The Application of a Solar–Air-Source Heat Pump Dual-Supply Heating System in a High-Cold Area in China

Abstract

1. Introduction

1.1. Background

1.2. Literature Review

1.3. Novelty and Aims

2. Materials and Methods

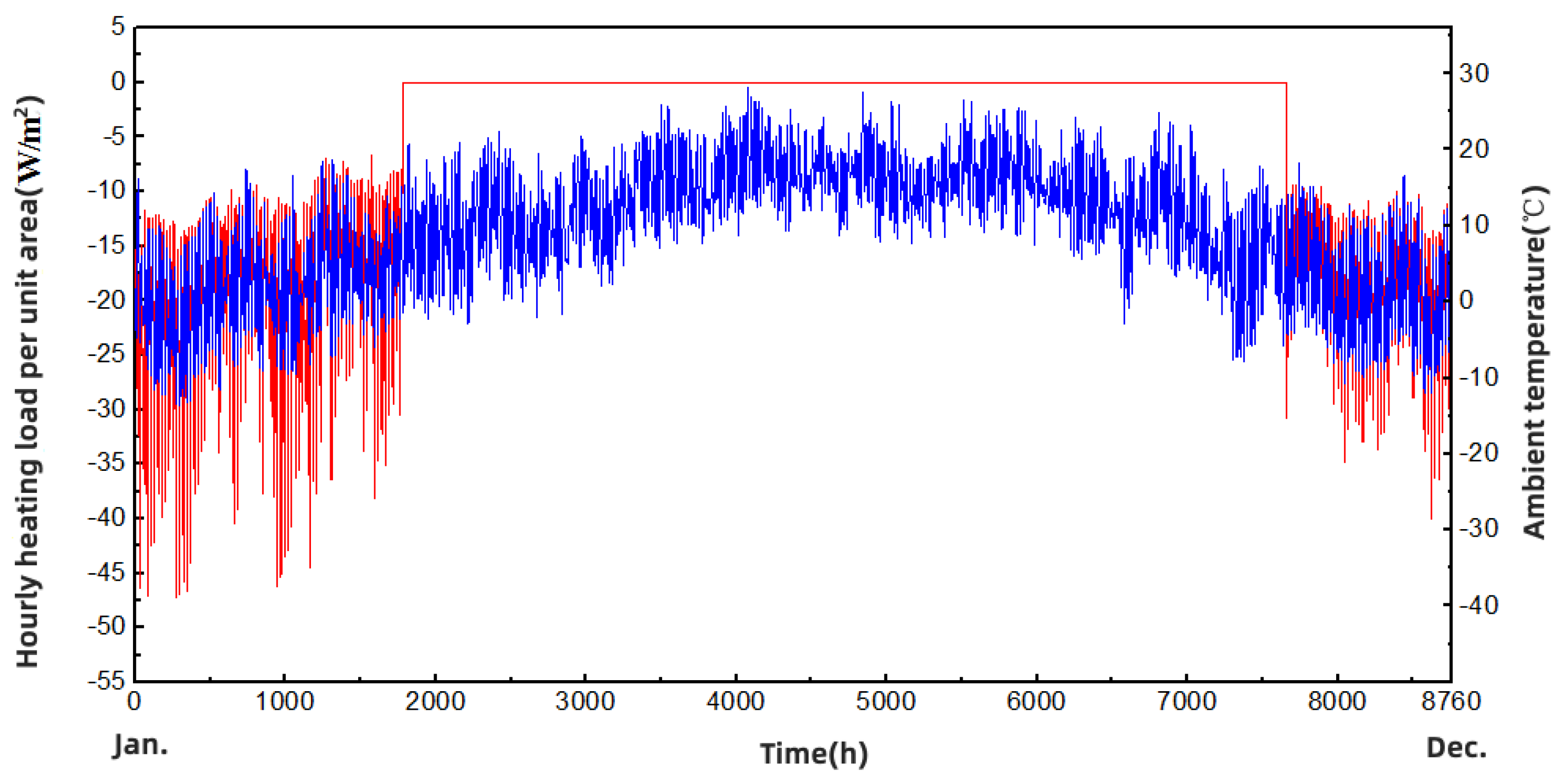

2.1. Target Heating Building Description

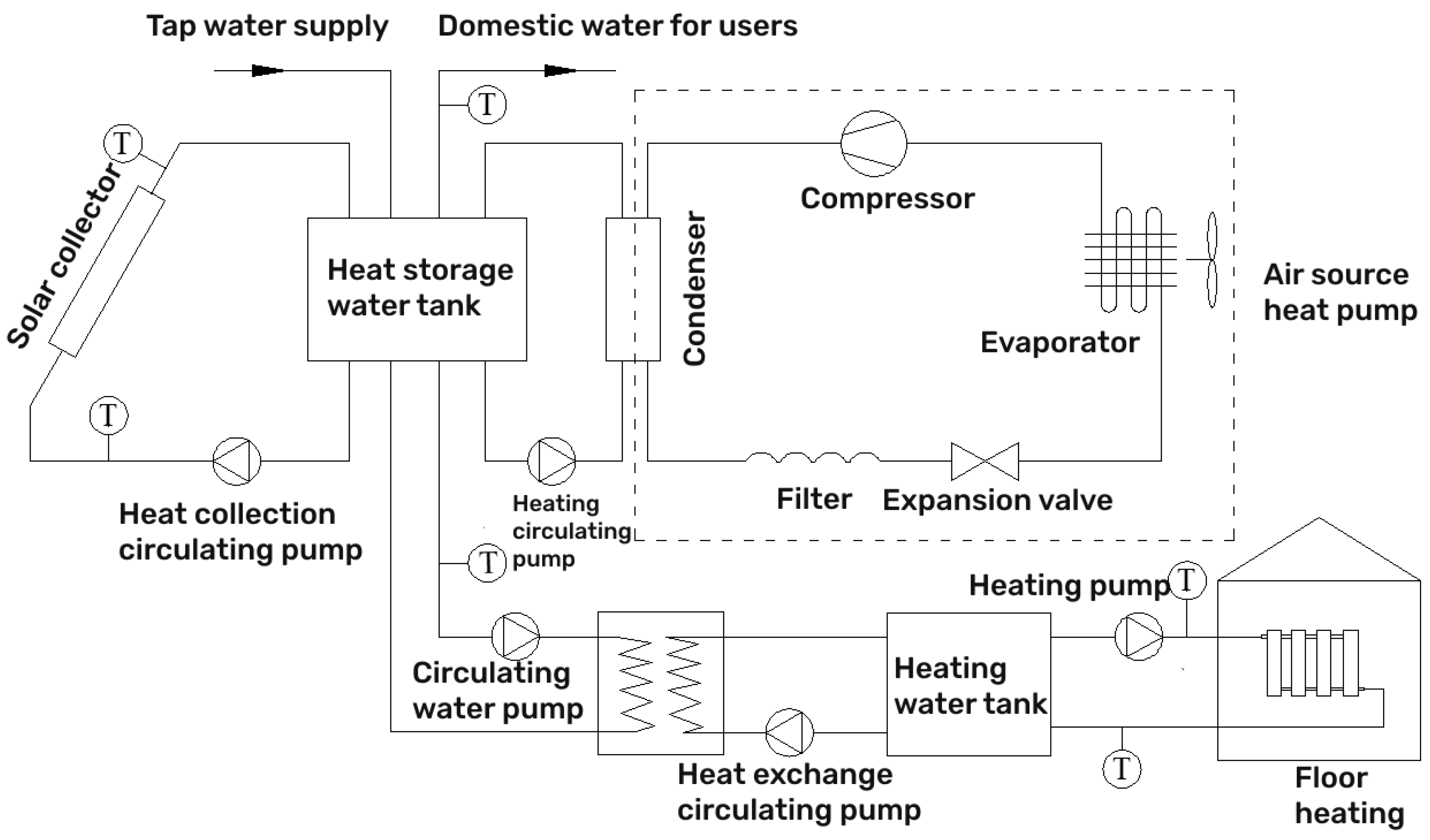

2.2. System Description

2.3. Design of S/AS-HP Dual-Supply Heating System

2.3.1. Solar Collector

2.3.2. Heat Storage Water Tank

2.4. Simulation Models

2.4.1. TRNSYS Model

2.4.2. Model Assumptions

2.5. Thermal Performance Criteria

2.6. Economic Performance of the System

3. Results and Discussion

3.1. Validation of Simulation Results

