Abstract

This study investigates the effectiveness of microwave treatment (MW) on the antifungal properties of Norway spruce wood and the leaching of preservatives. Given the environmental and health concerns about conventional wood preservatives, this study evaluates microwave treatment as a sustainable pretreatment to limit the leaching of preservatives from wood. In the experiment, wood samples were treated with microwaves at five different energy levels before being impregnated with copper–ethanolamine- and boron-based preservatives. We assessed preservative retention by leaching tests and assessed the resistance of the wood to fungal attack. The results show that MW treatment improves the uptake and fixation of preservatives, reduces leachability, and significantly improves the durability of an otherwise perishable wood against fungal attack. This study emphasises the potential of microwave treatment for wood preservation. It offers an environmentally friendly approach to extending the life of wood products while maintaining their protective properties against decay.

1. Introduction

Wood is currently one of the most important and sought-after building materials. It is an extremely versatile natural resource that has been used for centuries in construction, furniture, and various other applications. The use of wood has increased significantly in recent decades due to its favourable environmental impact, sustainability, availability, and desirable properties [1,2]. However, wood has some inherent properties that somewhat limit its widespread use, such as lower dimensional stability, flammability, susceptibility to decay and degradation, etc. [3,4,5,6]. The wood used for construction purposes is often exposed to harsh climatic conditions, which also have a significant impact on its performance. Therefore, it is essential to monitor the performance of wood in use and to limit the susceptibility of wood to different types of biotic and abiotic degradation. To meet the needs of users, wood products must also have sufficient durability to be suitable for certain indoor and outdoor applications. To overcome these challenges associated with the processing and use of wood, various wood preservation methods have been introduced over the years in which the wood is treated with different chemical compositions to reduce its susceptibility to decay. While these biocides are highly effective, they are often associated with environmental concerns and health risks, which has led to many of them being banned [7].

Due to the widespread restriction of conventional biocides because of mammalian toxicity, associated environmental hazards, and a public backlash against their use [7], research philosophies are shifting towards increasing robustness and extending the service life of wood in use [8]. As a result, several wood modification techniques have emerged in recent decades that have the potential to compensate for the disadvantages associated with the use and processing of wood [9]. Using appropriate modification techniques and processes, it is possible to convert a variety of secondary and nondurable woods, both domestic and imported, into materials that are suitable for specific uses and ensure sustainable utilisation of existing resources. In recent years, wood science research has paid more attention to the treatment of refractory wood and its modification for specific end uses using microwave energy (MW). Microwave energy has been used to significantly reduce the drying time of wood [10], improve the properties of wood, including its permeability [11], reduce drying defects [12], improve the uptake and penetration of wood preservatives, and thus, contribute to the sustainable use of wood by improving its treatability [13] without significantly affecting the wood’s appearance [14] through the application of MW power. In 1945/1946, Percy Spencer, who worked for the Raytheon Manufacturing Company, invented and built the first MW oven. Currently, almost all applications of MW energy in materials are based on this heating mechanism [15]. However, the application of the magnetron in the wood industry dates back to the early 1960s [16], and dielectric heating was first used in the manufacture of plywood and the curing of synthetic resins [17].

When wood is modified by microwaves, the wood is heated to high temperatures by electromagnetic radiation, which leads to structural delamination of the microstructure and possible depolymerisation of some of the main polymer components in the wood. This process leads to a more porous and permeable structure [11,13,18,19], which allows preservatives to penetrate deeper into the wood. In addition, microwave modification in combination with other chemicals has been reported to improve the dimensional stability and thus the durability of wood, making it an attractive alternative to conventional chemical treatments. One of the most important advantages of microwave-modified wood is its ability to retain preservatives better than untreated wood [13,20]. According to several studies [19,21,22], the main cause of this increased permeability is the rupture of weak anatomical elements, leading to the formation of micropores and microcracks, as well as to an increase in pore diameters, destruction of pit membranes, and damage to cell walls.

Assuming that wood becomes a highly porous material when subjected to a high degree of MW treatment [11], it is important to investigate the behaviour of MW-modified wood against decay fungi both in the laboratory and under outdoor conditions to evaluate the performance of modified wood for possible commercial use and application. During the heat treatment (HT) of wood, the changes in the structure of the main polymer components make the wood unpalatable to decay pathogens, thus improving its durability [23]. In the case of MW modification, the treatment time is significantly shorter compared to HT, so the structural change in hemicelluloses and lignin in the wood is only minor and may not be sufficient to achieve biological resistance. In addition, Poonia and Tripathi (2018) [24] pointed out in a study that the MW modification makes the wood slightly acidic, which can also favour fungal decay. The effectiveness of wood preservatives depends on several factors, including the type of wood, the formulation of the preservative, and the environmental conditions to which the treated wood is exposed during use. If the porosity and permeability of the wood are increased many times over after MW modification, the mobility and transport of water and vapours should also increase and, with them, the mobilisation and transport of preservative chemicals. This in turn can influence the fixation and leaching of preservatives. Therefore, the investigation of the leaching behaviour of preservatives after MW is extremely important from a commercial point of view. However, the studies carried out to date on the MW modification of wood have not addressed these issues in detail.

The research conducted in this study aims to build on the existing literature by investigating the effect of microwave modification on preservative retention and the efficacy of the modified wood against the fungal bioassay. The study focuses on evaluating the retention of copper–ethanolamine-based preservative and boron-based preservative at different concentrations on microwave-modified Norway spruce wood, assessing their leaching behaviour and testing the efficacy of the modified wood against decay-causing fungi in laboratory bioassays.

