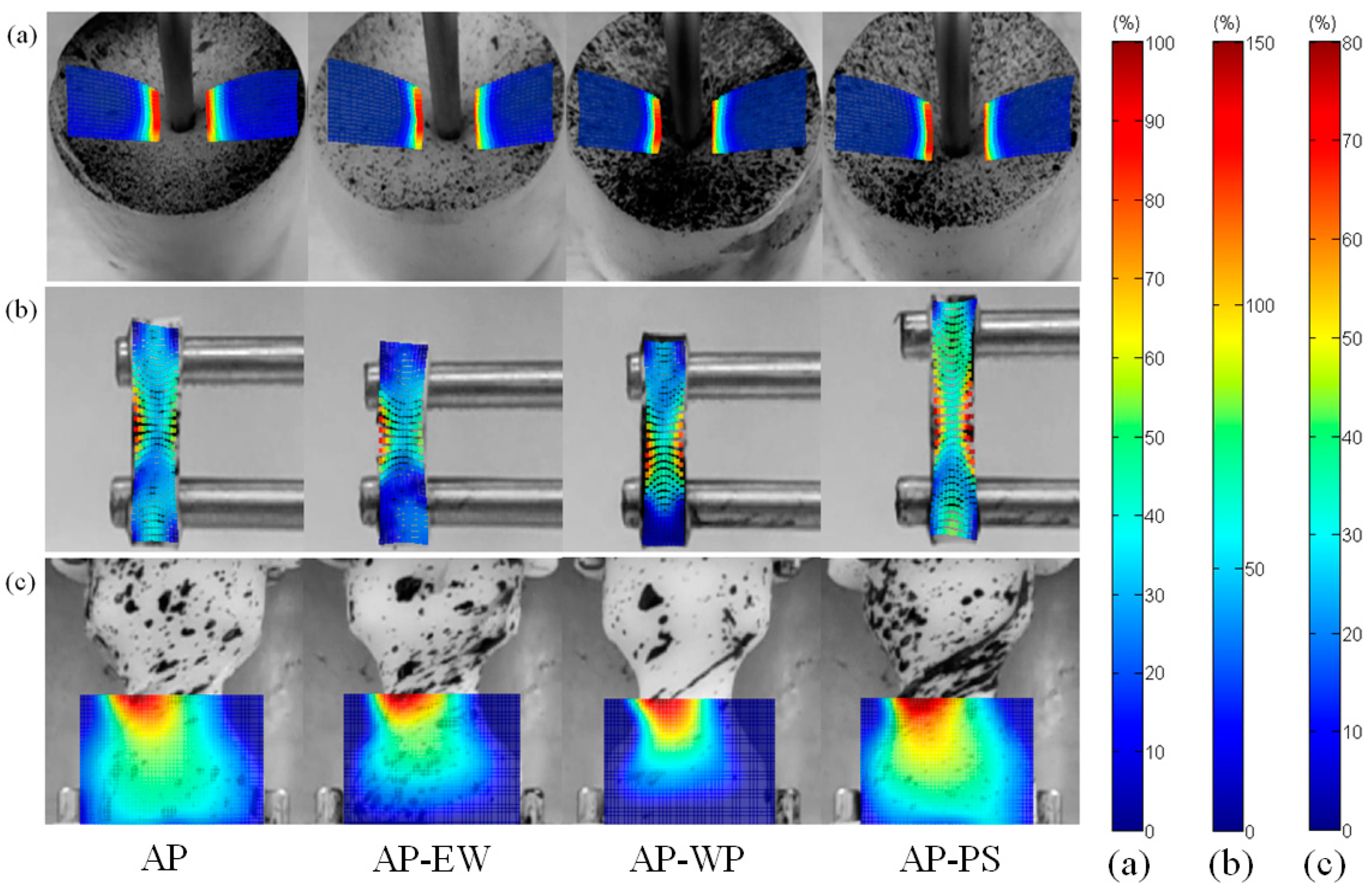

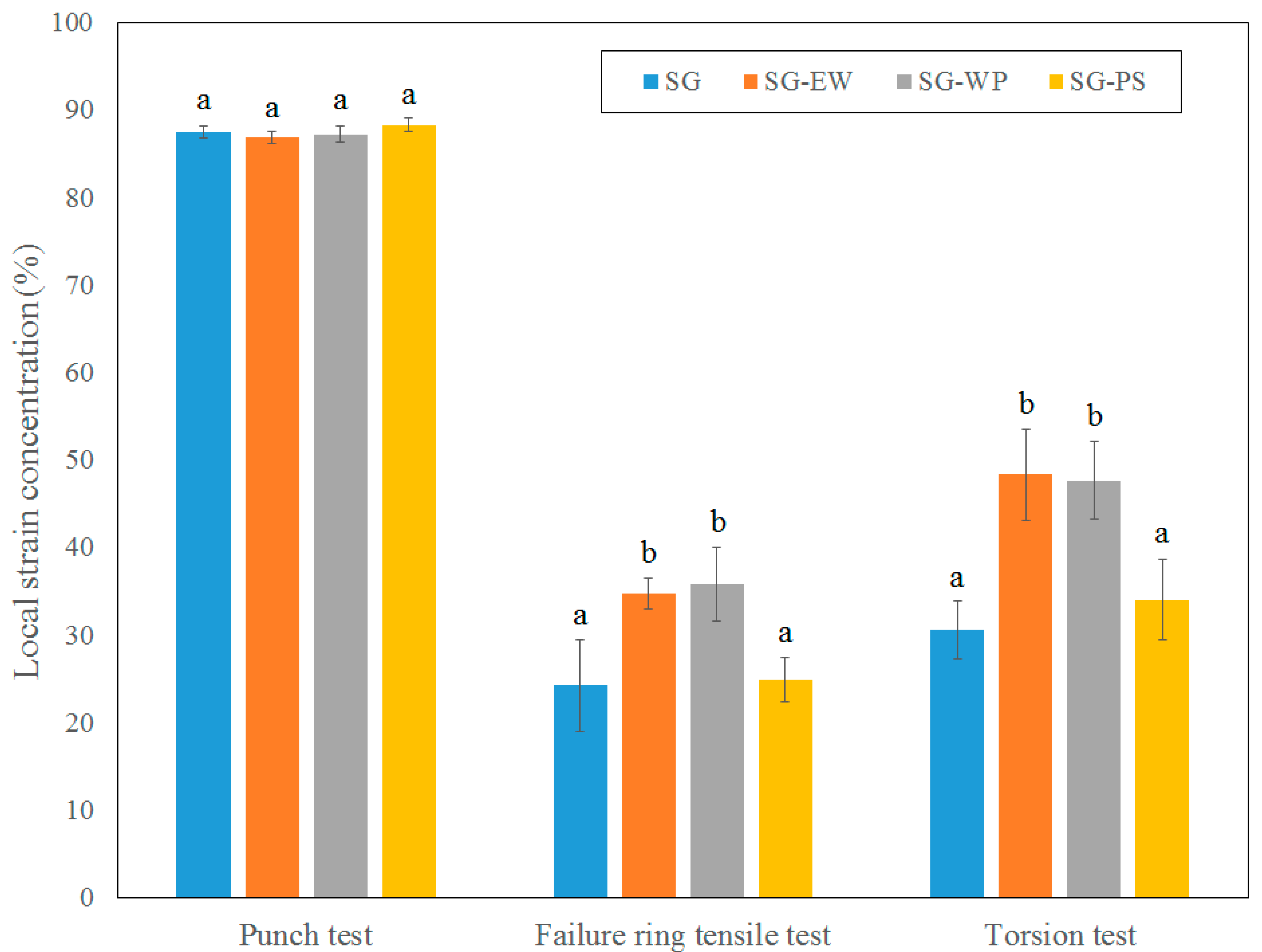

3.3. Evaluation of Local Strain

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Park, J.W. Surimi and Surimi Seafood, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Park, J.D.; Park, J.W.; Yoon, W.B. Semi-empirical relationship between rupture properties of surimi pastes and failure shear stress of surimi gels at different moisture contents. J. Texture Stud. 2013, 44, 247–252. [Google Scholar] [CrossRef]

