Abstract

Visual quality inspection of part surfaces is a crucial step in industrial production. Image edge detection is a common technique for assessing the surface conditions of parts. However, current methods have limitations, including poor noise filtering, low adaptability, and inadequate accuracy of edge detection. To overcome these challenges, this study proposes an adaptive edge detection method for part images using selective processing. Firstly, this method divides the input image into noise, edge, and noise-free blocks, followed by selective mixed filtering to remove noise while preserving original image details. Secondly, a four-parameter adaptive selective edge detection algorithm model is constructed, which adaptively adjusts parameter values based on image characteristics to address issues of missing edges and false detections, thereby enhancing the adaptability and accuracy of the method. Moreover, by comparing and adjusting the four parameter values, different edge information can be selectively detected, enabling rapid acquisition of desired edge detection results and improving detection efficiency and flexibility. Experimental results demonstrated that the proposed method outperformed existing classical techniques in both subjective and objective evaluations, maintaining stable detection under varying noise conditions. Thus, this method was validated for its effectiveness and stability, enhancing production efficiency in manufacturing processes of parts.

1. Introduction

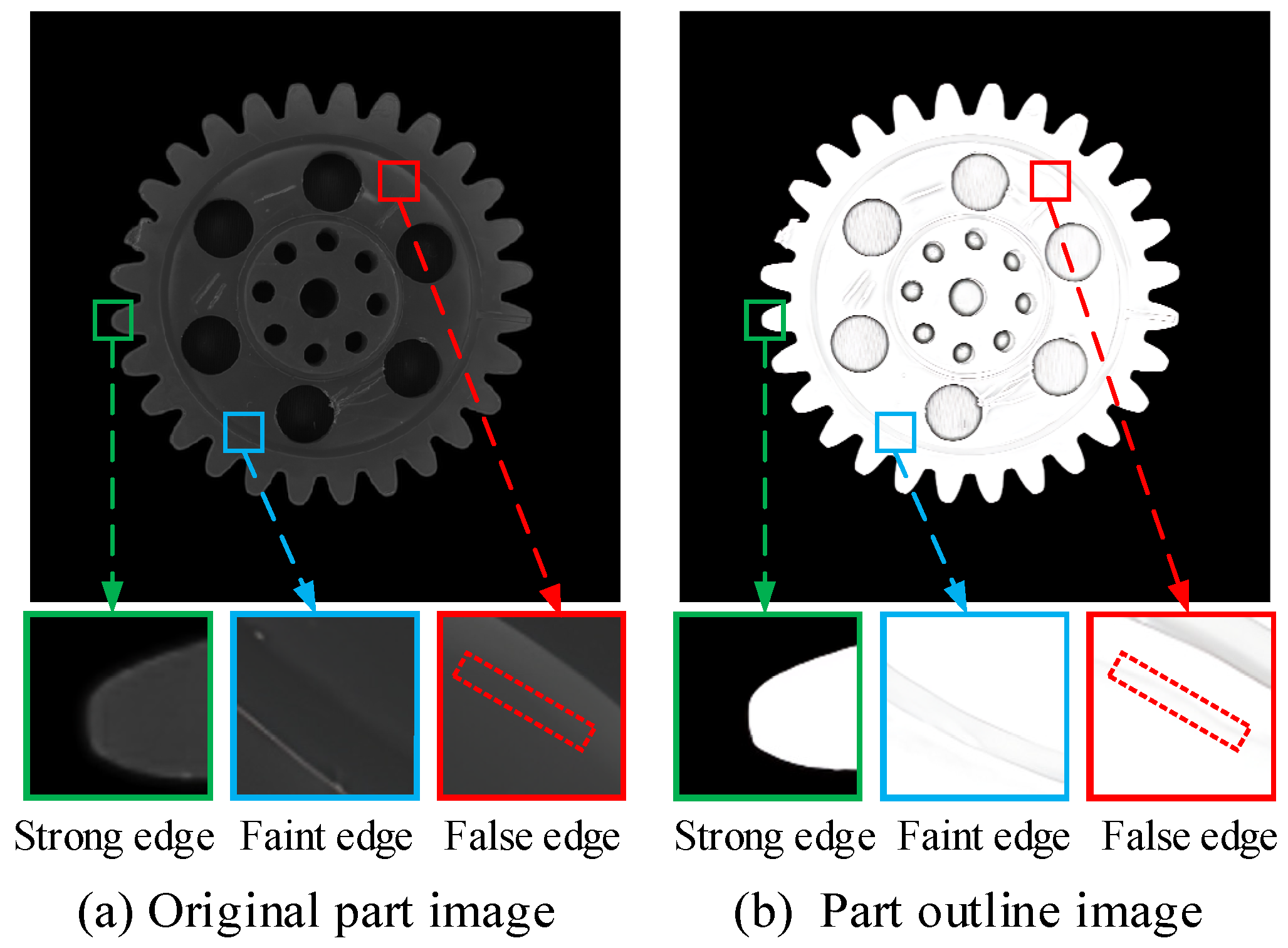

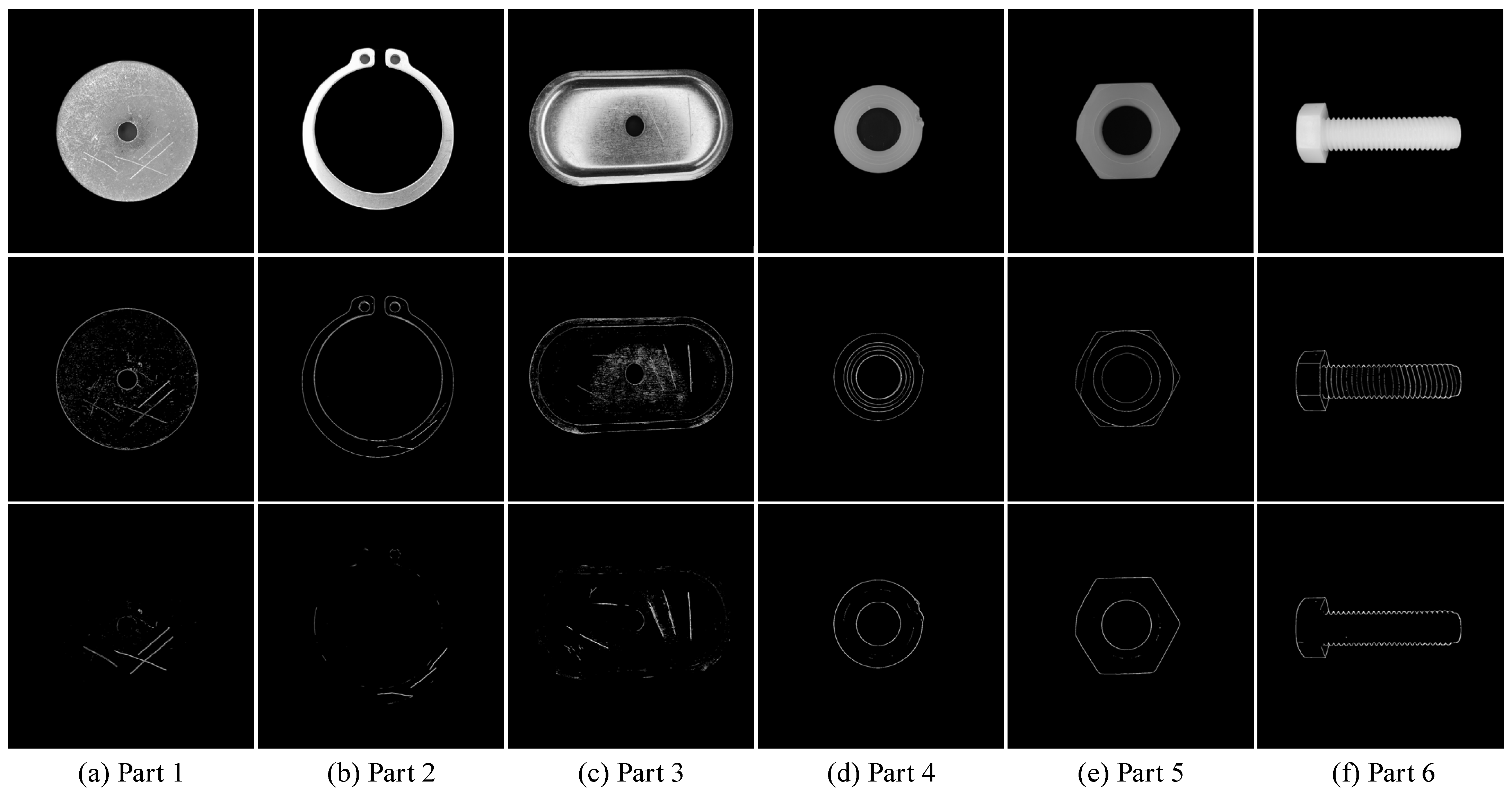

The surface quality of industrial parts is vital in ensuring their safety and stability in subsequent operations. As a result, inspecting the surface quality of parts becomes a critical step in the manufacturing process. Traditional manual inspection methods, however, have drawbacks such as low efficiency, high costs, and a lack of automation [1]. With the continuous advancement of computer technology, machine vision based on image processing techniques has emerged as a superior alternative for part quality inspection, rapidly gaining traction in industrial applications. Specifically, the edge information extracted from images can describe parameters such as part dimensions, orientation, and position, making it a crucial indicator for evaluating part quality [2]. As illustrated in Figure 1, part images contain various types of information, including strong edges, faint edges, false edges, low-frequency information, and slight noise. Among these, the strong edges represent the surface contours and main structural features of the part. Faint edges, which primarily reflect the texture features of the part’s surface, present lower contrast and are therefore more challenging to detect. The red box in Figure 1a indicates that due to factors such as uneven lighting, material properties, and slight camera vibrations, banded brightness transition areas may appear on the part’s surface. These transitions, clearly visible in the red box of Figure 1b, can be mistakenly identified as edges during detection, despite not being actual edges. Additionally, this type of information exhibits lower contrast compared to faint edges and closely resembles low-frequency information, complicating the detection process. Low-frequency information, a significant component of part images, occupies the largest proportion of the image. During edge detection, it is crucial to highlight edge details. Thus, in researching edge detection methods for part images, effectively detecting both strong and faint edges while resisting noise interference and suppressing false edge detection is of great significance.

Figure 1.

Different edge information features in a part image.

Currently, widely used methods for image edge detection in industrial parts include the Roberts, Sobel, and Laplacian operators. These methods detect edges by identifying pixels with the highest local grayscale values, fulfilling the real-time inspection needs of the industry. However, due to the challenges posed by uneven industrial lighting, micro-vibrations of the camera, and the intrinsic conditions of acquisition devices, part images often contain noise. These algorithms are sensitive to noise and may incorrectly interpret it as high-frequency information, leading to detection failures [3]. Consequently, they are not ideal for edge detection in industrial part images. The Canny edge detection algorithm [4] addresses this issue by applying linear filtering to image noise before edge detection. This preprocessing step significantly improves the signal-to-noise ratio, resulting in higher edge detection accuracy compared to earlier methods, making it a popular choice in visual inspection tasks [5,6,7]. However, while this algorithm effectively reduces noise, it can also result in the loss of image detail features, thereby diminishing edge localization accuracy [8]. To address this limitation, He et al. [9] proposed enhancing blurred edges post-denoising using the OTSU method. By refining the detection threshold, this approach improves edge detection performance, but it struggles to preserve detailed image features. Zheng et al. [10] introduced an edge detection method based on gray entropy theory and edge information characteristics, which effectively distinguishes between noise and edge pixels, preserving image details while eliminating noise. Yang et al. [11] proposed an adaptive edge detection method based on multi-scale grid division, using multi-scale nearest-neighbor operators to filter out noise and remove small texture areas, thereby enhancing edge detection accuracy compared to the Canny algorithm. However, this method may result in the loss of faint edge information. Liu et al. [12] suggested adjusting the median filter window size to accommodate different image characteristics, which successfully removes noise while suppressing artifacts. Nevertheless, balancing noise removal with edge sharpening remains challenging, often leading to indistinct detected edges [13]. To tackle this issue, Sun et al. [14] developed an improved Gaussian filter that better balances noise reduction and detail preservation. Although this method can effectively remove noise and sharpen edges, its performance deteriorates when dealing with high-intensity impulse noise. In response to high-intensity impulse noise, some studies have suggested hybrid filtering [15] or neural network-based convolutional approaches [16] to achieve satisfactory noise filtering. However, these methods process all image information during filtering, which is not only time-consuming but also potentially harmful to essential information. Additionally, most edge detection methods assume the presence of a single type of noise when analyzing image degradation models, whereas in practical applications, images often contain a mixture of nonlinear and linear noise forms [17]. Focusing on just one type of noise may leave residual noise post-filtering, reducing edge detection accuracy. Therefore, image edge detection research must consider the presence of various noise types to effectively remove them while preserving image details and protecting original information.

Moreover, the selection of thresholds in edge detection algorithms significantly influences detection outcomes. Traditional methods typically employ two fixed thresholds, which are manually set [18]. If the thresholds are too low, the detected edges may appear dense and indistinct; if set too high, important edges might go undetected, leading to the loss of crucial feature information. This introduces randomness into edge detection results [19]. To overcome this challenge, Chen et al. [20] proposed an adaptive threshold edge detection method based on two-dimensional entropy, which selects thresholds by calculating the gradient information of image blocks to detect edge and texture information. However, this method still struggles to produce complete edge contours. Yu et al. [21] developed a segmented adaptive Canny edge detection method that adaptively determines segmentation thresholds at the optimal granularity level, enhancing edge detection while maintaining more complete edge contours. Zhu et al. [22] suggested using texture information to repair broken edges. Additionally, some researchers have employed the Elastic model [23] and the Mumford–Shah model [24] to fill in missing parts of detected edges, though these methods increase the computational load of edge detection algorithms, thus reducing detection efficiency. To address computational load issues, some researchers have focused on minimizing the analysis of prior information to automatically adapt to different images, thereby improving algorithm real-time performance while ensuring complete edge detection [25]. Others have combined the Sobel algorithm for edge feature extraction with data compression techniques to lower computational requirements [26]. By shifting from global to local computation in threshold acquisition, improvements to the OTSU method have also reduced computational load [27]. Furthermore, some have optimized the Canny algorithm for FPGA implementation to enhance real-time performance [28]. Therefore, improving the computational efficiency of algorithms remains a current research focus in edge detection.

