Multi-Scale Fractal Characteristics of the Pore System in Low-Permeability Conglomerates from the Junggar Basin

Abstract

:1. Introduction

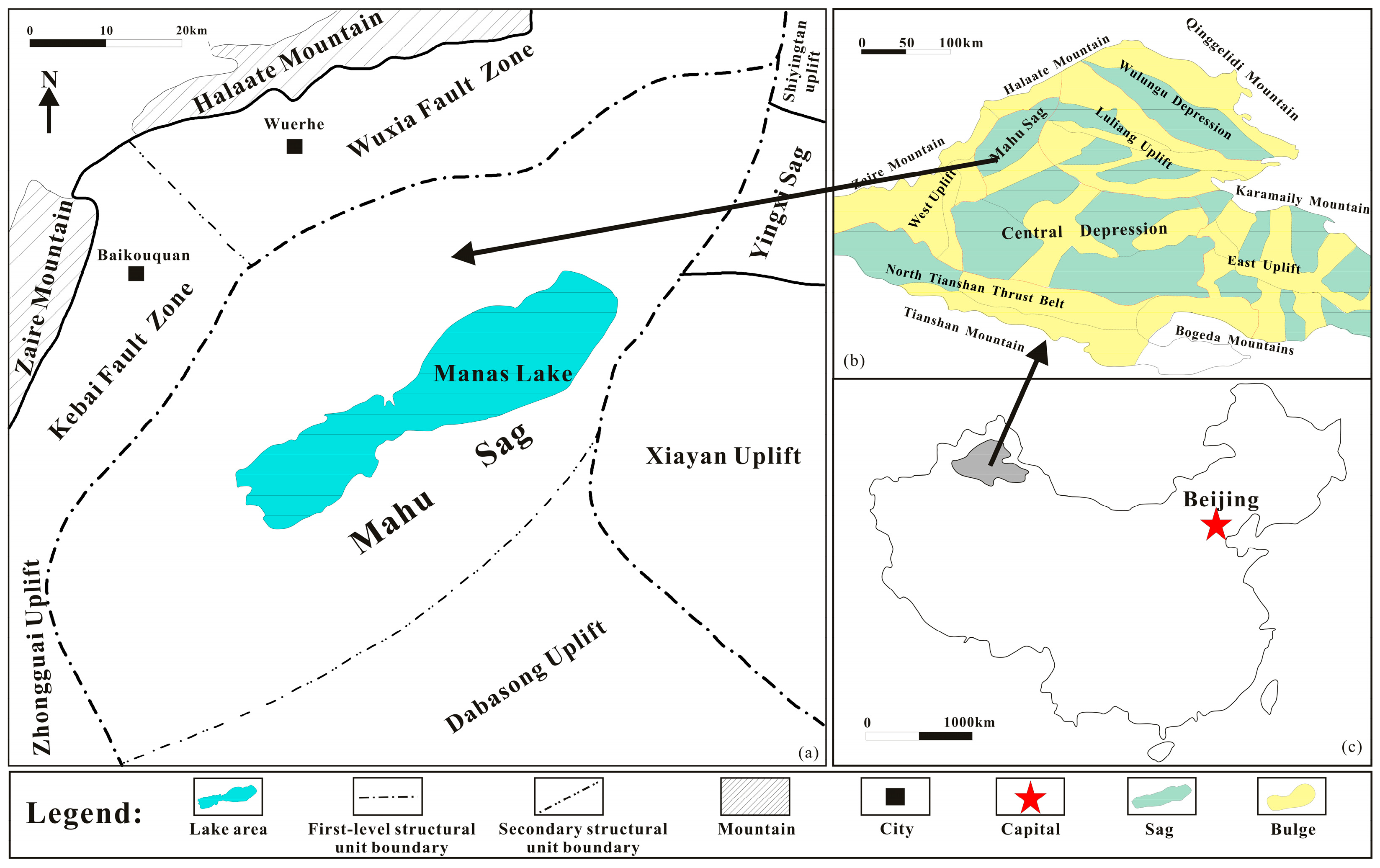

2. Geological Setting

3. Samples and Experiments

3.1. Samples

3.2. Experiments

4. Results

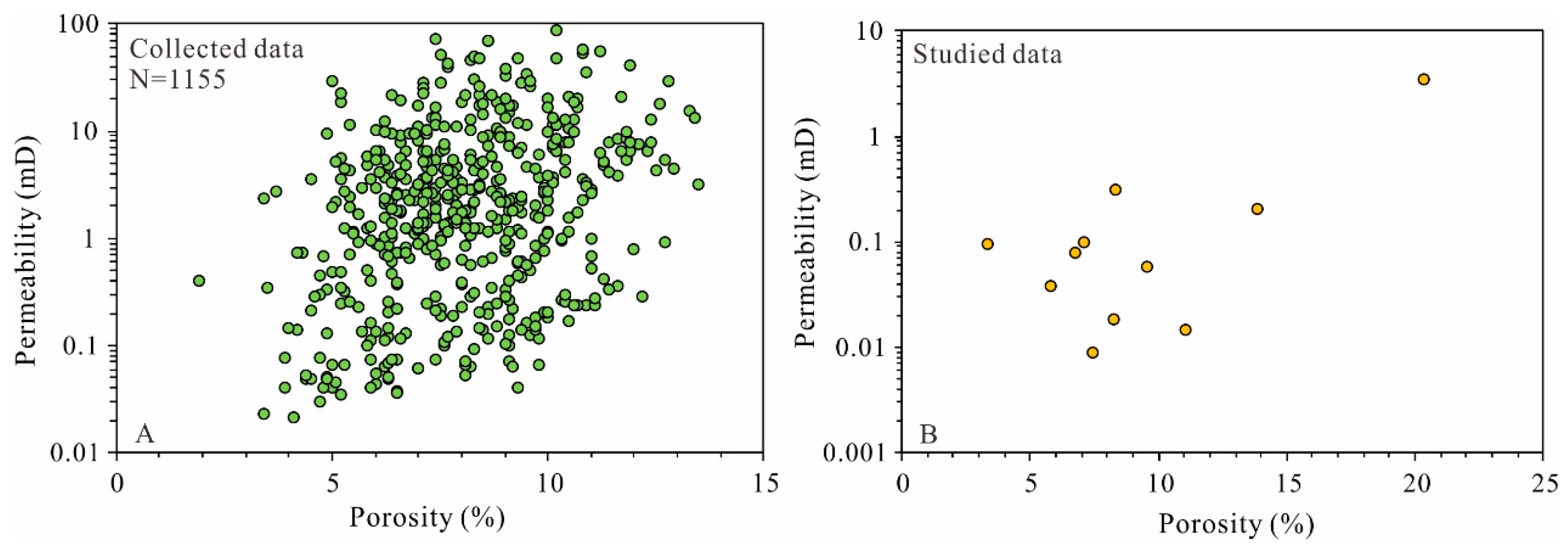

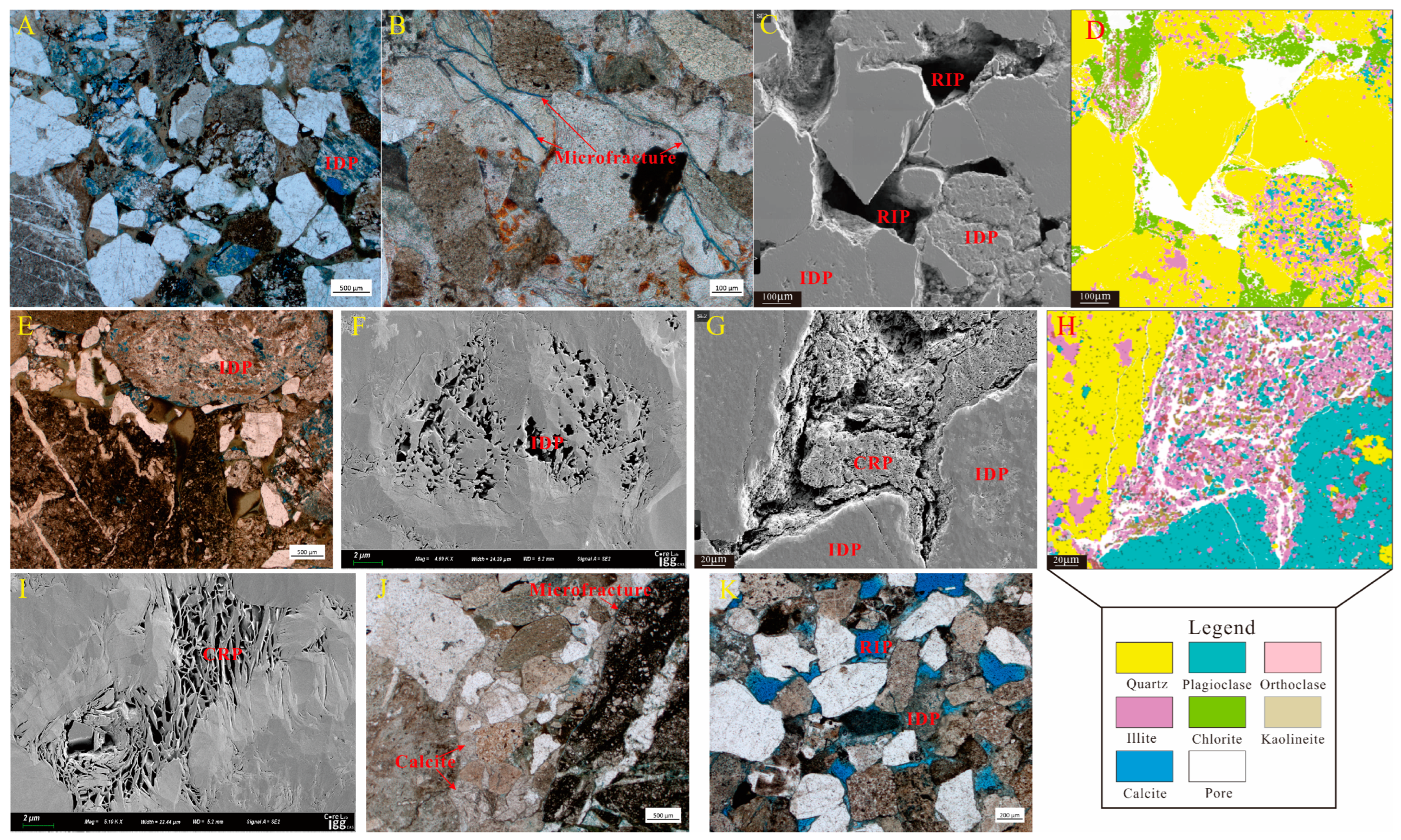

4.1. Porosity, Permeability, and Pore Types

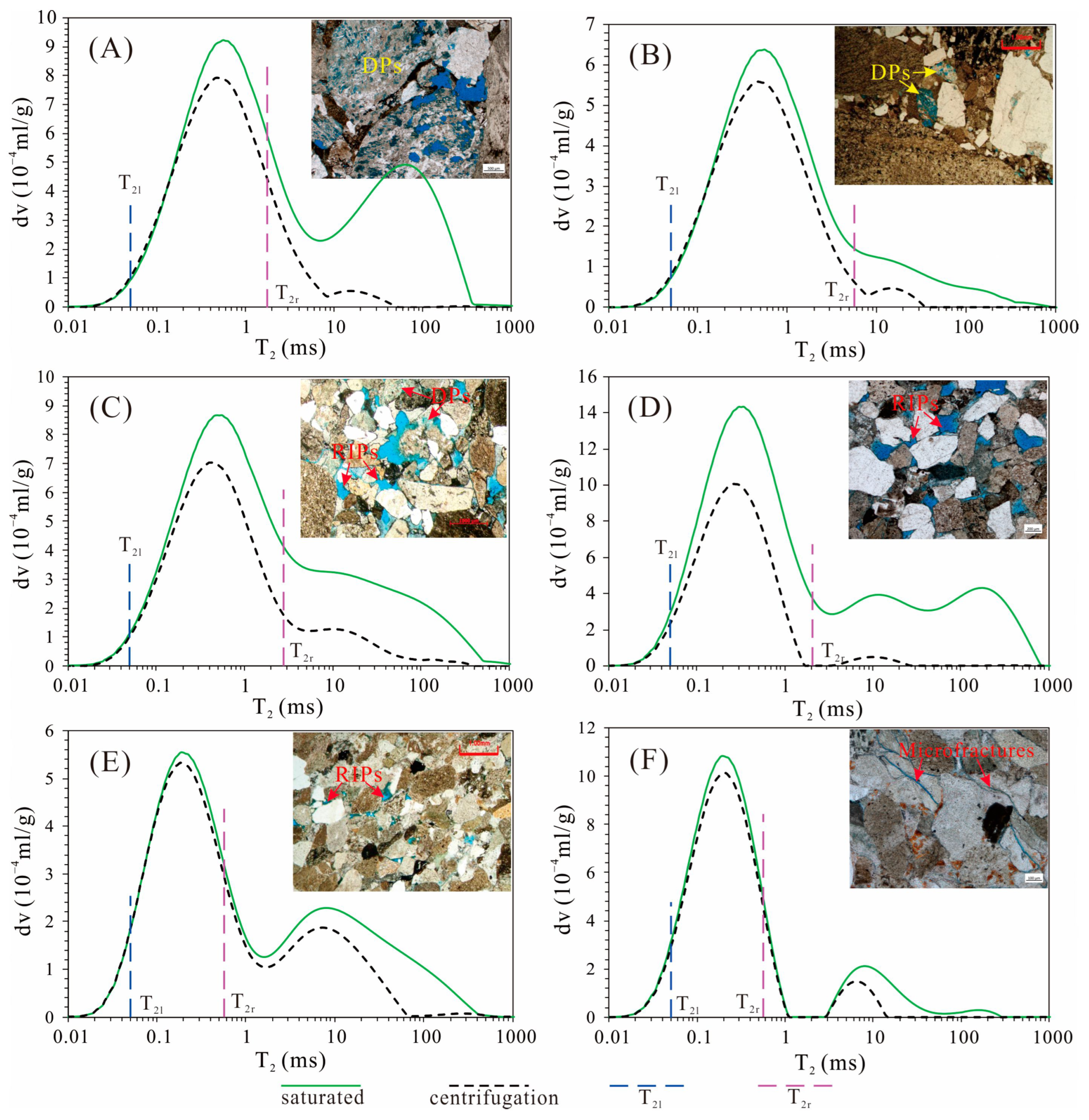

4.2. Pore Structure and Movable Fluid Saturation from NMR

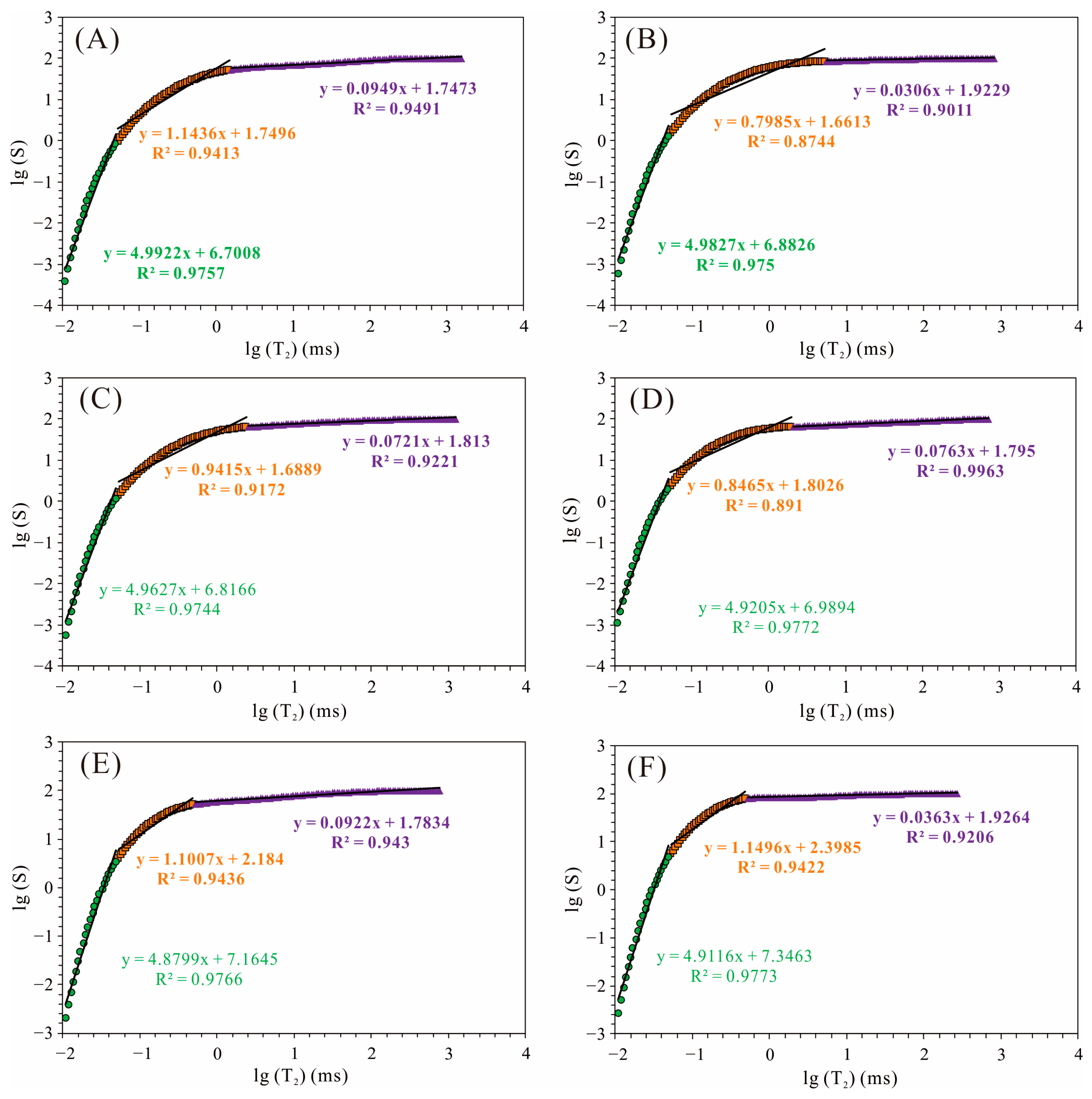

4.3. Fractal Characteristics Derived from NMR

5. Discussion

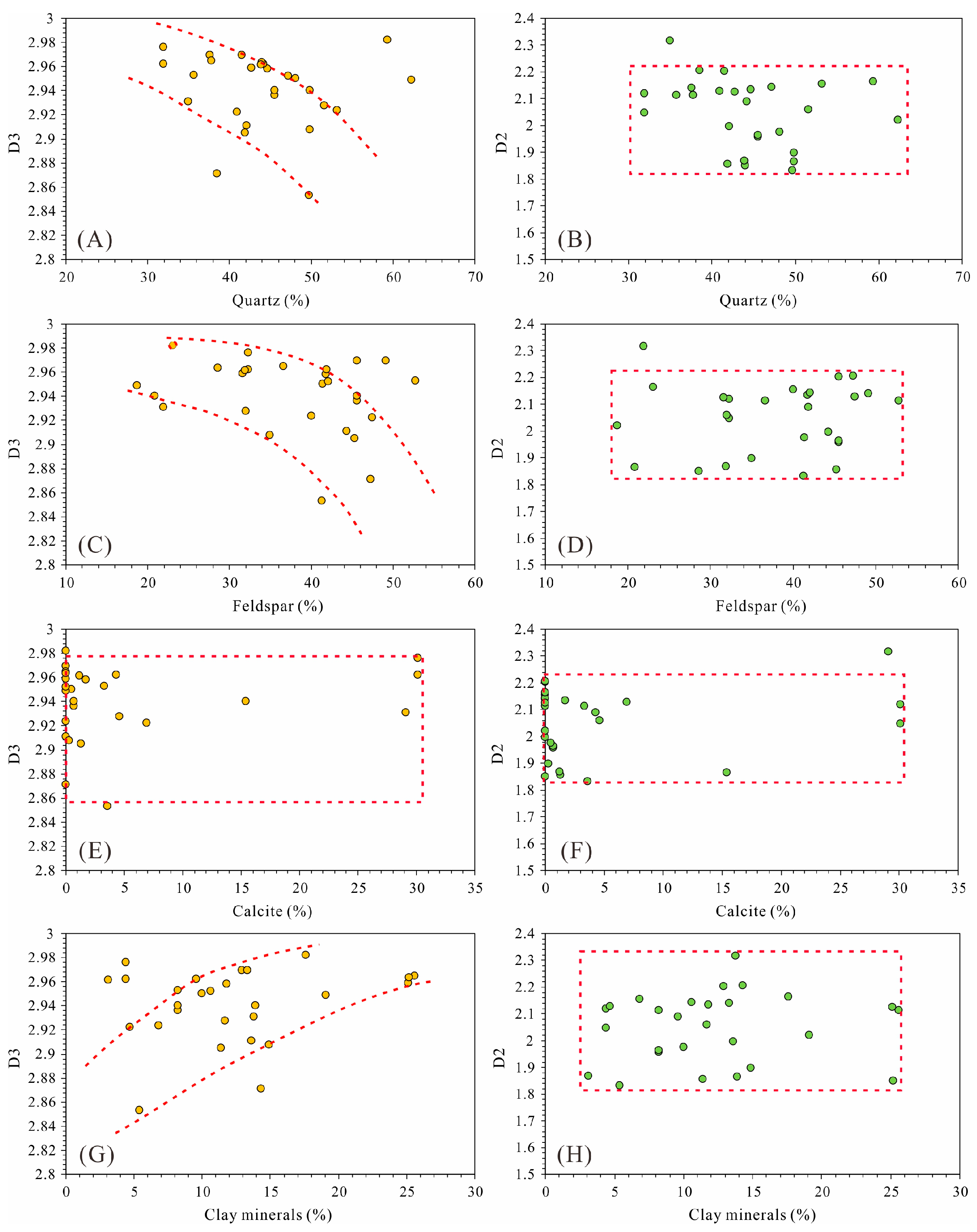

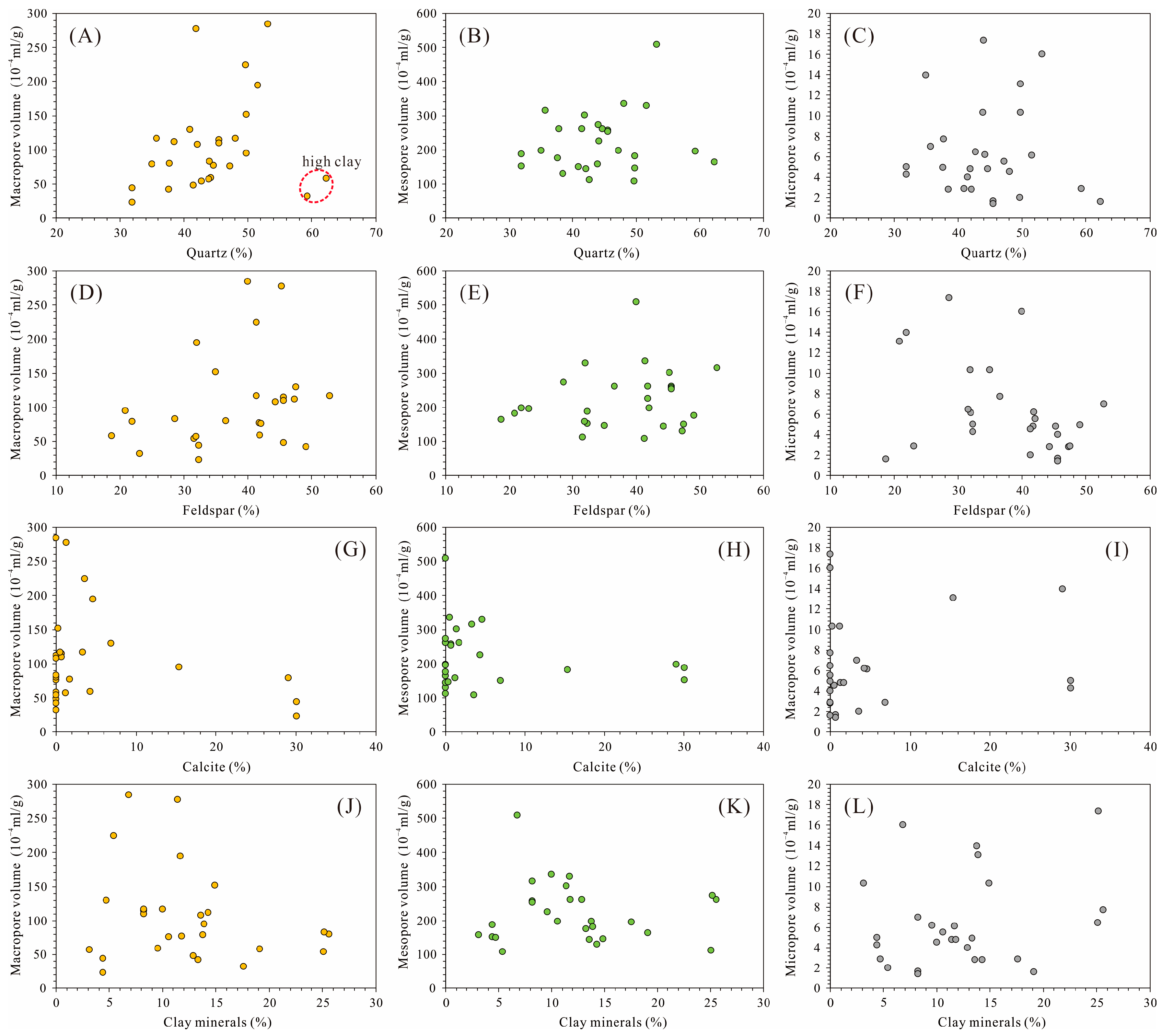

5.1. Correlations between Fractal Characteristics and Mineral Compositions

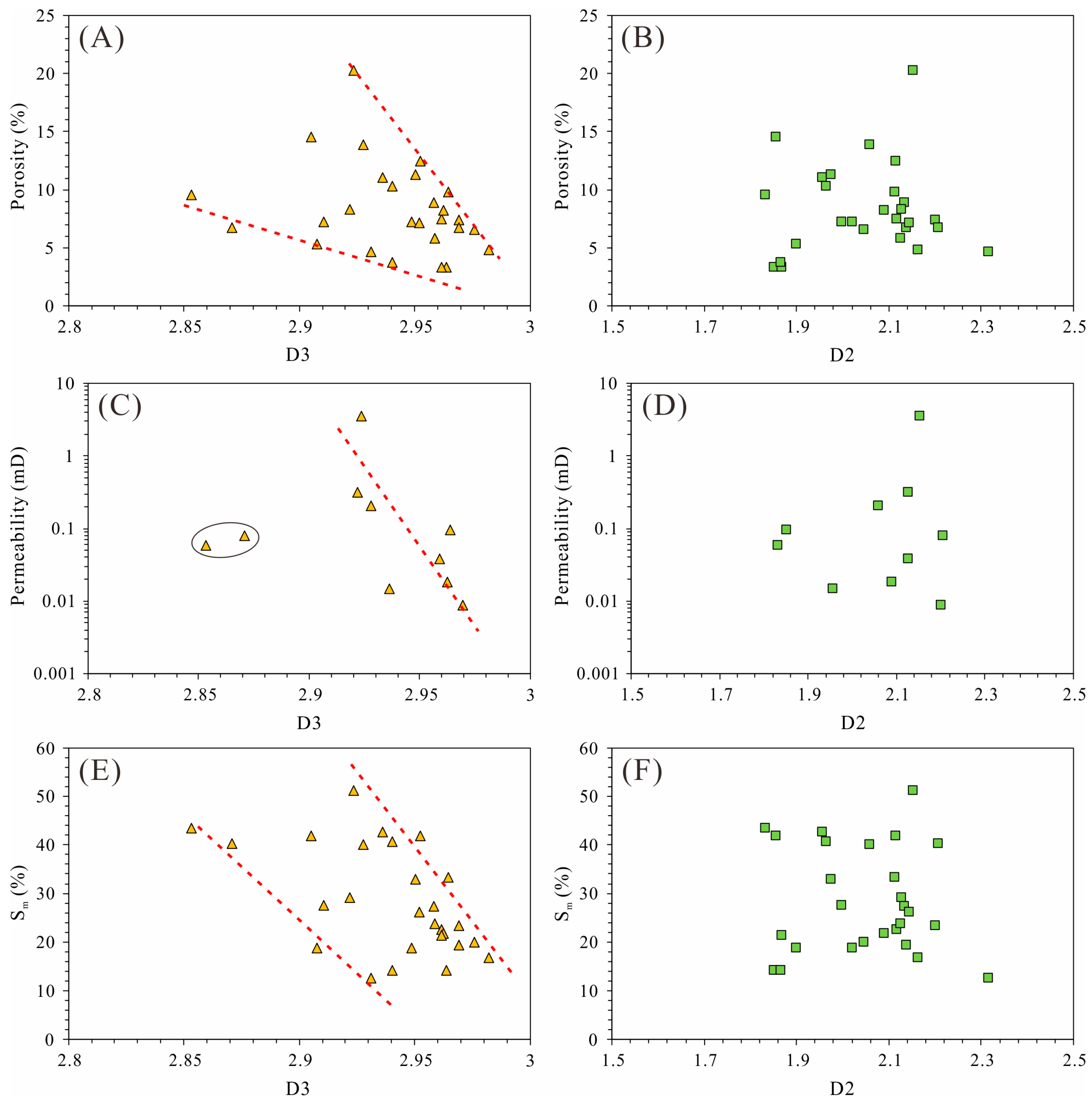

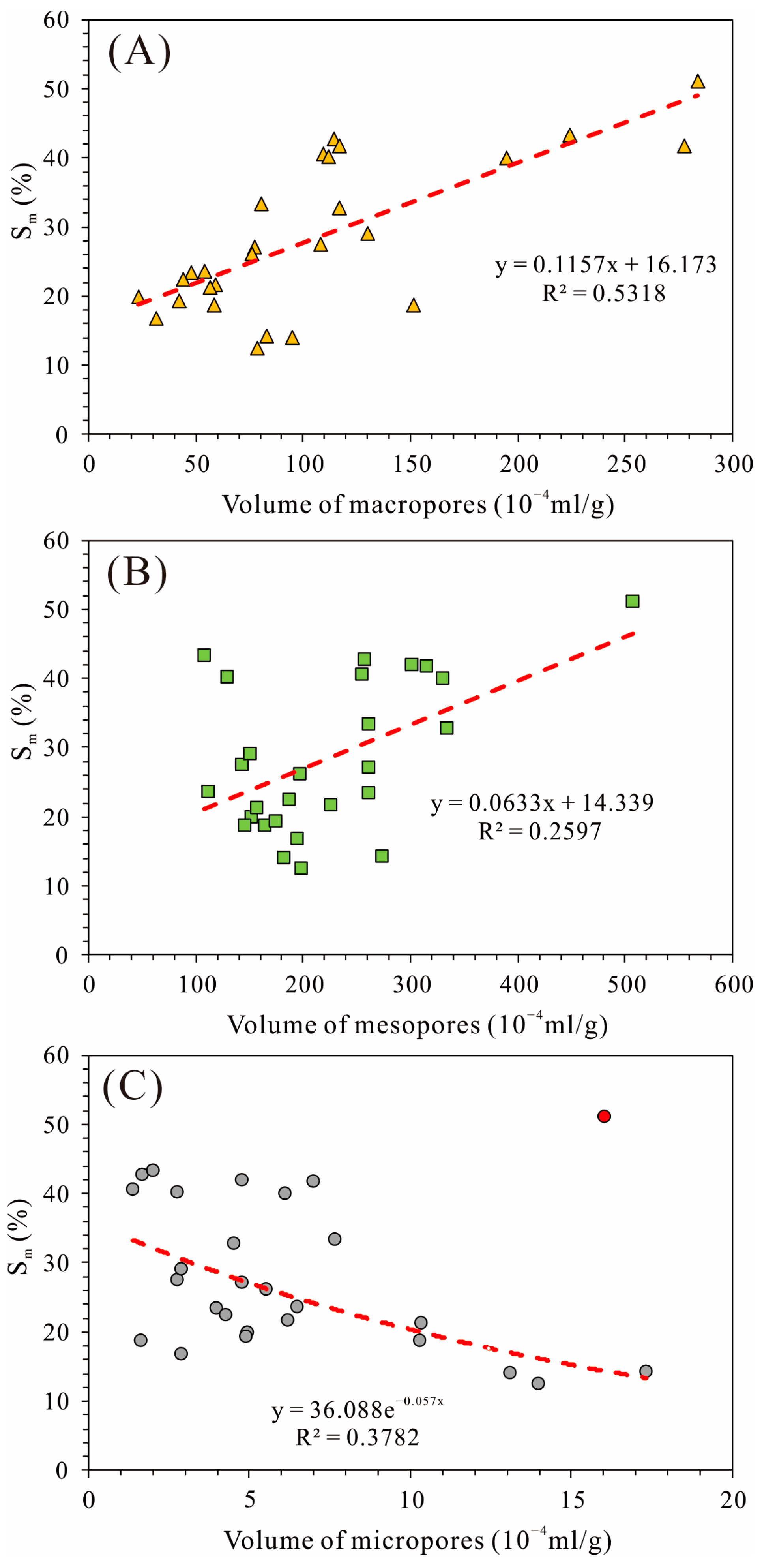

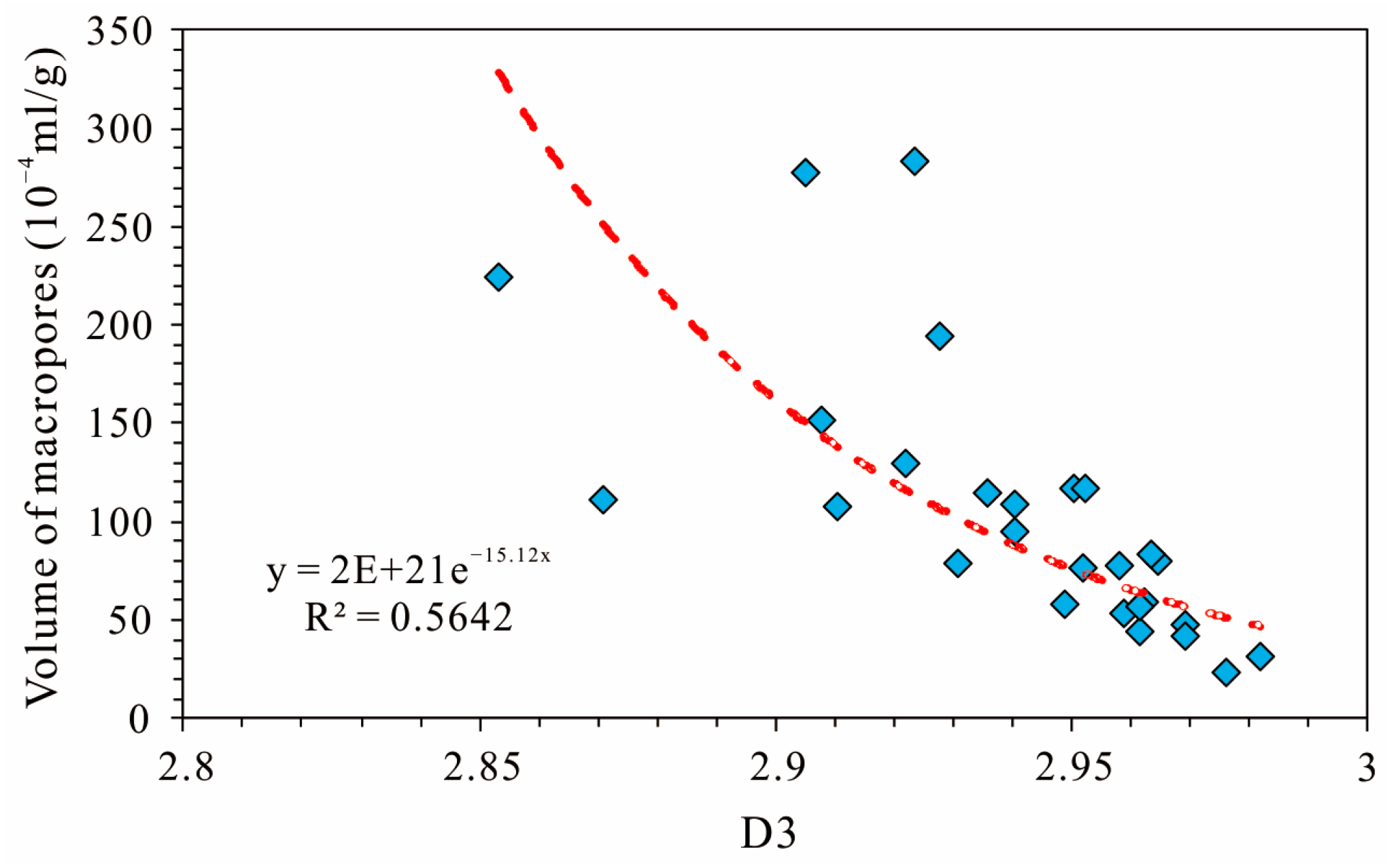

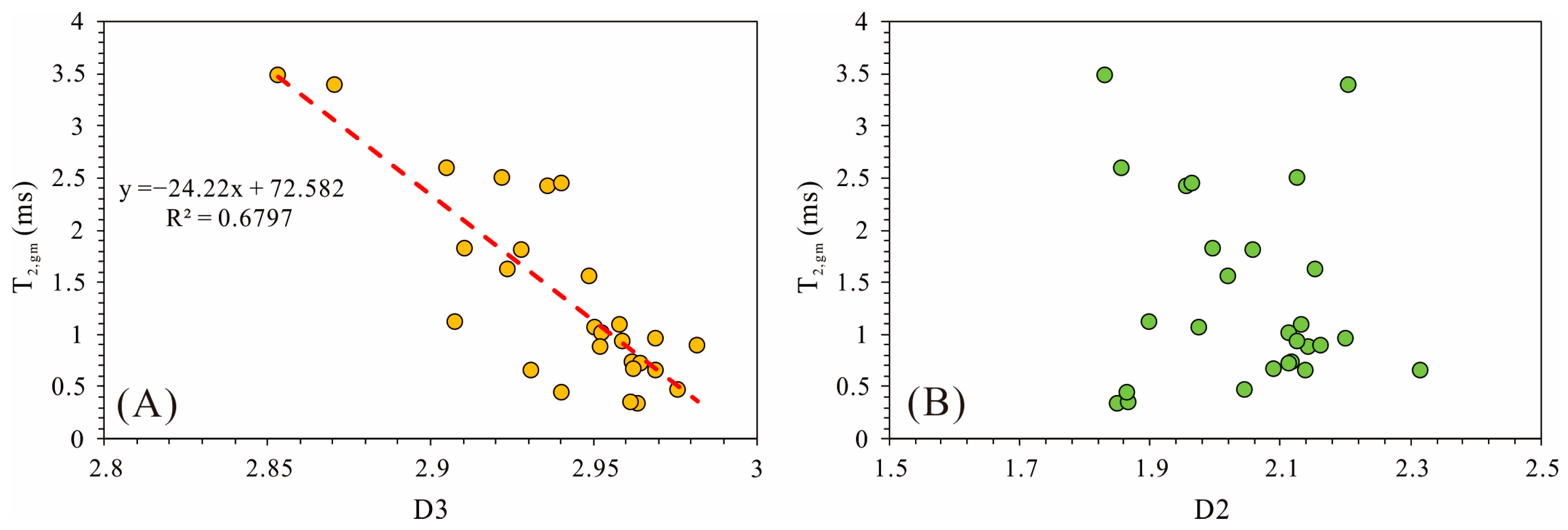

5.2. Correlations between Fractal Characteristics, Porosity, Permeability, and Movable Fluid Saturation

