Wind Turbine Emulators—A Review

Abstract

1. Introduction

- This work presents an overview of WTEs and summarizes the different WTEs available in the literature. To the best of our knowledge, no previous research has been investigated on reviewing WTEs in detail.

- Detailed classification and investigation were conducted for various WTEs. Furthermore, this review presents a comparative analysis of different methodologies adapted for WTEs based on cost, accuracy, and complexity.

- Furthermore, an extensive analysis of the different WTEs, such as a combination of physical and computation emulators and pure computation emulators, are investigated and illustrated based on parameters such as drive train dynamics, tower shadow, wind shear, curve, torque and inertia compensation, hardware, and converter topologies.

- Finally, a comparative study was performed based on the following parameters, such as: (1) realization cost; (2) accuracy of the emulator; (3) level of complexity; and (4) hardware implementation.

2. Classification of Wind Turbine Emulator

2.1. Combination of a Physical and Computational Emulator

2.2. Pure Computation Emulator

3. Classification of Combination of Physical and Computational

3.1. DC Motor Based WTEs

3.1.1. Reference Current

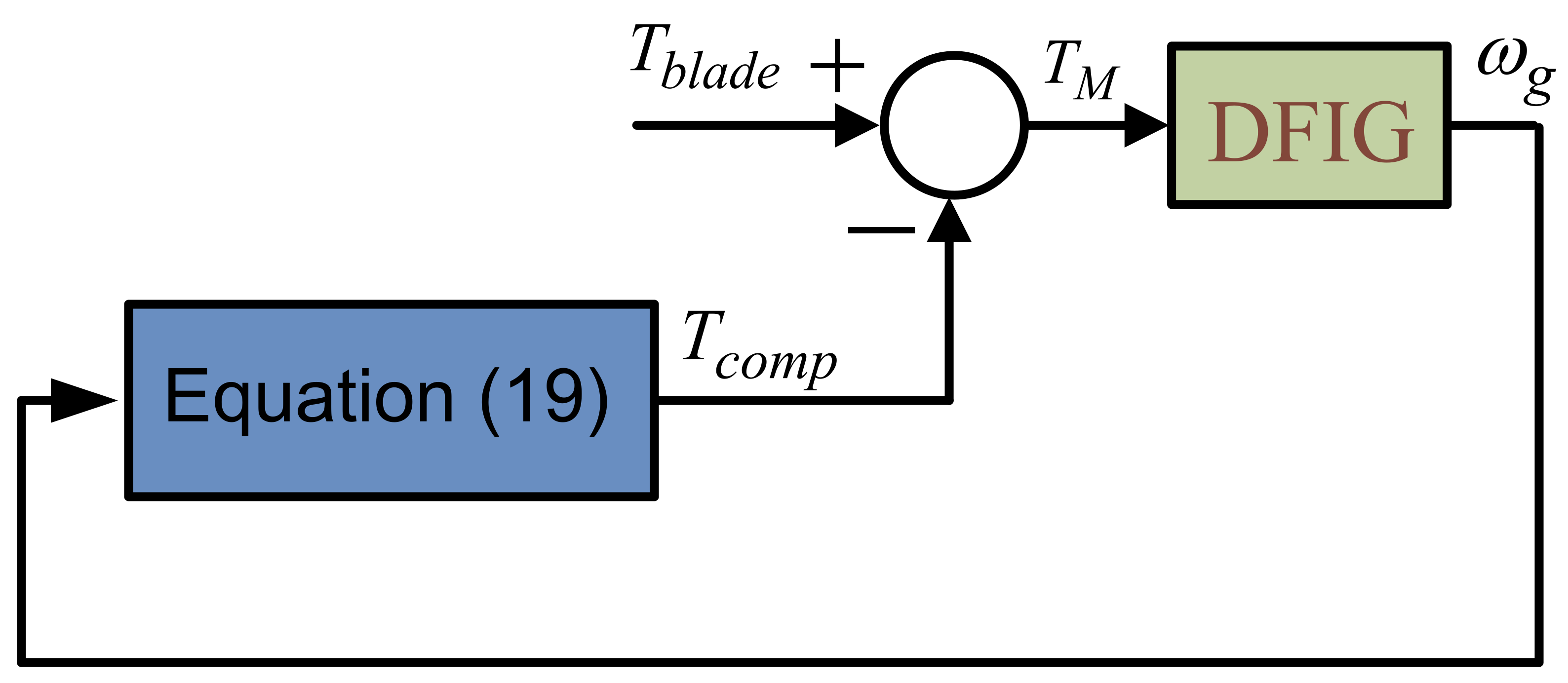

3.1.2. Reference Torque and Torque Compensation Based

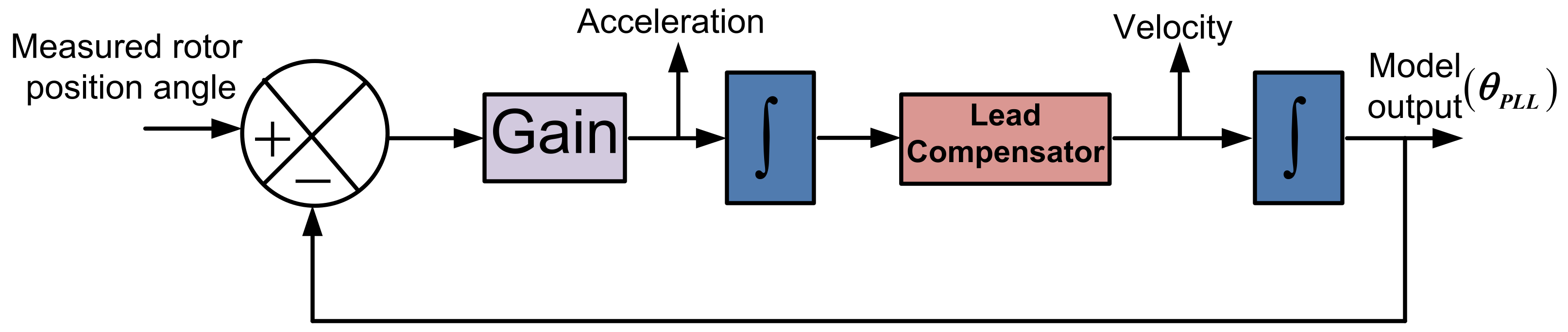

3.1.3. Observer Based

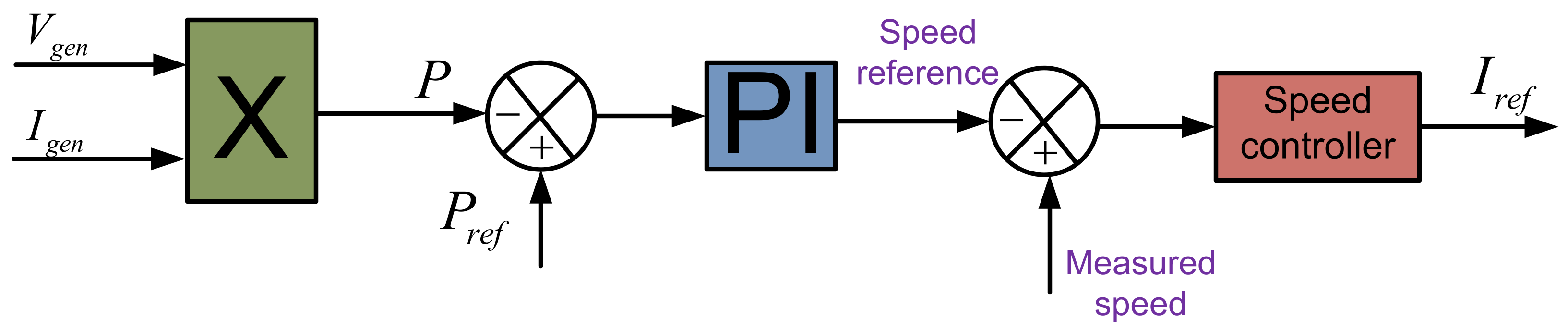

3.1.4. Power Based

3.1.5. Open Loop

3.1.6. Polynomial Approximation

3.1.7. Conventional PI Controller

3.1.8. Commercially Available Wind Turbine Emulators

3.2. Induction Motor-Based WTEs

3.2.1. Power Reference Based

3.2.2. Open-Loop Torque Control

3.2.3. Observer-Based Torque Control

3.2.4. Torque Compensation-Based Torque Control

3.2.5. Torque Control

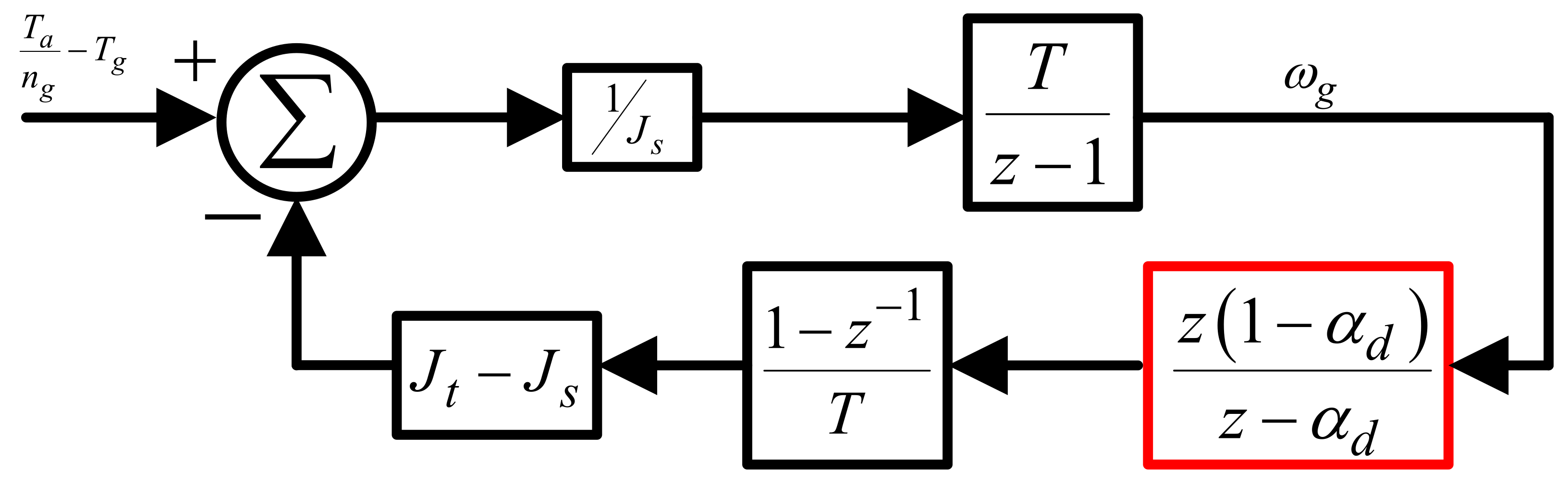

3.2.6. Improved Inertia Torque Calculation

