Coal Pillar Size Determination and Surrounding Rock Control for Gob-Side Entry Driving in Deep Soft Coal Seams

Abstract

1. Introduction

2. Engineering Overview

2.1. Geological Conditions of the Panel and Roadway

2.2. Characteristics of Coal Deformation and Failure

3. Determination of GSED Coal Pillar Size in Deep Soft Coal Seams

3.1. Theoretical Calculation

- (1)

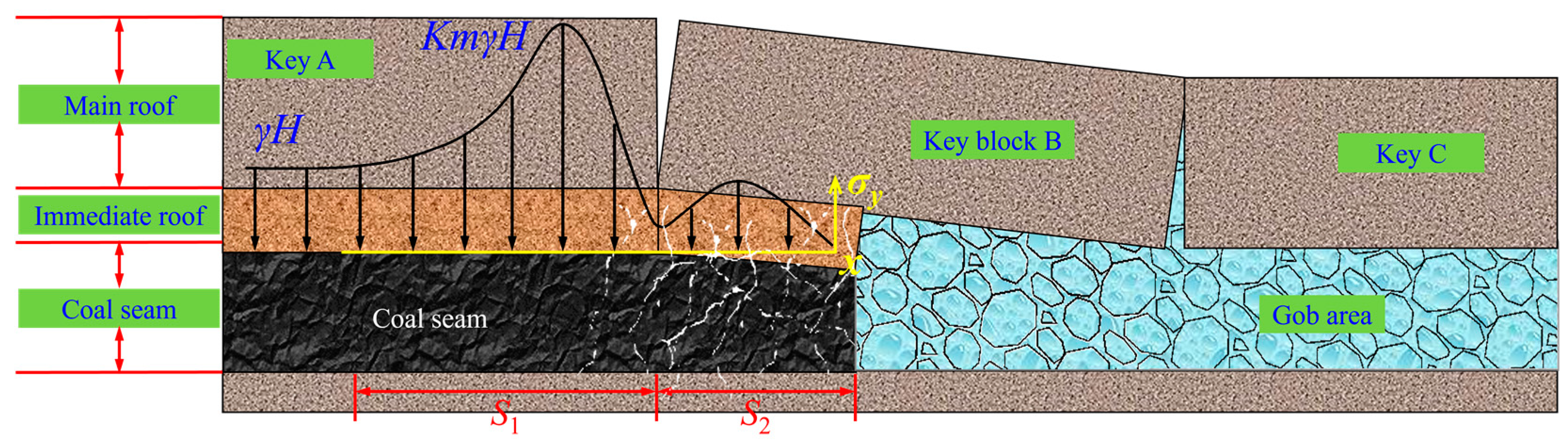

- The relationship between the main roof breaking line position and the coal pillar size.

- (2)

- Relationship between limit equilibrium zone and coal pillar size.

3.2. Numerical Calculation Analysis

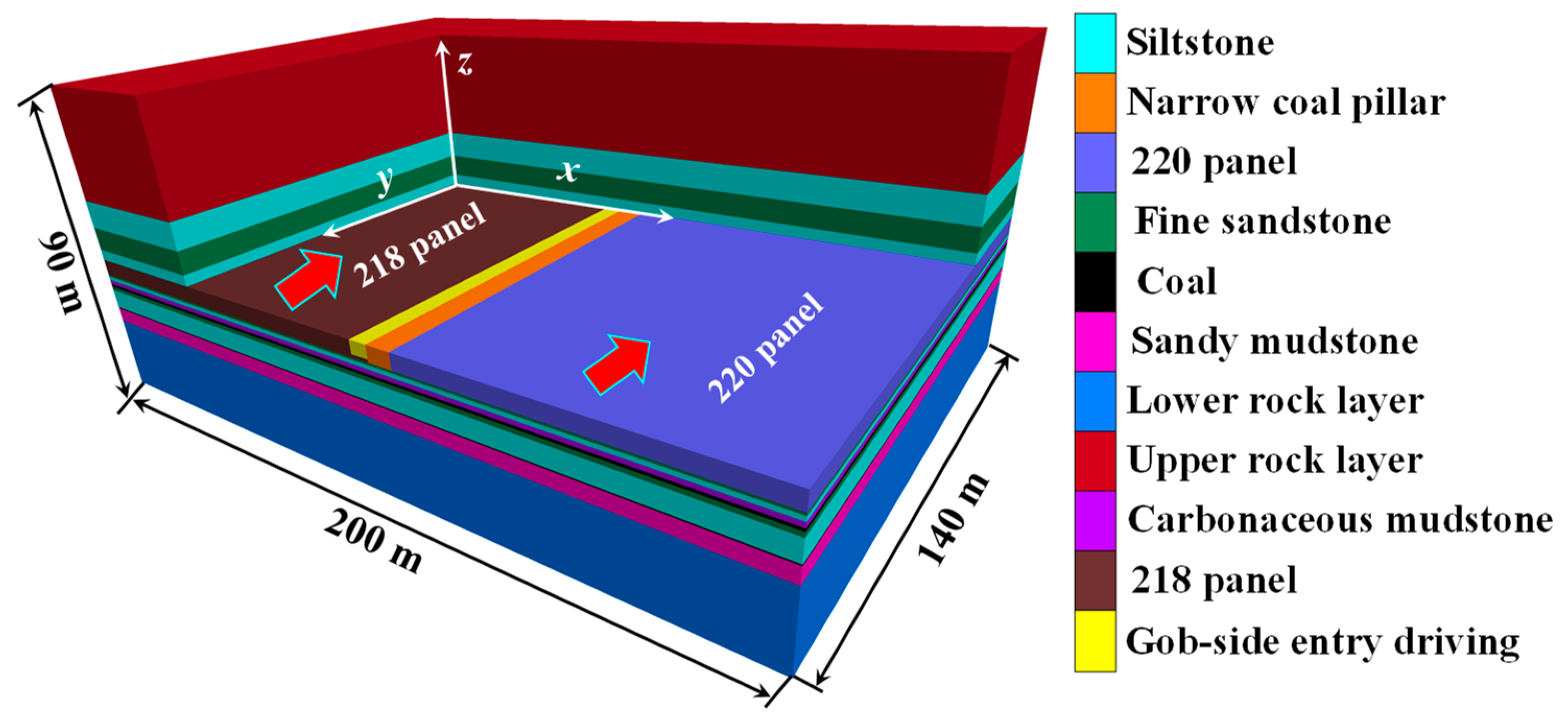

3.2.1. Numerical Model

3.2.2. Superiority of Deviatoric Stress Analysis Indicator

3.2.3. Failure Characteristics of GSED under Different Coal Pillar Sizes

- (1)