- Park, H.W.; Park, J.W.; Yoon, W.B. Effect of Dehydration on the Rheological Measurement of Surimi Paste in Cone-Plate Rheometry: Heat and Mass Transfer Simulation. Processes 2020, 8, 234. [Google Scholar] [CrossRef]

- Jung, H.; Oyinloye, T.M.; Yoon, W.B. Stress and strain characteristics under the large deformation of surimi gel during penetration and extension tests using digital image correlation and the numerical simulation method. Gels 2022, 8, 740. [Google Scholar] [CrossRef]

- Park, H.W.; Yoon, W.B. Measuring ring tensile stress and strain of surimi gels using a novel ring tensile test with image analysis. J. Food Eng. 2015, 163, 9–16. [Google Scholar] [CrossRef]

- Shi, L.; Wang, X.; Chang, T.; Wang, C.; Yang, H.; Cui, M. Effects of vegetable oils on gel properties of surimi gels. LWT-Food Sci. Technol. 2014, 57, 586–893. [Google Scholar] [CrossRef]

- Fang, Q.; Shi, L.; Ren, Z.; Hao, G.; Chen, J.; Weng, W. Effects of emulsified lard and TGase on gel properties of threadfin bream (Nemipterus virgatus) surimi. LWT 2021, 146, 111513. [Google Scholar] [CrossRef]

- Kim, S.M.; Kim, H.W.; Park, H.J. Preparation and characterization of surimi-based imitation crab meat using coaxial extrusion three-dimensional food printing. Innov. Food Sci. Emerg. Technol. 2021, 71, 102711. [Google Scholar] [CrossRef]

- Dickinson, A.S.; Taylor, A.C.; Browne, M. The influence of acetabular cup material on pelvis cortex surface strains, measured using digital image correlation. J. Biomech. 2012, 45, 719–723. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.J.; Opara, U.L. Evaluating the displacement field of paperboard packages subjected to compression loading using digital image correlation (DIC). Food Bioprod. Process. 2020, 123, 60–71. [Google Scholar] [CrossRef]

- Godara, A.; Raabe, D.; Bergmann, I.; Putz, R.; Müller, U. Influence of additives on the global mechanical behavior and the microscopic strain localization in wood reinforced polypropylene composites during tensile deformation investigated using digital image correlation. Compos. Sci. Technol. 2009, 69, 139–146. [Google Scholar] [CrossRef]

- Liu, H.; Nie, Y.; Chen, H. Effect of different starches on colors and textural properties of surimi-starch gels. Int. J. Food Prop. 2014, 17, 1439–1448. [Google Scholar] [CrossRef]

- Luo, H.; Guo, C.; Lin, L.; Si, Y.; Gao, X.; Xu, D.; Jia, R.; Yang, W. Combined use of rheology, LF-NMR, and MRI for characterizing the gel properties of hairtail surimi with potato starch. Food Bioprocess Technol. 2020, 13, 637–647. [Google Scholar] [CrossRef]

- Tabilo-Munizaga, G.; Barbosa-Canovas, G.V. Color and textural parameters of pressurized and heat-treated surimi gels as affected by potato starch and egg white. Food Res. Int. 2004, 37, 767–775. [Google Scholar] [CrossRef]

- Yu, X.; Wang, Y.; Xie, Y.; Wei, S.; Ding, H.; Yu, C.; Dong, X. Gelation properties and protein conformation of grass carp fish ball as influenced by egg white protein. J. Texture Stud. 2022, 53, 277–286. [Google Scholar] [CrossRef]

