A Method for Predicting Surface Finish of Polylactic Acid Parts Printed Using Fused Deposition Modeling

Abstract

1. Introduction

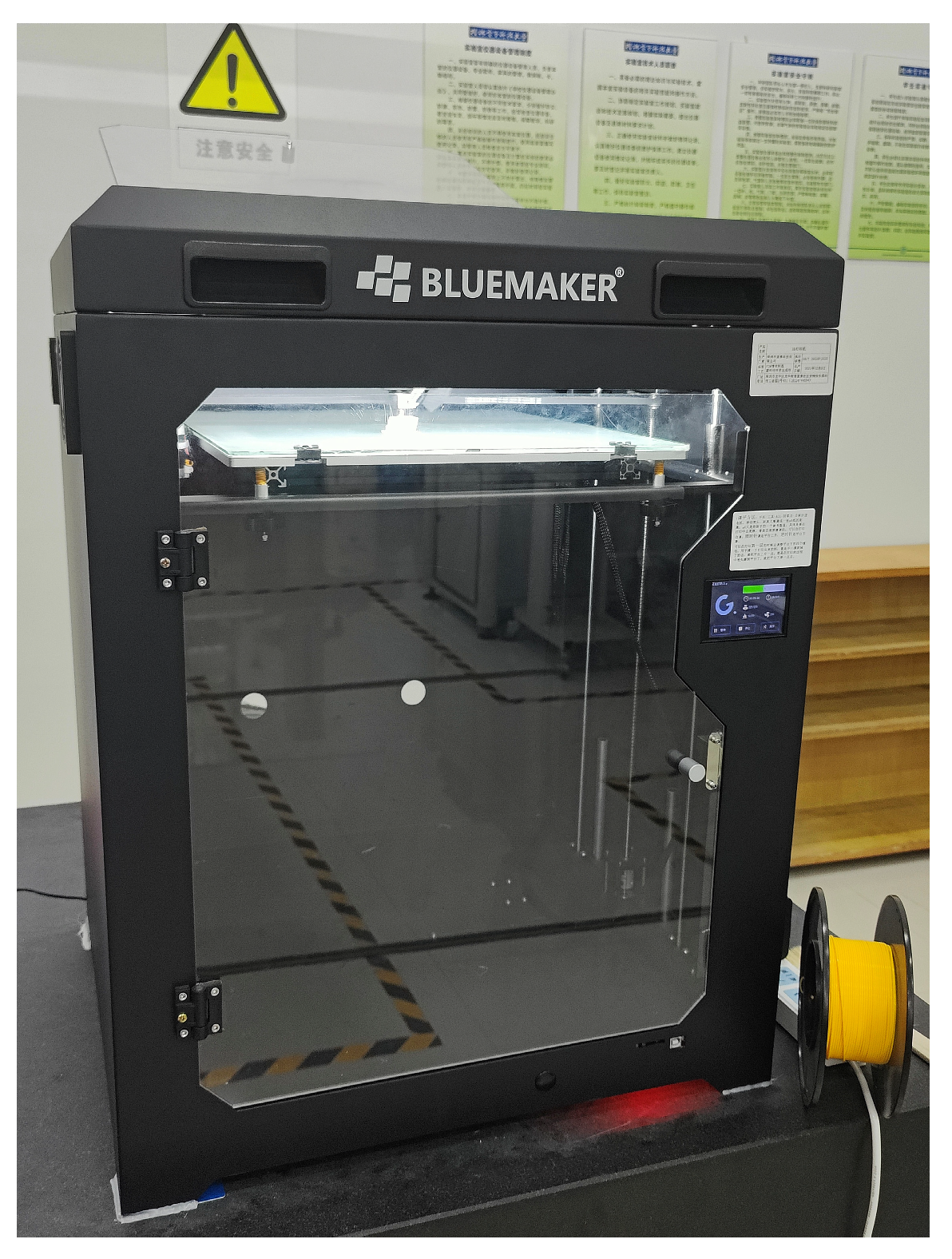

2. Materials and Methods

2.1. K-Nearest Neighbors

2.2. Adaptive Particle Swarm Optimization

2.3. APSO-KNN

3. Experiments

4. Results and Discussion

4.1. Results of Surface Roughness Measurements

4.2. Experimental Data Classification

4.3. Evaluation of Predictive Model Performance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| FDM | Fused Deposition Modeling |

