Vehicle Routing Problem Model with Practicality

Abstract

:1. Introduction

- (1)

- The deadline for vehicles is considered;

- (2)

- Continuous-time unit is applied for reality;

- (3)

- The different fuel reduction rates of the leading and following vehicles are employed;

- (4)

- The constraints to avoid traffic congestion are employed;

- (5)

- A new greedy heuristic model is designed for more practical use with less computation time;

- (6)

- The platooning among heterogeneous vehicles, where the dispatching and routing are centrally controlled, is considered.

2. Literature Review on Vehicle Platooning

2.1. Subsection Vehicle Routing Problem for Platooning (VRPP)

2.2. VRPP and VRP Variants

3. Model

3.1. Problem Description

- The schedule of each vehicle, including the earliest time of departure from the origin and the latest time of arrival at the final destination, is known and deterministic;

- Each vehicle can wait at any node for the vehicle platooning if his/her time schedule is not violated;

- The time distance for each link is constant; i.e., congestion due to the climate or accidents is not considered;

- The fuel consumption of each vehicle is directly proportional to the time distance;

- The fuel reduction rate is defined as the percentage of fuel reduction due to the platooning and is only applied for the following vehicles, i.e., the fuel reduction rate is set as 0 for the lead vehicle;

- The fuel reduction rate resulting from platooning is constant for all the vehicles and links;

- The vehicles are identical;

- There is no time schedule violation.

3.2. Mathematical Model

| Notation | |

| number of nodes | |

| number of vehicles | |

| total fuel consumption of the initial solution | |

| total fuel consumption of the final solution | |

| total number of vehicles | |

| total number of vehicles that are platooned with any other vehicles | |

| total number of vehicles that changed their route for a detour | |

| total number of arcs platooned by vehicles | |

| total number of arcs used by vehicles | |

| Constants | |

| origin node for the vehicle k, | |

| destination node for the vehicle k, | |

| earliest departure time from for vehicle k | |

| latest arrival time at for vehicle k | |

| unit fuel cost per unit time distance | |

| following vehicle’s fuel reduction rate, resulting from vehicle platooning | |

| leading vehicle’s fuel reduction rate | |

| slack time of vehicles | |

| big number | |

| Decision variables | |

| , 1; otherwise, 0 | |

| , 1; otherwise 0 | |

| arrival time at node j from node i of vehicle k when . | |

| total number of vehicles that achieve reduced fuel consumption by platooning on arc , i.e., total number of following vehicles in platooning groups on arc | |

| Variables for heuristics | |

| set of routes, i.e., arcs (i,j), for vehicle k | |

| earliest possible departure time from origin of arc (i,j) for vehicle k | |

| latest possible departure time from origin of arc (i,j) for vehicle k | |

| actual departure time from origin of arc (i,j) for vehicle k | |

| is applied | |

| random number generated from the uniform distribution U(0,1) | |

4. Proposed Heuristic for Optimizing VRPP

4.1. Platooning Algorithm 1

| Algorithm1: Platooning |

| 1: |

| 2: while do |

| 3: randomly select k in ; |

| 4: ; |

| 5: while is not updated do |

| 6: randomly select arc (i,j) in ; |

| 7: ; |

| 8: set is subset of of which route has arc (i,j); |

| 9: while do |

| 10: randomly select l in ; |

| 11: ; |

| 12: if , then |

| 13: generate random number u; |

| 14: if u < 0.5 then |

| 15: ; |

| 16: update departure times at nodes from node i to destination of the vehicle k according to ; |

| 17: else |

| 18: ; |

| 19: change departure times at nodes from node i to destination of the vehicle l according to ; |

| 20: end if |

| 21: update based on changed VTS; |

| 22: else if then |

| 23: ; |

| 24: change departure times at nodes from node i to destination of the vehicle k based on ; |

| 25: update based on changed VTS; |

| 26: else if then |

| 27: ; |

| 28: change departure times at nodes from node i to destination of the vehicle l based on ; |

