Paddy Drying Technologies: A Review of Existing Literature on Energy Consumption

Abstract

1. Introduction

- Convective dryers are the most widely used method for paddy drying due to their efficiency, simplicity, and relatively low cost. They utilize a combination of hot air and mechanical agitation to remove moisture from the paddy.

- Vacuum and freeze dryers reduce the air pressure or temperature, respectively, and are used in some specialized applications [20].

- Solar-assisted dryers, ranging from simple solar dryers to advanced hybrid systems, utilize solar energy to reduce operational costs and environmental impact. These methods not only expedite the drying process but also align with sustainable agricultural practices by leveraging renewable energy sources and optimizing energy consumption [21,22,23,24].

2. Materials and Methods

2.1. Data Availability

2.2. Drying Data Unifying

2.3. Drying Temperature

2.4. Comparison of Relative Humidity of Regional Environment

2.5. Energy Consumption vs. Processing Capacity

2.6. Statistical Test

- R = the sum of ranks for a group

- n = the number of observations within that group

3. Results

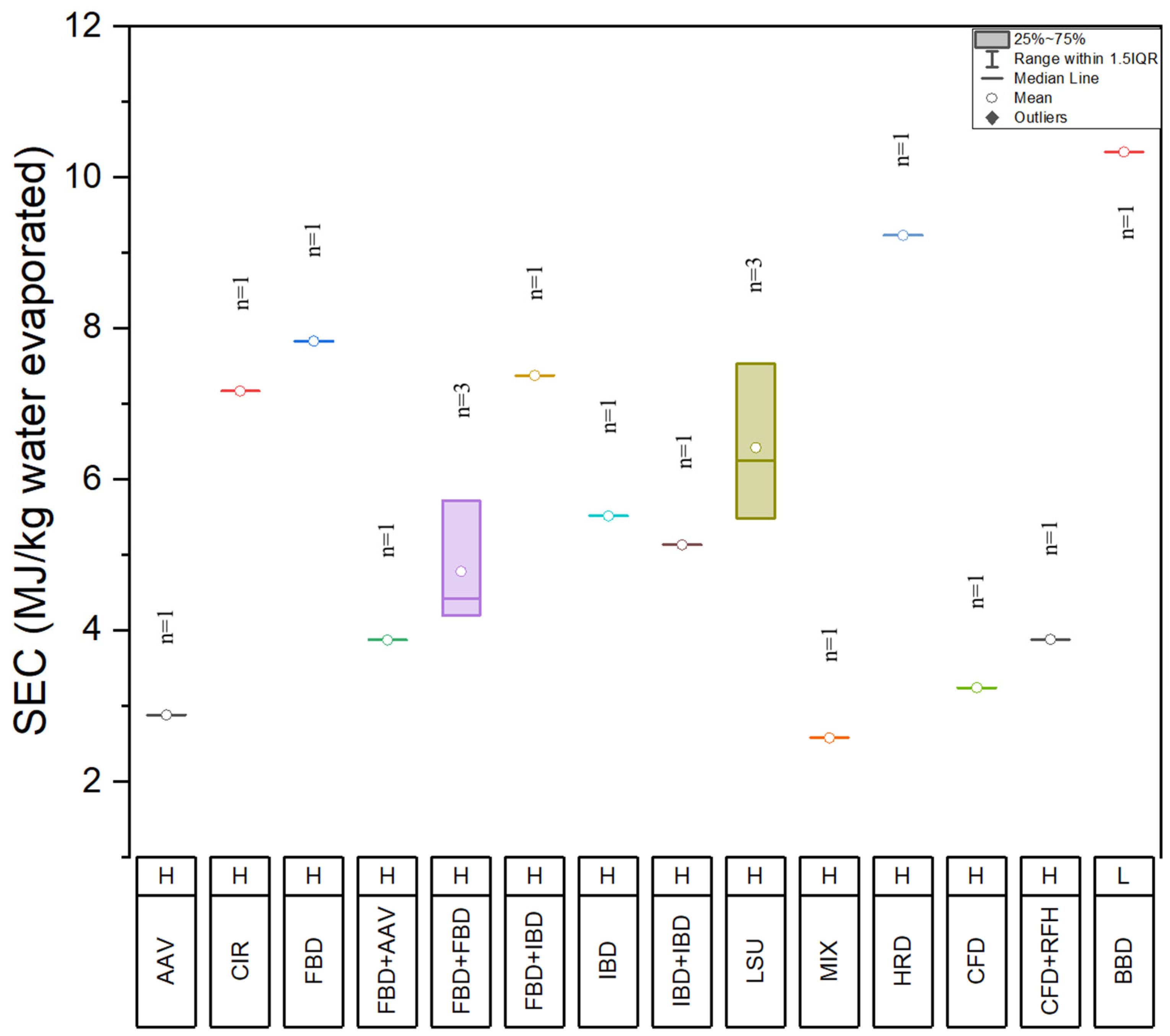

3.1. Industrialized Drying Technology

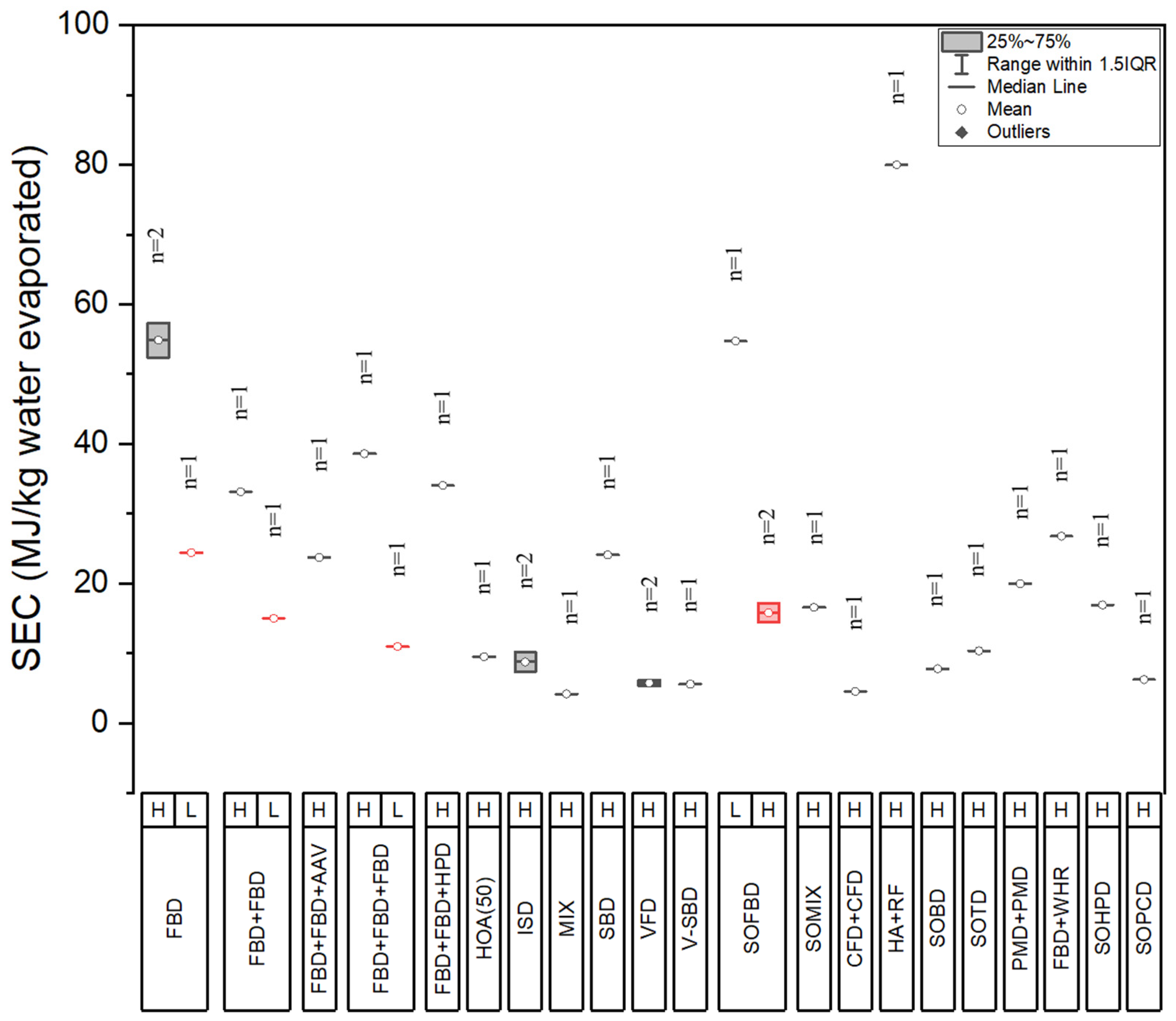

3.2. Laboratory and Simulation Drying Technology

3.3. Difference between Laboratory and Industrial Dryer

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Total Stage | Type | Country/Region | Specific Energy Consumption (MJ/kg Water) | Reference |