For images with complex texture details, faint edges differ significantly from strong edges, exhibiting less grayscale variation [29]. Whether using adaptive or fixed edge detection thresholds, relying solely on pixel similarity or discontinuity as boundary conditions may result in the omission of low-gradient faint edges, thereby reducing detection accuracy [30]. Additionally, the algorithm’s computational process may struggle to converge, failing to achieve the desired results [31]. To address these challenges, Ye et al. [32] proposed a deep learning-based edge detection method to resolve issues related to coarse edge detection and ineffective texture detail detection. This method leverages the Canny algorithm to refine edges, improving edge detection accuracy and clarity. However, some detected edges may still exhibit breaks. Zhang et al. [33] proposed an adaptive edge repair detection method that uses the Canny algorithm to detect initial edges and then repairs broken edges using the improved curvature-driven diffusions (CDDs) model, enhancing edge integrity. However, this method is less effective in detecting faint edges compared to the method proposed by reference [32]. Karim et al. [34] developed a method combining artificial neural networks with statistical regression to enhance the Canny algorithm’s parameter selection, resulting in improved detection of faint edge information, such as image textures, while offering better detection accuracy. Liu et al. [35] proposed a deep learning-based approach that extracts faint edges using image texture characteristics, but it requires long computation times, rendering it unsuitable for industrial applications. As edge detection algorithms improve their ability to detect faint edges, they inevitably detect false edges, leading to a reduction in overall edge detection accuracy. To mitigate this, reference [36] proposed a wavelet transform filtering model that removes image noise before applying the Canny algorithm, thereby suppressing false edge detection and enhancing accuracy. However, this method may blur faint edges during noise removal, reducing detection precision. Drawing on the feature selection strategy under fuzzy rules proposed by Chung et al. [37], reference [38] integrates an improved Canny algorithm with fuzzy techniques to control the detection of different edge information, achieving high detection accuracy and clear edges. Nevertheless, this method requires manual parameter adjustments, introducing uncertainty into the detection results. Thus, distinguishing between false edges, low-frequency information, and faint edges remains a significant challenge due to their similar attributes, making the suppression and detection of false edges a crucial aspect of ongoing research. The relevant feature information of the edge detection methods mentioned above is summarized in Table 1.

Table 1.

Relevant feature information of different edge detection methods.

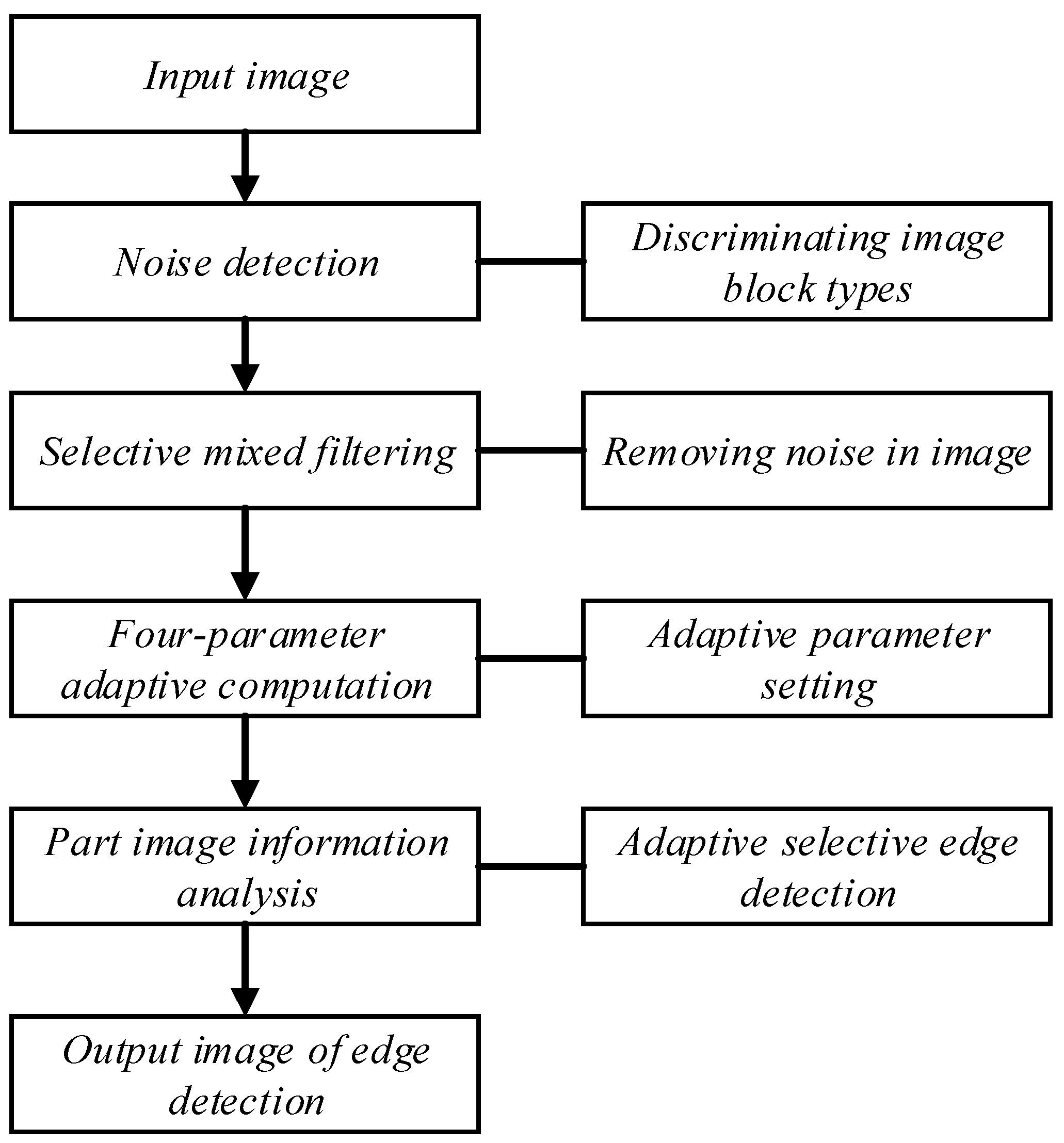

In conclusion, edge detection research for part images must account for various influencing factors, including effective noise filtering, while avoiding excessive edge smoothing. The detection method must be adaptive, ensuring high edge detection accuracy and efficiency while suppressing false edge detection. Therefore, this paper proposes a selective processing adaptive edge detection method for part images. This method first addresses the presence of both nonlinear and linear mixed noise forms in part images by combining root mean square nonlinear filtering with linear Gaussian filtering algorithms. It then filters out noise based on the detection results while protecting the original information. Subsequently, a four-parameter adaptive edge detection algorithm model is constructed, with all parameters adaptively set using image similarity, local characteristics, and statistical information. This model distinguishes between strong edges, faint edges, false edges, and low-frequency information. Additionally, different selective detection strategies are employed based on the application scenarios of part surface quality inspection, facilitating observation of part surfaces while avoiding unnecessary computations, thus improving edge detection efficiency and providing technical support for real-time part surface inspection. Finally, the performance of the proposed method is validated through experiments on natural images and part image edge detection. The framework of the proposed method is depicted in Figure 2.

Figure 2.

Basic flowchart of the proposed edge detection method.

The contributions of the proposed method in this paper can be summarized as follows:

- (1)

- This paper proposes a selective mixed filtering method, which processes noise blocks and edge blocks using different filtering methods based on the noise detection results, while avoiding processing noise-free blocks. This method can effectively remove the mixed noise present in the image, protect the original information of the image from being damaged, and improve the computational efficiency of the algorithm, providing good preconditioning for edge detection.

- (2)

- A four-parameter adaptive selective edge detection algorithm model is constructed, which adaptively sets four parameters in the edge detection algorithm using prior image information analysis. It also uses the similarity between image information to improve faint edge detection capabilities while suppressing false edge detection, thereby enhancing the adaptive ability and accuracy of the edge detection method.

- (3)

- The proposed edge detection method selectively detects the edge information of different parts by comparing and adjusting the four parameters in the model, allowing rapid acquisition of the required edge detection results, improving the efficiency and flexibility of edge detection, and thus meeting the needs of different edge detection application scenarios.

This paper is organized as follows. The content of Section 2 focuses on the selective mixed filtering part of the proposed method. Section 3 describes the specific details of the constructed four-parameter adaptive selective edge detection model. Section 4 presents an experimental section to verify the effectiveness and stability of the proposed method. A summary of the entire paper is given in Section 5.

2. Selective Processing Adaptive Edge Detection Method

2.1. Selective Mixed Filter

In industrial production, the captured images of parts often contain noise, which usually appears in a mixed form. The noise can interfere with edge detection in images, leading to a decrease in detection accuracy. It is necessary to remove the noise before edge detection. However, in traditional denoising research for edge detection methods, a single algorithm is often applied uniformly across all image regions. This approach tends to be less adaptive to the different information in various regions of the image and has compatibility issues with different types of noise, resulting in original information being destroyed, details being lost, and poor noise removal effectiveness [15]. Therefore, to effectively remove noise while preserving the original data of the image, this paper proposes a selective mixed filtering method that applies different filtering techniques to different regions and noise of the image. Firstly, by conducting noise detection on the input image, the image is segmented into noise blocks, edge blocks, and noise-free blocks. Then, a mixed filtering algorithm composed of root mean square nonlinear filtering and linear Gaussian filtering is selectively used to filter out the nonlinear and linear mixed noise present in the noise blocks and edge blocks, while the information from the noise-free blocks is directly mapped onto the filtered image. This ensures that effective noise removal is achieved without damaging the original information of the image, while also enhancing computational efficiency. Finally, the effectiveness of the filtering algorithm proposed in this paper is validated through noise reduction experiments, in comparison with existing classical filtering algorithms.

2.1.1. Image Noise Detection

The traditional noise variance method determines whether there is noise in a block of the image by using the gradient information of the image, and then performs denoising on the entire image. This approach can significantly damage the normal information in the image. To address this issue, this paper proposes a new noise detection method that distinguishes between normal image information and abnormal information, achieving the protection of original data, the preservation of image detail features, and a reduction in algorithm runtime. First, a threshold detection method is employed to determine the category of the image blocks. Based on the directional characteristics of the image, horizontal and vertical scanning is conducted across the image. Each time the detection window moves one pixel distance, information within the n × n window is extracted. Then, the pixel values within the matrix are used to calculate the difference in grayscale information of the detected image block, which is then compared with the noise thresholds β1 and β2 to determine the category of the image block. To effectively reduce noise, these thresholds can be dynamically adjusted based on the local characteristics of the image, determined by calculating the mean and variance within the image block. The formulas for thresholds β1 and β2 for the image block are as follows:

where α, λ represents the local mean value and local variance of the image block, respectively; I(i+a,j+b) is the set of input pixel values within n × n window; C = 1.

Furthermore, performing a grayscale difference operation between the central pixel gi,j in the n × n window and the surrounding pixels g(i+n,j+n), and introducing the Gaussian distribution weight w(x,y) to obtain the Gaussian-weighted grayscale difference ∆gN. This is used to evaluate the detected grayscale information difference in the image block, and by comparing it with the preset noise threshold β, the category of the image block is determined.

where , x and y represent the horizontal distance and vertical distance, respectively, from the other pixels to the central pixel B; σ = 1.

After the image is affected by noise pollution, there is a significant difference among the pixels within the noise-polluted blocks, which is characterized by a discrete or intermittent distribution of information; the information within the edge blocks exhibits partial continuity; while in the non-noise blocks, the differences between pixels are minimal, and the information displays a smooth distribution. Therefore, based on the characteristics of these different types of blocks, after calculating the grayscale information difference for each block in the image, we set thresholds β1 and β2 as the standards for noise discrimination, comparing ∆g with β1 and β2, and depending on the following situations, corresponding measures will be taken:

- (1)

- If the grayscale value gi,j of the central pixel is compared with the grayscale values gi+a,i+b of the surrounding pixels, and all ∆g are greater than β1, it is determined that the image block is located in a noise-polluted area and requires Gaussian filtering.

- (2)

- If the grayscale value gi,j of the central pixel is compared with the grayscale values gi+a,i+b of the surrounding pixels, and some ∆g are less than β1 but greater than β2, it indicates that the image block is a suspected noise block and may be located in an edge or texture area. To suppress the noise around the edges, the image block will undergo root mean square filtering to remove the noise points.

- (3)

- If the grayscale value gi,j of the central pixel is compared with the grayscale values gi+a,i+b of the surrounding pixels, and all ∆g are less than β2, the block is considered a non-noise block, requiring no processing, preserving the original information.

Based on the above derivation process, the aforementioned judgment conditions can be transformed into the following distinguishing function F(i,j) mathematical model:

2.1.2. Mixed Filter

After completing the classification of image blocks, a selective mixed filtering noise reduction method is formed by combining nonlinear filtering algorithms with linear filtering algorithms. On one hand, based on the characteristic of the image information distribution being nonlinear [39], this paper constructs a root mean square nonlinear filtering algorithm model that follows the sigmoid function and aligns with edge distribution properties [40]. This model can remove both nonlinear noise and linear noise. However, compared to Gaussian linear filtering algorithms, this method has a larger computational load and may cause texture details to become coarser, which is not conducive to subsequent faint edge detection. On the other hand, Gaussian filtering is not effective for nonlinear noises such as salt-and-pepper noise, and the noise information around edge blocks is similar to the edge information, making separation difficult. The Gaussian filtering method is prone to smoothing out edge information as if it were noise, leading to the loss of image details [41]. Therefore, addressing the problems identified in the aforementioned filtering process, based on the noise detection results, Gaussian linear filtering is used to process noise blocks, while the root mean square nonlinear filtering method is applied to handle the noise present within edge blocks. This approach achieves noise removal while preserving image detail features and enhancing computational efficiency. The functional definitions of the root mean square nonlinear filtering and Gaussian linear filtering are as follows:

where gi+a,i+b is given by the grayscale values of the surrounding pixels of the image block; σ = 1.

