Corn Extrudates Enriched with Health-Promoting Ingredients: Physicochemical, Nutritional, and Functional Characteristics

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemical Reagents

2.2. Raw Materials

2.3. Formulations and Extrusion Process

2.4. Proximate Analysis of Extrudates

2.5. Physical Properties

2.5.1. Expansion Ratio and Bulk Density

2.5.2. Water Absorption Index and Water Solubility Index

2.5.3. Hardness

2.5.4. Color Measurement

2.6. Differential Scanning Calorimetry

2.7. Total Polyphenolic Content and Antioxidant Activity

2.8. In Vitro Protein Digestibility

2.9. In Vitro Starch Digestibility and Predicted Glycemic Index

2.10. Headspace–Electronic Nose Measurements

2.11. Sensory Analysis of the Extrudates

2.12. Statistical Analysis

3. Results

3.1. Proximate Composition of Extrudates

3.2. Extrudate Characteristics

3.2.1. Expansion Ratio and Bulk Density

3.2.2. Water Absorption Index and Water Solubility Index

3.2.3. Hardness

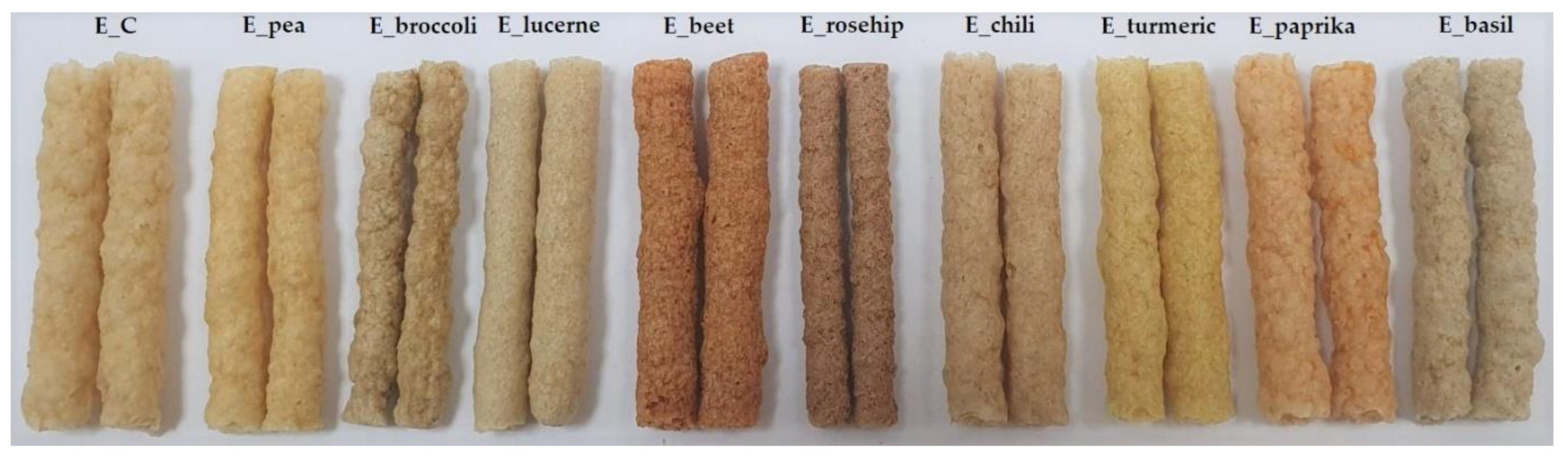

3.2.4. Color Analysis

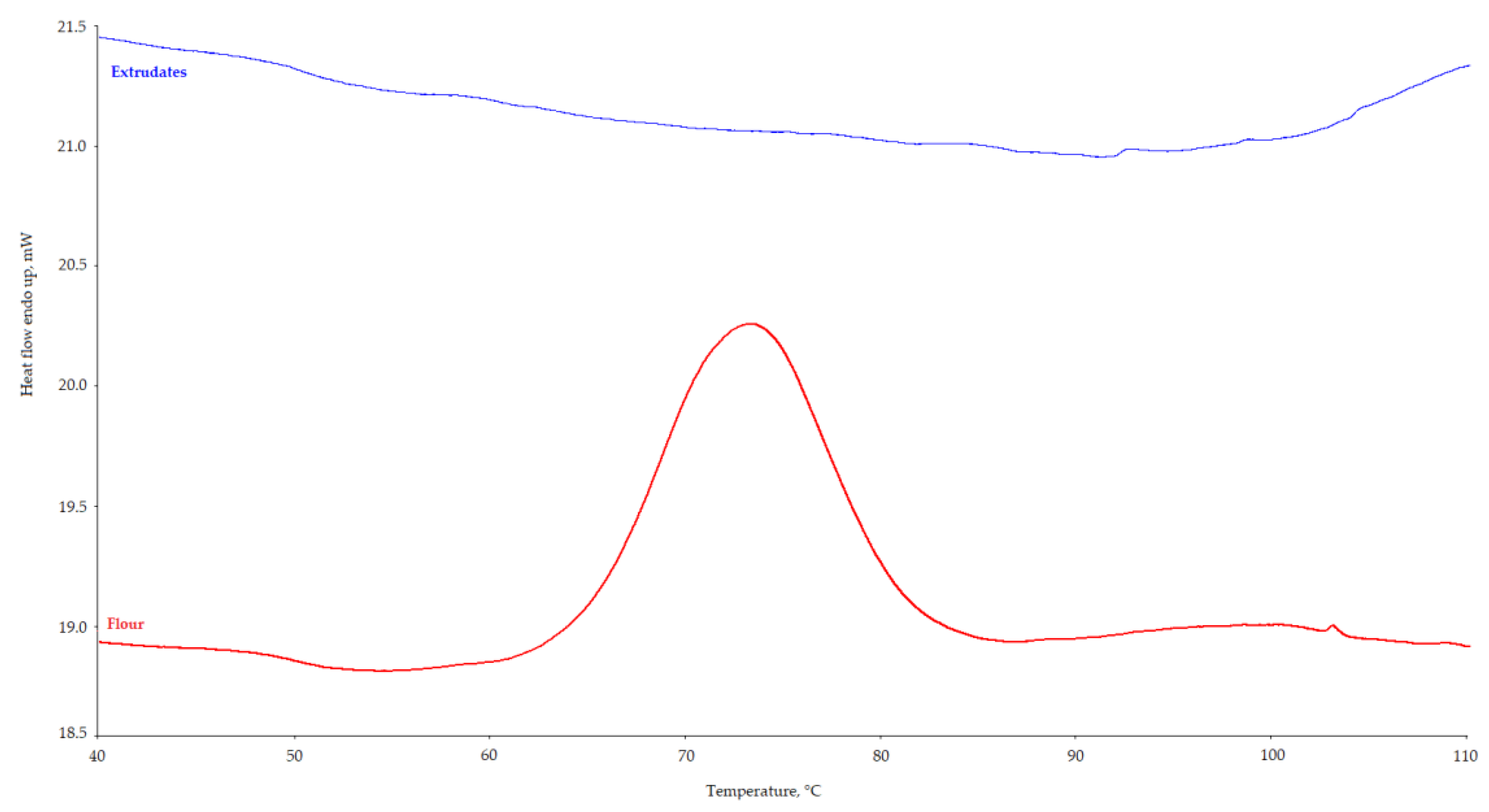

3.3. Thermal Properties

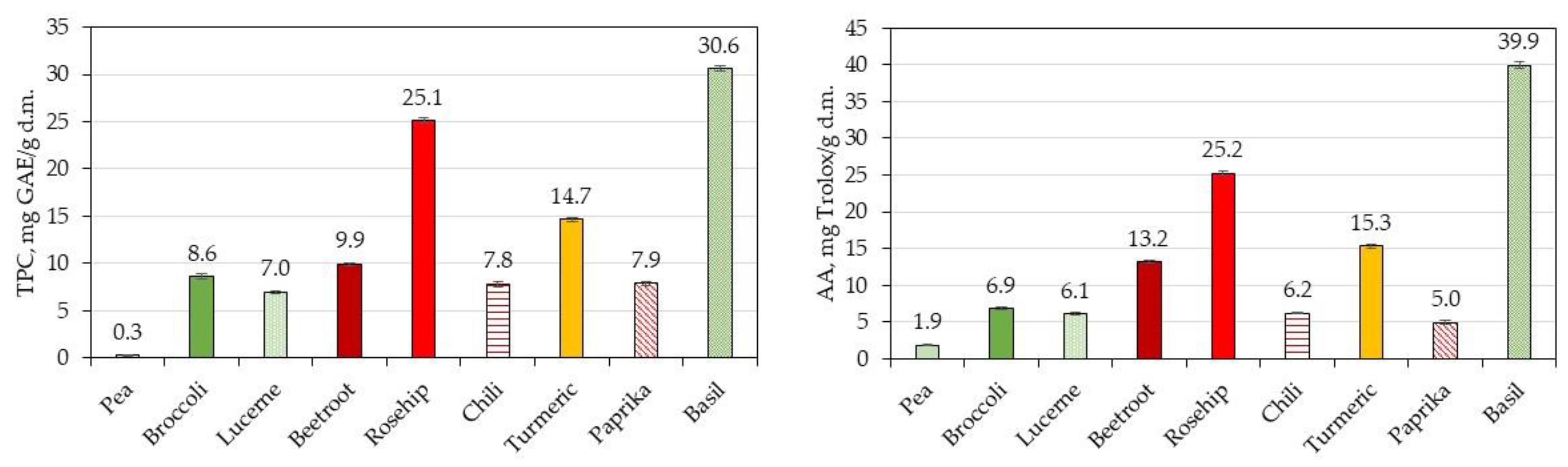

3.4. Total Polyphenolic Content and Antioxidant Activity of Extrudates

3.5. In Vitro Protein Digestibility of Extrudates

3.6. Predicted Glycemic Index of the Extrudates

3.7. Discrimination of the Extrudates with the Electronic Nose

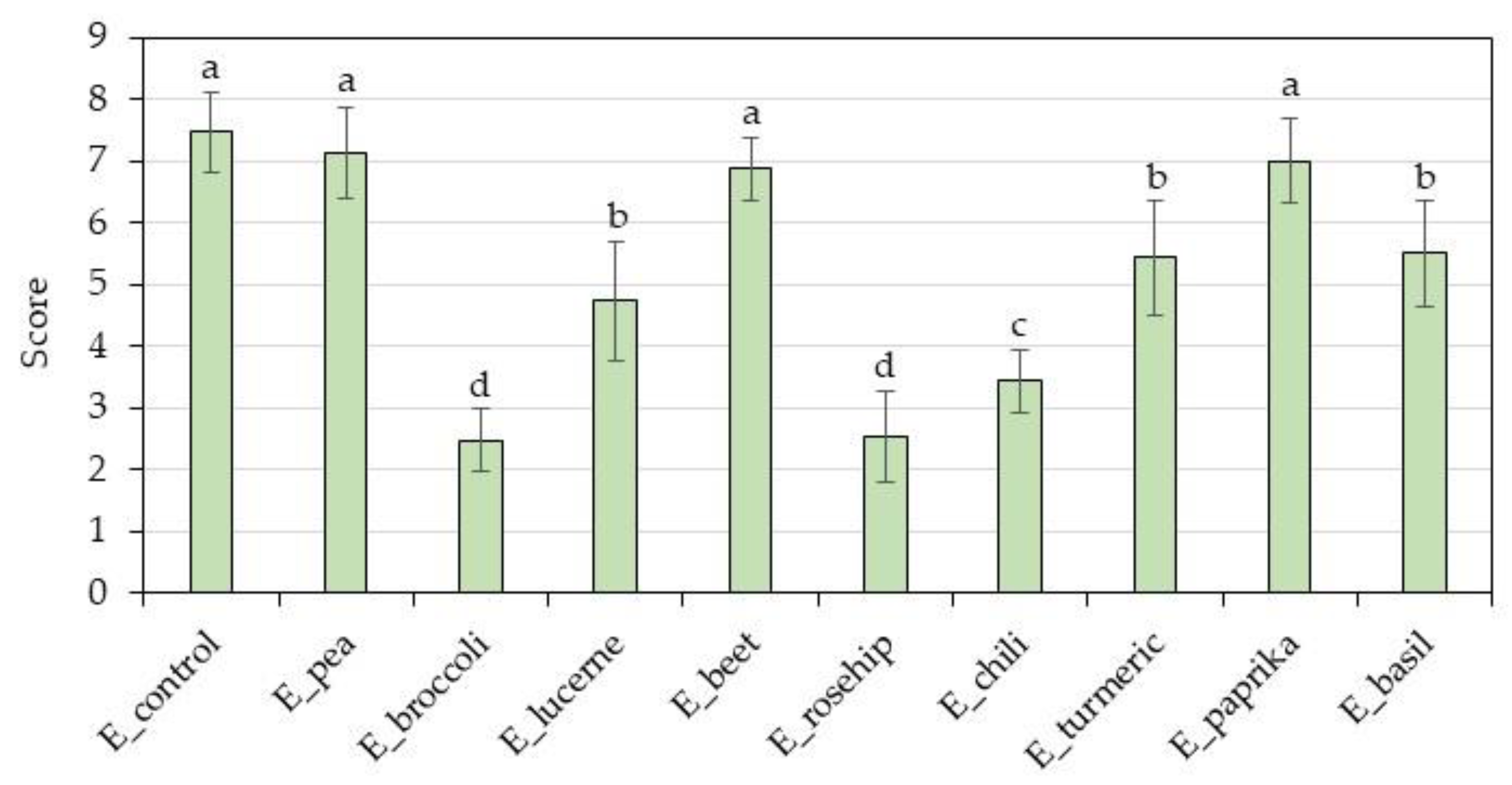

