The Study of an Energy Management Strategy within a Microgrid with Photovoltaic Production of the <<PROPRE.MA>> Project in the City of Tangier and Integrating V2G Technology

Abstract

:1. Introduction

2. Materials and Methods

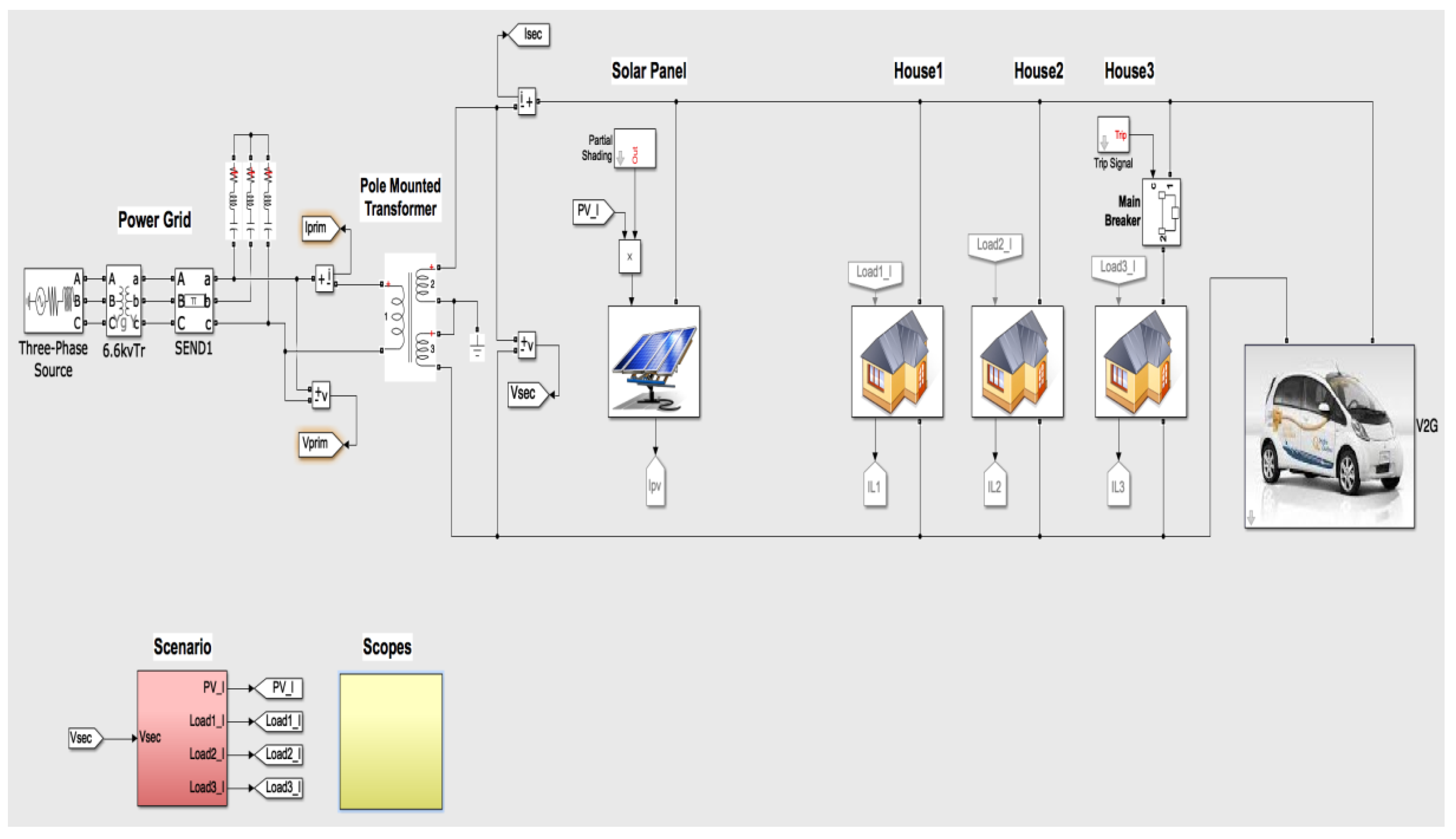

2.1. Description of the System

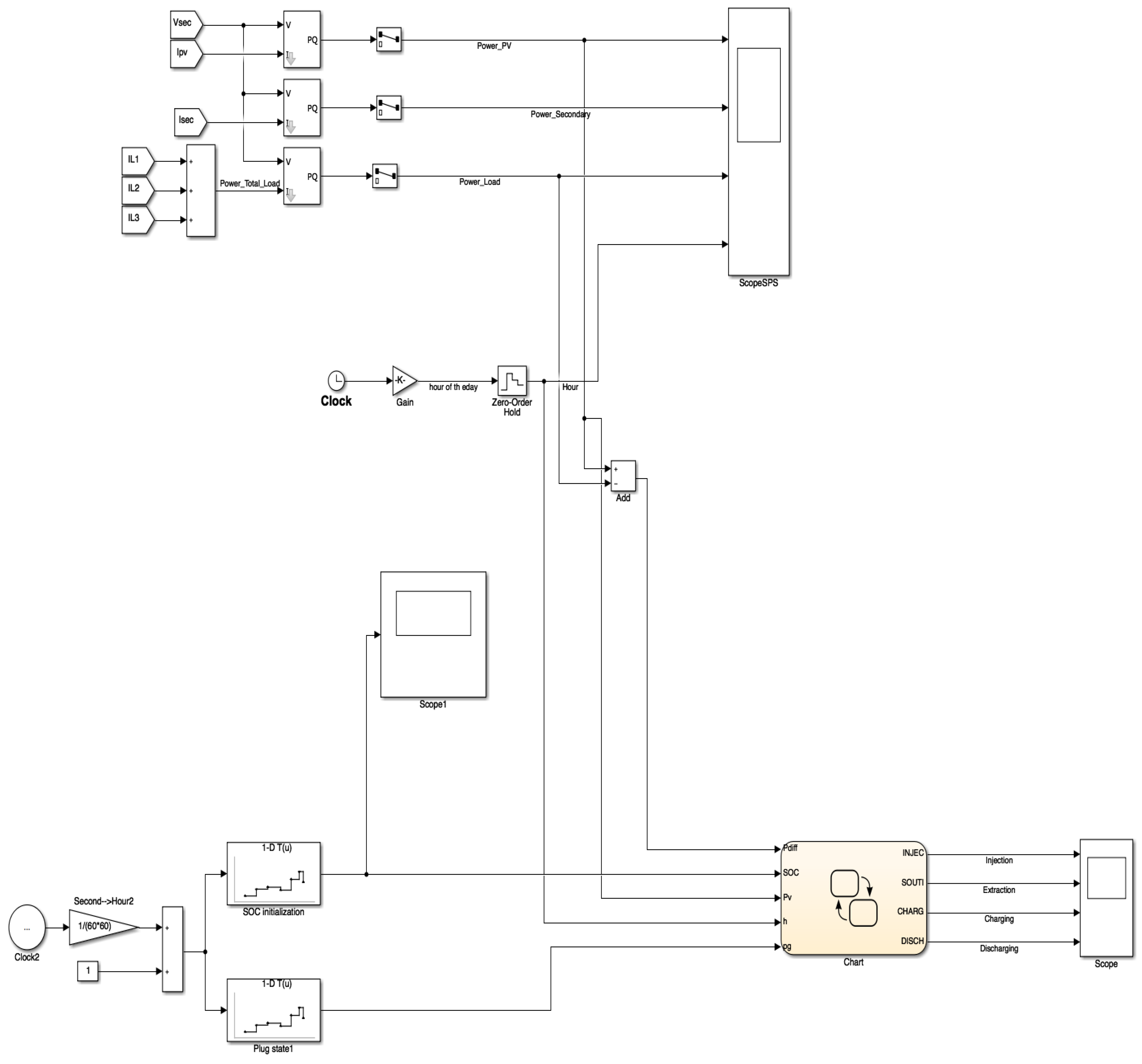

2.2. Control and Operational Strategy

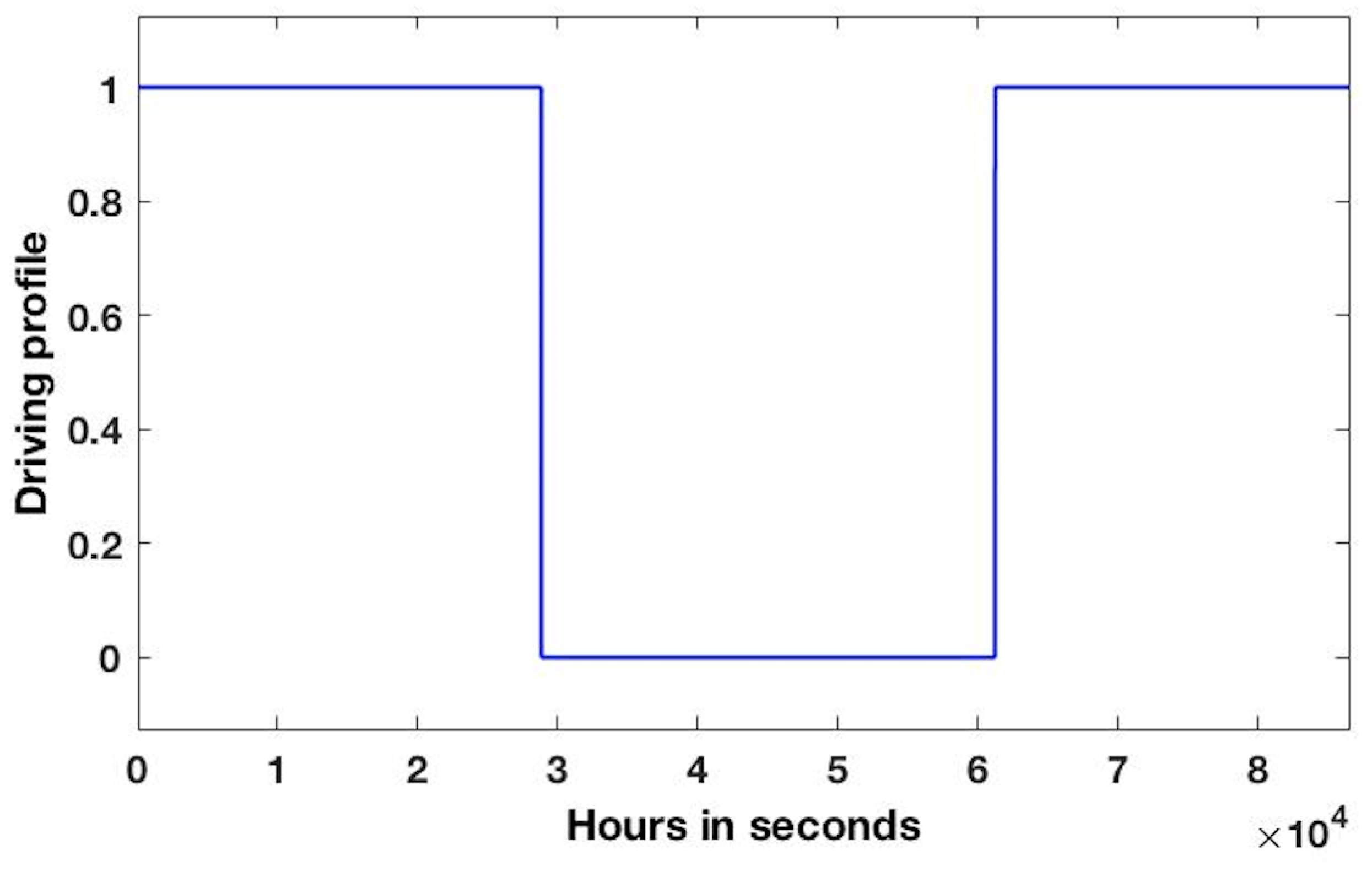

2.3. Description of the Different Cases of the Simulation