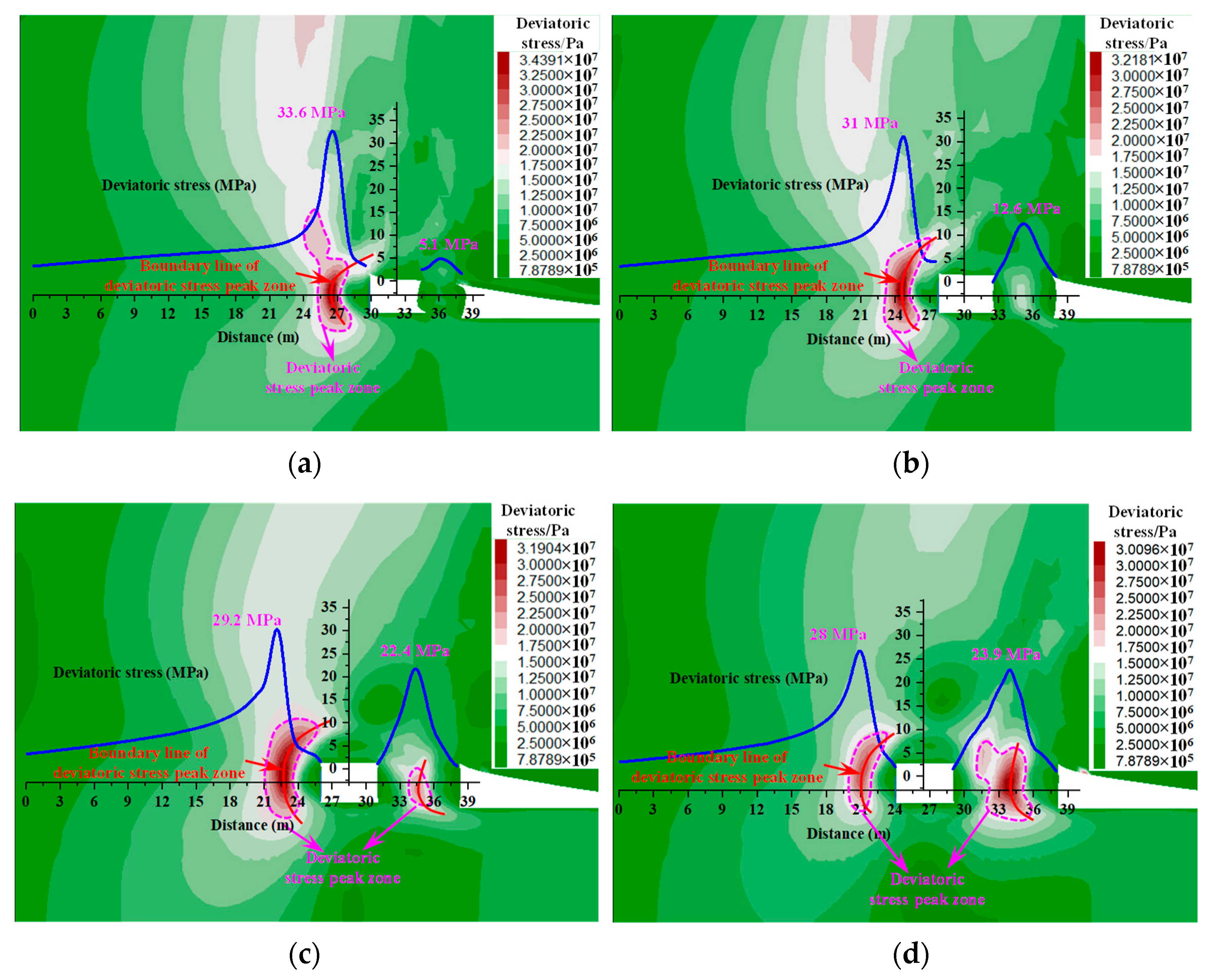

- Distribution characteristics and evolution law of deviatoric stress.

- (2)

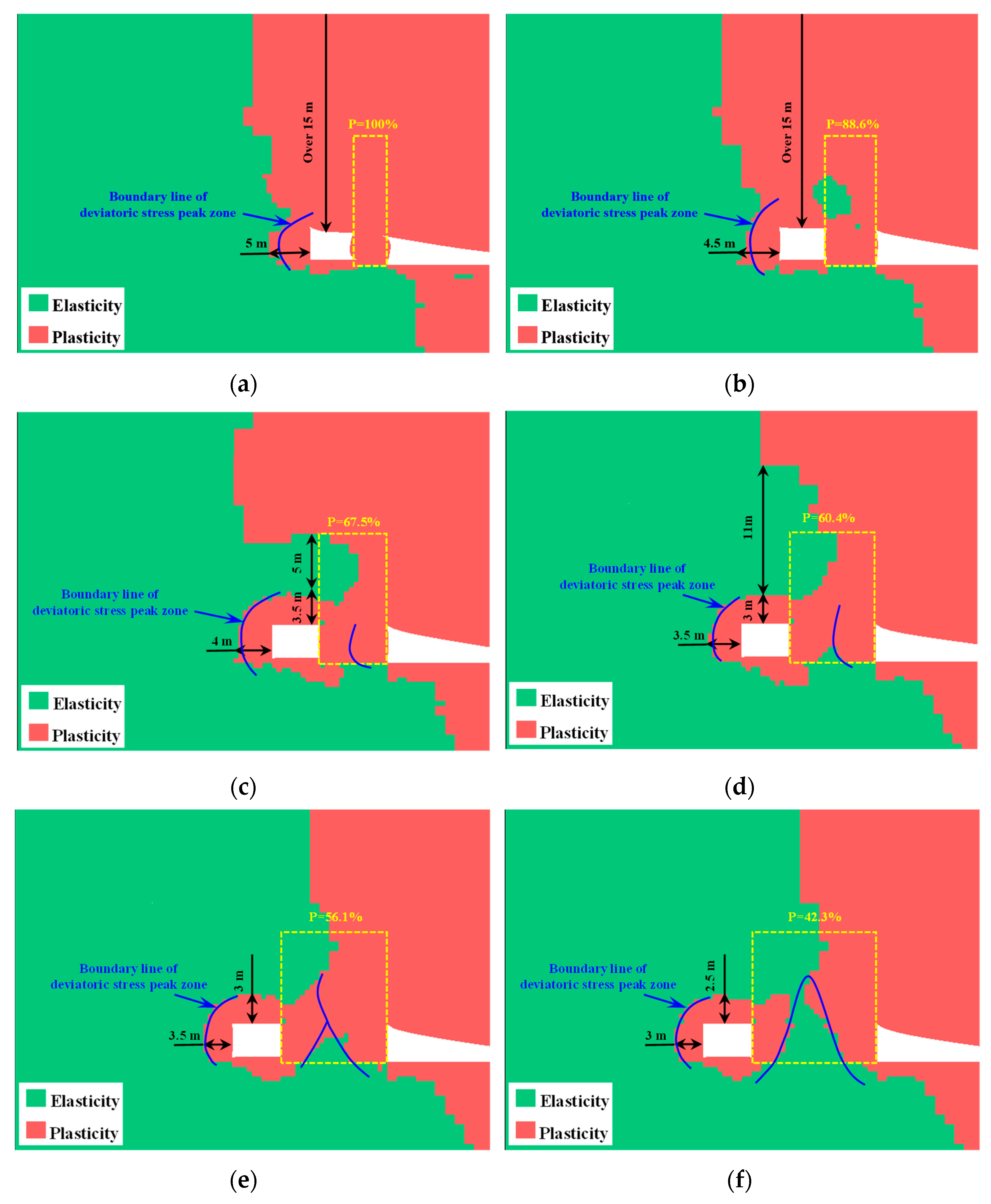

- Distribution characteristics and evolution law of plastic zone.