2. Materials and Methods

2.1. Materials

This study used 35-year-old Norway spruce wood harvested in the northeastern part of Slovenia. The logs were processed into boards in a local sawmill. About three weeks after the tree was felled, planning and further processing, such as resawing, began. Samples with a semi-radial orientation were used for the study. To ensure the accuracy of the test, sapwood and heartwood samples were kept separate. Only samples that showed no visual anomalies or defects were selected for the test. For each of the 20 randomly selected parallel samples of heartwood and sapwood, the initial moisture content (IMC) was determined using the gravimetric technique before the MW process began. In contrast to the heartwood samples, where the IMC was 31.5 ± 0.45%, the sapwood samples had an IMC of 61.23 ± 0.62%. The dimensions of the samples used for the entire duration of the study were (l × w × h = 5 × 2.5 × 1.5 cm3). A total of 30 replicates were considered for each test series, corresponding to a total number of 420 samples (Table 1).

Table 1.

Specification for MW treatment and sample distribution.

2.2. Preservative Formulation

Two preservative solutions were used in this study. First, 30 g of sodium tetraborate and 30 g of boric acid were dissolved in 1 litre of deionised water to prepare a 6% sodium tetraborate–boric acid (BBA) solution. Silvanolin is a commercial preservative manufactured by Silvaprodukt (Ig, Slovenia). The patent by Humar and Pohleven (2008) [25] contains a full description of the ingredients of Silvanolin, which include copper hydroxide carbonate, ethanolamine, quaternary ammonium compounds, boric acid, and octanoic acid. A 4% total concentration of Silvanolin with an active copper concentration of 2.5% (cCu = 2500 ppm) was prepared by dissolving the substance in an aqueous solution.

2.3. Microwave Treatment

The treatment of wood with microwaves (MW) was carried out using an MW oven (model: M020MW, Gorenje, Velenje, Slovenia) with a frequency of 2.45 GHz and a maximum power of 700 W. Five MW energies in the range between 700 MJ/m3 and 1260 MJ/m3 were applied to the wood samples. The supplied energy range was selected based on preliminary tests and taking into account the high refractory nature of Norway spruce wood, especially the heartwood. The duration of MW irradiation and details of the energies can be found in Table 1. The parameters of the MW treatments were determined based on the MW power and volume of the samples as suggested by Kol and Çayir (2021) [26]. The MW-treated samples were allowed to cool in a desiccator and weighed before being treated with preservatives.

2.4. Pressure Treatment

All the microwave-modified samples and samples belonging to the treatment set CP, as shown in Table 1, were first immersed in the preservative solutions. The immersion was carried out for 20 h in a plastic vessel under laboratory conditions. The samples were fully immersed in the preservation solutions and weighed to prevent floating. After completion of the 20 h immersion cycle, the samples were pressure-impregnated in a laboratory-scale impregnation chamber (Kambič, Semič, Slovenia) at room temperature. The samples were subjected to pressure impregnation using the full cell treatment. The samples were first kept under vacuum (−0.085 MPa) for 20 min, then under high pressure (1 MPa) for 3 h, and finally under vacuum (−0.085 MPa) for 20 min. The samples were immersed for a further 20 h at atmospheric pressure to ensure maximum retention as prescribed in the leaching standard ENV 1250-2:1994 (European Standard, 1994). At the end of each treatment, the samples were carefully wiped to remove any dripping preservatives and weighed to the nearest 0.01 g.

2.5. Calculation of Retention

The retention referred to here is a measure of the concentration of preservatives that remain after treatment. Retention is expressed in kg/m3 and is calculated from the weight of preservatives in a given volume of treated wood. The retention of preservatives was calculated using the following equation:

where G—mass of treatment solution absorbed by the block (g), C—the percentage of concentration of the treatment chemical, and V—volume of the test block (cm3).

2.6. Leaching Process

The European standard EN 84 [27] describes a method for leaching wood. This standard was developed to simulate extensive leaching by natural precipitation. For this study, five replicates were used for sapwood and heartwood for each treatment set (Table 1). The pressure-impregnated samples were oven-dried at 103 °C ± 2 °C for 24 h. The first step was impregnation with demineralised water. The samples were stacked in a container, weighted down, and impregnated with demineralised water under vacuum (0.08 MPa) for 20 min and soaked for a further 2 h; 100 mL of water was used per sample. The samples were then immersed in water for 14 days, during which the water was replaced 10 times. The leachates were collected for each of these 10 days and used for X-ray fluorescence analysis.

2.6.1. Analysis of Leachates Using XRF for Silvanolin

The copper content was determined at the end of each leaching day by X-ray fluorescence (XRF) analysis using a Twin-X instrument from Oxford Instruments (Abingdon, UK). Approximately 15 mL of the liquid sample (leachate) was poured directly into the Twin-X aluminium sample vials, which were assembled according to the manufacturer’s instructions. Poly4 film (Oxford Instruments, Abingdon, UK) was used as the window material due to its high X-ray transmission and low impurity level. The measurements were carried out using a PIN detector with the settings U = 26 kV and I = 112 µA and a duration of t = 360 s. No special preparation of the leachates was required. For each treatment set, five replicates were used for both the sapwood and the heartwood.