| 29: update based on changed VTS; |

| 30: end if |

| 31: end while |

| 32: end while |

| 33: end while |

4.2. Platooning Algorithm 2

| Algorithm2: Platooning |

| 1: |

| 2: while do |

| 3: |

| 4: randomly select vehicle k in ; |

| 5: ; |

| 6: while is not updated do |

| 7: randomly select arc (i,j) in ; |

| 8: ; |

| 9: for vehicle k; |

| 10: while do |

| 11: ; |

| 12: }; |

| 13: ); |

| 14: ; |

| 15: do Platooning Algorithm 1 (lines 5–32) for vehicle k; |

| 16: if then |

| 17: go to out; |

| 18: else |

| 19: ; |

| 20: end if |

| 21: end while |

| 22: end while |

| 23: out: |

| 24: end while |

| SimulationProcedure |

| Step1: Let ; = 0 |

Step2: Initialization

|

Step3: Vehicle platooning with the same route

|

Step4: Vehicle platooning with detour routes

|

| Step5: + 1 |

| Step6: If the best solution is updated at Step 3 or 4, let = 0. |

| Step7: If = 10,000, terminate the simulation procedure. Otherwise, go to Step 3. |

5. Experiments and Results

5.1. Settings

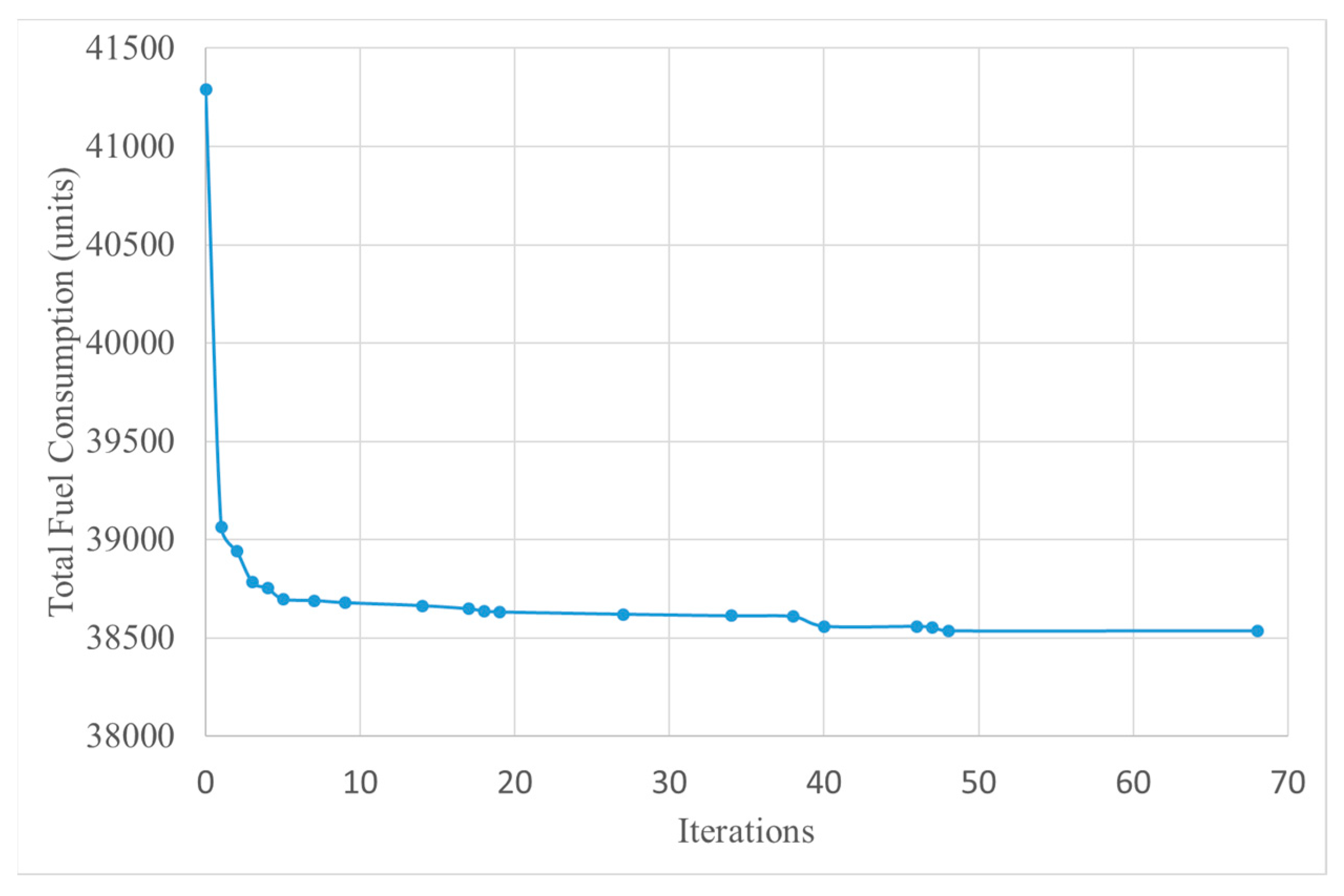

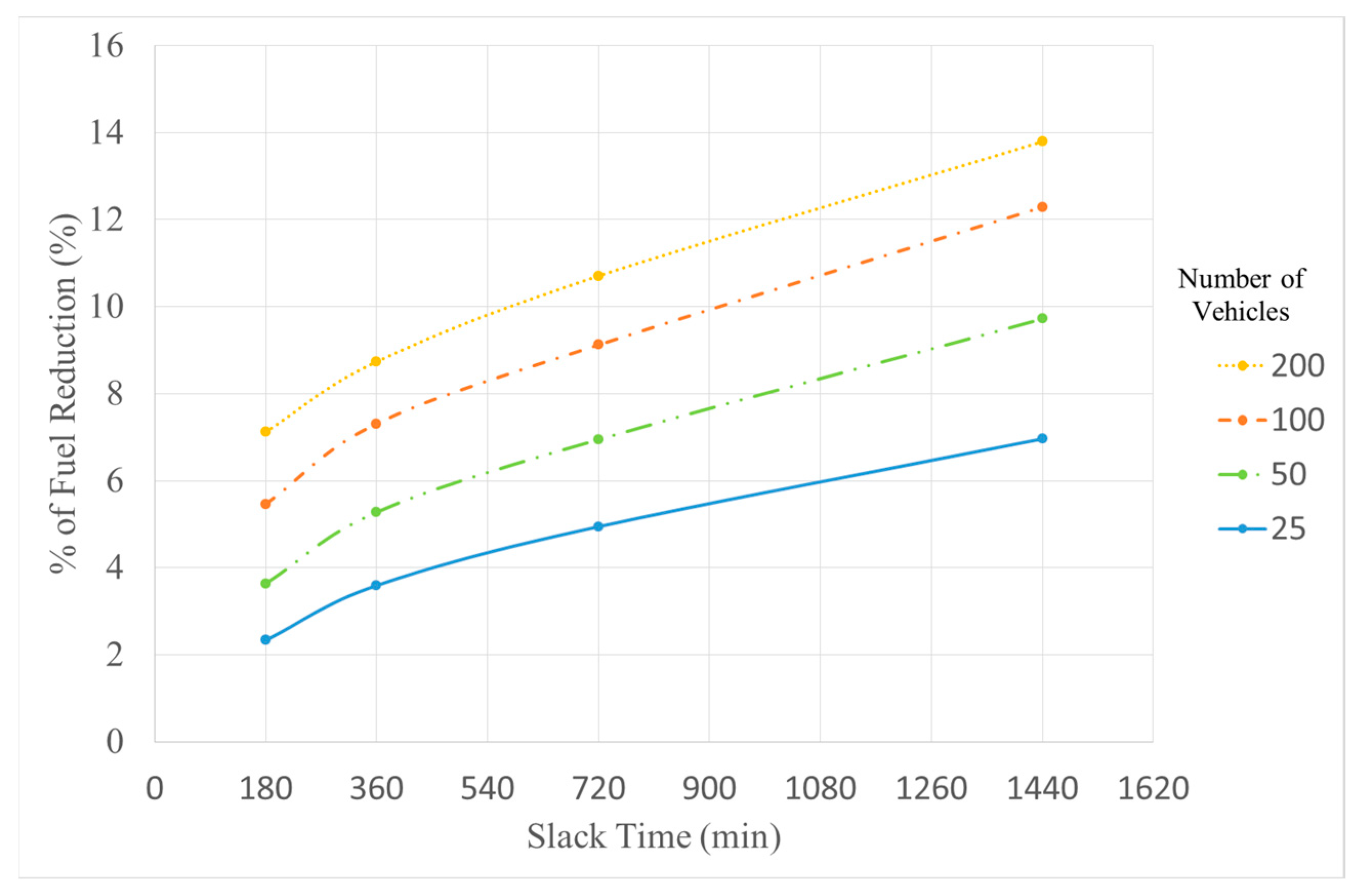

5.2. Results and Analyses

6. Conclusions and Future Research

- (1)