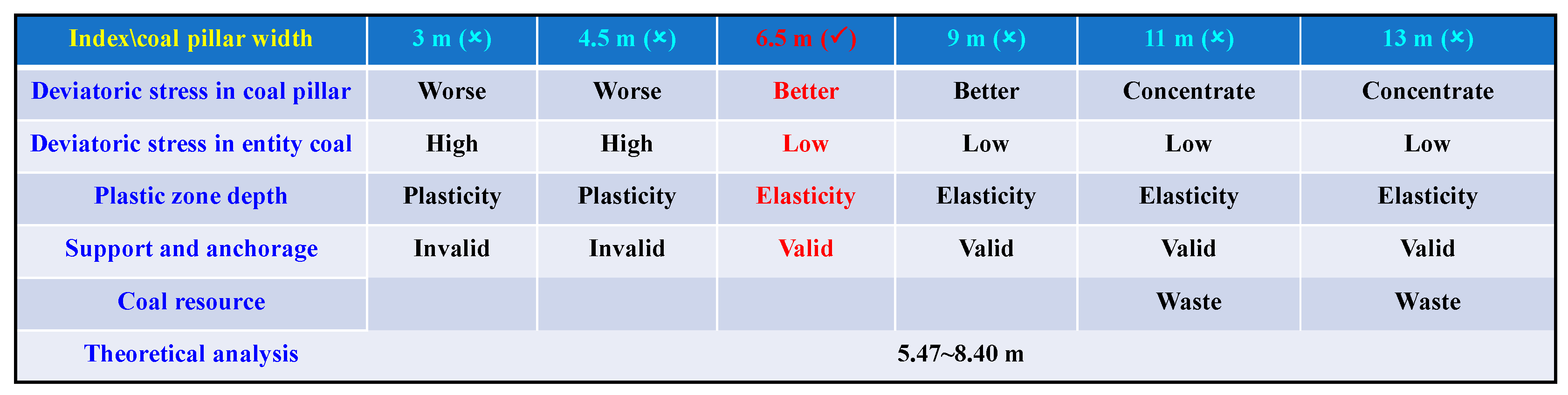

3.3. Optimal Design of Narrow Coal Pillar Size in GSED

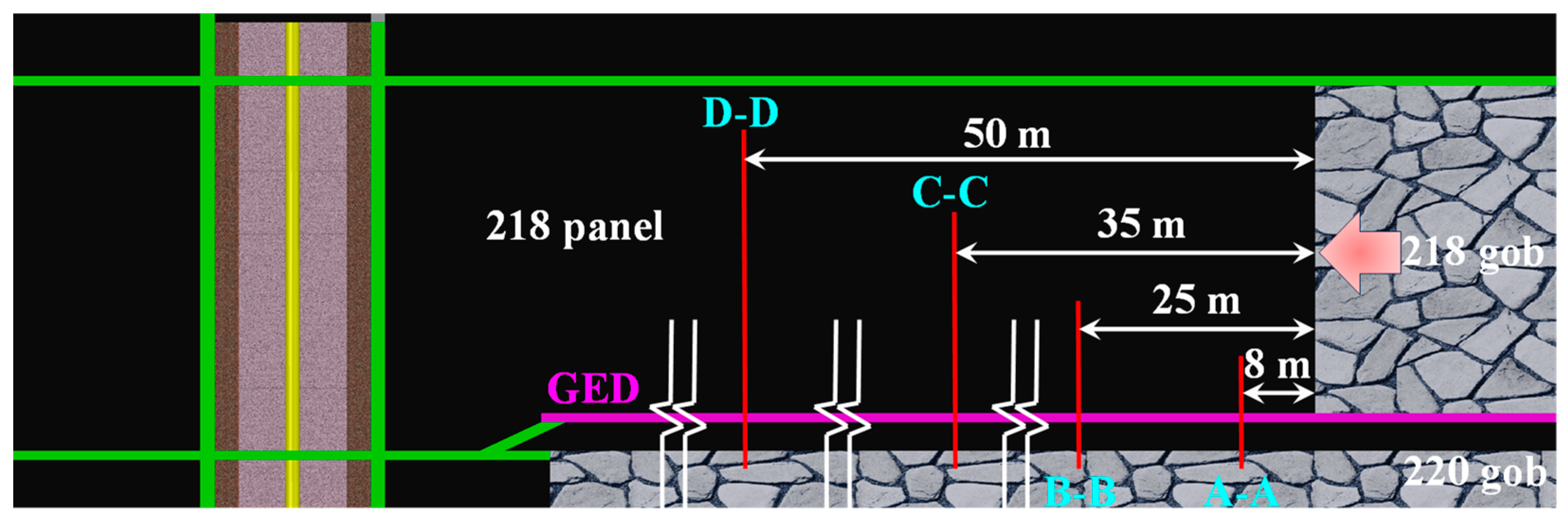

4. Failure Characteristics of GSED Surrounding Rock of the Advanced Panel

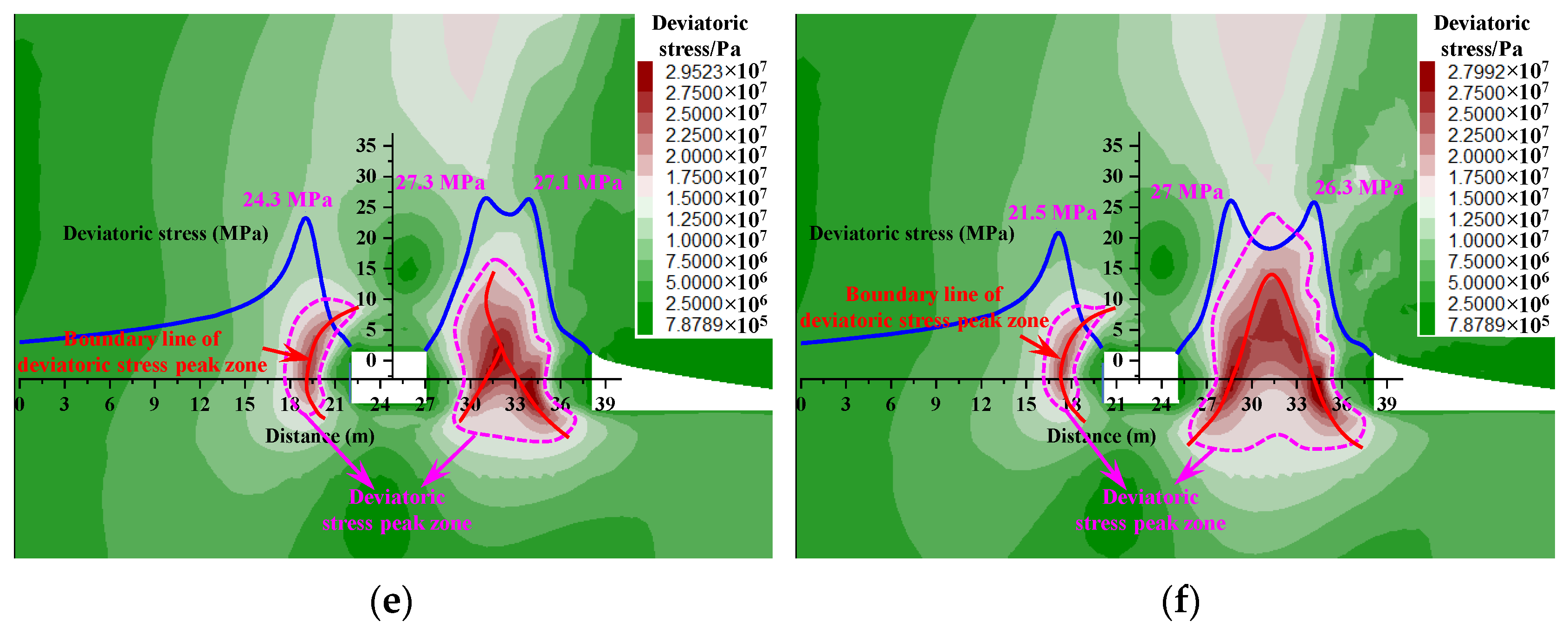

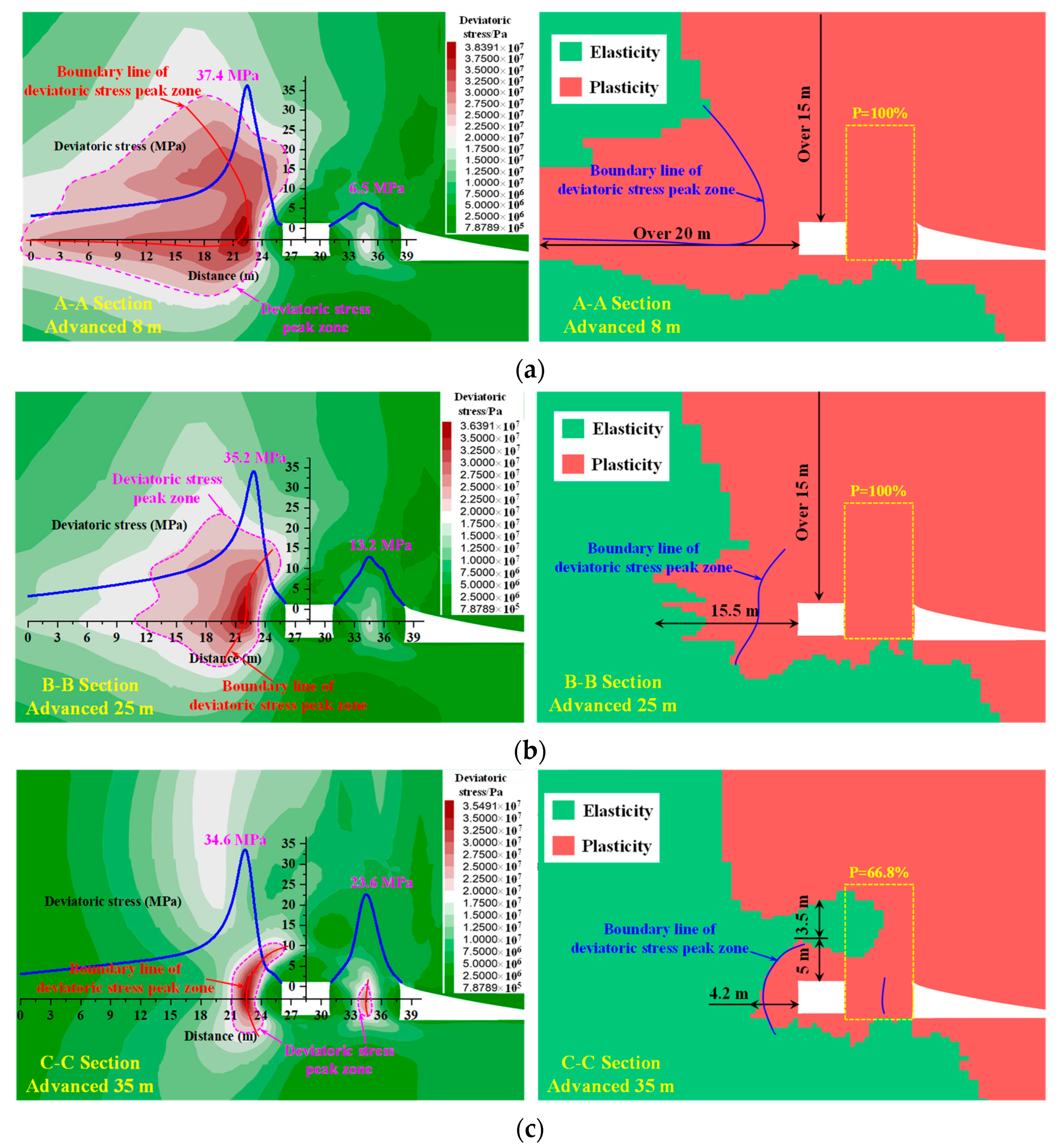

- (1)

- The closer the panel is, the greater the concentration of the peak deviatoric stress band, and the peak deviatoric stress band is mainly concentrated on the entity coal rib. Therefore, the entity coal rib primarily bears the overlying load pressure.