3.8. Sensory Evaluation of the Extrudates

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Igual, M.; Chiș, M.S.; Păucean, A.; Vodnar, D.C.; Ranga, F.; Mihăiescu, T.; Török, A.I.; Fărcas, A.; Martínez-Monzó, J.; García-Segovia, P. Effect on Nutritional and Functional Characteristics by Encapsulating Rose canina Powder in Enriched Corn Extrudates. Foods 2021, 10, 2401. [Google Scholar] [CrossRef]

- Market Research Report. Extrudet Snacks Market. 2022. Available online: https://www.fortunebusinessinsights.com/industry-reports/extruded-snacks-market-101510 (accessed on 22 October 2022).

- Brennan, M.A.; Derbyshire, E.; Tiwari, B.K.; Brennan, C.S. Ready-to-eat snack products: The role of extrusion technology in developing consumer acceptable and nutritious snacks. Int. J. Food Sci. Technol. 2013, 48, 893–902. [Google Scholar] [CrossRef]

- Vishwakarma, S.; Dalbhagat, C.G.; Mandliya, S.; Mishra, H.N. Investigation of natural food fortificants for improving various properties of fortified foods: A review. Food Res. Int. 2022, 156, 111186. [Google Scholar] [CrossRef] [PubMed]

- Tas, A.A.; Shah, A.U. The replacement of cereals by legumes in extruded snack foods: Science, technology and challenges. Trends Food Sci. Technol. 2021, 116, 701–711. [Google Scholar] [CrossRef]

- Mitrus, M.; Wójtowicz, A.; Oniszczuk, T.; Combrzyński, M.; Bouasla, A.; Kocira, S.; Czerwińska, E.; Szparaga, A. Application of Extrusion-Cooking for Processing of White and Red Bean to Create Specific Functional Properties. Appl. Sci. 2023, 13, 1671. [Google Scholar] [CrossRef]

