Study on the Variation Laws and Fractal Characteristics of Acoustic Emission during Coal Spontaneous Combustion

Abstract

:1. Introduction

2. Experimental System and Experimental Protocol

2.1. Large-Scale Coal Spontaneous Combustion AE Experiment

2.1.1. Preparation and Analysis of Coal Samples

2.1.2. Experimental System

2.1.3. Experimental Methods and Steps

- (1)

- First, the 4 waveguide rods are extended into the furnace through the pores, and the horizontal distance of each waveguide rod from the nearest vent is 10 cm, 20 cm, 20 cm, and 40 cm. The distance from the bottom of the furnace is 37 cm, 35 cm, 15 cm, and 35 cm. The 4 waveguide rods are defined as channels 1–4, and 1 thermocouple probe is arranged at the top of the 4 waveguide rods and 3 outlets to measure the temperature of the surrounding coal body.

- (2)

- After the arrangement is completed, 3 tons of raw coal are poured into the inside of the furnace body, the top cover of the furnace body is covered, and the top cover is sealed with glue, the ventilation hole is reserved, and the air is pressed into the heating tank by the air pump, and the heated air enters the bottom of the furnace body through the metal hose, flows out through 3 outlets, and continuously heats the coal body inside the furnace body, of which the ventilation pipe is located in the middle of the furnace body close to the bottom of the furnace body.

- (3)

- The top of the waveguide rod extends into the inside of the furnace, and the tail end is connected to the AE probe. The sound wave can be transmitted to the AE probe by low loss through the waveguide rod to be monitored and recorded, and the waveform is finally saved to the AE host.