| ML | Machine Learning |

| DT | Decision Tree |

| LH | Layer Height |

| T | Temperature |

| ND | nozzle diameter |

| PS | Print Speed |

| PA | Print Acceleration |

| F | Flow Rate |

| WA | Wall Angle |

| NP | Number of Perimeters |

| BO | Build Orientation |

| KNN | K-nearest Neighbor |

| APSO | Adaptive Particle Swarm Optimization |

| PSO | Particle Swarm Optimization |

| PLA | Polylactic Acid |

| SVM | Support Vector Machine |

| ANN | Artificial Neural Network |

| TPR | True Positive Rate |

| FNR | False Negative Rate |

| SD | Standard Deviations |

| Ra | Surface Roughness |

Nomenclature

| xi,j | The numerical values of particle displacement (no unit) |

| vi,j | The numerical values of particle velocity (no unit) |

| k | The number of neighbors (no unit) |

| ω | The inertia weight (no unit) |

| c1 | The learning factors (no unit) |

| c2 | The learning factors (no unit) |

| r1 | Uniformly distributed random numbers within [0, 1] (no unit) |

| r2 | Uniformly distributed random numbers within [0, 1] (no unit) |

| pi,j | The individual best value of the particle (no unit) |

| pg,j | The global best value of the particle (no unit) |

| f | The real-time objective function value of the particle (no unit) |

| favg | The average value of all particles at present (no unit) |

| fmin | The minimum target value of all particles at present (no unit) |

| ωmax | The maximum values of the inertia weight (no unit) |

| ωmin | The minimum values of the inertia weight (no unit) |

| acc | The value of accuracy (no unit) |

| NC | The number of correct classifications (no unit) |

| NT | The total number of classification labels (no unit) |

References

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Sun, B.; Ma, Q.; Wang, X.; Liu, J.; Rejab, M.R.M. Additive manufacturing in medical applications: A brief review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1078, 12007. [Google Scholar] [CrossRef]

- Khorasani, M.; Loy, J.; Ghasemi, A.H.; Sharabian, E.; Leary, M.; Mirafzal, H.; Cochrane, P.; Rolfe, B.; Gibson, I. A review of Industry 4.0 and additive manufacturing synergy. Rapid Prototyp. J. 2022, 28, 1462–1475. [Google Scholar] [CrossRef]

- Nair, A.; Aditya, S.D.; Adarsh, R.N.; Nandan, M.; Dharek, M.S.; Sreedhara, B.M.; Prashant, S.C.; Sreekeshava, K.S. Additive Manufacturing of Concrete: Challenges and opportunities. IOP Conf. Ser. Mater. Sci. Eng. 2020, 814, 12022. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Kumar, L.J.; Pandey, P.M.; Wimpenny, D.I. 3D Printing and Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2019; Volume 311. [Google Scholar]

- Sathies, T.; Senthil, P.; Anoop, M.S. A review on advancements in applications of fused deposition modelling process. Rapid Prototyp. J. 2020, 26, 669–687. [Google Scholar] [CrossRef]

- Parada, L.R.; Mayuet, P.F.; Gámez, A.J. Industrial product design: Study of FDM technology for the manufacture of thermoformed prototypes. Procedia Manuf. 2019, 41, 587–593. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Zaoutsos, S.P. Optimising fused filament fabrication surface roughness for a dental implant. Mater. Manuf. Process. 2023, 38, 954–959. [Google Scholar] [CrossRef]

- Di Angelo, L.; Di Stefano, P.; Marzola, A. Surface quality prediction in FDM additive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 93, 3655–3662. [Google Scholar] [CrossRef]

- Ferretti, P.; Leon-Cardenas, C.; Santi, G.M.; Sali, M.; Ciotti, E.; Frizziero, L.; Donnici, G.; Liverani, A. Relationship between FDM 3D Printing Parameters Study: Parameter Optimization for Lower Defects. Polymers 2021, 13, 2190. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Sánchez-Casas, X.; Luis-Pérez, C.J. Analysis of AM Parameters on Surface Roughness Obtained in PLA Parts Printed with FFF Technology. Polymers 2021, 13, 2384. [Google Scholar] [CrossRef] [PubMed]

