Process Optimization of Sea Buckthorn Fruit Powder Effervescent Tablets by Random Centroid Methodology Combined with Fuzzy Mathematical Sensory Evaluation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

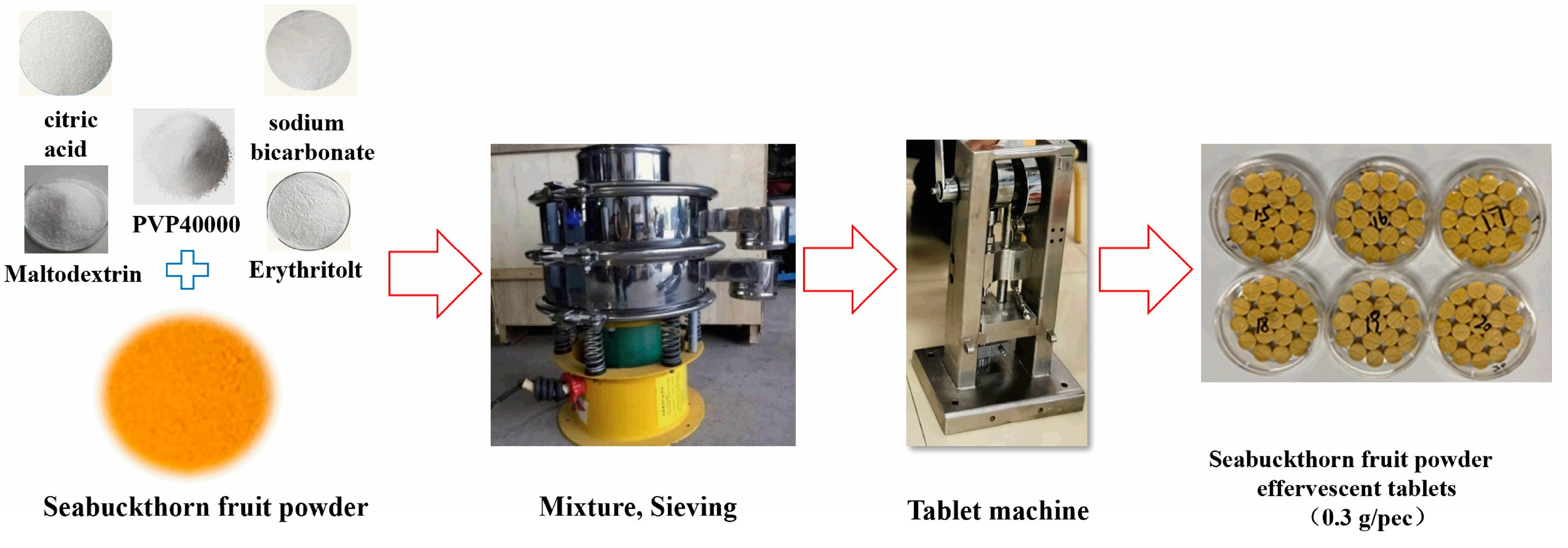

2.2. Sample Preparation

2.3. Random Centroid Optimization

2.4. Sensory Quality Evaluation

2.5. Fuzzy Mathematical Sensory Comprehensive Evaluation Model Establishment

2.6. Ascorbic Acid Content

2.7. Carotenoids Content

2.8. Total Phenol Content

2.9. Total Flavonoids Content

2.10. Tablet Weight Difference

2.11. Hardness

2.12. Disintegration Time Limit

2.13. Statistical Analysis

3. Results

3.1. Sensory Evaluation

3.2. Design of RCO Optimization Conditions

3.3. Correlation Analysis of Sensory Evaluation Additive Content

3.4. Product Validation Test

3.5. Comparison Characteristics of Powder Effervescent Tablet

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ficzek, G.; Mátravölgyi, G.; Furulyás, D.; Rentsendavaa, C.; Jócsák, I.; Papp, D.; Simon, G.; Végvári, G.Y.; Stéger-Máté, C.D. Analysis of bioactive compounds of three sea buckthorn cultivars (Hippophaë rhamnoides L.‘Askola’,‘Leikora’, and ‘Orangeveja’) with HPLC and spectrophotometric methods. Eur. J. Hortic. Sci. 2019, 84, 31–38. [Google Scholar] [CrossRef]