5.3. Implications of Fractal Characteristics for Characterizing the Pore Structure of Conglomerates

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blasko, D.P.; Wenger, W.J.; Morris, J.C. Oilfields and Crude Oil Characteristics: Cook Inlet Basin, Alaska; US Department of Interior, Bureau of Mines: Wanshington, DC, USA, 1972.

- Zonneveld, J.P.; Moslow, T.F. Exploration Potential of the Father G Shoreface Conglomerate Trend: Evidence from Outcrop. Bull. Can. Pet. Geol. 2004, 52, 23–38. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, S.; Xiao, D.; Gu, M. Characterization of Full Pore Size Distribution and Its Significance to Macroscopic Physical Parameters in Tight Glutenites. J. Nat. Gas Sci. Eng. 2017, 38, 434–449. [Google Scholar] [CrossRef]

- Zhu, X.M.; Zhao, D.N.; Jiang, S.X.; Ge, J.W.; Zhang, S.P.; Han, X.F.; Liu, X. Digenetic Sequence of Low Porosity and Permeability Reservoirs from Nearshore Subaqeous Fan of Shahejie Formation in the Steep Slope Zone of Chezhen Depression, Bohai Bay Basin. J. Earth Sci. Environ. 2014, 36, 1–9. [Google Scholar] [CrossRef]

