Experimental Water Activity Suppression and Numerical Simulation of Shale Pore Blocking

Abstract

:1. Introduction

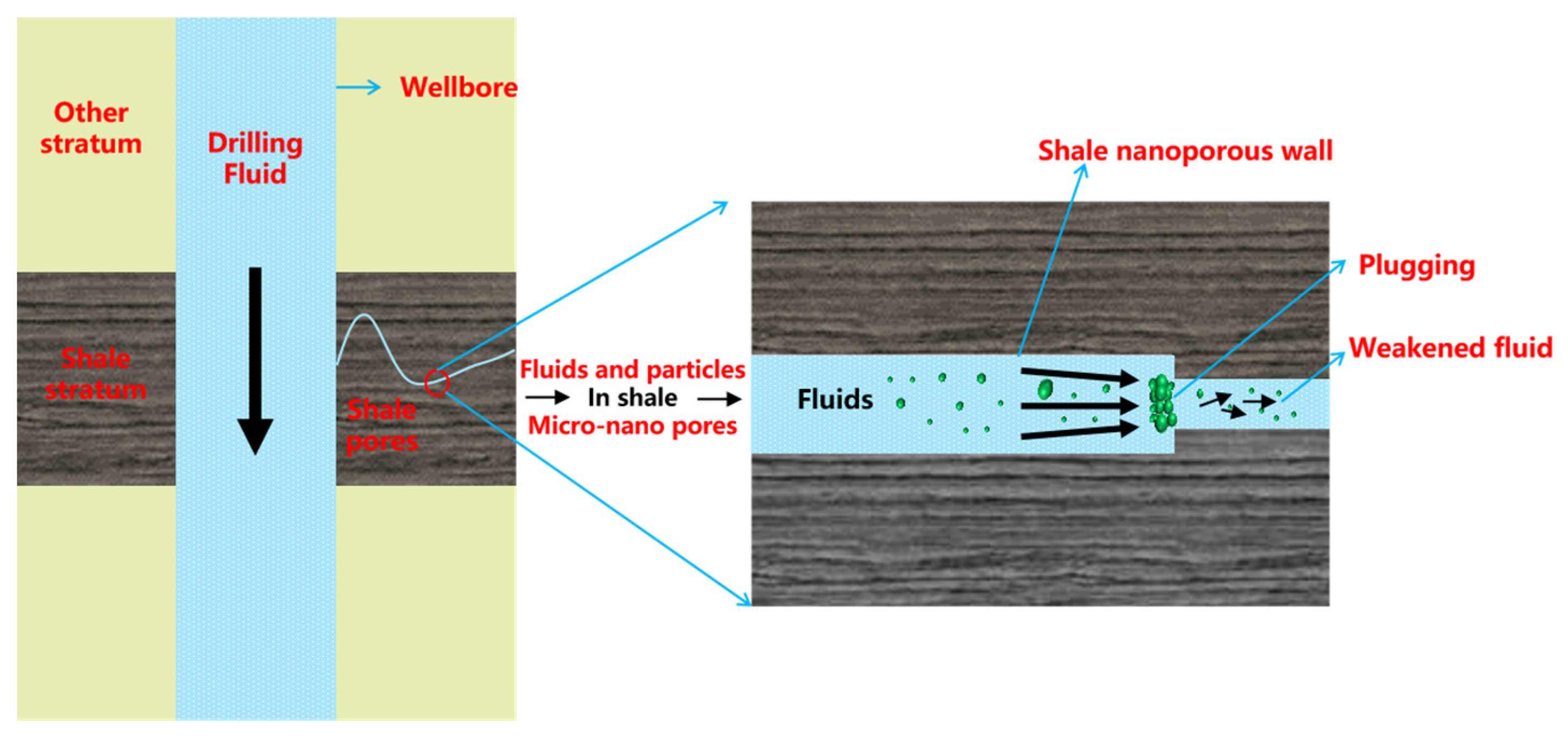

- In this paper, we study the effect of different parameters of nanoparticles on the physical plugging performance of shale pores through hydrodynamic simulation.

- The effects of salt solution on the chemical percolation performance of shale under the effects of differential pressure are studied using a shale pressure transmission experimental apparatus.