|---|---|---|---|---|

| AAV | Ind | Thailand | 2.88 | [58] |

| CIR | Ind | United States | 7.72 | [40] |

| FBD | Ind | Malaysia | 7.83 | [46] |

| FBD + AAV | Ind | Thailand | 3.87 | [9] |

| FBD + FBD | Ind | Thailand | 4.42 | [9] |

| FBD + FBD | Ind | Thailand | 5.72 | [48] |

| FBD + FBD | Ind | Thailand | 4.20 | [59] |

| FBD + IBD | Ind | Malaysia | 7.38 | [46] |

| HRD | Ind | Iran | 10.34 | [45] |

| IBD | Ind | Malaysia | 5.52 | [46] |

| IBD + IBD | Ind | Malaysia | 5.14 | [46] |

| LSU | Ind | Bangladesh | 6.25 | [53] |

| LSU | Ind | Malaysia | 5.48 | [60] |

| LSU | Ind | Bangladesh | 7.53 | [52] |

| MIX | Ind | United States | 2.58 | [61] |

| IBD | Ind | Malaysia | 3.18 | [62] |

| CFD | Ind | China | 3.24 | [63] |

| CFD + RFH | Ind | Thailand | 3.88 | [64] |

| FBD | Lab | Iran | 24.39 | [12] |

| FBD | Lab | Australia | 57.33 | [49] |

| FBD | Lab | Thailand | 52.36 | [47] |

| FBD + FBD | Lab | Iran | 14.97 | [12] |

| FBD + FBD | Lab | Thailand | 33.11 | [44] |

| FBD + FBD + AAV | Lab | Thailand | 23.71 | [44] |

| FBD + FBD + FBD | Lab | Iran | 10.93 | [12] |

| FBD + FBD + FBD | Lab | Thailand | 38.57 | [44] |

| FBD + FBD + HPD | Lab | Thailand | 34.04 | [44] |

| HOA(50) | Lab | Thailand | 9.49 | [44] |

| ISD | Lab | Thailand | 10.13 | [41] |

| ISD | Lab | Thailand | 7.36 | [65] |

| MIX | Lab | Bangladesh | 4.14 | [52] |

| SBD | Lab | Australia | 24.06 | [49] |

| VFD | Lab | Thailand | 5.29 | [62] |

| VFD | Lab | Thailand | 6.16 | [66] |

| V-SBD | Lab | Thailand | 5.54 | [42] |

| SOFBD | Lab | Iran | 54.72 | [21] |

| CFD + CFD | lab | China | 4.51 | [26] |

| CFD | Lab | Thailand | 3.60 | [67] |

| CFD | Lab | Thailand | 6.39 | [68] |

| HA + RF | Lab | China | 79.98 | [36] |

| SOBD | Lab | India | 7.74 | [22] |

| SOTD | Lab | India | 10.33 | [22] |

| PMD + PMD | Lab | Thailand | 19.95 | [69] |

| FBD + WHR | Lab | Indonesia | 26.75 | [23] |

| SOFBD | Lab | Indonesia | 17.14 | [70] |

| SOFBD | Lab | Indonesia | 14.40 | [71] |

| SOHPD | Lab | Indonesia | 16.88 | [72] |

| SOMIX | Lab | Indonesia | 16.54 | [73] |

| SOPCD | Lab | India | 6.18 | [24] |

| DPB | Sim | Iran | 7.48 | [74] |

| MIX | Sim | China | 3.90 | [54] |

References

- Madamba, P.S.; Yabes, R.P. Determination of the optimum intermittent drying conditions for rough rice (Oryza sativa L.). LWT—Food Sci. Technol. 2005, 38, 157–165. [Google Scholar] [CrossRef]