- The optimality gap by our model, the ratio of the difference between the heuristic solution and optimal solution to the optimal solution, is, on average, 3.4%. The model by Larson et al. obtained the 1% optimality gap in small problems within 60–100 s;

- (2)

- As the fuel reduction rate increased, a larger proportion of vehicles were platooned via alternative routes. As the fuel reduction rate increased, the percentage of vehicles detoured for platooning increased from 2.31% to 9.66%. The percentage of platooned arcs increased by approximately 4%;

- (3)

- As the number of vehicles and slack time increased, the proportion of platooned vehicles increased. The percentage of fuel reduction increased more than 15% when there were 200 vehicles, and the slack time was 1440 min, compared with the case of 25 vehicles and a slack time of 180 min;

- (4)

- Increasing the number of platooned vehicles saved space on the road;

- (5)

- In the future study, a more in-depth analysis of the relationship between the structure of nodes and arcs and the detouring tendency of platooned vehicles is planned.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Node | 1 | 2 | 3 | 4 | 5 |

| 1 | 5 | 100 | |||

| 2 | 5 | 5 | 50 | ||

| 3 | 5 | 100 | |||

| 4 | 50 | 50 | |||

| 5 | 100 | 100 | 50 |

| Vehicle | Origin | Destination | Deadline |

|---|---|---|---|

| 1 | 3 | 1 | 177.2948 |

| 2 | 5 | 3 | 19.54208 |

| 3 | 1 | 2 | 4.058831 |

| 4 | 4 | 5 | 29.75503 |

| 5 | 4 | 2 | 8.943096 |

| Vehicle | Initial Solution | Final Solution |

|---|---|---|

| 1 | 3→1 | 3→1 |

| 2 | 5→3 | 5→4→2→3 |

| 3 | 1→2 | 1→2 |

| 4 | 4→5 | 4→5 |

| 5 | 4→2 | 4→2 |

| Total cost | 215 | 205 |

Appendix B

| Country | Min. Iteration | Avg. Iteration | Max. Iteration | Standard Deviation of Iteration |

|---|---|---|---|---|

| Germany | 20 | 37.006 | 131 | 17.470 |

| Japan | 20 | 31.069 | 110 | 13.617 |

| Korea | 20 | 33.131 | 155 | 15.079 |

| Country | Avg. Initial Solution | Std. Initial Solution | Avg. Final Solution | Std. Final Solution |

|---|---|---|---|---|

| Germany | 18,632.9 | 135,22.29 | 16,978.99 | 12,034.14 |

| Japan | 26,699.2 | 19,327.19 | 23,752.9 | 17,021.86 |

| Korea | 17,260.75 | 12,384.05 | 15,525.39 | 10,829.63 |

References

- Scania Group. Platooning—Automated Driving. Available online: https://www.scania.com/group/en/platooning-automated-driving-for-fuel-savings/ (accessed on 2 January 2021).