- Santos, D.; Pintado, M.; Lopes da Silva, J.A. Potential nutritional and functional improvement of extruded breakfast cereals based on incorporation of fruit and vegetable by-products—A review. Innov. Food Sci. Emerg. Technol. 2018, 47, 517–524. [Google Scholar] [CrossRef]

- Medina-Rendon, E.A.; Guatemala-Morales, G.M.; Padilla-Camberos, E.; Corona-González, R.I.; Arriola-Guevara, E.; García-Fajardo, J.A. Production of extrudate food with mango by-products (Mangifera indica): Analysis of physical, chemical, and sensorial properties. Processes 2021, 9, 1660. [Google Scholar] [CrossRef]

- Kosińska-Cagnazzo, A.; Bocquel, D.; Marmillod, I.; Andlauer, W. Stability of goji bioactives during extrusion cooking process. Food Chem. 2017, 230, 250–256. [Google Scholar] [CrossRef]

- Bisharat, G.I.; Oikonomopoulou, V.P.; Panagiotou, N.M.; Krokida, M.K.; Maroulis, Z.B. Effect of extrusion conditions on the structural properties of corn extrudates enriched with dehydrated vegetables. Food Res. Int. 2013, 53, 1–14. [Google Scholar] [CrossRef]

- Singh, J.P.; Kaur, A.; Shevkani, K.; Singh, N.; Singh, B. Physicochemical characterisation of corn extrudates prepared with varying levels of beetroot (Beta vulgaris) at different extrusion temperatures. Int. J. Food Sci. Technol. 2016, 51, 911–919. [Google Scholar] [CrossRef]