- The effects of fluid viscosity on the blocking of shale pores are investigated using numerical simulations.

- The research content can provide a basis for inhibiting shale hydration and maintaining the stability of shale gas horizontal wells.

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Experimental Instruments

2.3. Shale X-ray Diffraction and Microstructure Analysis

2.4. Numerical Simulation Method for Physical Containment

2.5. Experimental Methods of Chemical Inhibition

3. Results

3.1. Results of Chemical Inhibition Experiments

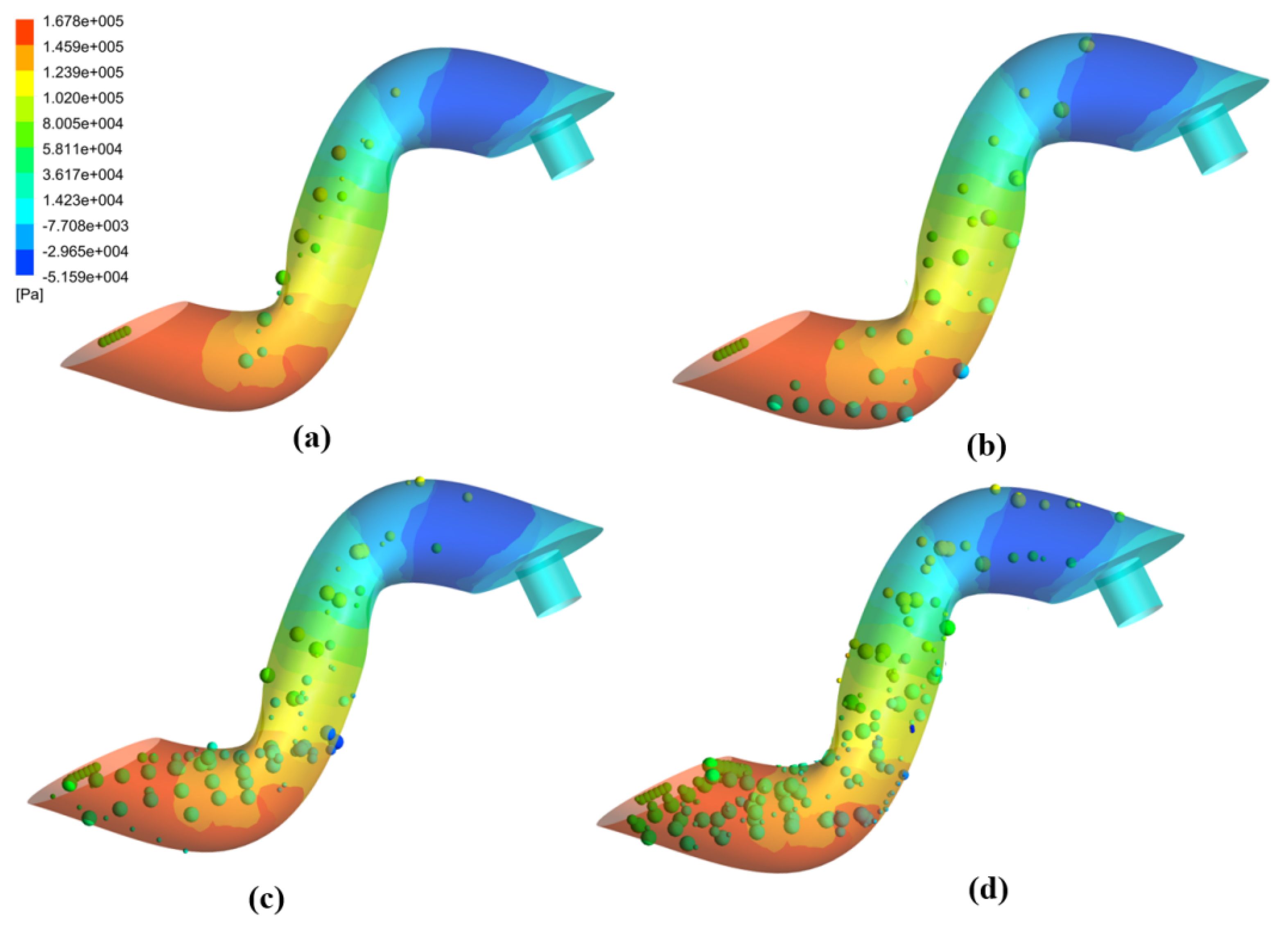

3.2. Numerical Simulation Results of Physical Blocking

4. Discussion

5. Conclusions

- The salt solution is most capable of blocking the pressure transfer in the shale pore space when the salt solution adopts a formate system with a water activity of 0.092. At this time, the drilling fluid does not easily penetrate into the shale pore space and is more capable of maintaining the shale wellbore stability.

