Abstract

In addressing the issue of climate change, the Chinese government has established a definitive objective to attain its peak carbon emissions by 2030 and strive for carbon neutrality by 2060. This effort aims to progressively achieve a state of net-zero carbon dioxide (CO2) emissions. In the given scenario, this research examines challenges in promoting low-carbon manufacturing (LCM) within the Chinese automotive sector, specifically in the context of Green Tech projects. In view of greater emphasis on environmental sustainability and technological innovation, this study aims to uncover challenges restraining the adoption of LCM in one of the world’s largest automotive markets, China. A three-step methodology was adopted by incorporating a literature review, the Delphi method, Interpretive Structural Modeling (ISM), and MICMAC analysis. In the first stage, relevant articles were selected scientifically to identify the main challenges in previous studies by following the relevant keyword criteria. Further, challenges identified from the comprehensive literature review were screened through the Delphi method, and finally, challenges were modeled and clustered through ISM and MICMAC analysis. Data collected from the experts highlight that “difficulties in the transition towards energy efficient technologies”, “insufficient operational efficiency”, and “information imbalances and asymmetry” were the most critical challenges that hinder LCM initiatives in the automotive industry. This research serves as a valuable resource for academia, industry professionals, and policymakers in the quest to adopt LCM in the dynamic context of the Chinese automotive sector.

1. Introduction

Presently, societies worldwide are combating the challenges of global warming and climate change. The accelerating industrialization across the globe is depleting vast reserves of fossil resources, leading to increased carbon emissions [1]. Global carbon emissions continue to be a significant concern for climate scientists, policymakers, and researchers. The situation regarding global carbon emissions can vary based on several factors, including economic growth, energy consumption, industrial expansion, and government policies. To overcome excessive carbon emissions [2], Böttcher and Müller [3] introduced the concept of low-carbon manufacturing (LCM) as “the process of producing goods while minimizing carbon emissions and reducing the overall environmental impact”. However, the adoption of LCM in today’s enterprises is contingent upon various activities such as system planning, execution, and control. LCM could be useful and a significant stride towards fulfilling the COP26 commitments, ensuring global net-zero emissions by 2030 [4].

Carbon emissions can have several detrimental effects on the growth and development of emerging economies including environmental degradation, industrial disruptions, infrastructure damage, resource scarcity, and investment risks [5]. Addressing carbon emissions and transitioning to a low-carbon economy through LCM can mitigate these negative effects, promoting sustainable growth and development in emerging economies. International cooperation, sustainable technology adoption, and policy initiatives are essential for reducing the impact of carbon emissions on economic progress [6].

The Chinese automotive industry has been investing in green tech projects to reduce carbon emissions and promote sustainability. Several green tech initiatives have been implemented, contributing significantly to lowering carbon emissions in the transportation sector. Electric vehicles, battery technology advancement, and the development of charging infrastructure are some examples of green tech projects in the Chinese automotive industry and their contributions towards reducing carbon emissions and LCM [7]. These green tech projects and initiatives in the Chinese automotive sector are contributing significantly to the reduction in carbon emissions, fostering a transition towards cleaner and more sustainable mobility solutions. Prior to December 2021, China housed nearly 50% of the world’s electric cars and 95% of electric buses and trucks. Additionally, China held a significant proportion of the global markets for electric two- and three-wheelers [8]. The count of EV charging stations in China is experiencing swift growth. In January 2022, the Chinese Electric Vehicle Charging Infrastructure Promotion Agency (EVCIPA) revealed that there are 2.6 million EV charging ports in China, marking a 47% increase within a year. Among these, approximately 1.1 million were public chargers, including 470,000 DC fast chargers [9]. Despite these initiatives, the concept of green technologies and LCM in the Chinese automotive sector has not been embraced rapidly. Further, research on guiding automotive companies regarding LCM is scarce.

Earlier research on LCM and its challenges has focused mainly on the industrial sector or manufacturing sector; for example, Liu [10] identified challenges in implementing low-carbon production in Chinese industrial firms. Kannan et al. [11] identified challenges in adopting carbon regulatory environmental policies in the manufacturing industry of China. Only one study was conducted in the automotive sector related to challenges in adopting low-carbon manufacturing, and it was in the UK [12]. However, LCM-based studies in China are scarce and especially there is no study emphasizing the adoption of LCM in green tech projects in the Chinese automotive sector. Further, none of the studies focused on modeling and clustering of challenges by using some robust methodology such as interpretive structural modeling.

Therefore, the scarcity of LCM-based research in green tech projects in the Chinese automotive sector, the need to adopt sustainable and low-carbon emission technologies, and integrating LCM into operations, are the major challenges that need to be addressed. This study attempts to address the following research questions: (1) what are the main challenges to LCM in the Chinese automotive sector? (2) What are the inter-relationships between different barriers to LCM in the Chinese automotive sector? (3) What are the main policies to overcome challenges to LCM in the Chinese automotive sector? Based on this analysis, a comprehensive understanding of challenges to LCM will support the proposal of sustainable solutions for its progression. Based on the nature of our research, this study aims to achieve the following:

- Identify and filter challenges to LCM adoption in the Chinese automotive sector.

- Model and cluster challenges to LCM adoption in the Chinese automotive sector through ISM and MICMAC approaches.

- Develop policy recommendations to address challenges to LCM adoption in the Chinese automotive sector.

Research on LCM adoption in the Chinese automotive sector will not only contribute to academic knowledge but also have profound practical implications, promoting environmental preservation, economic growth, and corporate responsibility. Theoretically, this research would enrich our comprehension of the interrelationship between different challenges to LCM in the Chinese automotive sector, and more specifically, by taking the case of green tech projects, it could lead to understanding the difficulties and prospects specific to it. Practically, this research would suggest policy implications to overcome LCM adoption challenges. Further, it could offer actionable insights to the Chinese automotive sector for adopting LCM technologies to foster greener industrial practices across green tech projects.

2. Literature Review

2.1. Chinese Automotive Sector and LCM in Green Tech Projects

The Chinese automotive industry is one of the largest and most dynamic in the world. In recent years, China’s automotive sector has undergone rapid expansion, transforming the nation into the world’s largest automobile market and a global center for vehicle production and inventive transportation solutions. The country boasts a substantial consumer base, witnessing the sale of millions of vehicles annually, spanning across categories such as passenger cars, trucks, and buses. China has emerged as a significant player in the electric vehicle industry, with the government implementing policies and incentives to boost the manufacturing and adoption of electric vehicles [13]. Domestic automakers have become key automobile players in the electric vehicle market. The continuous growth and evolution of the Chinese automotive industry are influenced by a combination of internal policies, consumer needs, technological progress, and global market trends. As the industry progresses, it is poised to have a crucial impact on the future of transportation, both domestically and internationally [9].

