Study on the Flow Behavior of Wellbore Fluids of a Natural Gas Hydrate Well with the Combined Depressurization and Heat Injection Method

Abstract

:1. Introduction

2. Mechanism Study

2.1. Mechanism of Combined Depressurization and Heat Injection Method of NGH Exploitation

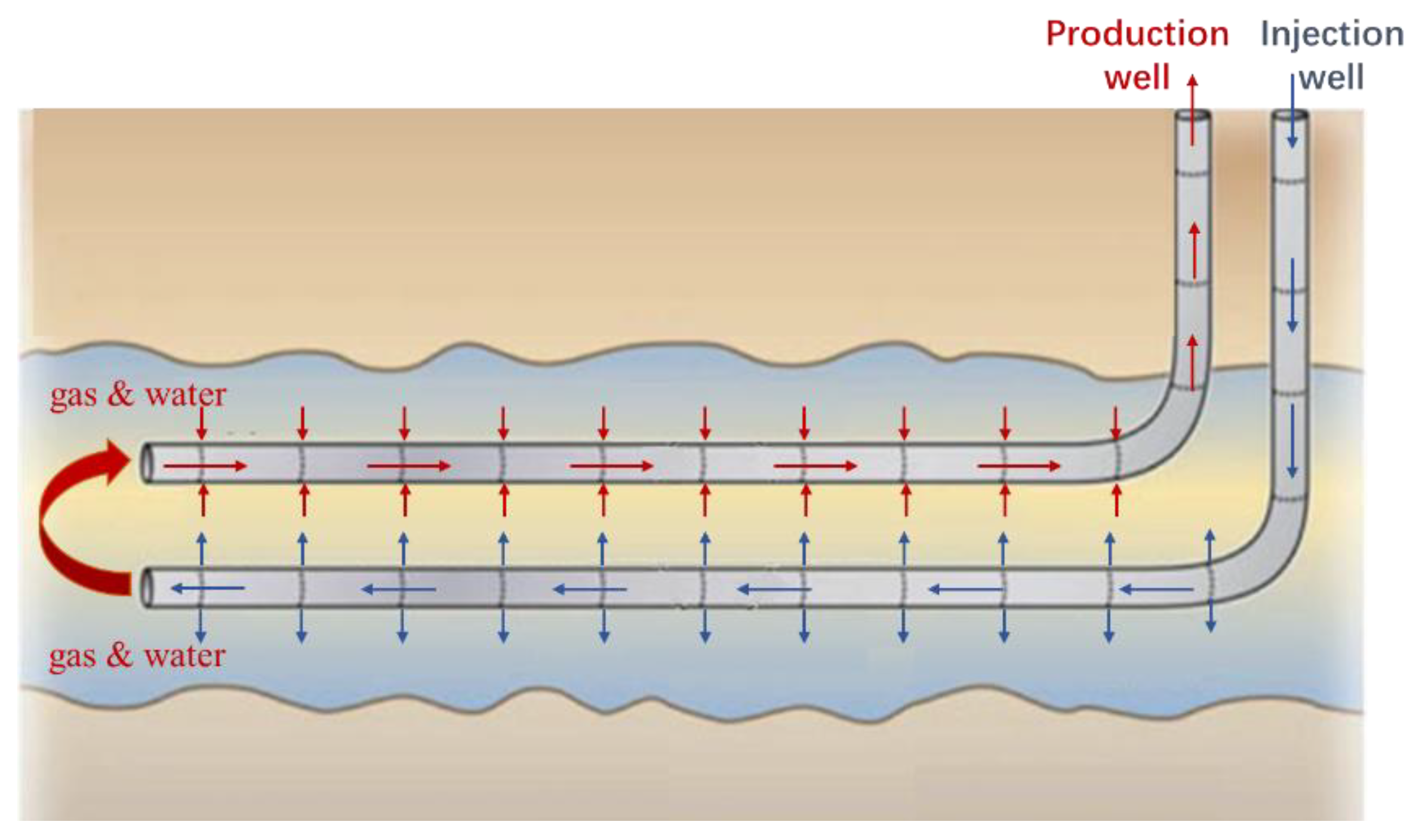

2.2. Mechanism of Parallel Horizontal Wells in NGH Reservoirs

3. Model Assumptions and Establishment

3.1. Model Assumptions

3.2. Mass Balance Equation

3.3. Momentum Conservation Equation

3.4. Energy Conservation Equation

3.5. Auxiliary Equation

4. Results and Discussion

4.1. Main Parameters for Simulation

4.2. Analysis of Multiphase Flow Law in Wellbore

4.3. Analysis of the Influence of Temperature and Pressure Distributions in the Injection Well

4.4. Analysis of the Influence of Pressure Distributions in the Production Well

4.5. Risk Analysis of Hydrate Reformation in the Wellbore

5. Conclusions

- (1)

- The combined depressurization and heat injection method is suitable for onshore NGH exploitation in the permafrost zone. The dual horizontal NGH production system with the combined depressurization and heat injection method can produce more gas and less water than the production system with the injection well below the production well and with the injection well above the production well due to gravity.

- (2)

- Gas and liquid are extracted together in the production well in the process of combined depressurization and heat injection exploitation of NGH. ESP has a great influence on the flow law of the fluids in the production well, and temperature and pressure change abruptly at the position of ESP. Increasing the casing pressure of the wellhead, pump depth, and ESP working frequency can reduce the risk of continuous water production in the annulus in the production well.

- (3)

- Increasing the injection rate and injection temperature can both improve the heat injection effect, while increasing the injection rate has a better heat injection effect.

- (4)

- The risk of hydrate reformation in the pump discharge is the greatest in the wellbore due to the pressurization effect of the pump.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| The density of the injected water, kg/m3; | |