2.6.2. Analysis of Leachates Gravimetrically for BBA

As no mechanism was available at the time of this study to measure the leachates of the BBA-treated samples using XRF, they were subjected to gravimetric measurement. The samples were oven-dried before and after leaching and weighed to the nearest 0.01 g both times. The difference between these two weights was considered as the leached amount of preservatives (in grammes). It goes without saying that during this extensive leaching process, the samples also lose some of their extractives, which can be washed out after a prolonged immersion cycle of 14 days. Therefore, the mean mass loss of the control set was taken as a reference and assumed to be the weight of the extractants. The same weight (in grammes) was subtracted from the other MW-modified and BBA-treated sets to obtain a total value, which was taken as the amount of leached BBA and expressed in grammes.

2.7. Durability Test against Wood-Decaying Basidiomycetes

The laboratory tests were carried out following standard EN 113 [28]. The 140 samples per fungal culture were first conditioned at 103 °C ± 2 °C for 24 h. The conditioned samples were steam-sterilised in an autoclave before being exposed to the wood-decaying fungi. Then, 350 mL experimental glass containers with aluminium lids and cotton wool were cleaned and prepared for the study; 50 mL of 4% potato dextrose agar (DIFCO) was prepared per glass container and inoculated with the white rot fungus Trametes versicolor (L.) Lloyd (ZIM L057) and the brown rot fungus Rhodonia placenta (ZIM L033). The fungal isolates come from the fungal collection of the Biotechnical Faculty of the University of Ljubljana. The fungal isolates are available for research institutions on request. Information on the origin of the fungal isolates and identification details can be found in the corresponding catalogue [29]. One week after inoculation, two samples per jar were placed on an HDPE plastic net to avoid direct contact between the samples and the PDA medium. The prepared test jars were then incubated at 25 °C and 85% relative humidity (RH). After 16 weeks of incubation, the samples were cleaned of adhering fungal mycelium, and the mass loss was determined gravimetrically after drying the samples first at 60 °C ± 2 °C for 24 h and then at 103 °C ± 2 °C for 24 h.

2.8. Statistical Analysis

The percentage values for mass loss were transformed in Excel using the arcsine transformation. IBM® SPSS® Version 28 software was used for the statistical analysis. To analyse the data, the mean values of the different treatments were evaluated. A one-way ANOVA was used to analyse the mean values of the treatments. In addition, Duncan’s post hoc analysis was performed at α = 0.05 to test for significant differences between treatment means.

3. Results and Discussions

3.1. Preservative Retention

The results of the experiment to evaluate the effects of different microwave energies (MW) on the retention of preservatives in the heartwood and sapwood of Norway spruce samples are shown in Table 2. The data show the mean retention values (expressed in kg/m3) for different treatments, including BBA and Silvanolin, for both heartwood and sapwood. The standard errors are also shown in brackets to emphasise the variability of the measurements. Statistical significance was determined using Duncan’s post hoc analysis with α = 0.05.

Table 2.

Mean retention values (kg/m3) for sapwood and heartwood for different sets of MW-modified samples.

In both heartwood and sapwood, BBA consistently shows higher mean retention values for most microwave treatment durations (exceptions are the CP and MW 20 samples for heartwood) compared to Silvanolin. In addition to the fact that BBA was used in higher concentrations for the study, this also indicates that BBA is retained more effectively in the wood samples than Silvanolin across all treatment durations.

With the increasing energy intensity of the microwave treatment from MW 20 to MW 36, there is a general tendency towards increasing mean retention values for both preservatives in both heartwood and sapwood. This indicates that high-intensity microwave treatments lead to higher preservative retention, which can be attributed to improved penetration and diffusion of the preservatives into the wood structure. For the heartwood samples, the results of Duncan’s post hoc analysis to determine statistically significant differences between treatments for both BBA and Silvanolin show that there is no significant difference between MW 24, MW 28, MW 32, and MW 36, suggesting that in the case of the Norway spruce heartwood samples, a shorter microwave treatment duration has the same effect on retention as a longer one. This means that from the point of view of energy consumption, a shorter microwave treatment is sufficient.

Surprisingly, the heartwood showed higher mean retention values than the sapwood for both preservatives and across all microwave treatment durations. One explanation for this could be the lower IMC in the heartwood samples compared to their sapwood counterparts. The extent and implementation of MW treatments vary from species to species and are highly dependent on the initial moisture content (IMC) of the wood [18]. Greenwood absorbs MW energy very well [22]. The MW energy thus absorbed by the sapwood samples was used more to vaporise the water present in the wood, resulting in less structural damage. In the heartwood samples, on the other hand, the structural damage was more profound due to the lower availability of moisture compared to the sapwood.

Samples without visible knots and other defects were used in this study because we assume that the presence of defects could lead to uneven treatment with microwaves, possibly resulting in uneven treatment or unintended changes in properties. As far as the authors are aware, no studies have been performed to assess the impact of the defects on the quality of the MW treatment. An analysis of the anatomical changes in the wood after moderate and high-intensity microwave modification in our previous study showed that the effect of MW treatment on the microstructure of heartwood samples was greater compared to sapwood samples [18]. The MW treatment may also have flushed out the extractives and other deposits from the heartwood, leading to its increased permeability. In a recent publication on the chemical constituents of wood after high-intensity MW modification, it was reported that the effect of MW treatment at higher intensities was significantly greater on heartwood than on sapwood [30]. The same study [30] also indicated the possibility of hydrothermal modification of heartwood by MW treatment, which may also have affected permeability and led to higher uptake of preservatives. This suggests that heartwood has a greater ability to retain preservatives when treated with MW compared to sapwood. However, further studies on heartwood and sapwood samples with identical IMC are required to further investigate this possibility and confirm this claim.