- (2)

- The range of peak deviatoric stress zone on the entity coal rib of the roadway within the 25 m range of the advanced panel is large, and the peak deviatoric stress on the entity coal rib is large, reaching over 35 MPa, whereas the deviatoric stress on the coal pillar rib is weak, less than 14 MPa. The plastic zone depth of the roadway entity coal rib and roof within the 25 m range of the advanced panel exceeds 15 m, and the plasticization degree of the coal pillar is 100%. The roadway within this section is severely damaged and requires advanced support. This project uses single hydraulic supports for advanced support to maintain normal coal production.

- (3)

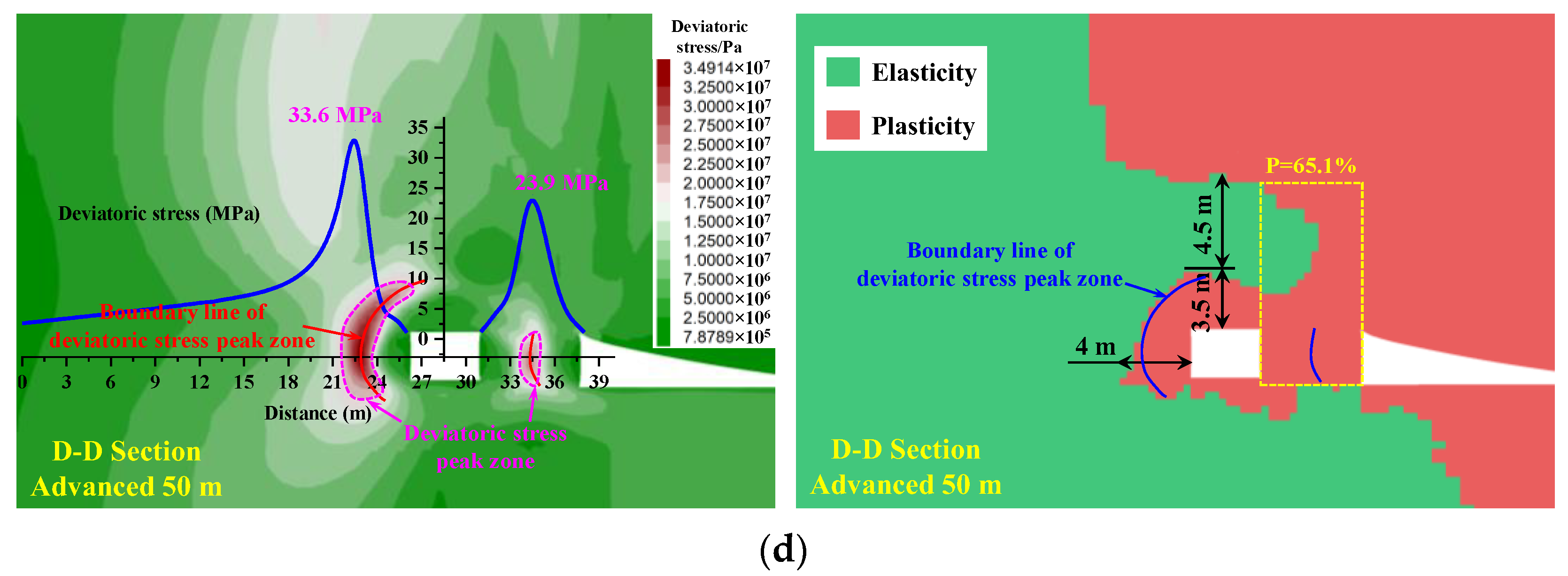

- The deviatoric stress on the entity coal rib and coal pillar rib of the roadway outside the range of 35 m ahead of the panel gradually stabilizes, with a peak deviatoric stress on the entity coal rib of about 34 MPa. The deviatoric stress state on the coal pillar rib is excellent, about 24 MPa. When the advanced panel distance is 35 m, the plastic zone depth on the entity coal rib of the roadway is 4.2 m, the plasticization degree of the coal pillar is 66.8%, the plastic zone depth on the roof is 5 m, and an elastic zone with a size of 3.5 m appears above the roof. When the advanced panel distance is 50 m, the plastic zone depth on the entity coal rib of the roadway is 4 m, the plasticization degree of coal pillar is 65.1%, the plastic zone depth on the roof is 3.5 m, and an elastic zone with a size of 4.5 m appears above the roof.