| The velocity of the injected water, m/s; | |

| Time, s; | |

| The density of the water produced by the dissociation of the hydrate reservoir into the production well, kg/m3; | |

| The density of the gas produced by the dissociation of the hydrate reservoir into the production well, kg/m3; | |

| Liquid holdup in the production well, dimensionless; | |

| Gas holdup in the production well, dimensionless; | |

| Liquid velocity in the production well, m/s; | |

| Gas velocity in the production well, m/s; | |

| Mass flow rate of the gas decomposed from the hydrate reservoir per unit volume, kg/(m3·s); | |

| Mass flow rate of the water decomposed from the hydrate reservoir per unit volume, kg/(m3·s); | |

| Pressure of the fluid in the injection well, MPa; | |

| Pressure of the fluid in the production well, MPa; | |

| Density of the mixed fluid in the production well, kg/m3; | |

| Velocity of the mixed fluid in the production well, m/s; | |

| Fanning friction factor, dimensionless; | |

| Inside diameter of the injection well, m; | |

| Inside diameter of the production well, m; | |

| Diameter of the wellbore, m; | |

| Roughness of the wall, m; | |

| Reynolds number, dimensionless; | |

| Heat transfer rate, J/m; | |

| Overall heat transfer coefficient, J/m; | |

| Tubing outside diameter of the injection and production wells, m; | |

| Tubing inside diameter of the injection and production wells, m; | |

| Casing outside diameter of the injection and production wells, m; | |

| Casing inside diameter of the injection and production wells, m; | |

| Cement sheath outside diameter of the injection and production wells, m; | |

| Forced-convection heat transfer coefficient for the tubing fluid, W/(m2·K); | |

| Convective heat transfer coefficient for annulus fluid, W/(m2·K); | |

| Radiative heat transfer coefficient for the annulus, W/(m2·K); | |

| Tubing thermal conductivity, W/(m·K); | |

| Casing thermal conductivity, W/(m·K); | |

| Cement thermal conductivity, W/(m·K); | |

| Heat loss rate of the horizontal section of the injection well, J/m; | |

| Heat loss rate of the horizontal section of the production well, J/m; | |

| Thermal conductivity of the rock matrix around the injection well, W/(m·K); | |