- Oliveira, L.C.; Alencar, N.M.M.; Steel, C.J. Improvement of sensorial and technological characteristics of extruded breakfast cereals enriched with whole grain wheat flour and jabuticaba (Myrciaria cauliflora) peel. LWT 2018, 90, 207–214. [Google Scholar] [CrossRef]

- Kojić, J.; Belović, M.; Krulj, J.; Pezo, L.; Teslić, N.; Kojić, P.; Tukuljac, L.P.; Šeregelj, V.; Ilić, N. Textural, Color and Sensory Features of Spelt Wholegrain Snack Enriched with Betaine. Foods 2022, 11, 475. [Google Scholar] [CrossRef] [PubMed]

- Martin, A.; Schmidt, V.; Osen, R.; Bez, J.; Ortner, E.; Mittermaier, S. Texture, sensory properties and functionality of extruded snacks from pulses and pseudocereal proteins. J. Sci. Food. Agric. 2022, 102, 5011–5021. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Gutiérrez, M.G.; Sánchez-Madrigal, M.Á.; Quintero-Ramos, A. The extrusion cooking process for the development of functional foods. In Extrusion of Metals, Polymers and Food Products; Qamar, S.Z., Ed.; InTech: London, UK, 2017; pp. 83–102. [Google Scholar] [CrossRef]

- Prabha, K.; Ghosh, P.; Abdullah, S.; Joseph, R.M.; Krishnan, R.; Rana, S.S.; Pradhan, R.C. Recent development, challenges, and prospects of extrusion technology. Future Foods 2021, 3, 100019. [Google Scholar] [CrossRef]

- Choton, S.; Gupta, N.; Bandral, J.D.; Anjum, N.; Choudary, A. Extrusion technology and its application in food processing: A review. Pharma Innov. J. 2020, 9, 162–168. [Google Scholar] [CrossRef]

- Singha, P.; Muthukumarappan, K. Single screw extrusion of apple pomace-enriched blends: Extrudate characteristics and determination of optimum processing conditions. Food Sci. Technol. Int. 2018, 24, 447–462. [Google Scholar] [CrossRef]

- Jan, R.; Saxena, D.C.; Singh, S. Effect of extrusion variables on antioxidant activity, total phenolic content and dietary fibre content of gluten-free extrudate from germinated Chenopodium (Chenopodium album) flour. Int. J. Food Sci. Technol. 2017, 52, 2623–2630. [Google Scholar] [CrossRef]

- Bisharat, G.I.; Lazou, A.E.; Panagiotou, N.M.; Krokida, M.K.; Maroulis, Z.B. Antioxidant potential and quality characteristics of vegetable-enriched corn-based extruded snacks. J. Food Sci. Technol. 2015, 52, 3986–4000. [Google Scholar] [CrossRef]

- Patil, S.; Brennan, M.; Mason, S.; Brennan, C. The Effects of Fortification of Legumes and Extrusion on the Protein Digestibility of Wheat Based Snack. Foods 2016, 5, 26. [Google Scholar] [CrossRef]

- Dilrukshi, H.N.N.; Torrico, D.D.; Brennan, M.A.; Brennan, C.S. Effects of extrusion processing on the bioactive constituents, in vitro digestibility, amino acid composition, and antioxidant potential of novel gluten-free extruded snacks fortified with cowpea and whey protein concentrate. Food Chem. 2022, 389, 133107. [Google Scholar] [CrossRef]

- Brennan, C.; Brennan, M.; Derbyshire, E.; Tiwari, B.K. Effects of extrusion on the polyphenols, vitamins and antioxidant activity of foods. Trends Food Sci. Technol. 2011, 22, 570–575. [Google Scholar] [CrossRef]

- Sajid Mushtaq, B.; Zhang, W.; Al-Ansi, W.; Ul Haq, F.; Rehman, A.; Omer, R.; Mahmood Khan, I.; Niazi, S.; Ahmad, A.; Mahdi, A.A.; et al. A critical review on the development, physicochemical variations and technical concerns of gluten free extrudates in food systems. Food Rev. Int. 2021. [Google Scholar] [CrossRef]

- AOAC International. Official Methods of Analysis of AOAC International, 20th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2016. [Google Scholar]

- European Commission. Regulation (EC) No. 1169/2011 of 25/10/2011, on the Provision of Food Information to Consumers. Off. J. Eur. Union 2011, L304, 18–63. [Google Scholar]

- Horszwald, A.; Andlauer, W. Characterisation of bioactive compounds in berry juices by traditional photometric and modern microplate methods. J. Berry Res. 2011, 1, 189–199. [Google Scholar] [CrossRef]

- Hsu, H.W.; Vavak, D.L.; Satterlee, L.D.; Miller, G.A. A multienzyme technique for estimating protein digestibility. J. Food Sci. 1977, 42, 1269–1273. [Google Scholar] [CrossRef]

- Germaine, K.A.; Samman, S.; Fryirs, C.G.; Griffiths, P.J.; Johnson, S.K.; Quail, K.J. Comparison of in vitro starch digestibility methods for predicting the glycaemic index of grain foods. J. Sci. Food Agric. 2008, 88, 652–658. [Google Scholar] [CrossRef]

- Rosa-Sibakov, N.; Heiniö, R.L.; Cassan, D.; Holopainen-Mantila, U.; Micard, V.; Lantto, R.; Sozer, N. Effect of bioprocessing and fractionation on the structural, textural and sensory properties of gluten-free faba bean pasta. LWT 2016, 67, 27–36. [Google Scholar] [CrossRef]

- Pasqualone, A.; Costantini, M.; Coldea, T.E.; Summo, C. Use of Legumes in Extrusion Cooking: A Review. Foods 2020, 9, 958. [Google Scholar] [CrossRef]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and Extruded Products: Changes in Quality Attributes as Affected by Extrusion Process Parameters: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef]