- Pérez, M.; Medina-Sánchez, G.; García-Collado, A.; Gupta, M.; Carou, D. Surface Quality Enhancement of Fused Deposition Modeling (FDM) Printed Samples Based on the Selection of Critical Printing Parameters. Materials 2018, 11, 1382. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Zheng, N.; Qin, Y.; Tang, Z.; Zhang, H.; Fan, B.; Qin, L. Description Logic Ontology-Supported Part Orientation for Fused Deposition Modelling. Processes 2022, 10, 1290. [Google Scholar] [CrossRef]

- Qin, Y.; Qi, Q.; Shi, P.; Scott, P.J.; Jiang, X. Status, issues, and future of computer-aided part orientation for additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 115, 1295–1328. [Google Scholar] [CrossRef]

- Taufik, M.; Jain, P.K. A Study of Build Edge Profile for Prediction of Surface Roughness in Fused Deposition Modeling. J. Manuf. Sci. Eng. 2016, 138, 4032193. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Domínguez-Fernández, A.; Durán-Llucià, R. Influence of Print Orientation on Surface Roughness in Fused Deposition Modeling (FDM) Processes. Materials 2019, 12, 3834. [Google Scholar] [CrossRef]

- Xu, F.; Wong, Y.S.; Loh, H.T. Toward generic models for comparative evaluation and process selection in rapid prototyping and manufacturing. J. Manuf. Syst. 2001, 19, 283–296. [Google Scholar] [CrossRef]

- Luis Perez, C.J.; Vivancos, J.; Sebastián, M.A. Surface roughness analysis in layered forming processes. Precis. Eng. 2001, 25, 1–12. [Google Scholar] [CrossRef]

- Pandey, P.M.; Venkata Reddy, N.; Dhande, S.G. Improvement of surface finish by staircase machining in fused deposition modeling. J. Mater. Process. Technol. 2003, 132, 323–331. [Google Scholar] [CrossRef]

- Vahabli, E.; Rahmati, S. Application of an RBF neural network for FDM parts’ surface roughness prediction for enhancing surface quality. Int. J. Precis. Eng. Manuf. 2016, 17, 1589–1603. [Google Scholar] [CrossRef]

- Wu, D.; Wei, Y.; Terpenny, J. Predictive modelling of surface roughness in fused deposition modelling using data fusion. Int. J. Prod. Res. 2019, 57, 3992–4006. [Google Scholar] [CrossRef]

- Boschetto, A.; Giordano, V.; Veniali, F. Surface roughness prediction in fused deposition modelling by neural networks. Int. J. Adv. Manuf. Technol. 2013, 67, 2727–2742. [Google Scholar] [CrossRef]

- Reddy, V.; Flys, O.; Chaparala, A.; Berrimi, C.E.; Amogh, V.; Rosen, B.G. Study on surface texture of Fused Deposition Modeling. Procedia Manuf. 2018, 25, 389–396. [Google Scholar] [CrossRef]

- Meng, L.; McWilliams, B.; Jarosinski, W.; Park, H.; Jung, Y.; Lee, J.; Zhang, J. Machine Learning in Additive Manufacturing: A Review. JOM 2020, 72, 2363–2377. [Google Scholar] [CrossRef]

- UNE-EN ISO 1302-2002; Geometrical Product Specifications (GPS)—Indication of Surface Texture in Technical Product Documentation. International Organization for Standardization: Geneva, Switzerland, 2002.

- Aoyagi, K.; Wang, H.; Sudo, H.; Chiba, A. Simple method to construct process maps for additive manufacturing using a support vector machine. Addit. Manuf. 2019, 27, 353–362. [Google Scholar] [CrossRef]

- Molero, E.; Fernández, J.J.; Rodríguez-Alabanda, O.; Guerrero-Vaca, G.; Romero, P.E. Use of Data Mining Techniques for the Prediction of Surface Roughness of Printed Parts in Polylactic Acid (PLA) by Fused Deposition Modeling (FDM): A Practical Application in Frame Glasses Manufacturing. Polymers 2020, 12, 840. [Google Scholar] [CrossRef] [PubMed]

- Barrios, J.M.; Romero, P.E. Decision Tree Methods for Predicting Surface Roughness in Fused Deposition Modeling Parts. Materials 2019, 12, 2574. [Google Scholar] [CrossRef] [PubMed]

