Advancements in Bioelectrochemical Systems for Solid Organic Waste Valorization: A Comprehensive Review

Abstract

:1. Introduction

2. Characteristics of Solid Waste

3. Types of Solid Waste Used for Treatment in BES

- Municipal solid waste (MSW): It consists of waste produced in towns and cities, including industrial, commercial, and domestic waste. MSW is the perfect substrate for BES since it contains a considerable amount of biodegradable organic materials [2].

- Food waste: It corresponds to the organic waste produced by restaurants, households, and the food processing industry [2,37]. Food waste is a great substrate for BES since it includes a lot of effortlessly biodegradable organic materials. Food waste is one of the most significant waste components, accounting for 18% of the worldwide waste stream. Every year, more than 1.3 billion tonnes of food waste are generated, with the majority of this trash being disposed of in landfills or incinerated. Food waste contains a high concentration of lipids, carbohydrates, proteins, and other macromolecules, and its composition varies based on cultural routines, geography, climate, economic level, and so on. Due to its high organic content and potential for biodegradation, this waste might serve as a useful substrate for anaerobic digestion. It is possible to use the soluble organic compounds produced by the acidogenesis of carbon-rich food waste as both carbon and energy sources for microorganisms and also in the production of biohydrogen and biodegradable polyhydroxyalkanoates. For biological phosphorus and nitrogen removal, fatty acids produced from food wastes during anaerobic digestion are thought to be superior electron donors.