2.2. Coal Sample Low-Temperature Nitrogen Adsorption Experiment with Different Temperature Treatment

3. Study on the Thermal Damage Law of Coal Body during Spontaneous Combustion and Heating Process of Coal

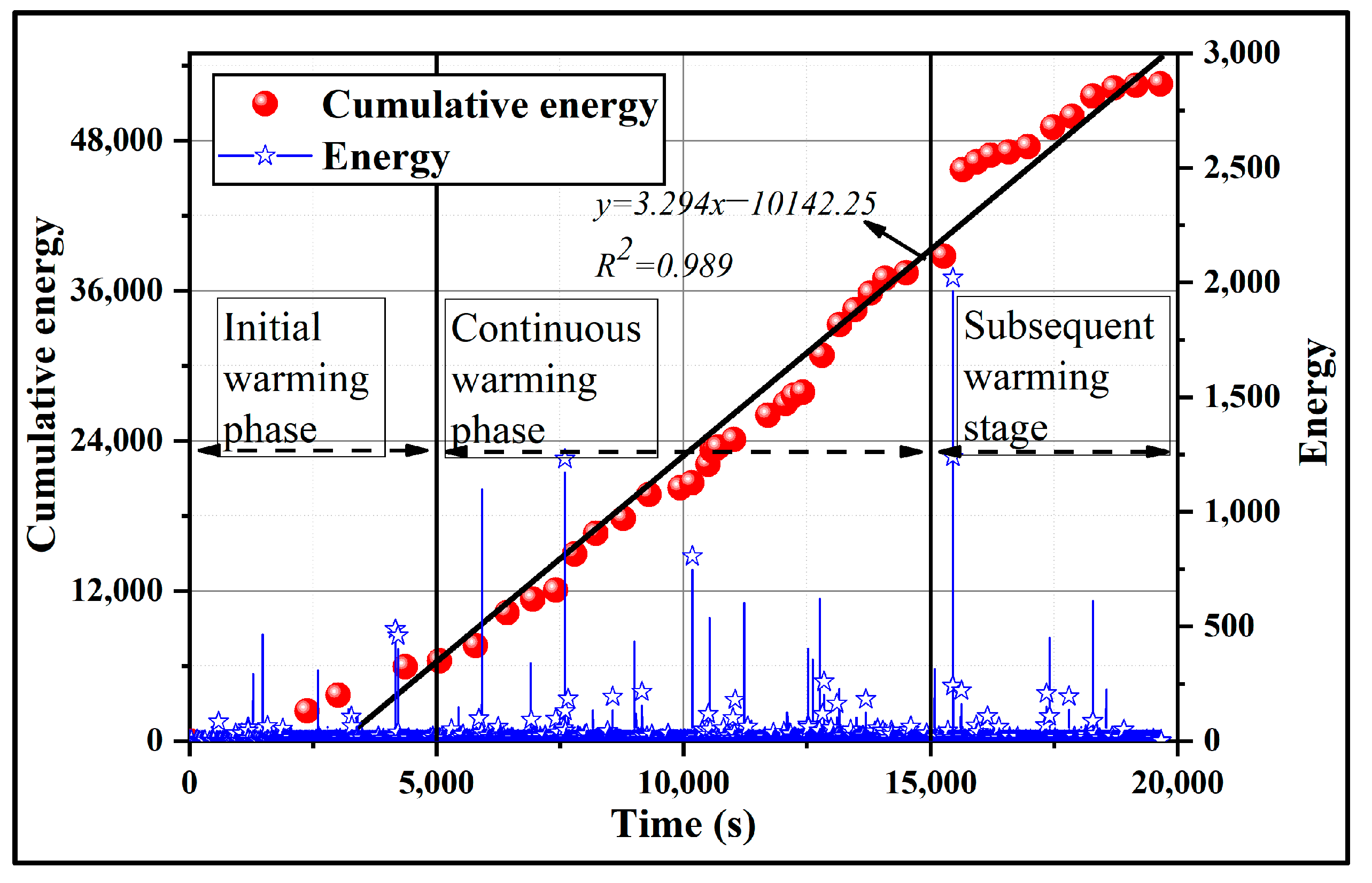

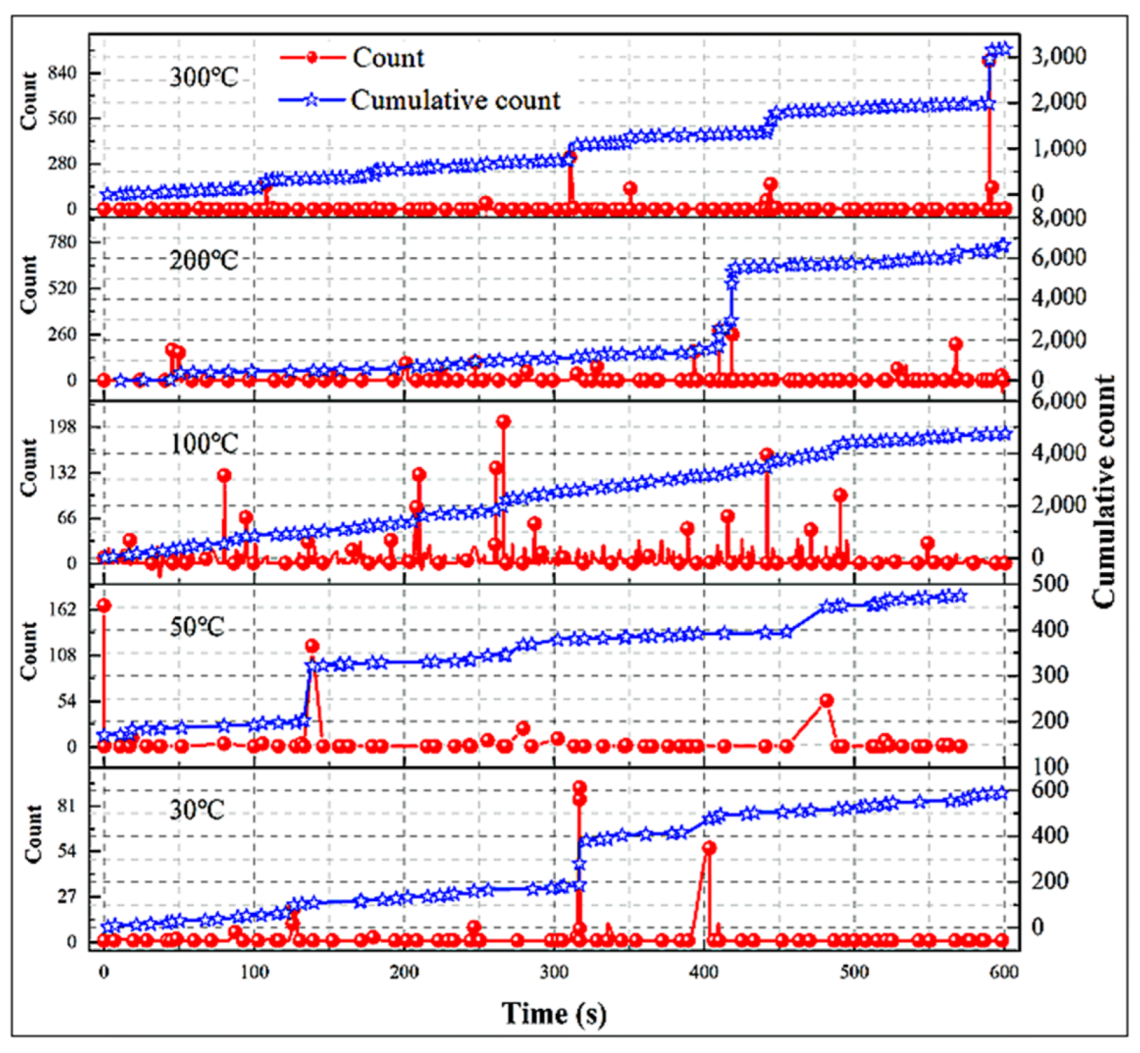

3.1. AE Counting and Energy Analysis during Spontaneous Combustion and Heating of Coal

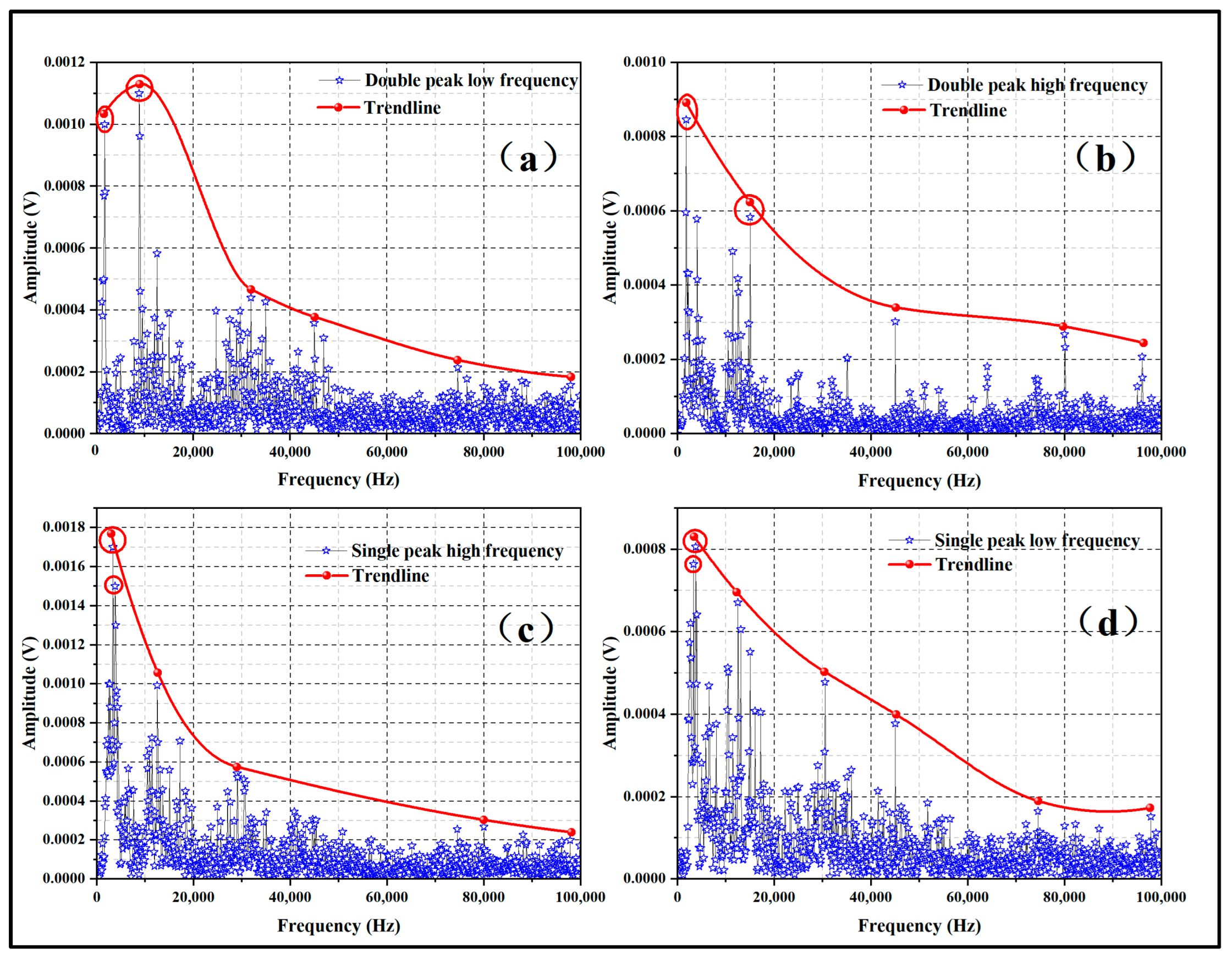

3.2. Time-Frequency Analysis of AE Signals during Coal Spontaneous Combustion Heating

4. Study on the Fractal Law of Coal Spontaneous Combustion Heating Process

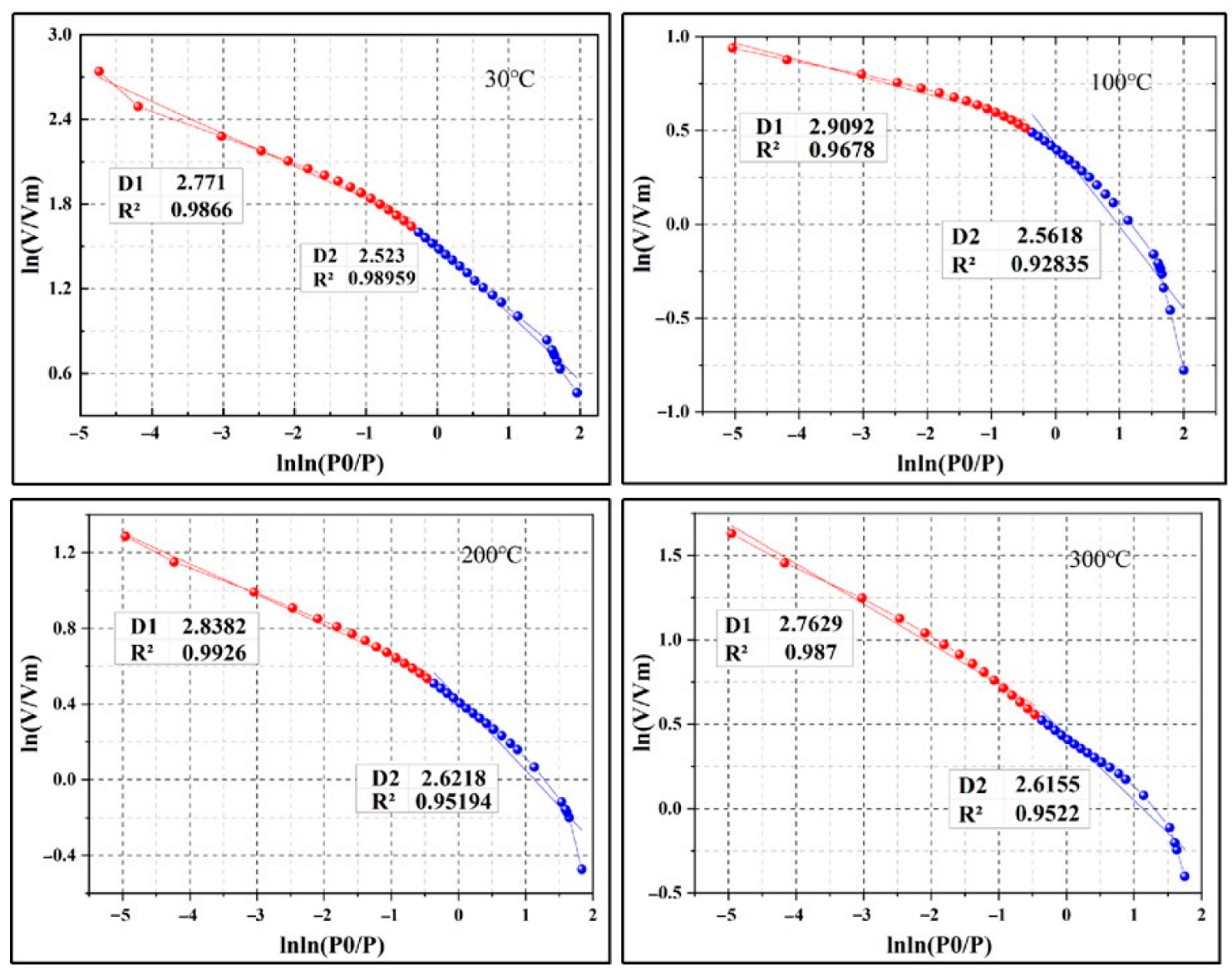