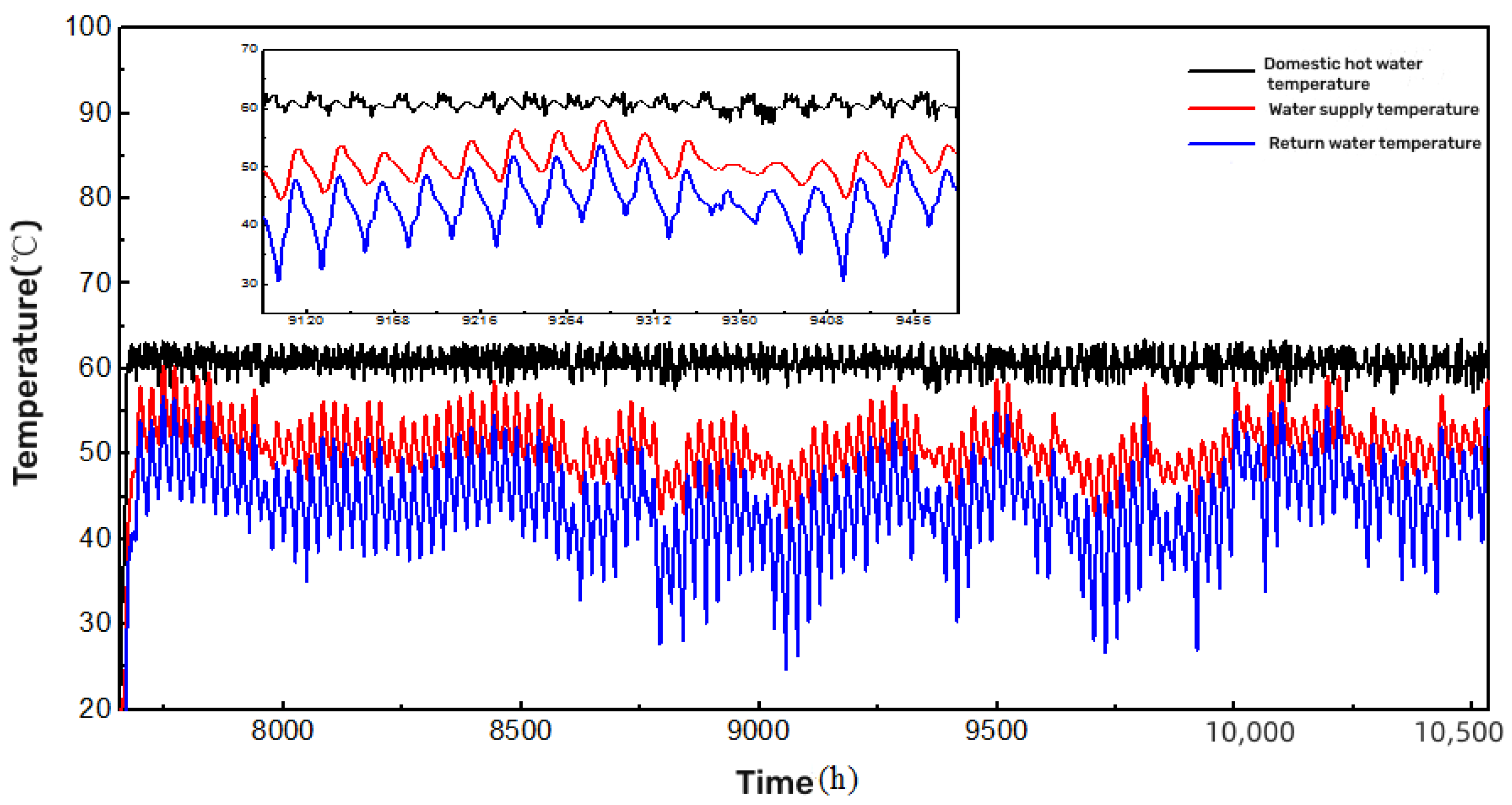

3.2. Hot Water Temperature

3.3. Operation Mode and Time Ratio

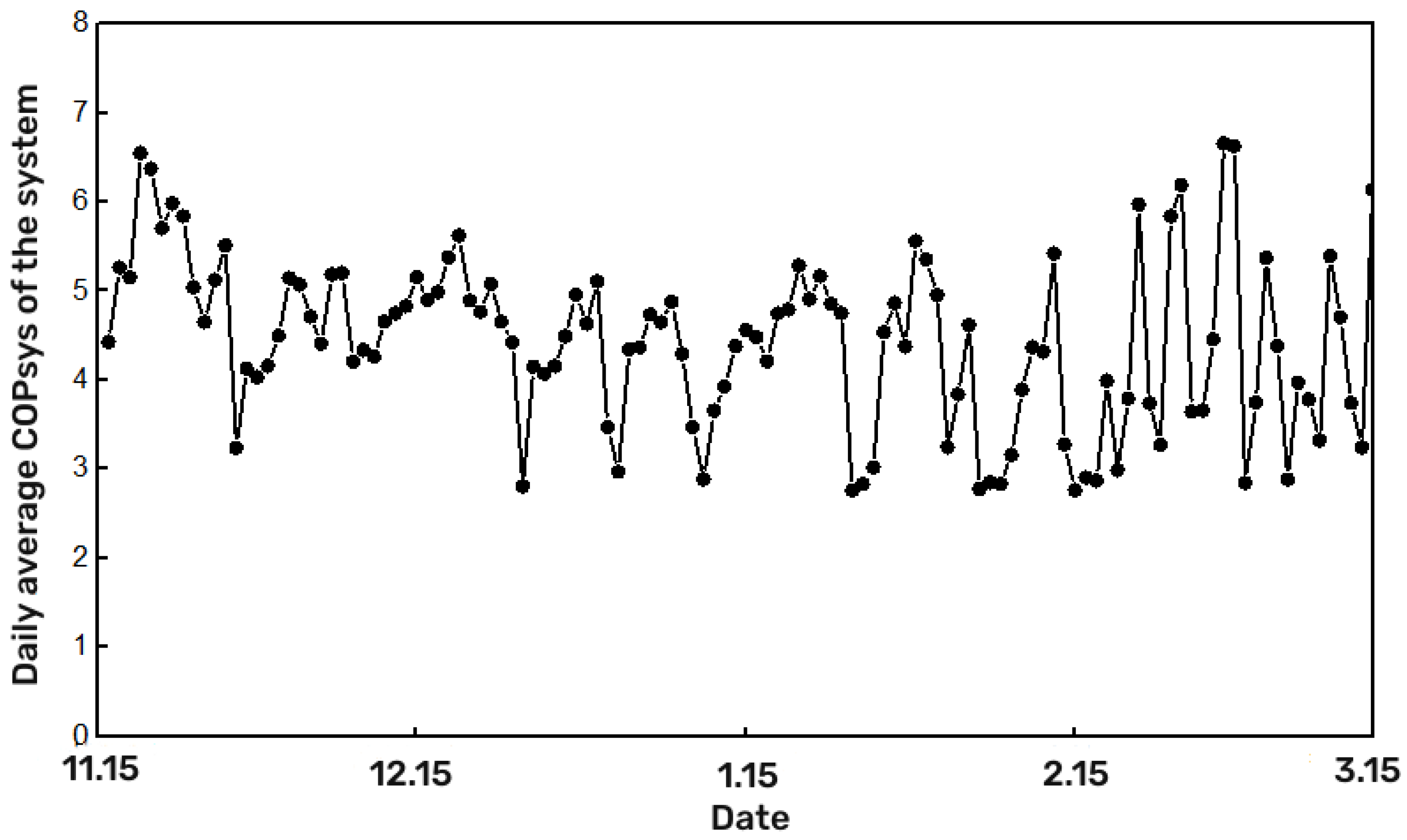

3.4. Comprehensive Energy Efficiency Ratio of Dual-Supply Heating System

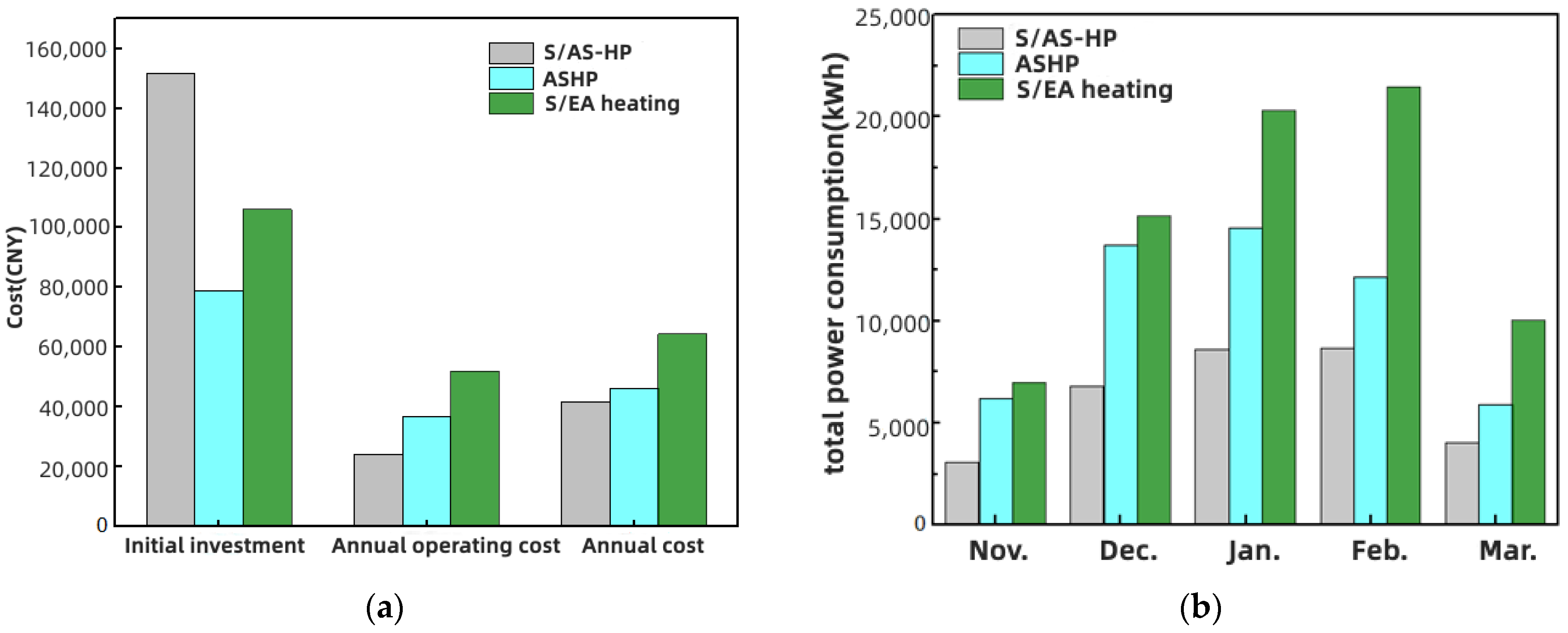

3.5. Comparison of Different Schemes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deng, P.J. Research on Application of ASHP and Solar Energy Combined Heating System in New Rural Community in Northern China; Qingdao University of Technology: Qingdao, China, 2017. [Google Scholar]

- Zhou, X.; Liu, G.Q.; Yan, J.W. Optimal Operation Strategy of Parallel-Connection Solar Air-Source He Pump Hot-Water System. J. South China Univ. Technol. 2017, 45, 16–25. [Google Scholar]