- Igual, M.; Chis, M.S.; Socaci, S.A.; Vodnar, D.C.; Ranga, F.; Martínez-Monzó, J.; García-Segovia, P. Effect of Medicago sativa Addition on Physicochemical, Nutritional and Functional Characteristics of Corn Extrudates. Foods 2021, 10, 928. [Google Scholar] [CrossRef]

- Sarawong, C.; Schoenlechner, R.; Sekiguchi, K.; Berghofer, E.; Ng, P.K.W. Effect of extrusion cooking on the physicochemical properties, resistant starch, phenolic content and antioxidant capacities of green banana flour. Food Chem. 2014, 143, 33–39. [Google Scholar] [CrossRef]

- Jin, Z.; Hsieh, F.; Huff, H. Effects of soy fiber, salt, sugar and screw speed on physical properties and microstructure of corn meal extrudate. J. Cereal Sci. 1995, 22, 185–194. [Google Scholar] [CrossRef]

- Shruthi, V.H.; Hiregoudar, S.; Nidoni, U. Evaluation of textural properties of corn based extruded products. Plant Arch. 2019, 19, 2405–2410. Available online: http://www.plantarchives.org/19-2/2405-2410%20(5310).pdf (accessed on 31 January 2023).

- Kaushal, P.; Sharma, H.K.; Singh, A.P. Effect of extrusion processing on microstructural, physical, functional, antioxidant and textural properties of jackfruit flesh flour, rice flour and pigeon pea flour based extrudates. Int. Food Res. J. 2019, 26, 1045–1058. [Google Scholar]

- Spinello, A.M.; Leonel, M.; Mischan, M.M.; do Carmo, E.Z. Cassava and turmeric flour blends as new raw materials to extruded snacks. Ciênc. Agrotec. 2014, 38, 68–75. [Google Scholar] [CrossRef]

- Singh, R.; Yu, C.-C.; Chen, G.-W.; Chen, C.-H.; Sinaki, N.Y.; Lin, J.; Koksel, F. Butterfly Pea Flower as a Novel Ingredient to Produce Antioxidant-Enriched Yellow Pea-Based Breakfast Cereals. Foods 2022, 11, 3447. [Google Scholar] [CrossRef]

- Mayachiew, P.; Charunuch, C.; Devahastin, S. Physicochemical and thermal properties of extruded instant functional rice porridge powder as affected by the addition of soybean or mung bean. J. Food Sci. 2015, 80, E2782–E2791. [Google Scholar] [CrossRef]

- Ribeiro Oliveira, A.; Chaves Ribeiro, A.E.; Resende Oliveira, É.; da Silva Ana Caroline, M.; Soares Soares Júnior, M.; Caliari, M. Broken rice grains pregelatinized flours incorporated with lyophilized açaí pulp and the effect of extrusion on their physicochemical properties. J. Food Sci. Technol. 2019, 56, 1337–1348. [Google Scholar] [CrossRef]

- Hegedűsová, A.; Mezeyová, I.; Timoracká, M.; Šlosár, M.; Musilová, J.; Juríková, T. Total polyphenol content and antioxidant capacity changes in dependence on chosen garden pea varieties. Potravinarstvo 2015, 9, 1–8. [Google Scholar] [CrossRef]

- Wruss, J.; Waldenberger, G.; Huemer, S.; Uygun, P.; Lanzerstorfer, P.; Müller, U.; Höglinger, O.; Weghuber, J. Compositional characteristics of commercial beetroot products and beetroot juice prepared from seven beetroot varieties grown in Upper Austria. J. Food Compost. Anal. 2015, 42, 46–55. [Google Scholar] [CrossRef]

- Kwee, E.M.; Niemeyer, E.D. Variations in phenolic composition and antioxidant properties among 15 basil (Ocimum basilicum L.) cultivars. Food Chem. 2011, 128, 1044–1050. [Google Scholar] [CrossRef]

- Fascella, G.; D’Angiolillo, F.; Mammano, M.M.; Amenta, M.; Romeo, F.V.; Rapisarda, P.; Ballistreri, G. Bioactive compounds and antioxidant activity of four rose hip species from spontaneous Sicilian flora. Food Chem. 2019, 289, 56–64. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.J.; Chang, S.K.C. A comparative study on phenolic profiles and antioxidant activities of legumes as affected by extraction solvents. J. Food Sci. 2007, 72, S159–S166. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, E.A.; Abdalla, I.G.; Alfawaz, M.A.; Mohammed, M.A.; Al Maiman, S.A.; Osman, M.A.; Yagoub, A.E.A.; Hassan, A.B. Effects of Extraction Solvents on the Total Phenolic Content, Total Flavonoid Content, and Antioxidant Activity in the Aerial Part of Root Vegetables. Agriculture 2022, 12, 1820. [Google Scholar] [CrossRef]

- Nisar, T.; Iqbal, M.; Raza, A.; Safdar, M.; Iftikhar, F.; Waheed, M. Estimation of Total Phenolics and Free Radical Scavenging of Turmeric (Curcuma longa). Am.-Euras. J. Agric. Environ. Sci. 2015, 15, 1272–1277. [Google Scholar]

- Kavalcová, P.; Bystrická, J.; Tomáš, J.; Karoičová, J.; Kovarovič, J.; Lenková, M. The content of total polyphenols and antioxidante activity in red beetroot. Potravinarstvo 2015, 9, 77–83. [Google Scholar] [CrossRef]

- Saccotelli, M.A.; Spinelli, S.; Conte, A.; Del Nobile, M.A. Gluten-free bread enriched with vegetable flours. Food Sci. Nutr. 2018, 9, 356–368. [Google Scholar] [CrossRef]

- Škrovánková, S.; Mlček, J.; Orsavová, J.; Juríková, T.; Dřímalová, P. Polyphenols content and antioxidant activity of paprika and pepper spices. Potravinarstvo 2017, 11, 52–57. [Google Scholar] [CrossRef]