5. Control Technology of GSED Surrounding Rock

5.1. Thoughts on Support Design

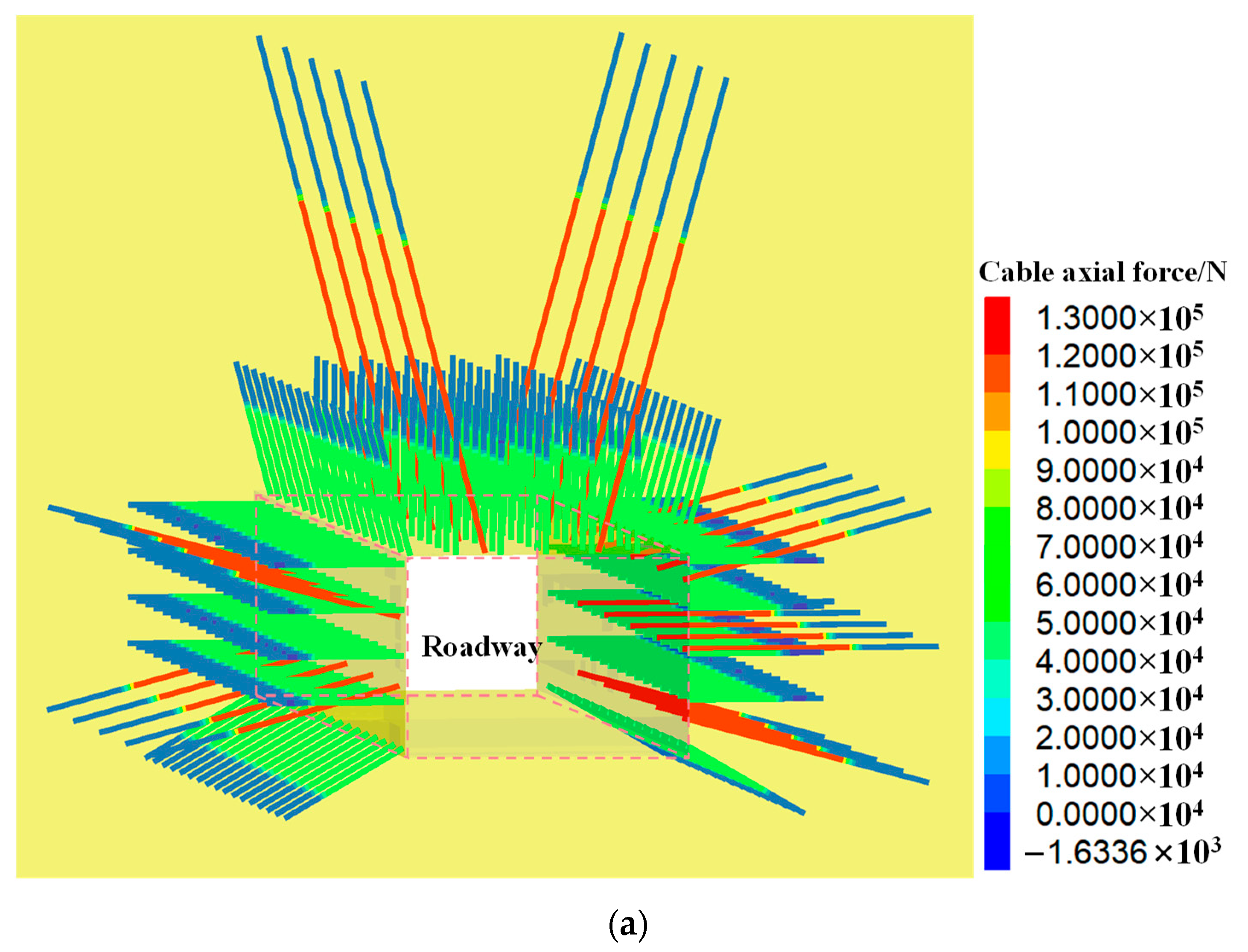

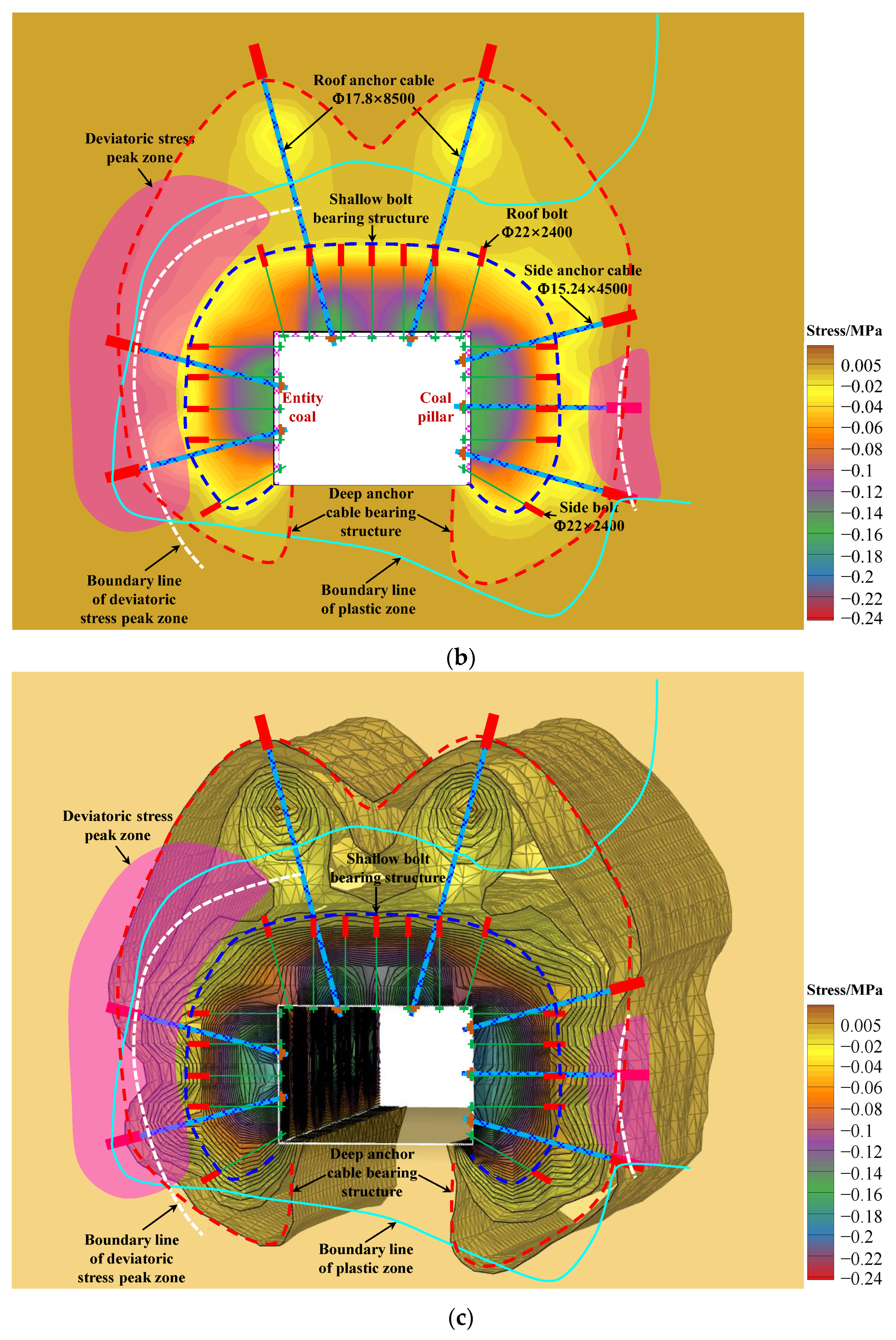

5.2. Control Measures for Surrounding Rock

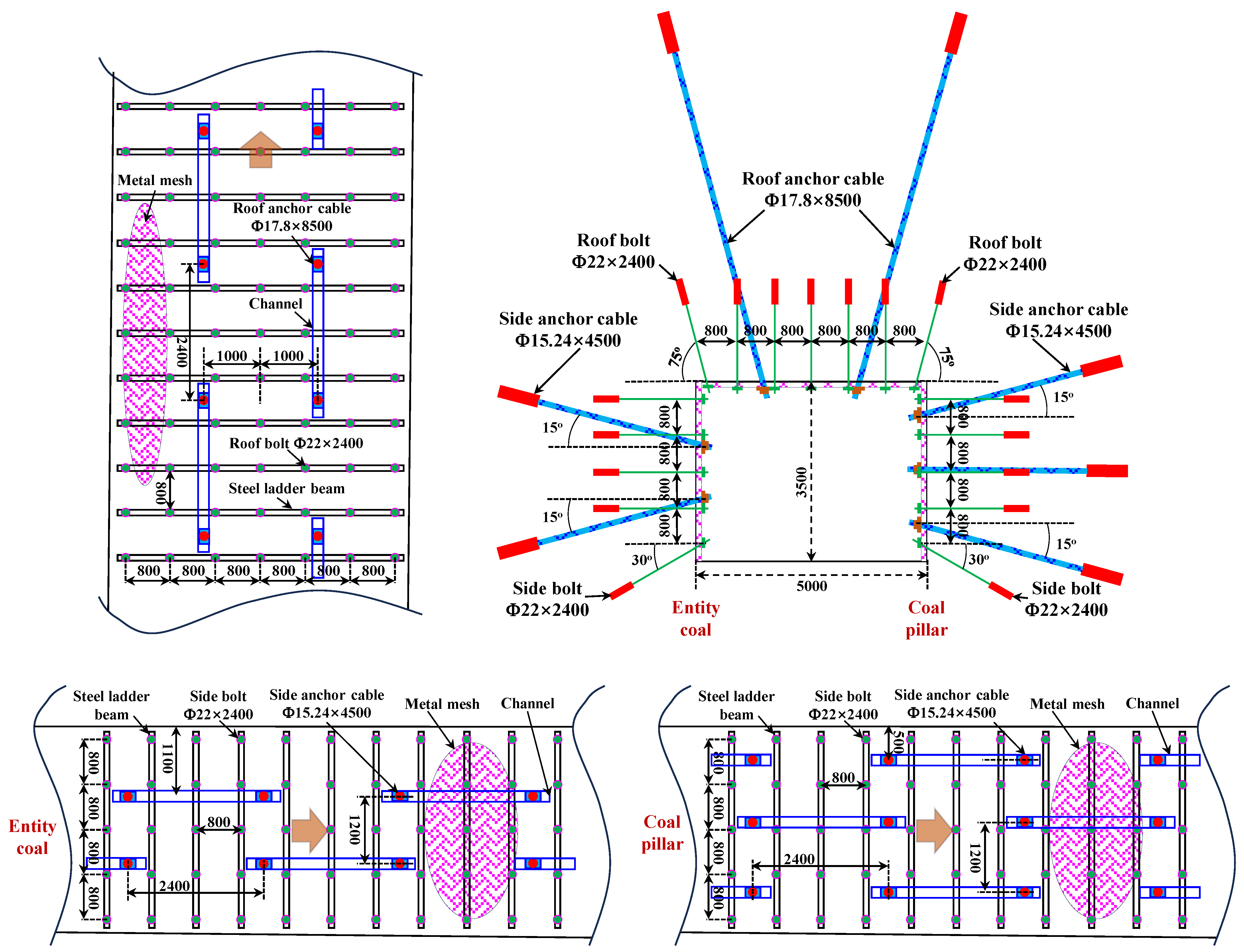

5.3. Support Programme of GSED Surrounding Rock

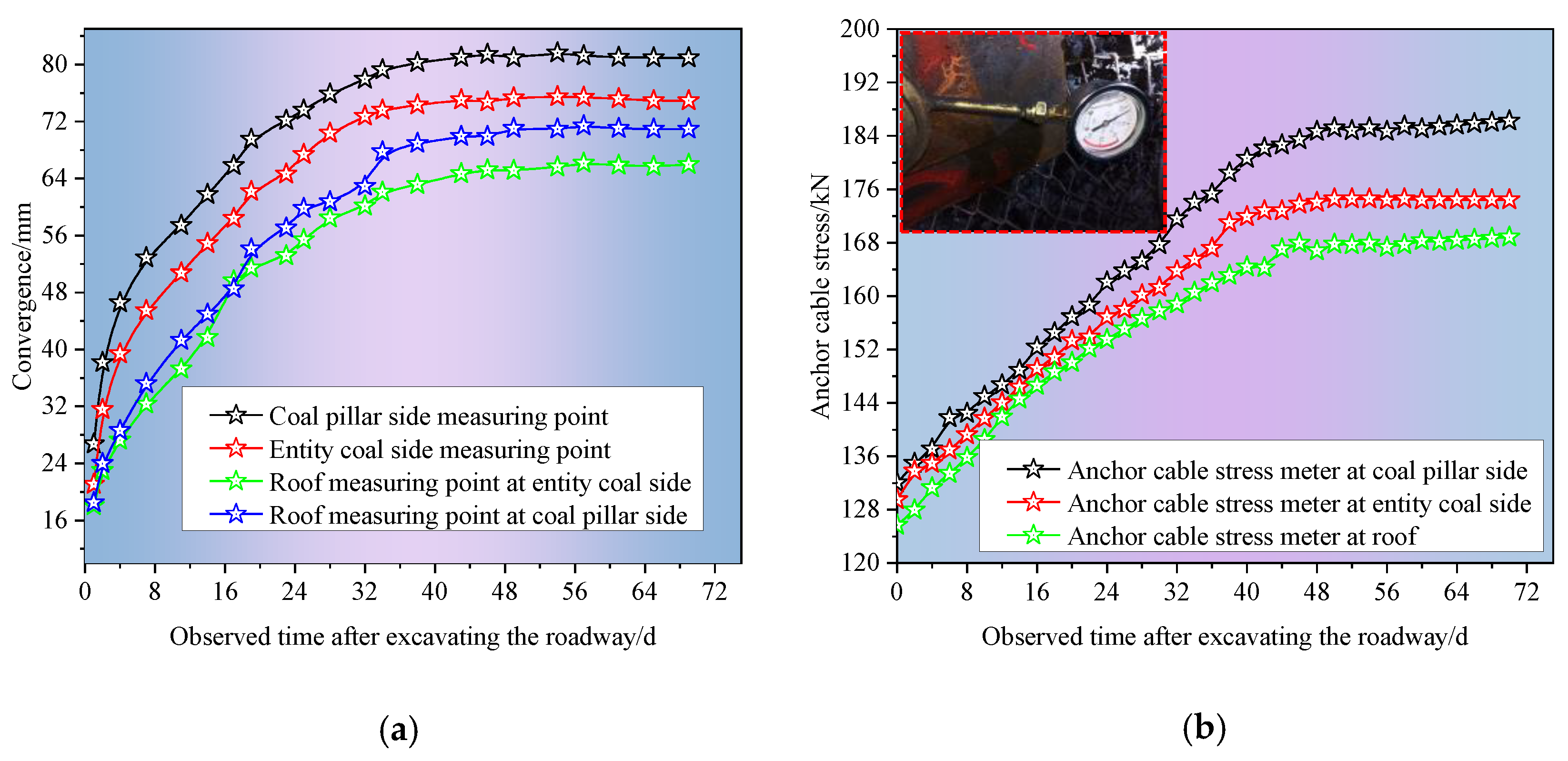

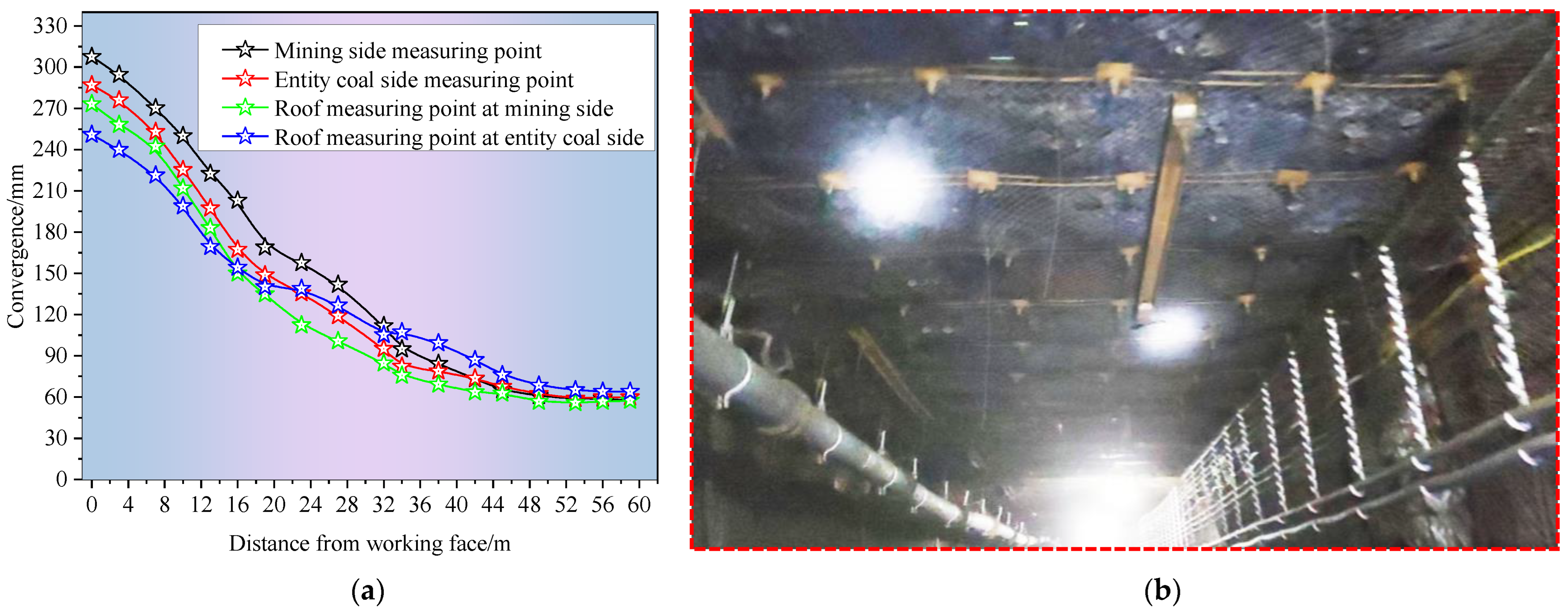

5.4. Engineering Application

6. Conclusions

- (1)

- Under the condition of ensuring that the coal pillar and roadway are in the stress low-value zone and the coal pillar has a self-stabilizing ability, the maximum size of the narrow coal pillar under this geological condition is 8.40 m, and the minimum size is 5.47 m. Numerical analysis shows that the reasonable size of the coal pillar should be within the range of 6.5 to 9 m. Within this range, the coal pillar has an excellent stress environment and roof support conditions, which can fully utilize the support effect of anchor cables. Based on the intersection of theoretical calculation and numerical analysis results, it is comprehensively determined that the size of the GSED narrow coal pillar is 6.5 m.

- (2)

- The disturbance of the mining face results in the peak deviatoric stress zone mainly concentrated on the entity coal rib, and the entity coal rib mainly bears the overlying load pressure. During mining, the surrounding rock of the roadway within a range of 25 m ahead of the panel is severely damaged, and it is necessary to strengthen support to control the unstable surrounding rock of the roof and rib.

- (3)

- After the excavation of the roadway and panel is stable, the plastic zone maximum depth of the roof and entity coal rib is about 3.5 m and 4 m, respectively. The plasticization degree of the coal pillar rib is about 67.5%. The boundary line of the peak deviatoric stress zone on the entity coal rib is about 3.5 m from the surface of the roadway, and the boundary line of the peak deviatoric stress zone on the coal pillar rib is about 3.8 m from the surface of the roadway.