- Rousi, A. The genus Hippophae, L. A taxonomic study. Ann. Bot. Fenn. 1971, 8, 177–227. [Google Scholar]

- Sundaram, M.S.; Iarahath, K.; Bawa, A.S. Development of sea buckthorn mixed fruit jelly. Int. J. Food Sci. Technol. 2007, 42, 403–410. [Google Scholar] [CrossRef]

- Sayegh, M.; Miglio, C.; Ray, S. Potential cardiovascular implications of Sea Buckthorn berry consumption in humans. Int. J. Food Sci. Nutr. 2014, 65, 521–528. [Google Scholar] [CrossRef]

- Tiitinen, K.M.; Hakala, M.A.; Kallio, H.P. Quality components of sea buckthorn (Hippophae rhamnoides) varieties. J. Agric. Food Chem. 2005, 53, 1692–1699. [Google Scholar] [CrossRef]

- Kanayama, Y.; Kato, K.; Stobdan, T.; Galitsyn, G.G.; Kochetov, A.V.; Kanahama, K. Research progress on the medicinal and nutritional properties of sea buckthorn (Hippophae rhamnoides)—A review. J. Hortic Sci. Biotechnol. 2012, 87, 203–210. [Google Scholar] [CrossRef]

- Zielińska, A.; Nowak, I. Abundance of active ingredients in sea-buckthorn oil. Lipids Health Dis. 2017, 16, 95. [Google Scholar] [CrossRef]

- Socaci, S.A.; Socaciu, C.; Tofană, M.; Raţi, I.V.; Pintea, A. In-tube extraction and GC–MS analysis of volatile components from wild and cultivated sea buckthorn (Hippophae rhamnoides L. ssp. Carpatica) berry varieties and juice. Phytochem. Anal. 2013, 24, 319–328. [Google Scholar] [CrossRef]

- Ciesarová, Z.; Murkovic, M.; Cejpek, K.; Kreps, F.; Tobolková, B.; Koplík, R.; Belajová, E.; Kukurová, K.; Daško, Ľ.; Panovská, Z.; et al. Why is sea buckthorn (Hippophae rhamnoides L.) so exceptional? A review. Food Res. Int. 2020, 133, 109–170. [Google Scholar] [CrossRef]

- Naji-Tabasi, S.; Emadzadeh, B.; Shahidi-Noghabi, M.; Abbaspour, M.; Akbari, E. Physico-chemical and antioxidant properties of barberry juice powder and its effervescent tablets. Chem. Biol. Technol. Age 2021, 8, 1–11. [Google Scholar] [CrossRef]

- Saifullah, M.; Yusof, Y.A.; Chin, N.L.; Aziz, M.G.; Mohammed, M.A.P.; Aziz, N.A. Tableting and dissolution characteristics of mixed fruit powder. Agric. Agric. Sci. Procedia 2014, 2, 18–25. [Google Scholar] [CrossRef]

- Yousefi, S.; Emam-Djomeh, Z.; Mousavi, S.M. Effect of carrier type and spray drying on the physicochemical properties of powdered and reconstituted pomegranate juice (Punica granatum L.). J. Food Sci. Technol 2011, 48, 677–684. [Google Scholar] [CrossRef] [PubMed]

- Ong, M.Y.; Yusof, Y.A.; Aziz, M.G.; Chin, N.L.; Amin, N.A. Characterisation of fast dispersible fruit tablets made from green and ripe mango fruit powders. J. Food Eng. 2014, 125, 17–23. [Google Scholar] [CrossRef]