- Duangmal, K.; Taluengphol, A. Effect of protein additives, sodium ascorbate, and microbial transglutaminase on the texture and colour of red tilapia surimmi gel. Int. J. Food Sci. Technol. 2010, 45, 48–55. [Google Scholar] [CrossRef]

- Jung, H.; Moon, J.H.; Park, J.W.; Yoon, W.B. Texture of surimi-canned corn mixed gels with conventional water bath cooking and ohmic heating. Food Biosci. 2020, 35, 100580. [Google Scholar] [CrossRef]

- Wasinnitiwong, N.; Tavakoli, S.; Benjakul, S.; Hong, H. Improving the gel quality of Threadfin bream (Nemipterus spp.) surimi using salted duck egg white powder. Foods 2022, 11, 3350. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, X.; Zeng, L.; Huang, Q.; Zhang, J.; Wen, X.; Xiong, S.; Yin, T.; Zhang, B. Effects of oil-modified crosslinked/acetylated starches on silver carp surimi gel: Texture properties, water mobility, microstructure, and related mechanisms. Food Res. Int. 2022, 158, 111521. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 15th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1990. [Google Scholar]

- Dieter, G.E. Mechanical Metallurgy, 3rd ed.; McGraw-Hill: New York, NY, USA, 1986. [Google Scholar]

- Hamann, D.D. Structural failure in solid foods. In Physical Properties of Foods; Bagley, E.B., Peleg, M., Eds.; AVI Publishing Co.: Westport, CT, USA, 1983; pp. 351–383. [Google Scholar]

- Lanier, T.C.; Hard, K.; Martin, R.E. A Manual of Standard Methods for Measuring and Specifying the Properties of Surimi; National Fisheries Institute: Washington, DC, USA, 1991. [Google Scholar]

- Nadai, A. Plastic behavior of metals in the strain-hardening range. J. Appl. Physics. Part A 1937, 8, 205. [Google Scholar] [CrossRef]

- Neuber, H. Theory of Notch Stresses: Principles for Exact Calculation of Strength with Reference to Structural from and Material; USAEC Office of Technical Information: Houston, TX, USA, 1958. [Google Scholar]

- Diehl, K.C.; Hamann, D.D.; Whitfield, J.K. Structural failure in selected raw fruits and vegetables. J. Texture Stud. 1979, 10, 371–400. [Google Scholar] [CrossRef]

- Pan, B. Digital image correlation for surface deformation measurement: Historical developments, recent advances and future goals. Meas. Sci. Technol. 2018, 29, 082001. [Google Scholar] [CrossRef]

- Jones, E.M.C.; Silverstein, M.N.; White, S.R.; Sottos, N.R. In situ measurements of strains in composite battery electrodes during electrochemical cycling. Exp. Mech. 2014, 54, 971–985. [Google Scholar] [CrossRef]

- Kim, J.; Kim, M. Derivation of transverse tensile properties of alloy 690 steam generator tubes using ring-tensile specimen and finite element analysis. In Proceedings of the ASME 2018 Pressure Vessels and Piping Conference, American Society of Mechanical Engineers, San Antonio, TX, USA, 15–20 July 2018. [Google Scholar]

- Shriwastaw, R.S.; Sawarn, T.K.; Banerjee, S.; Rath, B.N.; Dubey, J.S.; Kumar, S.; Bhasin, V. Estimation of ring tensile properties of steam oxidized Zircaloy-4 fuel cladding under simulated LOCA condition. J. Nucl. Mater. 2017, 493, 460–470. [Google Scholar] [CrossRef]

- Laterreur, V.; Ruel, J.; Auger, F.A.; Vallieres, K.; Tremblay, C.; Lacroix, D.; Tondreau, M.; Bourger, J.; Germain, L. Comparison of the direct burst pressure and the ring tensile test methods for mechanical characterization of tissue-engineered vascular substitutes. J. Mech. Behav. Biomed. Mater. 2014, 34, 253–263. [Google Scholar] [CrossRef]