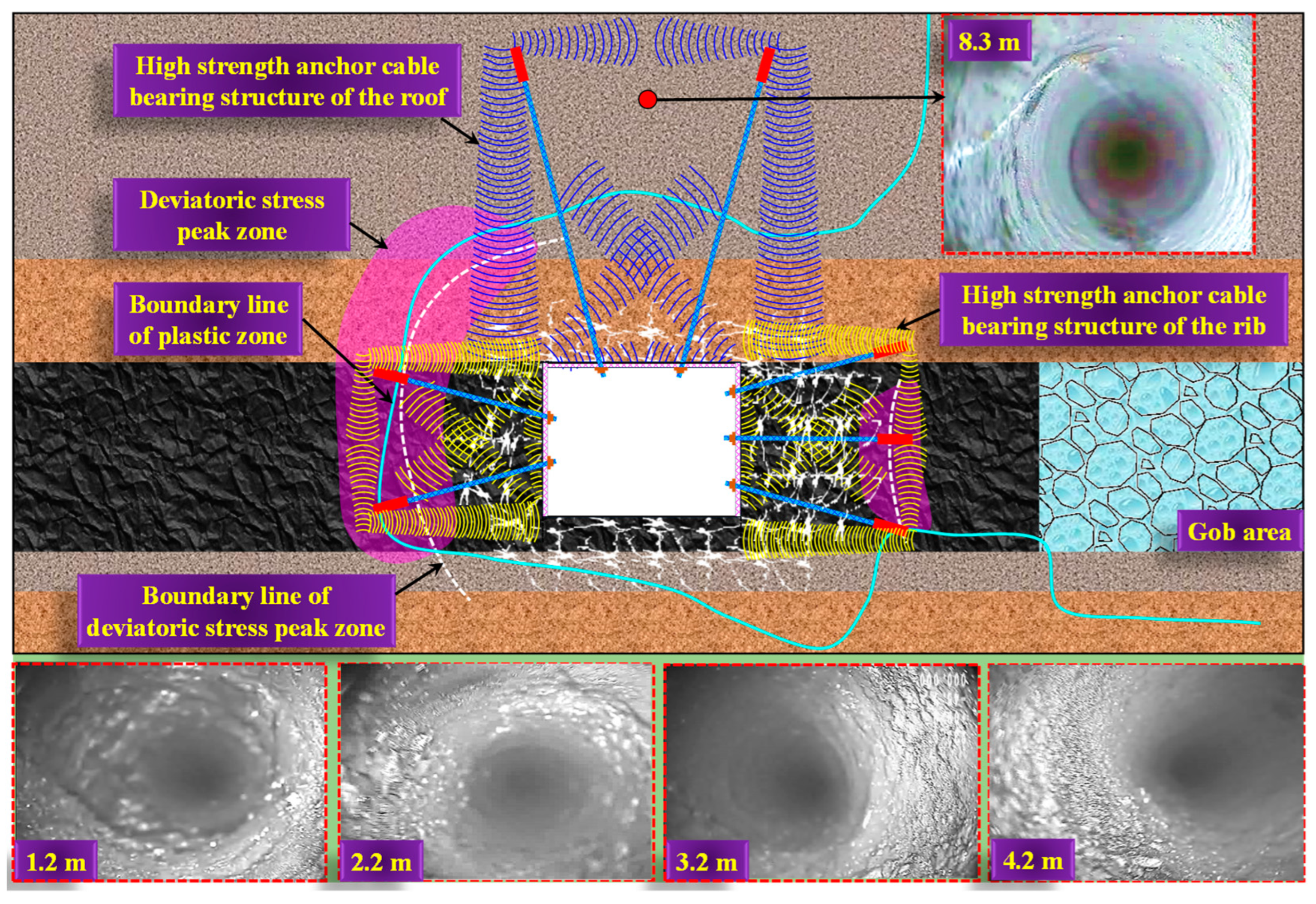

- (4)

- The rock integrity is good at a depth of 8.3 m in the roof, without obvious cracks. The roof anchor cable anchors at this position will have an excellent anchoring effect. There is a certain degree of fragmentation and various irregular cracks in the surrounding rock within the range of 3.2 m of the entity coal rib. The coal mass of the roadway rib is relatively complete at a depth of 4.2 m, and the rib anchor cable anchors at this position will have an excellent anchoring effect. The development of shallow cracks inside the coal pillar is more pronounced than in the entity coal rib. The key area for controlling the GSED surrounding rock is the coal pillar rib.

- (5)

- The support design of the GSED needs to make the anchor cable pass through the boundary line of the deviatoric stress peak zone of the surrounding rock and make the contour line of the plastic zone on the entity coal rib anchor into the relatively intact rock mass. Joint control technology for surrounding rock is proposed, which includes a combination of a roof channel steel anchor beam mesh, a rib asymmetric channel steel truss anchor cable beam mesh, a grouting modification in local fractured areas, and an advanced strengthened support using a single hydraulic support, effectively controlling the deformation of the surrounding rock.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Batugin, A.; Wang, Z.Q.; Su, Z.H.; Sidikovna, S.S. Combined support mechanism of rock bolts and anchor cables for adjacent roadways in the external staggered split-level panel layout. Int. J. Coal Sci. Technol. 2021, 8, 659–673. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, C.; Gu, W.; Yuan, C.F.; Wu, Y.Y.; Liu, Z.C.; Song, T.Q.; Sheng, F.T. Research on floor heave mechanisms and control technology for deep dynamic pressure roadways. Processes 2023, 11, 467. [Google Scholar] [CrossRef]

- Chen, J.H.; Zhao, H.B.; He, F.L.; Zhang, J.W.; Tao, K.M. Studying the performance of fully encapsulated rock bolts with modified structural elements. Int. J. Coal Sci. Technol. 2021, 8, 64–76. [Google Scholar] [CrossRef]

- Xie, S.R.; Li, E.P.; Li, S.J.; Wang, J.G.; He, C.C.; Yang, Y.F. Surrounding rock control mechanism of deep coal roadways and its application. Int. J. Min. Sci. Technol. 2015, 25, 429–434. [Google Scholar] [CrossRef]

- Zhang, Z.; Ning, J.; Wang, J.; Wang, K.; Yang, S.; Yan, R.; Sun, G.Q.; Du, M.H. Coal pillar stress weakening technology and application by gob-side entry driving and hydraulic roof cutting in deep shafts mines. Processes 2022, 10, 827. [Google Scholar] [CrossRef]

- Liu, F.; Han, Y. Deformation mechanism and control of the surrounding rock during gob-side entry driving along deeply fully mechanized caving Island panel. Geofluids 2021, 2021, 5515052. [Google Scholar] [CrossRef]

- Chen, D.D.; Zhu, J.K.; Ye, Q.C.; Ma, X.; Xie, S.R.; Guo, W.K.; Li, Z.J.; Wang, Z.Q.; Feng, S.H.; Yan, X.X. Application of gob-side entry driving in fully mechanized caving mining: A review of theory and technology. Energies 2023, 16, 2691. [Google Scholar] [CrossRef]

- Tan, Y.; Xu, H.; Yan, W.; Guo, W.B.; Sun, Q.; Yin, D.W.; Zhang, Y.J.; Zhang, X.Q.; Jing, X.F.; Li, X.S.; et al. Development law of water-conducting fracture zone in the fully mechanized caving face of gob-side entry driving: A case study. Minerals 2022, 12, 557. [Google Scholar] [CrossRef]

- Wang, Q.; He, M.; Li, S.; Jiang, Z.H.; Wang, Y.; Qin, Q.; Jiang, B. Comparative study of model tests on automatically formed roadway and gob-side entry driving in deep coal mines. Int. J. Min. Sci. Technol. 2021, 31, 591–601. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Wang, H.H.; Shi, L.; Su, Y. Sequential extraction technology for high-intensity super-long two-entry longwall panels. J. China Coal Soc. 2017, 42, 302–310. [Google Scholar]

- Chen, D.D.; Guo, F.F.; Xie, S.R.; Wang, E.; Wu, Y.Y.; Jiang, Z.S.; Wang, L.; Cui, J.Q.; Zhang, X.; Liu, R.P. Mining-induced failure characteristics and surrounding rock control of gob-side entry driving adjacent to filling working face in the deep coal mine. Energy Sci. Eng. 2022, 10, 2593–2611. [Google Scholar] [CrossRef]

- Ma, Z.; Chen, C.; Liang, X.; Chen, A.; Song, W. Field and numerical investigation on the stability of coal pillars of gob-side entry driving with top coal. Arab. J. Geosci. 2020, 13, 1193. [Google Scholar] [CrossRef]

- Chen, A. Width design of small coal pillar of gob-side entry driving in soft rock panel and its application of zaoquan coal mine. Adv. Civ. Eng. 2021, 2021, 9999957. [Google Scholar]