3.2. Leaching Process

3.2.1. Analysis of Leachates Using XRF for Silvanolin

This study investigates the dynamics of copper leaching from Silvanolin-treated Norway spruce samples containing both sapwood and heartwood. The analysis of the data shows the average copper leaching over 10 days of samples subjected to different treatments (control, CP, and microwave treatments with different intensities), as shown in Table 3 and Table 4 for sapwood and heartwood, respectively. An initial increase in leachate levels on the first day, particularly in the CP- and microwave-treated samples, which then drops to a negligible level, indicates a rapid discharge of loosely adhering copper, which then stabilises. This indicates rapid precipitation of the loose copper, while the more tightly bound copper remains embedded in the wood structure. Comparative analysis of sapwood and heartwood samples emphasises the tendency of heartwood to leach slightly more copper under similar conditions, probably due to inherent differences in anatomical and chemical composition, which in turn influence the absorption, retention, and subsequent leaching of preservatives. These observations have implications for the use of Silvanolin in wood preservation, particularly with regard to the resistance of wood to fungal attack. The observed leaching patterns indicate that, despite the effectiveness of Silvanolin in impregnating the wood, some of the copper is susceptible to leaching, which should be taken into account in order not to compromise the quality of the treatment. Humar and Thaler (2017) [31] reported that copper stands out as a highly effective biocide for wood and provides robust protection when applied in appropriate amounts. However, premature failures are often due to insufficient penetration and retention and possibly to the leaching and translocation of active ingredients in critical zones. Furthermore, if the copper content falls below the levels prescribed for a particular preservative, this can lead to premature failure of the treated timber.

Table 3.

Leaching of Copper in ppm from Silvanolin-Treated Norway Spruce Sapwood.

Table 4.

Leaching of Copper in ppm from Silvanolin-Treated Norway Spruce Heartwood.

3.2.2. Gravimetrical Analysis of Leachates for BBA

The results presented in Table 5 give a clear indication of the effects of microwave treatment on the leaching behaviour of boron-containing active ingredients (BBA) from Norway spruce wood, whereby both sapwood and heartwood samples were considered. The data show a recognisable trend in which microwave treatment, particularly at higher intensities (from MW 20 to MW 36), led to a significant reduction in the amount of BBA leached from the wood. This indicates that the preservative is better retained in the wood matrix by the microwave treatment. Both the sapwood and heartwood samples showed a remarkable decrease in BBA leaching, especially at higher microwave intensities. This trend emphasises the potential of microwave treatment not only to increase the retention of wood preservatives but also to improve the durability and longevity of wood products. Importantly, this approach could also help to reduce the environmental impact associated with the leaching of wood preservatives and provide a more sustainable solution for wood preservation.

Table 5.

Gravimetric Analysis of BBA Leachates from Microwave-Treated Norway Spruce Sapwood and Heartwood.

3.3. Durability Test against Wood-Destroying Basidiomycetes

The preservation of wood is crucial for extending its service life, especially in applications where it is susceptible to fungal attack. This study investigates the synergistic effect of pretreating wood samples with microwaves in combination with the use of fungicides to improve the protection of wood against wood-destroying fungi. As shown in Table 6, longer microwave treatments and impregnation with wood preservatives appear to increase the resistance of the wood to fungal attack, as the percentage mass losses are lower. In both sapwood and heartwood, Silvanolin frequently leads to lower mean mass losses from the two fungal species used compared to BBA under all treatment conditions. This indicates that Silvanolin offers better protection against wood decay caused by fungi than does BBA. Exceptions are the sapwood and heartwood samples for treatments C and CP, as well as the heartwood samples treated with Silvanolin and exposed to Trametes versicolor. For both preservatives, there is a general trend of decreasing mean mass loss as the energy intensity of the microwave treatment increases from MW 20 to MW 36. Longer microwave treatments increase the resistance of the wood to fungal attack, as shown by the lower percentage of mass loss. Mascarenhas et al. (2021) [32] wrote that the combination of longer exposure time and higher MW intensity can lower the pH in the wood. The metabolism of fungi during wood decay is influenced by various factors, including the pH value of the wood. Fungi can adapt to a wide range of pH values, with certain fungi showing optimal growth and enzymatic activity at certain pH values. For example, certain wood-decay fungi, such as brown-rot fungi, have been observed to significantly lower the pH of wood before mass loss occurs, indicating early stages of decomposition by brown-rot fungi [33]. In addition, white-rot fungi degrade cellulose and lignin, leaving bleached fibre residues. During wood decomposition, white-rot fungi excrete a large amount of organic acids (e.g., oxalic acid) into their microenvironment, creating ideal conditions (pH 3–5) for the function of lignin-decomposing enzymes and simultaneously promoting Fenton reactions that lead to the decomposition of crystalline cellulose [34]. In the study conducted by Lupsea et al. (2013) [35], they concluded that copper is bound to carboxyl and phenolic sites and forms soluble complexes with extractives. The balance between binding to solid and extractable components, as well as the acid/base properties of the binding sites, lead to a lower release at neutral pH. In our study, the combination of both treatments, MW modification of the wood and the use of a fungicide, synergistically resulted in lower mass losses due to fungal attack, although retention did not increase significantly, for heartwood with longer durations of microwave treatment. The fact that MW modification is an effective way of significantly reducing pathogen loads due to heat damage and desiccation rather than denaturing DNA was also confirmed in the study of Knox et al. (2013) [36]. The results presented by Xing et al. (2023) [30] show that MW treatment causes changes in the chemical composition of wood, including an increase in relative lignin concentration and a decrease in relative cellulose and hemicellulose content. There may be some correlation between the chemical changes caused by MW treatment and the effectiveness of wood-decaying fungi, but further tests should be conducted to investigate this issue.