- Yang, Y.L. Operation Strategy and Evaluation of Air Source Heat Pump Integrated with Solar Energy Heating System; Shandong University: Jinan, China, 2018. [Google Scholar]

- He, X. Research of Combining Parabolic Trough Collectors and CO2 Air-Source Heat Pump Heating System in Alpine Region; Southwest Jiaotong University: Chengdu, China, 2018. [Google Scholar]

- Guo, H.W.; Wang, Y.; Gao, W.X. Performance Evaluation of Solar-air Source Heat Pump Hot Water System in Different Climatic Zones. J. Refrig. 2019, 40, 45–51+100. [Google Scholar]

- Wu, B.; Tian, Q.; Dong, X. Mathematical model construction and analysis of combined solar energy and air-source heat pump hot water unit system. Heat. Vent. Air Cond. 2019, 49, 131–137. [Google Scholar]

- Sterling, S.J.; Collins, M.R. Feasibility analysis of an indirect heat pump assisted solar domestic hot water system. Appl. Energy 2012, 93, 11–17. [Google Scholar] [CrossRef]

- Kegel, M.; Tamasauskas, J.; Sunye, R.; Langlois, A. Assessment of a Solar Assisted Air Source and a Solar Assisted Water Source Heat Pump System in a Canadian Household. Energy Procedia 2012, 30, 654–663. [Google Scholar] [CrossRef]

- Panaras, G.; Mathioulakis, E.; Belessiotis, V. Investigation of the performance of a combined solar thermal heat pump hot water system. Sol. Energy 2013, 93, 169–182. [Google Scholar] [CrossRef]

- Poppi, S.; Bales, C.; Heinz, A.; Hengel, F.; Chèze, D.; Mojic, I.; Cialani, C. Analysis of system improvements in solar thermal and air source heat pump combisystems. Appl. Energy 2016, 173, 606–623. [Google Scholar] [CrossRef]

- Dong, X.; Tian, Q.; Li, Z. Experimental investigation on heating performance of solar integrated air source heat pump. Appl. Therm. Eng. 2017, 123, 1013–1020. [Google Scholar] [CrossRef]

- GB 50736-2012; Ministry of Housing and Urban-Rural Development, Design Code for Heating Ventilation and Air Conditioning of Civil Buildings. China Architecture and Building Press: Beijing, China, 2012.