- Tech-F.A.Q. Vehicle Platooning. Available online: http://www.tech-faq.com/vehicle-platooning.html (accessed on 2 January 2021).

- Larsson, E.; Sennton, G.; Larson, J. The vehicle platooning problem: Computational complexity and heuristics. Transp. Res. C 2015, 60, 258–277. [Google Scholar] [CrossRef] [Green Version]

- Nourmohammadzadeh, A.; Hartmann, S. The fuel-efficient platooning of heavy duty vehicles by mathematical programming and genetic algorithm. Lect. Notes Comput. Sci. 2016, 10071, 46–57. [Google Scholar] [CrossRef]

- Larson, J.; Munson, T.; Sokolov, V. Coordinated platoon routing in a metropolitan network. In Proceedings of the Seventh SIAM Workshop on Combinatorial Scientific Computing, Albuquerque, NM, USA, 10–12 October 2016; pp. 73–82. [Google Scholar] [CrossRef] [Green Version]

- Zhao, L.; Sun, J. Simulation framework for vehicle platooning and car-following behaviors under connected-vehicle environment. Procedia Soc. Behav. Sci. 2013, 96, 914–924. [Google Scholar] [CrossRef] [Green Version]

- Segata, M.; Dressler, F.; Lo Cigno, R.; Gerla, M. A simulation tool for automated platooning in mixed highway scenarios. In Proceedings of the 18th Annual International Conference on Mobile Computing and Networking; ACM Press: New York, NY, USA, 2012; Volume 16, p. 389. [Google Scholar] [CrossRef] [Green Version]

- Nasri, M.I.; Bektaş, T.; Laporte, G. Route and speed optimization for autonomous trucks. Comput. Oper. Res. 2018, 100, 89–101. [Google Scholar] [CrossRef] [Green Version]

- Dukkanci, O.; Kara, B.Y.; Bektaş, T. The green location-routing problem. Comput. Oper. Res. 2019, 105, 187–202. [Google Scholar] [CrossRef]

- Demir, E.; Bektaş, T.; Laporte, G. An adaptive large neighborhood search heuristic for the pollution-routing problem. Eur. J. Oper. Res. 2012, 223, 346–359. [Google Scholar] [CrossRef]

- Kramer, R.; Maculan, N.; Subramanian, A.; Vidal, T. A speed and departure time optimization algorithm for the pollution-routing problem. Eur. J. Oper. Res. 2015, 247, 782–787. [Google Scholar] [CrossRef] [Green Version]

- Bhoopalam, A.K.; Agatz, N.; Zuidwijk, R. Planning of truck platoons: A literature review and directions for future research. Transport. Res. Part B Methodolog. 2018, 107, 212–228. [Google Scholar] [CrossRef] [Green Version]

- Larson, J.; Kammer, C.; Liang, K.Y.; Johansson, K.H. Coordinated route optimization for heavy duty vehicle platoons. In Proceedings of the 16th International IEEE Conference on Intelligent Transportation Systems (ITSC 2013), The Hague, The Netherlands, 6–9 October 2013; pp. 1196–1202. [Google Scholar]

- Sokolov, V.; Larson, J.; Munson, T.; Auld, J.; Karbowski, D. Platoon formation maximization through centralized routing and departure time coordination. arXiv 2017, arXiv:1701.01391. [Google Scholar] [CrossRef]

- Nourmohammadzadeh, A.; Hartmann, S. Fuel-efficient truck platooning by a novel meta-heuristic inspired from ant colony optimization. Soft Comput. 2019, 23, 1439–1452. [Google Scholar] [CrossRef]