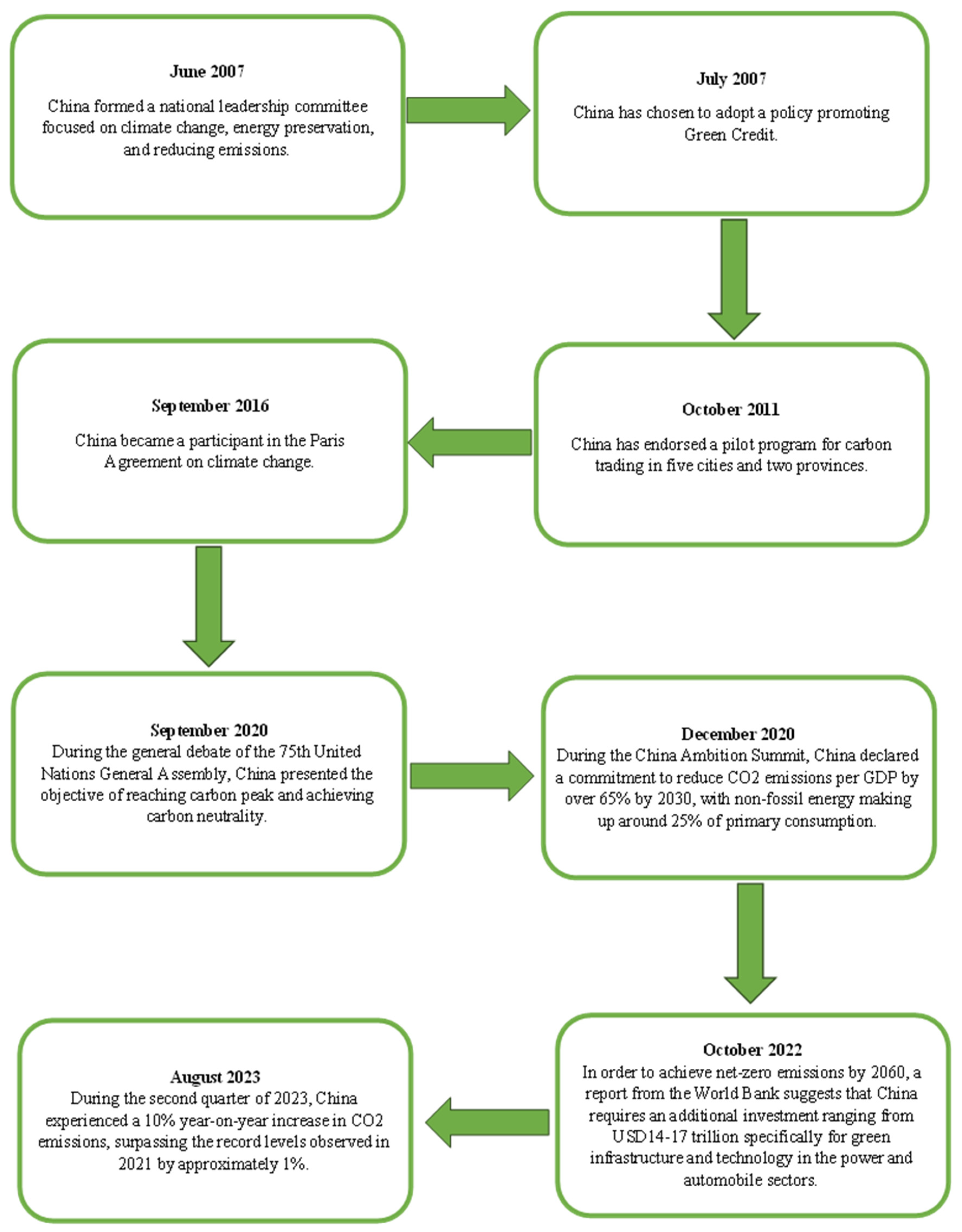

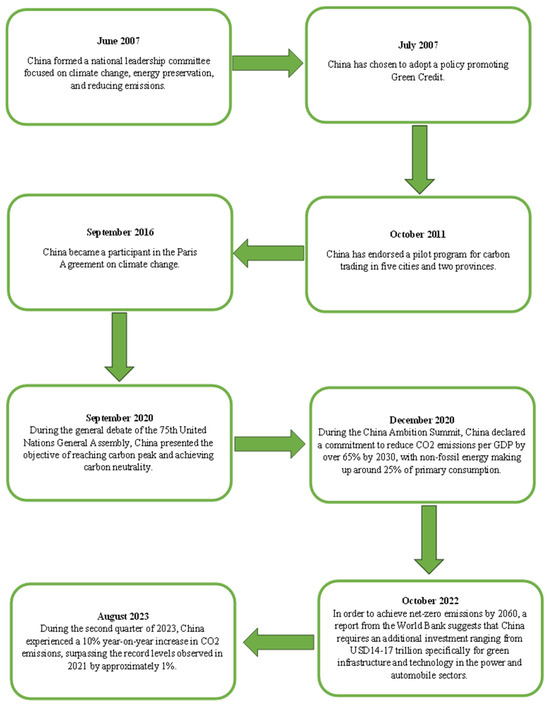

Green tech initiatives within the sector encompass a diverse range of endeavors aimed at fostering a more sustainable future through the utilization of innovative technologies and environmentally friendly practices. China’s seriousness regarding carbon reduction policies started in 2007 and this country is continuously trying to set targets for carbon reduction and neutrality as shown in Figure 1. The concept of LCM in these green tech initiatives pertains to the adoption of eco-friendly production processes and technologies designed to minimize carbon emissions and ecological footprints, aligning seamlessly with the industry’s sustainability goals [14]. There are different forms of LCM in the Chinese automotive sector. Implementing energy-efficient manufacturing processes, utilizing environmentally friendly materials, waste reduction and recycling, establishing sustainable supply chains, lean manufacturing, and continuous improvements are different ways to implement LCM [15]. By integrating these strategies, the Chinese automotive sector can achieve LCM, contributing to a more sustainable and environmentally responsible industry. These efforts align with global initiatives to fight climate change and promote green technologies in the automotive sector. Further, the Chinese automotive sector is not only interested in expanding green tech projects locally but also internationally. Currently, a major Chinese automotive company is planning to invest CNY 106 million in green tech projects through a joint venture in Malaysia. A state-owned Chinese automotive company is going to invest CNY 279 million in developing an EV plant in Thailand. Another major investment is by a Chinese battery tech giant with a collaboration in Indonesia of CNY 5.97 billion to establish an end-to-end lithium-ion battery supply chain [16].

Figure 1.

China’s Carbon reduction initiatives from 2007–2023.

2.2. Identification of Challenges to LCM Adoption

Research on challenges to LCM adoption is a critical area of study, reflecting the obstacles and complexities associated with transitioning industrial processes toward sustainability. These challenges hinder the widespread adoption and implementation of environmentally sustainable manufacturing practices. Different studies have been found in the literature addressing sustainable manufacturing barriers, e.g., de Sousa Jabbour and Chiappetta Jabbour [17] found that implementing low-carbon technologies and processes often requires significant upfront investments, which can be prohibitive for many businesses, especially smaller ones. Ohene, Chan [18] indicated that insufficient financial incentives or subsidies from governments may discourage companies from investing in low-carbon technologies.

Shen, Wu [19] highlighted technological obstacles and specified that the limited availability of advanced, cost-effective low-carbon technologies and solutions can hinder the transition from conventional to sustainable manufacturing processes. Chen, Zhang [20] emphasized that inconsistent or unclear regulations related to environmental standards and carbon emissions can create confusion and compliance challenges for manufacturers.

Singh, Jindel [21] found that limited awareness and understanding of the benefits of LCM among industry stakeholders can hinder its widespread adoption. Further, supply chain complexity was also considered a major roadblock to LCM adoption as supply chains often involve multiple partners and complex networks, making it challenging to ensure that all entities involved adhere to low-carbon practices. Liu, Wang [22] focused on the information-based barriers and found that lack of access to reliable information, data, and tools for measuring carbon emissions and environmental impact can hinder decision-making processes. Vimal, Kumar [23] showed that lack of management commitment and organizational factors are the major hurdles to LCM adoption and emphasized that the poor organizational culture that resists change and does not prioritize sustainability, as well as a lack of skilled workforce trained in sustainable practices, can act as barriers. Further, resistance within organizations to change existing processes, especially if they have been in place for a long time, can impede the adoption of new low-carbon methods. The authors of [24] specified resource constraints as one of the major obstacles to LCM. Limited availability of raw materials or resources for low-carbon manufacturing, especially if they are region-specific, can create challenges in sourcing sustainable inputs. Sindhwani, Singh [25] explained that short-term focus can restrict companies from adopting LCM as businesses focused on short-term profitability might not invest in long-term, sustainable practices due to the perceived delay in realizing returns on investment. Based on this literature review, this research initially attempted to develop a list of challenges to LCM adoption, and different keywords were used to identify challenges in the Web of Science database. These keywords included “Challenges” and “Low carbon manufacturing” or “Low carbon technology” or “Carbo-conscious production” or “Zero emission manufacturing” or “reduced carbon footprint production”. This established list from the literature review was further presented to the experts to select the most relevant challenges in high-tech projects of the Chinese automotive industry. The list of challenges to LCM is given below in the Table 1:

Table 1.

List of LCM challenges.

2.3. Research Motivations

Based on the above-mentioned literature review and context of LCM adoption in green projects of the automotive industry, this research is based on the following motivations:

- First, focusing on the Chinese automotive industry adds a practical dimension, considering China as a global leader in automotive production. Analyzing the challenges specific to this influential industry in the context of LCM and green tech projects aligns with the contemporary global focus on sustainable practices, making the research highly relevant and timely for both academia and industry stakeholders.

- Second, employing the ISM framework in the context of LCM challenges in China’s automotive industry offers a unique perspective. ISM allows for the identification and modeling of complex interrelationships among various challenges, providing a comprehensive understanding of the issue.

- Third, integrating MICMAC analysis enhances the research’s depth by categorizing challenges into driving and dependent factors, thereby offering strategic insights into which challenges are pivotal and which are influenced by others.