| Thermal conductivity of the rock matrix around the production well, W/(m·K); | |

| Thermal diffusion coefficient of the rock matrix around the injection well, m2/s; | |

| Thermal diffusion coefficient of the rock matrix around the production well, m2/s; | |

| Heat injection time, day; | |

| Heat injection time, day; | |

| Heat changes caused by the decomposition of natural gas hydrates and Joule–Thomson effect, J; | |

| Heat capacity at constant pressure, J/K; | |

| Decomposition rate of hydrates, m3/min; | |

| Decomposition rate constant of hydrates, = 1.24 × 1011 mol/(m2·MPa·s); | |

| Total surface area of hydrate particles, m2; | |

| Activation energy, = 78.3 kJ/mol; | |

| Ideal gas constant, = 8.314 J/(mol·K); | |

| Temperature, K; | |

| Pressure under phase equilibrium conditions, MPa; | |

| Pressure, MPa; | |

| Dissociation enthalpies of hydrates, J/mol. | |

| Abbreviations and symbols | |

| NGH | Natural gas hydrate; |

| ESP | Electric submersible pump; |

| SAGD | Steam assisted gravity drainage. |

References

- Janicki, G.; Schlüter, S.; Hennig, T.; Deerberg, G. Simulation of Subsea Gas Hydrate Exploitation. Energy Procedia 2014, 59, 82–89. [Google Scholar] [CrossRef]

- Kurihara, M.; Sato, A.; Funatsu, K.; Ouchi, H.; Ashford, D. Analysis of Production Data for 2007/2008 Mallik Gas Hydrate Production Tests in Canada. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010. [Google Scholar]

- Birkedal, K.A.; Hauge, L.P.; Graue, A.; Ersland, G. Transport Mechanisms for CO2-CH4 Exchange and Safe CO2 Storage in Hydrate-Bearing Sandstone. Energies 2015, 8, 4073–4095. [Google Scholar] [CrossRef]

- Sakurai, S.; Nishioka, I.; Matsuzawa, M.; Matzain, B.; Goto, A.; Lee, J.E. Issues and Challenges with Controlling Large Drawdown in the First Offshore Methane-Hydrate Production Test. SPE Prod. Oper. 2017, 32, 500–516. [Google Scholar] [CrossRef]

- Yamamoto, K.; Wang, X.-X.; Tamaki, M.; Suzuki, K. The second offshore production of methane hydrate in the Nankai trough and gas production behavior from a heterogeneous methane hydrate reservoir. RSC Adv. 2019, 9, 25987–26013. [Google Scholar] [CrossRef]

- Li, J.F.; Ye, J.L.; Qin, X.W.; Qiu, H.J.; Wu, N.Y.; Lu, H.L.; Xie, W.W.; Lu, J.A.; Peng, F.; Xu, Z.Q. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Wei, N.; Zhao, J.; Sun, W.; Zhou, S.; Zhang, L.; Li, Q.; Fu, Q.; Lü, X.; Zheng, L. Non-equilibrium multiphase wellbore flow characteristics in solid fluidization exploitation of marine gas hydrate reservoirs. Nat. Gas Ind. B 2019, 6, 282–292. [Google Scholar] [CrossRef]

- Konno, Y.; Jin, Y.; Shinjou, K.; Nagao, J. Experimental evaluation of the gas recovery factor of methane hydrate in sandy sediment. RSC Adv. 2014, 4, 51666–51675. [Google Scholar] [CrossRef]

- Li, G.; Li, X.-S.; Yang, B.; Duan, L.-P.; Huang, N.-S.; Zhang, Y.; Tang, L.-G. The use of dual horizontal wells in gas production from hydrate accumulations. Appl. Energy 2013, 112, 1303–1310. [Google Scholar] [CrossRef]

- Jin, Y.; Li, S.; Yang, D.; Jiang, X. Determination of dissociation front and operational optimization for hydrate development by combining depressurization and hot brine stimulation. J. Nat. Gas Sci. Eng. 2018, 50, 215–230. [Google Scholar] [CrossRef]