- Nanoparticle concentration is the most critical factor affecting shale pore plugging efficiency for physical plugging numerical simulations. Particle size has a large effect on the blocking efficiency of shale pores, and a 30% increase in particle diameter increases the pore blocking efficiency by 13% when the maximum particle size is smaller than the pore outlet.

- Particle density has a small effect on the final sealing effect of pores. The pore sealing efficiency was only increased by 4%, and the particle density was increased by 60%.

- Fluid viscosity is significant for shale pore sealing. The sealing efficiency of the particles in the pore space is increased by approximately 16% when the fluid viscosity is increased to 5 mPa·s.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, S.; Tang, X.; Wang, J.; Zhang, B.; Sun, W.; Höök, M.J.R. Environmental Impacts from Conventional and Shale Gas and Oil Development in China Considering Regional Differences and Well Depth. Resour. Conserv. Recycl. 2021, 167, 105368. [Google Scholar] [CrossRef]

- Ghamartale, A.; Afzali, S.; Rezaei, N.; Zendehboudi, S. (Eds.) Chapter Three—Fundamentals of Chemical Inhibitors of Asphaltenes. In Asphaltene Deposition Control by Chemical Inhibitors; Gulf Professional Publishing: Houston, TX, USA, 2021; pp. 47–83. [Google Scholar]

- Khormali, A. Effect of Water Cut on the Performance of an Asphaltene Inhibitor Package: Experimental and Modeling Analysis. Pet. Sci. Technol. 2022, 40, 2890–2906. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; Dotsenko, N.; Kotenko, M. Influence of recipe factors on the structure and properties of non-autoclaved aerated concrete of increased strength. Appl. Sci. 2022, 12, 6984. [Google Scholar] [CrossRef]

- Li, H.; Yin, S.; Ding, W. Quantitative Characterization and Engineering Application of Pores and Fractures of Different Scales in Unconventional Reservoirs—Volume Ii. Front. Earth Sci. 2023, 11, 1133707. [Google Scholar] [CrossRef]

- Huang, X.; Wang, Y.; Long, Y.; Liu, J.; Zheng, H.; Nie, W.; Han, H.J.P. Experimental Research on Seepage Law and Migration Characteristics of Core-Shell Polymeric Nanoparticles Dispersion System in Porous Media. Polymers 2022, 14, 1803. [Google Scholar] [CrossRef] [PubMed]

- Medici, G.; West, L.J. Review of groundwater flow and contaminant transport modelling approaches for the Sherwood Sandstone aquifer, UK, insights from analogous successions worldwide. Q. J. Eng. Geol. Hydrogeol. 2022, 55, qjegh2021-176. [Google Scholar] [CrossRef]

- Fisher, Q.; Kaminskaite, I.; del Pino Sanchez, A. Shale barrier performance in petroleum systems: Implications for CO2 storage and nuclear waste disposal. Geoenergy 2023, qjegh2023-006. [Google Scholar] [CrossRef]

- Ruan, J.Y.; Lu, M.J.; Zhang, W.; Zhang, Y.X.; Zhou, Y.H.; Gong, J.; Wang, F.; Guan, Y.X. Optimization of the Plugging Agent Dosage for High Temperature Salt Profile Control in Heavy Oil Reservoirs. Fluid Dyn. Mater. Process. 2023, 19, 421–436. [Google Scholar] [CrossRef]

