Recent Progress in Fill Media Technology for Wet Cooling Towers

Abstract

:1. Introduction

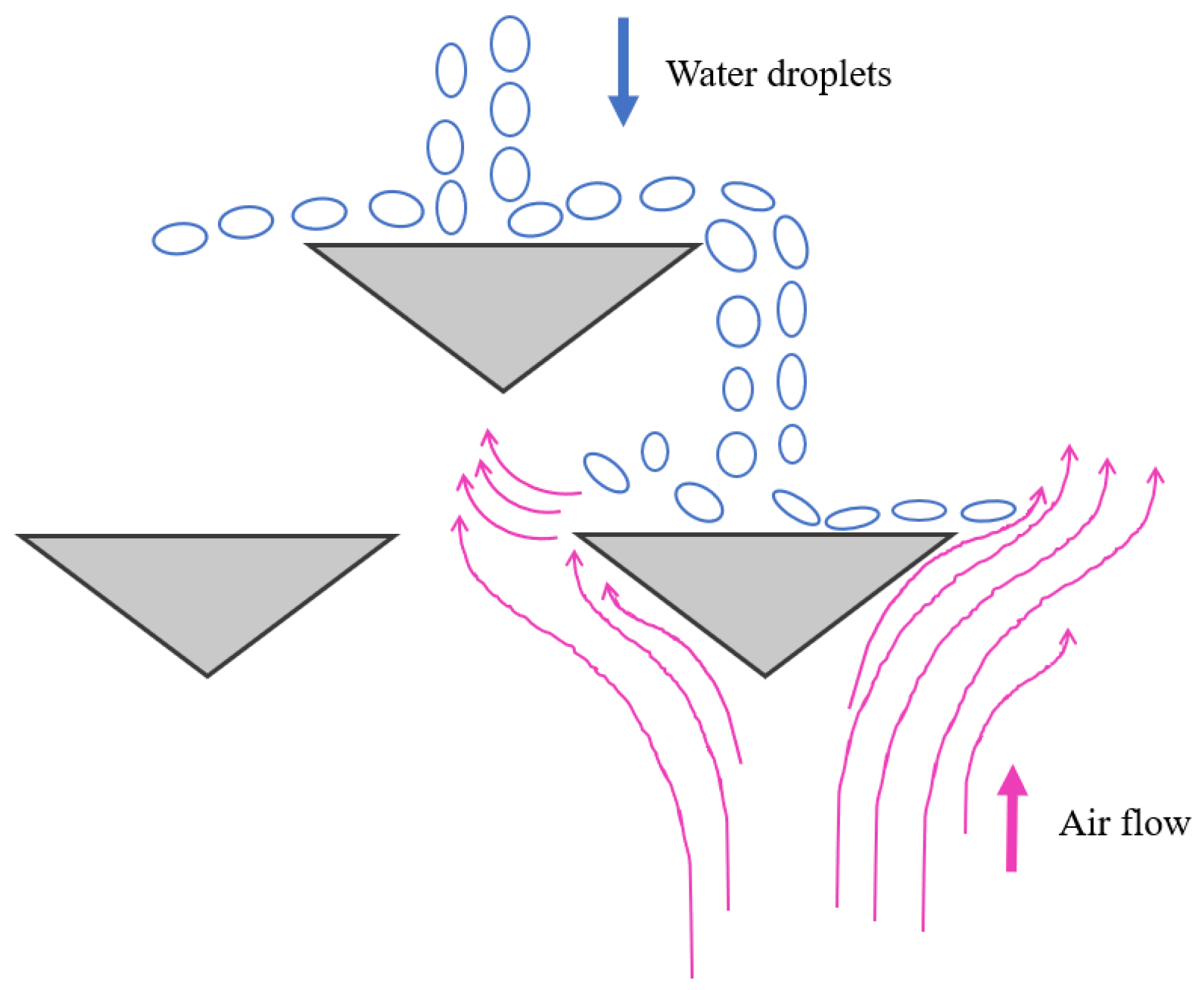

2. Fill Media in Cooling Towers

2.1. Significance of Fill Media

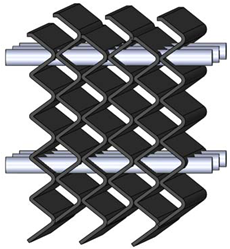

2.2. Types of Fill Media

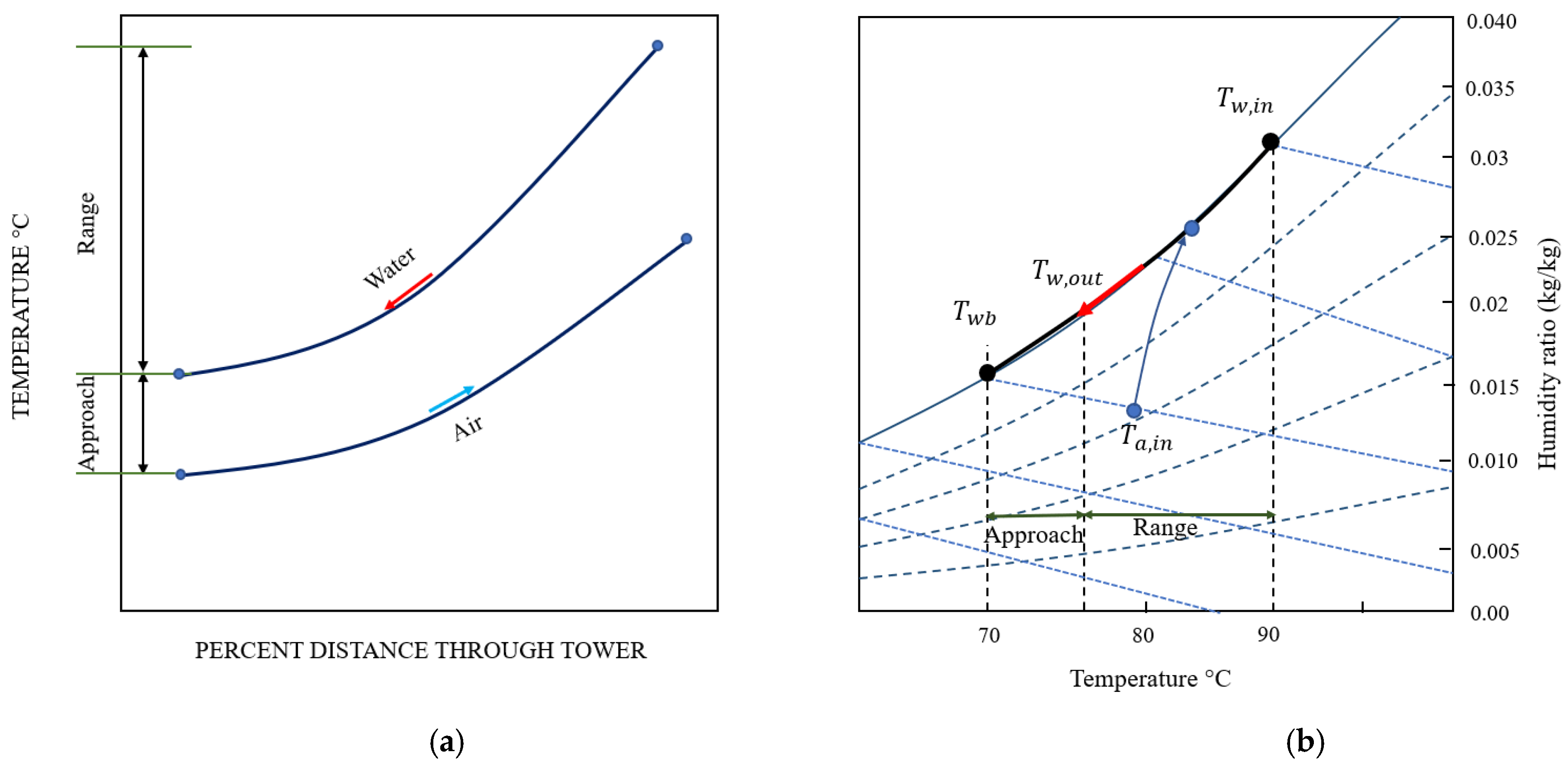

3. Performance Indices

4. Recent Progress in Fill Materials

5. Effect of Fill Media on Cooling Tower Performance

6. Recent Progress in Fill Configurations

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahmed, S.A.; Aljaberi, F.Y.; Makki, H.F. Experimental investigation of the thermal performance of wet cooling tower with splash fills packing. Therm. Sci. 2022, 26, 1603–1613. [Google Scholar] [CrossRef]

- American Society of Heating, Refrigerating and Air-Conditioning Engineers. ASHRAE Handbook: HVAC Systems and Equipment; SI ed.; ASHRAE: Atlanta, GA, USA, 2020. [Google Scholar]

- Williamson, N.; Behnia, M.; Armfield, S. Comparison of a 2D axisymmetric CFD model of a natural draft wet cooling tower and a 1D model. Int. J. Heat Mass Transf. 2008, 51, 2227–2236. [Google Scholar] [CrossRef]

- Zayed, M.E.; Kamal, A.; Diab, M.R.; Essa, F.A.; Muskens, O.L.; Fujii, M.; Elsheikh, A.H. Novel design of double slope solar distiller with prismatic absorber basin, linen wicks, and dual parallel spraying nozzles: Experimental investigation and energic–exergic-economic analyses. Water 2023, 15, 610. [Google Scholar] [CrossRef]

- Salins, S.S.; Kumar, S.; González, A.T.; Shetty, S. Influence of packing configuration and flow rate on the performance of a forced draft wet cooling tower. J. Build. Eng. 2023, 72, 106615. [Google Scholar] [CrossRef]