- Prakash, B.; Pan, Z. Modeling moisture movement in rice. In Advanced Topics in Mass Transfer, 1st ed.; EI-Amin, M., Ed.; IntechOpen: London, UK, 2011; pp. 283–304. [Google Scholar]

- Sarker, M.S.H.; Ibrahim, M.N.; Aziz, N.A.; Punan, M.S. Overall energy requisite and quality feature of industrial rice drying. Dry. Technol. 2015, 33, 1360–1368. [Google Scholar] [CrossRef]

- Dong, R.; Lu, Z.; Liu, Z.; Nishiyama, Y.; Cao, W. Moisture distribution in a rice kernel during tempering drying. J. Food Eng. 2009, 91, 126–132. [Google Scholar] [CrossRef]

- Akhtaruzzaman, M.; Mondal, M.H.T.; Sarker, M.S.H.; Biswas, M.; Shanta, S.A.; Sheikh, M.A.M. Evaluation of drying characteristics, energy consumption and quality of parboiled paddy: Two stage drying. J. Agric. Food Res. 2022, 8, 100284. [Google Scholar] [CrossRef]

- Mossman, A.P.; Miller, G.E. A review of basic concepts in rice-drying research. Crit. Rev. Food Sci. Nutr. 1986, 25, 49–71. [Google Scholar] [CrossRef] [PubMed]

- Hasatani, M.; Itaya, Y.; Miura, K. Hybrid drying of granular materials by combined radiative and convective heating. Dry. Technol. 1988, 6, 43–68. [Google Scholar] [CrossRef]

- Song, Z.; Yao, L.; Jing, C.; Zhao, X.; Wang, W.; Ma, C. Drying behavior of lignite under microwave heating. Dry. Technol. 2017, 35, 433–443. [Google Scholar] [CrossRef]

- Jittanit, W.; Srzednicki, G.; Driscoll, R. Corn, rice, and wheat seed drying by two-stage concept. Dry. Technol. 2010, 28, 807–815. [Google Scholar] [CrossRef]

- Sarker, M.S.H.; Ibrahim, M.N.; Aziz, N.A.; Salleh, P.M. Energy and rice quality aspects during drying of freshly harvested paddy with industrial inclined bed dryer. Energy Convers. Manag. 2014, 77, 389–395. [Google Scholar] [CrossRef]

- Xangsayasane, P.; Vongxayya, K.; Phongchanmisai, S.; Mitchell, J.; Fukai, S. Rice milling quality as affected by drying method and harvesting time during ripening in wet and dry seasons. Plant Prod. Sci. 2019, 22, 98–106. [Google Scholar] [CrossRef]

- Golmohammadi, M.; Assar, M.; Rajabi-Hamaneh, M.; Hashemi, S.J. Energy efficiency investigation of intermittent rice dryer: Modeling and experimental study. Food Bioprod. Process. 2015, 94, 275–283. [Google Scholar] [CrossRef]

- Poomsa-ad, N.; Soponronnarit, S.; Prachayawarakorn, S.; Terdyothin, A. Effect of tempering on subsequent drying of paddy using fluidisation technique. Dry. Technol. 2002, 20, 195–210. [Google Scholar] [CrossRef]

- Bootkote, P.; Soponronnarit, S.; Prachayawarakorn, S. Process of producing parboiled rice with different colors by fluidized bed drying technique including tempering. Food Bioprocess Technol. 2016, 9, 1574–1586. [Google Scholar] [CrossRef]

- Ben Mustapha, N.; Boumnijel, I.; Mihoubi, D. Tempering drying and energy consumption. J. Heat Transf. 2022, 144, 102103. [Google Scholar] [CrossRef]

- Golmohammadi, M.; Rajabi-Hamane, M.; Hashemi, S.J. Optimization of drying–tempering periods in a paddy rice dryer. Dry. Technol. 2012, 30, 106–113. [Google Scholar] [CrossRef]

- Abhiram, G.; Amarathunga, K.S.P. Effects of far-infrared radiation on the gelatinized rice starch granules. Dry. Technol. 2024, 42, 114–124. [Google Scholar] [CrossRef]

- Jafari, H.; Kalantari, D.; Azadbakht, M. Energy consumption and qualitative evaluation of a continuous band microwave dryer for rice paddy drying. Energy 2018, 142, 647–654. [Google Scholar] [CrossRef]