3. Research Methodology

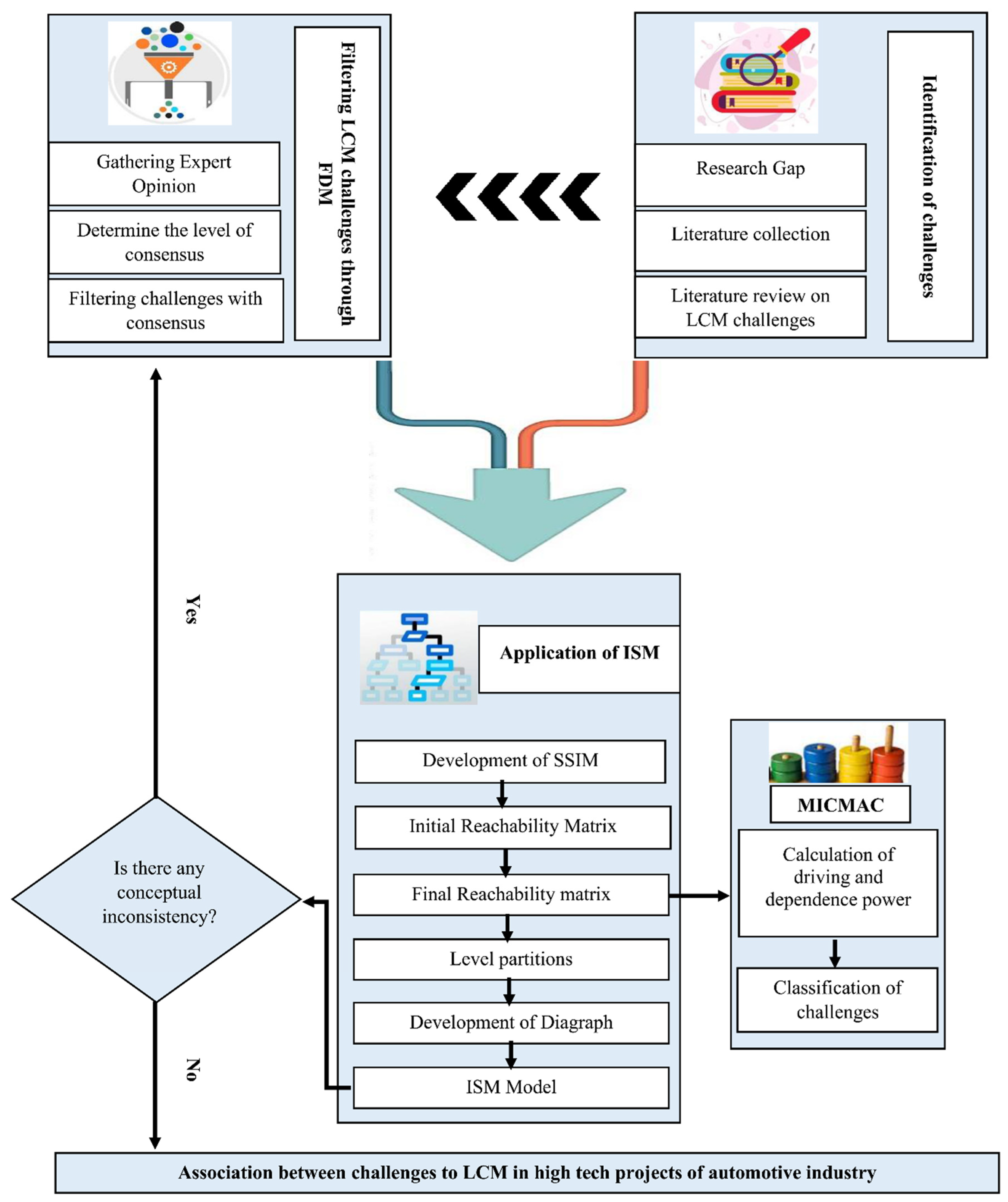

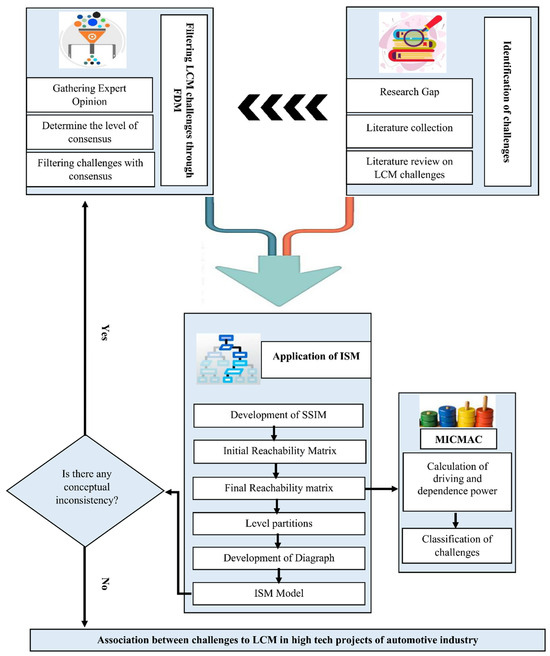

After the identification of LCM challenges from the literature review, this study adopted a three-step methodology to highlight the critical challenges of LCM adoption. The Three Steps Methodology, incorporating the Delphi methodology, ISM, and MICMAC analysis, presents a comprehensive strategy for addressing complex problem-solving and decision-making challenges. Many studies have used similar methodologies to identify the criticality or severity of challenges, strategies, measures, or critical success factors (as shown in Table 2).

- In the initial phase, the Delphi methodology is utilized, gathering expert opinions through iterative rounds of structured questionnaires and feedback and developing a level of consensus. This process taps into collective intelligence, allowing the identification of the most relevant challenges and interconnections within the problem domain.

- The second stage employs ISM to establish a hierarchical structure of these challenges, revealing their interdependencies and the fundamental framework beneath. ISM offers a clear visual representation of these relationships, aiding in the recognition of influential factors.

- Lastly, the third step incorporates MICMAC analysis, categorizing variables into quadrants based on their driving power and dependence. This categorization aids in prioritizing variables and understanding their impact on the system, facilitating strategic decision-making and policy formulation.

Based on these steps, a framework was developed that shows the main steps and sub-steps of each methodology, as shown in Figure 2. Collectively, these methodologies provide a systematic and rigorous approach to tackling intricate problems, ensuring a comprehensive understanding and effective resolution. Further, details for steps in relevant methodologies are given below:

Figure 2.

Step-by-step research methodology.

3.1. Filtering LCM Challenges through Fuzzy Delphi Methodology (Step 1)

The Delphi method, a structured and iterative method for gathering expert opinions, involves different key steps. First, experts are selected, and a set of questionnaires are presented based on the literature review. Experts from the automotive industry having different designations and experience ranges were invited and a total of ten experts were part of the study. Two academicians (Professors) were also invited to provide responses regarding challenges in adopting LCM. In the initial round, experts individually respond to close-ended questions related to the research topic. After each round, a facilitator summarizes the responses and shares the anonymous aggregated results with the experts. The experts are then given the opportunity to revise their opinions considering the group’s feedback. This process is repeated over several rounds until a consensus is reached. In this research, 3 rounds were performed and the consensus of the experts was achieved by following the guidelines of earlier studies [26].

Table 2.

Earlier studies using related methodology.

Table 2.

Earlier studies using related methodology.

| Studies | Authors | Purpose |

|---|---|---|

| 1 | [27] | This study utilized ISM-MICMAC approach to analyze driving forces of green lean and six sigma integrations in construction firms |

| 2 | [28] | In this study, Delphi and ISM-MICMAC approach was used to identify the major barriers in adopting CSR and promoting sustainability in manufacturing firms |

| 3 | [29] | The aim of the study was to investigate the critical success factors influencing the success of energy-efficient supply chains of construction firms. |

| 4 | [30] | This study identified factors affecting open innovation in post-COVID-19 situation by adopting FDM and ISM-MICMAC approach |

| 5 | [31] | Enablers of supply chain agility were identified by using Delphi and ISM-MICMAC approach in this study. |

| 6 | [32] | The main objective of this study was to identify main lean leadership competencies by using Delphi and ISM-MICMAC approach. |

Despite the effectiveness of the Delphi method, it is also associated with some limitations. Firstly, this method is based on expert opinion, which can offer biases. Secondly, anonymous input by the experts might not lead to a robust discussion. Multiple rounds can also be time-consuming, and lastly, this method is based on group thinking, where experts provide their responses based on given circumstances rather than evaluating alternatives. Despite these alternatives, this method is still effective in filtering factors for a system as suggested by earlier related studies; the Delphi method is an effective supportive methodology to filter factors of a system, which are gathered to develop a hierarchal structure through the ISM-MICMAC approach [26]. Therefore, different strategies might overcome the limitations of the Delphi method, including careful selection of experts, transparent and systematic results validation, critical feedback, and iterative improvement through multiple rounds.

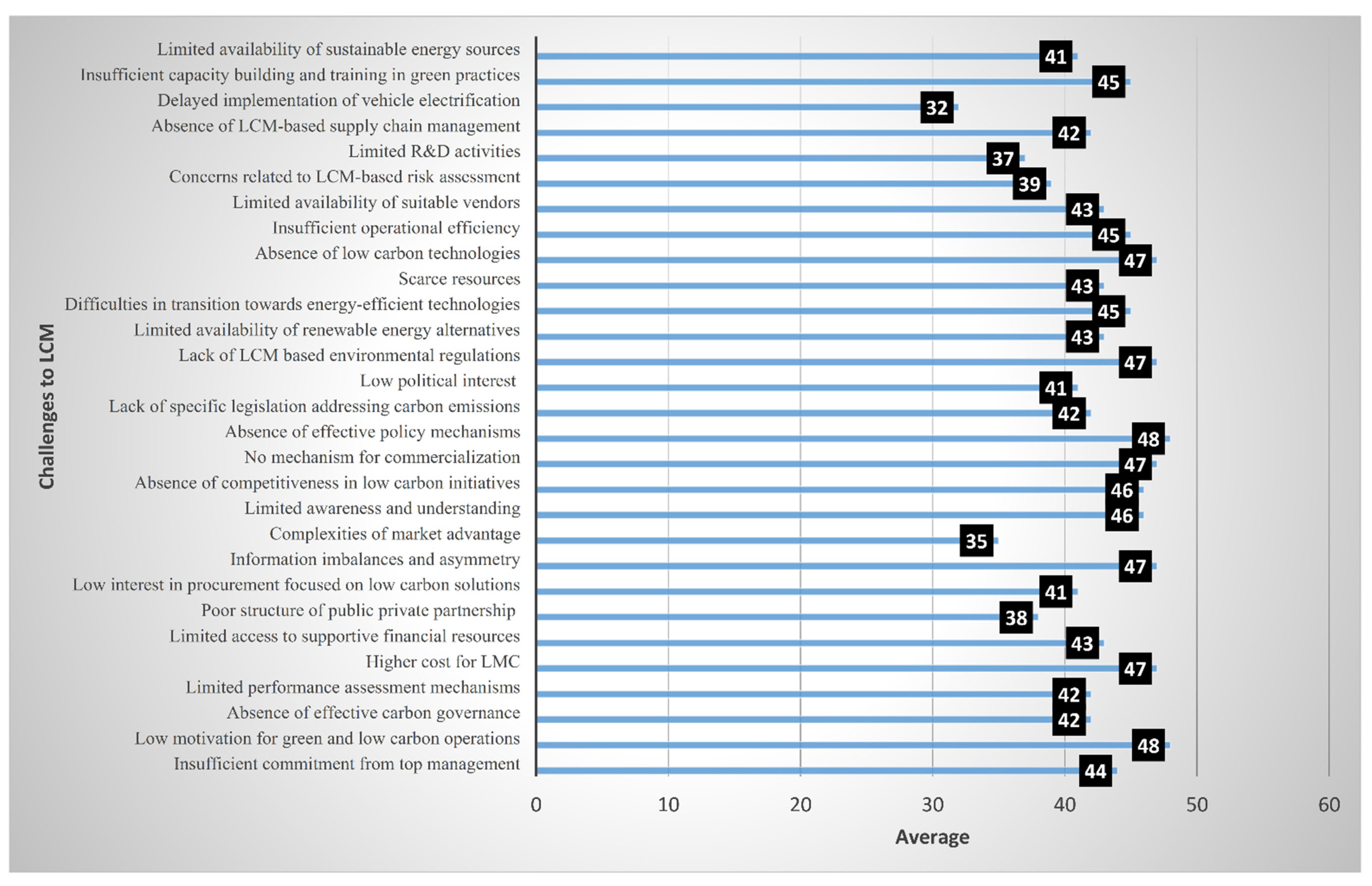

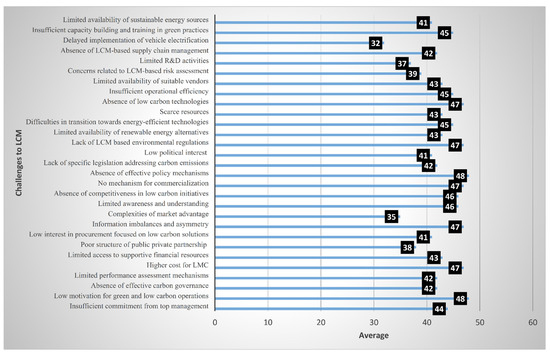

The challenges were assessed using a Likert scale, where a rating from 1 (indicating low importance) to 5 (signifying high importance) was assigned. Experts had the freedom to select any response between 1 and 5. To filter out pertinent challenges related to LCM, the 80/20 rule, known as the Pareto Principle, was employed. According to this principle, approximately 80% of effects stem from 20% of causes. In this study, 10 experts were chosen to pinpoint significant challenges, and a cumulative Likert scale threshold of 40 was established. Challenges with scores exceeding 40 were retained, as depicted in Figure 3, while those below this threshold were discarded. Upon analyzing the data using the Decision Matrix (DM), it was found that five challenges “Poor structure of public private partnership, Complexities of market advantage, Concerns related to LCM-based risk assessment, Limited R&D activities, Delayed implementation of vehicle electrification” fell below the threshold of 40, leading to their exclusion for further exploration in the ISM-MICMAC study. The results for the Delphi method are shown in Figure 3.