- Alsaiari, A.O.; Shanmugan, S.; Abulkhair, H.; Bamasag, A.; Moustafa, E.B.; Alsulami, R.A.; Ahmad, I.; Elsheikh, A. Applications of TiO2/Jackfruit peel nanocomposites in solar still: Experimental analysis and performance evaluation. Case Stud. Therm. Eng. 2022, 38, 102292. [Google Scholar] [CrossRef]

- Tejero-González, A.; Franco-Salas, A. Optimal operation of evaporative cooling pads: A review. Renew. Sustain. Energy Rev. 2021, 151, 111632. [Google Scholar] [CrossRef]

- Goshayshi, H.; Missenden, J. The investigation of cooling tower packing in various arrangements. Appl. Therm. Eng. 2000, 20, 69–80. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Kareem, S.B.A.; Makki, H.F. Investigation hydraulic performance of splash fills packing in cooling tower. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2020; p. 020156. [Google Scholar]

- Pradana, M.R.; Dewi, A.K.; Septiani, N.A.; Wardhana, A.S.; Ramdhan, M.; Nugroho, W.T. Performance Analysis Cooling Tower Type Induced Draft with PVC Plate Filling Material. J. Polimesin 2023, 21, 152–157. [Google Scholar]

- Kariem, N.O.; Rasheed, M.A.; Al-Sharify, Z.T. Performance of a cooling tower with the use of a new kind of high-density polyethylene (HDPE) packing. J. Eng. Res. 2022, 10, 72–83. [Google Scholar] [CrossRef]

- Jourdan, N.; Kanniche, M.; Neveux, T.; Potier, O. Experimental characterization of liquid flows in cooling tower packing. Ind. Eng. Chem. Res. 2022, 61, 2926–2936. [Google Scholar] [CrossRef]

- Bakhtiyar, N.K.; Javadpour, R.; Heris, S.Z.; Mohammadpourfard, M. Improving the thermal characteristics of a cooling tower by replacing the operating fluid with functionalized and non-functionalized aqueous MWCNT nanofluids. Case Stud. Therm. Eng. 2022, 39, 102422. [Google Scholar] [CrossRef]

- Chomiak, M.; Rojek, M.; Stabik, J.; Szymiczek, M. Prediction of Strength Properties of Filling Packets in Selected Cooling Towers. Polymers 2021, 13, 3840. [Google Scholar] [CrossRef]