4.1. Fractal Law of Pore Structure of Coal Body after Treatment at Different Temperatures

4.2. Fractal Law of Large-Scale Coal Spontaneous Combustion AE Count

4.2.1. Fractal Theory and the Determination of Phase Space Dimensions

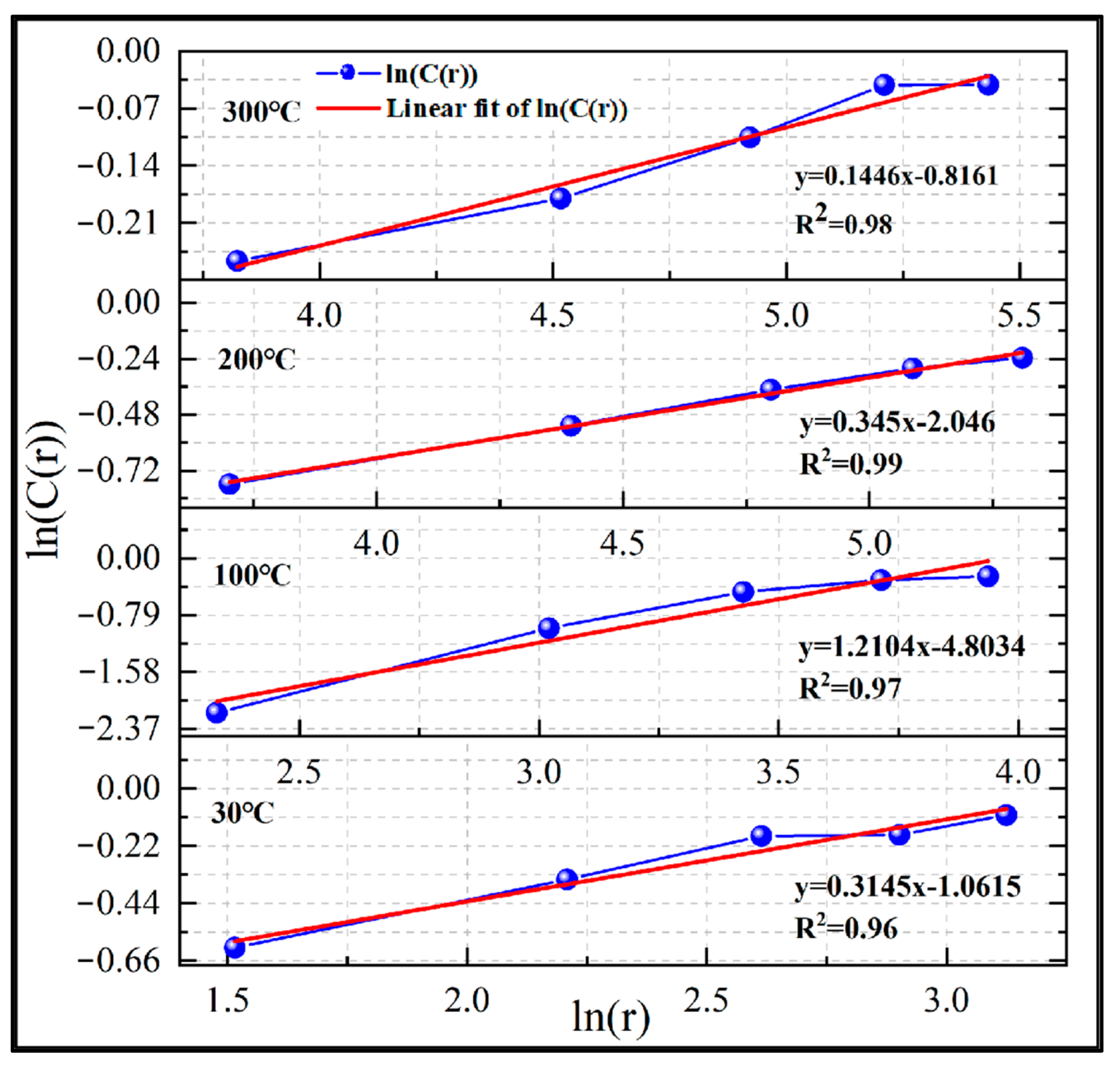

4.2.2. Determination of Fractal Features of AE Counts

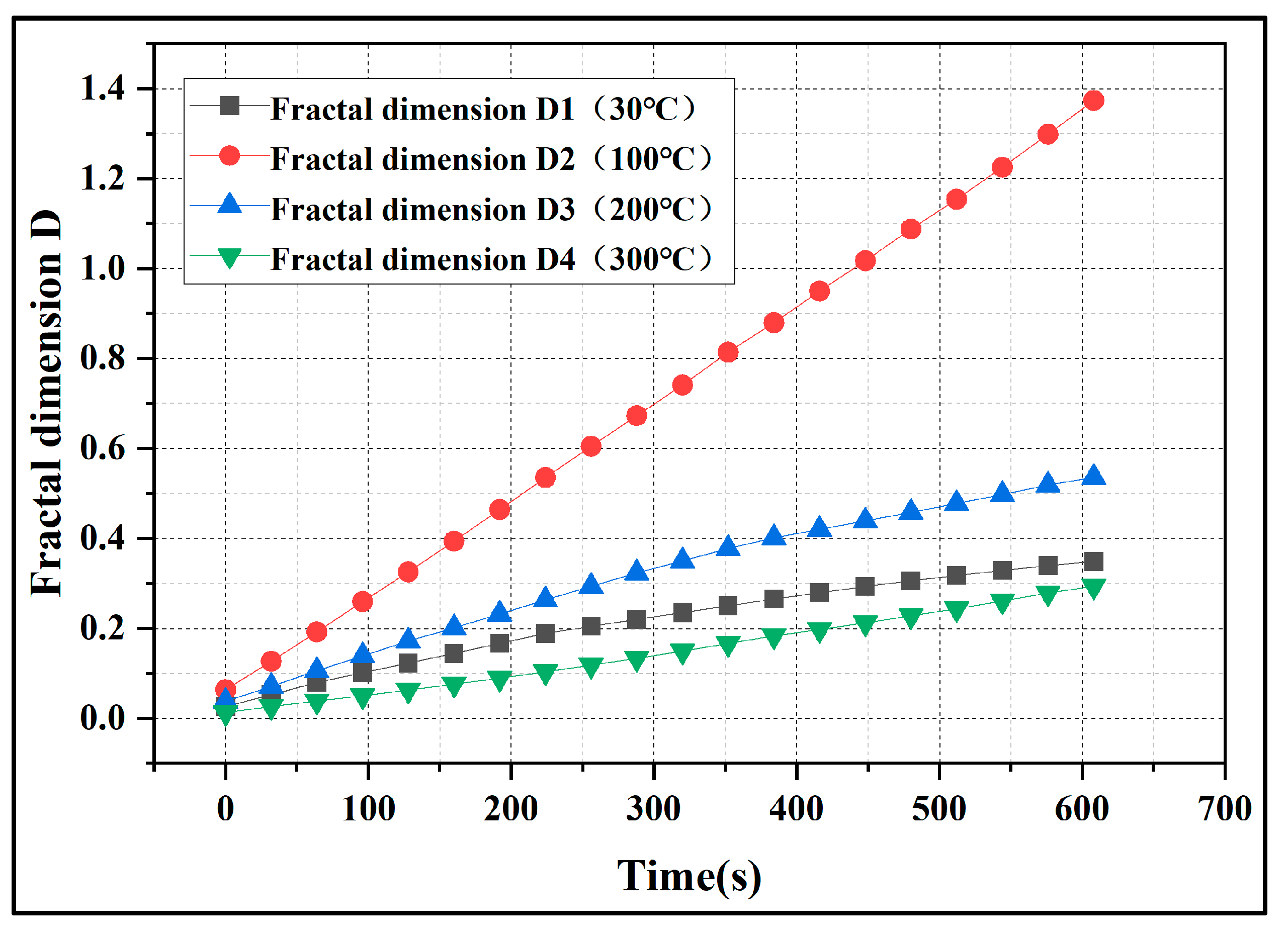

4.2.3. Fractal Characteristics of AE Counting

4.3. Discussion

5. Conclusions

- With the increase in time and temperature, the count and energy of AE continue to increase, and the maximum count and maximum energy of AE continue to increase. The cumulative count of AE and the cumulative energy of AE continue to increase; it shows that the integrity of coal samples is destroyed during the heating process, the pore structure is constantly complex, the number of pores is increasing, the thermal damage rupture is increasing, and the AE signal released by the coal body is continuously enhanced.

- The probability of the occurrence of high-frequency main frequency AE signals increases with the increase in temperature. The average frequency of the main frequency also increases. The main frequency of the acoustic transmission signal and its average frequency show a positive correlation with temperature; it shows that with the increase in temperature, the thermal damage of the coal body increases, and the AE signal continues to increase.

- During the spontaneous combustion heating process of the coal body, with the increase of time and the increase of temperature, the fractal dimension of the low-temperature nitrogen adsorption curve and the fractal dimension of the AE count appear to rise first and then decline. It shows that due to the thermal expansion of the coal body in the process of heating up, the growth of the number of pores in the coal body rises first and then declines. The AE signal intensity of the coal body rises first and then declines, and the AE signal from order to disorder, from disorder to order, shows an increasing trend.