Here, it is worth mentioning that during the filtering process, not all pixels within the window are involved; instead, only the outlier pixels within the window are selected for filtering, while normal information is excluded. This approach can reduce the runtime and still achieve good noise reduction performance even in cases where the image is contaminated by high-density noise.

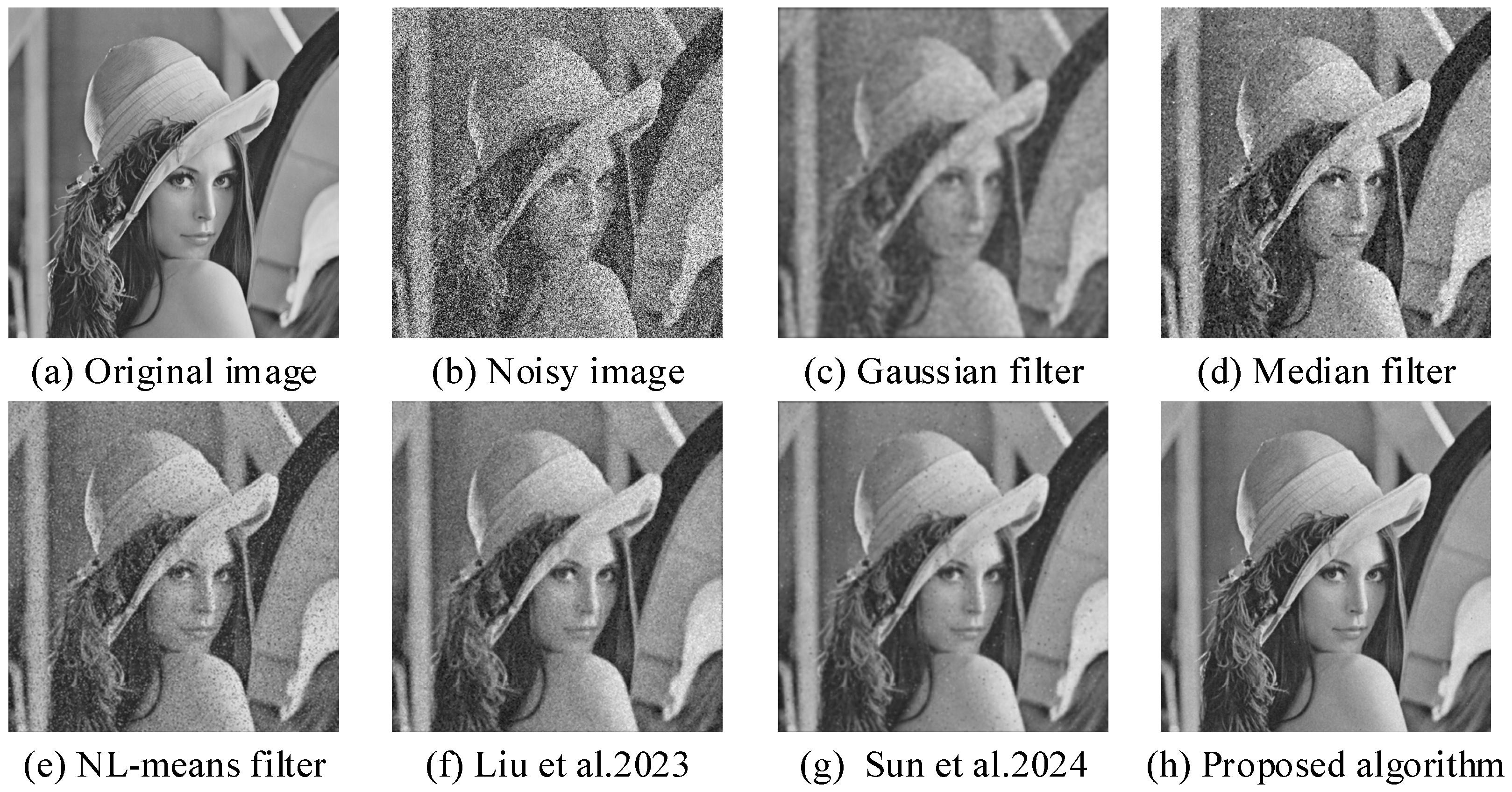

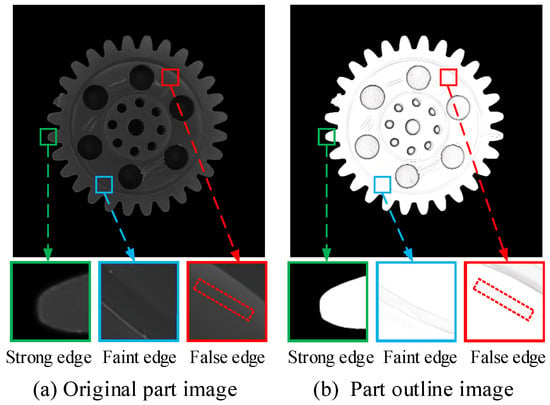

2.1.3. Testing of Proposed Filter Effectiveness

To verify the effectiveness of the proposed selective mixed filtering method, the Lena image was selected as the experimental subject, and salt-and-pepper noise and Gaussian mixed noise with levels of ρ = 0.2 and σ = 0.3 were added, with n = 5 and C = 1. Gaussian filtering, median filtering, non-local means filtering (NL-means filter) [42], and filtering algorithms from references [12,14] were selected as comparison methods to evaluate the noise removal performance and the ability to preserve image details. As shown in Figure 3c,d, Gaussian filtering removed a large amount of detail from the image, and compared to the original image in Figure 3a, it is completely distorted. Although median filtering is effective at removing salt-and-pepper noise, it performs poorly at removing Gaussian noise, leaving behind significant residual noise. Figure 3e presents the image processed using the NL-means filter, which demonstrates enhanced noise reduction and improved detail preservation compared to the previous two methods. However, some residual mixed noise persists, leading to a suboptimal subjective result. Figure 3f displays the adaptive filtering algorithm from reference [12], which shows significant improvement in detail preservation compared to traditional median filtering, but there is still some residual Gaussian noise, and some edge details are lost. Figure 3g shows the improved Gaussian filtering algorithm from reference [14], which significantly enhances the filtering effect compared to previous methods, although it still results in some degree of over-smoothing. In contrast, the image produced by the proposed algorithm in Figure 3g is closer to the original image, effectively removing noise while minimizing damage to the original information and preserving more image details. In summary, through the filtering experiments, it is demonstrated that the proposed selective smoothing filtering method can effectively remove mixed noise from images while retaining detail features well and maintaining high fidelity of the original information, providing a good preprocessing condition for better implementation of the proposed edge detection method.

Figure 3.

Comparison of the images processed by different algorithms and the original image [12,14].

In addition, the selection of the detection window size significantly influences the accuracy of noise detection. A small window size results in poor detection capability for edge information of image, while a large window size, conversely, enhances detection capability but risks misidentifying noise blocks as noiseless blocks [43]. Therefore, to accurately discern block categories while filtering out noise, the detection window sizes in this paper are adaptively selected based on the level of noise contamination in the image. Through a series of experiments, the selection suggestions for window size are shown in Table 2.

Table 2.

The selection suggestions of window size.

2.2. Four-Parameter Adaptive Selective Edge Detection Model

Traditional edge detection methods typically set the threshold manually [44] or employ image gradient information to determine the thresholds [45]. However, these approaches cannot comprehensively measure the distribution of image information, which often leads to broken edges in the detected results. To address this issue, this paper proposes a four-parameter adaptive selective edge detection algorithm model based on the diversities in regional information content, local features, and statistical information, which are important reflections of the disparities among different image regions. After filtering out noise from the input image, the model constructs four parameters adaptively based on the characteristics of the image information: the detection threshold T1 for high- and low-frequency regions of the image, the detection threshold T2 for edge and texture detail regions, Gaussian kernel weighted gradient variation , and the similarity of edges and texture details . Additionally, to solve the problem that traditional edge detection algorithms often extract all information features from the image before observation, thereby consuming a significant amount of time [46], this study proposes a method for selectively detecting edge information in component images according to industrial inspection requirements, utilizing the four parameters obtained through the aforementioned adaptive solution to improve the efficiency of edge detection for part images while reducing computation time and enhancing algorithm flexibility.

2.2.1. Four-Parameter Adaptive Computation

Employing a single threshold or two fixed thresholds in edge detection methods to measure changes in image information leads to a decline in detection performance and results in missed detection of faint edges such as texture details [31]. Therefore, to enhance the adaptability and detection effectiveness of the proposed edge detection method, an improvement is suggested for the calculation of information differentiation parameters used in traditional edge detection methods.

Firstly, the detection thresholds T1 for high- and low-frequency regions of the image and T2 for edge and texture detail regions are calculated. The specific solving process for T1 and T2 is as follows:

- (1)

- The detection threshold T1 for high- and low-frequency regions of the image is a parameter used to separate high-frequency information from low-frequency information, which is calculated by improving the OTSU method [47]. In this improved OTSU method, an arbitrary initial threshold is selected based on prior image information, and optimal thresholds are obtained iteratively by calculating local thresholds one by one according to the iteration rules. Additionally, to reduce the number of iterations while ensuring accuracy, the following is established:

The parameters obtained above are used to compute the inter-class variance , and, simultaneously, the local variance is derived:

Based on the above derivations, T1 is defined as the threshold that maximizes the inter-class variance of the image blocks:

- (2)

- Based on the characteristic that local statistical information of image blocks can effectively depict the similarity of image information, the threshold T2 for detecting faint edge regions such as edges and texture details is proposed. It is calculated using the local mean square error in conjunction with T1 and the local average variance . Among these, the local mean square error measures the dispersion of a pixel collection, while the local average variance describes the gray level similarity within local regions of the image, defined as follows:

Secondly, considering the significant contrasts in information distribution characteristics between high-frequency and low-frequency regions, where the frequency variation in high-frequency regions is relatively strong compared to low-frequency regions, the image’s frequency characteristics can be analyzed by calculating the gradient variations of image blocks. This method allows for an analysis of edge information and low-frequency information in part images. However, this approach has its limitations. As shown in Figure 1, false edges and faint edges are extremely similar in terms of contrast, making it easy to misidentify false edges as faint edges. Therefore, this paper proposes using a Gaussian kernel weighting function to weigh the gradient variation, ensuring that edge information is distinguished from low-frequency information while also identifying faint edges and false edges. Additionally, traditional edge detection methods often overlook faint edges, such as texture details, resulting in low detection accuracy for image detail features and limited feature extraction capabilities. To address this issue, this paper proposes using a local similarity measure to differentiate between strong and faint edges in the image, while distinguishing false edges from low-frequency information. This approach enhances the clarity of detected faint edges, such as texture details, while suppressing false edge detection by combining the Gaussian kernel weighted gradient variation.

- (3)

- The Gaussian-weighted gradient variation is calculated by applying a weighting process to the detection window n × n. Specifically, it involves computing the weighted sum of the gradient of the center pixel and its neighboring pixels, defined as follows:

- (4)

- Considering the significant diversities in similarity between edge and texture features within image blocks, the root mean square deviation of local region pixels can reflect the distribution characteristics and spatial properties of pixel gray values in the image block [48]. Additionally, this deviation corresponds to the root mean square nonlinear filtering function from the denoising stage mentioned above, which can characterize edge information using the nonlinear properties of image edge information and restore features lost due to over-smoothing during the denoising phase. On the other hand, the mean deviation of local area pixels reflects the variation in gray values of pixels within the image block and also indicates the trend of change in regional image information. Therefore, by combining these two different scale values, we can comprehensively assess the similarity of information in the image region. The local region pixel root mean square deviation r(i,j) and the local region pixel mean deviation u(i,j) are defined as follows:

2.2.2. Image Edge Information Analysis and Detection

After removing noise through selective mixed filtering, adaptive double thresholds T1 and T2 are set to analyze image information, allowing for the selective detection of edge information by comparing two parameters, and . This process results in four possible outcomes: strong edges, low-frequency information, faint edges, and false edges. The detection principle is based on the fact that both strong edges and faint edges belong to high-frequency information, exhibiting similar variations in gradient differences. However, the similarity of pixel values between strong edges is lower than that of faint edges. Low-frequency information shows slow changes in gradient differences and has significant diversities from both strong and faint edge information. Although false edges have gradient variations similar to low-frequency information, their distinct contrasts from surrounding information results in low similarity, making them easily distinguishable from low-frequency information and faint edges. Therefore, by integrating these different characteristics, selective extraction of image information can be achieved during edge detection in parts, while suppressing false edge detection to enhance edge detection effectiveness and computational efficiency. The selective detection process can be represented as the piecewise function X(i,j) shown below:

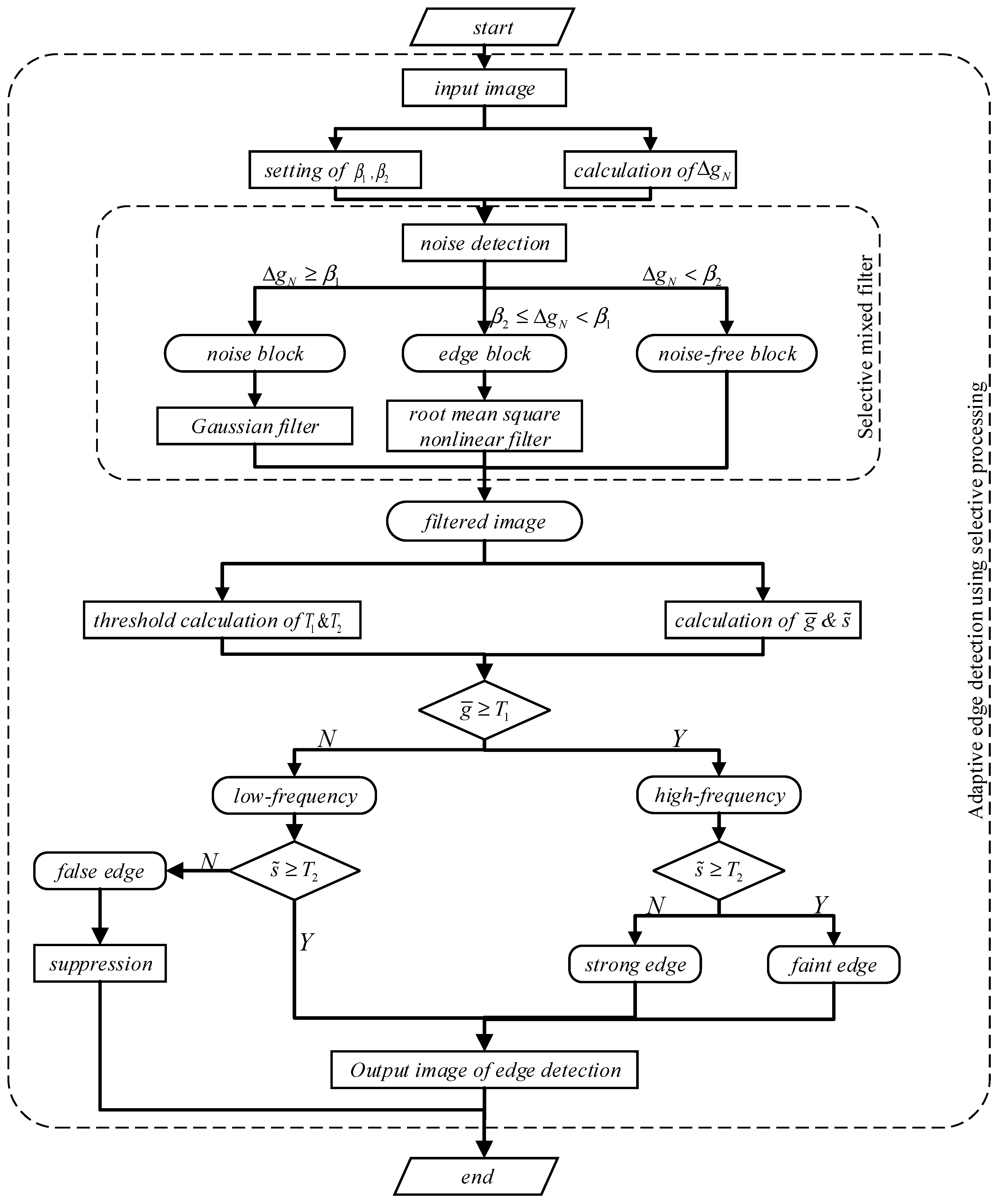

In the end, the specific operational flow of the proposed selective processing adaptive edge detection algorithm for part images is illustrated in Figure 4.

Figure 4.

The operational flow of the proposed selective processing adaptive edge detection algorithm for part images.

3. Experimental Results and Analysis

To verify the effectiveness and comprehensiveness of the method proposed in this paper, edge detection experiments on natural images were carried out at first. Four natural images were selected as experimental subjects: Lena, building, baboon, and paper. The proposed method is compared with the Canny algorithm and the algorithms presented in references [11,12,14] under different mixed noise concentration conditions to subjectively and objectively evaluate the edge detection results. All algorithms in the experiment were implemented in MATLAB 2019a, running on a computer with the Windows 11 operating system, configured with an Intel Corporation i7-1170 processor and 16.00 GB of RAM. In the experiment, the size of window n = 5, C = 1, and σ = 1. The parameter settings for comparative algorithms followed the recommended values from the original literature. Furthermore, the ground-truth data used in the experiment were generated through manual annotation, based on the main detailed features of the original images. Peak Signal-to-Noise Ratio (PSNR) [49], Structure Similarity Index Measure (SSIM) [49], Figure of Merit (FOM) [19], and F-Measure [20] were chosen as objective evaluation metrics for the image edge detection results, providing a comprehensive assessment of the strengths and faintness of the edge detection algorithms. The definitions and calculation formulas of the above four evaluation metrics are as follows.

- (1)

- PSNR: The PSNR is a widely used metric for evaluating image quality in compression and reconstruction. It compares the original image to the processed one, measuring the ratio of signal strength to noise. A higher PSNR value indicates better quality, reflecting a smaller difference between the two images. The formula is as follows:

- (2)

- SSIM: The SSIM assesses image quality by modeling the human visual system’s perception of structure. Unlike PSNR, SSIM evaluates not only pixel errors but also luminance, contrast, and structural similarity, providing a more comprehensive measure of perceived quality. The calculation formula is as follows:

- (3)

- FOM: The FOM is commonly used in edge detection to assess how well the detected edges match the true edges. It measures the accuracy based on the number of correctly detected edges and their alignment with the ground truth. It is defined as follows:

- (4)

- F-Measure: F-Measure is a widely used metric in edge detection. It is the harmonic mean of Precision and Recall, providing a balanced evaluation of edge detection performance. It is particularly useful for assessing the overall effectiveness of the detection, balancing the trade-off between precision and recall. The calculation formula is as follows:

3.1. Edge Detection Experiments for Natural Images

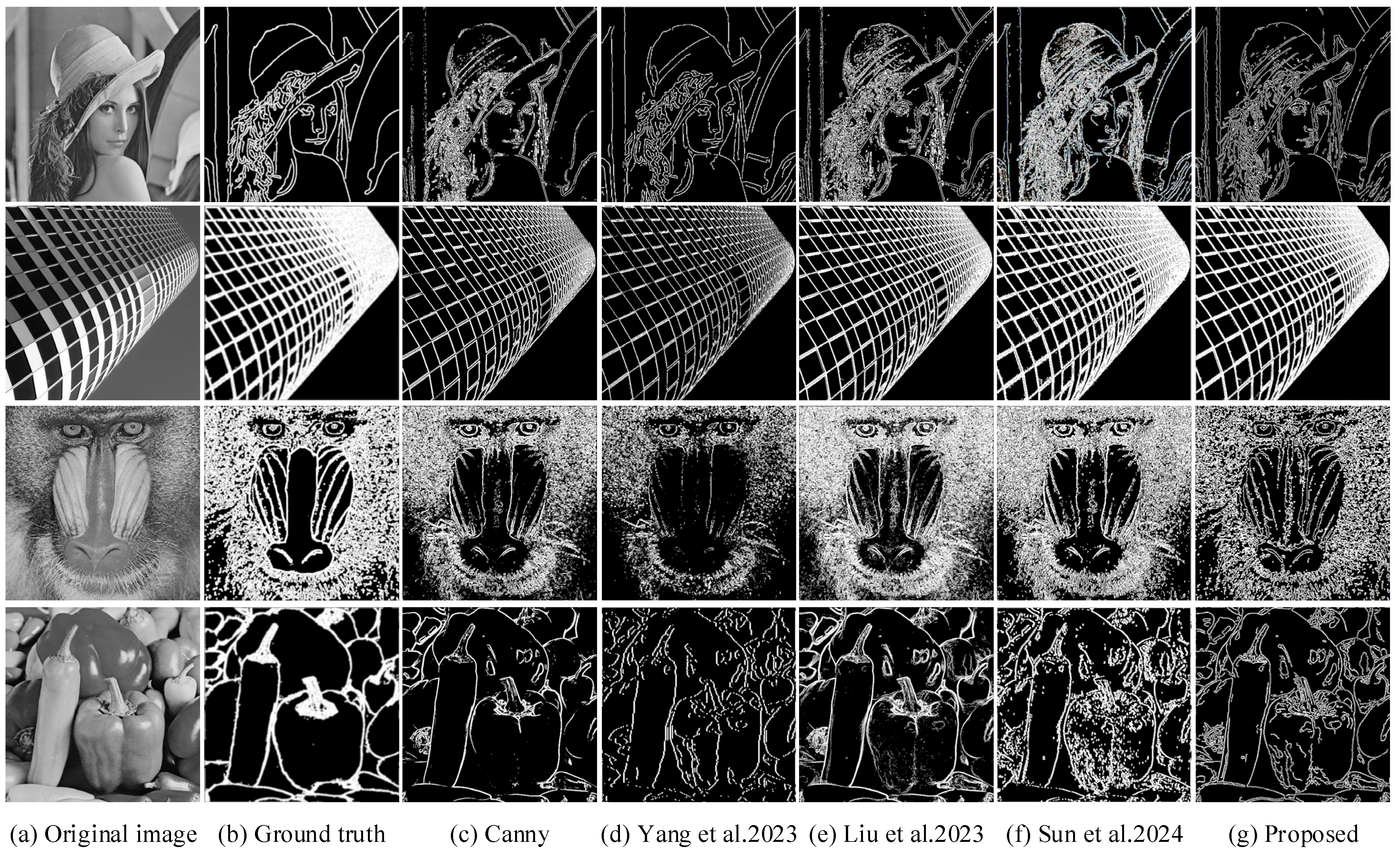

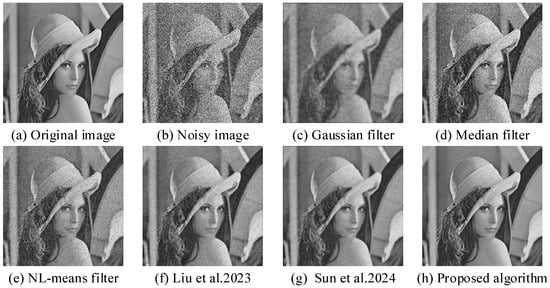

Table 3 presents a comparison of objective experimental data for different edge detection algorithms under noise-free conditions, while Figure 5 shows the corresponding subjective edge detection results. As indicated in Table 3, the proposed method achieves the best performance based on the objective experimental metric FOM, followed by the method from reference [11]. In terms of F-Measure, the proposed method outperforms all other algorithms except for the Peppers image, where it is slightly lower than the algorithm in reference [14]. In Figure 5, it can be observed that under noise-free conditions, the Canny algorithm yields generally poor subjective edge detection results, with incomplete and severely broken edges. Although the edges detected by the algorithm from reference [11] are clear in hierarchy, they fail to effectively extract detailed feature information from the image. The edges detected by the algorithm in reference [12] are robust and possess a strong three-dimensional feel; however, their clarity is lower compared to the algorithm from reference [11]. The edges detected by the algorithm in reference [14] are prominent but appear chaotic compared to the earlier algorithms, lacking independent separation of edges. Furthermore, in detecting faint edges in texture details, all algorithms except for the one in reference [11] failed to perform effectively. The method proposed in this paper demonstrates high fidelity in edge detection under noise-free experimental conditions, producing clear and distinctive edges. As illustrated by the edge detection results for the baboon image, the proposed method effectively detects faint edges such as texture details, significantly improving the ability to extract detailed features compared to other algorithms.

Table 3.

Comparison of the FOM and F-Measure obtained from different edge detection methods under noise-free conditions.

Figure 5.

Comparison of the detection results of different edge detection methods under noise-free conditions [11,12,14].

Table 4 presents a comparison of the objective experimental data of PSNR, SSIM, FOM, and F-Measure obtained from different algorithms under mixed Gaussian and salt-and-pepper noise conditions σ = 0.3 and ρ = 0.2. Compared to the FOM and F-Measure data obtained under noise-free conditions, all edge detection algorithms exhibit varying degrees of decline, which are listed in Table 5. Notably, the Canny algorithm shows the largest decrease, with reductions of 23.73% and 36.39% for FOM and F-Measure, respectively, while the proposed method has the least decline, with reductions of only 0.64% and 9.76%. In terms of PSNR, except for the Baboon image, which achieved a slightly lower PSNR than the method proposed in reference [14], the proposed method outperforms others in all other image comparisons. Regarding SSIM, the proposed method also demonstrates optimal performance.

Table 4.

Comparison of the PSNR, SSIM, FOM, and F-Measure obtained from different edge detection methods under mixed noise conditions σ = 0.3 and ρ = 0.2.

Table 5.

The decline in average FOM and F-Measure for different edge detection methods under mixed noise compared to noise-free conditions.

Additionally, as shown in Figure 6, a subjective comparison of the detection results for each algorithm under mixed noise conditions σ = 0.3 and ρ = 0.2 indicates that the Canny algorithm cannot effectively detect image edges, leading to significant degradation of detailed information. The algorithm from reference [11] detects a markedly reduced number of edges compared to noise-free conditions, and these edges are not pronounced. Algorithms from references [12,14] exhibit varying degrees of noise residue issues, with an increase in false edges and noticeably thickened image edges, resulting in ineffective detection of faint edges such as texture details. In contrast, the edges detected by the proposed method are prominent, with clear and reasonable representations of faint edges like texture details, and no false edges are identified. This validates that the proposed method can resist noise interference, removing noise while preserving detailed information, thus establishing a solid foundation for subsequent edge detection. Furthermore, the proposed adaptive edge detection algorithm effectively detects strong edges while extracting features of faint edges such as texture details and suppressing false edge detections, yielding satisfactory edge detection results.

Figure 6.

Comparison of the detection results of different edge detection methods under mixed noise conditions σ = 0.3 and ρ = 0.2 [11,12,14].

