Characterization and Quantitative Assessment of Shale Fracture Characteristics and Fracability Based on a Three-Dimensional Digital Core

Abstract

:1. Introduction

2. Extraction of Fractures Based on Three-Dimensional Digital Core of Shale

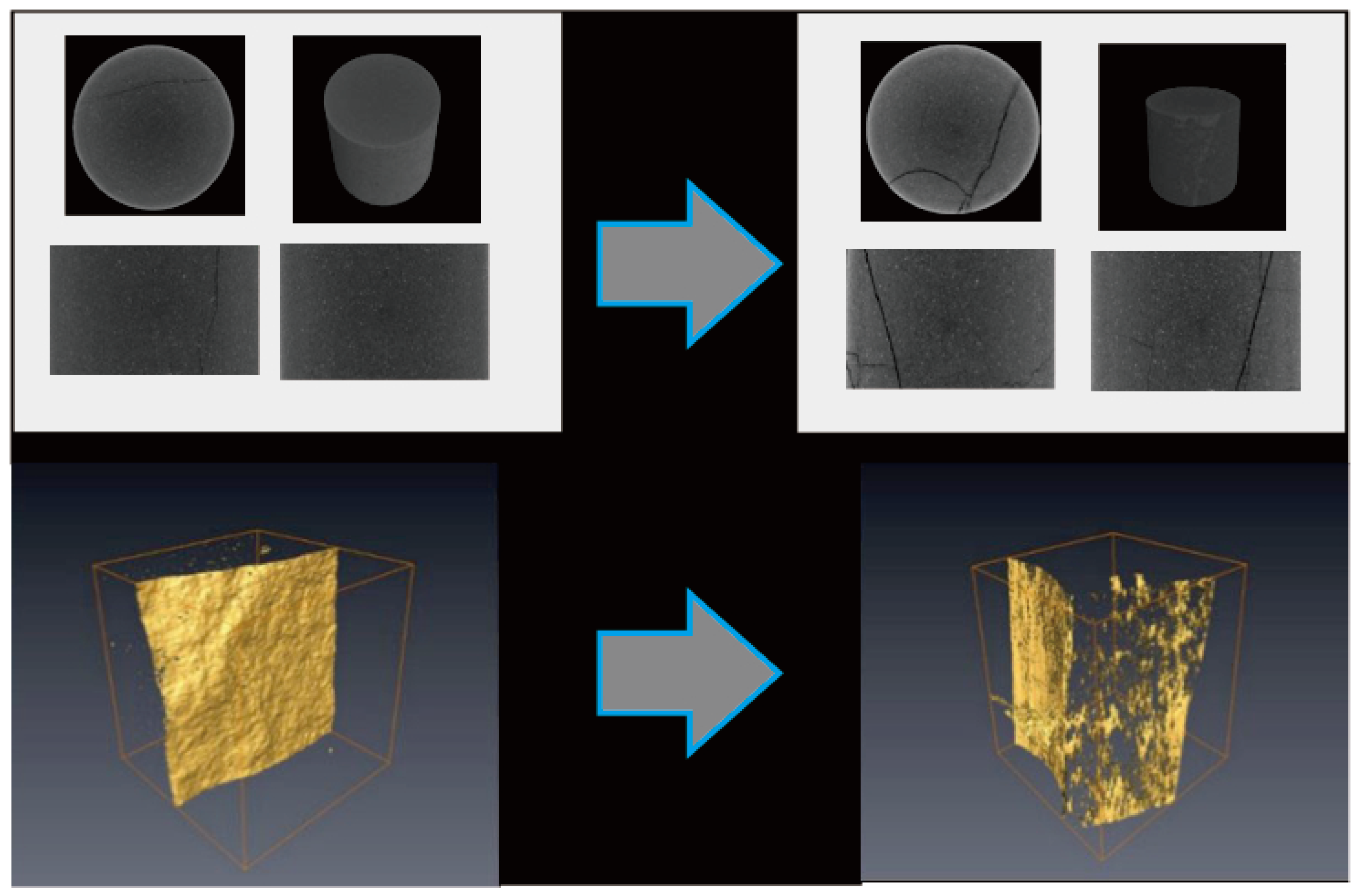

2.1. Construction of Pre- and Post-Fracturing Three-Dimensional Digital Cores Using CT Scanning

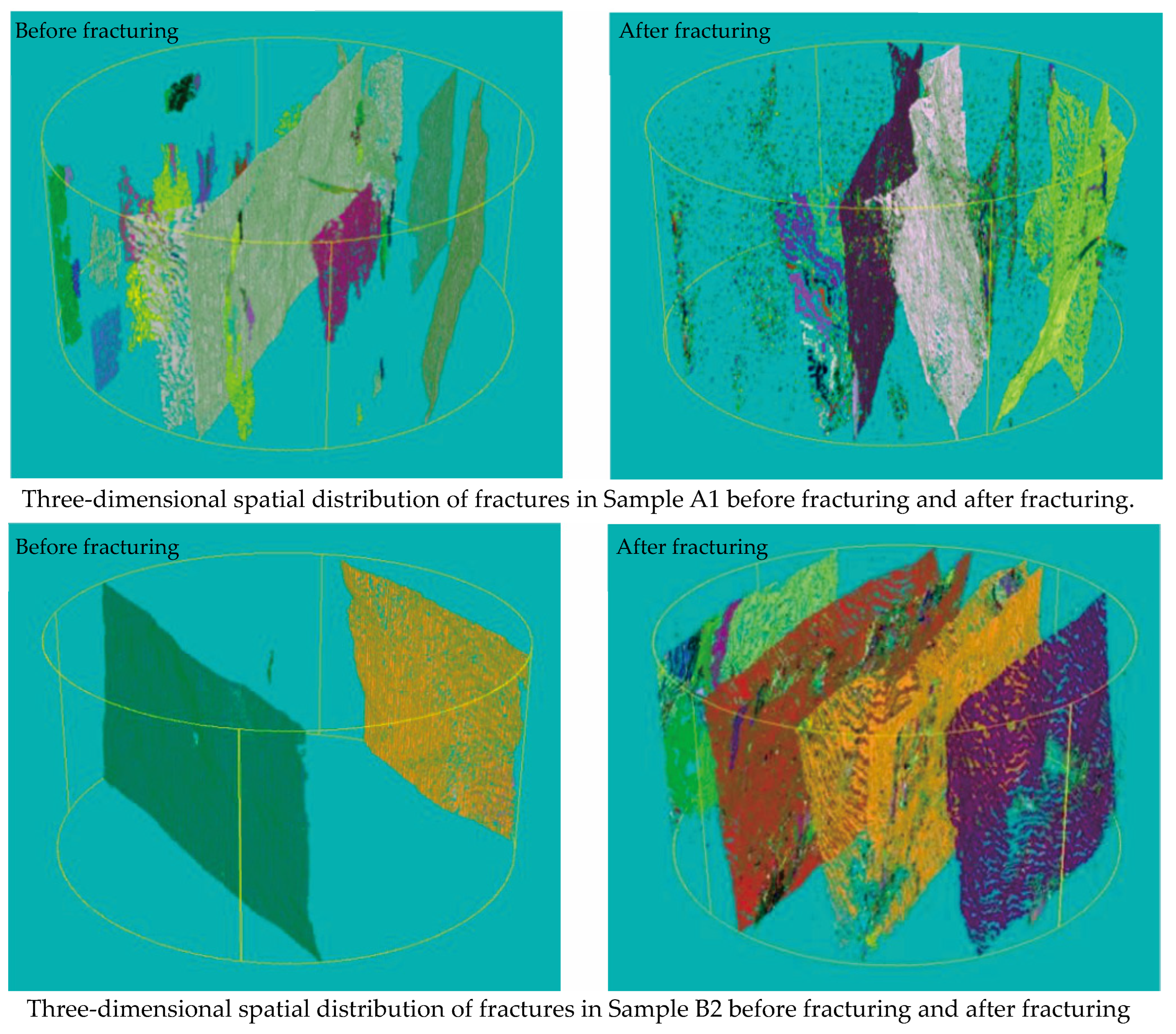

2.2. Quantitative Characterization of Three-Dimensional Fracture Distribution in Space

- (1)

- Three-dimensional shape factorwhere Vp represents the target volume, and Sp represents the target surface area. When the value of F approaches 1, the target becomes closer to a sphere. Therefore, targets that satisfy F < 0.05 have planar characteristics, possibly indicating fractures, which should be retained.