- The law that the pore structure of the coal body is continuously generated and gradually enhanced during the heating process of the coal body further illustrated that the AE signal in the process of heating and heating of the coal body comes from the generation of the pore structure. The number of pores in the spontaneous combustion and heating process of the coal body continues to increase, and the complexity increases, which in turn leads to the continuous enhancement of the AE signal. Therefore, the AE signal provides favorable conditions for monitoring and early warning of coal spontaneous combustion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, L.X. The responsibility and development of coal under the double carbon target. Coal Econ. Res. 2021, 41, 1. [Google Scholar] [CrossRef]

- Liu, C.; Xie, J.; Xin, L. A review of the theory and technology of spontaneous combustion prediction and forecasting of coal. Min. Saf. Environ. Prot. 2019, 46, 92–95+99. [Google Scholar]

- Lu, W.; Wen, J.M.; Wang, D.; Zhang, W.R.; Hu, X.M.; Wu, H.; Kong, B. Study on gas transport characteristics of positive pressure beam tube system and its application to coal spontaneous combustion early warning. J. Clean. Prod. 2021, 316, 128342. [Google Scholar] [CrossRef]

- Kong, B.; Li, J.H.; Lu, W.; Fu, W.; Song, H.Z.; Liu, J.F. Research on a Spontaneous Combustion Prevention System in Deep Mine: A Case Study of Dongtan Coal Mine. Combust. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Zhang, W.T.; Hou, Y.H.; Peng, D.H.; Fan, C. Distributed fiber optic temperature measurement and fire warning system in coal mines. In Proceedings of the 23rd National Conference on Coal Mine Automation and Informatization and the 5th China High Level Forum on Coal Mine Informatization and Automation, Beijing, China, 6–7 December 2013; pp. 74–80. [Google Scholar]

- Zhang, X.H.; Liu, Q.; Zheng, X.Z.; Wang, W.F. Analysis of ZigBee-based wireless self-assembled temperature measurement system in mining area. Coal Eng. 2012, 9, 122–124. [Google Scholar]

- Ganne, P.; Vervoort, A.; Wevers, M. Quantification of pre-peak brittle damage: Correlation between acoustic emission and observed micro-fracturing. Int. J. Rock Mech. Min. Sci. 2007, 44, 720–729. [Google Scholar] [CrossRef]

- Ishida, T.; Kanagawa, T.; Kanaori, Y. Source distribution of acoustic emissions during an in-situ direct shear test: Implications for an analog model of seismogenic faulting in an inhomogeneous rock mass. Eng. Geol. 2010, 110, 66–76. [Google Scholar] [CrossRef] [Green Version]

- Han, J.; Han, S.Z.; Ma, S.W.; Zhang, L.Y.; Cao, C. Study on acoustic emission characteristics of coal bodies of different strengths. Chin. J. Undergr. Space Eng. 2021, 17, 739–747. [Google Scholar]

- Kong, B.; Zhuang, Z.D.; Zhang, X.Y.; Jia, S.; Lu, W.; Zhang, X.Y.; Zhang, W.R. A study on fractal characteristics of acoustic emission under multiple heating and loading damage conditions. J. Appl. Geophys. 2022, 197, 104532. [Google Scholar] [CrossRef]

- Kong, B.; Zhong, J.H.; Hu, X.M.; Xin, L.; Zhang, B.; Zhang, X.L.; Zhuang, Z.D. Study on the change pattern of acoustic emission signal and generation mechanism during coal heating and combustion process. Coal Sci. Technol. 2023, 1–8. [Google Scholar] [CrossRef]

- Kong, B.; Zhu, S.X.; Zhang, W.R.; Sun, X.L.; Lu, W.; Ma, Y.K. Mechanical deterioration and thermal deformations of high-temperature-treated coal with evaluations by EMR. Geomechanics and Engineering. Geomech. Eng. 2023, 32, 233–244. [Google Scholar] [CrossRef]

- Chen, C. Laboratory Study of Deformational Characteristics and Acoustic Emission Properties of Coal with Different Strengths under Uniaxial Compression. Minerals 2021, 11, 1070. [Google Scholar]

- Zhang, R.; Liu, J.; Sa, Z.; Wang, Z.; Lu, S.; Wang, C. Experimental investigation on multi-fractal characteristics of acoustic emission of coal samples subjected to true triaxial loading-unloading. Fractals 2020, 28, 2050092. [Google Scholar] [CrossRef]

- Wang, H.Y.; Wang, G.D.; Zhang, G.J.; Du, F.; Ma, J. Acoustic Emission Response Characteristics of Anthracitic Coal under Uniaxial Compression. Shock. Vib. 2020, 1–12. [Google Scholar] [CrossRef]

- Li, H.G.; Li, H.M.; Gao, B.B. Study on acoustic emission characteristics of rupture process of different coal-thick coal-rock assemblies. J. Henan Polytech. Univ. (Nat. Sci. Ed.) 2021, 40, 30–37. [Google Scholar]

- Cai, Y.; Liu, D.; Yao, Y.; Li, J.; Liu, J. Fractal Characteristics of Coal Pores Based on Classic Geometry and Thermodynamics Models. Acta Geol. Sin. 2011, 85, 1150–1162. [Google Scholar] [CrossRef]