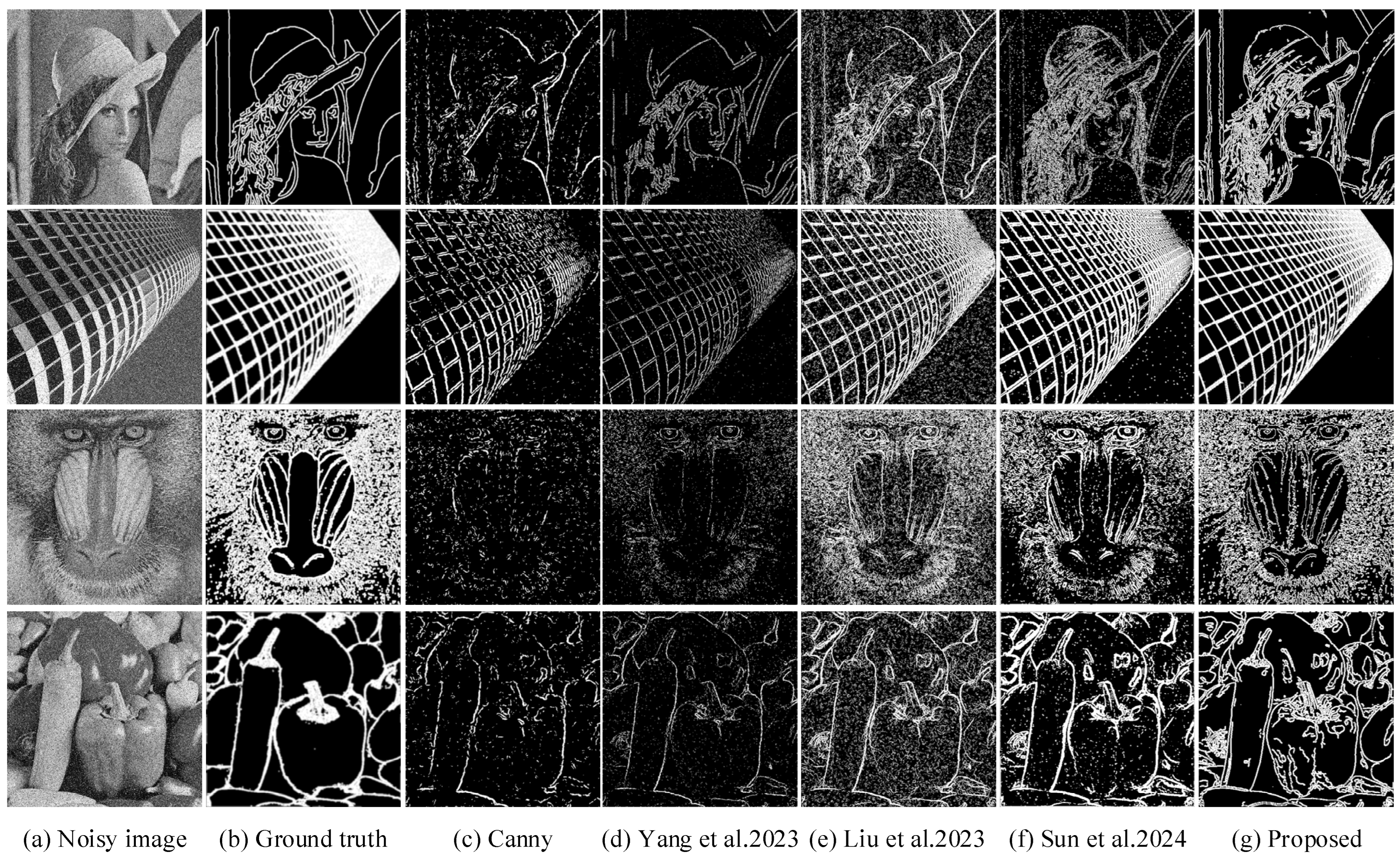

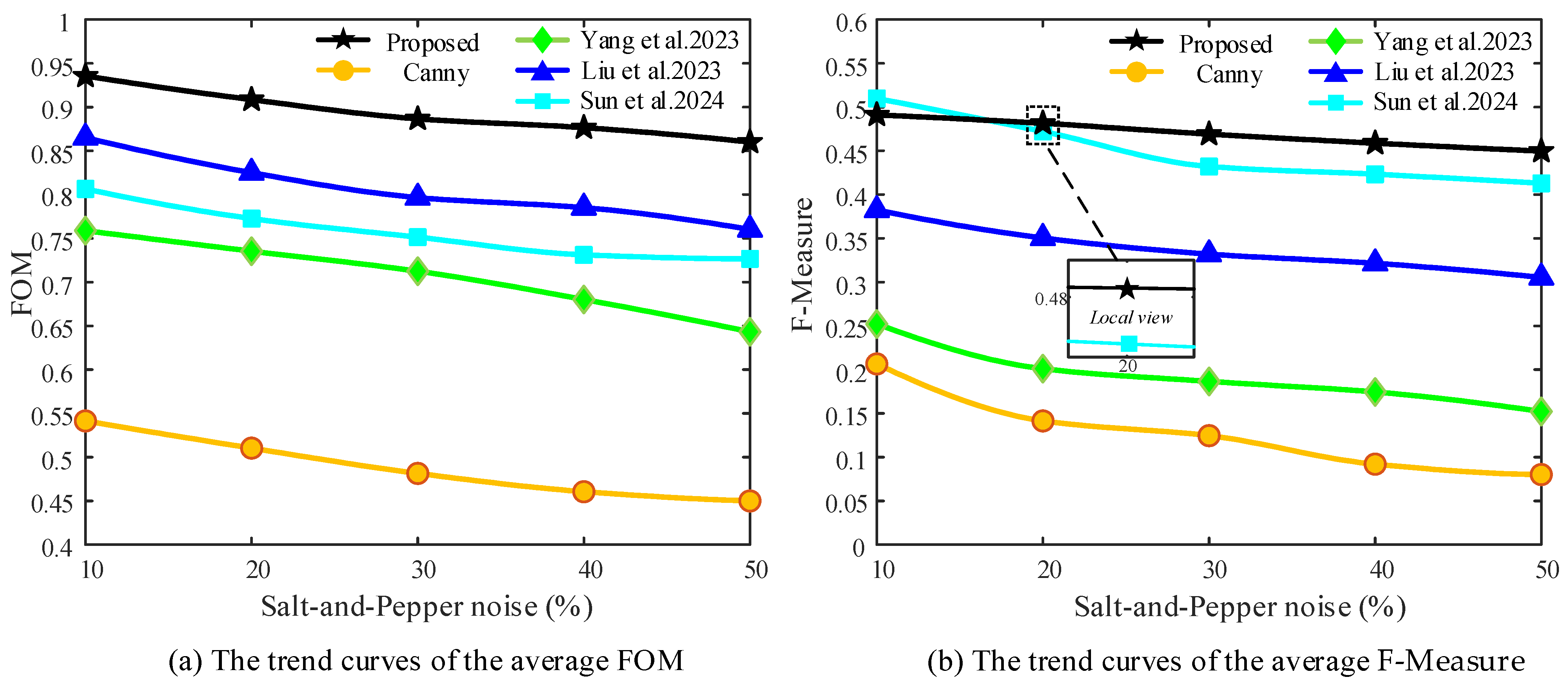

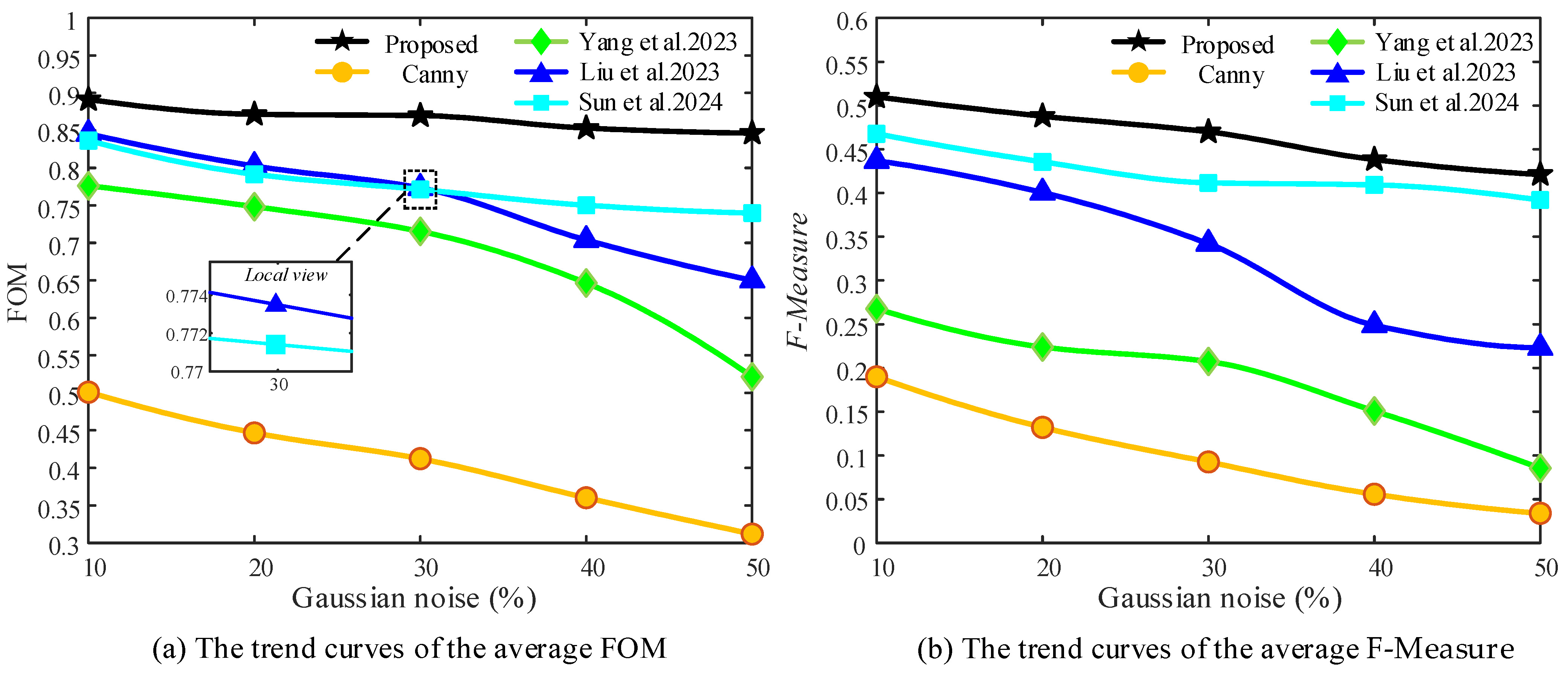

To further validate the stability of the proposed edge detection method, the BSDS500 natural image dataset [50] was selected as the experimental subject. This dataset contains 500 images of various natural scenes, which were subjected to two sets of mixed Gaussian-salt-and-pepper noise conditions σ = 0.3/ρ = 0.1~0.5 and σ = 0.1~0.5/ρ = 0.3, respectively. Figure 7 and Figure 8 illustrate the trend curves of the average FOM and F-Measure obtained from different edge detection algorithms applied to the BSDS500 dataset. It is evident that with the increase in mixed noise intensity, the average FOM and F-Measure values processed by each edge detection method show varying degrees of decline. In Figure 7, as the level of salt-and-pepper noise gradually increases, the numerical curve of the proposed method remains at the top and exhibits the slowest declining trend, while the numerical curve of the Canny algorithm is at the bottom and shows the steepest decline. In Figure 8, except for the proposed method and the algorithm from reference [14], other algorithms experience a greater degree of decline compared to Figure 7, particularly the average F-Measure curve of the algorithm from reference [12], which exhibits a cliff-like drop after condition σ = 0.3. The proposed edge detection method takes into account the presence of noise in both nonlinear and linear mixed forms in images. By employing selective mixed filtering to remove noise, it ensures that noise is filtered out while preserving image detail information. Therefore, the aforementioned experiments demonstrate that the proposed edge detection method can resist the interference of mixed noise, resulting in stable detection performance without significant fluctuations, and compared to other classical edge detection algorithms, the edge detection results are more stable.

Figure 7.

The trend curves of the average FOM and F-Measure for different edge detection methods applied to the BSDS500 dataset under the mixed noise environment with σ = 0.3 and ρ = 0.1~0.5 [11,12,14].

Figure 8.

The trend curves of the average FOM and F-Measure for different edge detection methods applied to the BSDS500 dataset under the mixed noise environment with σ = 0.1~0.5 and ρ = 0.3 [11,12,14].