3.2.7. Lookup Table

3.2.8. Power and Wind Speed Relationship

3.2.9. FAST Simulator-Based Emulator

3.2.10. Approximation

3.2.11. Indirect Field-Oriented Control

3.2.12. Fuzzy Based Field Oriented Control

3.2.13. Intelligent Relay Based Frequency Inverter

3.2.14. Commercial Drive-Based Wind Emulator

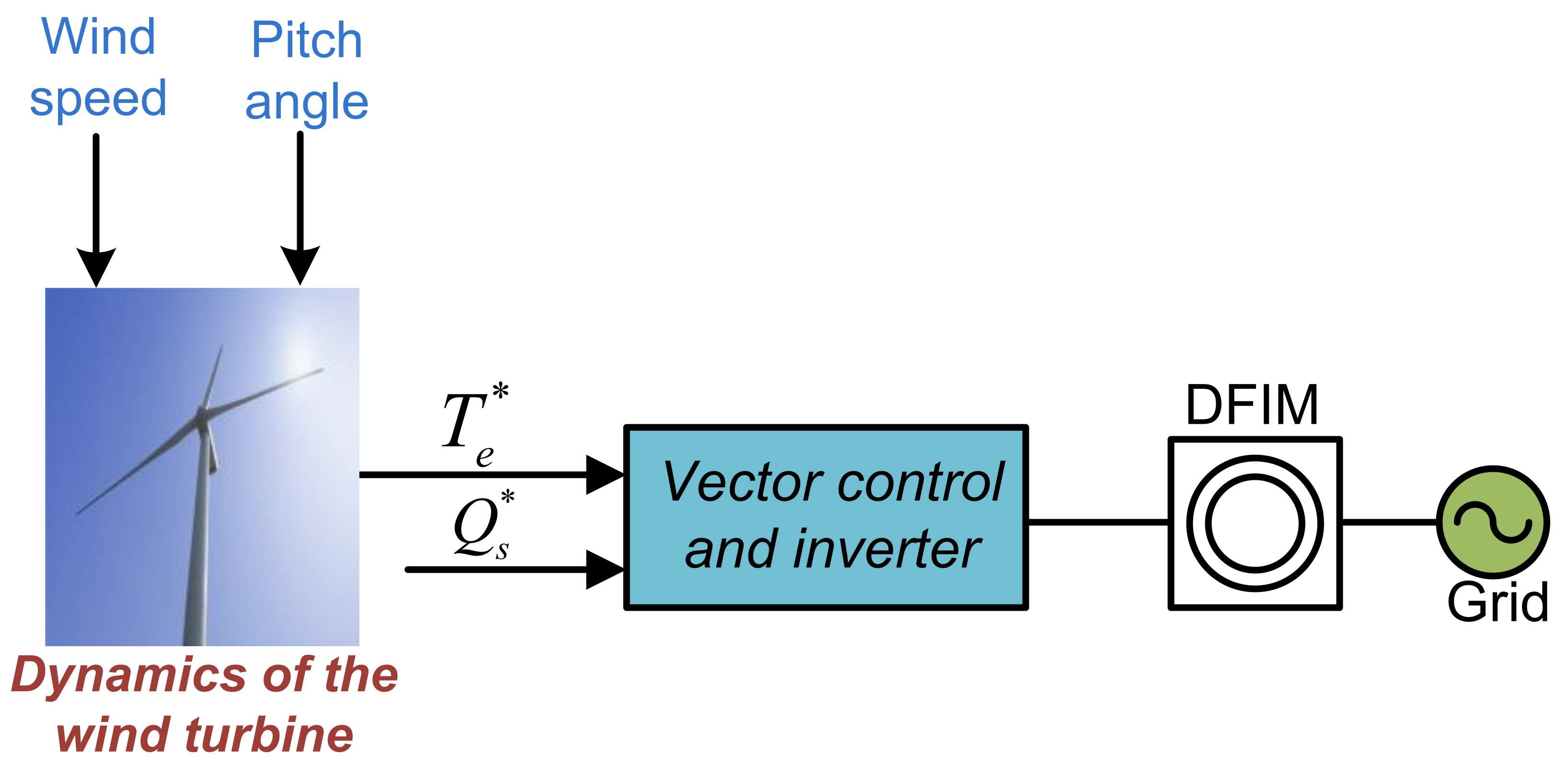

3.3. Doubly Fed Induction Motor

3.4. Servo Motor

3.5. Permanent Magnet Synchronous Motor

4. Computational Based Wind Turbine Emulator

5. Comparative Study

5.1. Realization Cost

5.2. Accuracy of the Emulator

5.3. Level of Complexity

5.4. Hardware Implementation

6. Conclusions and Future Recommendations

- The majority of real-time WTEs focus on electrical systems, whereas WT mechanical systems either model steady-state or low-order models. These models ignore the rotor blades, tower structure, and drive train dynamics.

- Some authors have linearized the dynamics of the mechanical system at a single point, and the power curves are incorporated to derive the torque. However, these assumptions are no longer valid because the WTs operating curves are highly nonlinear.

- Most of the emulators available in the literature come under a combination of physical and computing-based emulators. Thus, these emulators are lab-scale and case-specific.

- A sufficient number of WT mechanical dynamics should be considered for modeling the WT mechanical subsystem so that the nonlinear nature of the PWT could be addressed in the emulator.

- As discussed earlier, in most WTEs, the electric motor acts as a prime mover. Therefore, the emulator requires inertia compensation due to the lower inertia of the electric motor.

- An emulator can shift the operating point corresponding to changes in actual wind speed and the capability of adapting the new control strategies and power converter topologies for further development in wind power systems.