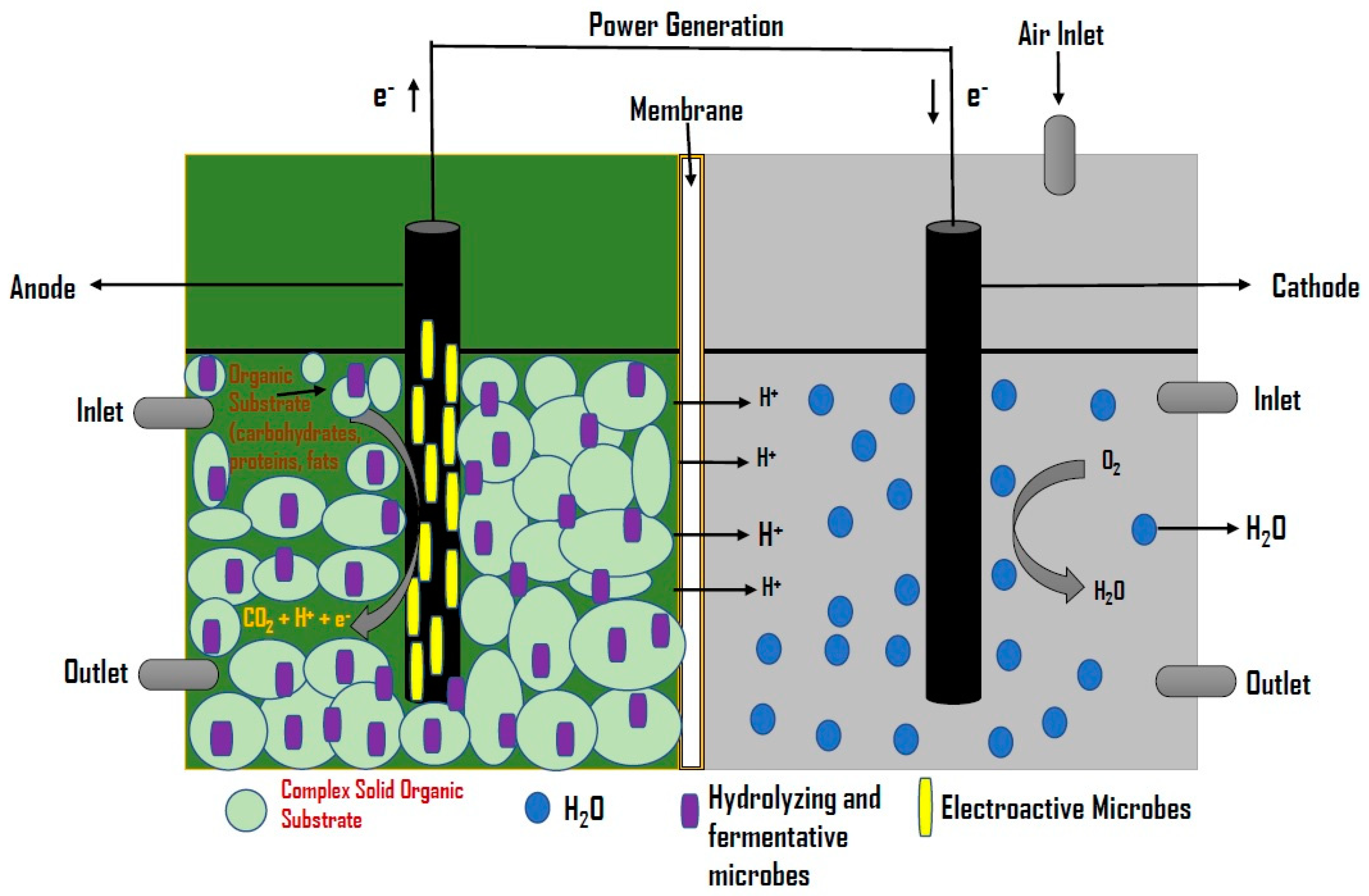

4. Fundamentals of Bioelectrochemical System (BES)

5. BES Configuration for Solid Waste Treatment

5.1. Anode Chamber Process

5.2. Cathode Chamber Process

6. Microorganisms Involved in Solid Waste Treatment Using BES

| S.No. | Type of BES | Substrate | Types of Microorganism | References |

|---|---|---|---|---|

| 1 | Substrate-enhanced microbial fuel cell (SEMFC) | Secondary clarifier wastewater supplemented with ChitoRemTM SC-20 (Chitin 20) | Clostridium sticklandii, Enterobacter cloacae strain E717, Fusibacter paucivorans, and Bacillus sp. R-31029 | [61] |

| 2 | MFC | Cattle manure (livestock organic solid waste) | Hydrogen-generating bacteria (HGB) | [62] |

| 3 | MEC | Air-dried corn stalk | Cow dung compost as H2-producing microflora | [63] |

| 4 | MFC | Organic Fraction of Solid Municipal Waste (OFSMW) | Hydrogen-producing mixed consortia | [64] |

| 5 | MFC | Organic fraction of municipal solid waste (OFMWS) | Geobacter, Bacteroides, and Clostridium | [65] |

| 6 | MFC | Organic fraction of municipal solid waste (OFMSW) (food waste (FW), paper–cardboard waste (PCW), and garden waste (GW)) and their blends | Bacteroidetes and b-proteobacteria | [66] |

| 7 | MFC | Solid potato waste | Anaerobically cultured waste-activated sludge (WAS) | [67] |

| 8 | MFC | MFC spent substrate as AD feedstock | Lactobacillaceae, Bacillaceae, Clostridia, Pseudomonadaceae, and Pseudomonas aeruginosa | [31] |

| 9 | Solid-phase microbial fuel cells (SMFC) | Solid waste containing boiled rice (60 ± 5%), cooked vegetables (14 ± 2%), un-cooked vegetables (spoiled) (2 ± 1%), cooking oil (6 ± 2%), and vegetable peelings (3 ± 1%) | Anodophilic bacteria | [33] |

| 10 | Solid-phase microbial fuel cells (SPMFCs) | Rice hull, bean residue, ground coffee waste | Native microbial population in individual waste | [32] |

7. Hydrolysis and Degradation Rate Parameters for Solid Waste

8. Municipal Solid Waste Landfill Mature Leachate and Dairy Wastewater as Co-Substrate in BES

9. Synergy of BES-Solid Waste Treatment with Other Solid Treatment Technology

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sridevi, V.; Modi, M.; Lakshmi, M.V.V.C.; Kesavarao, L.; Tech, M. A Review on Integrated Solid Waste Management. Int. J. Eng. Sci. Adv. Technol. 2012, 2, 1491–1499. [Google Scholar]

- Gattrell, M.; Gupta, N.; Co, A.; Cavinato, C.; Giuliano, A.; Bolzonella, D.; Pavan, P.; Cecchi, F.; Liu, Z.; Zhang, C.; et al. Investigation of Microbial Biofilm Structure by Laser Scanning Microscopy. Bioresour. Technol. 2018, 5, 9391–9410. [Google Scholar] [CrossRef]

- Zhao, Q.; Yu, H.; Zhang, W.; Kabutey, F.T.; Jiang, J.; Zhang, Y.; Wang, K.; Ding, J. Microbial Fuel Cell with High Content Solid Wastes as Substrates: A Review. Front. Environ. Sci. Eng. 2017, 11, 13. [Google Scholar] [CrossRef]

- Valdez-vazquez, I.; Sparling, R.; Risbey, D. Hydrogen Generation via Anaerobic Fermentation of Paper Mill Wastes. Bioresour. Technol. 2005, 96, 1907–1913. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.H.; Behera, S.K.; Kim, J.W.; Park, H.S. Methane Production Potential of Leachate Generated from Korean Food Waste Recycling Facilities: A Lab-Scale Study. Waste Manag. 2009, 29, 876–882. [Google Scholar] [CrossRef] [PubMed]