- Zhao, J.; Yu, T.; Song, Y.; Liu, D.; Liu, W.; Liu, Y.; Yang, M.; Ruan, X.; Li, Y. Numerical simulation of gas production from hydrate deposits using a single vertical well by depressurization in the Qilian Mountain permafrost, Qinghai-Tibet Plateau, China. Energy 2013, 52, 308–319. [Google Scholar] [CrossRef]

- Moridis, G.J.; Reagan, M.T.; Boyle, K.L.; Zhang, K. Evaluation of the Gas Production Potential of Some Particularly Challenging Types of Oceanic Hydrate Deposits. Transp. Porous Media 2011, 90, 269–299. [Google Scholar] [CrossRef]

- Ros, N.C.J. Simultaneous Flow of Gas and Liquid As Encountered in Well Tubing. J. Pet. Technol. 1961, 13, 1037–1049. [Google Scholar] [CrossRef]

- Duns, H., Jr.; Ros, N.C.J. Vertical flow of gas and liquid mixtures in wells. In Proceedings of the 6th World Petroleum Congress, Frankfurt am Main, Germany, 19–26 June 1963; pp. 451–465. [Google Scholar]

- Hagedorn, A.R.; Brown, K.E. Experimental Study of Pressure Gradients Occurring during Continuous Two-Phase Flow in Small-Diameter Vertical Conduits. J. Pet. Technol. 1965, 17, 475–484. [Google Scholar] [CrossRef]

- Orkiszewski, J. Predicting Two-Phase Pressure Drops in Vertical Pipes. J. Pet. Technol. 1967, 19, 829–838. [Google Scholar] [CrossRef]

- Hasan, A.R.; Jang, M. An analytic model for computing the countercurrent flow of heat in tubing and annulus system and its application: Jet pump. J. Pet. Sci. Eng. 2021, 203, 108492. [Google Scholar] [CrossRef]

- Wei, N.; Sun, W.; Meng, Y.; Zhou, S.; Li, G.; Guo, P.; Dong, K.; Li, Q. Sensitivity analysis of multiphase flow in annulus during drilling of marine natural gas hydrate reservoirs. J. Nat. Gas Sci. Eng. 2016, 36, 692–707. [Google Scholar] [CrossRef]

- Sun, B.; Gao, Y.; Wang, Z.; Li, H. Temperature Calculation and Prediction of Gas Hydrates Formed Region in Wellbore in Deepwater Drilling. In Proceedings of the ISOPE-2008, International Offshore and Polar Engineering Conference, Vancouver, BC, Canada, 6–11 July 2008. [Google Scholar]

- Liao, Y.; Sun, X.; Sun, B.; Gao, Y.; Wang, Z. Transient gas-liquid-solid flow model with heat and mass transfer for hydrate reservoir drilling. Int. J. Heat Mass Transf. 2019, 141, 476–486. [Google Scholar] [CrossRef]

- Ping, X.; Han, G.; Cen, X.; Bai, Z.; Zhu, W.; Peng, L.; Ma, B. Prediction of Pressure and Temperature Profiles and Hydrate Formation Region in ESP-Lifted Natural Gas Hydrate Wells. In Proceedings of the SPE Western Regional Meeting, Bakersfield, CA, USA, 26–28 April 2022. [Google Scholar]

- Yang, S.; Lang, X.; Wang, Y.; Wen, Y.; Fan, S. Numerical simulation of Class 3 hydrate reservoirs exploiting using horizontal well by depressurization and thermal co-stimulation. Energy Convers. Manag. 2014, 77, 298–305. [Google Scholar] [CrossRef]

- Ning, H.C. An Explicit Equation for Friction Factor in Pipe. Ind. Eng. Chem. Fundam. 1979, 18, 296–297. [Google Scholar]