- An emulator could be capable of incorporating the structural dynamics of WT without local linearization.

- The transient modes of the WT mechanical system have to be considered for developing WTEs. In addition, future research could focus on hybrid wind emulators.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blaabjerg, F.; Teodorescu, R.; Liserre, M.; Timbus, A. Overview of Control and Grid Synchronization for Distributed Power Generation Systems. IEEE Trans. Ind. Electron. 2006, 53, 1398–1409. [Google Scholar] [CrossRef]

- Sinsel, S.R.; Riemke, R.L.; Hoffmann, V.H. Challenges and solution technologies for the integration of variable renewable energy sources—A review. Renew. Energy 2020, 145, 2271–2285. [Google Scholar] [CrossRef]

- Devashish; Thakur, A.; Panigrahi, S.; Behera, R.R. A review on wind energy conversion system and enabling technology. In Proceedings of the 2016 International Conference on Electrical Power and Energy Systems (ICEPES), Bhopal, India, 14–16 December 2016; pp. 527–532. [Google Scholar] [CrossRef]

- Willis, D.; Niezrecki, C.; Kuchma, D.; Hines, E.; Arwade, S.; Barthelmie, R.; DiPaola, M.; Drane, P.; Hansen, C.; Inalpolat, M.; et al. Wind energy research: State-of-the-art and future research directions. Renew. Energy 2018, 125, 133–154. [Google Scholar] [CrossRef]

- Global Wind Energy Council. Global Wind Energy Report 2021; Global Wind Energy Council: Brussels, Belgium, 2021. [Google Scholar]

- Kouadria, S.; Belfedhal, S.; Meslem, Y.; Berkouk, E.M. Development of real time Wind Turbine Emulator based on DC Motor controlled by hysteresis regulator. In Proceedings of the 2013 International Renewable and Sustainable Energy Conference (IRSEC), Ouarzazate, Morocco, 7–9 March 2013; pp. 246–250. [Google Scholar] [CrossRef]

- Battaiotto, P.; Mantz, R.; Puleston, P. A Wind Turbine Emulator Based on a Dual DSP Processor System. IFAC Proc. Vol. 1995, 28, 249–254. [Google Scholar] [CrossRef]