- Chang, Q.L.; Ge, S.G.; Shi, X.Y.; Sun, Y.S.; Wang, H.B.; Li, M.D.; Wang, Y.Z.; Wu, F.F. Determination of narrow coal pillar width and roadway surrounding rock support technology in gob driving roadway. Sustainability 2022, 14, 4848. [Google Scholar] [CrossRef]

- Wang, W.; Wu, Y.; Lu, X.; Zhang, G. Study on small coal pillar in gob-side entry driving and control technology of the surrounding rock in a high-stress roadway. Front. Earth Sci. 2023, 10, 1020866. [Google Scholar] [CrossRef]

- Jiang, L.; Yang, Z.; Li, G. Research on the reasonable coal pillar width and surrounding rock supporting optimization of gob-side entry under inclined seam condition. Adv. Civ. Eng. 2021, 2021, 7145821. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, H.; Li, G. Study on size optimization of a protective coal pillar under a double-key stratum structure. Appl. Sci. 2022, 12, 11868. [Google Scholar] [CrossRef]

- Shi, X.; Jing, H.; Zhao, Z.; Gao, Y.; Zhang, Y.; Bu, R. Physical experiment and numerical modeling on the failure mechanism of gob-side entry driven in thick coal seam. Energies 2020, 13, 2023. [Google Scholar] [CrossRef]

- He, F.L.; Zhai, W.L.; Song, J.Y.; Xu, X.H.; Wang, D.Q.; Wu, Y.H. Reasonable coal pillar width and surrounding rock control of gob-side entry driving in inclined short-distance coal seams. Appl. Sci. 2023, 13, 6578. [Google Scholar] [CrossRef]

- Wang, H.; Shuang, H.; Li, L.; Xiao, S. The stability factors’ sensitivity analysis of key rock b and its engineering application of gob-side entry driving in fully-mechanized caving faces. Adv. Civ. Eng. 2021, 2021, 9963450. [Google Scholar] [CrossRef]

- Zhao, S.K.; Sui, Q.R.; Cao, C.; Wang, X.C.; Wang, C.L.; Zhao, D.M.; Yin, W.; Zhao, Y. Mechanical model of lateral fracture for the overlying hard rock strata along coal mine goaf. Geomach. Eng. 2021, 27, 77–87. [Google Scholar]

- Huang, S.J.; Wang, X.Q.; Li, Y.M.; Wang, L.; Liu, G.; Xiao, F.K.; Bashkov, O.V. Analysis on evolution law of small structure stress arch and composite bearing arch in island gob-side entry driving. Geofluids 2022, 2022, 4303681. [Google Scholar] [CrossRef]

- Xue, Y.; Cao, Z.Z.; Shen, W.L. Destabilization and energy characteristics of coal pillar in roadway driving along gob based on rockburst risk assessment. R. Soc. Open Sci. 2019, 6, 190094. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.Y.; Wang, Y.L.; Zhuo, R.S.; Lou, F.; Jin, S.K.; Zhao, P.X. Research on the safety control technology of gob-side entry in inclined thick coal seam. Process Saf. Environ. Prot. 2022, 166, 241–248. [Google Scholar] [CrossRef]

- Yang, X.R.; Yu, F.H.; Zhao, X. Study on floor heave characteristics and the control method of gob-side entry driving in weakly cemented soft rock. Sustainability 2023, 15, 3969. [Google Scholar] [CrossRef]

- Han, C.L.; Yuan, Y.X.; Zhang, N.; Zhao, Y.; Zhang, Q.S.; Song, K.; Wei, M.; Guo, Y.X. Thick-anchored dual-layer locking supporting technique in gob-side entry driving with the narrow pillar: A case study. Geofluids 2022, 2022, 5815411. [Google Scholar] [CrossRef]

- Zang, C.; Zhang, G.; Tao, G.; Zhu, H.; Li, Y.; Zuo, H. Numerical investigation on the ground response of a gob-side entry in an extra-thick coal seam. Shock Vib. 2021, 2021, 8838505. [Google Scholar] [CrossRef]

- Li, G.; Wang, X.; Bai, J.; Wu, B.; Wu, W. Research on the failure mechanism and control technology of surrounding rock in gob-side entry driving under unstable overlying strata. Eng. Fail. Anal. 2022, 138, 106361. [Google Scholar] [CrossRef]

- Liu, P.Z.; Gao, L.; Zhang, P.D.; Wu, G.Y.; Wang, C.; Ma, Z.Q.; Kong, D.Z.; Kang, X.T.; Han, S. A case study on surrounding rock deformation control technology of gob-side coal-rock roadway in inclined coal seam of a mine in Guizhou, China. Processes 2022, 10, 863. [Google Scholar] [CrossRef]

- Lv, J.K.; Wan, Z.J.; Zhang, Y.; Wang, J.H.; Yan, W.Z.; Xiong, L.C. Effect of multi-factor dynamic loading on gob-side entry driving during longwall face extraction: A case study. Bull. Eng. Geol. Environ. 2022, 81, 409. [Google Scholar] [CrossRef]

- Chen, D.D.; He, F.L.; Xie, S.R.; Zeng, J.C. Time-space relationship between periodic fracture of plate structure of main roof and rebound in whole region with elastic foundation boundary. Chin. J. Rock Mech. Eng. 2019, 38, 1172–1187. [Google Scholar]

- Xie, S.R.; Chen, D.D.; Zeng, J.C.; Gao, M.M.; Zhang, T.; Liu, J. First fracturing characteristics of main roof plate structure considering coal pillars and elastic coal foundation on both sides of stope. J. China Coal Soc. 2019, 44, 115–126. [Google Scholar]

- Qi, F.K.; Zhou, X.J.; Cao, Z.Z.; Zhang, Q.; Li, N. Width optimization of narrow coal pillar of roadway driving along goaf in fully mechanized top coal caving face. J. Min. Saf. Eng. 2016, 33, 475–480. [Google Scholar]

- Hou, C.J.; Ma, N.J. Stress in in-seam roadway sides and limit equilibrium zone. J. China Coal Soc. 1989, 4, 21–29. [Google Scholar]

- Chen, D.D.; Wang, E.; Xie, S.R.; He, F.L.; Wang, L.; Zhang, Q.; Wu, X.Y.; Jiang, Z.S.; Li, Y.B.; Shi, S.H. Roadway surrounding rock under multi-coal-seam mining: Deviatoric stress evolution and control technology. Adv. Civ. Eng. 2020, 2020, 9891825. [Google Scholar] [CrossRef]

| Rock Stratum | /kg·m−3 | /GPa | /GPa | /° | /MPa | /Mpa |

|---|---|---|---|---|---|---|

| Upper rock layer | 2700 | 6.98 | 5.11 | 33 | 3.51 | 2.51 |

| Lower rock layer | 2762 | 7.52 | 6.11 | 32 | 3.43 | 2.35 |

| Sandy mudstone | 2450 | 6.61 | 4.91 | 28 | 2.71 | 2.25 |

| Fine sandstone | 2600 | 6.41 | 5.23 | 34 | 3.65 | 2.49 |

| Siltstone | 2552 | 7.26 | 6.05 | 35 | 3.14 | 2.20 |

| Coal seam | 1400 | 3.01 | 1.86 | 19 | 1.02 | 0.91 |

| Carbonaceous mudstone | 2200 | 7.25 | 5.81 | 30 | 2.81 | 2.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Z.; Guo, W.; Xie, S. Coal Pillar Size Determination and Surrounding Rock Control for Gob-Side Entry Driving in Deep Soft Coal Seams. Processes 2023, 11, 2331. https://doi.org/10.3390/pr11082331

Jiang Z, Guo W, Xie S. Coal Pillar Size Determination and Surrounding Rock Control for Gob-Side Entry Driving in Deep Soft Coal Seams. Processes. 2023; 11(8):2331. https://doi.org/10.3390/pr11082331

Chicago/Turabian StyleJiang, Zaisheng, Wenke Guo, and Shengrong Xie. 2023. "Coal Pillar Size Determination and Surrounding Rock Control for Gob-Side Entry Driving in Deep Soft Coal Seams" Processes 11, no. 8: 2331. https://doi.org/10.3390/pr11082331

APA StyleJiang, Z., Guo, W., & Xie, S. (2023). Coal Pillar Size Determination and Surrounding Rock Control for Gob-Side Entry Driving in Deep Soft Coal Seams. Processes, 11(8), 2331. https://doi.org/10.3390/pr11082331