- Chun, K.H.; Lee, C.M. Function of nonfish proteins in surimi-based gel products. Korean J. Food Cook. Sci. 1994, 10, 146–150. [Google Scholar]

- Hamann, D.D.; Zhang, J.; Daubert, C.R.; Foegeding, E.A.; Diehl, K.C. Analysis of compression, tension and torsion for testing food gel fracture properties. J. Texture Stud. 2006, 37, 620–639. [Google Scholar] [CrossRef]

- Mi, H.; Li, Y.; Wang, C.; Yi, S.; Li, X.; Li, J. The interaction of starch-gums and their effect on gel properties and protein conformation of silver carp surimi. Food Hydrocoll. 2021, 112, 106290. [Google Scholar] [CrossRef]

- Yu, J.; Song, L.; Xiao, H.; Xue, Y.; Xue, C. Structuring emulsion gels with peanut protein isolate and fish oil and analyzing the mechanical and microstructural characteristics of surimi gel. LWT 2022, 154, 112555. [Google Scholar] [CrossRef]

- Borderias, A.J.; Tovar, C.A.; Dominguez-Timon, F.; Diaz, M.T.; Pedrosa, M.M.; Moreno, H.M. Characterization of healthier mixed surimi gels obtained through partial substitution of myofibrillar proteins by pea protein isolates. Food Hydrocoll. 2020, 107, 105976. [Google Scholar] [CrossRef]

- Harte, A.M.; Fleck, N.A. Deformation and failure mechanisms of braided composite tubes in compression and torsion. Acta Mater. 2000, 48, 1259–1271. [Google Scholar] [CrossRef]

- Truong, V.D.; Daubert, C.R. Comparative study of large strain methods for assessing failure characteristics of selected food gels. J. Texture Stud. 2000, 31, 335–353. [Google Scholar] [CrossRef]

- Truong, V.D.; Daubert, C.R. Textural characterization of cheeses using vane rheometry and torsion analysis. J. Food Sci. 2001, 66, 716–721. [Google Scholar] [CrossRef]

- Yoon, W.B.; Park, J.W.; Jung, H. Effects of potato protein isolated using ethanol on the gelation and anti-proteolytic properties in Pacific Whiting surimi. Foods 2022, 11, 3114. [Google Scholar] [CrossRef] [PubMed]

- Chaijan, M.; Srirattanachot, K.; Panpipat, W. Biochemical property and gel-forming ability of surimi-like material from goat meat. Int. J. Food Sci. Technol. 2021, 56, 988–998. [Google Scholar] [CrossRef]

- Panpipat, W.; Cheong, L.; Chaijan, M. Impact of lecithin incorporation on gel properties of bigeye snapper (Priacanthus tayenus) surimi. Int. J. Food Sci. Technol. 2021, 56, 2481–2491. [Google Scholar] [CrossRef]

- Hastings, R.J.; Currall, E.P. Effects of water, oil, egg white and starch on the texture of cod surimi gels by response surface methodology. J. Texture Stud. 1988, 19, 431–451. [Google Scholar] [CrossRef]

- Hunt, A.; Getty, K.J.K.; Park, J.W. Roles of starch in surimi seafood: A review. Food Rev. Int. 2009, 25, 299–312. [Google Scholar] [CrossRef]

- Zhou, X.; Chen, T.; Lin, H.; Chen, H.; Liu, J.; Lyu, F.; Ding, Y. Physicochemical properties and microstructure of surimi treated with egg white modified by tea polyphenols. Food Hydrocoll. 2019, 90, 82–89. [Google Scholar] [CrossRef]

- Li, X.; Fan, M.; Huang, Q.; Zhao, S.; Xiong, S.; Yin, T.; Zhang, B. Effect of micro- and nano-starch on the gel properties, microstructure and water mobility of myofibrillar protein from grass carp. Food Chem. 2022, 366, 130579. [Google Scholar] [CrossRef]