- Diop, A.; Nichita, C.; Belhache, J.; Dakyo, B.; Ceanga, E. Error Evaluation for Models of Real Time Wind Turbine Simulators. Wind Eng. 2000, 24, 203–221. [Google Scholar] [CrossRef]

- Farret, F.; Gules, R.; Marian, J. Micro-turbine simulator based on speed and torque of a DC motor to drive actually loaded generators. In Proceedings of the First International Caracas Conference on Devices, Circuits and Systems, Caracas, Venezuela, 12–14 December 1995; pp. 89–93. [Google Scholar] [CrossRef]

- Dekali, Z.; Baghli, L.; Boumediene, A.; Djemai, M. Control of a Grid Connected DFIG Based Wind Turbine Emulator. In Proceedings of the 2018 5th International Symposium on Environment-Friendly Energies and Applications (EFEA), Rome, Italy, 24–26 September 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Benzaouia, S.; Mokhtari, M.; Zouggar, S.; Rabhi, A.; Elhafyani, M.L.; Ouchbel, T. Design and implementation details of a low cost sensorless emulator for variable speed wind turbines. Sustain. Energy Grids Netw. 2021, 26, 100431. [Google Scholar] [CrossRef]

- Chinchilla, M.; Arnaltes, S.; Rodriguez-Amenedo, J. Laboratory set-up for wind turbine emulation. In Proceedings of the 2004 IEEE International Conference on Industrial Technology (IEEE ICIT ’04), Hammamet, Tunisia, 8–10 December 2004; Volume 1, pp. 553–557. [Google Scholar] [CrossRef]

- Song, S.H.; Jeong, B.C.; Lee, H.I.; Kim, J.J.; Oh, J.H.; Venkataramanan, G. Emulation of output characteristics of rotor blades using a hardware-in-loop wind turbine simulator. In Proceedings of the Twentieth Annual IEEE Applied Power Electronics Conference and Exposition (APEC 2005), Austin, TX, USA, 6–10 March 2005; Volume 3, pp. 1791–1796. [Google Scholar] [CrossRef]

- Lopes, L.; Lhuilier, J.; Khokhar, M.; Mukherjee, A. A Wind Turbine Emulator that Represents the Dynamics of the Wind Turbine Rotor and Drive Train. In Proceedings of the 2005 IEEE 36th Power Electronics Specialists Conference, Dresden, Germany, 16 June 2005; pp. 2092–2097. [Google Scholar] [CrossRef]

- Monfared, M.; Madadi Kojabadi, H.; Rastegar, H. Static and dynamic wind turbine simulator using a converter controlled dc motor. Renew. Energy 2008, 33, 906–913. [Google Scholar] [CrossRef]

- Monfared, M.; Rastegar, H.; Moradzadeh, B. A more accurate dynamic wind energy conversion system emulator. In Proceedings of the 2nd International Conference on Electrical and Control Technologies (ECT–2007), Kaunas, Lithuania, 3–4 May 2007; pp. 151–156. [Google Scholar]

- Munteanu, I.; Bratcu, A.I.; Bacha, S.; Roye, D.; Guiraud, J. Hardware-in-the-Loop-based Simulator for a Class of Variable-speed Wind Energy Conversion Systems: Design and Performance Assessment. IEEE Trans. Energy Convers. 2010, 25, 564–576. [Google Scholar] [CrossRef]

- Hemeida, A.; Mahgoub, O.A.; Farag, W.A. Design of a Comprehensive 5MW Direct-Driven PMSG Wind Turbine Emulator Using FAST Nonlinear Wind Turbine Model. J. Autom. Control. Eng. 2013, 2, 190–196. [Google Scholar]

- Gong, B.; Xu, D. Real time wind turbine simulator for wind energy conversion system. In Proceedings of the 2008 IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008; pp. 1110–1114. [Google Scholar] [CrossRef]

- Moore, I.; Ekanayake, J. Design and development of a hardware based wind turbine simulator. In Proceedings of the 45th International Universities Power Engineering Conference UPEC2010, Cardiff, UK, 31 August–3 September 2010; pp. 1–5. [Google Scholar]

- Martinez, F.; Herrero, L.C.; de Pablo, S. Open loop wind turbine emulator. Renew. Energy 2014, 63, 212–221. [Google Scholar] [CrossRef]

- Moussa, I.; Bouallegue, A.; Khedher, A. New wind turbine emulator based on DC machine: Hardware implementation using FPGA board for an open-loop operation. IET Circuits Devices Syst. 2019, 13, 896–902. [Google Scholar] [CrossRef]

- Arifujjaman, M.; Iqbal, M.; Quaicoe, J.E. Maximum Power Extraction from a Small Wind Turbine Emulator using a DC–DC Converter Controlled by a Microcontroller. In Proceedings of the 2006 International Conference on Electrical and Computer Engineering, Dhaka, Bangladesh, 19–21 December 2006; pp. 213–216. [Google Scholar] [CrossRef]

- Arifujjaman, M.; Iqbal, M.; Quaicoe, J.E. Emulation of a small wind turbine system with a separately-excited dc machine. IU-J. Electr. Electron. Eng. 2008, 8, 569–579. [Google Scholar]

- Li, W.; Xu, D.; Zhang, W.; Ma, H. Research on Wind Turbine Emulation based on DC Motor. In Proceedings of the 2007 2nd IEEE Conference on Industrial Electronics and Applications, Harbin, China, 23–25 May 2007; pp. 2589–2593. [Google Scholar] [CrossRef]

- Sahoo, N.C.; Satpathy, A.S.; Kishore, N.K.; Venkatesh, B.D.C. Motor-Based Wind Turbine Emulator Using LabVIEW for Wind Energy Conversion System Laboratory Setup. Int. J. Electr. Eng. Educ. 2013, 50, 111–126. [Google Scholar] [CrossRef]

- Hussain, J.; Mishra, M.K. An Efficient Wind Speed Computation Method Using Sliding Mode Observers in Wind Energy Conversion System Control Applications. IEEE Trans. Ind. Appl. 2020, 56, 730–739. [Google Scholar] [CrossRef]