- (2)

- Equivalent sphere radius and minimum circumscribed sphere radius

- (3)

- Ratio of the longest and shortest sides of the approximately minimum circumscribed cuboid:

- (1)

- Calculation of the fitting plane:

- (2)

- Approximate height of the minimum circumscribed cuboid:

- (3)

- Approximate length of the minimum circumscribed cuboid

- (4)

- Approximate width of the minimum circumscribed cuboid

3. Quantitative Study on the Formation Potential of Effective Fracture Network Based on Post-Fracturing Three-Dimensional Fracture Complexity

3.1. Factors Affecting Three-Dimensional Fracture Complexity

3.2. Quantitative Characterization Method for Three-Dimensional Fracture Complexity

- ①

- Normalization

- ②

- ③

- Combination weighting: Assuming Wi as the subjective weight and Ki as the objective weight, the distance function between them is defined as:

- ④

- Simple linear weighting method for determining the coefficient of three-dimensional fracture complexity is formulated in the following function:

3.3. Study on Quantitative Characterization of Shale Fracability

4. Application and Verification of Shale Fracability Characterization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, X.S.; Sun, Z.T.; Yang, T.T. Global progress in exploration and development of unconventional hydrocarbons and assessment of resources potential. Mar. Geol. Front. 2020, 36, 1–17. [Google Scholar] [CrossRef]

- Tian, F.; Fu, Y.; Liu, X.; Li, D.; Jia, Y.; Shao, L.; Yang, L.; Zhao, Y.; Zhao, T.; Yin, Q.; et al. A Comprehensive Evaluation of Shale Oil Reservoir Quality. Processes 2024, 12, 472. [Google Scholar] [CrossRef]

- Dou, L.B.; Yang, H.J.; Xiao, Y.J.; Gao, H.; Li, T.T.; Sun, H.B. Probability study of formation brittleness and new quantitative evaluation of fracability for shale reservoirs. Prog. Geophys. 2021, 36, 576–584. [Google Scholar]

- Liu, Y.; Chen, Z.; Ji, D.; Peng, Y.; Hou, Y.; Lei, Z. Pore Fluid Movability in Fractured Shale Oil Reservoir Based on Nuclear Magnetic Resonance. Processes 2023, 11, 3365. [Google Scholar] [CrossRef]

- Rickman, R.; Mullen, M.; Petre, E.; Grieser, B.; Kundert, D. A Practical Use of Shale Petrophysics for Stimulation Design Optimization: All Shale Plays Are Not Clones of the Barnett Shale. In Proceedings of the SPE Annual Technical Conference & Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Han, W.Z.; Dou, Y.; Li, H.D.; Zhang, W.; Shi, Z.N.; Dong, J.C. Optimization and application of brittleness evaluation methods for continental organic-rich shale: A case study of the 2nd Member of Kongjiadian Formation, Cangdong Sag, Bohai Bay Basin. Oil Drill. Prod. Technol. 2022, 44, 191–198. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Wang, G.W.; Song, L.T.; Wang, S.; Zhang, Y.L.; Huang, L.L.; Lai, J. Fracture logging identification and effectiveness analysis of shale reservoir of the Permian Fengcheng Formation in Mahu sag, Junggar Basin. J. Palaeogeogr. (Chin. Ed.) 2022, 24, 540–555. [Google Scholar]

- Chen, H.Z. Recognition and Study of Structural Fractures in Shale Reservoirs. Master’s Thesis, China University of Geosciences, Beijing, China, 2021. [Google Scholar]

- Fan, Y.R.; Li, X.G.; Yi, K.; Zhu, D.W.; Zhang, Q. Fracability Quantitative Interpretation of Shale Reservoir Based on Digital Core Technology. Well Logging Technol. 2017, 41, 685–690. [Google Scholar] [CrossRef]

- Jiang, L.M.; Sun, J.M.; Liu, X.F.; Wang, H.T. Numerical Study of the Effect of Natural Gas Saturation on the Reservoir Rocks’ Elastic Parameters. Well Logging Technol. 2012, 36, 239–243. [Google Scholar] [CrossRef]

- Jiang, L.M.; Yu, C.H.; Qi, B.Q.; Zhu, H.B.; Wang, Y.J. A novel saturation model of vuggy carbonate reservoirs and its application. Nat. Gas Geosci. 2017, 28, 1250–1256. [Google Scholar]

- Li, X.W.; Jiang, L.M.; Kou, X.P.; Luo, J.L.; Jie, L.B.; Jin, R.G. Determination of Gas-water Distribution in Reservoir Pore Using Lattice Boltzmann Method. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2017, 32, 49–54. [Google Scholar]

- Zhao, J.; Zhang, Y.; Zhang, M.; Mao, Z.; Wang, C.; Hu, R.; Yang, L.; Liu, Y. Research on Micro-Pore Structure and 3D Visual Characterization of Inter-Salt Shale Based on X-CT Imaging Digital Core Technology. Processes 2022, 10, 1321. [Google Scholar] [CrossRef]