- Zea, L.P.; Yusof, Y.A.; Aziz, M.G.; Ling, C.N.; Amin, N.A.M. Compressibility and dissolution characteristics of mixed fruit tablets made from guava and pitaya fruit powders. Powder Technol. 2013, 247, 112–119. [Google Scholar] [CrossRef]

- Saifullah, M.; Yusof, Y.A.; Chin, N.L.; Aziz, M.G.; Mohammed, M.A.P.; Aziz, N.A. Dissolution profling and its comparison of natural fruit powder effervescent tablets. J. Food Eng. 2016, 178, 60–70. [Google Scholar] [CrossRef]

- Naji-Tabasi, S.; Emadzadeh, B.; Shahidi-Noghabi, M.; Abbaspour, M.; Akbari, E. Physico-chemical properties of powder and compressed tablets based on barberry fruit pulp. J. Food Meas. Charact. 2021, 15, 2469–2480. [Google Scholar] [CrossRef]

- Yusof, Y.A.; Mohd Salleh, F.S.; Chin, N.L.; Talib, R.A. The drying and tabletting of pitaya powder. J. Food Process Eng. 2012, 35, 763–771. [Google Scholar] [CrossRef]

- Pushkar, S.; Sachan, N.K.; Ghosh, S.K. Pharmacotechnical Assessment of Processed Watermelon Flesh as Novel Tablet Disintegrant. Chemistry of Phytopotentials: Health, Energy and Environmental Perspectives; Khemani, L.D., Srivastava, M.M., Srivastava, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 159–163. [Google Scholar]

- Rahardjo, B.; Noor, Z. Optimization of processing technique of the fruit juice effervescent tablet with response surface method. J. Teknol. San. Industri. Pangan. 2009, 20, 25–31. [Google Scholar]

- Xin, L.; Guo, L.; Edirs, S.; Zhang, Z.; Cai, C.; Yang, Y.; Lian, Y.; Yang, H. An Efficient Deacidification Process for Safflower Seed Oil with High Nutritional Property through Optimized Ultrasonic-Assisted Technology. Molecules 2022, 27, 2305. [Google Scholar] [CrossRef]

- Bao, J.; Zhang, X. Mixed fermentation of Spirulina platensis with Lactobacillus plantarum and Bacillus subtilis by random-centroid optimization. Food Chem. 2018, 264, 64–72. [Google Scholar] [CrossRef]

- Rahman, Z.; Zidan, A.S.; Korang-Yeboah, M.; Yang, Y.; Siddiqui, A.; Shakleya, D.; Khan, M.A.; Cruz, C.; Ashraf, M. Effects of excipients and curing process on the abuse deterrent properties of directly compressed tablets. Int. J. Pharmaceut. 2017, 517, 303–311. [Google Scholar] [CrossRef]

- Rahman, Z.; Yang, Y.; Korang-Yeboah, M.; Siddiqui, A.; Xu, X.M.; Ashraf, M.; Khanet, M.A. Assessing impact of formulation and process variables on in-vitro performance of directly compressed abuse deterrent formulations. Int. J. Pharmaceut. 2016, 502, 138–150. [Google Scholar] [CrossRef]

- Dou, J.; Toma, S.; Nakai, S. Random-centroid optimization for food formulation. Food Res. Int. 1993, 26, 27–37. [Google Scholar] [CrossRef]

- Uscanga, M.A.; Salvador, A.; Camacho, M.D.M. Impact of freeze-drying shelf temperature on the bioactive compounds, physical properties and sensory evaluation of a product based on orange juice. Int. J. Food Sci. Technol. 2021, 56, 5409–5416. [Google Scholar] [CrossRef]

- Oruña-Concha, M.J.; Gonzalez-Castro, M.J.; Lopez-Hernandez, J.; Simal-Lozano, J. Monitoring of the vitamin C content of frozen green beans and Padrón peppers by HPLC. J. Sci. Food Agric. 1998, 76, 477–480. [Google Scholar] [CrossRef]