- Guo, H.; Yuan, L.; Cheng, Y.; Wang, K.; Xu, C. Experimental investigation on coal pore and fracture characteristics based on fractal theory. Powder Technol. 2019, 346, 341–349. [Google Scholar] [CrossRef]

- Li, Z.H.; Tian, H.; Niu, Y.; Wang, E.Y.; Zhang, X.; He, S.; Wang, F.Z.; Zheng, A.Q. Study on the acoustic and thermal response characteristics of coal samples with various prefabricated crack angles during loaded failure under uniaxial compression. J. Appl. Geophys. 2022, 200, 104618. [Google Scholar] [CrossRef]

- Zhao, S.; Chen, X.J.; Li, X.J.; Qi, L.L.; Zhang, G.X. Experimental analysis of the effect of temperature on coal pore structure transformation. Fuel 2021, 305, 121613. [Google Scholar] [CrossRef]

- Yi, M.H.; Cheng, Y.P.; Wang, C.H.; Wang, Z.Y.; Hu, B.; He, X.X. Effects of composition changes of coal treated with hydrochloric acid on pore structure and fractal characteristics. Fuel 2021, 294, 120506. [Google Scholar] [CrossRef]

- Xu, C.P.; Li, H.; Lu, Y.; Liu, T.; Lu, J.X.; Shi, S.L.; Ye, Q.; Jia, Z.Z.; Wang, Z. Influence of microwave-assisted oxidant stimulation on pore structure and fractal characteristics of bituminous coal based on low-temperature nitrogen adsorption. Fuel 2022, 327, 125173. [Google Scholar] [CrossRef]

- Jiang, L.; Chen, Z.; Ali, S.F. Thermal-hydro-chemical-mechanical alteration of coal pores in underground coal gasification. Fuel 2020, 262, 116543. [Google Scholar] [CrossRef]

- Cheng, Q.Y.; Huang, B.X.; Li, Z.H. Research status of porosity and fracture of coal. Coal Eng. 2011, 12, 91–93. [Google Scholar]

- Li, H.; Shi, S.L.; Lu, J.X.; Ye, Q.; Lu, Y.; Zhu, X.N. Pore structure and multifractal analysis of coal subjected to microwave heating. Powder Technol. 2019, 346, 97–108. [Google Scholar] [CrossRef]

- Kong, B.; Wang, E.Y.; Li, Z.H.; Lu, W. Study on the feature of electromagnetic radiation under coal oxidation and temperature rise based on multifractal theory. Fractals 2019, 27, 1950038. [Google Scholar] [CrossRef]

- Yang, S.Q. Study on the Evolution of Microstructure and Mechanical Response Law of Oil Shale under High Temperature Real-Time Action. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2021. [Google Scholar]

- Li, J.H.; Xue, C.Z.; Han, Q. Study on the evolution characteristics of pore fractures in coal under different thermal fracture temperatures. Coal Mine Saf. 2020, 51, 22–25+29. [Google Scholar]

- Lu, W.; Zhuang, Z.; Zhang, W.; Zhang, C.; Song, S.; Wang, R.; Kong, B. Study on the Pore and Crack Change Characteristics of Bituminous Coal and Anthracite after Different Temperature Gradient Baking. Energy Fuels 2021, 35, 19448–19463. [Google Scholar] [CrossRef]

- Gan, Q.; Xu, J.; Peng, S.; Yan, F.; Wang, R.; Cai, G. Effects of heating temperature on pore structure evolution of briquette coals. Fuel 2021, 296, 120651. [Google Scholar] [CrossRef]

- Gbadamosi, A.R.; Onifade, M.; Genc, B.; Rupprecht, S. Analysis of spontaneous combustion liability indices and coal recording standards/basis. Int. J. Min. Sci. Technol. 2020, 30, 723–736. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Meng, Q.R.; Kang, T.H. Micro-CT experimental technology and meso-investigation on thermal fracturing characteristics of granite. Rock Mech. Eng. 2008, 27, 28–34. [Google Scholar]

- Kong, B.; Wang, E.; Li, Z.; Wang, X.; Chen, L.; Kong, X. Nonlinear characteristics of AEs during the deformation and fracture of sandstone subjected to thermal treatment. Int. J. Rock Mech. Min. Sci. 2016, 90, 43–52. [Google Scholar] [CrossRef]

- Zhao, K.; Yang, D.X.; Gong, C.; Zhuo, Y.L.; Wang, X.J.; Zhong, W. Evaluation of internal microcrack evolution in red sandstone based on time–frequency domain characteristics of acoustic emission signals. Constr. Build. Mater. 2020, 260, 120435. [Google Scholar] [CrossRef]

- Jia, X.N.; Jiang, Q.G.; He, M.C.; Ren, F.Q.; Du, S. Characteristic analysis of acoustic radio frequency spectroscopy of rhesus rock burst experiment in Laizhou granite. J. Undergr. Space Eng. 2018, 14, 51–57. [Google Scholar]

- Song, X.X.; Tang, Y.G.; Li, W.; Wang, S.Q.; Yang, M.M. Fractal characteristics of structural coal adsorption holes in Zhongliangshannan Mine. J. China Coal Soc. 2013, 38, 134–139. [Google Scholar]

- Ji, H.G.; Wang, J.C.; Shan, X.Y.; Cai, M.F. Fractal characteristics of acoustic emission process of concrete materials and their application in fracture analysis. Chin. J. Rock Mech. Eng. 2001, 6, 801–804. [Google Scholar]