- Xin Yu, X.Y.; John Kemeny, J.K.; Weidong Song, W.S.; Yuye Tan, Y.T. Progressive Fracturing of Rock/Backfill Specimens under Triaxial Compression—Experiments and Modeling. In Proceedings of the 55th U.S. Rock Mechanics/Geomechanics Symposium 2021, Houston, TX, USA, 18–25 June 2021. [Google Scholar]

- Zhou, X.; Han, L.; Bi, J.; Shou, Y. Experimental and numerical study on dynamic mechanical behaviors of shale under true triaxial compression at high strain rate. Int. J. Min. Sci. Technol. 2024, 34, 149–165. [Google Scholar] [CrossRef]

- Li, B.; Gong, J.; Long, Y.; Hu, H.; Cao, Y.-B. Experimental investigations on mechanical and failure behaviors of transversely isotropic shale containing twin fissures under true triaxial stresses. Arch. Appl. Mech. 2023, 93, 3205–3228. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhou, X.-P. 3D Digital Analysis of Cracking Behaviors of Rocks through 3D Reconstruction Model under Triaxial Compression. J. Eng. Mech. 2020, 146, 04020084. [Google Scholar] [CrossRef]

- Deng, Z.Q.; Teng, Q.Z. Three-dimensional Image-based Core Crack Automatig Recognition. Comput. Digit. Eng. 2013, 41, 98–100. [Google Scholar]

- Mutalipu, M.A.; Li, T.; Gu, W.B.; Cai, W.; Xue, Q.N.; Jing, J.H.; Wang, G.W.; Wang, Q. Seepage characteristic of gas water based on pore network model. J. China Coal Soc. 2023, 48, 2802–2812. [Google Scholar]

- Wang, Z.Y. Research of Permeability Model of Reservoirs Based on Digital Core. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2022. [Google Scholar]

- Song, X.D. Based on Digital Cores Numerical Simulation of Elastic Properties of Rock. Ph.D. Thesis, China University of Geosciences, Beijing, China, 2017. [Google Scholar]

- Yan, G.L. Based on Digital CoresResearch of Permeability Models of Reservoirs. Ph.D. Thesis, China University of Petroleum (East China), Qingdao, China, 2015. [Google Scholar]

- Li, X. Rock Physical Experiment and Fracturing Potential Characterization of Shale Gas Reservoir. Ph.D. Thesis, NorthWest University, Xi’an, China, 2017. [Google Scholar]

- Wang, Z. Least Square-Total Least Square Method Analysis and Application of Flow Detection Curve Based on hybrid least squares method. Ph.D. Thesis, Shenyang University of Technology, Shenyang, China, 2021. [Google Scholar]

- Li, J.; Zheng, B. A New method for fractal characterization of microscopic pores and its application in shale reservoirs. Nat. Gas Ind. 2015, 35, 52–59. [Google Scholar] [CrossRef]

- Hu, Y.; Perdomo, M.E.G.; Wu, K.; Chen, Z.; Zhang, K.; Yi, J.; Ren, G.; Yu, Y. New models of brittleness index for shale gas reservoirs: Weights of brittle minerals and rock mechanics parameters. In Proceedings of the SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, QLD, Australia, 9–11 November 2015. [Google Scholar]

- Skogan, D.; Grønmo, R.; Solheim, I. 11th IEEE International Enterprise Distributed Object Computing Conference-Copyright notice. In Proceedings of the 10th IEEE International Enterprise Distributed Object Computing Conference, Annapolis, MD, USA, 15–19 October 2007; IEEE Computer Society: Washington, DC, USA, 2006. [Google Scholar] [CrossRef]

- Liu, X.H.; Zhao, Q.S.; Chen, J.G. Experimental study on size effect to the uniaxial compressive strength of slate specimen as to the height diameter ratio. Geotech. Investig. Surv. 2015, 43, 6–11. [Google Scholar]

- Wu, J.J.; Zhang, S.H.; Cao, H.; Zheng, M.M.; Sun, P.H.; Luo, X. Fracability evaluation of shale gas reservoir—A case study in the Lower Cambrian Niutitang formation, northwestern Hunan, China—ScienceDirect. J. Pet. Sci. Eng. 2018, 164, 675–684. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Q.; Chen, J.P.; Gu, F.G.; Zhang, W. Evaluation of debris flow risk in Jinsha River based on combined weight process. Rock Soil Mech. 2011, 32, 831–836. [Google Scholar] [CrossRef]

- Guo, Q.Q.; Liu, L.L.; Zhang, S.H.; Wang, X.M. Prediction of Rockburst by Combination Weight Method and Cluster Analysis Method. J. Chang. River Sci. Res. Inst. 2013, 30, 54–59. [Google Scholar]