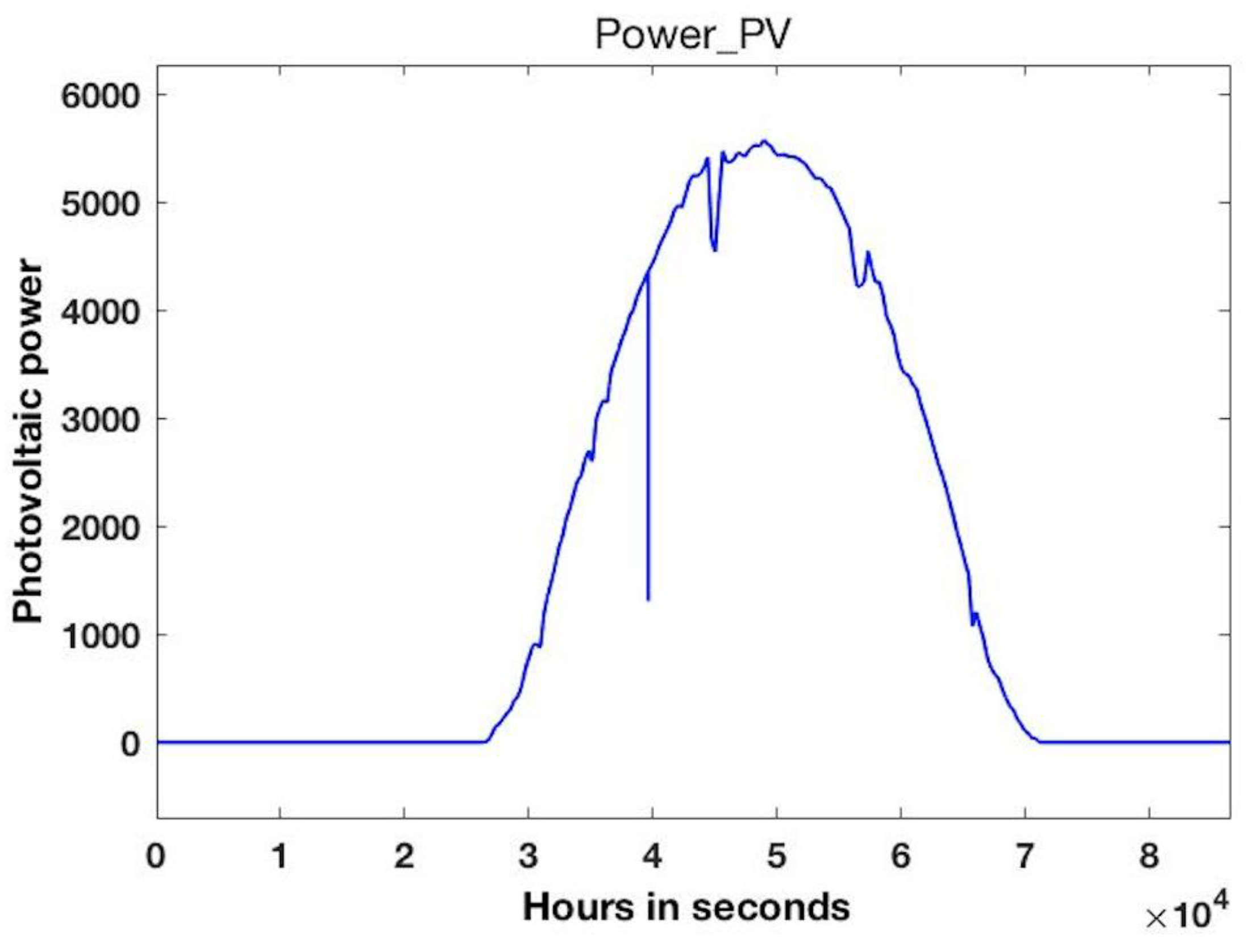

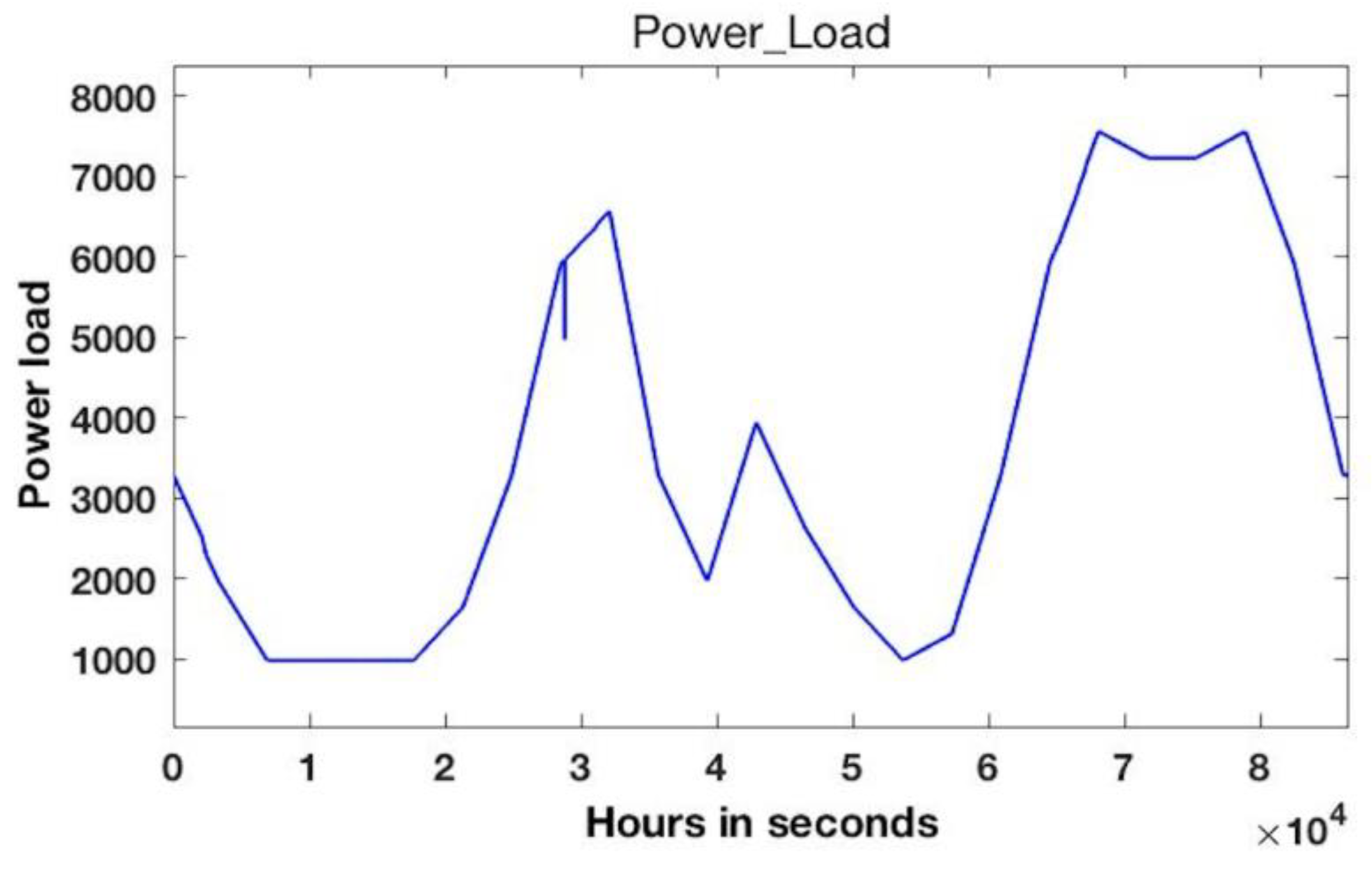

3. Results

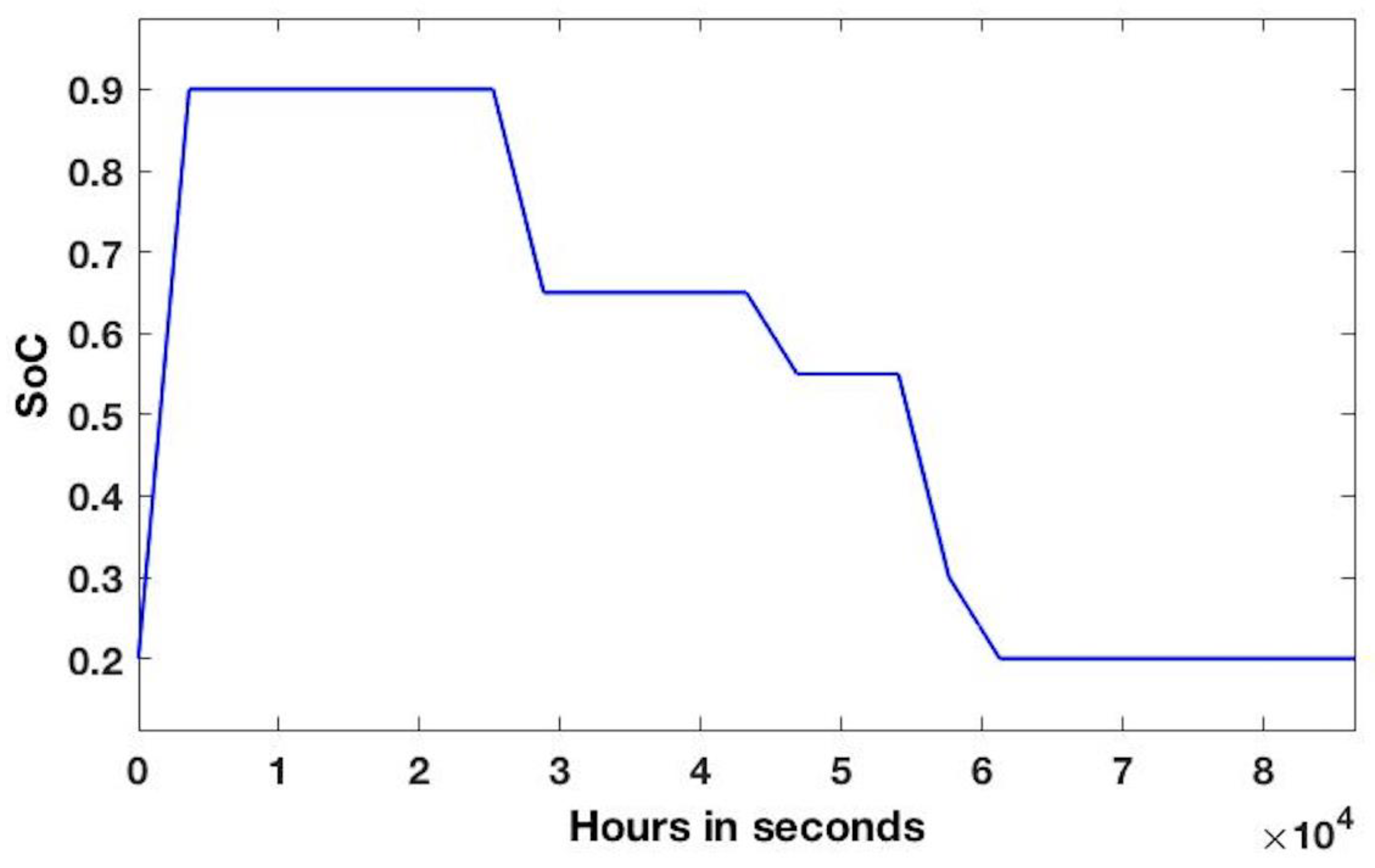

3.1. Case (i)

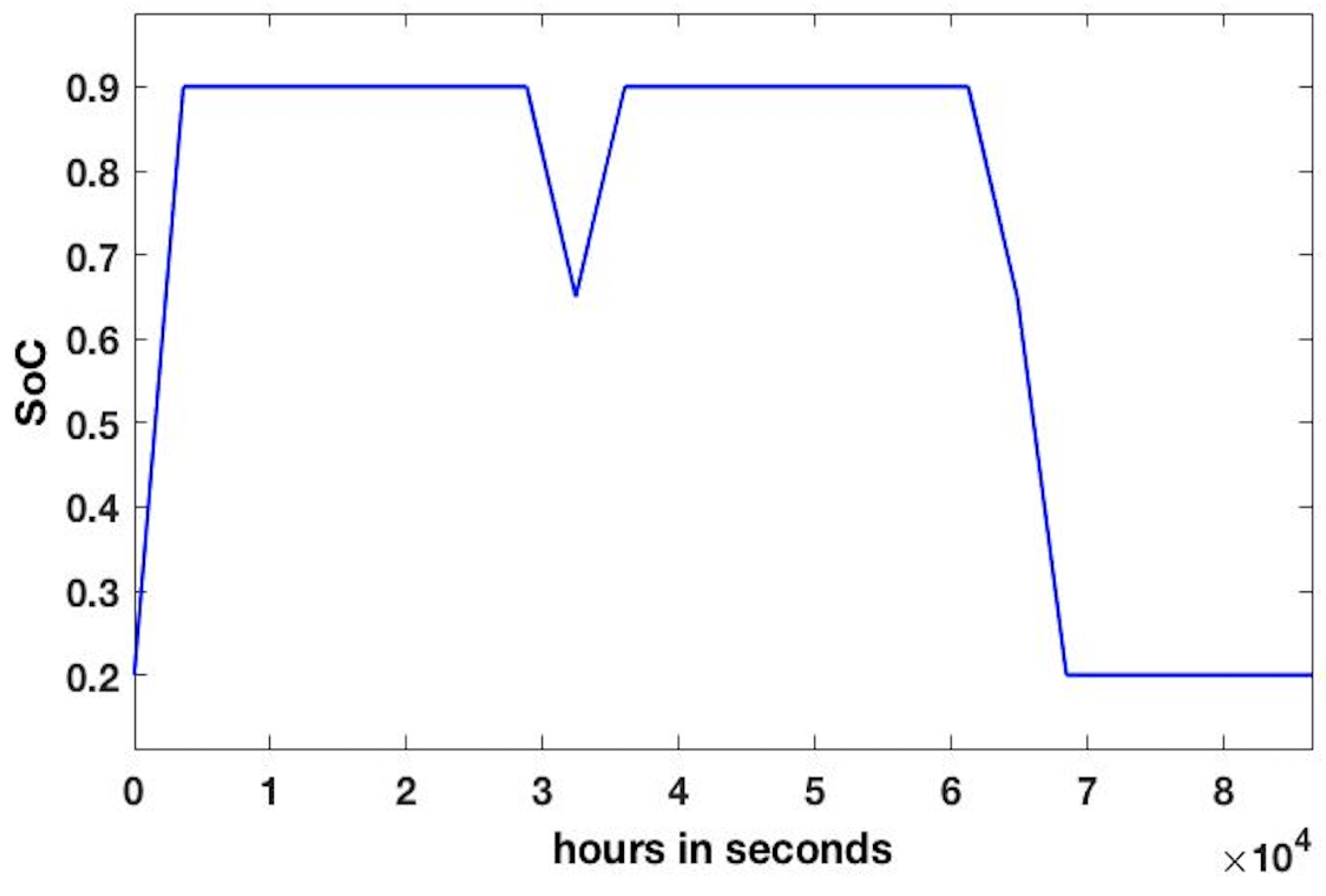

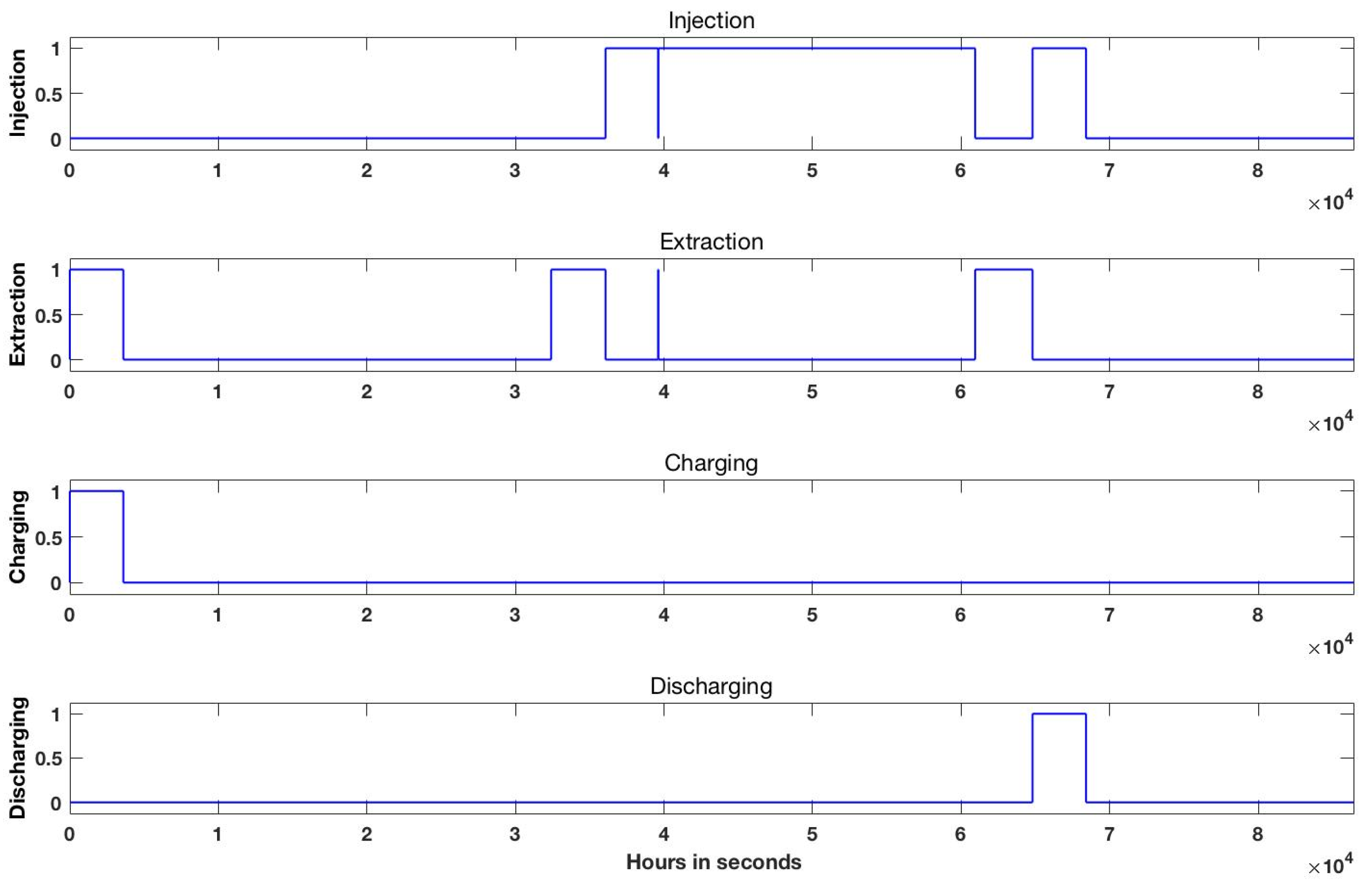

3.2. Case (ii)

4. Discussion of the Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- White, C.D.; Zhang, K.M. Using vehicle-to-grid technology for frequency regulation and peak-load reduction. Power Sources 2011, 196, 3972–3980. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, X. Vehicle to grid technology: A review. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015. [Google Scholar]

- Tchagang, A.; Yoo, Y. V2B/V2G on Energy Cost and Battery Degradation under Different Driving Scenarios, Peak Shaving, and Frequency Regulations. World Electr. Veh. J. 2020, 11, 14. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Li, K. Incorporating Demand Response of Electric Vehicles in Scheduling of Isolated Microgrids with Renewables Using a Bi-Level Programming Approach. IEEE Access 2019, 7, 116256–116266. [Google Scholar] [CrossRef]

- AbuElrub, A.; Hamed, F.; Saadeh, O. Microgrid integrated electric vehicle charging algorithm with photovoltaic generation. J. Energy Storage 2020, 32, 101858. [Google Scholar] [CrossRef]

- Sassi, H.B.; Errahimi, F.; Essbai, N.; Alaoui, C. V2G and Wireless V2G concepts: State of the Art and Current Challenges. In Proceedings of the 2019 International Conference on Wireless Technologies, Embedded and Intelligent Systems(WITS), Fez, Morocco, 3–4 April 2019. [Google Scholar]

- Tehrani, K. A smart cyber physical multi-source energy system for an electric vehicle prototype. J. Syst. Archit. 2020, 111, 101804. [Google Scholar] [CrossRef]

- Gamil, M.M.; Senjyu, T.; Masrur, H.; Takahashi, H.; Lotfy, M.E. Controlled V2Gs and battery integration into residential microgrids: Economic and environmental impacts. Energy Convers. Manag. 2022, 253, 115171. [Google Scholar] [CrossRef]

- Kazerani, M.; Tehrani, K. Grid of Hybrid AC/DC Microgrids: A New Paradigm for Smart City of Tomorrow. In Proceedings of the 2020 IEEE 15th International Conference of System of Systems Engineering (SoSE), Budapest, Hungary, 2–4 June 2020. [Google Scholar]

- Bennouna, A.; Aarich, N.; Erraissi, N.; Akhsassi, M.; Asselman, A.; Barhdadi, A.; Boukhattem, L.; Cherkaoui, A.; Darmane, Y.; Doudou, A.; et al. Energy performance of 3 silicon-based PV module technologies in 20 sites of Morocco. Energy Sustain. Dev. 2019, 53, 30–56. [Google Scholar] [CrossRef]

- Aarich, N.; Erraissi, N.; Akhsassi, M.; Bennouna, A.; Asselman, A.; Barhdadi, A.; Boukhattem, L.; Cherkaoui, A.; Darmane, Y.; Doudou, A.; et al. Photovoltaic DC yield maps for all Morocco validated with ground measurements. Energy Sustain. Dev. 2018, 47, 158–169. [Google Scholar] [CrossRef]

- Available online: https://www.renault.fr/vehicules-electriques/twingo-electric.html (accessed on 3 January 2023).