3.2. Integrity Edge Detection Experiments for Part Images

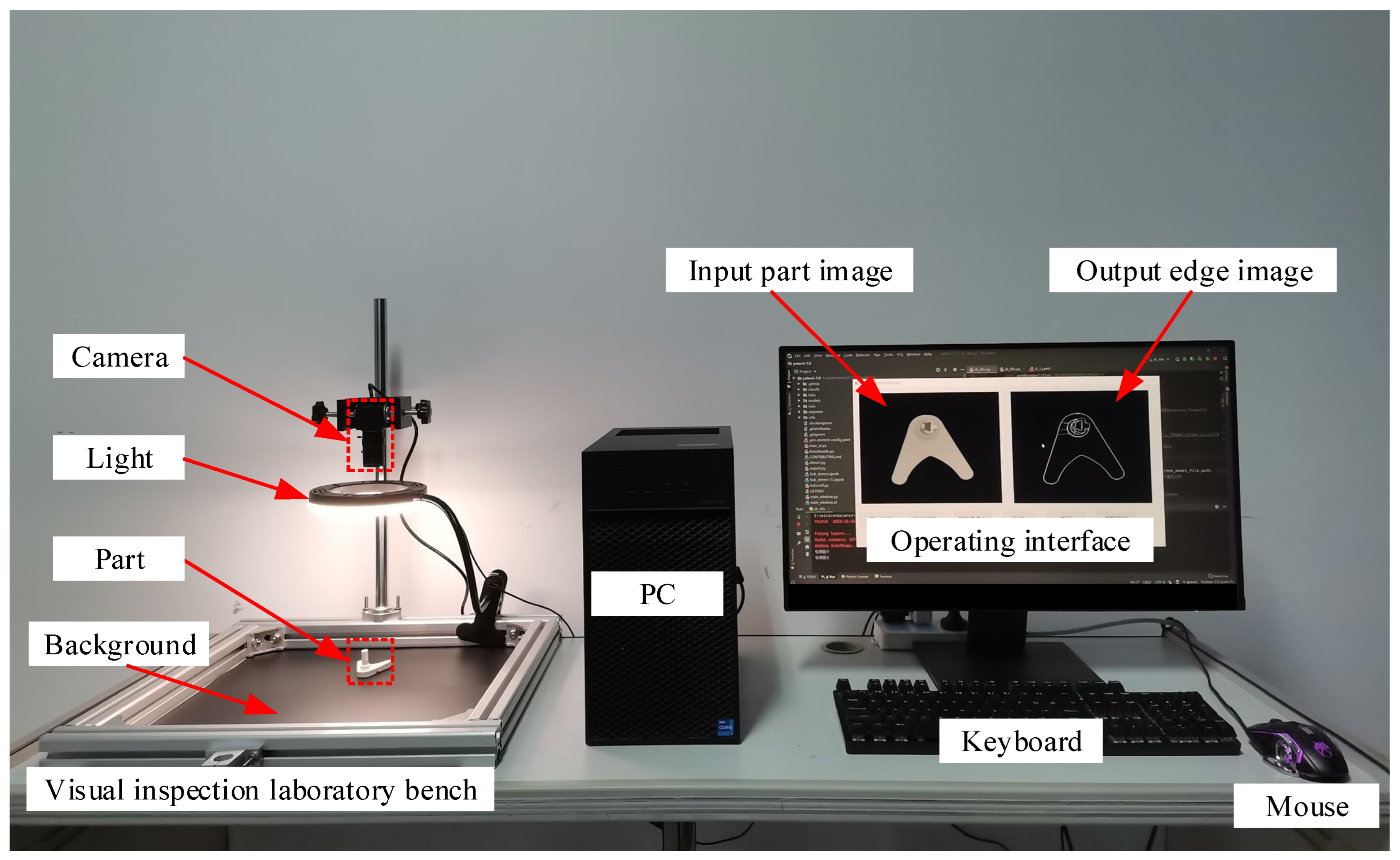

The edge detection experiment for part images was conducted on the part surface quality inspection experimental platform, as shown in Figure 9. The platform primarily consists of a charge coupled device camera, light source, and computer system. The computer system runs Windows 11, equipped with an Intel Core i7 processor and 16 GB of RAM, and the experiment was performed using the Python 3.9 software platform. During the experiment, the Python platform was used to acquire and display images. The interface shows the original or noise-added part image on the left and the processed edge detection image on the right. This interface facilitates subjective visual comparison between the input and output images during the experiment, allowing for an accurate evaluation of the proposed method’s performance.

Figure 9.

Part surface quality inspection experimental platform.

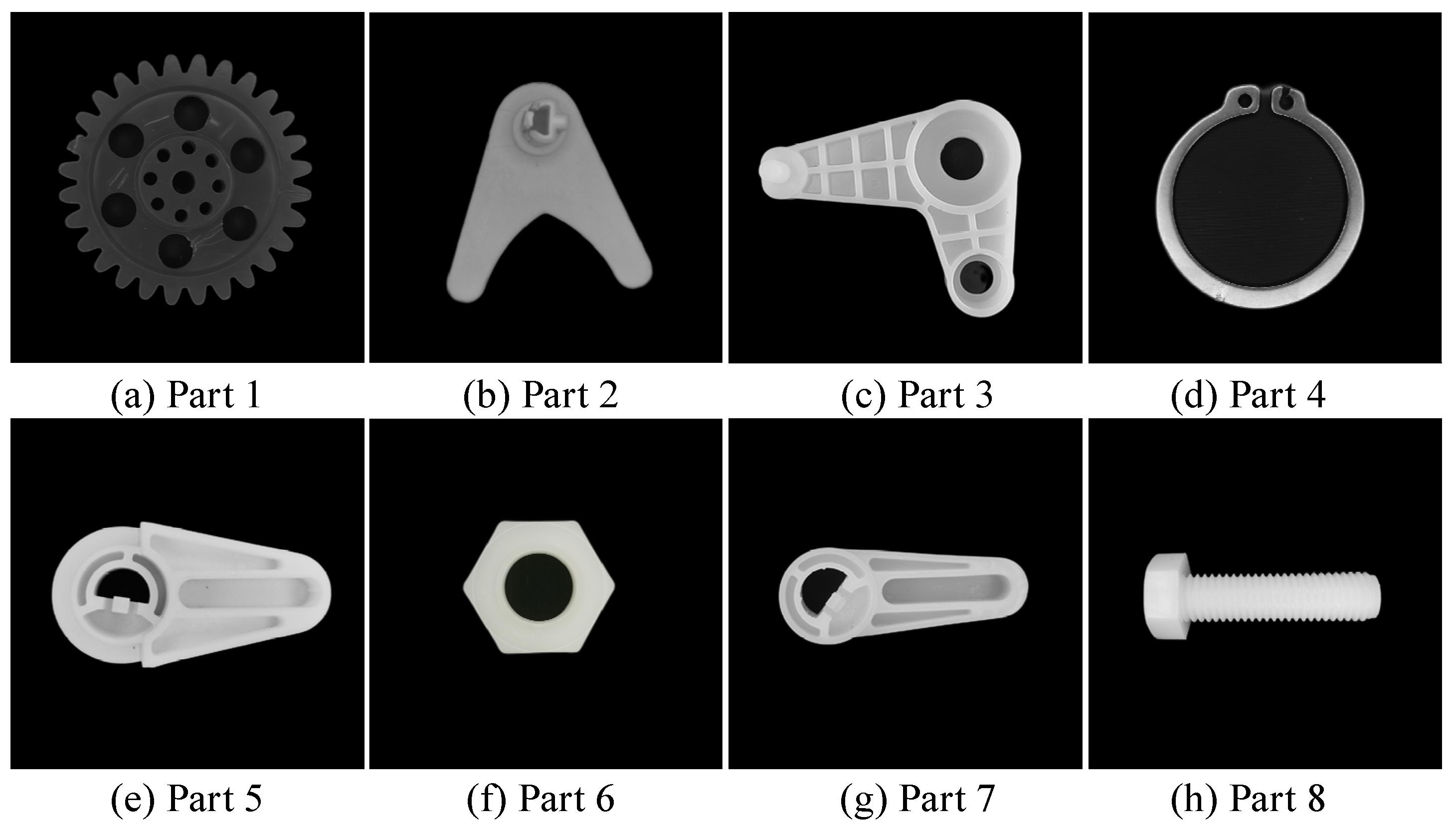

Figure 10 displays eight original images of parts collected by the camera of the experimental platform, which served as the subjects for this experiment. The selected parts varied in material, shape, and size to ensure a more comprehensive evaluation while validating the effectiveness of the proposed method. Edge detection was performed under experimental conditions without noise and with added mixed Gaussian and salt-and-pepper noise σ,ρ = 0.1~0.5, and both subjective and objective data from the final edge detection results were obtained. PSNR, SSIM, FOM, and F-Measure were chosen as objective evaluation metrics for edge detection. Finally, the analysis focuses on the proposed method’s ability to resist interference from different intensities of noise during edge detection of part images, its capability to extract image information features, and its effectiveness in suppressing false edge detection results.

Figure 10.

Part images collected by the camera.

Table 6 presents the objective data of PSNR, SSIM, FOM, and F-Measure obtained for each part image under different noise conditions. It can be observed that as the noise intensity increases, the values of all evaluation metrics gradually decline. The diversity in FOM and F-Measure between the mixed noise experimental conditions and the no-noise conditions for each part image ranges from 0.01 to 0.08 dB and from 0.01 to 0.03 dB, respectively. The reductions in PSNR and SSIM for each part image under the mixed noise conditions from σ,ρ = 0.1 to σ,ρ = 0.5 were observed to be from 1 to 2.8 dB and 0.01 to 0.02 dB, respectively. Additionally, the PSNR, SSIM, FOM, and F-Measure obtained for each part image under different noise conditions show minor discrepancies from the final calculated average values, with the SSIM for all denoised part images remaining around 0.9. Therefore, the above objective data results demonstrate that the method proposed in this paper provides stable edge detection effects for part images and also verifies that the selective mixed filtering algorithm achieves good denoising results with a certain degree of stability.

Table 6.

PSNR, SSIM, FOM, and F-Measure obtained from each part image under different noise conditions.

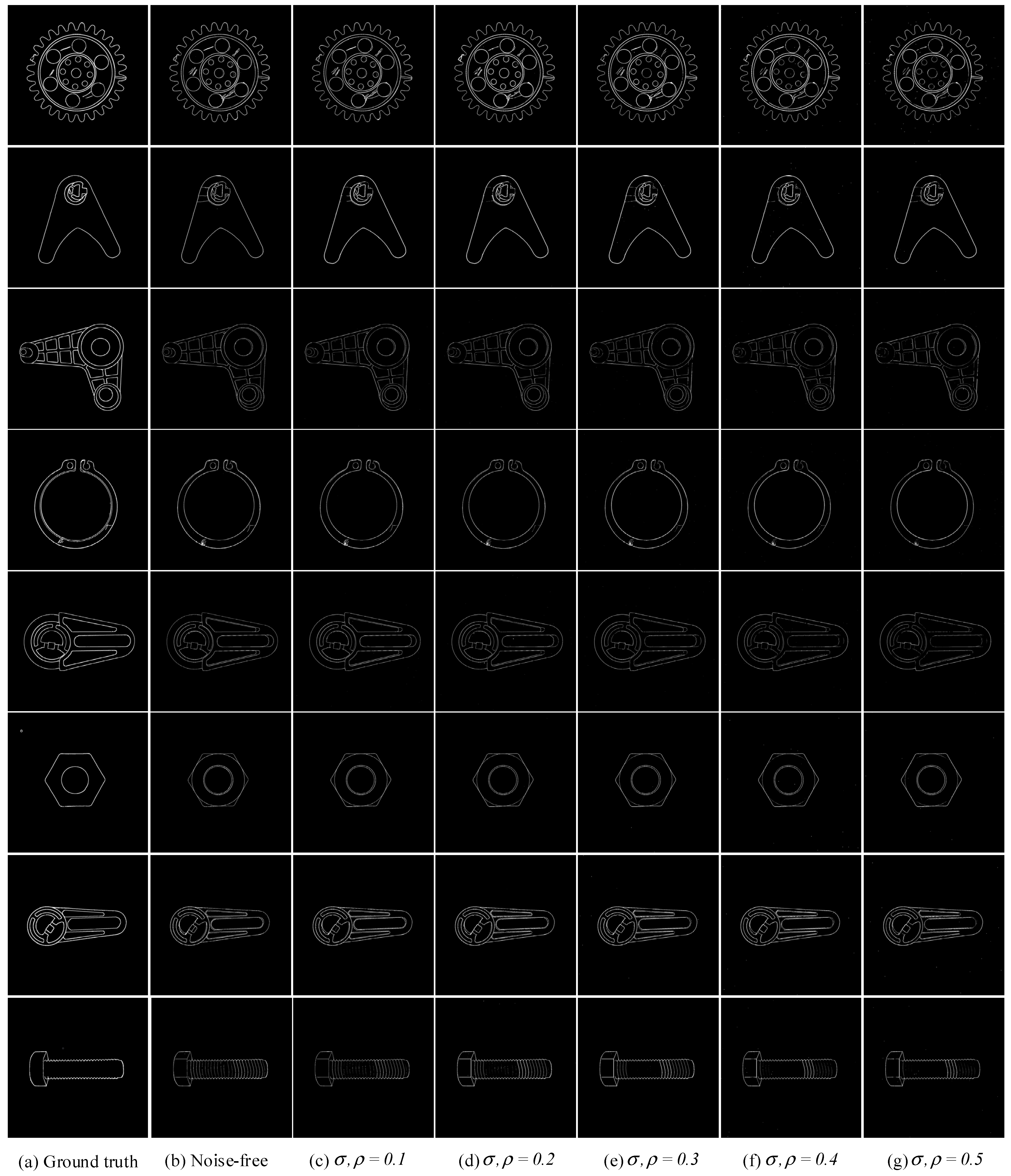

Figure 11 shows the subjective results of edge detection for each part image under noise-free and mixed noise conditions. The first column on the left presents the edge detection results for each part image under noise-free conditions, while the second to sixth columns from left to right display the edge detection results for each part image under mixed noise conditions ranging from σ,ρ = 0.1 to σ,ρ = 0.5. It is evident that the edge detection of part 1 shows a clear gear outline under noise-free conditions, with surface scratches and other faint edges appearing clearly and reasonably. As the noise intensity increases, some faint edges of holes show slight breaks, and in a high-intensity mixed noise environment where σ,ρ = 0.5, a small amount of noise residue is observed. For part 2, aside from minor breaks in the faint edges to the right of the raised portion, the strong and faint edges on the surface are detected completely without breaks. However, similar to part 1, noise residue is detected under high-intensity noise conditions. The edge detection of part 3 under noise-free conditions reveals relatively complete and clear strong edges of the part’s cavity, but due to part 3 being made of white nylon plastic, which has reflective physical properties, some contours become blurred under lighting. After filtering, these contours become even more subtle, leading to broken edges in the detection results, and the breaks become more severe as the noise intensity increases. The edge detection results for part 4 show clear object outlines, allowing clear observation of faint edges such as scratches on the surface of the ring. For part 5, the edge detection results under both noise-free and mixed noise conditions σ,ρ = 0.1~0.3 indicate no significant breaks in the edges. However, the faint edge contours of part 5 exhibit obvious breaks under mixed noise conditions where σ,ρ = 0.4 and σ,ρ = 0.5, with some faint edges even completely disappearing. The edge detection results for parts 6 and 7 show only slight breaks in faint edges such as surface textures under high-intensity mixed noise conditions where σ,ρ = 0.4 and σ,ρ = 0.5, while other detected edges remain complete and clear. The edge detection results for part 8 not only allow for a clear observation of the bolt’s surface thread outline but also make faint edges like the threads clearly visible. However, as the noise intensity increases, some faint edges of the threads exhibit large-area breaks.

Figure 11.

The subjective results of edge detection for each part image under noise-free and mixed noise conditions.

