Plasma Agricultural Nitrogen Fixation Using Clean Energies: New Attempt of Promoting PV Absorption in Rural Areas

Abstract

1. Introduction

2. Materials and Methods

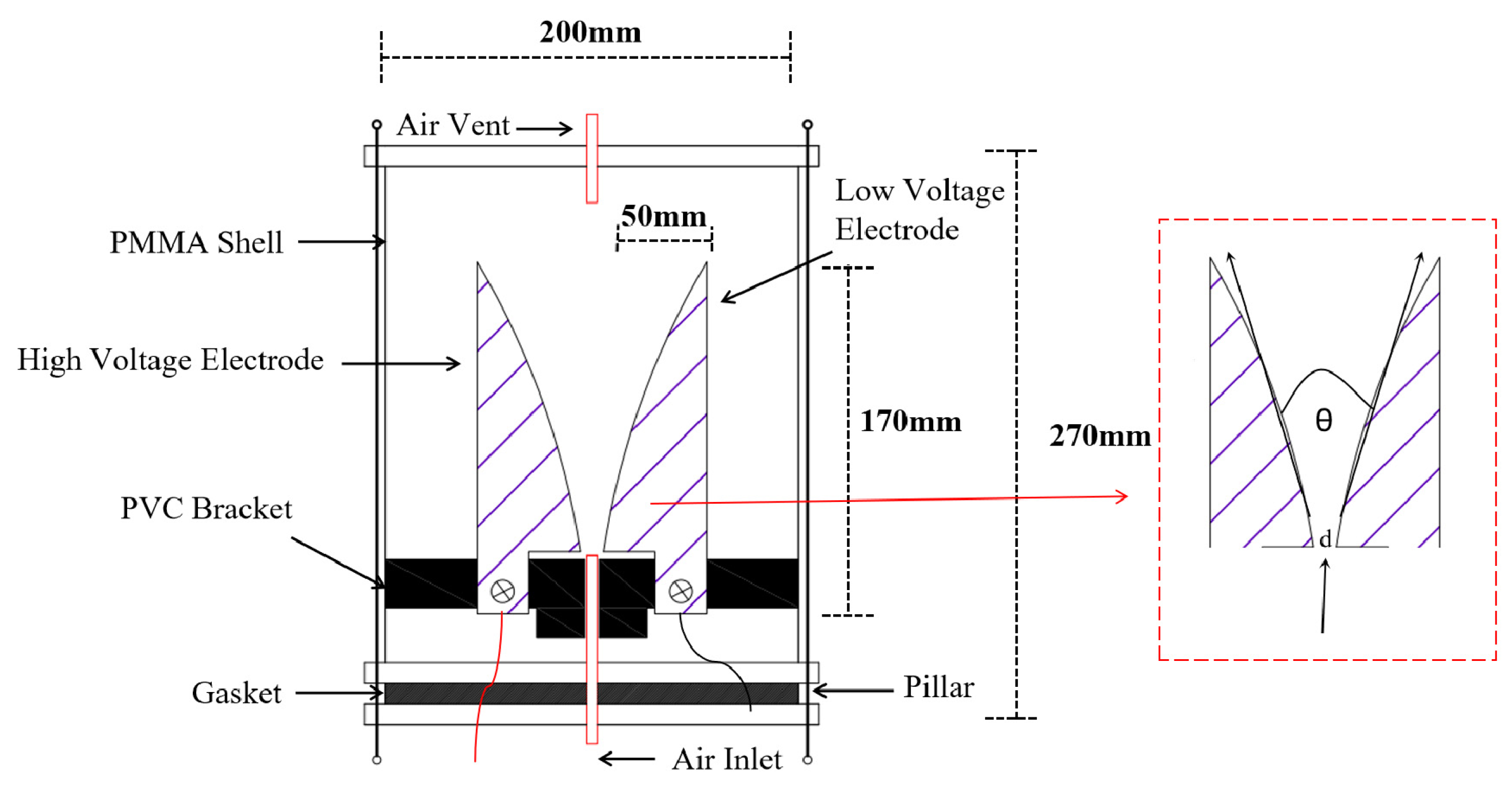

2.1. Experimental Setup and Methods

2.2. Performance Assessment

3. Results

3.1. Electrical Characteristics of Gliding Arc Plasma Nitrogen Fixation

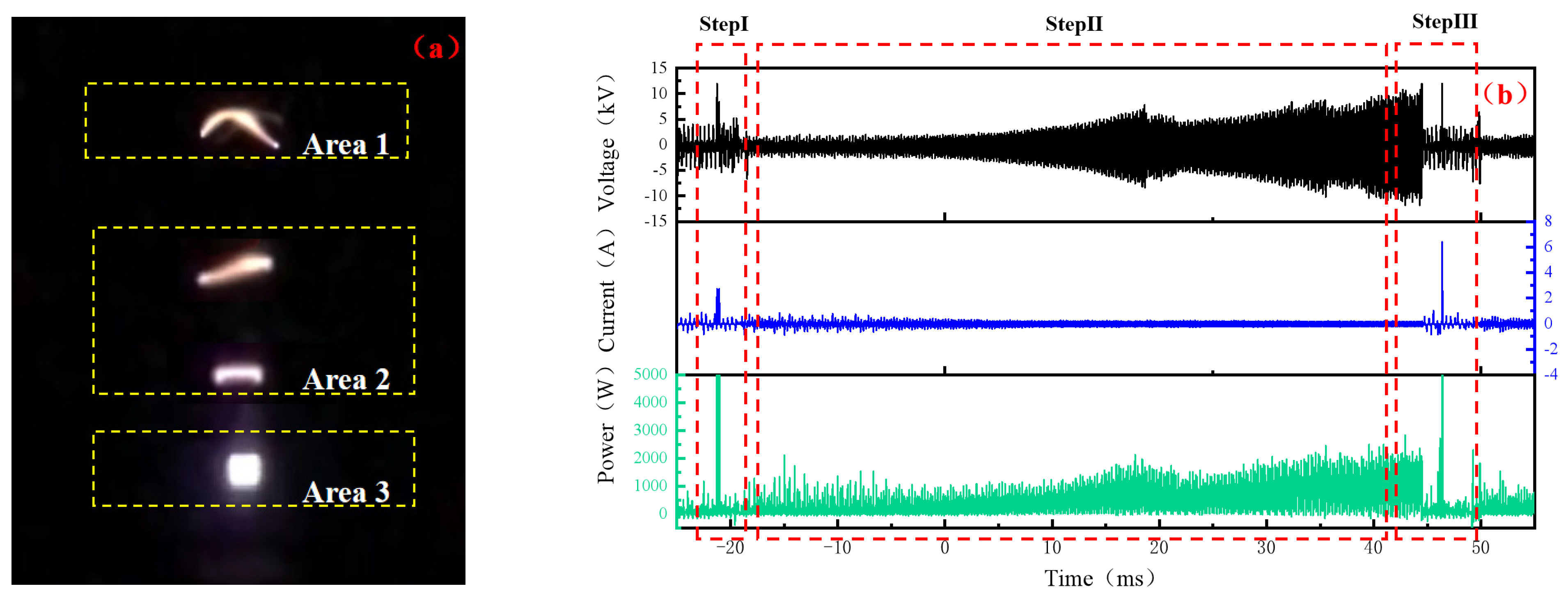

3.1.1. Electrical Characteristics

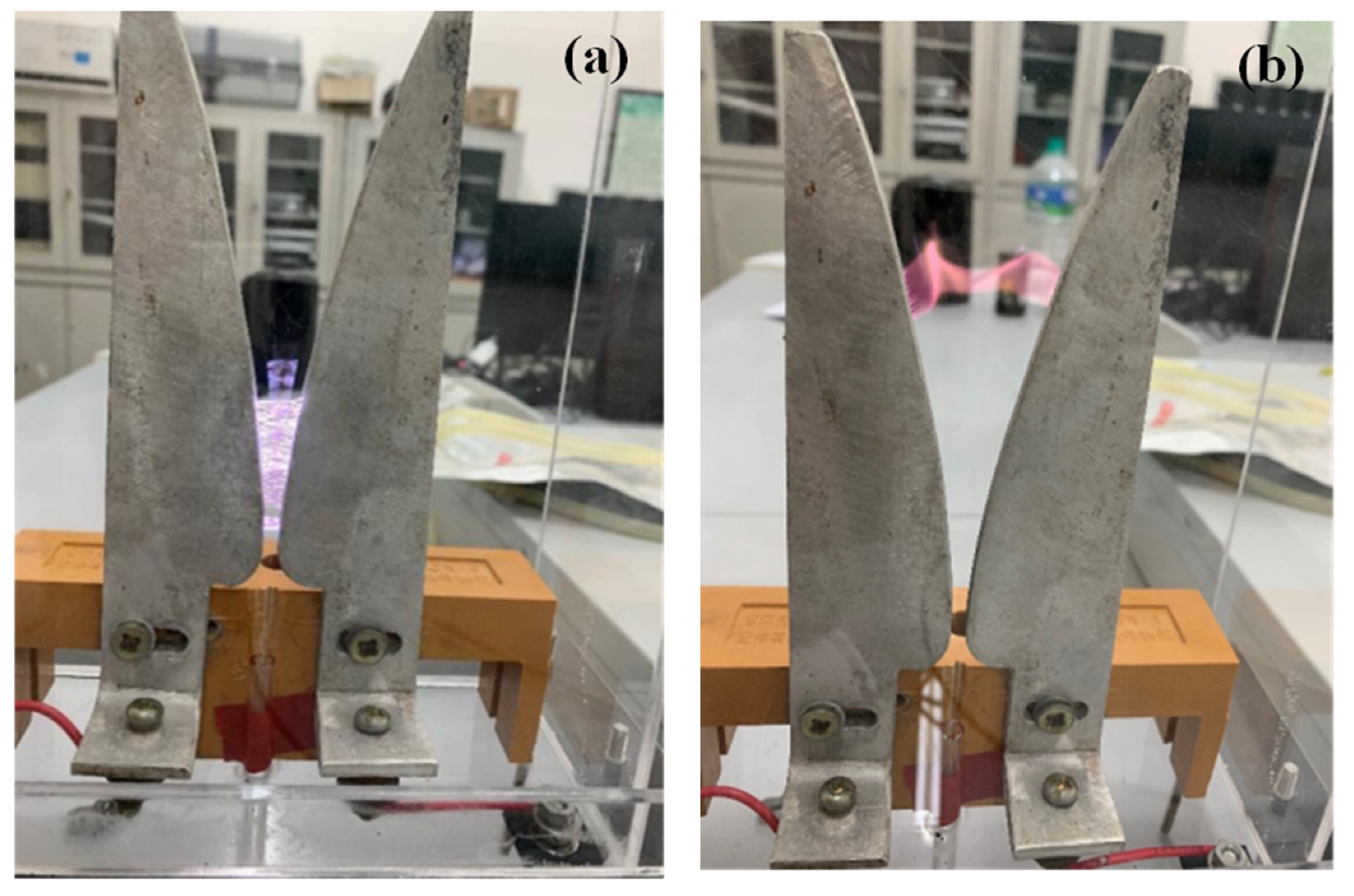