- Cerro, A.; Romero, P.E.; Yiğit, O.; Bustillo, A. Use of machine learning algorithms for surface roughness prediction of printed parts in polyvinyl butyral via fused deposition modeling. Int. J. Adv. Manuf. Technol. 2021, 115, 2465–2475. [Google Scholar] [CrossRef]

- García Plaza, E.; Núñez López, P.J.; Caminero Torija, M.Á.; Chacón Muñoz, J.M. Analysis of PLA Geometric Properties Processed by FFF Additive Manufacturing: Effects of Process Parameters and Plate-Extruder Precision Motion. Polymers 2019, 11, 1581. [Google Scholar] [CrossRef] [PubMed]

- Taşcıoğlu, E.; Kıtay, Ö.; Keskin, A.Ö.; Kaynak, Y. Effect of printing parameters and post-process on surface roughness and dimensional deviation of PLA parts fabricated by extrusion-based 3D printing. J. Braz. Soc. Mech. Sci. 2022, 44, 139. [Google Scholar] [CrossRef]

- Ramli, F.R.; Faudzie, M.; Nazan, M.A.; Alkahari, M.R.; Sudin, M.N.; Mat, S.; Khalil, S.N. Dimensional accuracy and surface roughness of part features manufactured by open source 3D printer. ARPN J. Eng. Appl. Sci. 2018, 13, 1139–1144. [Google Scholar]

- Alsoufi, M.S.; Elsayed, A.E. How surface roughness performance of printed parts manufactured by desktop FDM 3D printer with PLA+ is influenced by measuring direction. Am. J. Mech. Eng. 2017, 5, 211–222. [Google Scholar]

- Wu, Q.; Liu, H.; Yan, X. Multi-label classification algorithm research based on swarm intelligence. Clust. Comput. 2016, 19, 2075–2085. [Google Scholar] [CrossRef]

- Wu, S. Simulation of classroom student behavior recognition based on PSO-kNN algorithm and emotional image processing. J. Intell. Fuzzy Syst. 2021, 40, 7273–7283. [Google Scholar] [CrossRef]

- Han, J.; Abdelaziz, M. The Method for Identifying Employees’ Emotions in Adverse States Incorporating PSO-kNN Algorithm and Multiple Physiological Parameters. Comput. Intel. Neurosci. 2022, 2022, 4371162. [Google Scholar] [CrossRef]

- Sasirekha, K.; Thangavel, K. Optimization of K-nearest neighbor using particle swarm optimization for face recognition. Neural Comput. Appl. 2019, 31, 7935–7944. [Google Scholar] [CrossRef]

- Eberhart, R.; Kennedy, J. A new optimizer using particle swarm theory. In Proceedings of the MHS’95 Sixth International Symposium on Micro Machine and Human Science, Nagoya, Japan, 4–6 October 1995; IEEE: Piscataway, NJ, USA, 1995; pp. 39–43. [Google Scholar]

- Song, X.; Zhang, Y.; Gong, D.; Gao, X. A fast hybrid feature selection based on correlation-guided clustering and particle swarm optimization for high-dimensional data. IEEE Trans. Cybern. 2021, 52, 9573–9586. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Zhang, Y.; Gong, D.; Sun, X. Dual-surrogate-assisted cooperative particle swarm optimization for expensive multimodal problems. IEEE Trans. Evol. Comput. 2021, 25, 794–808. [Google Scholar] [CrossRef]

- Zhang, Y.; Gong, D.; Ding, Z. A bare-bones multi-objective particle swarm optimization algorithm for environmental/economic dispatch. Inf. Sci. 2012, 192, 213–227. [Google Scholar] [CrossRef]

- Deng, H.; Peng, L.; Zhang, H.; Yang, B.; Chen, Z. Ranking-based biased learning swarm optimizer for large-scale optimization. Inf. Sci. 2019, 493, 120–137. [Google Scholar] [CrossRef]

- Kramer, O.; Kramer, O. K-nearest Neighbors. In Dimensionality Reduction with Unsupervised Nearest Neighbors; 2013; Volume 51, pp. 13–23. Available online: https://link.springer.com/chapter/10.1007/978-3-642-38652-7_2 (accessed on 5 June 2023).