Figure 3.

Results of the Delphi method.

3.2. Application of ISM Methodology (Step 2)

ISM methodology was applied by following the guidelines and applications of earlier studies [28]. The following major steps should be followed to develop a hierarchal-based structure of LCM adoption:

Identify Elements (E): Identify all the elements or factors related to the problem or system under consideration. Represent these elements as E = (E1, E2 …, En).

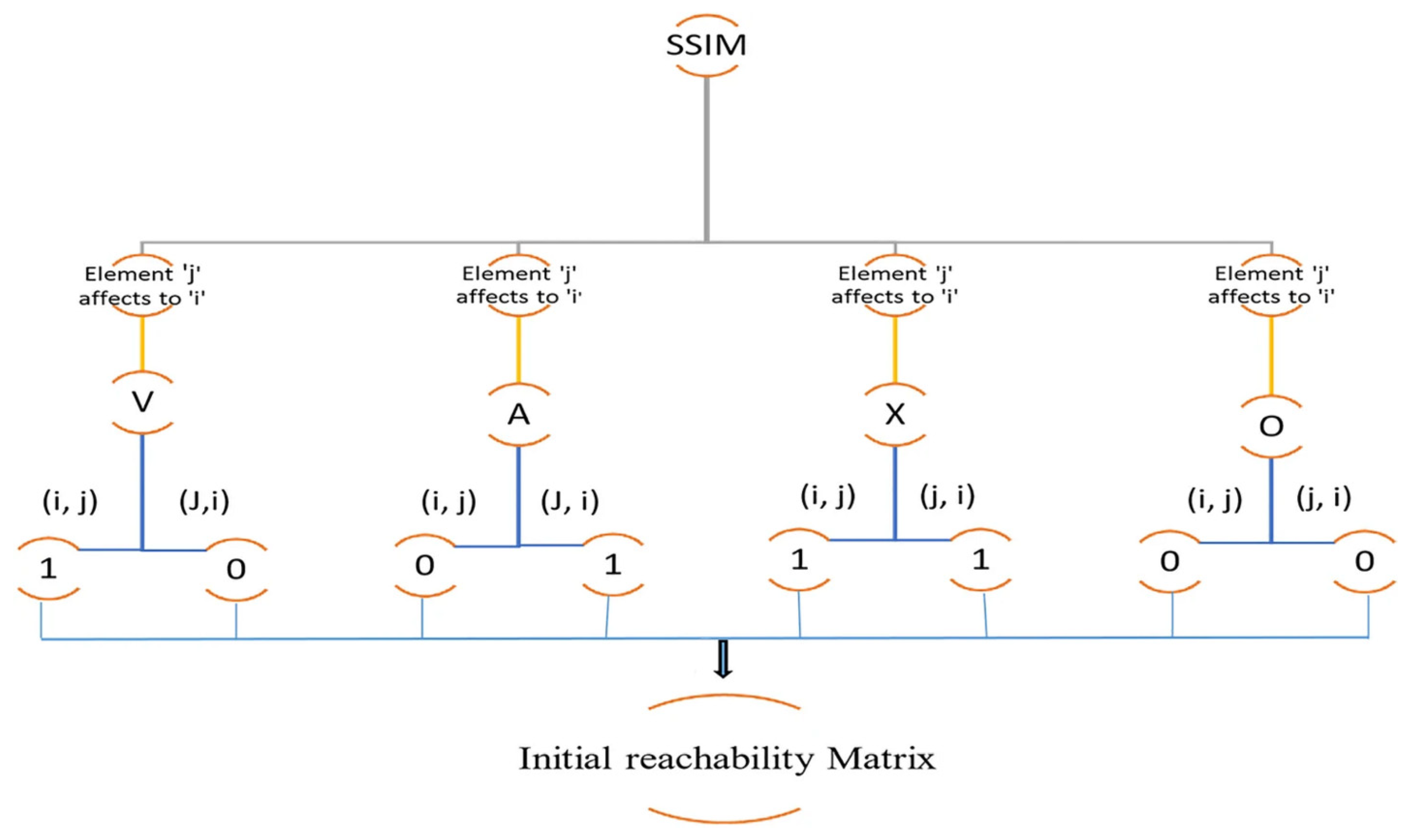

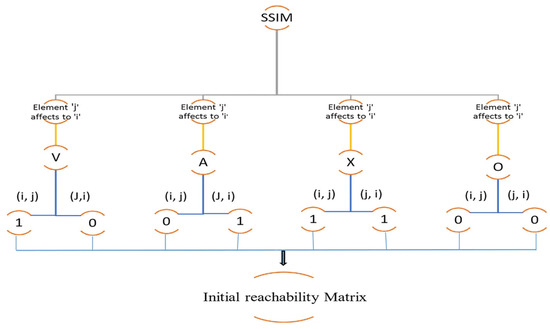

Define Relationships (R) through SSIM: Define the relationships between the identified elements. Represent these relationships as R = (), where represents the relationship between element Ei and element Ej. Mainly, there are four kinds of relationships between elements, denoted with V, A, X, and O, where:

V: influences ;

A: influences ;

X: and influences each other;

O: and have no relationship.

The experts mentioned above in the Delphi method were requested again to complete the SSIM according to the adoption state of LCM in green tech projects of the Chinese automotive industry. The SSIM results are shown in Table 3.

Table 3.

SSIM.

Formulate Reachability Matrix (A): Create a reachability matrix based on the defined relationships. The reachability matrix (A) is a binary matrix representing the reachability of one element from another. If can influence then = 1; otherwise, = 0. Further, the rules for converting SSIM into the reachability matrix (A) are also shown in Figure 4. Moreover, the initial reachability matrix can be found in Table 4.

Figure 4.

Transformation of SSIM into IRM through Binary Rules.

Table 4.

Initial Reachability Matrix.

Check for Transitivity and Reflexivity: Check the relationship matrix for transitivity and reflexivity. Transitivity means if is related to and is related to , then must also be related to Reflexivity means elements are related to themselves ( = 1).

Final Reachability matrix: Calculate the final reachability matrix (T) using the Warshall algorithm or Floyd’s algorithm. The reachability matrix shows the direct and indirect relationships between elements.

= or .

Further, the final reachability matrix can be found in Table 5.

Table 5.

Final Reachability Matrix.

Extracting levels through partition: After the development of the final reachability matrix, the next step is to extract different levels through partitions as shown in Table 6.

Table 6.

Level partitions.