3.1.2. Discharge Mode

3.2. The Influence of Discharge Characteristics on Nitrogen Fixation by Gliding Arc Plasma

3.2.1. Influence on Discharge Parameters

3.2.2. Influence on Discharge Period

3.2.3. Influence on Discharge Mode

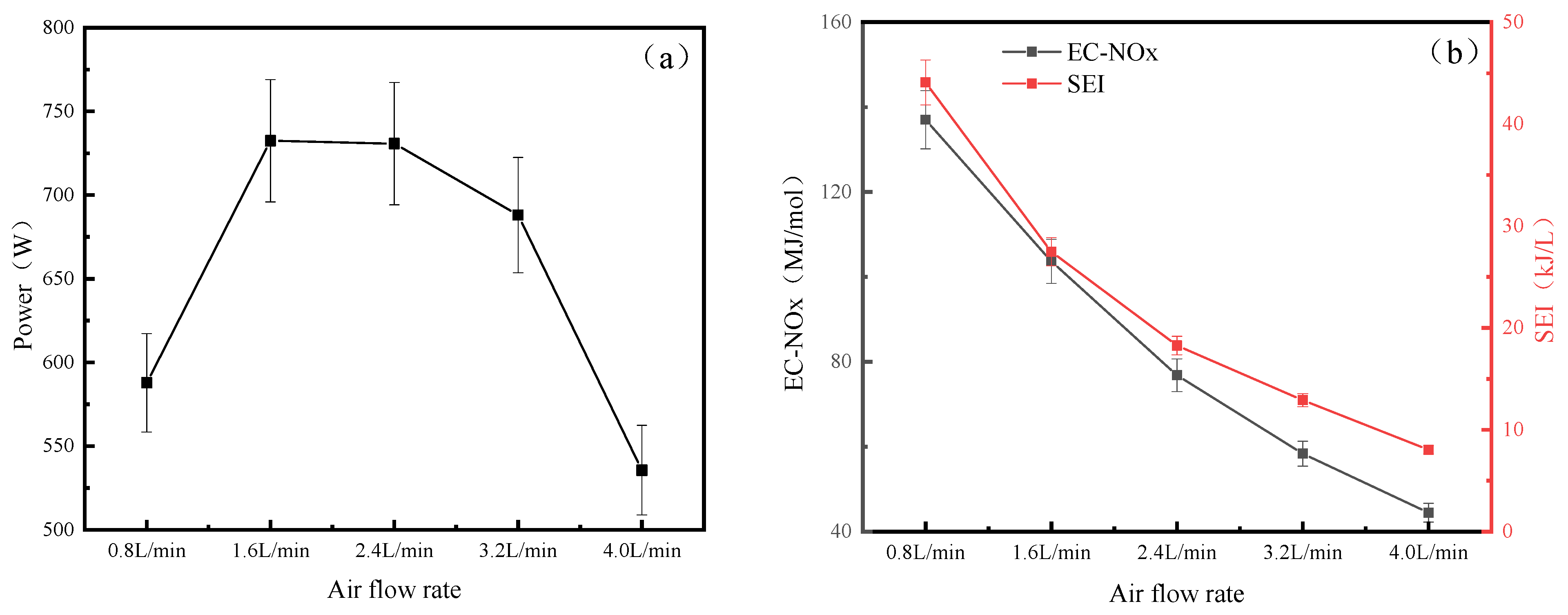

3.3. Influence of Air Flow Rate on Plasma Nitrogen Fixation

3.3.1. Influence on Nitrogen Oxide Concentration

3.3.2. Influence on Nitrogen Fixation Performance

4. Conclusions

- (1)

- The gliding arc plasma nitrogen fixation has a certain periodicity during discharge, and its electrical parameters, including current, voltage, and power, change periodically. The gliding arc plasma also mainly discharges in two modes during nitrogen fixation, one of which is the bright channel B-G mode discharge generated at the bottom of the electrode in a strong convection and high flow rate environment. At this time, the arc combustion is not stable, and there are many high-voltage points, which are due to the unstable breakdown of the air gap, and the repeated arc breakdown, causing extinction. The other is the red-purple channel A-G mode discharge at a low flow rate and a weak convection environment. At this time, the arc combustion is stable, and with an increase in the arc height, the arc resistance also increases, resulting in a gradual increase in the arc voltage. In the end, the power supply energy is not enough to maintain stable arc combustion, and the arc is extinguished.