- Kumar, A.; Dutta, A.; Makineni, S.K.; Herbig, M.; Petrov, R.H.; Sietsma, J. In-situ observation of strain partitioning and damage development in continuously cooled carbide-free bainitic steels using micro digital image correlation. Mater. Sci. Eng. A 2019, 757, 107–116. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Jackson, T.; Da Fonseca, J.Q. High-resolution digital image correlation study of the strain localization during loading of a shot-peened RR1000 nickel-based superalloy. Acta Mater. 2021, 220, 117306. [Google Scholar] [CrossRef]

- Uematsu, Y.; Kakiuchi, T.; Niimi, K.; Caiza, P.D.T. Local strain analysis under quasi-static tensile loading in Al/steel dissimilar friction stir weld by a digital image correlation method. Int. J. Adv. Manuf. Technol. 2022, 120, 349–360. [Google Scholar] [CrossRef]

| Strain Property | Test Method | Surimi Gel | |||

|---|---|---|---|---|---|

| AP | AP-EW | AP-WP | AP-PS | ||

| Textural properties | Penetration test (mm) | 7.12 ± 0.04 a* | 6.97 ± 0.16 ab | 6.86 ± 0.21 b | 6.94 ± 0.09 b |

| Failure ring tensile test | 0.53 ± 0.04 b | 0.41 ± 0.05 c | 0.35 ± 0.04 c | 0.66 ± 0.07 a | |

| Torsion test | 1.58 ± 0.06 a | 1.37 ± 0.09 bc | 1.35 ± 0.08 c | 1.49 ± 0.06 b | |

| Maximum local strain (%) | Penetration test | 95.3 ± 3.8 a | 94.2 ± 3.3 a | 95.4 ± 2.5 a | 94.5 ± 2.2 a |

| Failure ring tensile test | 132.9 ± 7.7 a | 130.0 ± 9.2 a | 127.4 ± 14.2 a | 139.6 ± 10.5 a | |

| Torsion test | 76.5 ± 5.8 a | 74.7 ± 11.8 a | 72.8 ± 11.6 a | 72.6 ± 5.4 a | |

| Local strain concentration (%) | Penetration test | 87.1 ± 0.5 a | 86.9 ± 0.8 a | 86.8 ± 1.0 a | 88.2 ± 1.0 a |

| Failure ring tensile test | 26.2 ± 5.0 bc | 35.1 ± 3.0 a | 36.5 ± 5.5 ab | 24.2 ± 3.2 c | |

| Torsion test | 31.3 ± 6.4 b | 51.2 ± 4.9 a | 49.8 ± 3.5 a | 32.2 ± 4.7 b | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, H.W.; Park, J.W.; Yoon, W.B. The Relationship between Penetration, Tension, and Torsion for the Fracture of Surimi Gels: Application of Digital Image Correlation (DIC). Processes 2023, 11, 265. https://doi.org/10.3390/pr11010265

Park HW, Park JW, Yoon WB. The Relationship between Penetration, Tension, and Torsion for the Fracture of Surimi Gels: Application of Digital Image Correlation (DIC). Processes. 2023; 11(1):265. https://doi.org/10.3390/pr11010265

Chicago/Turabian StylePark, Hyeon Woo, Jae W. Park, and Won Byong Yoon. 2023. "The Relationship between Penetration, Tension, and Torsion for the Fracture of Surimi Gels: Application of Digital Image Correlation (DIC)" Processes 11, no. 1: 265. https://doi.org/10.3390/pr11010265

APA StylePark, H. W., Park, J. W., & Yoon, W. B. (2023). The Relationship between Penetration, Tension, and Torsion for the Fracture of Surimi Gels: Application of Digital Image Correlation (DIC). Processes, 11(1), 265. https://doi.org/10.3390/pr11010265