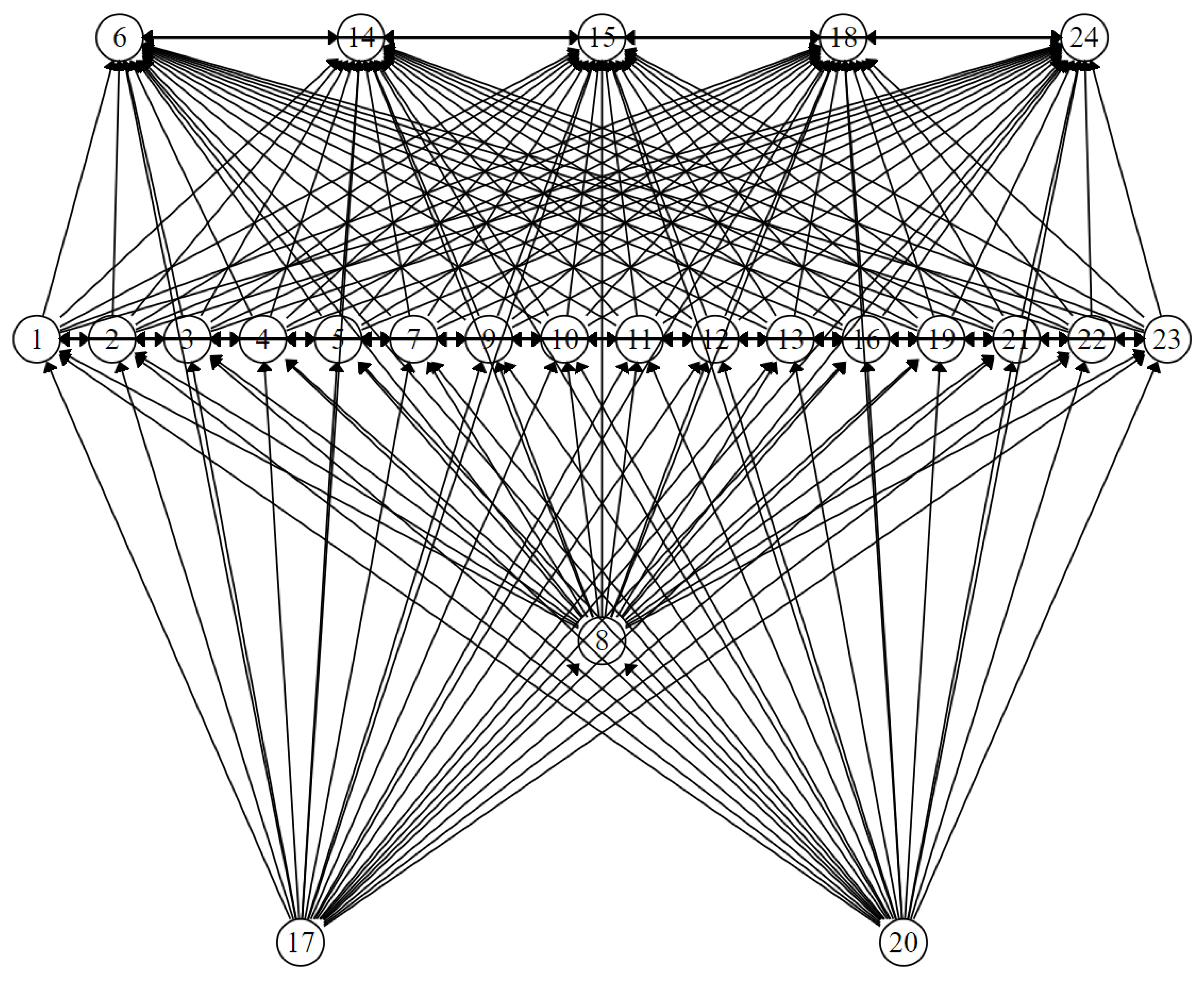

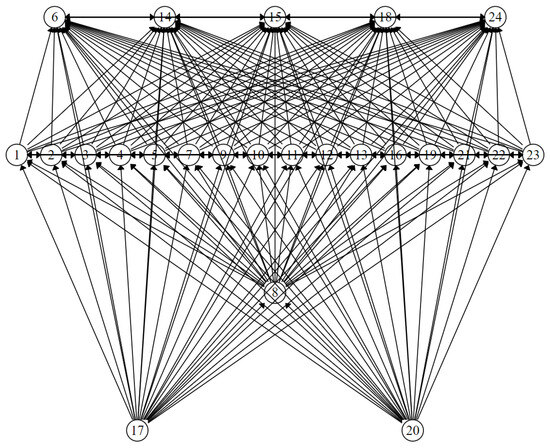

Generate the Digraph: Create a directed graph (digraph) based on the reachability matrix. In the graph, nodes represent elements and directed edges represent the relationships between elements. The diagraph for LCM challenges is shown in Figure 5.

Figure 5.

Diagraph of LCM challenges.

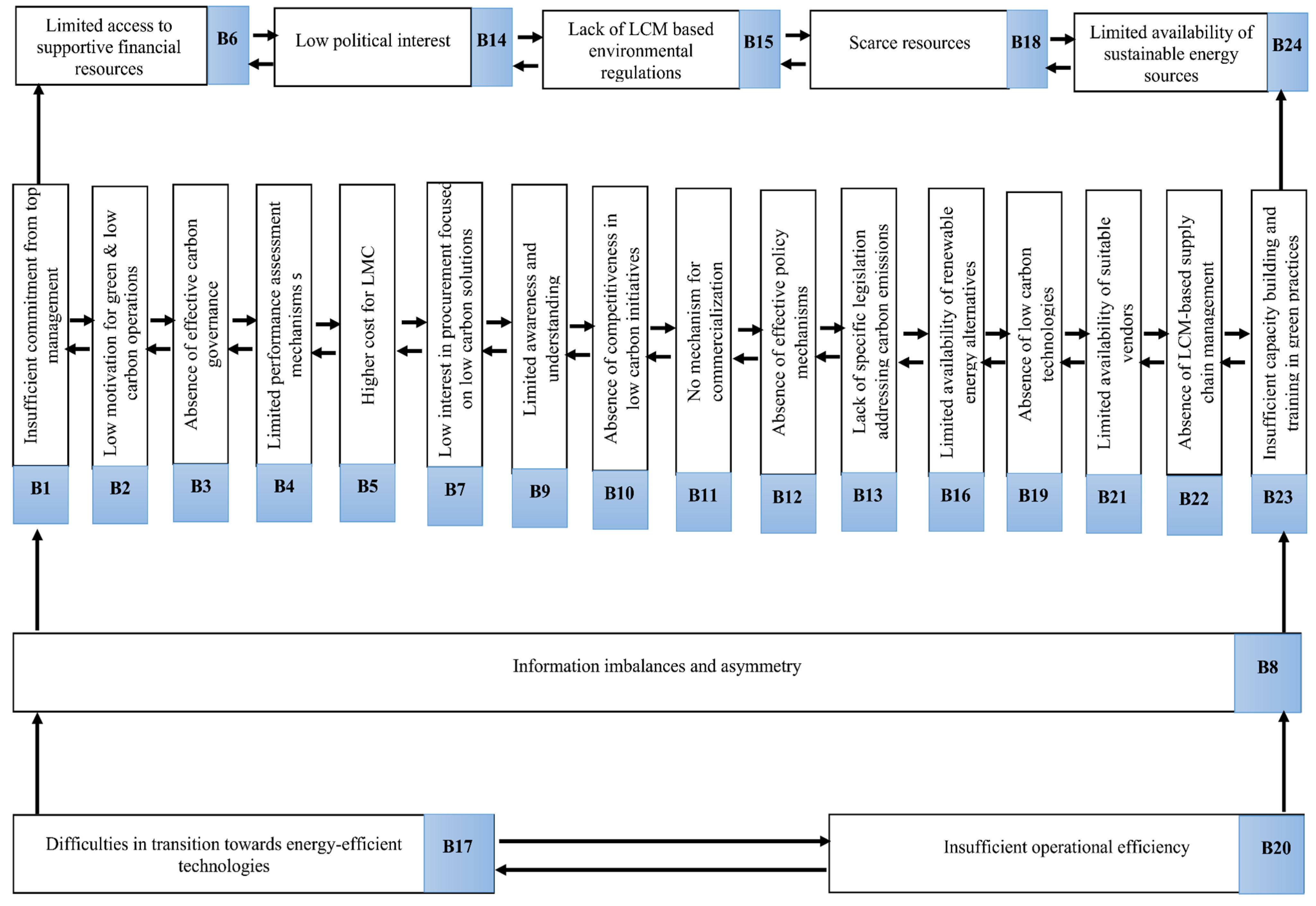

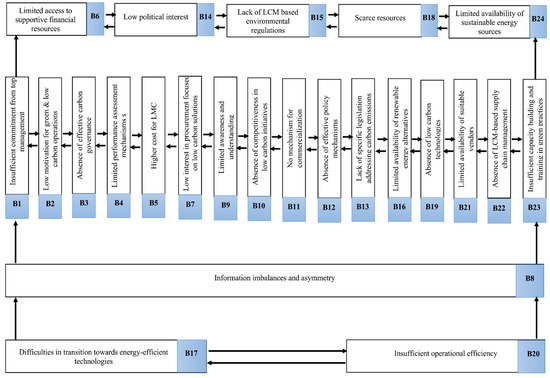

Draw the ISM Graph: Analyze the digraph and draw the ISM graph. Identify clusters of elements that are closely related and arrange them hierarchically. Finally, an ISM-based model of LCM challenges is shown in Figure 6.

Figure 6.

ISM model of LCM in green tech projects of the automotive industry.