- (2)

- There is a correlation between the air air flow of the reactor and the periodicity of nitrogen fixation in the gliding arc, which affects the discharge time of the gliding arc and the number of cycles under the same acquisition time. When the air flow rate of the air inlet in the reactor increased from 0.8 L/min to 4 L/min, the discharge period was significantly reduced, and the average discharge period was reduced from 49.5 ms to 10.1 ms, and the shortest discharge period was as short as 3 ms. With the gradual increase in the inlet flow rate of the reactor, the reduction in the arc hanging time at the tip of the electrode can significantly shorten the gliding arc discharge period and accelerate the dissipation of gliding arc energy by strengthening the convection, so that it quickly generates a new arc in the throat of the blade electrode to enter the next cycle.

- (3)

- There is a correlation between the flow rate of the reactor and the nitrogen fixation performance of the gliding arc plasma, which affects the nitrogen oxide concentration, energy density, energy consumption, and other performance parameters of the gliding arc plasma. With an increase in air flow, the nitrogen oxide generated by atmospheric nitrogen fixation decreased; in particular, the nitrogen oxide generated at 4 L/min was only 4338 ppm, which was 56.18% of the nitrogen oxide generated at 0.8 L/min. When the air flow rate is 0.8 L/min, the generated nitrogen oxide concentration is higher, but because of the energy consumption of generating 1 mol of nitrogen oxide, the energy consumption is also quite high. Therefore, when the flow rate is 4 L/min, the minimum energy consumption for generating 1 mol of NOx is 42.69 MJ/mol.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krishan, O.; Suhag, S. Techno-economic analysis of a hybrid renewable energy system for an energy poor rural community. J. Energy Storage 2019, 23, 305–319. [Google Scholar] [CrossRef]

- Chaurey, A.; Kandpal, T.C. Assessment and evaluation of PV based decentralized rural electrification: An overview. Renew. Sustain. Energy Rev. 2010, 14, 2266–2278. [Google Scholar] [CrossRef]

- Shahsavari, A.; Akbari, M. Potential of solar energy in developing countries for reducing energy-related emissions. Renew. Sustain. Energy Rev. 2018, 90, 275–291. [Google Scholar] [CrossRef]

- Xie, M.; Jia, T.; Dai, Y. Hybrid photovoltaic/solar chimney power plant combined with agriculture: The transformation of a decommissioned coal-fired power plant. Renew. Energy 2022, 191, 1–16. [Google Scholar] [CrossRef]

- Xue, J. Photovoltaic agriculture-New opportunity for photovoltaic applications in China. Renew. Sustain. Energy Rev. 2017, 73, 1–9. [Google Scholar] [CrossRef]

- Krouk, G.; Kiba, T. Nitrogen and phosphorus interactions in plants: From agronomic to physiological and molecular insights. Curr. Opin. Plant Biol. 2020, 57, 104–109. [Google Scholar] [CrossRef]

- Parsons, C.; Stüeken, E.E.; Rosen, C.J.; Mateos, K.; Anderson, R.E. Radiation of nitrogen-metabolizing enzymes across the tree of life tracks environmental transitions in Earth history. Geobiology 2021, 19, 18–34. [Google Scholar] [CrossRef]

- Takai, K. The nitrogen cycle: A large, fast, and mystifying cycle. Microbes Environ. 2019, 34, 223–225. [Google Scholar] [CrossRef]

- Anastasopoulou, A.; Keijzer, R.; Butala, S.; Lang, J.; Van Rooij, G.; Hessel, V. Eco-efficiency analysis of plasma-assisted nitrogen fixation. J. Phys. D Appl. Phys. 2020, 53, 234001. [Google Scholar] [CrossRef]

- Chen, S.; Liu, D.; Peng, T. Fundamentals and recent progress of photocatalytic nitrogen-fixation reaction over semiconductors. Sol. Rrl 2021, 5, 2000487. [Google Scholar] [CrossRef]

- Vu, M.H.; Sakar, M.; Hassanzadeh-Tabrizi, S.A.; Do, T.O. Photo (electro) catalytic nitrogen fixation: Problems and possibilities. Adv. Mater. Interfaces 2019, 6, 1900091. [Google Scholar] [CrossRef]