- Bhayo, M.; Aziz, M.; Idris, N.; Yatim, A. Design and development of a wind turbine emulator for analyzing the performance of stand-alone wind energy conversion system. Int. J. Power Electron. Drive Syst. (IJPEDS) 2017, 8, 454–461. [Google Scholar] [CrossRef]

- Dey, J.; Saha, T.K.; Barman, J.C. Performance analysis of a digitally controlled wind turbine emulator. In Proceedings of the International Conference on Electronics, Communication and Instrumentation (ICECI), Kolkata, India, 16–17 January 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Eldahab, Y.A.; Saad, N.H.; Zekry, A. Assessing Wind Energy Conversion Systems Based on Newly Developed Wind Turbine Emulator. Int. J. Smart Grid-ijSmartGrid 2020, 4, 139–148. [Google Scholar] [CrossRef]

- Premkumar, K.; Vishnupriya, M.; Sudhakar Babu, T.; Manikandan, B.V.; Thamizhselvan, T.; Nazar Ali, A.; Rabiul Islam, M.; Kouzani, A.Z.; Parvez Mahmud, M.A. Black Widow Optimization-Based Optimal PI-Controlled Wind Turbine Emulator. Sustainability 2020, 12, 10357. [Google Scholar] [CrossRef]

- Behera, P.K.; Mendi, B.; Sarangi, S.K.; Pattnaik, M. Robust wind turbine emulator design using sliding mode controller. Renew. Energy Focus 2021, 36, 79–88. [Google Scholar] [CrossRef]

- Balaji, M.; Sarangi, S.K.; Pattnaik, M. Design of a DC Motor based Wind Turbine Emulator using Sliding Mode Control Approach. In Proceedings of the 2019 IEEE 1st International Conference on Energy, Systems and Information Processing (ICESIP), Chennai, India, 4–6 July 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Ecosense. Wind Turbine Emulator System. Available online: https://www.ecosenseworld.com/labs/wind-energy-labs/wind-turbine-emulator (accessed on 15 January 2023).

- Chang, L.; Doraiswami, R.; Boutot, T.; Kojabadi, H. Development of a wind turbine simulator for wind energy conversion systems. In Proceedings of the 2000 Canadian Conference on Electrical and Computer Engineering. Conference Proceedings. Navigating to a New Era (Cat. No.00TH8492), Halifax, NS, Canada, 7–10 May 2000; Volume 1, pp. 550–554. [Google Scholar] [CrossRef]

- Kojabadi, H.; Chang, L.; Boutot, T. Development of a novel wind turbine simulator for wind energy conversion systems using an inverter-controlled induction motor. IEEE Trans. Energy Convers. 2004, 19, 547–552. [Google Scholar] [CrossRef]

- Teodorescu, R.; Iov, F.; Blaabjerg, F. Flexible development and test system for 11 kW wind turbine. In Proceedings of the IEEE 34th Annual Conference on Power Electronics Specialist (PESC ’03), Acapulco, Mexico, 15–19 June 2003; Volume 1, pp. 67–72. [Google Scholar] [CrossRef]

- Muntean, N.; Tutelea, L.; Petrila, D.; Pelan, O. Hardware in the loop wind turbine emulator. In Proceedings of the International Aegean Conference on Electrical Machines and Power Electronics and Electromotion, Joint Conference, Istanbul, Turkey, 8–10 September 2011; pp. 53–58. [Google Scholar] [CrossRef]

- Lu, L.; Xie, Z.; Zhang, X.; Yang, S.; Cao, R. A Dynamic Wind Turbine Simulator of the Wind Turbine Generator System. In Proceedings of the 2012 Second International Conference on Intelligent System Design and Engineering Application, Sanya, China, 6–7 January 2012; pp. 967–970. [Google Scholar] [CrossRef]

- Neammanee, B.; Sirisumrannukul, S.; Chatratana, S. Development of a wind turbine simulator for wind generator testing. Int. Energy J. 2007, 8, 21–28. [Google Scholar]

- Li, S.; Zhang, X.; Xie, Z.; Yang, S.; Zhang, C.; Cao, R. A Study on Dynamic Model And Analyse of Wind Turbine Generation System. In Proceedings of the 2010 Asia-Pacific Power and Energy Engineering Conference, Chengdu, China, 28–31 March 2010; pp. 1–4. [Google Scholar] [CrossRef]

- Nair, R.; Narayanan, G. Emulation of Wind Turbine System Using Vector Controlled Induction Motor Drive. IEEE Trans. Ind. Appl. 2020, 56, 4124–4133. [Google Scholar] [CrossRef]

- Karakasis, N.; Mesemanolis, A.; Mademlis, C. Wind turbine simulator for laboratory testing of a wind energy conversion drive train. In Proceedings of the 8th Mediterranean Conference on Power Generation, Transmission, Distribution and Energy Conversion (MEDPOWER 2012), Cagliari, Italy, 1–3 October 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Sokolovs, A.; Grigans, L.; Kamolins, E.; Voitkans, J. An Induction Motor Based Wind Turbine Emulator. Latv. J. Phys. Tech. Sci. 2014, 51, 11. [Google Scholar] [CrossRef]

- Tammaruckwattana, S.; Ohyama, K.; Yue, C. Experimental assessment with wind turbine emulator of variable-speed wind power generation system using boost chopper circuit of permanent magnet synchronous generator. J. Power Electron. 2015, 15, 246–255. [Google Scholar] [CrossRef]

- Tammaruckwattana, S.; Ohyama, K.; Arinaga, S. Wind turbine emulator based on blade element momentum theory for variable-speed wind power generation system. IEEJ Trans. Electr. Electron. Eng. 2015, 10, S96–S107. [Google Scholar] [CrossRef]

- Tammaruckwattana, S.; Ohyama, K. Experimental verification of variable speed wind power generation system using permanent magnet synchronous generator by wind turbine emulator. In Proceedings of the IECON 2012—38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 5827–5832. [Google Scholar] [CrossRef]

- Ohyama, K.; Nakashima, T. Wind turbine emulator using wind turbine model based on blade element momentum theory. In Proceedings of the SPEEDAM 2010, Pisa, Italy, 14–16 June 2010; pp. 762–765. [Google Scholar] [CrossRef]