- Butkutė, B.; Benetis, R.; Padarauskas, A.; Cesevičienė, J.; Dagilytė, A.; Taujenis, L.; Rodovičius, H.; Lemežienė, N. Young herbaceous legumes—A natural reserve of bioactive compounds and antioxidants for healthy food and supplements. J. Appl. Bot. Food Qual. 2017, 90, 346–353. [Google Scholar] [CrossRef]

- Dhillon, N.K.; Toor, B.S.; Kaur, A.; Kaur, J. Characterization and evaluation of yellow pea flour for use in ‘Missi Roti’ a traditional Indian flat bread in comparison with Desi chickpea flour. Pharma Innov. J. 2022, 115, 58–64. [Google Scholar]

- Arribas, C.; Pereira, E.; Barros, L.; Alves, M.J.; Clhelha, R.C.; Guillamón, E.; Pedrosa, M.M.; Ferreira, I.C.F.R. Healthy novel gluten-free formulations based on beans, carob fruit, and rice: Extrusion effect on organic acids, tocopherols, phenolic compounds, and bioactivity. Food Chem. 2019, 292, 304–313. [Google Scholar] [CrossRef] [PubMed]

- dos Santos D’Almeida, C.T.; Mameri, H.; dos Santos Menezes, N.; de Carvalho, C.W.P.; Queiroz, V.A.V.; Cameron, L.C.; Morel, M.H.; Takeiti, C.Y.; Ferreira, M.S.L. Effect of extrusion and turmeric addition on phenolic compounds and kafirin properties in tannin and tannin-free sorghum. Food Res. Int. 2021, 149, 110663. [Google Scholar] [CrossRef] [PubMed]

- Nayak, B.; Berrios, J.J.; Powers, J.P.; Tang, J. Effect of extrusion on the antioxidant capacity and color attributes of expanded extrudates prepared from purple potato and yellow pea flour mixes. J. Food Sci. 2011, 76, 874–883. [Google Scholar] [CrossRef]

- Felix-Medina, J.V.; Gutierrez-Dorado, R.; Lopez-Valenzuela, J.A.; Lopez-Angulo, G.; Quintero-Soto, M.F.; Perales-Sanchez, J.X.K.; Montes-Avila, J. Nutritional, antioxidant and phytochemical characterization of healthy ready-to-eat expanded snack produced from maize/common bean mixture by extrusion. LWT 2021, 142, 111053. [Google Scholar] [CrossRef]

- Felix-Medina, J.V.; Montes-Avila, J.; Reyes-Moreno, C.; Perales-Sanchez, J.X.K.; Gomez-Favela, M.A.; Aguilar-Palazuelos, E.; Gutierrez-Dorado, R. Second-generation snacks with high nutritional and antioxidant value produced by an optimized extrusion process from corn/common bean flours mixtures. LWT 2020, 124, 109172. [Google Scholar] [CrossRef]

- Stojceska, V.; Ainsworth, P.; Plunkett, A.; Ibanoǧlu, E.; Ibanoǧlu, S. Cauliflower by-products as a new source of dietary fibre, antioxidants and proteins in cereal based ready-to-eat expanded snacks. J. Food Eng. 2008, 87, 554–563. [Google Scholar] [CrossRef]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. The effect of extrusion on the bioactive compounds and antioxidant capacity of novel gluten-free expanded products based on carob fruit, pea and rice blends. Innov. Food Sci. Emerg. Technol. 2019, 52, 100–107. [Google Scholar] [CrossRef]

- Sumargo, F.; Gulati, P.; Weier, S.A.; Clarke, J.; Rose, D.J. Effects of processing moisture on the physical properties and in vitro digestibility of starch and protein in extruded brown rice and pinto bean composite flours. Food Chem. 2016, 211, 726–733. [Google Scholar] [CrossRef] [PubMed]

- Lopez-Moreno, M.; Garces-Rimon, M.; Miguel, M. Antinutrients: Lectins, goitrogens, phytates and oxalates, friends or foe? J. Funct. Foods 2022, 89, 104938. [Google Scholar] [CrossRef]

- Adhikari, S.; Schop, M.; de Boer, I.J.M.; Huppertz, T. Protein Quality in Perspective: A Review of Protein Quality Metrics and Their Applications. Nutrients 2022, 14, 947. [Google Scholar] [CrossRef]

- Ohanenye, I.C.; Ekezie, F.-G.C.; Sarteshnizi, R.A.; Boachie, R.T.; Emenike, C.U.; Sun, X.; Nwachukwu, I.D.; Udenigwe, C.C. Legume Seed Protein Digestibility as Influenced by Traditional and Emerging Physical Processing Technologies. Foods 2022, 11, 2299. [Google Scholar] [CrossRef] [PubMed]

- Nayak, B.; Berrios, J.D.J.; Tang, J. Impact of food processing on the glycemic index (GI) of potato products. Food Res. Int. 2014, 56, 35–46. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Lim, S.T. Digestibility of legume starches as influenced by their physical and structural properties. Carbohydr. Polym. 2008, 71, 245–252. [Google Scholar] [CrossRef]

- Patil, S.; Brennan, M.A.; Mason, S.; Brennan, C.S. Investigation of the combination of legumes and cereals in the development of extrudate snacks and its effect on physico-chemical properties and in vitro starch digestion. J. Food Nutr. Res. 2017, 56, 32–41. [Google Scholar]

- Castro-Mendoza, M.P.; Palma-Rodriguez, H.M.; Heredia-Olea, E.; Hernández-Uribe, J.P.; López-Villegas, E.O.; Serna-Saldivar, S.O.; Vargas-Torres, A. Characterization of a mixture of oca (Oxalis tuberosa) and oat extrudate flours: Antioxidant and physicochemical attributes. J. Food Qual. 2019, 2019, 1238562. [Google Scholar] [CrossRef]