- Amini, M.; Zareh, M.; Maleki, S. Thermal performance analysis of mechanical draft cooling tower filled with rotational splash type packing by using nanofluids. Appl. Therm. Eng. 2020, 175, 115268. [Google Scholar] [CrossRef]

- Dang, Z.; Gao, M.; Long, G.; Zou, J.; He, S.; Sun, F. Crosswind influence on cooling capacity in different zones for high level water collecting wet cooling towers based on field test. J. Wind. Eng. Ind. Aerodyn. 2019, 190, 134–142. [Google Scholar] [CrossRef]

- Kong, Q.J.; Liu, D.Y.; Wang, P.; Xie, D.Q.; Wu, Q.; Zhao, X.Y. Experimental study on the heat and mass transfer characteristics of a counter-flow wet cooling tower with foam ceramic packing. Thermophys. Aeromechanics 2019, 26, 267–279. [Google Scholar] [CrossRef]

- Tomás, A.; Araujo, S.; Paes, M.D.; Primo, A.R.; Da Costa, J.; Ochoa, A. Experimental analysis of the performance of new alternative materials for cooling tower fill. Appl. Therm. Eng. 2018, 144, 444–456. [Google Scholar] [CrossRef]

- Vitkovicova, R.; Vitkovic, P. Control of droplet size in rain-zone in wet cooling tower. In EPJ Web of Conferences; EDP Sciences: Les Ulis, France, 2018; p. 02119. [Google Scholar]

- Gao, M.; Guo, C.; Ma, C.; Shi, Y.; Sun, F. Thermal performance for wet cooling tower with different layout patterns of fillings under typical crosswind conditions. Energies 2017, 10, 65. [Google Scholar] [CrossRef]

- Lu, J.; Li, W.; Li, Y.; Zeng, L.; Yang, L.; Xie, L.; Li, Q.; Wang, M. Numerical study on heat and mass transfer characteristics of the counter-flow heat-source tower (CFHST). Energy Build. 2017, 145, 318–330. [Google Scholar] [CrossRef]

- Rahmati, M.; Alavi, S.R.; Tavakoli, M.R. Experimental investigation on performance enhancement of forced draft wet cooling towers with special emphasis on the role of stage numbers. Energy Convers. Manag. 2016, 126, 971–981. [Google Scholar] [CrossRef]

- Singla, R.K.; Singh, K.; Das, R. Tower characteristics correlation and parameter retrieval in wet-cooling tower with expanded wire mesh packing. Appl. Therm. Eng. 2016, 96, 240–249. [Google Scholar] [CrossRef]

- Merkel, F. Verdunstungskühlung. Z. Des Vereines Dtsch. Ingenieure 1925, 70, 123–128. [Google Scholar]

- Picón-Núnez, M.; Polley, G.T.; Canizalez-Dávalos, L.; Medina-Flores, J.M. Short cut performance method for the design of flexible cooling systems. Energy 2011, 36, 4646–4653. [Google Scholar] [CrossRef]

- Kloppers, J.C.; Kröger, D.G. Loss coefficient correlation for wet-cooling tower fills. Appl. Therm. Eng. 2003, 23, 2201–2211. [Google Scholar] [CrossRef]

- Kloppers, J.C. A Critical Evaluation and Refinement of the Performance Prediction of Wet-Cooling Towers; University of Stellenbosch: Stellenbosch, South Africa, 2003. [Google Scholar]

- Mitchell, J.W.; Braun, J.E. Principles of Heating, Ventilation, and Air Conditioning in Buildings; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- AHRI 450-2007; Water-Cooled Refrigerant Condensers, Remote Type. Air-Conditioning, Heating, and Refrigeration Institute: Arlington, VA, USA, 2007.

- Kusin, A.S.A.; Zahari, S.A.A.; Hatim, M.I.; Ruslan, M.A.M.; Adzim, M.N.; Omar, R.; Jamailudin, M.S.; Yaakub, A.R.W.; Puzi, S.M. Transport Properties of Evaporative Cooling in a Seashell Packed Bed Cooling Tower. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012026. [Google Scholar]

- Elsaid, A.M. A novel approach for energy and mass transfer characteristics in wet cooling towers associated with vapor-compression air conditioning system by using MgO and TiO2 based H2O nanofluids. Energy Convers. Manag. 2020, 204, 112289. [Google Scholar] [CrossRef]

- Grobbelaar, P.; Reuter, H.; Bertrand, T. Performance characteristics of a trickle fill in cross-and counter-flow configuration in a wet-cooling tower. Appl. Therm. Eng. 2013, 50, 475–484. [Google Scholar] [CrossRef]

- Fan, X.; Lu, X.; Wang, J.; Li, Z.; Wang, Q.; Dong, Z.; Zhang, R. Performance Evaluation of a Maisotsenko Cycle Cooling Tower with Uneven Length of Dry and Wet Channels in Hot and Humid Conditions. Energies 2021, 14, 8249. [Google Scholar] [CrossRef]

- Milosavljevic, N.; Heikkilä, P. A comprehensive approach to cooling tower design. Appl. Therm. Eng. 2001, 21, 899–915. [Google Scholar] [CrossRef]

- Johnson, B. Cooling Tower Performance Prediction and Improvement, Volume 1: Applications Guide; EPRI Report GS-6370; EPRI: Washington, DC, USA, 1989. [Google Scholar]

- Lowe, H.; Christie, D. Heat transfer and pressure drop data on cooling tower packings, and model studies of the resistance of natural draft towers to air flow. In Proceedings of the International Heat Transfer Conference, Boulder, CO, USA, 28 August–1 September 1961; p. 5. [Google Scholar]

- Lemouari, M.; Boumaza, M.; Kaabi, A. Experimental investigation of the hydraulic characteristics of a counter flow wet cooling tower. Energy 2011, 36, 5815–5823. [Google Scholar] [CrossRef]

- Goshayshi, H.; Missenden, J.; Tozer, R. Cooling tower—An energy conservation resource. Appl. Therm. Eng. 1999, 19, 1223–1235. [Google Scholar] [CrossRef]