- EL-Mesery, H.S.; El-Khawaga, S.E. Drying process on biomass: Evaluation of the drying performance and energy analysis of different dryers. Case Stud. Therm. Eng. 2022, 33, 101953. [Google Scholar] [CrossRef]

- Tumpanuvatr, T.; Jittanit, W.; Surojanametakul, V. Effects of drying conditions in hybrid dryer on the GABA rice properties. J. Stored Prod. Res. 2018, 77, 177–188. [Google Scholar] [CrossRef]

- Mehran, S.; Nikian, M.; Ghazi, M.; Zareiforoush, H.; Bagheri, I. Experimental investigation and energy analysis of a solar-assisted fluidized-bed dryer including solar water heater and solar-powered infrared lamp for paddy grains drying. Sol. Energy 2019, 190, 167–184. [Google Scholar] [CrossRef]

- Jyoti, Y.K.; Dash, S.K.; Rayaguru, K.; Pal, U.S.; Mishra, N.; Ananth, P.N.; Khandai, S. Enhancement of thermal and techno-economic performance and prediction of drying kinetics of paddy dried in solar bubble dryer. Energy Nexus 2023, 11, 100224. [Google Scholar] [CrossRef]

- Yahya, M.; Rachman, A.; Hasibuan, R. Performance analysis of solar-biomass hybrid heat pump batch-type horizontal fluidized bed dryer using multi-stage heat exchanger for paddy drying. Energy 2022, 254, 124294. [Google Scholar] [CrossRef]

- Dina, S.F.; Jufrizal, S.M.; Sipahutar, E.H.; Limbong, H.P.; Misran, E. Performance of paddy dryer with screw conveyor assisted parabolic cylinder collector as thermal generator. Indian J. Sci. Technol. 2020, 13, 4446–4453. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Li, T.; Zeng, Z.; Ou, W.; Li, C. Exergetic, energetic, and quality performance evaluation of paddy drying in a novel industrial multi-field synergistic dryer. Energies 2019, 12, 4588. [Google Scholar] [CrossRef]

- Li, C.; Fang, Z.; Zhong, J.; Li, B.; Li, C. Evaluating the dynamic characteristics and energetic performance of a paddy multistage counter-flow dryer. Biosyst. Eng. 2022, 221, 208–223. [Google Scholar] [CrossRef]

- Islam, M.A.; Mondal, M.H.T.; Akhtaruzzaman, M.; Sheikh, M.A.M.; Islam, M.M.; Haque, M.A.; Sarker, M.S.H. Energy, exergy, and milling performance of parboiled paddy: An industrial LSU dryer. Dry. Technol. 2022, 40, 2058–2072. [Google Scholar] [CrossRef]

- Madhiyanon, T.; Soponronnarit, S.; Tia, W. A mathematical model for continuous drying of grains in a spouted bed dryer. Dry. Technol. 2002, 20, 587–614. [Google Scholar] [CrossRef]

- Zhonghua, W.; Mujumdar, A.S. Simulation of the hydrodynamics and drying in a spouted bed dryer. Dry. Technol. 2007, 25, 59–74. [Google Scholar] [CrossRef]

- Djaeni, M.; Aishah, N.; Kiono, B.F.T.; van Boxtel, A.J.B. A novel energy efficient adsorption drying with zeolite for food quality product: A case study in paddy and corn drying. In Proceedings of the International Symposium of Advancing Engineering, Busan, Republic of Korea, 13 November 2013. [Google Scholar]

- Soontarapa, K.; Arnusan, J. Dehydration of paddy rice in a chitosan membrane drier. Sep. Purif. Technol. 2019, 209, 401–408. [Google Scholar] [CrossRef]

- VijayaVenkataRaman, S.; Iniyan, S.; Goic, R. A review of solar drying technologies. Renew. Sustain. Energy Rev. 2012, 16, 2652–2670. [Google Scholar] [CrossRef]

- Thakur, A.K.; Gupta, A.K. Two stage drying of high moisture paddy with intervening rest period. Energy Convers. Manag. 2016, 47, 3069–3083. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, T.; Ma, J.; Song, Q.; Wei, Q.; Sun, W. Application of two-stage variable temperature drying in hot air-drying of paddy rice. Foods 2022, 11, 888. [Google Scholar] [CrossRef]