- Xiao, F.; Yu, Z. The Applications of Weather Simulation in Calculation of Building Ener Consumption. Huazhong Archit. 2003, 2, 69–71. [Google Scholar]

- Shen, X.Y.; Li, S.Y.; Qi, J.X. Simulation Analysis of Solar Water Heating System With CPC Collector Based on TRNSYS. Sol. Energy 2020, 5, 38–44. [Google Scholar]

- Zhu, J.H.; Sun, Y.Y.; Wang, W.; Deng, S.M.; Ge, Y.J.; Li, L.T. Developing a new frosting map to guide defrosting control for air-source heat pump units. Appl. Therm. Eng. 2015, 90, 782–791. [Google Scholar] [CrossRef]

- Zhao, R.Y. Air Conditioning, 4th ed.; China Architecture and Building Press: Beijing, China, 2019. [Google Scholar]

- GB 50015-2019; State Market Regulatory Administration, General Code for Design of Building Water Supply and Drainage and Water Saving. China Planning Press: Beijing, China, 2019.

| Name | Enclosure Structure | Heat Transfer Coefficient (W/m2·K) |

|---|---|---|

| Outwalls | Cement mortar, high-density expanded polystyrene board insulation, concrete block | 0.38 |

| Roofs | Fine stone concrete, cement mortar, asphalt waterproofing membrane, expanded perlite, reinforced concrete | 0.22 |

| Windows | Low-E insulating glass (air) (6 + 12A + 6) | 1.9 |

| Doors | Stainless steel with wood finish | - |

| Module | TRNSYS Type |

|---|---|

| Meteorological data reading module | Type15-6 |

| Solar collector | Type1b |

| Air-source heat pump | Type941 |

| Heat storage water tank | Type158 |

| Heat exchanger | Type5b |

| Water pump | Type114 |

| Diverter | Type11f |

| Tee valve | Type11h |

| Calculation | / |

| Control module | Type2b |

| Terminal simulation module | Type682 |

| Data reader | Type9e |

| Integrating module | Type24 |

| On-line plotter | Type65a |

| Name | Price |

|---|---|

| Solar collector (flat-plate solar) | 430 CNY/m2 |

| Heat storage water tank | 900 CNY/m3 |

| Air-source heat pump | CNY 50,000 |

| Water pump | CNY 650 |

| Heat exchanger | CNY 2000 |

| electricity price | 0.675 CNY/kWh |

| Heating Mode | Mode 1 | Mode 2 | Mode 3 | Mode 4 |

|---|---|---|---|---|

| Total duration (h) | 667 | 1229 | 109 | 875 |

| Proportion (%) | 23.16 | 42.68 | 3.78 | 30.38 |

| Average daily operation time (h) | 5.56 | 10.24 | 0.91 | 7.29 |

| Month | Total Heat Supply of System (kWh) | Total Energy Consumption of System (kWh) | Monthly Average COPsys of the System |

|---|---|---|---|

| November | 18,314.012 | 3730.179 | 4.910 |

| December | 38,903.242 | 8519.245 | 4.567 |

| January | 41,016.888 | 9955.527 | 4.120 |

| February | 34,438.802 | 9259.452 | 3.719 |

| March | 17,060.497 | 4105.584 | 4.155 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Shen, M.; Feng, J. The Application of a Solar–Air-Source Heat Pump Dual-Supply Heating System in a High-Cold Area in China. Processes 2023, 11, 737. https://doi.org/10.3390/pr11030737

Wu J, Shen M, Feng J. The Application of a Solar–Air-Source Heat Pump Dual-Supply Heating System in a High-Cold Area in China. Processes. 2023; 11(3):737. https://doi.org/10.3390/pr11030737

Chicago/Turabian StyleWu, Jiarui, Miao Shen, and Junxiao Feng. 2023. "The Application of a Solar–Air-Source Heat Pump Dual-Supply Heating System in a High-Cold Area in China" Processes 11, no. 3: 737. https://doi.org/10.3390/pr11030737

APA StyleWu, J., Shen, M., & Feng, J. (2023). The Application of a Solar–Air-Source Heat Pump Dual-Supply Heating System in a High-Cold Area in China. Processes, 11(3), 737. https://doi.org/10.3390/pr11030737