- McAdams, W.; Pohlenz, J.; John, R.S. Transfer of heat and mass between air and water in a packed tower. Chem. Eng. Prog. 1949, 45, 241. [Google Scholar]

- Kong, Q.J.; Zhao, X.Y.; Xie, D.Q.; Zhang, B.; Wang, P. Experimental investigation of the heat and mass transfer phenomena in a counterflow wet cooling tower with foam ceramic packing. Adv. Mech. Eng. 2018, 10, 1687814017752579. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, X.; Ding, X. Theoretical investigation on thermal performance of new structure closed wet cooling tower. Heat Transf. Eng. 2018, 39, 460–472. [Google Scholar] [CrossRef]

- Wang, M.; Wang, J.; Wang, J.; Shi, C. Contrastive analysis of cooling performance between a high-level water collecting cooling tower and a typical cooling tower. J. Therm. Sci. 2018, 27, 39–47. [Google Scholar] [CrossRef]

- Keshtkar, M.M. Performance analysis of a counter flow wet cooling tower and selection of optimum operative condition by MCDM-TOPSIS method. Appl. Therm. Eng. 2017, 114, 776–784. [Google Scholar] [CrossRef]

- Zili-Ghedira, L.; Gouider, H.; Nasrallah, S.B. Numerical simulation of heat and mass transfer in humidifiers and cooling towers. J. Porous Media 2017, 20. [Google Scholar] [CrossRef]

- Singh, K.; Das, R. Simultaneous optimization of performance parameters and energy consumption in induced draft cooling towers. Chem. Eng. Res. Des. 2017, 123, 1–13. [Google Scholar] [CrossRef]

- Ning, T.; Chong, D.; Jia, M.; Wang, J.; Yan, J. Experimental investigation on the performance of wet cooling towers with defects in power plants. Appl. Therm. Eng. 2015, 78, 228–235. [Google Scholar] [CrossRef]

- Ramkumar, R.; Ragupathy, A. Thermal performance investigation of mechanical draft cooling tower using psychrometric gun technique. Heat Transf. Eng. 2014, 35, 1344–1353. [Google Scholar] [CrossRef]

- Shahali, P.; Rahmati, M.; Alavi, S.R.; Sedaghat, A. Experimental study on improving operating conditions of wet cooling towers using various rib numbers of packing. Int. J. Refrig. 2016, 65, 80–91. [Google Scholar] [CrossRef]

- Imani-Mofrad, P.; Saeed, Z.H.; Shanbedi, M. Experimental investigation of filled bed effect on the thermal performance of a wet cooling tower by using ZnO/water nanofluid. Energy Convers. Manag. 2016, 127, 199–207. [Google Scholar] [CrossRef]

- Zhao, Z.; Gao, J.; Zhu, X.; Qiu, Q. Experimental study of the corrugated structure of film packing on thermal and resistance characteristics of cross-flow cooling tower. Int. Commun. Heat Mass Transf. 2023, 141, 106610. [Google Scholar] [CrossRef]

- Javadpour, R.; Heris, S.Z.; Meyer, J.P. Experimental study of the effect of filled bed type on the performance of a cross-flow cooling tower with the approach of using nanofluids. Energy Rep. 2022, 8, 8346–8360. [Google Scholar] [CrossRef]

- Fan, X.; Lu, X.; Nie, H.; Zhu, H.; Wang, Q.; Kang, Y.; Liu, S.; Zheng, X.; Liu, Z.; Zhang, Y. An experimental study of a novel dew point evaporative cooling tower based on M-cycle. Appl. Therm. Eng. 2021, 190, 116839. [Google Scholar] [CrossRef]

- Rahmati, M. Effects of ZnO/water nanofluid on the thermal performance of wet cooling towers. Int. J. Refrig. 2021, 131, 526–534. [Google Scholar] [CrossRef]

- Zengin, G.; Onat, A. Experimental and theoretical analysis of mechanical draft counterflow wet cooling towers. Sci. Technol. Built Environ. 2020, 27, 14–27. [Google Scholar] [CrossRef]

- Qureshi, B.A.; Zubair, S.M. A complete model of wet cooling towers with fouling in fills. Appl. Therm. Eng. 2006, 26, 1982–1989. [Google Scholar] [CrossRef]

- Mrisky, G.; Monjoie, M.; Noble, R. Research of Fouling Film Fill. In Proceedings of the Cooling Tower Institute Annual Meeting, New Orleans, LA, USA, 17–19 February 1993. [Google Scholar]

- Guo, Q.; Qi, X.; Wei, Z.; Yin, Q.; Sun, P.; Guo, P.; Liu, J. Modeling and characteristic analysis of fouling in a wet cooling tower based on wavelet neural networks. Appl. Therm. Eng. 2019, 152, 907–916. [Google Scholar] [CrossRef]

- Bedekar, S.; Nithiarasu, P.; Seetharamu, K. Experimental investigation of the performance of a counter-flow, packed-bed mechanical cooling tower. Energy 1998, 23, 943–947. [Google Scholar] [CrossRef]

- Kelly, N.; Swenson, L. Comparative performance of cooling tower packing arrangements. Chem. Eng. Prog. 1956, 52, 263–268. [Google Scholar]

- Simpson, W.; Sherwood, T. Performance of small mechanical draft cooling towers. Refrig. Eng. 1946, 52, 525–543. [Google Scholar]

- Zhou, Y.; Wang, K.; Gao, M.; Dang, Z.; He, S.; Sun, F. Experimental study on the drag characteristic and thermal performance of non-uniform fillings for wet cooling towers under crosswind conditions. Appl. Therm. Eng. 2018, 140, 398–405. [Google Scholar] [CrossRef]

- Vitkovic, P. Droplet Measurement below Single-Layer Grid Fill. In EPJ Web of Conferences; EDP Sciences: Les Ulis, France, 2016; p. 02137. [Google Scholar]