- Cherkasov, N.; Ibhadon, A.O.; Fitzpatrick, P. A review of the existing and alternative methods for greener nitrogen fixation. Chem. Eng. Process. Process Intensif. 2015, 90, 24–33. [Google Scholar] [CrossRef]

- Chen, H.; Wu, A.; Mathieu, S.; Gao, P.; Li, X.; Xu, B.Z.; Yan, J.; Tu, X. Highly efficient nitrogen fixation enabled by an atmospheric pressure rotating gliding arc. Plasma Process. Polym. 2021, 18, 2000200. [Google Scholar] [CrossRef]

- Šerá, B.; Scholtz, V.; Jirešová, J.; Khun, J.; Julák, J.; Šerý, M. Effects of non-thermal plasma treatment on seed germination and early growth of leguminous plants—A review. Plants 2021, 10, 1616. [Google Scholar] [CrossRef]

- Sharma, H.P.; Patel, A.H.; Pal, M. Effect of plasma activated water (PAW) on fruits and vegetables. Am. J. Food Nutr 2021, 9, 60–68. [Google Scholar] [CrossRef]

- Kyere-Yeboah, K.; Bique, I.K.; Qiao, X.C. Advances of non-thermal plasma discharge technology in degrading recalcitrant wastewater pollutants. A comprehensive review. Chemosphere 2023, 320, 138061. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Medrano, J.A.; Hessel, V.; Gallucci, F. Recent progress of plasma-assisted nitrogen fixation research: A review. Processes 2018, 6, 248. [Google Scholar] [CrossRef]

- Chen, H.; Yuan, D.; Wu, A.; Lin, X.; Li, X. Review of low-temperature plasma nitrogen fixation technology. Waste Dispos. Sustain. Energy 2021, 3, 201–217. [Google Scholar] [CrossRef]

- Discepoli, G.; Cruccolini, V.; Ricci, F.; Di Giuseppe, A.; Papi, S.; Grimaldi, C.N. Experimental characterisation of the thermal energy released by a Radio-Frequency Corona Igniter in nitrogen and air. Appl. Energy 2020, 263, 114617. [Google Scholar] [CrossRef]

- Patil, B.S.; Peeters, F.J.J.; van Rooij, G.J.; Medrano, J.A.; Gallucci, F.; Lang, J.; Wang, Q.; Hessel, V. Plasma assisted nitrogen oxide production from air: Using pulsed powered gliding arc reactor for a containerized plant. AIChE J. 2018, 64, 526–537. [Google Scholar] [CrossRef]

- Malik, M.A.; Jiang, C.; Heller, R.; Lane, J.; Hughes, D.; Schoenbach, K.H. Ozone-free nitric oxide production using an atmospheric pressure surface discharge–a way to minimize nitrogen dioxide co-production. Chem. Eng. J. 2016, 283, 631–638. [Google Scholar] [CrossRef]

- Chen, W.; Jin, D.; Cui, W.; Huang, S. Characteristics of gliding arc plasma and its application in swirl flame static instability control. Processes 2020, 8, 684. [Google Scholar] [CrossRef]

- Hu, C.; He, L.; Chen, Y.; Zhao, B.; Jun, D.; Qu, M.J. Electrical and optical characterizations of a rotating gliding arc plasma-enhanced combustion dome in an aero-engine combustor. J. Phys. D Appl. Phys. 2021, 54, 205202. [Google Scholar] [CrossRef]

- Jardali, F.; Van Alphen, S.; Creel, J.; Eshtehardi, H.A.; Axelsson, M.; Ingels, R.; Snyders, R.; Bogaerts, A. NOx production in a rotating gliding arc plasma: Potential avenue for sustainable nitrogen fixation. Green Chem. 2021, 23, 1748–1757. [Google Scholar] [CrossRef]