- He, C.; Zhang, C. The World ’s Largest Conglomerate Oil Field Discovered in Junggar Basin, Xinjiang. Geol. China 2017, 44, 1174. [Google Scholar]

- Zhi, D.; Tang, Y.; Zheng, M.; Guo, W.; Wu, T.; Zou, Z. Discovery, Distribution and Exploration Practice of Large Oil Provinces of Above? Source Conglomerate in Mahu Sag. Xinjiang Pet. Geol. 2018, 39, 1–8+22. [Google Scholar] [CrossRef]

- Blair, T.C.; McPherson, J.G. Grain-Size and Textural Classification of Coarse Sedimentary Particles. J. Sediment. Res. 1999, 69, 6–19. [Google Scholar] [CrossRef]

- Xiao, M.; Wu, S.; Yuan, X.; Cao, Z.; Xie, Z. Diagenesis Effects on the Conglomerate Reservoir Quality of the Baikouquan Formation, Junggar Basin, China. J. Pet. Sci. Eng. 2020, 195, 107599. [Google Scholar] [CrossRef]

- Xiao, M.; Wu, S.; Yuan, X.; Xie, Z. Conglomerate Reservoir Pore Evolution Characteristics and Favorable Area Prediction: A Case Study of the Lower Triassic Baikouquan Formation in the Northwest Margin of the Junggar Basin, China. J. Earth Sci. 2021, 32, 998–1010. [Google Scholar] [CrossRef]