- Islam, M.; Nasrin, T.; Islam, M.; Sarker, S.H. Investigation on appropriate two-stage drying techniques for quality paddy seeds. J. Food Process Eng. 2021, 44, e13690. [Google Scholar] [CrossRef]

- Mahmood, N.; Liu, Y.; Munir, Z.; Zhang, Y.; Niazi, B.M.K. Effects of hot air assisted radio frequency drying on heating uniformity, drying characteristics and quality of paddy. LWT 2022, 158, 113131. [Google Scholar] [CrossRef]

- Chungcharoen, T.; Prachayawarakorn, S.; Tungtrakul, P.; Soponronnarit, S. Effects of germination time and drying temperature on drying characteristics and quality of germinated paddy. Food Bioprod. Process. 2015, 94, 707–716. [Google Scholar] [CrossRef]

- Beigi, M.; Torki, M.; Khoshnam, F.; Tohidi, M. Thermodynamic and environmental analyses for paddy drying in a semi-industrial dryer. J. Therm. Anal. Calorim. 2021, 146, 393–401. [Google Scholar] [CrossRef]

- Amantéa, R.P.; Fortes, M.; Ferreira, W.R.; Santos, G.T. Energy and exergy efficiencies as design criteria for grain dryers. Dry. Technol. 2018, 36, 491–507. [Google Scholar] [CrossRef]

- Amaratunga, K.S.P.; Pan, Z.; Zheng, X.; Thompson, J.F. Comparison of drying characteristics and quality of rough rice dried with infrared and heated air. In Proceedings of the 2005 ASAE Annual Meeting, Tampa, FL, USA, 17 July 2005. [Google Scholar]

- Kumklam, P.; Prachayawarakorn, S.; Devahastin, S.; Soponronnarit, S. Effects of operating parameters of impinging stream dryer on parboiled rice quality and energy consumption. Dry. Technol. 2020, 38, 634–645. [Google Scholar] [CrossRef]

- Madhiyanon, T.; Soponronnarit, S. High temperature spouted bed paddy drying with varied downcomer air flows and moisture contents: Effects on drying kinetics, critical moisture content, and milling quality. Dry. Technol. 2005, 23, 473–495. [Google Scholar] [CrossRef]

- Morey, R.V.; Cloud, H.A.; Lueschen, W.E. Practices for the efficient utilization of energy for drying corn. Trans. ASAE 1976, 19, 151–155. [Google Scholar] [CrossRef]

- Tumpanuvatr, T.; Jittanit, W.; Surojanametakul, V. Study of hybrid dryer prototype and its application in pregerminated rough rice drying. Dry. Technol. 2018, 36, 205–220. [Google Scholar] [CrossRef]

- Firouzi, S.; Alizadeh, M.R.; Haghtalab, D. Energy consumption and rice milling quality upon drying rice with a newly-designed horizontal rotary dryer. Energy 2017, 119, 629–636. [Google Scholar] [CrossRef]

- Sarker, M.S.H.; Ibrahim, M.N.; Aziz, N.A.; Punan, M.S. Drying kinetics, energy consumption, and quality of rice (MAR-219) during drying by the industrial inclined bed dryer with or without the fluidized bed dryer. Dry. Technol. 2013, 31, 286–294. [Google Scholar] [CrossRef]

- Khanali, M.; Banisharif, A.; Rafiee, S. Modeling of moisture diffusivity, activation energy and energy consumption in fluidized bed drying of rough rice. Heat Mass Transf. 2016, 52, 2541–2549. [Google Scholar] [CrossRef]

- Prachayawarakorn, S.; Poomsa-ad, N.; Soponronnarit, S. Quality maintenance and economy with high-temperature paddy-drying processes. J. Stored Prod. Res. 2005, 41, 333–351. [Google Scholar] [CrossRef]

- Jittanit, W.; Srzednicki, G.; Driscoll, R.H. Comparison between fluidized bed and spouted bed drying for seeds. Dry. Technol. 2013, 31, 52–56. [Google Scholar] [CrossRef]

- Abhiram, G.; Diraj, R.; Eeswaran, R. Optimization of Black Tea Drying Temperature in an Endless Chain Pressure (ECP) Dryer. AgriEngineering 2023, 5, 1989–1999. [Google Scholar] [CrossRef]