- Qiao, M.; Lin, F.; Hao, R.; You, X.; Zheng, T.Q. The Research and Development Platform for Wind Energy System Used Induction Motor Replacing Wind Turbine. In Proceedings of the 2007 2nd IEEE Conference on Industrial Electronics and Applications, Harbin, China, 23–25 May 2007; pp. 2579–2582. [Google Scholar] [CrossRef]

- Abo-Khalil, A.G. A new wind turbine simulator using a squirrel-cage motor for wind power generation systems. In Proceedings of the 2011 IEEE Ninth International Conference on Power Electronics and Drive Systems, Singapore, 5–8 December 2011; pp. 750–755. [Google Scholar] [CrossRef]

- Henz, G.; Koch, G.; Franchi, C.M.; Pinheiro, H. Development of a variable speed wind turbine emulator for research and training. In Proceedings of the 2013 Brazilian Power Electronics Conference, Gramado, Brazil, 27–31 October 2013; pp. 737–742. [Google Scholar] [CrossRef]

- Ozawa, F.; Rocha, M.; Lucas, G.; Souza, W.; Andreoli, A. Application of Torque Transducer and Rotary Encoder in a Hardware-in-the-Loop Wind Turbine Emulation. In Proceedings of the 6th International Electronic Conference on Sensors and Applications, Online, 15–30 November 2019. [Google Scholar] [CrossRef]

- de Oliveira, J.R.; Andreoli, A.L. Wind Turbine Emulator: A Tool for Experimental and Computational Study. IEEE Lat. Am. Trans. 2021, 19, 1832–1839. [Google Scholar] [CrossRef]

- de Oliveira, J.R.; de Souza, W.G.; Rocha, M.A.; Costa, C.F.d.; Leão, J.V.F.; Andreoli, A.L. Wind Turbine Emulator Using Induction Motor Driven by Frequency Inverter and Hardware-in-the-loop Control. In Proceedings of the 2018 13th IEEE International Conference on Industry Applications (INDUSCON), Sao Paulo, Brazil, 12–14 November 2018; pp. 381–385. [Google Scholar] [CrossRef]

- Ha, V.T.; Phuong, V.H.; Lam, N.T.; Quang, N.P. A dead-beat current controller based wind turbine emulator. In Proceedings of the 2017 International Conference on System Science and Engineering (ICSSE), Ho Chi Minh City, Vietnam, 21–23 July 2017; pp. 169–174. [Google Scholar] [CrossRef]

- Castelló, J.; Espí, J.M.; García-Gil, R. Development details and performance assessment of a Wind Turbine Emulator. Renew. Energy 2016, 86, 848–857. [Google Scholar] [CrossRef]

- Li, W.; Yin, M.; Chen, Z.; Zou, Y. Inertia compensation scheme for wind turbine simulator based on deviation mitigation. J. Mod. Power Syst. Clean Energy 2017, 5, 228–238. [Google Scholar] [CrossRef]

- Mohod, S.; Aware, M. Laboratory development of wind turbine simulator using variable speed induction motor. Int. J. Eng. Sci. Technol. 2011, 3, 73–82. [Google Scholar] [CrossRef]

- Mesbahi, A.; Khafallah, M.; Saad, A.; Nouaiti, A. Emulator design for a small wind turbine driving a self excited induction generator. In Proceedings of the 2017 International Conference on Electrical and Information Technologies (ICEIT), Rabat, Morocco, 15–18 November 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Mohammadi, E.; Fadaeinedjad, R.; Naji, H.R. Using a new wind turbine emulator to analyze tower shadow and yaw error effects. Energy Convers. Manag. 2018, 174, 378–387. [Google Scholar] [CrossRef]

- Mohammadi, E.; Fadaeinedjad, R.; Naji, H.R.; Moschopoulos, G. Investigation of Horizontal and Vertical Wind Shear Effects Using a Wind Turbine Emulator. IEEE Trans. Sustain. Energy 2019, 10, 1206–1216. [Google Scholar] [CrossRef]

- Martínez-Márquez, C.I.; Twizere-Bakunda, J.D.; Lundback-Mompó, D.; Orts-Grau, S.; Gimeno-Sales, F.J.; Seguí-Chilet, S. Small Wind Turbine Emulator Based on Lambda-Cp Curves Obtained under Real Operating Conditions. Energies 2019, 12, 2456. [Google Scholar] [CrossRef]

- Hsu, Y.C.; Lu, M.Z.; Liaw, C.M. A Wind Turbine Emulator Using Field-Oriented Induction Motor. J. Energy Power Technol. 2021, 3, 018. [Google Scholar] [CrossRef]

- Mousarezaee, E.; Polat, A.; Ergene, L.T. Wind Turbine Emulator Based on Small-Scale PMSG by Fuzzy FOC. In Proceedings of the 2020 21st International Symposium on Electrical Apparatus & Technologies (SIELA), Bourgas, Bulgaria, 3–6 June 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Dănuţ, L.D.; Hulea, D.; Cornea, O.; Muntean, N.; Iuoras, M.A.; Hinov, N. Low Cost Implementation of a Wind Turbine Emulator. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Sajadi, A.; Rosłaniec, Ł.; Kłos, M.; Biczel, P.; Loparo, K.A. An emulator for fixed pitch wind turbine studies. Renew. Energy 2016, 87, 391–402. [Google Scholar] [CrossRef]

- Gan, L.K.; Shek, J.K.H.; Mueller, M.A. Modeling and Characterization of Downwind Tower Shadow Effects Using a Wind Turbine Emulator. IEEE Trans. Ind. Electron. 2017, 64, 7087–7097. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Mondal, S.; Kastha, D.; Sinha, A.K.; Kishore, N.K. Wind turbine emulation using doubly fed induction motor. In Proceedings of the 2016 21st Century Energy Needs-Materials, Systems and Applications (ICTFCEN), Kharagpur, India, 17–19 November 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Peretti, L.; Särkimäki, V.; Faber, J. A wind turbine emulator for generator control algorithm development. In Proceedings of the 2013 IEEE International Conference on Industrial Technology (ICIT), Western Cape, South Africa, 25–28 February 2013; pp. 228–233. [Google Scholar] [CrossRef]

- Gokhale, R.V.; Mahajan, S.M.; Abegaz, B.W.; Craven, R.P. Development of a real time wind turbine emulator based on RTDS using advanced perturbation methods. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015; pp. 1713–1718. [Google Scholar] [CrossRef]