- Sevda, S.; Sreekrishnan, T.R. Removal of Organic Matters and Nitrogenous Pollutants Simultaneously from Two Different Wastewaters Using Biocathode Microbial Fuel Cell. J. Environ. Sci. Health Part A Toxic/Hazardous Subst. Environ. Eng. 2014, 49, 1265–1275. [Google Scholar] [CrossRef]

- Nayak, S.; Sevda, S. Urine Based Bioelectrochemical System: Resources Recovery and Domestic Wastewater Treatment Prospectives. Bioresour. Technol. Rep. 2022, 20, 101257. [Google Scholar] [CrossRef]

- Kuleshova, T.; Rao, A.; Bhadra, S.; Kumar, V.; Sharma, S.; Kaushik, A.; Goswami, P.; Sreekirshnan, T.R.; Sevda, S. Biomass and Bioenergy Plant Microbial Fuel Cells as an Innovative, Versatile Agro-Technology for Green Energy Generation Combined with Wastewater Treatment and Food Production. Biomass Bioenergy 2022, 167, 106629. [Google Scholar] [CrossRef]

- Sevda, S.; Dominguez-Benetton, X.; Graichen, F.H.M.; Vanbroekhoven, K.; De Wever, H.; Sreekrishnan, T.R.; Pant, D. Shift to Continuous Operation of an Air-Cathode Microbial Fuel Cell Long-Running in Fed-Batch Mode Boosts Power Generation. Int. J. Green Energy 2016, 13, 71–79. [Google Scholar] [CrossRef]

- Rodrigo, M.A.; Cañizares, P.; García, H.; Linares, J.J.; Lobato, J. Study of the Acclimation Stage and of the Effect of the Biodegradability on the Performance of a Microbial Fuel Cell. Bioresour. Technol. 2009, 100, 4704–4710. [Google Scholar] [CrossRef]

- Xie, X.; Ye, M.; Hsu, P.C.; Liu, N.; Criddle, C.S.; Cui, Y. Microbial Battery for Efficient Energy Recovery. Proc. Natl. Acad. Sci. USA 2013, 110, 15925–15930. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Jiao, S.; Ma, M.; Peng, S. Microbial Fuel Cell System: A Promising Technology for Pollutant Removal and Environmental Remediation. Environ. Sci. Pollut. Res. 2020, 27, 6749–6764. [Google Scholar] [CrossRef]

- Al-Salem, S.M. Thermal Pyrolysis of High Density Polyethylene (HDPE) in a Novel Fixed Bed Reactor System for the Production of High Value Gasoline Range Hydrocarbons (HC). Process Saf. Environ. Prot. 2019, 127, 171–179. [Google Scholar] [CrossRef]

- Aǧdaǧ, O.N.; Sponza, D.T. Co-Digestion of Mixed Industrial Sludge with Municipal Solid Wastes in Anaerobic Simulated Landfilling Bioreactors. J. Hazard. Mater. 2007, 140, 75–85. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, G.; Peng, L.; Su, H.; Tan, T. Bioresource Technology The Anaerobic Co-Digestion of Food Waste and Cattle Manure. Bioresour. Technol. 2013, 129, 170–176. [Google Scholar] [CrossRef] [PubMed]

- Richard, E.N.; Hilonga, A.; Machunda, R.L.; Njau, K.N. A Review on Strategies to Optimize Metabolic Stages of Anaerobic Digestion of Municipal Solid Wastes towards Enhanced Resources Recovery. Sustain. Environ. Res. 2019, 1, 36. [Google Scholar] [CrossRef]

- Naji, Z.; Hu, Z.; Sun, N.; Xiao, B.; Rajaa, N.; Liu, C. Batch Anaerobic Co-Digestion of OFMSW (Organic Fraction of Municipal Solid Waste), TWAS (Thickened Waste Activated Sludge) and RS (Rice Straw): In Fl Uence of TWAS and RS Pretreatment and Mixing Ratio. Energy 2016, 107, 131–140. [Google Scholar] [CrossRef]

- Ge, X.; Xu, F.; Li, Y. Solid-State Anaerobic Digestion of Lignocellulosic Biomass: Recent Progress and Perspectives. Bioresour. Technol. 2016, 205, 239–249. [Google Scholar] [CrossRef]