- Vazquez Oderiz, M.L.; Vazquez Blanco, M.E.; Lopez Hernandez, J.; Simal Lozano, J.; Romero Rodriguez, M.A. Simultaneous determination of organic acids and vitamin C in green beans by liquid chromatography. J. AOAC Int. 1994, 77, 1056–1059. [Google Scholar] [CrossRef] [PubMed]

- Korekar, G.; Dolkar, P.; Singh, H.; Srivastava, R.B.; Stobdan, T. Variability and the genotypic effect on antioxidant activity, total phenolics, carotenoids and ascorbic acid content in seventeen natural population of Seabuckthorn (Hippophae rhamnoides L.) from trans-Himalaya. LWT-Food Sci. Technol. 2014, 55, 157–162. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, Y.; Zhang, F.; Wang, Y.; Yi, J.; Liao, X. Effects of high hydrostatic pressure on enzymes, phenolic compounds, anthocyanins, polymeric color and color of strawberry pulps. J. Sci. Food Agric. 2011, 91, 877–885. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.H.; Ahn, J.B.; Kim, H.J.; Im, N.K.; Kozukue, N.; Levin, C.E.; Friedman, M. Changes in Free Amino Acid, Protein, and Flavonoid Content in Jujube (Ziziphus jujube) Fruit during Eight Stages of Growth and Antioxidative and Cancer Cell Inhibitory Effects by Extracts. J. Agric. Food Chem. 2012, 60, 10245–10255. [Google Scholar] [CrossRef]

- National Pharmacopoeia Committee. The Pharmacopoeia of the People’s Republic of China, 4th ed.; China Medical Science and Technology Press: Beijing, China, 2015; pp. 3–4. [Google Scholar]

- Cheng, P.; Fan, W.; Xu, Y. Quality grade discrimination of Chinese strong aroma type liquors using mass spectrometry and multivariate analysis. Food Res. Int. 2013, 542, 1753–1760. [Google Scholar] [CrossRef]

- Mukhopadhyay, S.; Majumdar, G.; Goswami, T.; Mishra, H. Fuzzy logic (similarity analysis) approach for sensory evaluation of chhana podo. LWT-Food Sci. Technol. 2013, 53, 204–210. [Google Scholar] [CrossRef]

- Xu, W.; Wang, B.; Zhang, H. Research on data fusion algorithm based on fuzzy mathematics and principal component analysis. Adv. Appl. Math. 2019, 8, 953–957. [Google Scholar] [CrossRef]

- Shinde, S.; Kulkarni, U. Extracting classification rules from modified fuzzy min–max neural network for data with mixed attributes. Appl. Soft Comput. 2016, 40, 364–378. [Google Scholar] [CrossRef]

- Cheng, H.; Xing, J.; Zheng, R. Comprehensive safety risk assessment of pesticide residues in agricultural products based on entropy-fuzzy analysis. J. Food Sci. Technol. 2021, 21, 331–339. [Google Scholar] [CrossRef]

- Liu, Y.; Qiao, Z.; Zhao, Z.; Wang, X.; Sun, X.; Han, S.; Pan, C. Comprehensive evaluation of Luzhou-flavor liquor quality based on fuzzy mathematics and principal component analysis. Food Sci. Nutr. 2022, 10, 1780–1788. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Yuan, Y.; Yin, J.; Hu, H.; Pei, H.; Li, W.; Zhang, X. Characteristics of effervescent tablets of Aronia melanocarpa: Response surface design and antioxidant activity evaluation. J. Food Meas. Charact. 2022, 16, 2969–2977. [Google Scholar] [CrossRef]

- Patel, S.G.; Siddaiah, M. Formulation and evaluation of effervescent tablets: A review. J. Drug Deliv. Therapeutics. 2018, 8, 296–303. [Google Scholar] [CrossRef]