- Shirani, G.; Ganesharanee, R. Extruded products with Fenugreek (Trigonella foenum-graecium) chickpea and rice: Physical properties, sensory acceptability and glycaemic index. J. Food Eng. 2009, 90, 44–52. [Google Scholar] [CrossRef]

- Wani, S.A.; Ganie, N.A.; Kumar, P. Quality characteristics, fatty acid profile and glycemic index of extrusion processed snacks enriched with the multicomponent mixture of cereals and legumes. Legum. Sci. 2021, 3, e76. [Google Scholar] [CrossRef]

- Ferreira, S.M.; Capriles, V.D.; Conti-Silva, A.C. Inulin as an ingredient for improvement of glycemic response and sensory acceptance of breakfast cereals. Food Hydrocoll. 2021, 114, 106582. [Google Scholar] [CrossRef]

- Uğur, H.; Çatak, J.; Özgür, B.; Efe, E.; Görünmek, M.; Belli, I.; Yaman, M. Effects of different polyphenol-rich herbal teas on reducing predicted glycemic index. Food Sci. Technol. 2022, 42, e03022. [Google Scholar] [CrossRef]

- Alpha MOS (2002) Application Note, Toulouse, France. Available online: https://www.alpha-mos.com (accessed on 9 December 2022).

- Altan, A.; McCarthy, K.L.; Maskan, M. Twin-screw extrusion of barley–grape pomace blends: Extrudate characteristics and determination of optimum processing conditions. J. Food Eng. 2008, 89, 24–32. [Google Scholar] [CrossRef]

- Gat, T.; Ananthanarayan, L. Use of paprika oily extract as pre-extrusion colouring of rice extrudates: Impact of processing and storage on colour stability. J. Food Sci. Technol. 2016, 53, 2887–2894. [Google Scholar] [CrossRef] [PubMed]

| Sample | Protein (% d.m.) | Ash (% d.m.) | Fat (% d.m.) | Total Fiber (% d.m.) | Energy Value (kcal/100 g) |

|---|---|---|---|---|---|

| E_control | 5.75 ± 0.01 e | 0.57 ± 0.02 f | 0.14 ± 0 d | 6.73 ± 0.04 f | 359.0 ± 0.16 b |

| E_pea | 7.53 ± 0.02 a | 0.82 ± 0.02 d | 0.23 ± 0 b | 6.88 ± 0.01 f | 359.74 ± 0.08 a |

| E_broccoli | 7.21 ± 0.02 b | 0.84 ± 0.02 d | 0.68 ± 0.02 a | 8.59 ± 0.08 c | 358.55 ± 0.04 c |

| E_lucerne | 6.34 ± 0.19 c | 0.95 ± 0.05 c | 0.16 ± 0 d | 8.64 ± 0.15 c | 356.19 ± 0.11 f |

| E_beet | 6.98 ± 0.05 b | 1.60 ± 0.02 a | 0.14 ± 0.01 d | 9.72 ± 0.06 b | 353.20 ± 0.13 g |

| E_rosehip | 6.19 ± 0.01 cd | 1.05 ± 0.01 b | 0.23 ± 0.01 bc | 13.11 ± 0.10 a | 349.84 ± 0.13 h |

| E_chili | 5.90 ± 0 e | 0.75 ± 0.01 de | 0.17 ± 0.02 d | 7.46 ± 0.03 de | 358.39 ± 0.08 cd |

| E_turmeric | 5.75 ± 0.02 e | 0.79 ± 0.03 d | 0.18 ± 0.02 cd | 7.23 ± 0.04 e | 358.04 ± 0.09 de |

| E_paprika | 5.97 ± 0.05 de | 0.68 ± 0.02 e | 0.18 ± 0.02 bcd | 7.57 ± 0.03 d | 358.25 ± 0.04 cd |

| E_basil | 5.93 ± 0.02 e | 0.77 ± 0.02 de | 0.17 ± 0.01 d | 7.48 ± 0.01 de | 357.71 ± 0.04 e |

| Sample | ER | D (mm) | BD (g/cm3) | Hardness (N) | WAI | WSI (%) |

|---|---|---|---|---|---|---|

| E_control | 2.19 ± 0.04 c | 8.78 ± 0.15 c | 1.45 ± 0.14 cdef | 8.83 ± 0.94 d | 3.59 ± 0.01 f | 18.01 ± 0.19 c |

| E_pea | 1.90 ± 0.05 e | 7.58 ± 0.20 e | 1.58 ± 0.14 bcd | 13.07 ± 1.94 c | 6.60 ± 0.02 a | 6.01 ± 0.02 i |

| E_broccoli | 1.61 ± 0.06 f | 6.44 ± 0.24 f | 3.36 ± 0.10 a | 26.07 ± 1.65 a | 4.16 ± 0.08 d | 7.86 ± 0.31 h |

| E_lucerne | 2.03 ± 0.07 d | 8.11 ± 0.28 d | 1.50 ± 0.13 cde | 13.11 ± 1.11 c | 5.65 ± 0.06 b | 10.59 ± 0.17 g |

| E_beet | 2.27 ± 0.05 bc | 9.06 ± 0.19 bc | 1.70 ± 0.07 bc | 7.87 ± 1.28 de | 3.57 ± 0.01 f | 19.53 ± 0.11 b |

| E_rosehip | 1.70 ± 0.08 f | 6.80 ± 0.33 f | 1.50 ± 0.11 cde | 16.16 ± 1.67 b | 3.00 ± 0.03 g | 32.62 ± 0.11 a |

| E_chili | 2.33 ± 0.07 ab | 9.33 ± 0.29 ab | 1.32 ± 0.05 def | 6.97 ± 0.41 ef | 3.61 ± 0.03 f | 16.20 ± 0.12 d |

| E_turmeric | 2.29 ± 0.08 bc | 9.15 ± 0.33 bc | 1.21 ± 0.13 f | 7.43 ± 1.01 def | 5.38 ± 0.11 c | 13.01 ± 0.33 e |