- Tyagi, V.K.; Fdez-Güelfo, L.A.; Zhou, Y.; Álvarez-Gallego, C.J.; Garcia, L.I.R.; Ng, W.J. Anaerobic Co-Digestion of Organic Fraction of Municipal Solid Waste (OFMSW): Progress and Challenges. Renew. Sustain. Energy Rev. 2018, 93, 380–399. [Google Scholar] [CrossRef]

- Du, Y.; Ju, T.; Meng, Y.; Lan, T.; Han, S.; Jiang, J. A Review on Municipal Solid Waste Pyrolysis of Different Composition for Gas Production. Fuel Process. Technol. 2021, 224, 107026. [Google Scholar] [CrossRef]

- Uddin, M.N.; Siddiki, S.Y.A.; Mofijur, M.; Djavanroodi, F.; Hazrat, M.A.; Show, P.L.; Ahmed, S.F.; Chu, Y.M. Prospects of Bioenergy Production From Organic Waste Using Anaerobic Digestion Technology: A Mini Review. Front. Energy Res. 2021, 9, 627093. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Luo, D.; Chong, Z.; Li, E.; Kong, X. A Review of Municipal Solid Waste in China: Characteristics, Compositions, Influential Factors and Treatment Technologies. Environ. Dev. Sustain. 2021, 23, 6603–6622. [Google Scholar] [CrossRef]

- Ding, Y.; Zhao, J.; Liu, J.-W.; Zhou, J.; Cheng, L.; Zhao, J.; Shao, Z.; Iris, Ç.; Pan, B.; Li, X.; et al. A Review of China’s Municipal Solid Waste (MSW) and Comparison with International Regions: Management and Technologies in Treatment and Resource Utilization. J. Clean. Prod. 2021, 293, 126144. [Google Scholar] [CrossRef]

- Panigrahi, S.; Dubey, B.K. A Critical Review on Operating Parameters and Strategies to Improve the Biogas Yield from Anaerobic Digestion of Organic Fraction of Municipal Solid Waste. Renew. Energy 2019, 143, 779–797. [Google Scholar] [CrossRef]

- Du, H.; Shao, Z. Synergistic Effects between Solid Potato Waste and Waste Activated Sludge for Waste-to-Power Conversion in Microbial Fuel Cells. Appl. Energy 2022, 314, 118994. [Google Scholar] [CrossRef]

- Zhang, F.; Ahn, Y.; Logan, B.E. Treating Refinery Wastewaters in Microbial Fuel Cells Using Separator Electrode Assembly or Spaced Electrode Configurations. Bioresour. Technol. 2014, 152, 46–52. [Google Scholar] [CrossRef]

- Zeller, M.A.; Hunt, R.; Jones, A.; Sharma, S. Bioplastics and Their Thermoplastic Blends from Spirulina and Chlorella Microalgae. J. Appl. Polym. Sci. 2013, 130, 3263–3275. [Google Scholar] [CrossRef]

- Huang, D.; Du, Y.; Xu, Q.; Ko, J.H. Quantification and Control of Gaseous Emissions from Solid Waste Landfill Surfaces. J. Environ. Manag. 2022, 302, 114001. [Google Scholar] [CrossRef]

- Pant, D.; Singh, A.; Van Bogaert, G.; Irving Olsen, S.; Singh Nigam, P.; Diels, L.; Vanbroekhoven, K. Bioelectrochemical Systems (BES) for Sustainable Energy Production and Product Recovery from Organic Wastes and Industrial Wastewaters. RSC Adv. 2012, 2, 1248–1263. [Google Scholar] [CrossRef]

- Budihardjo, M.A.; Syafrudin; Effendi, A.J.; Hidayat, S.; Purnawan, C.; Lantasi, A.I.D.; Muhammad, F.I.; Ramadan, S.B. Waste Valorization Using Solid-Phase Microbial Fuel Cells (SMFCs): Recent Trends and Status. J. Environ. Manag. 2021, 277, 111417. [Google Scholar] [CrossRef]

- Florio, C.; Nastro, R.A.; Flagiello, F.; Minutillo, M.; Pirozzi, D.; Pasquale, V.; Ausiello, A.; Toscano, G.; Jannelli, E.; Dumontet, S. Biohydrogen Production from Solid Phase-Microbial Fuel Cell Spent Substrate: A Preliminary Study. J. Clean. Prod. 2019, 227, 506–511. [Google Scholar] [CrossRef]

- Wang, C.T.; Liao, F.Y.; Liu, K.S. Electrical Analysis of Compost Solid Phase Microbial Fuel Cell. Int. J. Hydrogen Energy 2013, 38, 11124–11130. [Google Scholar] [CrossRef]