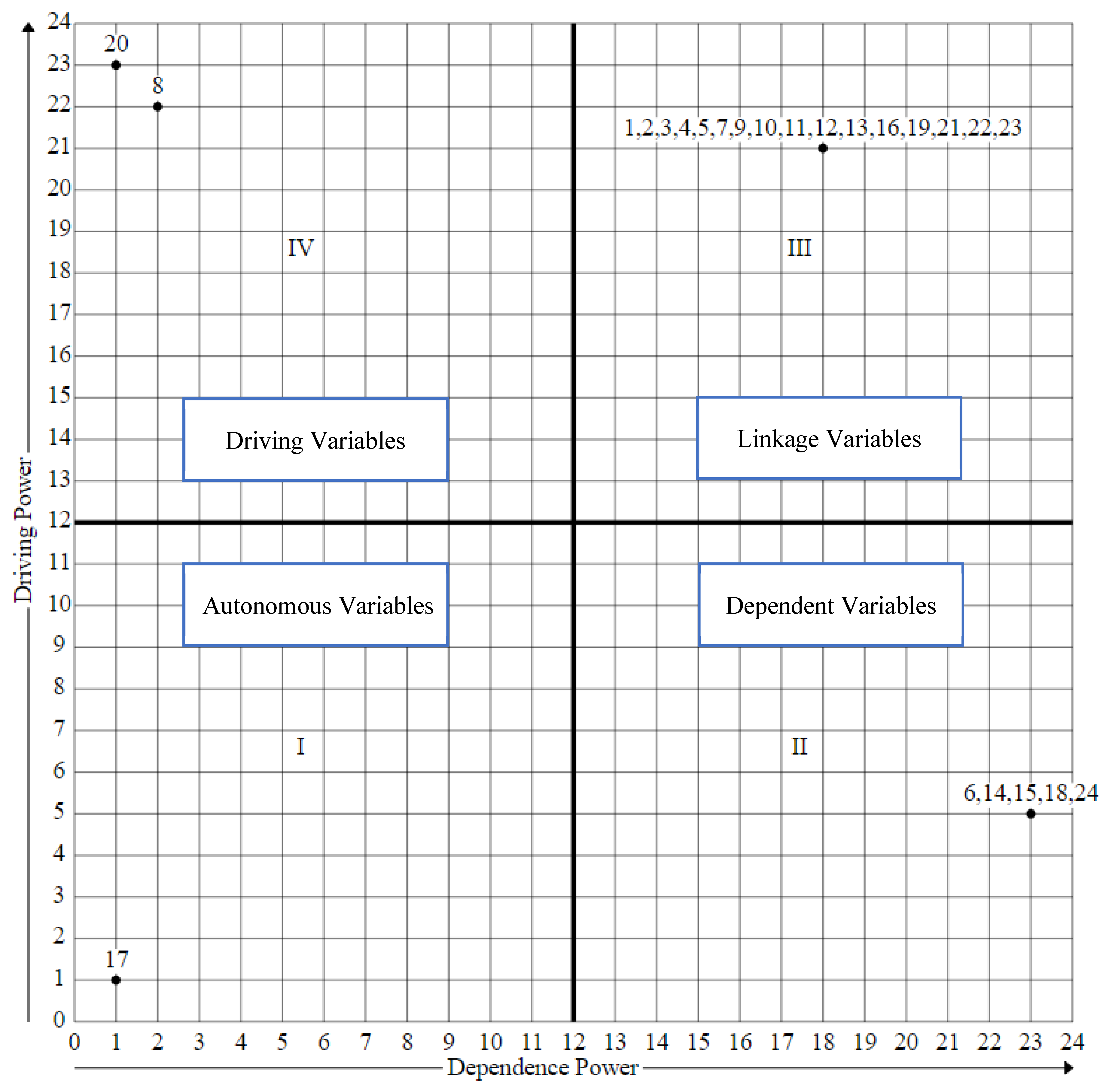

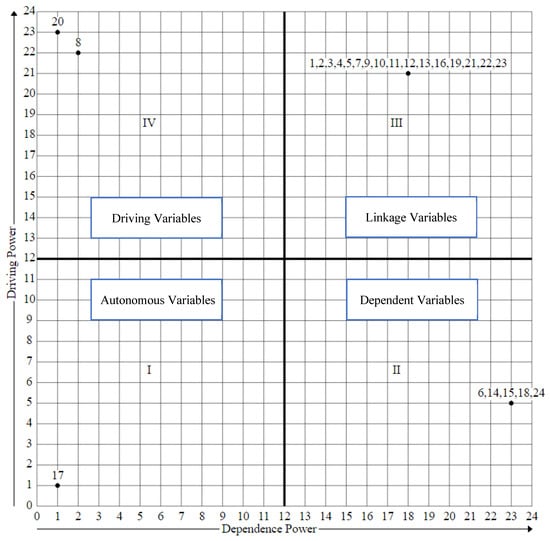

3.3. MICMAC Analysis (Step 3)

MICMAC analysis is used to categorize the factors of a system according to their importance and severity. This study applied MICMAC analysis by following the guidelines of Can Saglam [31].

Calculation of driving and dependence through Impact Matrix (I): Identify the elements in the system and create a square matrix where represents the impact of element i on element j. This matrix captures the driving and dependence strength between elements. Then, Square the Impact Matrix (I²) by multiplying the impact matrix I with itself to obtain the squared matrix I2 = I × I.

Classify the Elements: Classify the elements based on their impact and dependence using the following formulas:

- Independent/Drivers (A): Sum of elements in the corresponding column of I2 matrix, excluding diagonal ( for each i).

- Linkages (B): Sum of both row and column elements, excluding diagonal ( for each i).

- Dependent (C): Sum of elements in the corresponding row of I2 matrix, excluding diagonal ( for each i).

- Autonomous (D): Diagonal elements in I2 matrix (= for all i).

Interpret the Results: Analyze the classifications (A, B, C, and D) to understand the influence and dependence relationships between elements in the system.

Findings of MICMAC analysis are shown in Figure 7. In which two challenges (20,8) were placed in the independent/driving challenges, sixteen challenges (1,2,3,4,5,7,9,10,11,12,13,16,19,21,22,23) were placed in the linkage category, five challenges (6,14,15,18,24) were placed in the dependent category, and one challenge (17) was emerged in the autonomous category.

Figure 7.

MICMAC analysis of LCM in green tech projects of the Chinese automotive industry.

4. Results and Discussion

Based on the results of the ISM model, different challenges have been placed at different levels. Mainly, four levels were derived from the ISM model. Two challenges were identified at the first level, named “Difficulties in transition towards energy-efficient technologies-B17”, and “Insufficient operational efficiency–B20”. Further, one challenge was placed at the second level which is “Information imbalance and asymmetry”. At the third level, a total of sixteen challenges (B1, B2, B3, B4, B5, B7, B9, B10, B11, B12, B13, B16, B19, B21, B22, B23) were placed, which are more relevant to the lack of low-carbon-related policymaking by both organizations and government. Five challenges were placed at the fourth, which is the last level of the ISM model.

Difficulties in transition towards energy efficient technologies (B17) and insufficient operational efficiency (B20) were the most significant challenges arising at the first level of the ISM model. These challenges are the root cause of other major obstacles while implementing LCM in high tech projects of the Chinese automobile industry. Transitioning towards energy-efficient technologies and adopting LCM in the Chinese automotive industry presents unique challenges. It requires strategic planning, innovation, collaboration, and a proactive approach to overcome the challenge of transition towards energy-efficient technologies [33]. Allocation of government funds to research institutions and companies working on energy-efficient technologies and encouraging innovation and development might foster the adoption of LCM. By implementing different strategies (e.g., policy framework and regulatory support for energy efficient technologies, R&D, supply chain optimization, and international collaboration) and fostering a supportive ecosystem, the Chinese automotive industry can overcome the difficulties associated with transitioning towards energy-efficient technologies and LCM [29]. Continuous collaboration between the government, industry, research institutions, and international partners is essential for driving sustainable change and ensuring a greener future for the automotive sector. China has implemented various policies and initiatives to promote energy-efficient technologies and reduce carbon emissions, e.g., China’s 13th Five-year Plan (2016–2020) and 14th Five-year Plan (2021–2025) emphasize green development, low-carbon technologies, and energy efficiency across various sectors, including industry, transportation, construction, and automotive. Further, under these programs, the Five-Year Plan for Energy Conservation and Emission Reduction (2016–2020) also outlines targets for reducing energy intensity and carbon emissions. It emphasizes the development and utilization of clean and renewable energy sources [33,34].

Insufficient operational efficiency (B20) in high tech projects can be complex and multifaceted. For improving operational efficiency in high-tech projects, China needs to invest in comprehensive project planning, outlining clear goals, timelines, and milestones, and to utilize project management software to track progress and identify bottlenecks. Further, implementation of advanced project management tools, e.g., agile project management, allows for flexibility, continuous feedback, and iterative development. This is particularly useful for complex and rapidly evolving green tech projects. China’s automotive industry is a global leader in manufacturing, producing over 25 million vehicles in 2020, and is a major contributor and consumer of electric vehicles (EVs) with 1.3 million EVs sold in 2020 [35]. This ratio is increasing and, therefore, implementing Industry 4.0 initiatives and incorporating IoT devices and data analytics for predictive maintenance and real-time production monitoring might also improve operational efficiency [36].

Information imbalance and asymmetry (B8) emerged at the second level of the ISM model, causing a major obstacle towards the adoption of LCM in high-tech projects of the automotive industry. The Chinese automotive industry, particularly in green tech projects, faces a major challenge concerning information imbalance and asymmetry. While the industry is rapidly advancing in electric vehicles (EVs) and sustainable technologies, there is a significant gap in information dissemination. State-driven initiatives and significant investments have propelled China to become the world’s largest market for electric cars in the last five years [35]. However, due to the absence of comprehensive and transparent data, there is an information gap between what the government and major industry players know about green tech advancements and what is accessible to the public and smaller enterprises. This imbalance hinders the efficient dissemination of knowledge critical for the growth of the sector, potentially hindering collaborative efforts and innovation. Addressing this disparity is essential for fostering a more inclusive and knowledge-sharing environment in China’s green tech automotive projects [37].

At the third level of ISM, sixteen challenges were identified including B1, B2, B3, B4, B5, B7, B9, B10, B11, B12, B13, B16, B19, B21, B22, and B23. These challenges created a linkage between bottom-level challenges and top-level challenges. At this level, mainly, management, policy and cost related challenges emerged. The Chinese automotive industry encounters significant management and policy-related obstacles in adopting LCM methods in green tech projects. Despite China’s progress in green technology, the adoption of LCM techniques demands extensive managerial restructuring and financial investment. As per a report from the International Energy Agency, China’s industrial sector was responsible for over 60% of its total energy consumption and approximately 65% of the nation’s carbon dioxide emissions in 2020 [38]. Transformation towards LCM necessitates overcoming managerial and policy challenges related to integrating new technologies, developing standards and regulations, reorganizing supply chains, and providing workforce training. Additionally, data from the China Association of Automobile Manufacturers reveals that in 2020, China manufactured more than 25 million passenger cars and approximately 4 million commercial vehicles, underscoring the immense challenge of transforming such a vast and intricate industry [39]. Effective management strategies focusing on technology integration, skill development, and supply chain optimization are vital to successfully address these challenges and facilitate the adoption of low-carbon manufacturing practices in China’s automotive sector.

At the fourth level of the ISM model for LCM in green tech projects of the automotive industry, five challenges including B6, B14, B15, B18, and B24 were identified. These challenges are the least important and their role in the adoption of LCM in the automotive industry is less; therefore, automotive companies are less interested to overcome these challenges. These results were surprising. Challenges at this level are more related to politics and resources. China is a country equipped with plenty of resources; therefore, resource availability is not a main hurdle to the adoption of LCM. Despite China’s stated commitment to green initiatives, challenges arise due to inconsistencies in policies and variations in enforcement across regions. The World Bank’s report highlights how China’s political landscape often lacks policy coherence, making it difficult to efficiently execute environmentally friendly policies. Moreover, the influence exerted by state-owned enterprises, pivotal players in the automotive sector, can affect the prioritization and implementation of green manufacturing technologies. In 2020, China’s State-Owned Assets Supervision and Administration Commission disclosed that central government-owned enterprises generated revenue exceeding CNY 26 trillion (approximately USD 3.85 trillion), underscoring their substantial influence. Overcoming these political complexities necessitates strategic policy reforms, transparent governance, and consistent enforcement mechanisms to ensure the widespread adoption of low-carbon manufacturing practices in China’s automotive sector.