- Zhang, C.; Lv, K.H.; Gong, J.Q.; Wang, Z.; Huang, X.B.; Sun, J.S.; Yao, X.Y.; Liu, K.C.; Rong, K.S.; Li, M. Synthesis of a Hydrophobic Quaternary Ammonium Salt as a Shale Inhibitor for Water-Based Drilling Fluids and Determination of the Inhibition Mechanism. J. Mol. Liq. 2022, 362, 119474. [Google Scholar] [CrossRef]

- Fu, L.P.; Liao, K.L.; Ge, J.J.; He, Y.F.; Huang, W.Q.; Du, E.D. Preparation and Inhibition Mechanism of Bis-Quaternary Ammonium Salt as Shale Inhibitor Used in Shale Hydrocarbon Production. J. Mol. Liq. 2020, 309, 113244. [Google Scholar] [CrossRef]

- Lago, F.R.; Gonçalves, J.P.; Dweck, J.; da Cunha, A.L.C. Evaluation of Influence of Salt in the Cement Hydration to Oil Wells. Mater. Res. Ibero-Am. J. Mater. 2017, 20, 743–747. [Google Scholar] [CrossRef]

- Wei, J.; Cheng, Y.F.; Yan, C.L. Two-Dimensional Pore Pressure Distribution Model to Evaluate Effects of Shale Semipermeable Membrane Characteristics. J. Energy Resour. Technol. Trans. ASME 2020, 142, 012902. [Google Scholar] [CrossRef]

- Abdullah, A.H.; Ridha, S.; Mohshim, D.F.; Yusuf, M.; Kamyab, H.; Krishna, S.; Maoinser, M.A. A Comprehensive Review of Nanoparticles: Effect on Water-Based Drilling Fluids and Wellbore Stability. Chemosphere 2022, 308, 136274. [Google Scholar] [CrossRef] [PubMed]

- Sensoy, T.; Chenevert, M.E.; Sharma, M.M. Minimizing Water Invasion in Shales Using Nanoparticles: Minimizing Water Invasion in Shales Using Nanoparticles. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar]

- Taraghikhah, S.; Mohammadi, M.K.; Nowtaraki, K.T. Multifunctional Nanoadditive in Water Based Drilling Fluid for Improving Shale Stability. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 6–9 December 2015. [Google Scholar]

- Yang, X.Y.; Cai, J.H.; Jiang, G.S.; Xie, J.Y.; Shi, Y.P.; Chen, S.Y.; Yue, Y.; Yu, L.; He, Y.C.; Xie, K.Z. Nanoparticle Plugging Prediction of Shale Pores: A Numerical and Experimental Study. Energy 2020, 208, 118337. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, F. Mathematical Modeling and Numerical Simulation of Water-Rock Interaction in Shale under Fracturing-Fluid Flowback Conditions. Water Resour. Res. 2021, 57, e2020WR029537. [Google Scholar] [CrossRef]

- Wang, Y.P.; Liu, X.J.; Liang, L.X.; Xiong, J. Experimental Study on the Damage of Organic-Rich Shale During Water-Shale Interaction. J. Nat. Gas Sci. Eng. 2020, 74, 103103. [Google Scholar] [CrossRef]

- Wang, H.; Liu, W. Research on Numerical Simulation Method of Salt Dissolution and Recrystallization of Inter-Salt Shale Oil Reservoir. J. Pet. Sci. Eng. 2022, 213, 110464. [Google Scholar] [CrossRef]

- Yang, X.Y.; Cai, J.H.; Jiang, G.S.; Chen, S.Y.; Yue, Y.; Shi, Y.P.; Wei, Z.H. A Method of Determining Osmotic Pressure for Low-Clay Shale with Different Salt Ions Considering Effect of Dynamic Permeability on Flow. Eng. Geol. 2021, 295, 106434. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Xiao, C. Molecular Dynamics Simulation of Clay Hydration Inhibition of Deep Shale. Processes 2021, 9, 1069. [Google Scholar] [CrossRef]

- Dong, L.; Han, C.; Santosh, M.; Qiu, Y.; Liu, G.; Ma, J.; He, H.; Hu, C.J.G. Factors Influencing the Pore Structure and Gas-Bearing Characteristics of Shales: Insights from the Longmaxi Formation, Southern Sichuan Basin and Northern Yunnan-Guizhou Depression, China. Geofluids 2022, 2022, 1692516. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Lin, C.Y.; Yan, W.C.; Liu, Q.; Zhao, P.Q.; Ren, L.H. Pore-Scale Simulations of Electrical and Elastic Properties of Shale Samples Based on Multicomponent and Multiscale Digital Rocks. Mar. Pet. Geol. 2020, 117, 104369. [Google Scholar] [CrossRef]