- Saifullah, M.; Yusof, Y.; Chin, N.; Aziz, M. Physicochemical and flow properties of fruit powder and their effect on the dissolution of fast dissolving fruit powder tablets. Powder Technol. 2016, 301, 396–404. [Google Scholar] [CrossRef]

| Evaluating Indicator | Evaluation Standard | Grade | Score |

|---|---|---|---|

| Effervescent tablet appearance | Smooth, uniform in color, and no abnormality | Good | 16–20 |

| Relatively complete and smooth, with uniform color and a few spots | Medium | 10–15 | |

| Not smooth, with spots, loose or hard | Poor | ~10 | |

| Beverage appearance | Bright light yellow, uniform and clear, without precipitation and good dissolution | Good | 16–20 |

| Light in color, slightly turbid, slightly precipitated, and has good solubility | Medium | 10–15 | |

| Dark in color, turbid, precipitated and poor in solubility | Poor | ~10 | |

| Taste | Sweet and sour, with strong aroma | Good | 16–20 |

| Sour or sweet, and the aroma is not strong | Medium | 10–15 | |

| Slightly bitter and astringent, without flavor | Poor | ~10 | |

| Effervescent effect | Violent and rapid, and the foaming amount is large | Good | 16~20 |

| Violent and slightly rapid, and the foaming amount is slightly large | Medium | 10–15 | |

| Not violent and the foaming amount is small | Poor | ~10 | |

| Disintegration | Rapid disintegration and short time | Good | 16–20 |

| Rapid disintegration and relatively short time | Medium | 10–15 | |

| Slow disintegration speed and long time | Poor | ~10 |

| Optimization Cycles | Experiment Number | Sea Buckthorn Fruit Powder Content (%) | Erythritol Content (%) | Acid Base Ratio | Maltodextrin Content (%) | Polyvinylpyrrolidone Content (%) | Sensory Evaluation Score |

|---|---|---|---|---|---|---|---|

| The first round | 1 | 66.2 | 1.1 | 1.2:1 | 1.9 | 3.2 | 66.63 |

| 2 | 57.0 | 1.9 | 0.8:1 | 2.8 | 4.9 | 77.45 | |

| 3 | 55.0 | 0.6 | 1.1:1 | 2.0 | 2.8 | 80.84 | |

| 4 | 50.3 | 1.4 | 0.9:1 | 2.3 | 2.2 | 75.10 | |

| 5 | 64.4 | 1.2 | 0.7:1 | 0.9 | 1.9 | 67.12 | |

| 6 | 62.1 | 0.8 | 1.2:1 | 2.3 | 2.8 | 71.55 | |

| 7 | 39.7 | 2 | 1.3:1 | 2.8 | 4.1 | 72.67 | |

| 8 | 56.5 | 2.3 | 0.8:1 | 2.5 | 1.2 | 68.61 | |

| 9 | 35.4 | 2.3 | 1.2:1 | 0.8 | 2.9 | 73.30 | |

| 10 | 39.9 | 2.3 | 1.3:1 | 0.6 | 1.9 | 71.36 | |

| Centroid search | 11 | 47.5 | 1.6 | 1.1:1 | 2.1 | 3.4 | 82.69 |

| 12 | 52.0 | 1.4 | 1:1 | 2.0 | 3.1 | 69.43 | |

| 13 | 52.8 | 1.3 | 1.1 | 2.4 | 3.4 | 78.41 | |

| 14 | 49.8 | 1.5 | 1.1 | 2.1 | 3.5 | 79.64 |

| Optimization Cycles | Experiment Number | Sea Buckthorn Fruit Powder Content (%) | Erythritol Content (%) | Acid Base Ratio | Maltodextrin Content (%) | Polyvinylpyrrolidone Content (%) | Sensory Evaluation Score |