- Tian, W.; Lu, S.; Huang, W.; Wang, S.; Gao, Y.; Wang, W.; Li, J.; Xu, J.; Zhan, Z. Study on the Full-Range Pore Size Distribution and the Movable Oil Distribution in Glutenite. Energy Fuels 2019, 33, 7028–7042. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, Z.; Jiang, Q.; Wang, J.; Feng, Y.; Zheng, J.; Baffour, B.A. Evaluation of Low Permeability Conglomerate Reservoirs Based on Petrophysical Facies: A Case Study from the Triassic Baikouquan Formation, Northern Mahu Sag, Junggar Basin, China. J. Pet. Sci. Eng. 2022, 219, 111082. [Google Scholar] [CrossRef]

- Wang, Z.; Ge, H.; Zhou, W.; Wei, Y.; Wang, B.; Liu, S.; Zhou, H.; Du, S. Characterization of Pores and Microfractures in Tight Conglomerate Reservoirs. Int. J. Hydrogen Energy 2022, 47, 26901–26914. [Google Scholar] [CrossRef]

- Wu, Y.; Tahmasebi, P.; Lin, C.; Aleem, M.; Dong, C.; Golab, A.N.; Ren, L. A Comprehensive Study on Geometric, Topological and Fractal Characterizations of Pore Systems in Low-Permeability Reservoirs Based on SEM, MICP, NMR, and X-ray CT Experiments. Mar. Pet. Geol. 2019, 103, 12–28. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of Pore Types and Networks in Mudrocks and a Descriptive Classification for Matrix-Related Mudrock Pores. Am. Assoc. Pet. Geol. Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Anovitz, L.M.; Cole, D.R. Characterization and Analysis of Porosity and Pore Structures. Rev. Mineral. Geochem. 2015, 80, 61–164. [Google Scholar] [CrossRef]

- Kaufmann, J.; Loser, R.; Leemann, A. Analysis of Cement-Bonded Materials by Multi-Cycle Mercury Intrusion and Nitrogen Sorption. J. Colloid Interface Sci. 2009, 336, 730–737. [Google Scholar] [CrossRef]

- Xiao, D.; Jiang, S.; Thul, D.; Huang, W.; Lu, Z.; Lu, S. Combining Rate-Controlled Porosimetry and NMR to Probe Full-Range Pore Throat Structures and Their Evolution Features in Tight Sands: A Case Study in the Songliao Basin, China. Mar. Pet. Geol. 2017, 83, 111–123. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Z.; Yao, G.; Zhang, W.; Pan, Y.; Qu, T. Analysis Method of Full-Scale Pore Distribution Based on MICP, CT Scanning, NMR, and Cast Thin Section Imaging—A Case Study of Paleogene Sandstone in Xihu Sag, East China Sea Basin. Processes 2023, 11, 1869. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M. Multi-Scale Fractal Analysis of Pores in Shale Rocks. J. Appl. Geophys. 2017, 140, 1–10. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G. Fractal Analysis of Tight Gas Sandstones Using High-Pressure Mercury Intrusion Techniques. J. Nat. Gas Sci. Eng. 2015, 24, 185–196. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Huang, W. Fractal Characterization of Adsorption-Pores of Coals from North China: An Investigation on CH4 Adsorption Capacity of Coals. Int. J. Coal Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Xu, Q.; Ma, Y.; Liu, B.; Song, X.; Li, L.; Xu, J.; Su, J.; Wu, K.; Chen, Z. Fractal Characteristics of Lacustrine Tight Carbonate Nanoscale Reservoirs. Energy Fuels 2018, 32, 107–118. [Google Scholar] [CrossRef]