- Li, D.Q.; Wang, X.G.; Wang, R.L.; Han, Z.X.; Chen, Y.; Xie, G. Investigation of Poly (Mm-Em-Bm) as Nanosealing Materials in Oil-Based Drilling Fluids: Synthesis and Evaluation. ACS Omega 2023, 8, 9291–9297. [Google Scholar] [CrossRef] [PubMed]

- Hong, L.; Qing, W.; Kun, Z.; Hui, Z.Q.; Tao, S.; Chuang, Z.; Bin, Z.L.; Chen, H.; Ping, F.F.; Yuan, W.H.; et al. The Invasion Law of Drilling Fluid Along Bedding Fractures of Shale. Front. Earth Sci. 2023, 11, 1112441. [Google Scholar]

- Yang, X.; Zhou, W.N.; Liu, X.L.; Yan, Y.Y. A Multiscale Approach for Simulation of Shale Gas Transport in Organic Nanopores. Energy 2020, 210, 118547. [Google Scholar] [CrossRef]

- Froute, L.; Wang, Y.H.; McKinzie, J.; Aryana, S.A.; Kovscek, A.R. Transport Simulations on Scanning Transmission Electron Microscope Images of Nanoporous Shale. Energies 2020, 13, 6665. [Google Scholar] [CrossRef]

- Xie, X.Y.; Bauer, A.; Stenebraten, J.F.; Bakheim, S.; Lavrov, A.; Fjaer, E.; Kristiansen, T.G. Can Heating Induce Borehole Closure? Rock Mech. Rock Eng. 2020, 53, 5715–5744. [Google Scholar] [CrossRef]

- Kumar, S.; Acharya, S.; Beuerman, R.; Palkama, A. Numerical Solution of Ocular Fluid Dynamics in a Rabbit Eye: Parametric Effects. Ann. Biomed. Eng. 2006, 34, 530–544. [Google Scholar] [CrossRef]

- Gao, Y.; Wu, K.L.; Chen, Z.X.; Zhou, T.; Li, J.; Feng, D.; Gao, Y.L.; Tian, W.B. Effect of Wetting Hysteresis on Fluid Flow in Shale Oil Reservoirs. Energy Fuels 2021, 35, 12075–12082. [Google Scholar] [CrossRef]

- Huang, H.F.; Li, Z.; Luo, J.H.; Chang, Z.C. On the Stability of Carbon Shale Slope under Rainfall Infiltration. Fluid Dyn. Mater. Process. 2021, 17, 1165–1178. [Google Scholar] [CrossRef]

- Roshan, H.; Sari, M.; Arandiyan, H.; Hu, Y.B.; Mostaghimi, P.; Sarmadivaleh, M.; Masoumi, H.; Veveakis, M.; Iglauer, S.; Regenauer-Lieb, K. Total Porosity of Tight Rocks: A Welcome to the Heat Transfer Technique. Energy Fuels 2016, 30, 10072–10079. [Google Scholar] [CrossRef]

- Yang, X.; Feng, C. Effects of Zrc Coating on Mechanical Properties of Pip-C/Sic Composites. J. Alloys Compd. 2015, 632, 263–268. [Google Scholar] [CrossRef]

- Wu, P.C.; Zhong, C.X.; Li, Z.T.; Zhang, Z.; Wang, Z.Y.; Huang, W.A. Oil-Based Drilling Fluid Plugging Method for Strengthening Wellbore Stability of Shale Gas. Geofluids 2021, 2021, 6674574. [Google Scholar] [CrossRef]

- Yariv, S.; Cross, H. Formation of Aqueous Solutions and Suspensions of Hydrophobic Colloids. In Geochemistry of Colloid Systems: For Earth Scientists; Springer: Berlin/Heidelberg, Germany, 1979; pp. 157–206. [Google Scholar] [CrossRef]