- Tan, J.N.; Wang, B.; Feng, T.; Ning, Y.; Liu, B.B.; Zhao, F.J. acoustic emission characteristics of anchored sandstone under uniaxial compression and its connection with rock burst. J. Cent. South Univ. (Nat. Sci. Ed.) 2021, 52, 2828–2838. [Google Scholar]

- Ding, X.; Xiao, X.C.; Lv, X.F.; Wu, D.; Wang, L.; Fan, Y.F. Study on fractal characteristics and acoustic emission law of coal body rupture. J. China Coal Soc. 2018, 43, 3080–3087. [Google Scholar]

- Gao, B.; Li, H.; Li, H. Study on Acoustic Emission and Fractal Characteristics of Different Damage Types of Rock. J. Undergr. Space Eng. 2015, 11, 358–363. [Google Scholar]

- Gao, B.B.; Li, H.G.; Li, L.; Wang, X.L.; Yu, S.J. acoustic emission and fractal characteristics of soft hard coals in the same group. Chin. J. Rock Mech. Eng. 2014, 33, 3498–3504. [Google Scholar]

- Jin, P.J.; Wang, E.Y.; Song, D.Z. Study on Correlation of Acoustic Emission and Plastic Strain Based on Coal-rock Damage Theory. Geomech. Eng. 2017, 12, 627–637. [Google Scholar] [CrossRef]

- Li, H.R.; Shen, R.X.; Qiao, Y.F.; He, M.C. acoustic emission signal characteristics and its critical slowing down phenomenon during the loading process of water-bearing sandstone. J. Appl. Geophys. 2021, 194, 104458. [Google Scholar] [CrossRef]

- Yang, X.H.; Ren, T.; He, X.Q. Experimental study of coal burst risk prediction using fractal dimension analysis of acoustic emission spatial distribution. J. Appl. Geophys. 2020, 177, 104025. [Google Scholar] [CrossRef]

- Wang, C.L.; Hou Xl Liao, Z.F.; Chen, Z.; Lu, Z.J. Experimental investigation of predicting coal failure using acoustic emission energy and load-unload response ratio theory. J. Appl. Geophys. 2019, 161, 76–83. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M. Multi-scale fractal analysis of pores in shale rocks. J. Appl. Geophys. 2017, 140, 1–10. [Google Scholar] [CrossRef]

- Chai, M.Y.; Hou, X.L.; Zhang, Z.X.; Duan, Q. Identification and prediction of fatigue crack growth under different stress ratios using acoustic emission data. Int. J. Fatigue 2022, 160, 106860. [Google Scholar] [CrossRef]

- Ambrosio, D.; Dessein, G.; Wagner, V.; Yahiaoui, M.; Paris, J.-Y.; Fazzini, M.; Cahuc, O. On the potential applications of acoustic emission in friction stir welding. J. Manuf. Processes 2022, 75, 461–475. [Google Scholar] [CrossRef]

| DT Coal Sample (Room Temperature) | |||||

|---|---|---|---|---|---|

| Vdaf, wt% | Cdaf/% | Hdaf/% | Odaf/% | Ndaf/% | St.d/% |

| 40.96 | 81.16 | 6.11 | 0.33 | 1.16 | 11.20 |

| Waveform Type | Single Peak High Frequency | Single Peak Low Frequency | Bimodal High Frequency | Bimodal Low Frequency |

|---|---|---|---|---|

| 30 °C | 10% | 30% | 40% | 20% |

| 50 °C | 10% | 20% | 70% | 0% |

| 100 °C | 10% | 20% | 20% | 50% |

| 200 °C | 10% | 0% | 60% | 30% |

| 300 °C | 0% | 10% | 80% | 10% |

| 30 °C | 100 °C | 200 °C | 300 °C | |

|---|---|---|---|---|

| D1 | 2.771 | 2.909 | 2.838 | 2.763 |

| D2 | 2.523 | 2.562 | 2.622 | 2.616 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, J.; Shi, L.; Liu, Z.; Lu, W.; Pan, X.; Zhuang, Z.; Jiao, L.; Kong, B. Study on the Variation Laws and Fractal Characteristics of Acoustic Emission during Coal Spontaneous Combustion. Processes 2023, 11, 786. https://doi.org/10.3390/pr11030786

Yin J, Shi L, Liu Z, Lu W, Pan X, Zhuang Z, Jiao L, Kong B. Study on the Variation Laws and Fractal Characteristics of Acoustic Emission during Coal Spontaneous Combustion. Processes. 2023; 11(3):786. https://doi.org/10.3390/pr11030786

Chicago/Turabian StyleYin, Jueli, Linchao Shi, Zhen Liu, Wei Lu, Xingsong Pan, Zedong Zhuang, Lei Jiao, and Biao Kong. 2023. "Study on the Variation Laws and Fractal Characteristics of Acoustic Emission during Coal Spontaneous Combustion" Processes 11, no. 3: 786. https://doi.org/10.3390/pr11030786

APA StyleYin, J., Shi, L., Liu, Z., Lu, W., Pan, X., Zhuang, Z., Jiao, L., & Kong, B. (2023). Study on the Variation Laws and Fractal Characteristics of Acoustic Emission during Coal Spontaneous Combustion. Processes, 11(3), 786. https://doi.org/10.3390/pr11030786