- Zhang, J.; Tang, Y.; He, D.; Sun, P.; Zou, X. Full-Scale Nanopore System and Fractal Characteristics of Clay-Rich Lacustrine Shale Combining FE-SEM, Nano-CT, Gas Adsorption and Mercury Intrusion Porosimetry. Appl. Clay Sci. 2020, 196, 105758. [Google Scholar] [CrossRef]

- Shao, X.; Pang, X.; Li, H.; Zhang, X. Fractal Analysis of Pore Network in Tight Gas Sandstones Using NMR Method: A Case Study from the Ordos Basin, China. Energy Fuels 2017, 31, 10358–10368. [Google Scholar] [CrossRef]

- Dang, W.; Fao, G.; You, X.; Wu, J.; Liu, S.; Yan, Q.; He, W.; Guo, L. Genesis and Distribution of Oils in Mahu Sag, Junggar Basin, NW China. Pet. Explor. Dev. 2023, 50, 840–850. [Google Scholar] [CrossRef]

- Qu, J.; Yang, R.; Tang, Y. Large Area Petroleum Accumulation Model of the Triassic Glutenite Reservoirs in the Mahu Sag, Junggar Basin: Triple Controls of Fan, Fault and Overpressure. Acta Geol. Sin. 2019, 93, 915–927. [Google Scholar] [CrossRef]

- Xu, T.; Liu, L.; Wang, Y.; Ji, H.; Song, G.; Wan, Q.; Luo, Z.; Li, X.; Li, L.; Li, J. Diagenesis and Porosity Evolution of Clastic Reservoir of Baikouquan Formation in Wuerhe-Fengnan Area. J. Northeast Pet. Univ. 2018, 42, 27–39. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A Review on Pore Structure Characterization in Tight Sandstones. Earth-Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Xiao, D.; Jiang, S.; Thul, D.; Lu, S.; Zhang, L.; Li, B. Impacts of Clay on Pore Structure, Storage and Percolation of Tight Sandstones from the Songliao Basin, China: Implications for Genetic Classification of Tight Sandstone Reservoirs. Fuel 2018, 211, 390–404. [Google Scholar] [CrossRef]

- Neasham, J.W. The Morphology of Dispersed Clay in Sandstone Reservoirs and Its Effect on Sandstone Shaliness, Pore Space and Fluid Flow Properties. In Proceedings of the SPE Annual Fall Technical Conference and Exhibition, Denver, CO, USA, 9–12 October 1977; pp. 1–8. [Google Scholar]

- Wilson, M.D.; Pittman, E.D. Authigenic Clays in Sandstones; Recognition and Influence on Reservoir Properties and Paleoenvironmental Analysis. J. Sediment. Res. 1977, 47, 3–31. [Google Scholar] [CrossRef]

| No. | Well | Φ (%) | K (mD) | Mineral Composition (wt.%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q | F | Ca | CM | S | Ka | I | C | I/S | C/S | ||||