- Larson, J.; Liang, K.-Y.; Johansson, K.H. A distributed framework for coordinated heavy-duty vehicle platooning. IEEE Trans. Intell. Transport. Syst. 2015, 16, 419–429. [Google Scholar] [CrossRef]

- Luo, F.; Larson, J.; Munson, T. Coordinated platooning with multiple speeds. Transp. Res. Part C Emerg. Technol. 2018, 90, 213–225. [Google Scholar] [CrossRef]

- Laporte, G. Fifty years of vehicle routing. Transp. Sci. 2009, 43, 408–416. [Google Scholar] [CrossRef] [Green Version]

- Leung, S.C.; Zhang, Z.; Zhang, D.; Hua, X.; Lim, M.K. A meta-heuristic algorithm for heterogeneous fleet vehicle routing problems with two-dimensional loading constraints. Eur. J. Oper. Res. 2013, 225, 199–210. [Google Scholar] [CrossRef]

- Bräysy, O.; Gendreau, M. Vehicle routing problem with time windows, Part II: Metaheuristics. Transp. Sci. 2005, 39, 119–139. [Google Scholar] [CrossRef]

- Gendreau, M.; Tarantilis, C.D. Solving Large-Scale Vehicle Routing Problems with Time Windows: The State-of-the-Art; Cirrelt: Montreal, QC, Canada, 2010. [Google Scholar]

- Tasan, A.S.; Gen, M. A genetic algorithm based approach to vehicle routing problem with simultaneous pick-up and deliveries. Comput. Ind. Eng. 2012, 62, 755–761. [Google Scholar] [CrossRef]

- Pradenas, L.; Oportus, B.; Parada, V. Mitigation of greenhouse gas emissions in vehicle routing problems with backhauling. Expert Syst. Appl. 2013, 40, 2985–2991. [Google Scholar] [CrossRef]

- Brar, G.S.; Saini, G. Milk run logistics: Literature Review and directions. In Proceedings of the World Congress on Engineering, London, UK, 6–8 July 2011; Volume 1, pp. 797–801. [Google Scholar]

- Montoya-Torres, J.R.; Franco, J.L.; Isaza, S.N.; Jiménez, H.F.; Herazo-Padilla, N. A literature review on the vehicle routing problem with multiple depots. Comput. Ind. Eng. 2015, 79, 115–129. [Google Scholar] [CrossRef]

- Campbell, A.M.; Wilson, J.H. Forty years of periodic vehicle routing. Networks 2014, 63, 2–15. [Google Scholar] [CrossRef]

- Gulczynski, D.; Golden, B.; Wasil, E. The period vehicle routing problem: New heuristics and real-world variants. Transp. Res. E Logist. Transp. Rev. 2011, 47, 648–668. [Google Scholar] [CrossRef]

- Karimi-Mamaghan, M.; Mohammadi, M.; Pasdeloup, B.; Meyer, P. Learning to select operators in meta-heuristics: An integration of Q-learning into the iterated greedy algorithm for the permutation flowshop scheduling problem. Eur. J. Oper. Res. 2023, 304, 1296–1330. [Google Scholar] [CrossRef]

- Wang, M.; Jiang, H.; Li, Y.; Wu, S.; Xia, L. Location determination of hierarchical service facilities using a multi-layered greedy heuristic approach. Eng. Optim. 2022, 1–15. [Google Scholar] [CrossRef]

- Lu, F.; Feng, W.; Gao, M.; Bi, H.; Wang, S. The fourth-party logistics routing problem using ant colony system-improved grey wolf optimization. J. Adv. Transp. 2020, 2020, 8831746. [Google Scholar] [CrossRef]

- Lu, F.; Bi, H.; Huang, M.; Duan, S. Simulated annealing genetic algorithm based schedule risk management of IT outsourcing project. Math. Probl. Eng. 2017, 2017, 6916575. [Google Scholar] [CrossRef] [Green Version]

- Wen, H.; Wang, S.X.; Lu, F.Q.; Feng, M.; Wang, L.Z.; Xiong, J.K.; Si, M.C. Colony search optimization algorithm using global optimization. J. Supercomput. 2022, 78, 6567–6611. [Google Scholar] [CrossRef]

- Dijkstra, E.W. A Note on Two Problems in Connexion with Graphs. Numer. Math. 1959, 1, 269–271. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://worldpopulationreview.com/countries/cities/germany (accessed on 2 January 2023).