Table 6.

Mean mass loss (%) due to fungal decay for sapwood and heartwood for different sets of MW-modified samples treated with Silvanolin and BBA. The abbreviations PM and TV stand for Rhodonia placenta and Trametes versicolor, respectively.

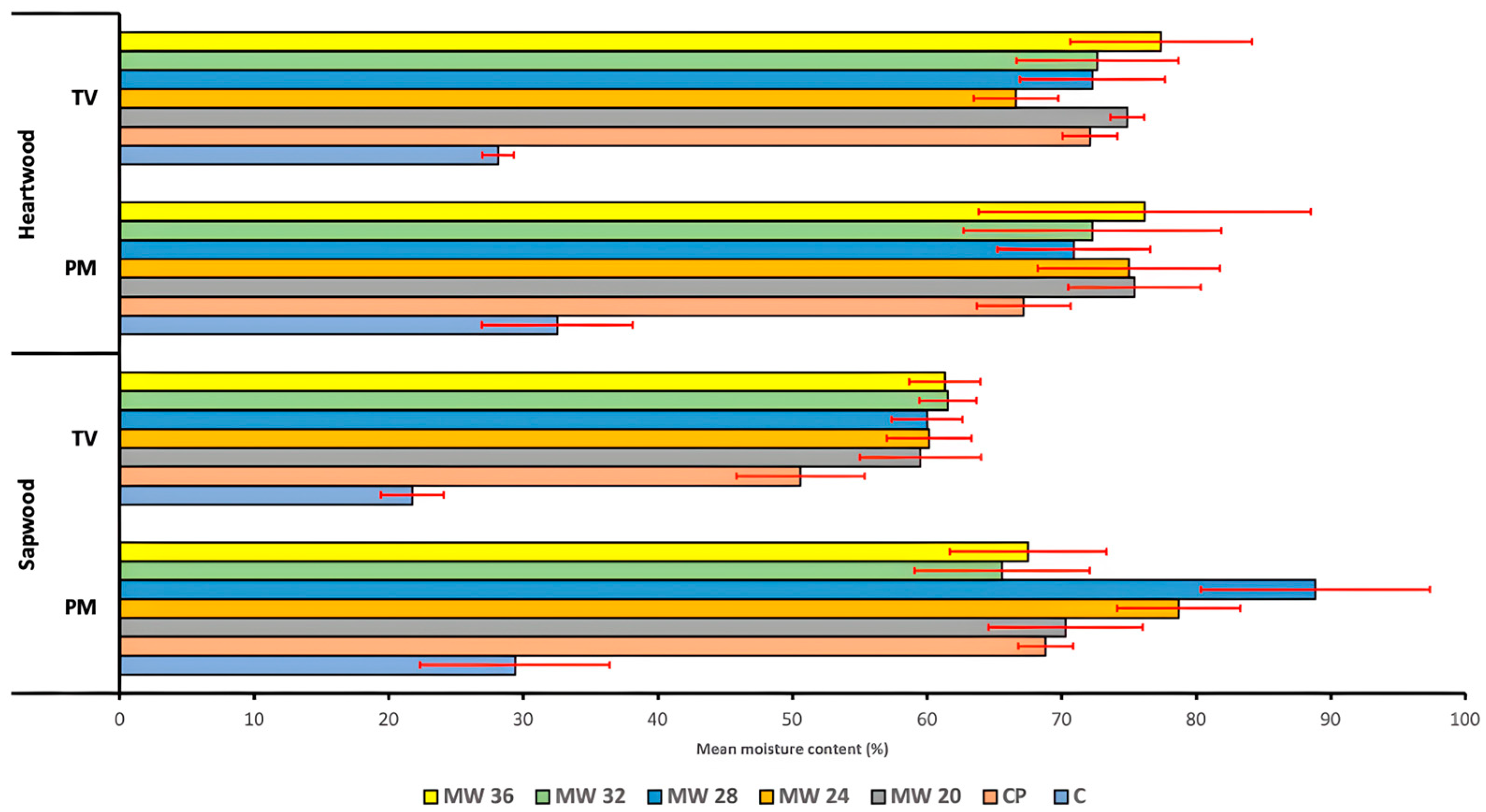

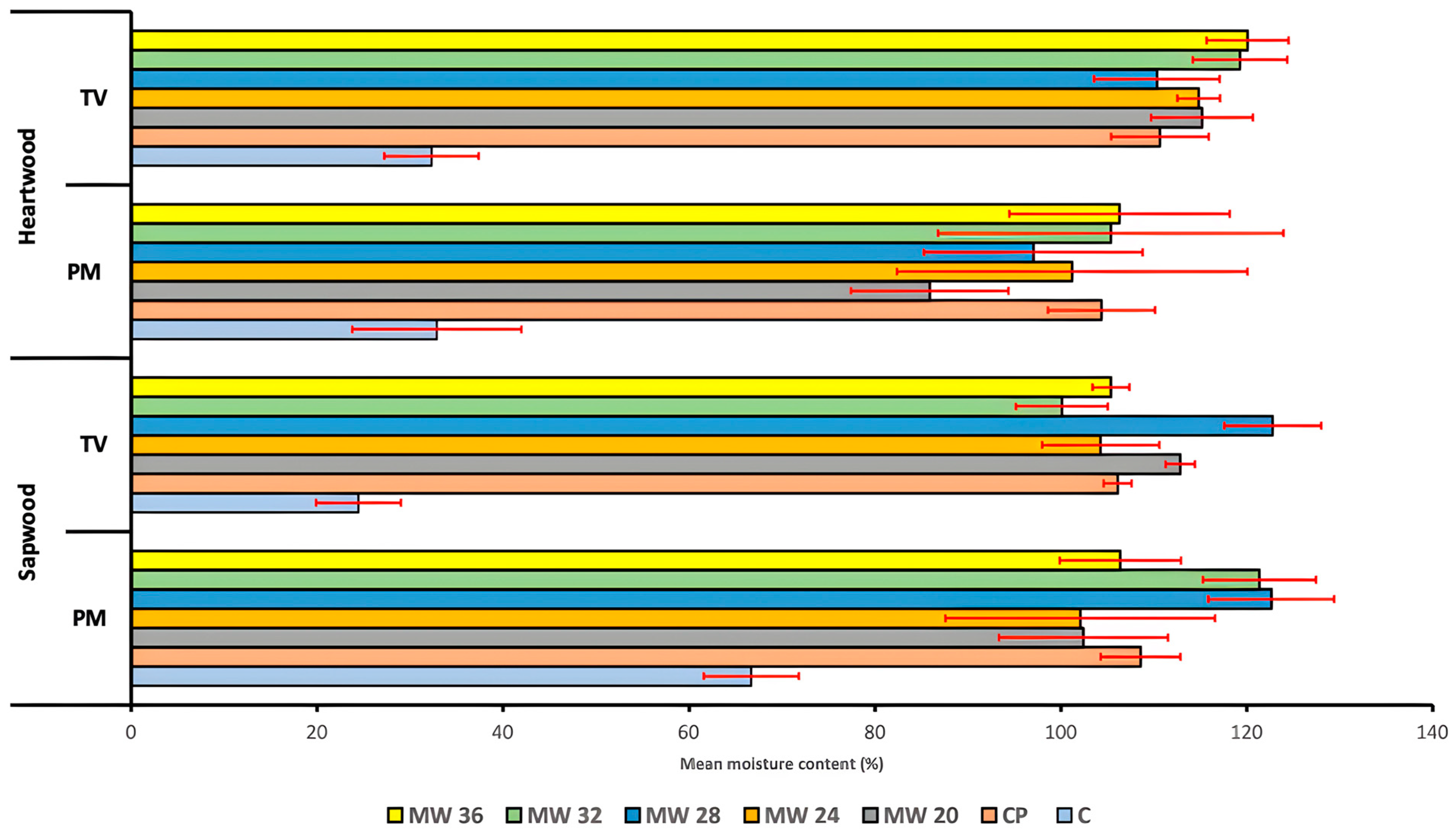

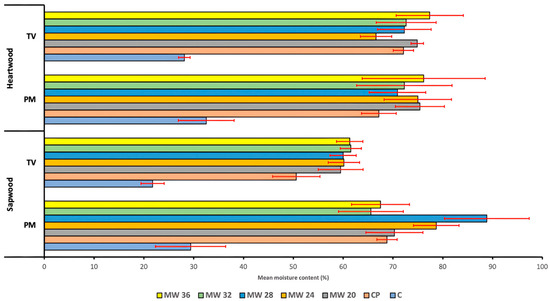

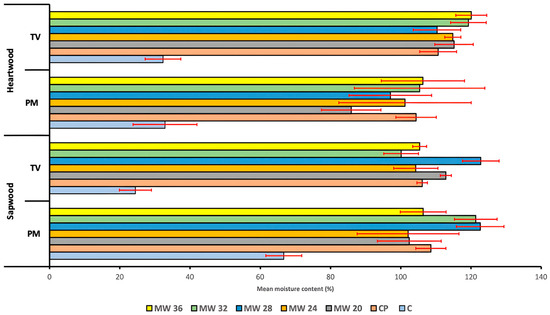

Figure 1 and Figure 2 show that Silvanolin-treated samples tended to have lower average moisture contents in both sapwood and heartwood after the incubation period compared to BBA-treated samples, regardless of the fungal culture used (PM and TV). This indicates that Silvanolin not only provides better protection against fungal attacks but also helps to reduce the moisture content of the wood. The mean moisture contents seem to be influenced by the duration of the microwave treatment. Longer treatment durations (MW 28, MW 32, and MW 36) generally result in lower moisture content in the wood samples, suggesting that longer microwave treatment contributes to lower moisture uptake by the wood. The heartwood samples generally have lower average moisture contents than the sapwood for both preservatives and under all treatment conditions. This suggests that heartwood has a natural advantage in resisting moisture uptake, which may contribute to its resistance to fungal attack.

Figure 1.

Mean moisture content exhibited by the samples impregnated with BBA after an incubation period of 16 weeks.

Figure 2.

Mean moisture content exhibited by the samples impregnated with Silvanolin after an incubation period of 16 weeks.

4. Conclusions

This study comprehensively investigated the synergistic effects of microwave pretreatment and subsequent fungicide impregnation on the durability of Norway spruce wood against fungal decay caused by white-rot fungi Trametes versicolor and brown-rot fungi Rhodonia placenta. The results showed that the combination of these treatments significantly increased the wood’s resistance to fungal attack. This is a promising approach to extend the service life of wood in applications that are susceptible to such deterioration.

One of the most important observations was that the preservatives were more effectively retained in the wood matrix after microwave treatment, which contributed to improved durability. In order to obtain more reliable results and gain a better insight into the leaching of wood preservatives, additional analyses using techniques such as atomic absorption spectroscopy (AAS) or inductively coupled plasma–mass spectrometry (ICP-MS) should be considered in future research. As far as the results are concerned, Silvanolin in particular, proved to be a more effective fungicide than BBA and showed a greater protective effect against wood-decay fungi. This was consistent across different treatment durations and intensities, suggesting that Silvanolin may be a more reliable solution for protecting wood from fungal attack.