- Ozgur, A.E.; Bayrakci, H.C. Experimental investigation of air side pressure loss for wet-cooling tower fills. Therm. Sci. 2020, 24, 2047–2053. [Google Scholar] [CrossRef]

- Ramkumar, R.; Ragupathy, A. Optimization of cooling tower performance with different types of packings using Taguchi approach. J. Braz. Soc. Mech. Sci. Eng. 2015, 37, 929–936. [Google Scholar] [CrossRef]

| Author | Cooling Tower Type | Configuration | Material |

|---|---|---|---|

Pradana et al. [10] | Induced draft counterflow/direct contact | A 20 cm tall, 0.5 mm thick rolled plate | PVC plate |

Kariem et al. [11] | Mechanical forced draught counterflow cooling tower—closed | Sheets arranged in splash type | High-density polyethylene |

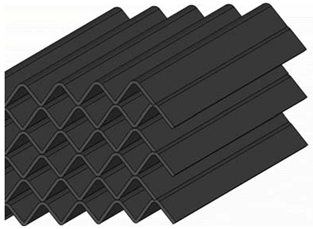

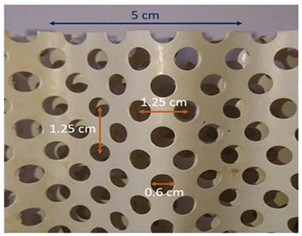

Jourdan et al. [12] | Wet cooling towers | Various thermoformed sheets with sinusoidal pattern: 0.06 cm thickness; 5 cm period; 1.7 cm amplitude | PVC |

Bakhtiyar et al. [13] | Crossflow cooling tower | Splash fill media (16 × 16 cm2 mesh) | Several mesh plates |

Chomiak et al. [14] | Wet cooling tower, natural draft | Filling packets with drip blocks | Polypropylene |

Amini et al. [15] | Mechanical draft/counterflow wet cooling tower | Non-uniform rotational splash-type: six circular horizontal plates | Aluminum |

Dang et al. [16] | Wet cooling tower | Film-type fill with area of 12,800 m2 and thickness of 1.5 m | --- |

Kong et al. [17] | Counterflow wet cooling tower | Corrugated sheets composed of sine wave, wave distance: 60 mm, height of wave: 35 mm, inclination of wave: 50° | New type FCP-08 foam ceramic |

Tomás et al. [18] | Forced counterflow wet cooling tower | Film-type fill with total dimension 57 × 64 × 25 cm3 | Coconut fiber, coconut husk and PET |

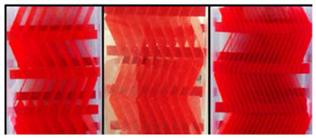

Vitkovicova et al. [19] | Wet cooling tower | Film fill (straight, slope, offset) and splash fill (trickle, grid) | PVC and metal |

Gao et al. [20] | Wet cooling tower | Five kinds of layout patterns, uniform and non-uniform | --- |

Lu et al. [21] | Counterflow cooling tower | Film-type fill Commercial corrugated packing with 98% porosity and dimensions: 5000 × 3300 × 2900 mm3 | --- |

Rahmati et al. [22] | Forced draft wet cooling tower | Film-type fill, VGA (vertical grid apparatus), height of 95 cm | PVC |

| --- Singla et al. [23] | Counterflow forced draft cooling tower | Expanded wire meshed fill | --- |

| Author | Material and Major Effects on Performance |

|---|---|

| Kariem et al. [11] | Material: high-density polyethylene (HDPE) |

| The results suggest that maintaining a constant air flux while increasing the water-to-air ratio results in a decline in the tower’s performance. This can be attributed to the higher water flow contributing to an increased heat load, which subsequently hinders the tower’s fill from effectively dissipating the excess heat. | |

| Kusin et al. [30] | Material: cockle shell, seashell-packed bed and HDPE pipe |

| The findings indicated that seashell packing demonstrated superior cooling efficiency compared to HDPE pipe packing due to its larger surface area and longer retention time. Moreover, treated seashell packing outperformed untreated packing. As for the cooling system, both the range of cooling water and the efficiency of tower decreased with higher water to air ratio, while the heat transfer coefficient decreased with an increase in the L/G (liquid-to-gas) ratio. | |

| Kong et al. [17] | Material: new type of packing named “FCP-08”—foam ceramic |

| Increasing the water/air mass flow ratio (L/G) leads to lower cooling tower efficiency (e) and cooling water range (R). However, the cooling characteristic coefficient (KαV/L) decreases slightly with higher L/G ratios but outperforms other packing types. Foam ceramic packing demonstrates superior cooling performance compared to alternatives, influencing thermal efficiency through effective heat and mass transfer. The study explores these aspects to aid engineering design and practical applications of cooling towers with foam ceramic packing. | |

| Tomás et al. [18] | Material: coconut fiber, coconut husk and PET |

| Based on the experimental data, it was observed that the alternative fills investigated were capable of cooling water up to 8 K, whereas the commercial fill achieved a higher cooling capacity of 10 K under identical operating conditions. | |

| Elsaid et al. [31] | Material: polypropylene (PP), paper cellulose (PC). |

| The study highlights the benefits of using PVC fill and a spiral sprayer with a 90° spray angle in improving the cooling tower’s effectiveness and coefficient of performance (COP). It also emphasizes that the overall system performance index increases with decreased filling sheet spacing and increased nanomaterial concentrations. The research predicts that the maximum overall system performance index is attained when employing PVC fill, a 1% concentration of MgO-based water nanoparticles, and a 90° spray angle. The investigation focuses on understanding the thermal conductivity characteristics and geometric design parameters of the fill material and their influence on the cooling tower’s characteristics and the COP of the vapor compression air conditioning cycle. |

| Fill Configuration | Fill Characteristic Equations for Me/Lfi, z | Correlation Coefficient |

|---|---|---|

| Crossflow | Me/Lfi, z = 1.2330 Gw−0.7550 Ga0.3450 Twi−0.0279 | 0.987 |

| Counterflow | Me/Lfi, z = 1.6293 Gw−0.9250 Ga0.7760Twi−0.0986 | 0.994 |

| Crossflow (counterflow config.) | Me/Lfi, z = 1.5258 Gw−0.7754 Ga0.7996 Twi−0.0730 | 0.983 |