|---|---|---|---|---|---|---|---|

| The second round | 15 | 59.7 | 0.7 | 0.9:1 | 1.7 | 2.4 | 63.51 |

| 16 | 54.3 | 1.0 | 0.9:1 | 1.8 | 1.8 | 84.92 | |

| 17 | 55.9 | 1.3 | 0.8:1 | 1.8 | 3.6 | 74.30 | |

| 18 | 45.8 | 1.2 | 1.2:1 | 1.7 | 2.4 | 80.96 | |

| 19 | 41.3 | 1.1 | 0.8:1 | 2.2 | 3.5 | 86.31 | |

| 20 | 40.3 | 0.7 | 1.1:1 | 2.5 | 3.5 | 76.10 | |

| Centroid search | 21 | 48.8 | 1.1 | 1:1 | 2 | 2.8 | 83.48 |

| 22 | 47.7 | 1.3 | 1:1 | 2 | 2.9 | 87.76 | |

| 23 | 49.6 | 1.2 | 1:1 | 2 | 3 | 76.84 | |

| 24 | 49.2 | 1.1 | 1:1 | 2 | 2.8 | 86.11 |

| Sensory Evaluation | Sensory Score | Sea Buckthorn Fruit Powder Content (%) | Erythritol Content (%) | Acid Base Ratio | Maltodextrin Content (%) | Polyvinylpyrrolidone Content (%) |

|---|---|---|---|---|---|---|

| Sensory score | 1 | |||||

| Sea buckthorn fruit powder content | −0.531 * | 1 | ||||

| Erythritol content | 0.540 | −0.033 | 1 | |||

| Acid base ratio | 0.100 | −0.417 | −0.078 | 1 | ||

| Maltodextrin Content | 0.250 | −0.778 ** | −0.291 | 0.112 | 1 | |

| Polyvinylpyrrolidone content | −0.038 | 0.459 | 0.145 | −0.231 | 0.627 * | 1 |

| Water Content (%) | Ascorbic Acid (mg/100 g) | Carotenoids (mg/100 g) | Total Phenol (mg/100 g) | Total Flavonoids (mg/g) | Hardness (N) | Disintegration Time Limit (s) | |

|---|---|---|---|---|---|---|---|

| Obtained effervescent tablets | 2.13 ± 0.15 a | 50.36 ± 0.04 a | 10.18 ± 0.14 a | 11.52 ± 0.13 a | 28.46 ± 0.11 a | 68.40 ± 0.73 b | 10.05 ± 0.15 a |

| Commercially available | 1.59 ± 0.37 b | 45.49 ± 0.55 b | 5.76 ± 0.18 b | 7.26 ± 0.05 b | 18.77 ± 0.36 b | 80.85 ± 0.93 a | 10 ± 0.13 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Lian, Y.; Meng, X.; Xu, M.; Zhang, T.; Zou, H.; Yang, H. Process Optimization of Sea Buckthorn Fruit Powder Effervescent Tablets by Random Centroid Methodology Combined with Fuzzy Mathematical Sensory Evaluation. Processes 2023, 11, 2639. https://doi.org/10.3390/pr11092639

Ma Y, Lian Y, Meng X, Xu M, Zhang T, Zou H, Yang H. Process Optimization of Sea Buckthorn Fruit Powder Effervescent Tablets by Random Centroid Methodology Combined with Fuzzy Mathematical Sensory Evaluation. Processes. 2023; 11(9):2639. https://doi.org/10.3390/pr11092639

Chicago/Turabian StyleMa, Yan, Yali Lian, Xintao Meng, Mingqiang Xu, Ting Zhang, Hui Zou, and Haiyan Yang. 2023. "Process Optimization of Sea Buckthorn Fruit Powder Effervescent Tablets by Random Centroid Methodology Combined with Fuzzy Mathematical Sensory Evaluation" Processes 11, no. 9: 2639. https://doi.org/10.3390/pr11092639

APA StyleMa, Y., Lian, Y., Meng, X., Xu, M., Zhang, T., Zou, H., & Yang, H. (2023). Process Optimization of Sea Buckthorn Fruit Powder Effervescent Tablets by Random Centroid Methodology Combined with Fuzzy Mathematical Sensory Evaluation. Processes, 11(9), 2639. https://doi.org/10.3390/pr11092639