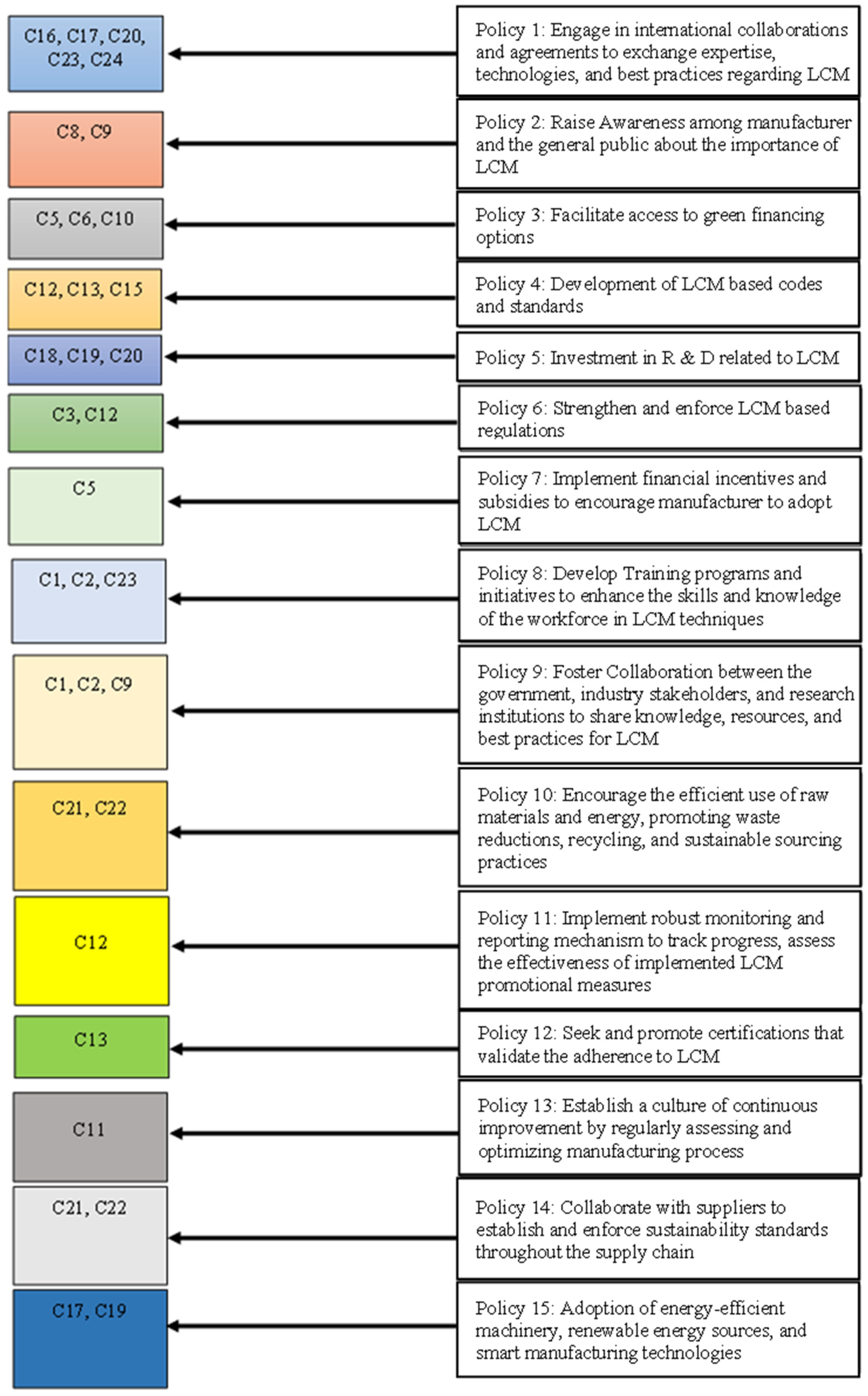

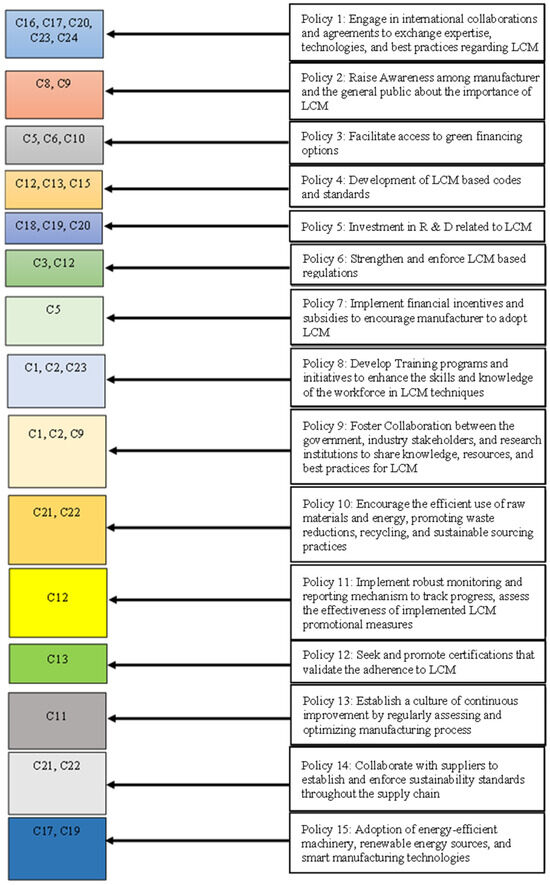

Based on the above-mentioned results and discussion, experts who have been part of the study were contacted again to suggest relevant strategies to overcome challenges to LCM. Initially, different strategies were discussed to handle challenges of LCM in automotive industry. After the consensus of those strategies, experts were asked to mark relevant challenges that can be overcome through different strategies. Experts were given different clusters of barriers and the proposed strategies and asked to match them. Based on the discussion, we finalized the set of suggested strategies in the form of a figure that is shown in Figure 8.

Figure 8.

Proposed strategies to overcome LCM challenges.

5. Conclusions

This study sheds light on the complexities and challenges faced in the adoption of LCM within the Chinese automotive industry, particularly in the context of green tech projects. This study is an initial attempt in promoting sustainable practices and environmentally friendly technologies, emphasizing the significant hurdles encountered during this transformative process.

The findings highlight the multifaceted challenges including difficulties in transition towards energy efficient technologies, insufficient operational efficiency, and information imbalances and asymmetry, which were the most critical challenges that hinder the adoption of LCM initiatives. Despite these challenges, the research underscores the critical importance of sustainable manufacturing in mitigating environmental impact, reducing carbon emissions, and fostering eco-friendly innovations within the automotive sector. Lastly, the establishment of strict laws that obligate automotive companies to maintain levels of pollution that are globally accepted and that do not affect the growth of output in China is necessary because some countries accept certain levels of pollution to maintain the growth of domestic product.

6. Practical Implications and Future Research Directions

As the global community increasingly emphasizes sustainable practices, the insights from this research provide valuable implications for policymakers, industry leaders, and stakeholders. Firstly, addressing the identified challenges demands collaborative efforts from relevant authorities, government, automotive companies, and research institutions to create conducive environments for green tech projects to flourish. By embracing energy efficient and innovative technologies, adopting supportive policies, and investing in R&D, the Chinese automotive sector can overcome these challenges and pave the way for a greener, more sustainable future.

Secondly, by embracing LCM in the automotive sector, companies might develop more appropriate strategies in combating climate change and environmental issues. More informed strategies might be developed to meet global targets such as contributions towards the UN-SDGs. Automotive companies should highlight these indicators in their annual reports as information imbalance was one of the main hurdles towards the adoption of LCM. Global ESG standards should be practiced. Further, information systems within the organizations should be strengthened as regulatory updates and complexities are needed to be shared among employees periodically. It will increase awareness and understanding of LCM among employees, and they will not be hesitant to adopt LCM in operational activities of green tech projects.

Lastly, findings of the study are useful for different stakeholder groups including investors, consumers, NGOs, and relevant environmental authorities. Investors are interested to invest in firms that are more inclined towards greener and LCM-based operations. Further, integrating LCM demonstrates firms’ interests in green decision-making, which will further attract investment and increase competitiveness. Consumers are also becoming more environmentally concerned these days and prefer products manufactured in an eco-friendly manner. Society, community, and work-based organizations and environmental authorities might leverage results of the study to develop appropriate policies and reforms to make the automotive sector more accountable for their GHG and environmental footprints.

In essence, this research article serves as a crucial reference point, guiding the industry towards the LCM paradigm, thereby contributing significantly to the global agendas aimed at building a greener and environmentally responsible automotive sector.

Despite significant findings, this study is associated with some limitations and proposes different future research directions accordingly. First, this study is based on challenges to LCM in green tech projects of automotive companies in China; however, the same context might be applied by using the same methodology in other sectors or industries such as the textile industry, beverages industry, healthcare industry etc. Secondly, these data were based on the experts’ opinions; therefore, future studies might conduct surveys to capture more in-depth responses. Thirdly, this study considered 24 challenges in adopting LCM; further studies might consider more or less challenges according to their scenario and research problem. Lastly, the ISM-MICMAC approach provides a hierarchal structure and clusters of different challenges to LCM; however, the relationship between variables in the hierarchal structure is not verified here; thus, future studies might incorporate structural equation modelling to verify the direct and indirect relationships between study variables.

Author Contributions

Methodology, validation, visualization, writing (reviewing and editing), funding acquisition, resources: H.Y. Conceptualization, project administration, supervision, Writing—review and editing: Y.Z. Software, data curation, formal analysis, writing—original draft preparation: N.A. All authors have read and agreed to the published version of the manuscript.