- Mita, H. Simplified Model of a Small Scaled Microgrid. Available online: https://fr.mathworks.com/help/physmod/sps/examples/simplified-model-of-a-small-scale-micro-grid.html (accessed on 4 September 2020).

- Available online: https://fr.mathworks.com/discovery/state-diagram.html (accessed on 5 December 2022).

| Winter from 1 October to 31 April | Summer from 1 March to 30 September | |

|---|---|---|

| Peak hours | 5 p.m. to 10 p.m. | 6 p.m. to 11 p.m. |

| Off-peak hours | from 7 a.m. to 5 p.m. and from 10 p.m. to 7 a.m. | from 7 a.m. to 6 p.m. and from 11 p.m. to 7 a.m. |

| Pv (kWh) | Pload (kWh) | Pinjection (kWh) | Pextraction (kWh) | |

|---|---|---|---|---|

| 8 a.m.–9 a.m. | 12.84 | 24.87 | 0 | 12.03 |

| 9 a.m.–10 a.m. | 32.02 | 33.90 | 0 | 1.88 |

| 10 a.m.–11 a.m. | 48.99 | 10.92 | 38.07 | 0 |

| 11 a.m.–12 a.m. | 61.96 | 13.33 | 48.63 | 0 |

| 12 a.m.–1 p.m. | 67.24 | 12.76 | 54.48 | 0 |

| 1 p.m.–2 p.m. | 59.79 | 8.84 | 50.95 | 0 |

| 2 p.m.–3 p.m. | 68.65 | 5.44 | 63.21 | 0 |

| 3 p.m.–4 p.m. | 60.43 | 4.90 | 55.53 | 0 |

| 4 p.m.–5 p.m. | 48.70 | 10.61 | 38.09 | 0 |

| 5 p.m.–6 p.m. | 33.03 | 20.69 | 12.34 | 0 |

| 6 p.m.–7 p.m. | 12.92 | 29.50 | 0 | 16.58 |

| Pv (kWh) | Pload (kWh) | Pinjection (kWh) | Pextraction (kWh) | |

|---|---|---|---|---|

| 8 a.m.–9 a.m. | 12.84 | 24.87 | 0 | 12.03 |

| 9 a.m.–10 a.m. | 32.02 | 33.90 | 0 | 1.88 |

| 10 a.m.–11 a.m. | 48.99 | 10.92 | 38.07 | 0 |

| 11 a.m.–12 a.m. | 61.96 | 13.33 | 48.63 | 0 |

| 12 a.m.–1 p.m. | 67.24 | 12.76 | 54.48 | 0 |

| 1 p.m.–2 p.m. | 59.79 | 8.84 | 50.95 | 0 |

| 2 p.m.–3 p.m. | 68.65 | 5.44 | 63.21 | 0 |

| 3 p.m.–4 p.m. | 60.43 | 4.90 | 55.53 | 0 |

| 4 p.m.–5 p.m. | 48.70 | 10.61 | 38.09 | 0 |

| 5 p.m.–6 p.m. | 33.03 | 20.69 | 12.34 | 0 |

| 6 p.m.–7 p.m. | 12.92 | 29.50 | 0 | 16.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doudou, Y.; Cherkaoui, A.; Ezziyyani, M. The Study of an Energy Management Strategy within a Microgrid with Photovoltaic Production of the <<PROPRE.MA>> Project in the City of Tangier and Integrating V2G Technology. Processes 2023, 11, 2090. https://doi.org/10.3390/pr11072090

Doudou Y, Cherkaoui A, Ezziyyani M. The Study of an Energy Management Strategy within a Microgrid with Photovoltaic Production of the <<PROPRE.MA>> Project in the City of Tangier and Integrating V2G Technology. Processes. 2023; 11(7):2090. https://doi.org/10.3390/pr11072090

Chicago/Turabian StyleDoudou, Youssra, Abdeljabbar Cherkaoui, and Mostafa Ezziyyani. 2023. "The Study of an Energy Management Strategy within a Microgrid with Photovoltaic Production of the <<PROPRE.MA>> Project in the City of Tangier and Integrating V2G Technology" Processes 11, no. 7: 2090. https://doi.org/10.3390/pr11072090