- Liang, B.; Dai, Y.-Y.; Chen, T.-Y.; Sun, W.-J.; Qin, B. Grey correlation optimization for shale gas exploration and development areas of complicated geological parameter features. Meitan Xuebao/J. China Coal Soc. 2014, 39, 524–530. [Google Scholar] [CrossRef]

- Wan, S.; Yuan, B.; Liu, H.; Meng, S.; Lei, Z.; Wang, W. An Improved Analytic-Hierarchy-Quantitative Pre-Evaluation Method for Post-fracturing Recoverability in Lamellation-Type Shale Oil Reservoir. In Proceedings of the 2023 SPE/AAPG/SEG Unconventional Resources Technology Conference, URTC 2023, Denver, CO, USA, 13–15 June 2023. [Google Scholar]

- Wang, J.; Xue, M.; Fan, J.; Bentley, Y.; Wang, X. Does shale gas exploitation contribute to regional sustainable development? Evidence from China. Sustain. Prod. Consum. 2023, 40, 169–181. [Google Scholar] [CrossRef]

- Chen, H.B.; Chen, M.X.; Su, D.F.; Li, Z.G. Optimization of mining methods based on least squares combined assignment-TOPSIS method. Ind. Miner. Process. 2023, 52, 10–15. [Google Scholar] [CrossRef]

- Guo, Y.; Li, Q.; Zhang, Q.J. Comprehensive evaluation of coal-fired units by integrating TOPSIS-combined assignment method. Mod. Ind. Econ. Inf. 2023, 13, 301–307. [Google Scholar]

- Su, X.Z. Evaluation of Shale Reservoir Properties and Brittleness in the Upper Nine Section of the Ludong Depression, Kailu Basin. Master’s Thesis, China University of Geosciences Beijing, Beijing, China, 2022. [Google Scholar]

- Wang, R.; Hu, Z.; Lai, F.; Liu, Y.; Wu, Z.; He, J.; Zou, G.g.; Wang, P.; Li, Z. Brittleness features and controlling factors of continental shale from Da’anzhai Member of the Lower Jurassic Ziliujing Formation, northeastern Sichuan Basin. Oil Gas Geol. 2023, 44, 366–378. [Google Scholar] [CrossRef]

- Wang, R.; Gong, D.; Ding, W.; Leng, J.; Yin, S.; Wang, X.; Sun, Y. Brittleness evaluation of the Lower Cambrian Niutitang shale in the Upper Yangtze region: A case study in the Cengong block, Guizhou Province. Earth Sci. Front. 2016, 23, 87–95. [Google Scholar] [CrossRef]

| Simple No. | Fracability | Mineral Brittleness Index | Acoustic Brittleness Index |

|---|---|---|---|

| A Group | 27.3 | 38.3 | 20.5 |

| B Group | 4.81 | 38.5 | 18.2 |

| Core No. | Fracability | Image Quality |

|---|---|---|

| A1 | 37.10961 | Optimal |

| A2 | 34.8375 | |

| A3 | 28.59897 | |

| A4 | 26.8989 | |

| B1 | 25.35907 | Good |

| B2 | 24.07041 | |

| B3 | 21.75481 | |

| B4 | 18.55319 | |

| C1 | 17.8772 | Normal |

| C2 | 17.20469 | |

| C3 | 13.58753 | |

| C4 | 13.47243 | |

| D1 | 10.64513 | Range |

| D2 | 8.170793 | |

| D3 | 7.412255 | |

| D4 | 5.185485 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, L.; Zhang, P.; Liu, J.; Zhang, W.; Lei, Y.; Zheng, X.; Nian, Z.; Ning, K.; Xu, J. Characterization and Quantitative Assessment of Shale Fracture Characteristics and Fracability Based on a Three-Dimensional Digital Core. Processes 2024, 12, 755. https://doi.org/10.3390/pr12040755

Qu L, Zhang P, Liu J, Zhang W, Lei Y, Zheng X, Nian Z, Ning K, Xu J. Characterization and Quantitative Assessment of Shale Fracture Characteristics and Fracability Based on a Three-Dimensional Digital Core. Processes. 2024; 12(4):755. https://doi.org/10.3390/pr12040755

Chicago/Turabian StyleQu, Le, Penghui Zhang, Jianping Liu, Weigang Zhang, Yu Lei, Xiaolei Zheng, Zhenzhen Nian, Kexiang Ning, and Jinze Xu. 2024. "Characterization and Quantitative Assessment of Shale Fracture Characteristics and Fracability Based on a Three-Dimensional Digital Core" Processes 12, no. 4: 755. https://doi.org/10.3390/pr12040755