- Chen, J.; Chen, J.; Gong, C.; Wang, H. Design and analysis of dynamic wind turbine simulator for wind energy conversion system. In Proceedings of the IECON 2012—38th Annual Conference on IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 971–977. [Google Scholar] [CrossRef]

- Yan, J.; Feng, Y.; Dong, J. Study on dynamic characteristic of wind turbine emulator based on PMSM. Renew. Energy 2016, 97, 731–736. [Google Scholar] [CrossRef]

- Chen, P.Y.; Hu, K.W.; Lin, Y.G.; Liaw, C.M. Development of a Prime Mover Emulator Using a Permanent-Magnet Synchronous Motor Drive. IEEE Trans. Power Electron. 2018, 33, 6114–6125. [Google Scholar] [CrossRef]

- Chen, H.; Sun, S.; Aliprantis, D.C.; Zambreno, J. Dynamic simulation of DFIG wind turbines on FPGA boards. In Proceedings of the 2010 Power and Energy Conference At Illinois (PECI), Urbana, IL, USA, 12–13 February 2010; pp. 39–44. [Google Scholar] [CrossRef]

- Guo, H.; Zhou, B.; Li, J.; Cheng, F.; Zhang, L. Real-time simulation of BLDC-based wind turbine emulator using RT-LAB. In Proceedings of the 2009 International Conference on Electrical Machines and Systems, Tokyo, Japan, 15–18 November 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Nailu, L.; Yuegang, L.; Peiyu, X. A real-time simulation system of wind power based on LabVIEW DSC module and Matlab/Simulink. In Proceedings of the 2009 9th International Conference on Electronic Measurement & Instruments, Beijing, China, 16–19 August 2009; pp. 1-547–1-552. [Google Scholar] [CrossRef]

- Moness, M.; Mahmoud, M.O.; Moustafa, A.M. A Real-Time Heterogeneous Emulator of a High-Fidelity Utility-Scale Variable-Speed Variable-Pitch Wind Turbine. IEEE Trans. Ind. Inform. 2018, 14, 437–447. [Google Scholar] [CrossRef]

- Kumsup, S.; Tarasantisuk, C. Real-time wind turbine emulator for testing wind energy conversion systems. In Proceedings of the 2010 IEEE International Energy Conference, Manama, Bahrain, 18–22 December 2010; pp. 7–9. [Google Scholar] [CrossRef]

- Thakur, D.; Jiang, J. Design and Construction of a Wind Turbine Simulator for Integration to a Microgrid with Renewable Energy Sources. Electr. Power Components Syst. 2017, 45, 949–963. [Google Scholar] [CrossRef]

- Abbes, D.; Martinez, A.; Champenois, G.; Robyns, B. Real time supervision for a hybrid renewable power system emulator. Simul. Model. Pract. Theory 2014, 42, 53–72. [Google Scholar] [CrossRef]

- Islam, R.R.; Liao, M.; Vo, T.H.; Ravishankar, J. Experimental setup of a microgrid with wind and solar power emulators. In Proceedings of the 2014 IEEE 2nd International Conference on Electrical Energy Systems (ICEES), Chennai, India, 7–9 January 2014; pp. 9–14. [Google Scholar] [CrossRef]

| S. No | References | Variable Required to Build an Emulator (Motor) | Dynamics Consideration for Emulator | Converter and Control Technique for Emulator | Hardware Implementation | Emulator Accuracy | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Curve | Tower Shadow Effect | Wind Shear Effect | Torque Compensation | Inertia Compensation | ||||||

| 1 | [9] | Speed | ✓ | Armature voltage control | Microcomputer | * | ||||

| 2 | [7] | Speed | ✓ | Current control | DSP | * | ||||

| 3 | [10] | Speed | ✓ | DC–DC converter | dSPACE DS1104 | * | ||||

| 4 | [11] | Speed | ✓ | DC–DC converter | dSPACE DS1104 | * | ||||

| 5 | [12] | Speed | ✓ | ✓ | ✓ | DC drive with torque control | dSPACE | ** | ||

| 6 | [13] | Speed | ✓ | ✓ | PWM IGBT vector control | DSP | *** | |||

| 7 | [14] | Speed | ✓ | ✓ | DC–DC converter | DSP | *** | |||

| 8 | [15,16] | Motor current | ✓ | ✓ | ✓ | Single phase half-controlled DC drive with torque control | MATLAB/Simulink real-time control software interfaced with I/O board | **** | ||

| 9 | [17] | Speed | ✓ | ✓ | Control rectifier and current control | DSP TMS320F28335 | *** | |||

| 10 | [18] | Speed | ✓ | ✓ | ✓ | 3-phase semi-controlled rectifier | DSP TMS320F28335 | ** | ||

| 11 | [19] | Position | ✓ | ✓ | DC–DC converter with current controller | DSP and FPGA board | ** | |||

| 12 | [20] | Speed | ✓ | Thyristor controlled armature current | DSP | * | ||||

| 13 | [21] | Speed | ✓ | Thyristor rectifier | Variable speed drive from Schneider Electric (ATV312HU15M3) | ** | ||||

| 14 | [22] | Speed | ✓ | DC–DC converter | FPGA board | * | ||||

| 15 | [23,24] | Speed | ✓ (Furling angle) | DC–DC converter | Lab Master I/O board | * | ||||

| 16 | [25] | Speed | ✓ | Thyristor controlled current controller regulator | DSP TMS 320LF2407 | * | ||||

| 17 | [26] | Speed | ✓ | Armature voltage regulator | LabVIEW | * | ||||

| 18 | [27] | Speed | ✓ | H bridge DC–DC converter | TMS 320LF28335 | * | ||||

| 19 | [28] | Speed and Current | ✓ | DC–DC converter | dSPACE DS1104 | * | ||||

| 20 | [30] | Speed | ✓ | DC drive | Arduino uno | * | ||||

| 21 | [31] | Speed | ✓ | DC–DC converter | Arduino mega | * | ||||

| 22 | [32] | Speed | ✓ | DC–DC converter | dSPACE DS1104 | * | ||||

| 23 | [33] | Speed | ✓ | DC–DC Converter | MATLAB/Simulink | * | ||||

| S. No | References | Variable Required to Build an Emulator (Motor) | Dynamics Consideration for Emulator | Converter and Control Technique for Emulator | Hardware Implementation | Emulator Accuracy | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Curve | Tower Shadow Effect | Wind Shear Effect | Torque Compensation | Inertia Compensation | ||||||