- Sedano, L.F.; Blazquez, S.; Noya, E.G.; Vega, C.; Troncoso, J. Maximum in Density of Electrolyte Solutions: Learning About Ion–Water Interactions and Testing the Madrid-2019 Force Field. J. Chem. Phys. 2022, 156, 154502. [Google Scholar] [CrossRef] [PubMed]

- Pan, Q.; Zhao, P.; Gao, L.; Liu, H.; Hu, H.; Dong, L.J.M. In-Depth Study on the Effects of Impurity Ions in Saline Wastewater Electrolysis. Molecules 2023, 28, 4576. [Google Scholar] [CrossRef]

- Sibille, L.; Marot, D.; Poullain, P.; Lominé, F. Phenomenological Interpretation of Internal Erosion in Granular Soils from a Discrete Fluid-Solid Numerical Model. In Scour and Erosion: Proceedings of the 8th International Conference on Scour and Erosion Oxford, UK, 12–15 September 2016; Harris, J., Whitehouse, R., Moxon, S., Eds.; Taylor Francis Group: London, UK, 2016. [Google Scholar]

- Ren, B.; Xu, B.; Li, C. Unified Particle System for Multiple-Fluid Flow and Porous Material. ACM Trans. Graph. 2021, 40, 1–14. [Google Scholar] [CrossRef]

- Mašek, J.; Eliáš, J. Coupling of Mechanics and Transport in Discrete Meso-Level Model: Model Verification. In Proceedings of the 16th International Conference on Computational Plasticity (COMPLAS 2021), Barcelona, Spain, 7–10 September 2022. [Google Scholar]

- Ai, X.; Chen, M.J.E. Wellbore Stabilization Technology of “Fluid-Solid-Chemical Coupling” in Continental Shale Oil—A Case Study of Shale Oil in Block Gl. Energies 2022, 15, 6962. [Google Scholar] [CrossRef]

| Component | Proportions (wt%) |

|---|---|

| Quartz | 58 |

| Chlorite | 6 |

| Plagioclase | 1 |

| Potassium feldspar | 3 |

| Calcite | 10 |

| Dolomite | 2 |

| Hematite | 1 |

| Illite | 19 |

| Parameters | Numerical Value |

|---|---|

| Pore length, μm | 20 |

| Pore bending, ° | 50 |

| Pore outlet diameter, μm | 2 |

| Particle release area, μm2 | 2 |

| Types of particles of different sizes | 15 |

| Average particle diameter, nm | 300 |

| Compute pattern | Pressure, transient |

| Particle track mode | Nonstationary tracking |

| Discrete phase reflection coefficient | 0.5 |

| Spring cushioning parameters | 1000 |

| Wall surface of grain | Reflection pattern |

| Physical Property | Parameters |

|---|---|

| Fluid properties | Deionized water |

| Fluid density, kg/m3 | 1000 |

| Fluid viscosity, mPa·s | 1, 3, 5 |

| Temperature, K | 298 |

| Granulation (sugar, chemical product) | Silicon dioxide (SiO2) |

| Particle density, g/cm3 | 2.2 |

| Diffusion coefficient | 4 |

| Particle size distribution | Rosin–Rammler |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, Y.; Zhao, H.; Liu, W.; Li, J.; Chi, H.; Xue, Z.; Zhang, Y.; Meng, X. Experimental Water Activity Suppression and Numerical Simulation of Shale Pore Blocking. Processes 2023, 11, 3366. https://doi.org/10.3390/pr11123366

Shan Y, Zhao H, Liu W, Li J, Chi H, Xue Z, Zhang Y, Meng X. Experimental Water Activity Suppression and Numerical Simulation of Shale Pore Blocking. Processes. 2023; 11(12):3366. https://doi.org/10.3390/pr11123366

Chicago/Turabian StyleShan, Yansheng, Hongbo Zhao, Weibin Liu, Juan Li, Huanpeng Chi, Zongan Xue, Yunxiao Zhang, and Xianglong Meng. 2023. "Experimental Water Activity Suppression and Numerical Simulation of Shale Pore Blocking" Processes 11, no. 12: 3366. https://doi.org/10.3390/pr11123366