| E_paprika | 2.43 ± 0.08 a | 9.70 ± 0.31 a | 1.29 ± 0.07 ef | 6.08 ± 0.57 f | 3.65 ± 0.02 f | 15.94 ± 0.32 d |

| E_basil | 2.26 ± 0.06 bc | 9.03 ± 0.24 bc | 1.84 ± 0.10 b | 7.56 ± 0.25 def | 3.83 ± 0.03 e | 11.45 ± 0.26 f |

| Extrudates | L* | a* | b* | ΔE1 | ΔE2 |

|---|---|---|---|---|---|

| E_control | 75.61 ± 0.04 a | 5.84 ± 0.01 e | 22.89 ± 0.02 e | - | 17.87 ± 0.04 f |

| E_pea | 74.65 ± 0.06 b | 6.86 ± 0.03 d | 26.24 ± 0.03 d | 3.64 ± 0.03 h | 18.11 ± 0.07 e |

| E_broccoli | 72.84 ± 0.05 d | 3.40 ± 0.02 g | 20.75 ± 0.04 i | 4.27 ± 0.06 g | 14.96 ± 0.06 h |

| E_lucerne | 71.75 ± 0.02 f | 2.43 ± 0.02 h | 21.07 ± 0.04 g | 5.46 ± 0.04 f | 12.59 ± 0.03 j |

| E_beet | 65.11 ± 0.03 j | 14.03 ± 0.01 a | 26.42 ± 0.03 c | 13.78 ± 0.03 b | 22.85 ± 0.04 a |

| E_rosehip | 66.64 ± 0.04 i | 8.10 ± 0.01 b | 18.31 ± 0.03 j | 10.32 ± 0.07 d | 15.59 ± 0.04 g |

| E_chili | 69.98 ± 0.02 g | 7.19 ± 0.01 c | 21.48 ± 0.02 f | 5.96 ± 0.05 e | 19.74 ± 0.02 d |

| E_turmeric | 73.34 ± 0.05 c | 3.65 ± 0.02 f | 37.00 ± 0.11 a | 14.46 ± 0.09 a | 20.31 ± 0.06 c |

| E_paprika | 69.88 ± 0.04 h | 14.03 ± 0.03 a | 28.98 ± 0.04 b | 11.70 ± 0.04 c | 21.98 ± 0.06 b |

| E_basil | 72.06 ± 0.04 e | 2.24 ± 0.03 i | 20.85 ± 0.06 h | 5.45 ± 0.03 f | 14.10 ± 0.04 i |

| Sample | TPC, mg GAE/100 g d.m. | AA, mg Trolox/100 g d.m. | ||

|---|---|---|---|---|

| Before Extrusion | After Extrusion | Before Extrusion | After Extrusion | |

| E_control | 95.23 ± 0.6 e A | 55.78 ± 2.14 e B | 90.33 ± 1.53 f A | 53.26 ± 1.64 g B |

| E_pea | 98.62 ± 0.65 de A | 72.97 ± 1.63 d B | 91.16 ± 0.71 f A | 59.44 ± 1.63 f B |

| E_broccoli | 122.96 ± 2.28 c A | 94.73 ± 3.76 c B | 109.77 ± 1.13 d A | 83.42 ± 0.86 d B |

| E_lucerne | 100.77 ± 2.37 de A | 81.17 ± 2.15 d B | 105.67 ± 3.06 de A | 83.48 ± 2.41 d B |

| E_beet | 213.01 ± 3.42 b A | 172.29 ± 2.67 b B | 254.39 ± 6.58 b A | 250.48 ± 4.25 b A |

| E_rosehip | 260.30 ± 5.70 a B | 312.02 ± 5.39 a A | 282.59 ± 4.58 a B | 329.20 ± 3.24 a A |

| E_chili | 98.05 ± 2.36 de A | 80.05 ± 5.34 d B | 97.97 ± 0.50 ef A | 63.68 ± 0.33 f B |

| E_turmeric | 104.11 ± 2.26 d A | 77.49 ± 2.68 d B | 101.59 ± 1.67 de A | 64.00 ± 1.05 ef B |

| E_paprika | 99.15 ± 3.42 de A | 74.81 ± 2.09 d B | 97.25 ± 1.74 ef A | 70.02 ± 1.25 e B |

| E_basil | 117.85 ± 3.48 c A | 104.16 ± 2.69 c B | 142.67 ± 2.08 c A | 104.15 ± 1.52 c B |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Culețu, A.; Susman, I.E.; Mulțescu, M.; Cucu, Ș.E.; Belc, N. Corn Extrudates Enriched with Health-Promoting Ingredients: Physicochemical, Nutritional, and Functional Characteristics. Processes 2023, 11, 1108. https://doi.org/10.3390/pr11041108

Culețu A, Susman IE, Mulțescu M, Cucu ȘE, Belc N. Corn Extrudates Enriched with Health-Promoting Ingredients: Physicochemical, Nutritional, and Functional Characteristics. Processes. 2023; 11(4):1108. https://doi.org/10.3390/pr11041108

Chicago/Turabian StyleCulețu, Alina, Iulia Elena Susman, Mihaela Mulțescu, Șerban Eugen Cucu, and Nastasia Belc. 2023. "Corn Extrudates Enriched with Health-Promoting Ingredients: Physicochemical, Nutritional, and Functional Characteristics" Processes 11, no. 4: 1108. https://doi.org/10.3390/pr11041108

APA StyleCulețu, A., Susman, I. E., Mulțescu, M., Cucu, Ș. E., & Belc, N. (2023). Corn Extrudates Enriched with Health-Promoting Ingredients: Physicochemical, Nutritional, and Functional Characteristics. Processes, 11(4), 1108. https://doi.org/10.3390/pr11041108