- Flach, P. Machine Learning: The Art and Science of Algorithms That Make Sense of Data; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Clerc, M. Particle Swarm Optimization; John Wiley & Sons: Hoboken, NJ, USA, 2010; Volume 93. [Google Scholar]

- Ravikumar, G.; Gomathi, D.; Kalaiselvi, M.; Uma, C. Adaptive particle swarm optimization. Electr. Eng. Jpn. 2010, 151, 41–49. [Google Scholar]

- Gao, G.; Xu, F.; Xu, J.; Liu, Z. Study of Material Color Influences on Mechanical Characteristics of Fused Deposition Modeling Parts. Materials 2022, 15, 7039. [Google Scholar] [CrossRef] [PubMed]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- Roy, R.K. A Primer on the Taguchi Method; Society of Manufacturing Engineers: Southfield, MI, USA, 2010. [Google Scholar]

- Matlab, S. Matlab; The MathWorks: Natick, MA, USA, 2021. [Google Scholar]

| Authors | Method | Data Balance | Factor | Classification |

|---|---|---|---|---|

| Molero et al. [28] | ML | √ | LT, T, PS, PA, F | 2 |

| Barrios et al. [29] | DT | √ | LT, T, PS, PA, F | 2 |

| Cerro et al. [30] | ML | √ | LT, PS, NP, T, BO | 2 |

| Authors | Layer Thickness | Temperature | Print Orientation | Print Speed | Nozzle Diameter | Filling Density | Wall Thickness |

|---|---|---|---|---|---|---|---|

| García Plaza et al. [31] | √ | – | √ | √ | – | – | – |

| Taşcıoğlu et al. [32] | √ | √ | – | √ | – | – | – |

| Ramli et al. [33] | √ | – | – | – | – | √ | – |

| Alsoufi et al. [34] | √ | – | – | – | √ | – | – |

| Cerro et al. [30] | √ | √ | √ | √ | – | – | √ |

| Chemical Name | Composition | Density (g/mm³) | Printing Temperature (°C) | Diameter (mm) | Color |

|---|---|---|---|---|---|

| Polylactic Acid | PLA (Polylactide Resin) 99% | 1.24 | 220 ± 20 | 1.75 ± 0.03 | white |

| Factors | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Nozzle diameter, ND (mm) | 0.40 | 0.60 | 0.80 |