- Available online: https://worldpopulationreview.com/countries/cities/japan (accessed on 2 January 2023).

- Available online: https://worldpopulationreview.com/countries/cities/south-korea (accessed on 2 January 2023).

- Available online: https://www.google.com/maps (accessed on 2 January 2023).

- Available online: https://map.naver.com/ (accessed on 2 January 2023).

| Objective | Constraints | Decisions | Dynamics | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | F | D | T | S | D | L | PC | R | S | SC | SS | RT | O |

| [3] | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | |||||||

| [13] | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | |||||

| [14] | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | |||||

| [5] | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ||||||

| [4] | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | |||||||

| [15] | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ||||||

| This study | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ∨ | ||||||

| VRPTW | VRPP | |

|---|---|---|

| Dependency of vehicles | Independent | Dependent |

| Heterogeneity of vehicles | N/A | Yes |

| Equal speed constraint | No | Yes |

| Type of problem | NP hard | NP hard |

| Number of departures/destinations | Single (or same) | Multiple (or different) |

| Tradeoff between time reduction and detouring | No | Yes |

| Problem | Type of Depots | Vehicles | Customers | Reference | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Set | Capacity | Vehicle Time Window | Same Schedule on the Link | Service | Vehicle Visit | Service Time Window | ||||

| VRP | CVRP | Not required | once | Laporte [18] | ||||||

| HFVRP | Not required | once | Leung et al. [19] | |||||||

| VRPTW | Not required | once | Bräysy and Gendreau [20]; Gendreau and Tarantilis [21] | |||||||

| VRPPD | Not required | once | Tasan and Gen [22] | |||||||

| VRPB | Not required | once | Pradenas et al. [23]; Brar and Saini [24] | |||||||

| MDVRP | Not required | once | Montoya-Torres et al. [25] | |||||||

| PVRP | Not required | multiple | Campbell and Wilson [26]; Gulczynski et al. [27] | |||||||

| VRPP | Required for each group | - | - | - | This article | |||||

| Parameter | Value |

|---|---|

| Fuel reduction rate (η) | 0.05; 0.1; 0.15; 0.2; 0.25; 0.3 |

| Number of vehicles ) | 25; 50; 100; 200 |

| Slack time (τ) | 3 × 60; 6 × 60; 12 × 60; 24 × 60 (min) |

| # of Nodes (Arcs) | # of Vehicles | Model | Problem | Total CPU Time (s) | Error | ||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |||||

| 5 (12 arcs) | 5 | G | 205 | 80.5 | 200.5 | 250 | 250 | 0.031 | 0.029 |

| O | 205 | 80.5 | 184 | 250 | 238.5 | 16.786 | |||

| 10 | G | 385.5 | 334 | 539 | 533.5 | 467 | 0.031 | 0.056 | |

| O | 355.5 | 332.5 | 502.5 | 519 | 429 | 1382.155 | |||

| 15 | G | 729 | 774 | 917 | 744.5 | 548 | 0.094 | ||

| O | (>12 h) | ||||||||

| 10 (24 arcs) | 5 | G | 397 | 172.5 | 295 | 178 | 282 | 0.068 | 0.017 |

| O | 385 | 172.5 | 295 | 175 | 275 | 270.676 | |||

| 10 | G | 588.5 | 594 | 588.5 | 677 | 465 | 0.078 | 0.091 | |

| O | 520.5 | 521 | 573.5 | 612 | 444 | 24481.321 | |||

| 15 | G | 768.5 | 881 | 776 | 758 | 882.5 | 0.125 | ||

| O | (>12 h) | ||||||||

| 14 (57 arcs) (Republic of Korea) | 5 | G | 879.2 | 855 | 966.7 | 744 | 1040 | 0.038 | 0.011 |