Funding

Research on the Implementation Path of Integrating Carbon Peak and Carbon Neutrality into the Overall Layout of Ecological Civilization Construction (No. 22CKS051).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yao, L.; Tan, S.; Xu, Z. Towards carbon neutrality: What has been done and what needs to be done for carbon emission reduction? Environ. Sci. Pollut. Res. 2023, 30, 20570–20589. [Google Scholar] [CrossRef]

- Li, W.; Zhang, S.; Lu, C. Research on the driving factors and carbon emission reduction pathways of China’s iron and steel industry under the vision of carbon neutrality. J. Clean. Prod. 2022, 361, 132237. [Google Scholar] [CrossRef]

- Böttcher, C.F.; Müller, M. Drivers, practices and outcomes of low-carbon operations: Approaches of German automotive suppliers to cutting carbon emissions. Bus. Strategy Environ. 2015, 24, 477–498. [Google Scholar] [CrossRef]

- Su, Y.; Xu, G.J. Low-carbon transformation of natural resource industry in China: Determinants and policy implications to achieve COP26 targets. Resour. Policy 2022, 79, 103082. [Google Scholar] [CrossRef]

- Akram, R.; Chen, F.; Khalid, F.; Ye, Z.; Majeed, M.T. Heterogeneous effects of energy efficiency and renewable energy on carbon emissions: Evidence from developing countries. J. Clean. Prod. 2020, 247, 119122. [Google Scholar] [CrossRef]

- Finon, D.J. Carbon policy in developing countries: Giving priority to non-price instruments. Energy Policy 2019, 132, 38–43. [Google Scholar] [CrossRef]

- Li, J. Charging Chinese future: The roadmap of China’s policy for new energy automotive industry. Int. J. Hydrog. Energy 2020, 45, 11409–11423. [Google Scholar] [CrossRef]

- Mao, S.; Zhang, Y.; Bieker, G.; Rodriguez, F. Zero-emission bus and truck market in China: A 2021 update. Work. Pap. Int. Counc. Clean Transp. 2023, 4. [Google Scholar]

- GlobalData. Electric Vehicle (EV) Charging Infrastructure Market Size, Trends and Analysis by Region, Level, Power and Segment Forecast to 2030. Available online: https://www.globaldata.com/store/report/ev-charging-infrastructure-market-analysis/ (accessed on 27 June 2023).

- Liu, Y. Barriers to the adoption of low carbon production: A multiple-case study of Chinese industrial firms. Energy Policy 2014, 67, 412–421. [Google Scholar] [CrossRef]

- Kannan, D.; Solanki, R.; Kaul, A.; Jha, P. Barrier analysis for carbon regulatory environmental policies implementation in manufacturing supply chains to achieve zero carbon. J. Clean. Prod. 2022, 358, 131910. [Google Scholar] [CrossRef]

- Giampieri, A.; Ling-Chin, J.; Taylor, W.; Smallbone, A.; Roskilly, A. Moving towards low-carbon manufacturing in the UK automotive industry. Energy Procedia 2019, 158, 3381–3386. [Google Scholar] [CrossRef]

- Lin, D.; Lee, C.K.; Lau, H.; Yang, Y. Strategic response to Industry 4.0: An empirical investigation on the Chinese automotive industry. Ind. Manag. Data Syst. 2018, 118, 589–605. [Google Scholar] [CrossRef]

- Guo, S.; Ma, H. Will companies take the initiative in green technology innovation? Empirical evidence from listed manufacturing companies in China. Appl. Econ. 2023, 55, 636–652. [Google Scholar] [CrossRef]

- Gao, M.; Li, Z.; Zhang, L. Analysis on the Development of China's New Energy Automobile Industry in the Era of Low-carbon Economy. Int. Core J. Eng. 2022, 8, 888–892. [Google Scholar]

- NikkeiAsia. China’s Biggest Green Tech Projects in Southeast Asia. 2023. Available online: https://asia.nikkei.com/Spotlight/The-Big-Story/China-s-biggest-green-tech-projects-in-Southeast-Asia (accessed on 4 October 2023).

- de Sousa Jabbour, A.B.L.; Chiappetta Jabbour, C.J.; Sarkis, J.; Gunasekaran, A.; Furlan Matos Alves, M.W.; Ribeiro, D.A. Decarbonisation of operations management–looking back, moving forward: A review and implications for the production research community. Int. J. Prod. Res. 2019, 57, 4743–4765. [Google Scholar] [CrossRef]

- Ohene, E.; Chan, A.P.; Darko, A. Prioritizing barriers and developing mitigation strategies toward net-zero carbon building sector. Build. Environ. 2022, 223, 109437. [Google Scholar] [CrossRef]

- Shen, L.; Wu, Y.; Lou, Y.; Zeng, D.; Shuai, C.; Song, X. What drives the carbon emission in the Chinese cities?—A case of pilot low carbon city of Beijing. J. Clean. Prod. 2018, 174, 343–354. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, X.; Chen, F. Do carbon emission trading schemes stimulate green innovation in enterprises? Evidence from China. Technol. Forecast. Soc. Change 2021, 168, 120744. [Google Scholar] [CrossRef]

- Singh, S.; Jindel, J.; Tikkiwal, V.A.; Verma, M.; Gupta, A.; Negi, A.; Jain, A. Electric vehicles for low-emission urban mobility: Current status and policy review for India. Int. J. Sustain. Energy 2022, 41, 1323–1359. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Y.; Song, Q.; Qi, Y. Low-carbon governance in China–Case study of low carbon industry park pilot. J. Clean. Prod. 2018, 174, 837–846. [Google Scholar] [CrossRef]

- Vimal, K.E.K.; Kumar, A.; Sunil, S.M.; Suresh, G.; Sanjeev, N.; Kandasamy, J. Analysing the challenges in building resilient net zero carbon supply chains using Influential Network Relationship Mapping. J. Clean. Prod. 2022, 379, 134635. [Google Scholar] [CrossRef]

- de Leon Barido, D.P.; Suffian, S.; Kammen, D.M.; Callaway, D. Opportunities for behavioral energy efficiency and flexible demand in data-limited low-carbon resource constrained environments. Appl. Energy 2018, 228, 512–523. [Google Scholar] [CrossRef]

- Sindhwani, R.; Singh, P.L.; Behl, A.; Afridi, M.S.; Sammanit, D.; Tiwari, A.K. Modeling the critical success factors of implementing net zero emission (NZE) and promoting resilience and social value creation. Technol. Forecast. Soc. Change 2022, 181, 121759. [Google Scholar] [CrossRef]

- Bike, Z.; Ruichang, W. Construction of equipment evaluation index system of emergency medical rescue based on Delphi method and analytic hierarchy process. Ain Shams Eng. J. 2023, 14, 101870. [Google Scholar] [CrossRef]

- Hussain, K.; He, Z.; Ahmad, N.; Iqbal, M.; Saeed, M.Z. Establishing a Green, Lean and Six Sigma implementation model for sustainable construction industry: An analysis of driving forces through ISM-MICMAC approach. Environ. Sci. Pollut. Res. 2023, 30, 30462–30492. [Google Scholar] [CrossRef]

- Bux, H.; Zhang, Z.; Ahmad, N. Promoting sustainability through corporate social responsibility implementation in the manufacturing industry: An empirical analysis of barriers using the ISM-MICMAC approach. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 1729–1748. [Google Scholar] [CrossRef]

- Iqbal, M.; Ma, J.; Ahmad, N.; Ullah, Z.; Hassan, A. Energy-Efficient supply chains in construction industry: An analysis of critical success factors using ISM-MICMAC approach. Int. J. Green Energy 2023, 20, 265–283. [Google Scholar] [CrossRef]

- Ullah, S.; Jianjun, Z.; Hayat, K.; Palmucci, D.N.; Durana, P. Exploring the factors for open innovation in post-COVID-19 conditions by fuzzy Delphi-ISM-MICMAC approach. Eur. J. Innov. Manag. 2023. [Google Scholar] [CrossRef]

- Can Saglam, Y. Fostering supply chain agility by prominent enablers’ identification and developing conceptual modeling based on the ISM-MICMAC approach. J. Model. Manag. 2023. [Google Scholar] [CrossRef]

- Bianco, D.; Godinho Filho, M.; Osiro, L.; Ganga, G.M.D.; Tortorella, G.L. The driving and dependence power between Lean leadership competencies: An integrated ISM/fuzzy MICMAC approach. Prod. Plan. Control 2023, 34, 1037–1061. [Google Scholar] [CrossRef]

- Fang, G.; Lu, L.; Tian, L.; He, Y.; Bai, Y. Can China achieve the energy-saving and emission reducing objectives during the “13th Five-Year-Plan”?—A systematic evolutionary analysis. J. Clean. Prod. 2020, 262, 121256. [Google Scholar] [CrossRef]

- Stern, N.; Xie, C. China’s new growth story: Linking the 14th Five-Year Plan with the 2060 carbon neutrality pledge. J. Chin. Econ. Bus. Stud. 2023, 21, 5–25. [Google Scholar] [CrossRef]

- Mazzocco, I. China’s Electric Vehicle Industry’s Internationalization. 2023. Available online: https://www.csis.org/analysis/chinas-electric-vehicle-industrys-internationalization (accessed on 10 November 2023).

- Bhagwan, N.; Evans, M. A review of industry 4.0 technologies used in the production of energy in China, Germany, and South Africa. Renew. Sustain. Energy Rev. 2023, 173, 113075. [Google Scholar] [CrossRef]

- Liu, J.; Liu, G.; Cui, H.; Chen, Y. The Chinese automobile industry’s research and development capability and innovative performance. Front. Psychol. 2023, 13, 1093305. [Google Scholar] [CrossRef]

- IEA. An Energy Sector Roadmap to Carbon Neutrality in China. Available online: https://www.iea.org/reports/an-energy-sector-roadmap-to-carbon-neutrality-in-china (accessed on 10 November 2023).

- CounterPoint. Insights Tag: Automotive Industry. Available online: https://www.counterpointresearch.com/insights_tag/automotive-industry/ (accessed on 10 November 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).