- Tirawanichakul, S.; Prachayawarakorn, S.; Varanyanond, W.; Tungtrakul, P.; Soponronnarit, S. Effect of fluidized bed drying temperature on various quality attributes of rice. Dry. Technol. 2004, 22, 1731–1754. [Google Scholar] [CrossRef]

- Mondal, M.H.T.; Shiplu, K.S.P.; Sen, K.P.; Roy, J.; Sarker, M.S.H. Performance evaluation of small-scale energy efficient mixed flow dryer for drying of high moisture rice. Dry. Technol. 2019, 37, 1541–1550. [Google Scholar] [CrossRef]

- Ahiduzzaman, M.; Sadrul Islam, A. Energy utilization and environmental aspects of rice processing industries in Bangladesh. Energies 2009, 2, 134–149. [Google Scholar] [CrossRef]

- Cao, C.W.; Yang, D.Y.; Liu, Q. Research on modeling and simulation of mixed flow grain dryer. Dry. Technol. 2007, 25, 681–687. [Google Scholar] [CrossRef]

- Billiris, M.A.; Siebenmorgen, T.J. Energy use and efficiency of rice-drying systems II. Commercial, cross-flow dryer measurements. Appl. Eng. Agric. 2014, 30, 217–226. [Google Scholar]

- Mann, H.B.; Whitney, D.R. On a test of whether one of two random variables is stochastically larger than the other. Ann. Math. Stat. 1947, 18, 50–60. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2024; Available online: https://www.R-project.org/ (accessed on 17 February 2021).

- Soponronnarit, S.; Chinsakoltanakorn, S. Energy consumption patterns in drying paddy by various drying strategies. In Proceedings of a Regional Seminar on Alternative Energy Applications in Agriculture; Chiang Mai University: Chiang Mai, Thailand, 1986; Volume 14. [Google Scholar]

- Sopanronnarit, S.; Rordprapat, W.; Wetchacama, S. Mobile fluidized bed paddy dryer. Dry. Technol. 1998, 16, 1501–1513. [Google Scholar] [CrossRef]

- Azmi, M.Z.; Rukunudin, I.H.; Ismail, H.A.; Aznan, A.A. Specific Energy Consumption and Drying Efficiency Analysis of Commercial Mixed-Flow Batch Type Seed Drying System. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 55, 39–50. [Google Scholar]

- Jennifer, L.B.; Johnson, A. Energy Efficiency Study on Two Wisconsin Grain Drying Systems: Mixed Flow and Continuous Cross Flow Grain Dryers. In Proceedings of the American Society of Agricultural and Biological Engineers 2010, Pittsburgh, PA, USA, 23 June 2020. [Google Scholar]

- Wetchacama, S.; Soponronnarit, S.; Jariyatontivait, W. Development of a commercial scale vibro-fluidized bed paddy dryer. Agric. Nat. Resour. 2000, 34, 423–430. [Google Scholar]

- Li, T.; Li, C.; Li, B.; Li, C.; Fang, Z.; Zeng, Z.; Ou, W.; Huang, J. Characteristic analysis of heat loss in multistage counter-flow paddy drying process. Energy Rep. 2020, 6, 2153–2166. [Google Scholar] [CrossRef]

- Chitsuthipakorn, K.; Thanapornpoonpong, S.N. Effect of large-scale paddy rice drying process using hot air combined with radio frequency heating on milling and cooking qualities of milled rice. Foods 2022, 11, 519. [Google Scholar] [CrossRef] [PubMed]

- Nimmol, C.; Devahastin, S. Evaluation of performance and energy consumption of an impinging stream dryer for paddy. Appl. Therm. Eng. 2010, 30, 2204–2212. [Google Scholar] [CrossRef]

- Soponronnarit, S.; Wetchacama, S.; Trutassanawin, S.; Jariyatontivait, W. Design, testing, and optimization of vibro-fluidized bed paddy dryer. Dry. Technol. 2001, 19, 1891–1908. [Google Scholar] [CrossRef]

- Hemhirun, S.; Bunyawanichakul, P. Effect of the initial moisture content of the paddy drying operation for the small community. J. Agric. Eng. 2020, 51, 176–183. [Google Scholar] [CrossRef]