| O | 859.1 | 855 | 940.9 | 744 | 1038.8 | 4842.662 | |||

| 10 | G | 1810.2 | 1615.7 | 1377.4 | 1576.7 | 2054.5 | 0.188 | ||

| O | (>12 h) | ||||||||

| 15 | G | 2874.5 | 2997.6 | 3160.8 | 2915.3 | 2607.8 | 0.7160044 | ||

| O | (>12 h) | ||||||||

| 21 (92 arcs) (Germany) | 5 | G | 675.5 | 1030 | 760.3 | 1145 | 1004 | 0.236 | 0.001 |

| O | 675.5 | 1030 | 760.3 | 1140 | 1004 | 20729.978 | |||

| 10 | G | 1920.9 | 2143.2 | 1599 | 1981.7 | 2279 | 0.562 | ||

| O | (>12 h) | ||||||||

| 15 | G | 2313.3 | 2689.1 | 3105.4 | 2561.6 | 2413.5 | 1.401 | ||

| O | (>12 h) | ||||||||

| Country | % of Fuel Reduction | % of Platooned Vehicles | % of Route-Changed Vehicles | % of Platooned Arcs |

|---|---|---|---|---|

| Germany | 6.94 | 64.36 | 6.69 | 60.68 |

| Japan | 9.95 | 77.38 | 7.09 | 61.64 |

| Korea | 7.98 | 62.19 | 4.49 | 62.98 |

| Fuel Reduction Rate | % of Fuel Reduction | % of Platooned Vehicles | % of Route-Changed Vehicles | % of Platooned Arcs |

|---|---|---|---|---|

| 0.05 | 2.10 | 68.97 | 2.31 | 59.61 |

| 0.1 | 4.36 | 68.61 | 3.99 | 60.52 |

| 0.15 | 6.77 | 68.21 | 5.52 | 61.44 |

| 0.2 | 9.34 | 67.82 | 6.75 | 62.12 |

| 0.25 | 12.10 | 67.47 | 8.32 | 63.08 |

| 0.3 | 15.06 | 66.81 | 9.66 | 63.84 |

| Number of Vehicles | % of Fuel Reduction | % of Platooned Vehicles | % of Route-Changed Vehicles | % of Platooned Arcs |

|---|---|---|---|---|

| 25 | 4.83 | 48.78 | 5.82 | 43.00 |

| 50 | 7.22 | 63.28 | 6.91 | 57.72 |

| 100 | 9.71 | 75.48 | 6.27 | 70.32 |

| 200 | 11.39 | 84.39 | 5.37 | 76.03 |

| Slack Time (min) | % of Fuel Reduction | % of Platooned Vehicles | % of Route-Changed Vehicles | % of Platooned Arcs |

|---|---|---|---|---|

| 180 | 5.20 | 54.02 | 5.63 | 45.53 |

| 360 | 7.02 | 64.95 | 6.20 | 56.82 |

| 720 | 8.97 | 73.91 | 6.43 | 66.90 |

| 1440 | 11.96 | 79.04 | 6.10 | 77.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.; Ha, C.; Seok, H. Vehicle Routing Problem Model with Practicality. Processes 2023, 11, 654. https://doi.org/10.3390/pr11030654

Park S, Ha C, Seok H. Vehicle Routing Problem Model with Practicality. Processes. 2023; 11(3):654. https://doi.org/10.3390/pr11030654

Chicago/Turabian StylePark, SeJoon, Chunghun Ha, and Hyesung Seok. 2023. "Vehicle Routing Problem Model with Practicality" Processes 11, no. 3: 654. https://doi.org/10.3390/pr11030654

APA StylePark, S., Ha, C., & Seok, H. (2023). Vehicle Routing Problem Model with Practicality. Processes, 11(3), 654. https://doi.org/10.3390/pr11030654