| Fill Configuration | Fill Characteristic Equations for Kfdm/Lfi | Correlation Coefficient |

|---|---|---|

| Crossflow | Kfdm/Lfi, x = 11.007Gw0.2458Ga−0.0974 + 3.4886 × 10−7 Gw5.6876 Ga6.5011 | 0.994 |

| Counterflow | Kfdm/Lfi, z = 3.1980 Gw0.4920 Ga−1.4110 + 7.6960 Gw0.1100 Ga0.0910 | 0.982 |

| Crossflow (counterflow config.) | Kfdm/Lfi,x = 29.0167 Gw0.1332 Ga−0.0774 + 2.9590 × 10−7 Gw8.9749 Ga2.0027 | 0.939 |

| Operating Regime | Pressure Drop Characteristic Equation | Correlation Coefficient |

|---|---|---|

| Pellicular regime (PR) | 0.900 | |

| Bubble and dispersion regime (BDR) | L′ = 0.45–2.027 kg/s m2 and G′ = 0.455–2.37 kg/s m2 | 0.840 |

| Operating Regime | Ka Equation |

|---|---|

| Pellicular regime (PR) | |

| Bubble and dispersion regime (BDR) |

| Author | Specification | Major Finding | |

|---|---|---|---|

| Ahmed et al. [1] 2022 | Fill type: splash Rang (°C): 8–11 Approach (°C): - | Air flow rate: 5000–6300 kg·m3·h−1 Water flow rate: 4000–8000 kg·m3·h−1 Applications: local stations in Baghdad | Major finding: Fix fill media and change the water inlet temperature. Considered the effects on characteristic of cooling tower by increasing the ratio of water/air flow rate. Performance will decrease, and by increasing the water inlet temperature, the range and heat dissipation will also increase. |

| Fan et al. [33] 2021 | Fill type: film Rang (°C): 5–14 Approach (°C): 0–5 | Air flow rate: 12 ton·m−2·h−1 Water flow rate: 518–2073 m3·h−1 Applications: a guideline for industries | Major finding: Proposed new fill media for industrial applications. Could increase cooling performance up to 50% by increasing dry length from 1.5 to 2.4 m. Compared to the conventional fill, the pressure drop is larger and so optimum value needs to be found for specific industries. |

| Kong et al. [40] 2018 | Fill type: pack Rang (°C): 4–15 Approach (°C): 0–5 | Air flow rate: L/G 0.5–1.7 Water flow rate: 518–2073 m3·h−1 Applications: a guideline for industries | Major finding: Explored how alterations in the ratio of water to air mass flow impact the heat and mass transfer traits of the cooling tower under varying inlet water temperatures. The findings indicate that as the water-to-air mass flow ratio (L/G) rises, both the cooling water range (R) and the efficiency of the cooling tower decline. |

| Zhou et al. [41] 2018 | Fill type: film Rang (°C): 4–9 Approach (°C): 2–10 | Air flow rate: 0.2–0.5 kg·s−1 Water flow rate: 0.5–3.7 kg·s−1 Applications: theoretical approach | Major finding: Under the same operating conditions, applying pack fill media brings 0.6 °C and 1.5 °C benefits for outlet temperature. Also, for efficiency, packing adds 6.0% and 14.8% compared to cooling tower without pack. |

| Wang et al. [42] 2018 | Fill type: film-S wave Rang (°C): 10 Approach (°C): - | Air flow rate: 11,500–14,500 kg·s−1 Water flow rate: 95,027 kg·s−1 Applications: Chongqing power plant | Major finding: Cooling performance of four kinds of fill height (1.25 m, 1.5 m, 1.75 m, and 2 m) was numerically simulated. The results demonstrate that the S wave has the highest cooling efficiency in three fills for both towers, indicating that fill characteristics are crucial to cooling performance. |

| Keshtkar [43] 2017 | Fill type: film Rang (°C): 7.63 Approach (°C): 3.5 | Air flow rate: 1.265 kg·s−1 Water flow rate: 1.008 kg·s−1 Applications: optimization | Major finding: The energetic performance of the cooling tower was used to describe the given problem. From the calculations, it can be seen that water exergy decreases from top to bottom of the fill. It reveals that the evaporative exergy of air mainly controls exergy of air. |

| Zili-Ghedira et al. [44] 2017 | Fill type: pack Rang (°C): 8 Approach (°C): - | Air flow rate: 0.4–0.64 kg·s−1 Water flow rate: 0.2–0.3 kg·s−1 Applications: numerical investigation | Major finding: Different packs were investigated numerically and the effect of pack on cooling tower was considered. Influences of the thermophysical properties of packing materials, along with the water–air exchange surface and humidifier aspect ratio, were studied in detail. |

| Singh and Das [45] 2017 | Fill type: splash fill Rang (°C): 3 Approach (°C): 6 | Air flow rate: 0.1-0.25 kg·s−1 Water flow rate: 0.1-0.25 kg·s−1 Applications: numerical investigation | Major finding: Numerical modeling exergy investigation of wooden splash fill. Different from previous neglecting of the five performance parameters, this study developed an unconstrained optimization of all objective functions with satisfactory results. |

| Gao et al. [20] 2017 | Fill type: pack Rang (°C): - Approach (°C): - | Air flow rate: - Water flow rate: 6 Liter·min−1 Applications: - | Major finding: The experimental findings demonstrated that in calm wind conditions, the heat transfer coefficient and total heat rejection of circulating water significantly improved by about 40% and 28%, respectively, when using the optimal non-uniform layout pattern, as opposed to the uniform layout pattern. |