| 1 | [35,36] | Torque and speed | ✓ | IGBT inverter with PI controller | Intel 80C196KD microcontroller | * | ||||

| 2 | [37] | Speed | ✓ | ✓ | Commercial frequency inverter (Danfoss-VLT 5022) | dSPACE | ** | |||

| 3 | [38] | Torque and speed | ✓ | Inverter with direct torque control | dSPACE | * | ||||

| 4 | [39] | Speed | ✓ | ✓ | ✓ | Inverter and dynamic torque control | DSP TMS320F2833 | ** | ||

| 5 | [40] | Speed | ✓ | Inverter and dynamic torque control | DSP dsPIC30f4011 | * | ||||

| 6 | [78] | Speed | ✓ | Inverter and torque control | dSPACE | * | ||||

| 7 | [41] | Speed | ✓ | ✓ | ✓ | Inverter and torque control | – | ** | ||

| 8 | [43] | Speed | ✓ | Torque-controlled drive | PLC | * | ||||

| 9 | [44] | Speed and torque | ✓ | Frequency converter and direct torque control | PIC32MX360F512L | * | ||||

| 10 | [45,46,47,48] | Speed | ✓ | ✓ | Off-the-shelf inverter | DSP | *** | |||

| 11 | [49] | Speed | ✓ | ✓ | IGBT inverter with PI controller | DSP | * | |||

| 12 | [50] | Speed | ✓ | ✓ | ✓ | 3-phase IGBT inverter | DSP | *** | ||

| 13 | [51] | Speed | ✓ | ✓ | Frequency converter | PLC, DSP, and SCADA | *** | |||

| 14 | [52] | Speed and torque | ✓ | 3-phase inverter | DAQ NI 6211 | * | ||||

| 15 | [53,54] | Torque | ✓ | Frequency inverter | DSP TMSF28335 | * | ||||

| 16 | [55] | Torque | ✓ | Torque control | DSP TMSF28335 | * | ||||

| 17 | [56] | Speed | ✓ | ✓ | AC drive | DSP | *** | |||

| 18 | [57] | Speed | ✓ | VACON variable-frequency drive | DCS based on Beckhoff PLC | ** | ||||

| 19 | [58] | Speed | ✓ | 3-phase IGBT Inverter with Volt/Hertz control | dSPACE | * | ||||

| 20 | [59] | Speed | ✓ | AC drive | PIC16F876A | * | ||||

| 21 | [60] | Torque and Speed | ✓ | Variable speed drive | LabVIEW | *** | ||||

| 22 | [61] | Torque and Speed | ✓ | Variable speed drive | LabVIEW | **** | ||||

| 23 | [62] | Torque and Speed | ✓ | Variable speed drive | DSP TMS320F28377 | * | ||||

| 24 | [63] | Torque and Speed | ✓ | Inverter | DSP | * | ||||

| 25 | [64] | Speed | ✓ | Field-oriented control | – | * | ||||

| 26 | [65] | Speed | ✓ | Frequency converter | SCADA | ** | ||||

| 27 | [66] | Speed | ✓ | IGBT driver board | Danfoss FC-51 Microdrive | ** | ||||

| 28 | [67] | Speed | ✓ | Variable-speed AC drive (Parker SSD Drive) | dSAPCE | *** | ||||

| S. No. | Reference | Emulator Model | Simulation Software | Platform | Computational Speed | Accuracy of the Emulator |

|---|---|---|---|---|---|---|

| 1 | [74] | DFIG-based emulator | VHDL and synthesized by Xilinx ISE | FPGA | 40-fold faster simulation speed than the PC-based simulation | ** |

| 2 | [75] | BLDC-based emulator | Matlab/Simulink | RT-LAB | - | ** |

| 3 | [76] | Real turbine model with gear box | LabVIEW DSC module and Matlab/Simulink | LabVIEW simulation interface toolkit | - | ** |

| 4 | [77] | 5 MW NREL | Matlab/Simulink | NVIDIA Jetson TK1 board | 2.73-fold faster speed compared to MATLAB | **** |

| S. No. | Methods | References | Cost | Complexity | Hardware Implementation | Accuracy |

|---|---|---|---|---|---|---|

| 1 | Current/power reference | [7,9,10,20,35,36] | Less | Less | Easy | Moderate |

| 2 | Open loop | [21,22,37] | High | Moderate | Easy | Moderate |

| 3 | Observer based | [19,38] | Less | Moderate | Moderate | Less |

| 4 | Torque compensation-based torque control | [13,14,15,16,17,18,39,40,41,42,78] | Moderate | Less | Easy | High |

| 5 | Improved inertia compensation | [56] | Less | Moderate | Easy | High |

| 6 | Lookup table | [58] | Less | Less | Easy | Less |

| 7 | Power and speed relation | [59] | High | Less | Easy | Less |

| 8 | approximation (polynomial approximation) | [23,24,62] | High | Less | Easy | Less |

| 9 | FAST Simulator | [60,61] | Less | Less | Easy | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajendran, S.; Diaz, M.; Devi, V.S.K.; Jena, D.; Travieso, J.C.; Rodriguez, J. Wind Turbine Emulators—A Review. Processes 2023, 11, 747. https://doi.org/10.3390/pr11030747

Rajendran S, Diaz M, Devi VSK, Jena D, Travieso JC, Rodriguez J. Wind Turbine Emulators—A Review. Processes. 2023; 11(3):747. https://doi.org/10.3390/pr11030747

Chicago/Turabian StyleRajendran, Saravanakumar, Matias Diaz, V. S. Kirthika Devi, Debashisha Jena, Juan Carlos Travieso, and José Rodriguez. 2023. "Wind Turbine Emulators—A Review" Processes 11, no. 3: 747. https://doi.org/10.3390/pr11030747

APA StyleRajendran, S., Diaz, M., Devi, V. S. K., Jena, D., Travieso, J. C., & Rodriguez, J. (2023). Wind Turbine Emulators—A Review. Processes, 11(3), 747. https://doi.org/10.3390/pr11030747