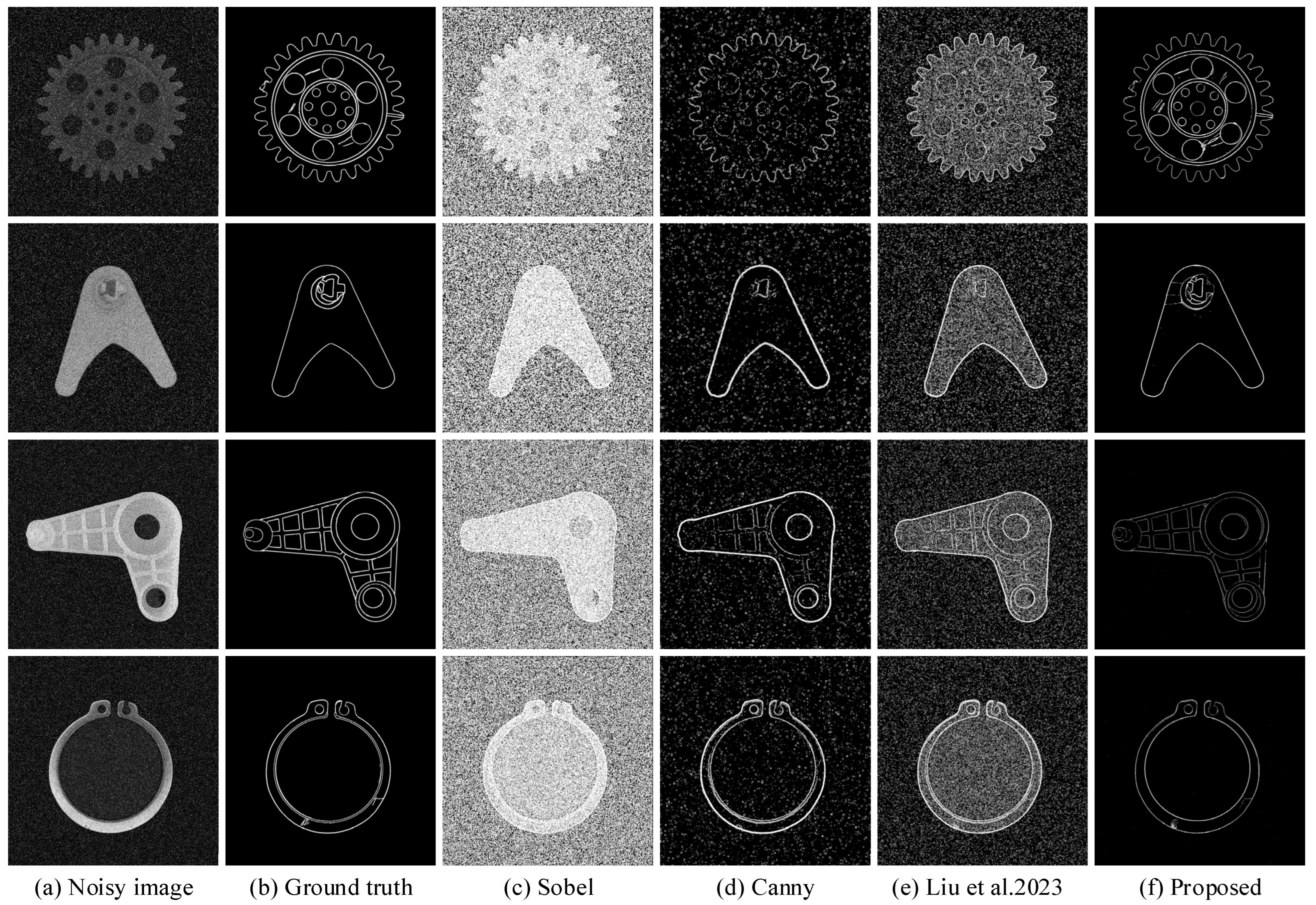

To verify the necessity of the proposed method in this paper, parts 1 to 4 were selected as experimental subjects, and subjective and objective edge detection performance were compared with common edge detection methods such as Sobel, Canny, and the proposed method from reference [12]. Table 7 and Figure 12 show the objective and subjective results of edge detection for different methods on part images, respectively. Since Sobel is sensitive to noise, it cannot resist noise interference during edge detection, resulting in the worst performance in both subjective and objective data. Canny, using Gaussian filtering, removed most of the noise, leading to a significant improvement over Sobel. However, compared to the ground-truth image, the number of effective edges detected was still lower and noise residues were significant. The proposed method from reference [12] showed a marked improvement in both subjective and objective data compared to the previous two methods, and the number of effective edges detected was significantly higher. However, noise residues were more severe than with Canny. In the subjective results for part 2, although this method had a clear advantage in objective data compared to Canny, the subjective results were not much different. This is because both methods failed to effectively detect the faint edges on the surface of part 2, leading to poor subjective edge detection performance. The method proposed in this paper achieved better objective results than the other methods, except for slightly lower FOM values on the images of parts 3 and 4 compared to the method in reference [12]. In terms of subjective edge detection, the proposed method not only effectively removed mixed noise present in the images but also detected the most effective edges on the surface of the parts compared to other methods. The strong edges were prominent, and faint edges were clear and reasonable. Therefore, compared to other edge detection methods for part images, the proposed method demonstrates certain advantages, proving the necessity of further research into it.

Table 7.

Comparison of the PSNR, SSIM, FOM, and F-Measure obtained from different edge detection methods for part under mixed noise conditions with σ,ρ = 0.3.

Figure 12.

Comparison of t the detection results of different edge detection methods for part under mixed noise conditions with σ,ρ = 0.3 [12].

In summary, the edge detection of different part images under noise-free conditions shows significant strong edges on the part surfaces and clear and reasonable faint edges, along with good objective experimental data. Furthermore, under mixed noise experimental conditions, although the subjective and objective data obtained from edge detection show a certain decline trend as noise intensity increases, the basic outlines of the parts remain intact, and there are no significant fluctuations in the objective data, which stay within a certain range. Additionally, whether under noise-free or mixed noise conditions, the edge detection results do not exhibit any obvious false edges when compared to the actual parts. On the other hand, a comparison of the proposed method with existing edge detection methods for part images showed that the experimental results, whether in terms of subjective evaluation or objective data, indicated certain advantages over the existing methods. Therefore, these experimental results validate the effectiveness and research necessity of the proposed edge detection method, which can effectively resist illumination changes and noise interference while stably detecting the edges of parts with different shapes, materials, and sizes. To some extent, this contributes positively to the improvement of the efficiency in practical industrial part surface quality inspection.

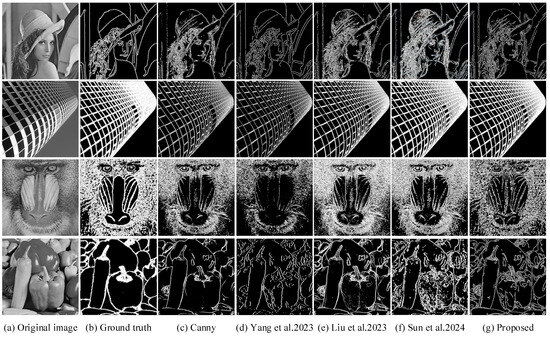

3.3. Selective Edge Detection Experiments for Part Images

To validate the selective edge detection performance of the method proposed in this paper, the first row in Figure 13 shows six images of parts captured by a camera on a visual inspection experimental platform. These images serve as the subjects for this experiment. Among them, the first three images feature metal parts, while the last three depict plastic components. The experimental design focuses specifically on detecting faint edges, such as surface scratches on metal parts, and strong edges, like the contours of plastic parts, thereby simulating selective detection scenarios commonly encountered in industrial production. Additionally, it is important to note that after the edges are detected, enhancement and sharpening techniques will be applied to facilitate the observation of the results obtained from the selective detection process.

Figure 13.

Comparison of integrity and selective edge detection results on different part images.

Table 8 is the comparison of the runtime of integrity and selective edge detection on different part images. Compared to integrity edge detection, selective detection can save 20% to 30% of computation time. As shown in Figure 13, the second row displays the results of integrity edge detection, while the third row shows the results of selective detection. It is evident that, compared to integrity edge detection results, selective detection makes surface scratches on metal parts 1, 2, and 3 more apparent in terms of location and size when no other information is present. This greatly aids in observing the required surface details of the detected parts. For plastic parts 4, 5, and 6, selective edge detection emphasizes strong edges like the object’s surface contours while reducing unnecessary detection of faint edges such as textures. This results in a clearer understanding of the positions and sizes of depressions on the object’s surface. Thus, the experimental results demonstrate that selective edge detection for part images has a significant advantage in processing efficiency compared to integrity detection. It minimizes the interference of excessive complex information, highlighting the information necessary for engineering inspections. This facilitates quicker observation of the required edge information on part surfaces, improving the efficiency of surface quality inspection and indirectly enhancing industrial production efficiency.

Table 8.

Comparison of runtime of integrity and selective edge detection on different parts images (t/ms).

4. Discussion of the Proposed Method

In experiments involving natural image edge detection, the proposed method demonstrates evident advantages over existing classical image edge detection methods, both in subjective and objective data. The Canny algorithm performs edge detection using image gradients and hysteresis thresholds, but it produces faster yet lower-quality edge detection results. Additionally, the use of Gaussian filtering to remove noise leads to a loss of original image detail features, significantly diminishing the effectiveness of edge detection. The method presented in reference [11] achieves clearer edge lines compared to other algorithms by suppressing redundant textures while removing noise. However, it is prone to missing faint edge detections and shows considerable decline in edge detection performance under high-intensity noise conditions. The method proposed in reference [12] struggles with effectively removing mixed noise, resulting in a significant amount of residual noise that adversely affects final edge detection outcomes. Although the method in reference [14] detects a small amount of residual noise during edge detection, it shows significant improvement in various objective data metrics compared to the previous two methods and achieves better results for faint edge detection. Nonetheless, it also detects false edges, making it difficult to balance the integrity of true edge detection with the suppression of false edges. In contrast, the method proposed in this paper employs selective mixed filtering to remove noise while preserving original information, leading to improved denoising results. The constructed four-parameter adaptive edge detection model considers the variations in pixel information and similarities among different image information, enhancing the accuracy of distinguishing strong edges, faint edges, and false edges. Thus, the proposed method exhibits substantial advantages in detecting edge integrity and continuity compared to the previously mentioned four classical methods. However, compared to the method presented in reference [11], while the edge extraction capability is significantly enhanced, the detection inevitably produces a considerable number of redundant textures, affecting the observation of edge detection results. Therefore, planning to adjust the similarity parameters in future work to modulate sensitivity to faint edge detections.

In the experiment on integrity edge detection of part images, a detailed observation of the objective and subjective data obtained from the proposed method in this paper reveals that the edge detection results remain relatively stable under different noise conditions, without significant fluctuations. The disparities in objective data for edge detection across various part images are maintained within a small range. Subjectively, the detection integrity and continuity of the basic contours of the part surfaces are notably good. Although the proposed method has been experimentally validated for its effectiveness, feasibility, and necessity, there are still areas for improvement. In both the part edge detection experiments under different mixed noise intensities and the comparative experiments with existing methods, the proposed method shows insufficient performance in detecting weak edges, such as the surface textures of parts made from reflective materials. Particularly in comparison with existing methods, under high-intensity mixed noise conditions, although the proposed method detects more effective edges, its completeness is still lower than the method proposed in [12]. The reason lies in the fact that, as shown in Figure 10, part 3 is made of white nylon plastic, which has a strong light-reflecting property, causing some edges to have low contrast with the background. Additionally, the filtering preprocessing did not fully account for weak edges, resulting in their blurring. With the increase in mixed noise intensity, weak edges on reflective parts showed varying degrees of fragmentation, or even disappearance. In future studies, edge detection accuracy for weak edges on reflective parts can be improved through image enhancement and optimization of selective mixed filtering. However, this approach may increase the overall computation time for edge detection. Furthermore, the experiments indicated that root mean square filtering has certain image sharpening properties. Therefore, it is recommended to further improve the root mean square nonlinear filtering algorithm to simultaneously remove mixed noise, enhance the image, and preserve weak edges.

In the selective edge detection of part images, observing the comparison of integrity and selective edge detection runtime reveals that although the computation time for selective detection improved by 20% to 30% compared to integrity detection, there is still significant room for enhancement, and it remains quite distant from achieving real-time edge detection. The reason lies in the proposed method’s execution process outlined in Figure 4, which first distinguishes between high-frequency and low-frequency information, then further differentiates strong and faint edges from the high-frequency information, and finally suppresses false edge detections. Consequently, this selectivity consumes a certain amount of computational time. Therefore, it is suggested that future work should focus on simplifying this edge detection program to save more time.

5. Conclusions

The existing edge detection methods face challenges such as poor noise filtering, low adaptability, and inadequate accuracy of edge detection. Therefore, this paper proposed a selectively processed adaptive edge detection method for part images. The proposed method first divides the image into different regions and utilizes a selective mixed filtering algorithm to remove mixed noise present in the image. Furthermore, experiments comparing the proposed filtering method with filtering algorithms from other classical edge detection methods revealed that the denoised image’s grayscale curve produced by our filtering method fits the original image’s grayscale curve the best. This demonstrates that the proposed filtering method effectively removes mixed noise while preserving detailed information and protecting the original data, providing good preprocessing conditions for image edge detection. Then, the method involves constructing a four-parameter adaptive selective edge detection algorithm model, where the four parameters are adaptively set based on the characteristics of the image information to enhance the algorithm’s adaptability. By utilizing the diversities in similarity between strong edges and faint edges, such as texture details, this approach addresses the problem of missing faint edge detection caused by lighting effects and overly smooth filtering, while also suppressing false edge detections and improving detection accuracy. Additionally, this method allows for selective detection of different edge information through the comparison of four parameters, enabling rapid acquisition of the desired edge detection results. This avoids interference from other information and facilitates quick observation of surface quality in parts. In experiments involving natural image edge detection, the proposed method shows significant advantages over existing classical edge detection methods in both subjective and objective data comparisons, with relatively stable edge detection results under various noise conditions. In edge detection experiments for part images, whether under noise-free or mixed noise conditions, the detection of strong edges such as surface contours are prominent, and faint edges like textures appear clear and reasonable, with no obvious false edges detected. Meanwhile, the results from the selective edge detection experiments indicate that this method provides higher efficiency for detecting part surface quality compared to integrity edge detection, as it better highlights the location and size of the required edge information, aiding in the quick observation of surface quality of parts. Therefore, the experimental results above verify the effectiveness, stability, and flexibility of the proposed method, which contributes to enhancing the production efficiency of industrial parts.