| Ning et al. [46] 2015 | Fill type: pack Rang (°C): 4–18 Approach (°C): 1–4 | Air flow rate: 5880–36,480 kg·h−1 Water flow rate: 8000–14,000 kg·h−1 Applications: power plant | Major finding: Based on the results, under normal and defect conditions, the cooling tower characteristic (KaV/L) and the efficiency coefficient (h) decrease as the water-to-air ratio increases. Compared to normal conditions, the cooling tower characteristics only decrease under nozzle and filling blockage but undergo remarkable decrease of over 60% when subjected to conditions involving nozzle drop. |

| Ramkumar and Ragupathy [47] 2014 | Fill type: pack Rang (°C): 4–18 Approach (°C): 1–4 | Air flow rate: 100–200 kg·h−1 Water flow rate: 100–200 kg·h−1 Applications: effect of pack geometry | Major finding: This research focuses on utilizing the Taguchi method to evaluate the maximum cooling tower efficiency in a counterflow cooling tower while employing various packing types. The study explores the application of the Taguchi method in this context. |

| Shahali et al. [48] 2016 | Fill type: pack Rang (°C): 2.5–25 Approach (°C): - | Air flow rate: 0.03–0.05 kg·s−1 Water flow rate: 40–140 L·h−1 Applications: effect of pack geometry | Major finding: This study aimed to experimentally examine the performance of a wet cooling tower (WCT). To achieve this, the thermal efficiency of the WCT was analyzed to consider the influence of water flow rate, inlet water temperature, rib numbers of packing, and mass flow rate of air. |

| Rahmati et al. [22] 2016 | Fill type: pack Rang (°C): 2.5–5.5 Approach (°C): - | Air flow rate: 0.02–0.07 kg·s−1 Water flow rate: 0.06–0.1 m3·h−1 Applications: effect of pack geometry | Major finding: Investigation of effect of rib number on efficiency and thermal performance. Results showed that the efficiency is strongly related to hot water temperature, stage numbers of packing, and air mass flow rate, and it diminishes by raising the water flow rate. |

| Imani-Mofrad et al. [49] 2016 | Fill type: pack Rang (°C): 12–16 Approach (°C): - | Air flow rate: 1.8 kg·min−1 Water flow rate: 1.8 kg·min−1 Applications: different types of fill | Major finding: Considered effect of nanofluid on water inlet and different fill types. Via nanofluids, cooling range, tower characteristic (TC), and effectiveness of cooling tower, TC enhanced by 21.5% and 22.5% for ZnO/water nanofluid with concentrations of 0.02 wt% and 0.05 wt%, respectively. |

| Lemouari et al. [37] 2011 | Fill type: pack Rang (°C): - Approach (°C): - | Air flow rate: 2000–10000 kg·m−2h−1 Water flow rate: 0.01–0.045 kg·s−1 Applications: nuclear electric power | Major finding: The relationship between the pressure drop behavior and the combined heat and mass transfer (air and water) within the cooling tower’s packing material was emphasized. The findings suggest that this particular tower demonstrates favorable hydraulic properties, resulting in energy conservation. |

| Zhao et al. [50] 2023 | Fill type: pack Rang (°C): 3–5 Approach (°C): 6–9 | Air flow rate: 77.87 kg·s−1 Water flow rate: 52.1–53.2 kg·s−1 Applications: actual cooling tower | Major finding: Incorporating four parallel small grooves into the packing design of a crossflow cooling tower was shown to enhance thermal performance by up to 12.2% compared to traditional corrugated packing. Conversely, the addition of less than four small grooves results in a decline in the cooling performance of the packing. |

| Javadpour et al. [51] 2022 | Fill type: pack Rang (°C): 4–18 Approach (°C): 6-9 | Water flow rate/ Air flow rate: 0.4–2 Applications: actual cooling tower | Major finding: This research explored the choice of an appropriate filled bed for a crossflow cooling tower when using either water or nanofluids as the fluid. Two types of fillers were examined: splash beds and film beds, which consisted of four grid splash fillers and two cylindrical and spherical film fillers. |

| Fan et al. [52] 2021 | Fill type: pack Rang (°C): - Approach (°C): - | Air flow rate: 15 ton·h·m−2 Water flow rate: - Applications: actual cooling tower | Major finding: The DPECT (dew point evaporative cooling tower) demonstrated an impressive wet-bulb effectiveness of up to 1.10 under specific conditions, including a dry-bulb temperature of 30 °C, relative humidity of 30%, and inlet water temperature of 30 °C. It was evident that the DPECT, based on the M-cycle, had the capability to cool the water below the wet-bulb temperature of the surrounding air, a feat not attainable with conventional cooling towers. This highlights the DPECT’s potential to surpass the temperature limitations of traditional cooling towers and further reduce the water temperature. |

| Rahmati et al. [53] 2021 | Fill type: pack Rang (°C): 12–15.5 Approach (°C): - | Air flow rate: Water flow rate: - Applications: laboratory cooling tower | Major finding: The study findings suggest that increasing the number of packing layers in the WCT (wet cooling tower) can enhance thermal performance, regardless of whether water or nanofluid is used. This effect is particularly prominent when nanofluid is employed, especially with denser packing. Moreover, the results demonstrate that elevating the nanofluid concentration also improves the WCT’s thermal performance. |

| Zengin et al. [54] 2020 | Fill type: pack Rang (°C): 10 Approach (°C): - | Air flow rate: 13–34 m3·h−1 Water flow rate: 17–52 m3·h−1 Applications: research | Major finding: This research examines the pressure losses and thermal efficiency of mechanical draft counterflow water cooling towers with varying cooling fill heights. The study conducted separate measurements of pressure losses through the cooling fill for each condition during the thermal performance tests. The researchers plotted the variation of pressure losses with air velocity across cooling fills at different loading heights. Performance curves were generated and compared, presenting graphs that illustrate the relationship between the liquid-to-gas ratio (L/G) and the Merkel number for cooling fills at heights ranging from 1500 mm to 2400 mm. Interestingly, despite the lowest and highest flow resistances being observed at fill heights of 1500 mm and 2400 mm, respectively, the cooling tower’s lowest and highest performances were calculated at fill heights of 1500 mm and 2400 mm, respectively. This suggests that the cooling tower’s thermal performance is not directly linked to flow resistance. |

| Configurations | Specifications |

|---|---|

Kong et al. [17] | Material: Foamed ceramic Specifications: The fill media consists of foamed ceramic corrugated board with sine waves, and surface retention groove is 1.0 m high and has a cross-sectional test area of 0.68 × 0.68 m2. Finding: Investigated how alterations in the ratio of water-to-air mass flow impact the heat and mass transfer traits of the cooling tower under varying inlet water temperatures. The findings indicate that as the water-to-air mass flow ratio (L/G) rises, both the cooling water range (R) and the efficiency of the cooling tower decline. |