| Layer thickness, LT (mm) | 0.10 | 0.25 | 0.35 |

| Number of perimeters, NP | 2 | 3 | 4 |

| Flow rate, F (%) | 90 | 100 | 110 |

| Printing speed, PS (mm/s) | 40 | 60 | 80 |

| Temperature, T (°C) | 190 | 210 | 230 |

| Build orientation, BO (°) | 30 | 45 | 75 |

| No. | ND (mm) | LT (mm) | NP | F (%) | PS (mm/s) | T (°C) | BO (°) |

|---|---|---|---|---|---|---|---|

| 1 | 0.40 | 0.10 | 2 | 90 | 40 | 190 | 30 |

| 2 | 0.40 | 0.10 | 2 | 90 | 60 | 210 | 45 |

| 3 | 0.40 | 0.10 | 2 | 90 | 80 | 230 | 75 |

| 4 | 0.40 | 0.25 | 3 | 100 | 40 | 190 | 30 |

| 5 | 0.40 | 0.25 | 3 | 100 | 60 | 210 | 45 |

| 6 | 0.40 | 0.25 | 3 | 100 | 80 | 230 | 75 |

| 7 | 0.40 | 0.35 | 4 | 110 | 40 | 190 | 30 |

| 8 | 0.40 | 0.35 | 4 | 110 | 60 | 210 | 45 |

| 9 | 0.40 | 0.35 | 4 | 110 | 80 | 230 | 75 |

| 10 | 0.60 | 0.10 | 3 | 110 | 40 | 210 | 75 |

| 11 | 0.60 | 0.10 | 3 | 110 | 60 | 230 | 30 |

| 12 | 0.60 | 0.10 | 3 | 110 | 80 | 190 | 45 |

| 13 | 0.60 | 0.25 | 4 | 90 | 40 | 210 | 75 |

| 14 | 0.60 | 0.25 | 4 | 90 | 60 | 230 | 30 |

| 15 | 0.60 | 0.25 | 4 | 90 | 80 | 190 | 45 |

| 16 | 0.60 | 0.35 | 2 | 100 | 40 | 210 | 75 |

| 17 | 0.60 | 0.35 | 2 | 100 | 60 | 230 | 30 |

| 18 | 0.60 | 0.35 | 2 | 100 | 80 | 190 | 45 |

| 19 | 0.80 | 0.10 | 4 | 100 | 40 | 230 | 45 |

| 20 | 0.80 | 0.10 | 4 | 100 | 60 | 190 | 75 |

| 21 | 0.80 | 0.10 | 4 | 100 | 80 | 210 | 30 |

| 22 | 0.80 | 0.25 | 2 | 110 | 40 | 230 | 45 |

| 23 | 0.80 | 0.25 | 2 | 110 | 60 | 190 | 75 |

| 24 | 0.80 | 0.25 | 2 | 110 | 80 | 210 | 30 |

| 25 | 0.80 | 0.35 | 3 | 90 | 40 | 230 | 45 |

| 26 | 0.80 | 0.35 | 3 | 90 | 60 | 190 | 75 |

| 27 | 0.80 | 0.35 | 3 | 90 | 80 | 210 | 30 |

| Test | Ra1 (μm) | Ra2 (μm) | Ra3 (μm) | Ra4 (μm) | Ra5 (μm) | Ra (μm) | SD (μm) |