Currently, the research focus of this method is on single-channel grayscale part images. In future work, we plan to study edge detection methods for multi-channel images. In addition, to better apply this method to the surface quality inspection of industrial parts, we also consider integrating it with a field-programmable gate array (FPGA) to accelerate the edge detection model using an efficient computing architecture, thereby achieving real-time part edge detection based on FPGA.

Author Contributions

Writing—original draft, formal analysis, investigation, Y.L.; data curation, writing—review and editing, project administration, L.J.; formal analysis, software, funding acquisition, supervision, M.L.; software, funding acquisition, supervision, Y.M., W.Z. and D.G.; conceptualization, Y.B. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Middle-aged and Young Teachers’ (Scientific research) Basic Ability Promotion Project of Guangxi, China under Grant No. 2024KY0362; the Innovation Project of Guangxi Graduate education, China under Grant No. YCSW2024510; the National Natural Science Foundation of China under Grant No. 51765007; the Guangxi Science and Technology Major Project, China under Grant No. AA2206806; the Central Government guides local funds for Science and Technology development, China under Grant No. ZY23055014; the Guangxi University of Science and Technology Doctoral Research Foundation, China under Grant No. 22Z34.

Data Availability Statement

Data will be made available on reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest, including specific financial interests and relationships relevant to the subject of this paper.

References

- Fang, Y.; Wu, Q.; Li, S.; Guan, J.; Cui, Y. Enhanced YOLOv5s-Based Algorithm for Industrial Part Detection. Sensors 2024, 24, 1183. [Google Scholar] [CrossRef]

- Shipko, V.V.; Samoilin, E.A.; Pozhar, V.E.; Machikhin, A.S. Edge Detection in Hyperspectral Images. Optoelectron. Instrum. Data Process. 2021, 57, 618–625. [Google Scholar] [CrossRef]

- Jing, J.; Liu, S.; Wang, G.; Zhang, W.; Sun, C. Recent Advances on Image Edge Detection: A Comprehensive Review. Neurocomputing 2022, 503, 259–271. [Google Scholar] [CrossRef]

- He, Y.; Ni, L.M. A Novel Scheme Based on the Diffusion to Edge Detection. IEEE Trans. Image Process. 2020, 28, 1613–1624. [Google Scholar] [CrossRef]

- Yan, W.; Wang, Y.; Xia, M.; Tao, Q. Edge-Guided Output Adaptor: Highly Efficient Adaptation Module for Cross-Vendor Medical Image Segmentation. IEEE Signal Process. Lett. 2020, 26, 1593–1597. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Z.; Gu, K.; Li, L.; Xia, Z.; Wu, L. Blind Quality Metric of DIBR-Synthesized Images in the Discrete Wavelet Transform Domain. IEEE Trans. Image Process. 2020, 29, 1802–1814. [Google Scholar] [CrossRef]

- Fujimoto, T.R.; Kawasaki, T.; Kitamura, K. Canny-Edge-Detection/Rankine-Hugoniot-Conditions Unified Shock Sensor for Inviscid and Viscous Flows. J. Comput. Phys. 2019, 396, 264–279. [Google Scholar] [CrossRef]

- Huo, Y.; Wang, D.; Qi, Y.; Lian, P. A New Gaussian Kernel Filtering Algorithm Involving the Sparse Criterion. Circuits Syst. Signal Process. 2022, 42, 522–539. [Google Scholar] [CrossRef]

- He, L.; Wu, S.; Wu, C. Robust Laser Stripe Extraction for Three-Dimensional Reconstruction Based on a Cross-Structured Light Sensor. Appl. Opt. 2018, 56, 823. [Google Scholar] [CrossRef]

- Zheng, Z.; Zha, B.; Xuchen, Y.; Yuan, H.; Gao, Y.; Zhang, H. Adaptive Edge Detection Algorithm Based on Grey Entropy Theory and Textural Features. IEEE Access 2021, 7, 92943–92954. [Google Scholar] [CrossRef]

- Yang, W.; Chen, X.-D.; Wang, H.; Mao, X. Edge Detection Using Multi-Scale Closest Neighbor Operator and grid Partition. Vis. Comput. 2023, 40, 1947–1964. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z.; Hou, A.; Qian, X.; Wang, H. Adaptive Edge Detection of Rebar Thread Head Image Based on Improved Canny Operator. IET Image Process. 2024, 18, 1145–1160. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, Y.; Breckon, T.P.; Chen, L. Noise Robust Image Edge Detection Based upon the Automatic Anisotropic Gaussian Kernels. Pattern Recognit. 2018, 63, 193–205. [Google Scholar] [CrossRef]

- Sun, X.; Sun, X.-F. An Edge Detection Algorithm Based upon the Adaptive Multi-Directional Anisotropic Gaussian Filter and Its Applications. J. Supercomput. 2024, 80, 15183–15214. [Google Scholar] [CrossRef]

- Mafi, M.; Rajaei, H.; Cabrerizo, M.; Adjouadi, M. A Robust Edge Detection Approach in the Presence of High Impulse Noise Intensity Through Switching Adaptive Median and Fixed Weighted Mean Filtering. IEEE Trans. Image Process. 2019, 27, 5475–5490. [Google Scholar] [CrossRef]

- Caliskan, A.; Cil, Z.A.; Badem, H.; Karaboga, D. Regression-Based Neuro-Fuzzy Network Trained by ABC Algorithm for High-Density Impulse Noise Elimination. IEEE Trans. Fuzzy Syst. 2020, 28, 1084–1095. [Google Scholar] [CrossRef]

- Sun, K.; Simon, S. Bilateral Spectrum Weighted Total Variation for Noisy-Image Super-Resolution and Image Denoising. IEEE Trans. Signal Process. 2021, 69, 6329–6341. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, W.; Lu, Y.; Di, H.; Cheng, X.; Liu, S.; Gao, P.; Wang, F.; Jia, Z. A 3D Measurement Method with Accurate Boundaries Based on Mutation Feature Detection of Laser Stripes. Meas. Sci. Technol. 2020, 30, 035009. [Google Scholar] [CrossRef]

- Cui, Y.; An, Y.; Sun, W.; Hu, H.; Song, X. Multiscale Adaptive Edge Detector for Images Based on a Novel Standard Deviation Map. IEEE Trans. Instrum. Meas. 2021, 70, 1–13. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Y.; Chen, X.; Yang, C.; Gui, W. Edge and Texture Detection of Metal Image under High Temperature and Dynamic Solidification Condition. J. Cent. South Univ. 2018, 25, 1501–1512. [Google Scholar] [CrossRef]

- Yu, C.; Ji, F.; Jing, X.; Liu, M. Dynamic Granularity Matrix Space Based Adaptive Edge Detection Method for Structured Light Stripes. Math. Probl. Eng. 2020, 2019, 1959671. [Google Scholar] [CrossRef]

- Zhu, M.; He, D.; Li, X.; Li, C.; Li, F.; Liu, X.; Ding, E.; Zhang, Z. Image Inpainting by End-to-End Cascaded Refinement With Mask Awareness. IEEE Trans. Image Process. 2022, 30, 4855–4866. [Google Scholar] [CrossRef]

- Wali, S.; Shakoor, A.; Samina; Basit, A.; Xie, L.; Huang, C.; Li, C. An Efficient Method for Euler’s Elastica Based Image Deconvolution. IEEE Access 2020, 7, 61226–61239. [Google Scholar] [CrossRef]

- Foare, M.; Pustelnik, N.; Condat, L. Semi-Linearized Proximal Alternating Minimization for a Discrete Mumford-Shah Model. IEEE Trans. Image Process. 2021, 29, 2176–2189. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, Z.; Liu, H. An Adaptive and Robust Edge Detection Method Based on Edge Proportion Statistics. IEEE Trans. Image Process. 2021, 29, 5206–5215. [Google Scholar] [CrossRef]

- Li, F.; Du, X.; Zhang, L.; Liu, A. Image Feature Fusion Method Based on Edge Detection. Inf. Technol. Control 2023, 52, 5–24. [Google Scholar] [CrossRef]

- Lu, Y.; Lin, D.; Zhai, Z.; Wang, Z. Application and Improvement of Canny Edge-Detection Algorithm for Exterior Wall Hollowing Detection Using Infrared Thermal Images. Energy Build. 2022, 274, 112421. [Google Scholar] [CrossRef]

- Lee, J.; Tang, H.; Park, J. Energy Efficient Canny Edge Detector for Advanced Mobile Vision Applications. IEEE Trans. Circuits Syst. Video Technol. 2018, 28, 1037–1046. [Google Scholar] [CrossRef]

- Li, D.; Zhang, G.; Wu, Z.; Yi, L. An Edge Embedded Marker-Based Watershed Algorithm for High Spatial Resolution Remote Sensing Image Segmentation. IEEE Trans. Image Process. 2010, 19, 2781–2787. [Google Scholar]

- Ofir, N.; Galun, M.; Alpert, S.; Brandt, A.; Nadler, B.; Basri, R. On Detection of Faint Edges in Noisy Images. IEEE Trans. Pattern Anal. Mach. Intell. 2021, 42, 894–908. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Y. Single-Shot Three-Dimensional Reconstruction Based on Structured Light Line Pattern. Opt. Lasers Eng. 2020, 106, 10–16. [Google Scholar] [CrossRef]

- Ye, Y.; Yi, R.; Gao, Z.; Cai, Z.; Xu, K. Delving Into Crispness: Guided Label Refinement for Crisp Edge Detection. IEEE Trans. Image Process. 2023, 32, 4199–4211. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, D.; Lin, P.; Ji, R. A Robust Method with Adaptive Inpainting for Edge Detection of Single Silicon Crystal. IEEE Sens. J. 2023, 23, 4500–4507. [Google Scholar] [CrossRef]

- Nemer Pelliza, K.A.; Pucheta, M.A.; Flesia, A.G. Optimal Canny’s Parameters Regressions for Coastal Line Detection in Satellite-Based SAR Images. IEEE Geosci. Remote Sens. Lett. 2021, 17, 82–86. [Google Scholar] [CrossRef]

- Liu, Y.; Cheng, M.-M.; Hu, X.; Bian, J.-W.; Zhang, L.; Bai, X.; Tang, J. Richer Convolutional Features for Edge Detection. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 41, 1939–1946. [Google Scholar] [CrossRef]

- Isar, A.; Nafornita, C.; Magu, G. Hyperanalytic Wavelet-Based Robust Edge Detection. Remote Sens. 2021, 13, 2888. [Google Scholar] [CrossRef]

- Chung, I.-F.; Chen, Y.-C.; Pal, N.R. Feature Selection with Controlled Redundancy in a Fuzzy Rule Based Framework. IEEE Trans. Fuzzy Syst. 2018, 26, 734–748. [Google Scholar] [CrossRef]

- Kumawat, A.; Panda, S. A Robust Edge Detection Algorithm Based on Feature-Based Image Registration (FBIR) Using Improved Canny with Fuzzy Logic. Vis. Comput. 2022, 38, 3681–3702. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, Y. Human Body Flexibility Fitness Test Based on Image Edge Detection and Feature Point Extraction. Soft Comput. 2021, 24, 8673–8683. [Google Scholar] [CrossRef]

- Zhong, Y.; Deng, W.; Hu, J.; Zhao, D.; Li, X.; Wen, D. Sface: Sigmoid-Constrained Hypersphere Loss for Robust Face Recognition. IEEE Trans. Image Process. 2022, 30, 2587–2598. [Google Scholar] [CrossRef]

- He, K.; Sun, J.; Tang, X. Guided Image Filtering. IEEE Trans. Pattern Anal. Mach. Intell. 2013, 35, 1397–1409. [Google Scholar] [CrossRef]

- Buades, A.; Coll, B.; Morel, J.-M. A Non-Local Algorithm for Image Denoising. In Proceedings of the 2005 IEEE Computer Society Conference on Computer Vision and Pattern Recognition, San Diego, CA, USA, 20–25 June 2005; Volume 2, pp. 60–65. [Google Scholar]

- Ng, P.E.; Ma, K.K. A Switching Median Filter with Boundary Discriminative Noise Detection for Extremely Corrupted Images. IEEE Trans. Image Process. 2006, 15, 1506–1516. [Google Scholar]

- Wang, S.; Liang, S.; Peng, F. Image Edge Detection Algorithm Based on Fuzzy Set. J. Intell. Fuzzy Syst. 2020, 38, 3557–3566. [Google Scholar] [CrossRef]

- Tang, J.; Wang, Y.; Huang, C.; Liu, H.; Al-Nabhan, N. Image Edge Detection Based on Singular Value Feature Vector and Gradient Operator. Math. Biosci. Eng. 2021, 17, 3721–3735. [Google Scholar] [CrossRef]

- He, J.; Zhang, S.; Yang, M.; Shan, Y.; Huang, T. BDCN: Bi-Directional Cascade Network for Perceptual Edge Detection. IEEE Trans. Pattern Anal. Mach. Intell. 2022, 44, 100–113. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. SMC 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Shi, Y.; Huo, Z.; Qin, J.; Li, Y. Automatic Prior Shape Selection for Image Edge Detection with Modified Mumford-Shah Model. Comput. Math. Appl. 2020, 79, 1644–1660. [Google Scholar] [CrossRef]

- Zhou, F.; Yao, R.; Liu, B.; Qiu, G. Visual Quality Assessment for Super-Resolved Images: Database and Method. IEEE Trans. Image Process. 2020, 28, 3528–3541. [Google Scholar] [CrossRef]

- Arbeláez, P.; Maire, M.; Fowlkes, C.; Malik, J. Contour Detection and Hierarchical Image Segmentation. IEEE Trans. Pattern Anal. Mach. Intell. 2011, 33, 898–916. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).