Javadpour et al. [51] | Material: Carbon nanotubes Specifications: The study involved the utilization of titanium dioxide nanofluids (TiO2), multi-walled carbon nanotubes (MWCNT), along with six different types of fill media categorized into films and splashes. Finding: The cooling range, effectiveness, and Merkel number experienced a substantial increase of 28%, 85%, and 131%, respectively. The cases of Bed 3 and Bed 5 were selected as the appropriate fill media. |

Shahali et al. [48] | Material: PVC pack Specifications: Three distinct PVC fill media (7, 9, and 18 ribs) are individually examined to explore the effects of rib numbers. The cooling tower was filled with the GA (vertical grid apparatus) packing. Finding: The research focused on examining the impact of rib numbers on three types of PVC packing. The findings indicate that both water temperature difference and cooling efficiency are influenced by several factors, including the inlet water temperature, the rib numbers of the packing, and the mass flow rate of air. |

Zhou et al. [61] | Material: Non-uniform pack Specifications: Fills have non-uniform layout and adopt different heights at the different radii. Finding: The study found that non-uniform fillings can alleviate the adverse effect of crosswind on thermal performance. Among the considered fills, the optimal non-uniform pattern from the perspective of drag characteristic and thermal performance under crosswind conditions and relatively water-saving fill were determined. It recommends selecting optimal non-uniform filling pattern by taking both energy conservation and water savings into account. |

Imani-Mofrad et al. [49] | Material: Metal, plastic, metal grid, metal wavy. Specifications: --- Finding: The metal reticular bed, known as Bed 1, was identified as the most appropriate option for utilizing nanofluids. Subsequently, the study focused on assessing the enhanced performance of the cooling tower when employing the metal reticular bed with various concentrations of ZnO/water nanofluid (ranging from 0.02% to 0.1%) in comparison to pure water. |

Vitkovic [62] | Material: Single-layer grid fill Specifications: --- Finding: Cooling towers generally employ film fill, grid fill, or splash fill. Compared to film fill, grid fill usually exhibits lower heat transfer performance. However, it offers the advantage of being highly resistant to blockage. Grid fill is constructed with separate layers made from plastic, typically featuring several interconnected bars in different shapes. In the experiment, the rhombus shape was utilized. The diameter of droplets was measured both above and below the grid fill. |

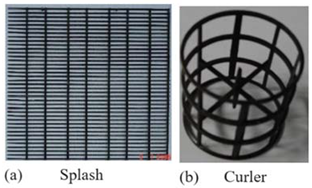

Ozgur and Bayrakci [63] | Material: Metal wire Specifications: The diameter of each curler filling material was 63 mm. However, each curler filling had 24 rectangular spacings. Finding: Among the parameters studied, air mass flux was identified as the most influential, followed by fill height and water mass flux. For fill heights of 0.6 m and 0.8 m, splash fill demonstrated lower pressure loss values. These findings offer valuable insights for cooling tower designers and have practical implications in various industrial applications, including cooling with dirty and limy water, dusty ambient air flow, and inlet water temperatures exceeding 60 °C. |

Zhao et al. [50] | Material: Commercial corrugated packing Specifications: Five kinds of fill media were made, incorporating small grooves with varying orientations and quantities. Finding: Incorporating four parallel small grooves led to an enhancement in the thermal performance of packing, with improvements of up to 12.2%. However, the addition of a lower number of grooves can result in a decline in cooling performance. Furthermore, when multiple crossed grooves are present, the cooling performance may decrease by 14.4% under specific conditions. |

Jourdan et al. [12] | Material: PVC Specifications: It is composed of various thermoformed PVC sheets of 0.06 cm thickness and forms a sinusoidal pattern with a period of 5 cm and an amplitude of 1.7 cm. Finding: The primary aim of this study was to fill the existing data gap concerning liquid flows in structured packings utilized in industrial cooling towers. To accomplish this goal, the researchers designed and constructed an experimental device specifically tailored to characterize the flows within the packings. |

Ramkumar and Ragupathy [64] Ramkumar and Ragupathy [64] | Material: Metal Specifications: The experiments were planned based on Taguchi’s L9 orthogonal array.Finding: The packing factor exerts the most significant influence on the total variation, accounting for 59.2% of the overall impact. Following closely, the liquid-to-gas ratio contributed to 29.1% of the variation, while water temperature had a relatively smaller effect at 9.6%. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashemi, Z.; Zamanifard, A.; Gholampour, M.; Liaw, J.-S.; Wang, C.-C. Recent Progress in Fill Media Technology for Wet Cooling Towers. Processes 2023, 11, 2578. https://doi.org/10.3390/pr11092578

Hashemi Z, Zamanifard A, Gholampour M, Liaw J-S, Wang C-C. Recent Progress in Fill Media Technology for Wet Cooling Towers. Processes. 2023; 11(9):2578. https://doi.org/10.3390/pr11092578

Chicago/Turabian StyleHashemi, Zahra, Abdolmajid Zamanifard, Maysam Gholampour, Jane-Sunn Liaw, and Chi-Chuan Wang. 2023. "Recent Progress in Fill Media Technology for Wet Cooling Towers" Processes 11, no. 9: 2578. https://doi.org/10.3390/pr11092578

APA StyleHashemi, Z., Zamanifard, A., Gholampour, M., Liaw, J. -S., & Wang, C. -C. (2023). Recent Progress in Fill Media Technology for Wet Cooling Towers. Processes, 11(9), 2578. https://doi.org/10.3390/pr11092578