This study also shed light on the effects of microwave treatment on potential changes in chemical composition of the wood, including possible changes in lignin concentration and the relative content of cellulose and hemicellulose based on a relevant reference. These changes could correlate with the observed improvements in resistance to fungal attack. However, further research is needed to fully understand these mechanisms.

To summarise, the research provides valuable insight into the potential of microwave pretreatment as a sustainable and effective method of improving wood preservation. By improving preservative retention and potentially altering the chemical composition of the wood, microwave treatment proves to be a promising technique for extending the service life of wood products in environments with an increased risk of fungal decay. Further research is recommended to explore the full extent of the benefits and to optimise treatment protocols for widespread application.

Author Contributions

Conceptualisation, S.G. and S.T.; methodology, S.G., M.P. and D.K.; validation, S.T. and M.P.; formal analysis, S.G.; investigation, S.G.; resources, S.G., M.P. and D.K.; data curation, S.G. and D.K.; writing—original draft preparation, S.G.; writing—review and editing, D.K.; visualisation, S.G.; supervision, M.P. and S.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Slovenian Research and Innovation Agency, grant numbers P4-0430 “Forest-wood value chain and climate change: transition to circular bioeconomy” and P4-0015 “Wood and lignocellulosic composites”.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

We would like to thank Miha Humar, Jure Žigon, Andreja Žagar, and Samo Grbec for their invaluable help in providing laboratory resources, conducting the study, sample preparation, and laboratory work. Special thanks go to Sanjeet Kumar Hom for his expertise in statistical and graphical analyses. The first author gratefully acknowledges the support of CMEPIUS Slovenia and UCOST Dehradun.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Humar, M.; Kržišnik, D.; Lesar, B.; Brischke, C. The Performance of Wood Decking after Five Years of Exposure: Verification of the Combined Effect of Wetting Ability and Durability. Forests 2019, 10, 903. [Google Scholar] [CrossRef]

- Skog, K.E.; Wegner, T.H.; Bilek, E.M.; Michler, C.H. Desirable Properties of Wood for Sustainable Development in the Twenty-First Century. Ann. For. Sci. 2015, 72, 671–678. [Google Scholar] [CrossRef]

- Hom, S.K.; Ganguly, S.; Samani, A.; Tripathi, S. Improvement in fire retardancy with double-step chemical modification on Pinus radiata D. Don using dimethyl methylphosphonate with propylene oxide and maleic anhydride. Int. Wood Prod. J. 2020, 11, 138–145. [Google Scholar] [CrossRef]

- Sivonen, H.; Nuopponen, M.; Maunu, S.L.; Sundholm, F.; Vuorinen, T. Carbon-Thirteen Cross-Polarization Magic Angle Spinning Nuclear Magnetic Resonance and Fourier Transform Infrared Studies of Thermally Modified Wood Exposed to Brown and Soft Rot Fungi. Appl. Spectrosc. 2003, 57, 266–273. [Google Scholar] [CrossRef]

- Jiang, J.X.; Li, J.Z.; Gao, Q. Effect of Flame Retardant Treatment on Dimensional Stability and Thermal Degradation of Wood. Constr. Build. Mater. 2015, 75, 74–81. [Google Scholar] [CrossRef]

- Rowell, R.M.; Ibach, R.E.; McSweeny, J.; Nilsson, T. Understanding Decay Resistance, Dimensional Stability and Strength Changes in Heat-Treated and Acetylated Wood. Wood Mater. Sci. Eng. 2009, 4, 14–22. [Google Scholar] [CrossRef]

- de Angelis, M.; Humar, M.; Kržišnik, D.; Tamantini, S.; Romagnoli, M. Influence of Thermal Modification and Impregnation with Biocides on Physical Properties of Italian Stone Pine Wood (Pinus pinea L.). Appl. Sci. 2022, 12, 3801. [Google Scholar] [CrossRef]

- Militz, H. Wood modification in Europe in the year 2015: A success story? In Proceedings of the Eighth European Conference on Wood Modification, Helsinki, Finland, 26–27 October 2015. [Google Scholar]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Oloyede, A.; Groombridge, P. The influence of microwave heating on mechanical properties of wood. J. Mater. Process. Technol. 2000, 100, 67–73. [Google Scholar] [CrossRef]

- Torgovnikov, G.; Vinden, P. Microwave wood modification technology and its applications. For. Prod. J. 2010, 60, 173–182. [Google Scholar] [CrossRef]

- Balboni, B.M.; Ozarska, B.; Garcia, J.N.; Torgovnikov, G. Microwave treatment of Eucalyptus macrorhyncha timber for reducing drying defects and its impact on physical and mechanical wood properties. Eur. J. Wood Wood Prod. 2018, 76, 861–870. [Google Scholar] [CrossRef]

- Samani, A.; Ganguly, S.; Kanyal, R.; Tripathi, S. Effect of microwave pre-treatment on preservative retention and treatability of Melia composita wood. J. For. Sci. 2019, 65, 391–396. [Google Scholar] [CrossRef]

- Weng, X.; Zhou, Y.; Fu, Z.; Gao, X.; Zhou, F.; Jiang, J. Effects of microwave pretreatment on drying of 50 mm-thickness Chinese fir lumber. J. Wood Sci. 2021, 67, 13. [Google Scholar] [CrossRef]