- Cheng, X.; Huimin, S.O.N.G.; Huang, S.; Yifei, Z.H.U.; Zhang, Z.; Zhenyang, L.I.; Min, J.I.A. Discharge and jet characteristics of gliding arc plasma igniter driven by pressure difference. Plasma Sci. Technol. 2022, 24, 115502. [Google Scholar] [CrossRef]

- Machala, Z.; Tarabová, B.; Sersenová, D.; Janda, M.; Hensel, K. Chemical and antibacterial effects of plasma activated water: Correlation with gaseous and aqueous reactive oxygen and nitrogen species, plasma sources and air flow conditions. J. Phys. D Appl. Phys. 2018, 52, 034002. [Google Scholar] [CrossRef]

- Wu, S.; Thapa, B.; Rivera, C.; Yuan, Y. Nitrate and nitrite fertilizer production from air and water by continuous flow liquid-phase plasma discharge. J. Environ. Chem. Eng. 2021, 9, 104761. [Google Scholar] [CrossRef]

- Ding, L.; Liu, S.; Mei, D.; Liu, F.; Fang, Z. Discharge Mode and Periodic Characteristics of an AC Gliding Arc Discharge in Nitrogen Environment. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2021, 41, 2939–2947. [Google Scholar] [CrossRef]

- Zhu, J.; Sun, Z.; Li, Z.; Ehn, A.; Aldén, M.; Salewski, M.; Leipold, F.; Kusano, Y. Dynamics, OH distributions and UV emission of a gliding arc at various flow-rates investigated by optical measurements. J. Phys. D Appl. Phys. 2014, 47, 295203. [Google Scholar] [CrossRef]

- Zhang, K.; Jin, D.; Huang, S.; Sun, J.; Song, F. Experimental Investigation on Multiple-Channel Gliding Arcs Plasma Cracking Kerosene. IEEE Trans. Plasma Sci. 2022, 50, 4732–4743. [Google Scholar] [CrossRef]

| Air Flow Rate | Number of Discharge Period | Average Discharge Period |

|---|---|---|

| 0.8 L/min | 12 | 48.5 ms |

| 1.6 L/min | 21 | 33.9 ms |

| 2.4 L/min | 37 | 18.7 ms |

| 3.2 L/min | 44 | 13.2 ms |

| 4.0 L/min | 64 | 10.1 ms |

| Air Flow Rate | Average Discharge Period |

|---|---|

| 0.8 L/min | 44.1 ms |

| 1.6 L/min | 30.8 ms |

| 2.4 L/min | 17.0 ms |

| 3.2 L/min | 12.0 ms |

| 4.0 L/min | 9.18 ms |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Q.; Li, L.; Xue, Z.; Liu, Y.; Zang, D.; Wang, Z.; Qu, H.; Yin, J.; Wang, L. Plasma Agricultural Nitrogen Fixation Using Clean Energies: New Attempt of Promoting PV Absorption in Rural Areas. Processes 2023, 11, 2030. https://doi.org/10.3390/pr11072030

Zheng Q, Li L, Xue Z, Liu Y, Zang D, Wang Z, Qu H, Yin J, Wang L. Plasma Agricultural Nitrogen Fixation Using Clean Energies: New Attempt of Promoting PV Absorption in Rural Areas. Processes. 2023; 11(7):2030. https://doi.org/10.3390/pr11072030

Chicago/Turabian StyleZheng, Qiyu, Liying Li, Zhihua Xue, Yanbin Liu, Dehua Zang, Zifeng Wang, Haowei Qu, Jiaxuan Yin, and Lidi Wang. 2023. "Plasma Agricultural Nitrogen Fixation Using Clean Energies: New Attempt of Promoting PV Absorption in Rural Areas" Processes 11, no. 7: 2030. https://doi.org/10.3390/pr11072030

APA StyleZheng, Q., Li, L., Xue, Z., Liu, Y., Zang, D., Wang, Z., Qu, H., Yin, J., & Wang, L. (2023). Plasma Agricultural Nitrogen Fixation Using Clean Energies: New Attempt of Promoting PV Absorption in Rural Areas. Processes, 11(7), 2030. https://doi.org/10.3390/pr11072030