- Bhawangirkar, D.R.; Adhikari, J.; Sangwai, J.S. Thermodynamic modeling of phase equilibria of clathrate hydrates formed from CH4, CO2, C2H6, N2 and C3H8, with different equations of state. J. Chem. Thermodyn. 2018, 117, 180–192. [Google Scholar] [CrossRef]

- Aspects of wellbore heat transfer during two-phase flow. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, A20. [CrossRef]

- Duong, A.N.; Tomberlin, T.A.; Cyrot, M. A New Analytical Model for Conduction Heating during the SAGD Circulation Phase. In Proceedings of the International Thermal Operations and Heavy Oil Symposium, Calgary, AB, Canada, 20–23 October 2008. [Google Scholar]

- Kim, H.C.; Bishnoi, P.R.; Heidemann, R.A.; Rizvi, S. Kinetics of methane hydrate decomposition. Chem. Eng. Sci. 1987, 42, 1645–1653. [Google Scholar] [CrossRef]

- Sun, S.; Gu, L.; Yang, Z.; Lin, H.; Li, Y. Thermophysical properties of natural gas hydrates: A review—ScienceDirect. Nat. Gas Ind. B 2022, 9, 246–263. [Google Scholar] [CrossRef]

- Chen, G.-J.; Guo, T.-M. A new approach to gas hydrate modelling. Chem. Eng. J. 1998, 71, 145–151. [Google Scholar] [CrossRef]

| Well Type | Measured Depth of Point A (m) | Vertical Depth of Point A (m) | Horizontal Section Length (m) | Casing Size (mm) | Tubing Size (mm) | Screen Size (mm) |

|---|---|---|---|---|---|---|

| Injection well | 550 | 440 | 400 | 244.5 | 73 | 177.8 |

| Production well | 530 | 430 | 400 | 244.5 | 73 | 177.8 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Thickness of reservoir (m) | 160 | Porosity of reservoir | 0.35 |

| Permeability of reservoir (md) | 0.068 | Surface temperature (°C) | −2 |

| Rock density (kg/m3) | 2650 | Initial saturation of water | 0.3 |

| Initial pressure of reservoir (MPa) | 5.1 | Initial saturation of hydrate | 0.68 |

| Earth thermal conductivity (W/m/K) | 2.1 | Gas flow rate (m3/d) | 20,000 |

| Tubing thermal conductivity (W/m/K) | 40 | Water flow rate (m3/d) | 100 |

| Casing thermal conductivity (W/m/K) | 40 | Surface injection rate (m3/d) | 100 |

| Cement thermal conductivity (W/m/K) | 1.1 | Gas-specific gravity | 0.65 |

| Geothermal gradient (°C/100m) | 3.2 | Depth of production well (m) | 920 |

| Bottom-hole temperature (°C) | 12 | Depth of injection well (m) | 938 |

| Surface injection temperature (°C) | 60 | Injection pressure (MPa) | 3 |

| Gas–water separation efficiency | 0.95 | Depth of ESP (m) | 450 |

| Flowing pressure at bottom (MPa) | 3 | ESP frequency (HZ) | 55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ping, X.; Han, G.; Zhang, J.; Chang, J.; Cen, X.; Tang, H. Study on the Flow Behavior of Wellbore Fluids of a Natural Gas Hydrate Well with the Combined Depressurization and Heat Injection Method. Processes 2023, 11, 1625. https://doi.org/10.3390/pr11061625

Ping X, Han G, Zhang J, Chang J, Cen X, Tang H. Study on the Flow Behavior of Wellbore Fluids of a Natural Gas Hydrate Well with the Combined Depressurization and Heat Injection Method. Processes. 2023; 11(6):1625. https://doi.org/10.3390/pr11061625

Chicago/Turabian StylePing, Xiaolin, Guoqing Han, Jiqun Zhang, Junhua Chang, Xueqi Cen, and Hui Tang. 2023. "Study on the Flow Behavior of Wellbore Fluids of a Natural Gas Hydrate Well with the Combined Depressurization and Heat Injection Method" Processes 11, no. 6: 1625. https://doi.org/10.3390/pr11061625