- Hemhirun, S.; Bunyawanichakul, P. Cross-flow paddy dryer application using infrared gas burner. Int. J. Adv. Res. Eng. Technol. 2020, 11, 204–214. [Google Scholar]

- Nimmol, C.; Yodrux, A.; Hirunwat, A. Rapid drying of high-moisture paddy using a pneumatic dryer with corrugated-surface drying column. In Proceedings of the E3S Web of Conferences, Virtual, 23–24 November 2020; Volume 141, p. 01006. [Google Scholar]

- Yahya, M.; Fahmi, H.; Fudholi, A.; Sopian, K. Performance and economic analyses on solar-assisted heat pump fluidised bed dryer integrated with biomass furnace for rice drying. Solar Energy 2018, 174, 1058–1067. [Google Scholar] [CrossRef]

- Yahya, M.; Fudholi, A.; Sopian, K. Energy and exergy analyses of solar-assisted fluidized bed drying integrated with biomass furnace. Renew. Energy 2017, 105, 22–29. [Google Scholar] [CrossRef]

- Yahya, M.; Fahmi, H.; Hasibuan, R.; Fudholi, A. Development of hybrid solar-assisted heat pump dryer for drying paddy. Case Stud. Therm. Eng. 2023, 45, 102936. [Google Scholar] [CrossRef]

- Yahya, M.; Fahmi, H.; Hasibuan, R. Experimental Performance Analysis of a Pilot-Scale Biomass-Assisted Recirculating Mixed-Flow Dryer for Drying Paddy. Int. J. Food Sci. 2022, 2022, 4373292. [Google Scholar] [CrossRef]

- Zare, D.; Chen, G. Evaluation of a simulation model in predicting the drying parameters for deep-bed paddy drying. Comput. Electron. Agric. 2009, 68, 78–87. [Google Scholar] [CrossRef]

| Drying Technology | Key Characteristics |

|---|---|

| Sun Drying | Simple and low-cost method; highly dependent on weather conditions (outside of research scope) |

| Infrared Dryer | Energy-efficient; short drying time; can lead to uneven drying |

| Microwave Dryer | Rapid and uniform drying; high initial investment cost |

| Vacuum Dryer | Low-temperature drying; preserves color and flavor; requires a high initial investment cost |

| Hybrid Dryer | Combines multiple drying technologies for improved efficiency and flexibility |

| Impinging Stream Dryer | Rapid and uniform drying; suited for heat-sensitive materials |

| Fluidized Bed Dryer | Efficient heat transfer and drying; produce uniform product quality |

| Spouted Bed Dryer | High heat and mass transfer rates; low investment and operating costs |

| Louisiana State Dryer | Multi-stage dryer with tempering function for energy-efficient drying |

| Vibro-Fluidized Bed Dryer | Produces uniform product quality; flexible operating parameters |

| Vertical Spouted Bed Dryer | High drying rate and uniformity; requires low investment and operating costs |

| Deep Bed Dryer | Suited for heat-sensitive and high-moisture products; low operating costs |

| Mix-Flow Dryer | Energy-efficient drying with low-temperature drying air; produces uniform product quality |

| Ambient Air Vacuum Dryer | Uses natural airflow and operates in batches. |

| Solar-Assisted Dryer | Low operational costs; environmentally sustainable; weather-dependent efficiency. |

| Cross (Counter)-Flow Dryer | Optimized moisture removal; energy-efficient; uniform product quality. |

| Pneumatic Dryer | Rapid drying; high versatility; efficient heat distribution. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ying, T.; Spang, E.S. Paddy Drying Technologies: A Review of Existing Literature on Energy Consumption. Processes 2024, 12, 532. https://doi.org/10.3390/pr12030532

Ying T, Spang ES. Paddy Drying Technologies: A Review of Existing Literature on Energy Consumption. Processes. 2024; 12(3):532. https://doi.org/10.3390/pr12030532

Chicago/Turabian StyleYing, Tianyu, and Edward S. Spang. 2024. "Paddy Drying Technologies: A Review of Existing Literature on Energy Consumption" Processes 12, no. 3: 532. https://doi.org/10.3390/pr12030532

APA StyleYing, T., & Spang, E. S. (2024). Paddy Drying Technologies: A Review of Existing Literature on Energy Consumption. Processes, 12(3), 532. https://doi.org/10.3390/pr12030532