|---|---|---|---|---|---|---|---|

| 1 | 15.43 | 14.24 | 16.50 | 18.32 | 15.22 | 15.94 | 1.55 |

| 2 | 16.93 | 12.60 | 12.63 | 15.21 | 15.50 | 14.58 | 1.90 |

| 3 | 10.90 | 10.67 | 9.89 | 10.72 | 11.73 | 10.78 | 0.65 |

| 4 | 44.53 | 44.61 | 44.25 | 45.79 | 44.11 | 44.66 | 0.66 |

| 5 | 34.19 | 31.29 | 32.69 | 34.22 | 29.11 | 32.30 | 2.15 |

| 6 | 24.58 | 24.91 | 26.7 | 28.17 | 21.46 | 25.17 | 2.52 |

| 7 | 52.91 | 49.05 | 54.76 | 51.82 | 48.08 | 51.32 | 2.75 |

| 8 | 43.75 | 41.16 | 43.25 | 48.18 | 41.05 | 43.48 | 2.89 |

| 9 | 37.76 | 34.28 | 35.22 | 35.29 | 36.61 | 35.83 | 1.35 |

| 10 | 9.03 | 8.92 | 7.97 | 9.88 | 7.98 | 8.76 | 0.80 |

| 11 | 18.74 | 14.19 | 15.40 | 19.86 | 14.64 | 16.57 | 2.56 |

| 12 | 11.23 | 12.48 | 13.81 | 10.90 | 11.56 | 11.99 | 1.17 |

| 13 | 25.71 | 21.30 | 21.67 | 23.15 | 24.35 | 23.24 | 1.84 |

| 14 | 37.56 | 43.28 | 42.84 | 43.96 | 39.59 | 41.45 | 2.74 |

| 15 | 34.02 | 29.64 | 32.96 | 30.23 | 31.59 | 31.69 | 1.83 |

| 16 | 31.66 | 30.21 | 31.80 | 28.21 | 32.16 | 30.81 | 1.62 |

| 17 | 52.47 | 50.76 | 53.15 | 49.82 | 52.84 | 51.81 | 1.44 |

| 18 | 38.20 | 37.42 | 39.64 | 43.37 | 41.49 | 40.02 | 2.43 |

| 19 | 18.01 | 17.81 | 16.59 | 16.67 | 16.07 | 17.03 | 0.83 |

| 20 | 7.30 | 8.11 | 7.43 | 8.83 | 7.41 | 7.81 | 0.65 |

| 21 | 24.90 | 22.98 | 23.81 | 25.22 | 24.16 | 24.21 | 0.89 |

| 22 | 29.83 | 28.42 | 30.70 | 29.89 | 28.89 | 29.55 | 0.90 |

| 23 | 20.02 | 16.33 | 20.91 | 21.98 | 22.95 | 20.44 | 2.55 |

| 24 | 33.60 | 33.57 | 34.31 | 33.90 | 34.87 | 34.05 | 0.54 |

| 25 | 41.54 | 40.78 | 41.91 | 41.96 | 40.38 | 41.31 | 0.70 |

| 26 | 30.42 | 32.67 | 29.87 | 30.30 | 28.26 | 30.30 | 1.57 |

| 27 | 59.04 | 58.72 | 55.41 | 52.35 | 52.88 | 55.68 | 3.14 |

| Roughness Value (μm) | Class Label |

|---|---|

| N10 | |

| N11 | |

| N12 | |

| N13 |

| Test | Ra (μm) | Class Label | Sign |

|---|---|---|---|

| 1 | 15.94 | N11 | 2 |

| 2 | 14.58 | N11 | 2 |

| 3 | 10.78 | N10 | 1 |

| 4 | 44.66 | N12 | 3 |

| 5 | 32.30 | N12 | 3 |

| 6 | 25.17 | N12 | 3 |

| 7 | 51.32 | N13 | 4 |

| 8 | 43.48 | N12 | 3 |

| 9 | 35.83 | N12 | 3 |

| 10 | 8.76 | N10 | 1 |

| 11 | 16.57 | N11 | 2 |

| 12 | 11.99 | N10 | 1 |

| 13 | 23.24 | N11 | 2 |

| 14 | 41.45 | N12 | 3 |

| 15 | 31.69 | N12 | 3 |

| 16 | 30.81 | N12 | 3 |

| 17 | 51.81 | N13 | 4 |

| 18 | 40.02 | N12 | 3 |

| 19 | 17.03 | N11 | 2 |

| 20 | 7.81 | N10 | 1 |

| 21 | 24.21 | N11 | 2 |

| 22 | 29.55 | N12 | 3 |

| 23 | 20.44 | N11 | 2 |

| 24 | 34.05 | N12 | 3 |

| 25 | 41.31 | N12 | 3 |

| 26 | 30.30 | N12 | 3 |

| 27 | 55.68 | N13 | 4 |

| Model | Hyperparameter | Minimum Error | Training Accuracy | Training Time (s) |

|---|---|---|---|---|

| APSO-KNN | c1:2; c2:2; wmax:0.8; wmin:0.6; M:2; D:7; k:1 | 0.01 | 99.0% | 14.40 |

| Decision Tree | Maximum number of divisions: 1. Split criterion: Gini diversity index. Optimizer: Bayesian optimization | 0.32 | 67.5% | 14.18 |

| SVM | Kernel function: linear. Box constraint level: 1. Multiple methods: one-to-one. Standardized data: true. Optimizer: Bayesian optimization | 0.41 | 59.3% | 36.63 |

| KNN | k:1. Distance Metric: Euclidean. Distance weight: equidistant. Standardized data: true. Optimizer: Bayesian optimization | 0.39 | 60.1% | 24.88 |

| ANN | Number of layers: 3. Activation function: ReLU. Iteration limit: 1000. Standardized data: true. Optimizer: Bayesian optimization | 0.32 | 67.1% | 39.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, M.; Jin, S.; Tang, Z.; Chen, Y.; Qin, Y. A Method for Predicting Surface Finish of Polylactic Acid Parts Printed Using Fused Deposition Modeling. Processes 2023, 11, 1820. https://doi.org/10.3390/pr11061820

Huang M, Jin S, Tang Z, Chen Y, Qin Y. A Method for Predicting Surface Finish of Polylactic Acid Parts Printed Using Fused Deposition Modeling. Processes. 2023; 11(6):1820. https://doi.org/10.3390/pr11061820

Chicago/Turabian StyleHuang, Meifa, Shangkun Jin, Zhemin Tang, Yuanqing Chen, and Yuchu Qin. 2023. "A Method for Predicting Surface Finish of Polylactic Acid Parts Printed Using Fused Deposition Modeling" Processes 11, no. 6: 1820. https://doi.org/10.3390/pr11061820

APA StyleHuang, M., Jin, S., Tang, Z., Chen, Y., & Qin, Y. (2023). A Method for Predicting Surface Finish of Polylactic Acid Parts Printed Using Fused Deposition Modeling. Processes, 11(6), 1820. https://doi.org/10.3390/pr11061820