- Osepchuk, J.M. The history of the microwave oven: A critical review. In Proceedings of the 2009 IEEE MTT-S International Microwave Symposium Digest, Boston, MA, USA, 7–12 June 2009; pp. 1397–1400. [Google Scholar]

- Egner, K.; Jagfeld, P. Verstiche zur künstlichen Trocknung von Holz durch Mikrowellen. Mod. Holzverarbeitung Holz-Zentralblatt. 1964, 129, 297–300. [Google Scholar]

- Vikberg, T.; Sandberg, D.; Elustondo, D. High frequency heating in solid wood modification. In The Seventh European Conference on Wood Modification, Lisbon, Portugal, 10–12 March 2014; Nunes, L., Jones, D., Hill, C., Militz, H., Eds.; Laboratorio Nacional Deengenharia Civil: Lisabon, Portugal, 2014; pp. 113–114. [Google Scholar]

- Ganguly, S.; Balzano, A.; Petrič, M.; Kržišnik, D.; Tripathi, S.; Žigon, J.; Merela, M. Effects of Different Energy Intensities of Microwave Treatment on Heartwood and Sapwood Microstructures in Norway Spruce. Forests 2021, 12, 598. [Google Scholar] [CrossRef]

- Weng, X.; Zhou, Y.; Fu, Z.; Gao, X.; Zhou, F.; Fu, F. Effects of Microwave Treatment on Microstructure of Chinese Fir. Forests 2020, 11, 772. [Google Scholar] [CrossRef]

- Ramezanpour, M.; Tarmian, A.; Taghiyari, H.R. Improving impregnation properties of fir wood to acid copper chromate (ACC) with microwave pre-treatment. iForest 2015, 8, 89–94. [Google Scholar] [CrossRef]

- Mekhtiev, M.A.; Torgovnikov, G. Method of check analysis of microwave-modified wood. Wood Sci. Technol. 2004, 38, 507–519. [Google Scholar] [CrossRef]

- Terziev, N.; Daniel, G.; Torgovnikov, G.; Vinden, P. Effect of Microwave Treatment on the Wood Structure of Norway Spruce and Radiata Pine. Bioresources 2020, 15, 5616. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Poonia, P.K.; Tripathi, S. Effect of microwave heating on pH and termite resistance of Pinus roxburghii Wood. Maderas Cienc. Y Tecnol. 2018, 20, 499–504. [Google Scholar] [CrossRef]

- Humar, M.; Pohleven, F. Solution for Wood Preservation. EP 1791682 (B1), 3 September 2008. [Google Scholar]

- Kol, H.Ş.; Çayır, B. Increasing the Impregnability of Oriental Spruce Wood via Microwave Pretreatment. Bioresources 2021, 16, 2513–2523. [Google Scholar]

- CEN EN 84; Durability of Wood and Wood-Based Products—Accelerated Ageing of Treated Wood Prior to Biological Testing—Leaching Procedure. European Committee for Standardization: Brussels, Belgium, 2020.

- CEN EN 113-1; Durability of Wood and Wood-Based Products—Test Method against Wood Destroying Basidiomycetes—Part 1: Assessment of Biocidal Efficacy of Wood Preservatives. European Committee for Standardization: Brussels, Belgium, 2020.

- Raspor, P.; Smole-Možina, S.; Podjavoršek, J.; Pohleven, F.; Gogala, N.; Nekrep, F.V.; Hacin, J. ZIM: Zbirka Industrijskih Mikroorganizmov-Collection of Industrial Microorganisms. Katalog Biokultur-Catalogue of Cultures; University of Ljubljana, Biotechnical Faculty: Ljubljana, Slovenia, 1995; 98p. [Google Scholar]

- Xing, X.; Li, S.; Jin, J.; Lin, L.; Zhou, Y.; Peng, L.; Fu, F. Effect of high-intensity microwave (HIMW) treatment on chemistry of radiata pine. Wood Sci. Technol. 2023, 57, 1–21. [Google Scholar] [CrossRef]

- Humar, M.; Thaler, N. Performance of copper treated utility poles and posts used in service for several years. Int. Biodeterior. Biodegrad. 2017, 116, 219–226. [Google Scholar] [CrossRef]

- Mascarenhas, F.J.R.; Dias, A.M.P.G.; Christoforo, A.L. State of the Art of Microwave Treatment of Wood: Literature Review. Forests 2021, 12, 745. [Google Scholar] [CrossRef]

- Humar, M.; Petrič, M.; Pohleven, F. Changes of the pH value of impregnated wood during exposure to wood-rotting fungi. Holz. Als. Roh. Werkstoff 2001, 59, 288–293. [Google Scholar] [CrossRef]

- Li, T.; Cui, L.; Song, X.; Cui, X.; Wei, Y.; Li, T.; Mu, Y.; Xu, Z. Wood decay fungi: An analysis of worldwide research. J. Soils Sedim. 2022, 22, 1688–1702. [Google Scholar] [CrossRef]

- Lupsea, M.; Mathies, H.; Schoknecht, U.; Tiruta-Barna, L.; Schiopu, N. Biocide leaching from CBA treated wood—A mechanistic interpretation. Sci. Total Environ. 2013, 444, 522–530. [Google Scholar] [CrossRef]

- Knox, O.G.G.; McHugh, M.J.; Fountaine, J.; Havis, N.D. Effects of microwave heat treatment on fungal growth, functional properties, total phenolic content, and antioxidant activity of sorghum (Sorghum bicolor L.) grain. Crop. Prot. 2013, 50, 12–16. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).