| B1 | M601 | 14.5 | / | 41.9 | 45.3 | 1.3 | 11.4 | 0.00 | 2.28 | 1.37 | 4.45 | 1.14 | 2.17 |

| B2 | M601 | 7.4 | 0.0088 | 41.5 | 45.6 | 0.0 | 12.9 | 0.00 | 2.32 | 2.45 | 4.77 | 1.03 | 2.32 |

| B3 | M603 | 11.1 | 0.0147 | 45.5 | 45.6 | 0.7 | 8.2 | 0.00 | 0.66 | 6.07 | 0.98 | 0.16 | 0.33 |

| B4 | M604 | 10.3 | / | 45.5 | 45.6 | 0.7 | 8.2 | 0.00 | 0.66 | 6.07 | 0.98 | 0.16 | 0.33 |

| B5 | M603 | 6.7 | 0.0795 | 38.5 | 47.3 | 0.0 | 14.3 | 0.00 | 3.15 | 3.43 | 5.15 | 1.43 | 1.14 |

| B7 | M604 | 8.9 | / | 44.7 | 41.8 | 1.7 | 11.8 | 0.00 | 2.12 | 1.53 | 4.84 | 1.30 | 2.01 |

| B8 | M154 | 11.3 | / | 48.1 | 41.4 | 0.5 | 10.0 | 0.00 | 1.30 | 2.90 | 4.10 | 0.30 | 1.40 |

| B9 | M154 | 6.6 | / | 31.9 | 32.3 | 30.1 | 4.4 | 0.00 | 0.75 | 0.84 | 1.98 | 0.22 | 0.62 |

| B10 | M154 | 7.5 | / | 31.9 | 32.3 | 30.1 | 4.4 | 0.00 | 0.75 | 0.84 | 1.98 | 0.22 | 0.62 |

| B11 | M154 | 7.2 | / | 42.1 | 44.3 | 0.0 | 13.6 | 0.00 | 1.36 | 6.66 | 3.26 | 0.54 | 1.77 |

| B12 | M154 | 7.2 | / | 62.3 | 18.7 | 0.0 | 19.1 | 2.10 | 1.72 | 4.78 | 6.69 | 0.00 | 3.82 |

| B13 | M136 | 13.9 | 0.2070 | 51.6 | 32.0 | 4.6 | 11.7 | 0.00 | 0.23 | 9.13 | 1.52 | 0.00 | 0.82 |

| B14 | M139 | 20.3 | 3.5200 | 53.2 | 40.0 | 0.0 | 6.8 | 0.00 | 1.09 | 2.24 | 2.45 | 0.48 | 0.54 |

| B15 | M139 | 12.5 | / | 35.7 | 52.8 | 3.3 | 8.2 | 0.08 | 0.33 | 4.35 | 2.71 | 0.16 | 0.57 |

| B16 | M139 | 6.8 | / | 37.6 | 49.1 | 0.0 | 13.3 | 1.06 | 0.40 | 5.59 | 4.92 | 0.00 | 1.33 |

| B17 | M139 | 7.2 | / | 47.2 | 42.1 | 0.0 | 10.6 | / | / | / | / | / | / |

| B18 | X723 | 9.5 | 0.0579 | 49.7 | 41.3 | 3.6 | 5.4 | 0.00 | 0.43 | 1.89 | 2.00 | 0.27 | 0.81 |

| B19 | X723 | 9.8 | / | 37.8 | 36.6 | 0.0 | 25.6 | 2.30 | 1.79 | 7.94 | 9.98 | 0.00 | 3.58 |

| B20 | X723 | 8.2 | 0.0185 | 44.2 | 41.9 | 4.3 | 9.6 | 0.00 | 1.15 | 2.98 | 3.65 | 0.48 | 1.34 |

| B21 | X723 | 8.3 | 0.3160 | 40.9 | 47.5 | 6.9 | 4.7 | 0.66 | 1.60 | 1.18 | 1.27 | 0.00 | 0.00 |

| W1 | M001 | 4.7 | / | 35.0 | 21.9 | 29.1 | 13.8 | 11.87 | 0.83 | 0.00 | 1.10 | 0.00 | 0.00 |

| W2 | M001 | 4.8 | / | 59.3 | 23.1 | 0.0 | 17.6 | 3.52 | 4.75 | 2.46 | 6.86 | 0.00 | 0.00 |

| W3 | M211 | 5.8 | 0.0378 | 42.7 | 31.6 | 0.0 | 25.1 | 13.30 | 2.51 | 1.51 | 7.78 | 0.00 | 0.00 |

| W4 | M211 | 5.3 | / | 49.8 | 35.0 | 0.3 | 14.9 | 9.24 | 1.94 | 0.00 | 3.73 | 0.00 | 0.00 |

| W5 | M218 | 3.4 | 0.0956 | 44.0 | 28.6 | 0.0 | 25.2 | 11.59 | 0.76 | 2.27 | 10.58 | 0.00 | 0.00 |

| W6 | M218 | 3.4 | / | 43.9 | 31.9 | 1.2 | 3.1 | 0.90 | 0.06 | 0.00 | 2.14 | 0.00 | 0.00 |

| W7 | M218 | 3.8 | / | 49.8 | 20.9 | 15.4 | 13.9 | 7.92 | 0.28 | 0.00 | 5.70 | 0.00 | 0.00 |

| No. | Depth /m | T2l /ms | T2r /ms | T2,gm /ms | Sm /% | Fractal Dimension | Pore Volume/10−4 mL·g−1 | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| D1 | D2 | D3 | Macro- | Meso- | Micro- | ||||||

| B1 | 3861.5 | 0.05 | 1.54 | 2.60 | 41.89 | −1.992 | 1.856 | 2.905 | 4.77 | 301.15 | 277.18 |

| B2 | 3892.0 | 0.05 | 5.36 | 0.96 | 23.39 | −1.983 | 2.202 | 2.969 | 3.97 | 261.20 | 47.80 |

| B3 | 3806.3 | 0.05 | 4.66 | 2.42 | 42.69 | −2.074 | 1.957 | 2.936 | 1.66 | 257.27 | 114.26 |

| B4 | 3806.3 | 0.05 | 500 | 2.44 | 40.65 | −2.148 | 1.965 | 2.940 | 1.40 | 254.20 | 109.34 |

| B5 | 3837.9 | 0.05 | 3.53 | 3.39 | 40.30 | −1.867 | 2.206 | 2.871 | 2.78 | 129.78 | 111.72 |

| B7 | 3881.0 | 0.05 | 3.30 | 1.10 | 27.23 | −1.969 | 2.133 | 2.958 | 4.78 | 260.48 | 77.27 |

| B8 | 3007.6 | 0.05 | 2.50 | 1.07 | 32.80 | −1.993 | 1.975 | 2.951 | 4.52 | 334.30 | 116.46 |

| B9 | 3027.1 | 0.05 | 1.89 | 0.47 | 20.03 | −1.967 | 2.046 | 2.976 | 4.96 | 152.24 | 23.41 |

| B10 | 3027.1 | 0.05 | 2.50 | 0.73 | 22.49 | −1.980 | 2.118 | 2.962 | 4.26 | 187.29 | 44.03 |

| B11 | 3034.1 | 0.05 | 1.89 | 1.82 | 27.49 | −1.896 | 1.997 | 2.911 | 2.77 | 143.06 | 108.14 |

| B12 | 3069.8 | 0.05 | 4.06 | 1.56 | 18.81 | −1.760 | 2.021 | 2.949 | 1.63 | 163.71 | 58.16 |

| B13 | 3270.7 | 0.05 | 2.50 | 1.81 | 40.06 | −1.963 | 2.059 | 2.928 | 6.10 | 329.54 | 194.77 |

| B14 | 3260.1 | 0.05 | 2.03 | 1.62 | 51.25 | −1.921 | 2.154 | 2.924 | 16.02 | 507.52 | 283.72 |

| B15 | 3273.3 | 0.05 | 2.50 | 1.01 | 41.78 | −1.923 | 2.115 | 2.953 | 6.97 | 315.34 | 116.48 |

| B16 | 3280.3 | 0.05 | 2.17 | 0.65 | 19.43 | −1.967 | 2.139 | 2.969 | 4.89 | 174.69 | 41.94 |

| B17 | 3309.9 | 0.05 | 2.17 | 0.88 | 26.19 | −1.969 | 2.144 | 2.952 | 5.54 | 197.47 | 75.90 |

| B18 | 2676.5 | 0.05 | 1.25 | 3.48 | 43.36 | −2.003 | 1.832 | 2.853 | 2.03 | 107.62 | 223.89 |

| B19 | 2686.7 | 0.05 | 1.89 | 0.72 | 33.33 | −1.911 | 2.114 | 2.965 | 7.68 | 260.93 | 80.12 |

| B20 | 2691.9 | 0.05 | 1.89 | 0.66 | 21.66 | −1.767 | 2.090 | 2.962 | 6.19 | 226.09 | 58.74 |

| B21 | 2734.0 | 0.05 | 2.87 | 2.50 | 29.20 | −1.874 | 2.127 | 2.922 | 2.88 | 150.57 | 129.98 |

| W1 | 3567.3 | 0.05 | 1.54 | 0.65 | 12.62 | −1.889 | 2.316 | 2.931 | 13.98 | 198.44 | 78.45 |

| W2 | 3572.8 | 0.05 | 4.66 | 0.89 | 16.81 | −2.112 | 2.163 | 2.982 | 2.87 | 194.97 | 31.59 |

| W3 | 3772.3 | 0.05 | 1.01 | 0.93 | 23.66 | −1.895 | 2.126 | 2.959 | 6.48 | 112.08 | 53.80 |

| W4 | 3768.4 | 0.05 | 0.51 | 1.12 | 18.73 | −1.880 | 1.899 | 2.908 | 10.30 | 145.71 | 151.50 |

| W5 | 3854.3 | 0.05 | 0.51 | 0.33 | 14.23 | −1.912 | 1.850 | 2.964 | 17.33 | 273.22 | 82.92 |

| W6 | 3915.3 | 0.05 | 0.51 | 0.35 | 21.39 | −1.911 | 1.868 | 2.962 | 10.32 | 156.93 | 56.67 |

| W7 | 3932.2 | 0.05 | 0.472 | 0.44 | 14.10 | −1.900 | 1.866 | 2.941 | 13.10 | 182.36 | 94.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Tian, W.; Gao, Y.; Wen, Z.; Fan, Y.; Gao, H.; Lu, S.; Zheng, X. Multi-Scale Fractal Characteristics of the Pore System in Low-Permeability Conglomerates from the Junggar Basin. Processes 2023, 11, 2667. https://doi.org/10.3390/pr11092667

Zheng J, Tian W, Gao Y, Wen Z, Fan Y, Gao H, Lu S, Zheng X. Multi-Scale Fractal Characteristics of the Pore System in Low-Permeability Conglomerates from the Junggar Basin. Processes. 2023; 11(9):2667. https://doi.org/10.3390/pr11092667

Chicago/Turabian StyleZheng, Jiayu, Weichao Tian, Yang Gao, Zhigang Wen, Yunpeng Fan, Heting Gao, Shuangfang Lu, and Xiaoyin Zheng. 2023. "Multi-Scale Fractal Characteristics of the Pore System in Low-Permeability Conglomerates from the Junggar Basin" Processes 11, no. 9: 2667. https://doi.org/10.3390/pr11092667

APA StyleZheng, J., Tian, W., Gao, Y., Wen, Z., Fan, Y., Gao, H., Lu, S., & Zheng, X. (2023). Multi-Scale Fractal Characteristics of the Pore System in Low-Permeability Conglomerates from the Junggar Basin. Processes, 11(9), 2667. https://doi.org/10.3390/pr11092667