- Mohan, S.V.; Chandrasekhar, K. Bioresource Technology Solid Phase Microbial Fuel Cell (SMFC) for Harnessing Bioelectricity from Composite Food Waste Fermentation: Influence of Electrode Assembly and Buffering Capacity. Bioresour. Technol. 2011, 102, 7077–7085. [Google Scholar] [CrossRef] [PubMed]

- Tommasi, T.; Salvador, G.P.; Quaglio, M. New Insights in Microbial Fuel Cells: Novel Solid Phase Anolyte. Sci. Rep. 2016, 6, 29091. [Google Scholar] [CrossRef] [PubMed]

- Pathy, A.; Ray, J.; Paramasivan, B. Challenges and Opportunities of Nutrient Recovery from Human Urine Using Biochar for Fertilizer Applications. J. Clean. Prod. 2021, 304, 127019. [Google Scholar] [CrossRef]

- Sonawane, J.M.; Mahadevan, R.; Pandey, A.; Greener, J. Recent Progress in Microbial Fuel Cells Using Substrates from Diverse Sources. Heliyon 2022, 8, e12353. [Google Scholar] [CrossRef]

- Sundberg, C.; Smårs, S.; Jönsson, H. Low PH as an Inhibiting Factor in the Transition from Mesophilic to Thermophilic Phase in Composting. Bioresour. Technol. 2004, 95, 145–150. [Google Scholar] [CrossRef]

- Lin, C.; Hung, C.; Chen, C.; Chung, W.; Cheng, L. Effects of Initial Cultivation PH on Fermentative Hydrogen Production from Xylose Using Natural Mixed Cultures. Process Biochem. 2006, 41, 1383–1390. [Google Scholar] [CrossRef]

- Lin, C.; Cheng, C. Fermentative Hydrogen Production from Xylose Using Anaerobic Mixed Microflora. Int. J. Hydrogen Energy 2006, 31, 832–840. [Google Scholar] [CrossRef]

- Bello, S.; Galán-Martín, Á.; Feijoo, G.; Moreira, M.T.; Guillén-Gosálbez, G. BECCS Based on Bioethanol from Wood Residues: Potential towards a Carbon-Negative Transport and Side-Effects. Appl. Energy 2020, 279, 115884. [Google Scholar] [CrossRef]

- Prasad, S.; Singh, A.; Joshi, H.C. Ethanol as an Alternative Fuel from Agricultural, Industrial and Urban Residues. Resour. Conserv. Recycl. 2007, 50, 1–39. [Google Scholar] [CrossRef]

- Sevda, S.; Sreekishnan, T.R.; Pous, N.; Puig, S.; Pant, D. Bioelectroremediation of Perchlorate and Nitrate Contaminated Water: A Review. Bioresour. Technol. 2018, 255, 331–339. [Google Scholar] [CrossRef] [PubMed]

- Dominguez-Benetton, X.; Sevda, S.; Vanbroekhoven, K.; Pant, D. The Accurate Use of Impedance Analysis for the Study of Microbial Electrochemical Systems. Chem. Soc. Rev. 2012, 41, 7228–7246. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Jiang, J.; Zhao, Q.; Wang, K.; Zhang, Y.; Zheng, Z.; Hao, X. Bioelectrochemically-Assisted Anaerobic Composting Process Enhancing Compost Maturity of Dewatered Sludge with Synchronous Electricity Generation. Bioresour. Technol. 2015, 193, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Fantozzi, F.; Buratti, C. Biogas Production from Different Substrates in an Experimental Continuously Stirred Tank Reactor Anaerobic Digester. Bioresour. Technol. 2009, 100, 5783–5789. [Google Scholar] [CrossRef] [PubMed]

- Abu-Reesh, I.M.; Kunju, A.; Sevda, S. Performance of Microbial Fuel Cells in Treating Petroleum Refinery Wastewater. J. Water Process Eng. 2022, 49, 103029. [Google Scholar] [CrossRef]

- Callegari, A.; Bolognesi, S.; Cecconet, D. Operation of a 2-Stage Bioelectrochemical System for Groundwater Denitrification. Water 2019, 11, 959. [Google Scholar] [CrossRef]

- Li, Z.; Yao, L.; Kong, L.; Liu, H. Electricity Generation Using a Baffled Microbial Fuel Cell Convenient for Stacking. Bioresour. Technol. 2008, 99, 1650–1655. [Google Scholar] [CrossRef]

- Kim, M.; Hyun, S.M.; Gadd, G.M.; Kim, G.T.; Lee, S.-J.; Kim, H.J. Membrane-Electrode Assembly Enhances Performance of a Microbial Fuel Cell Type Biological Oxygen Demand Sensor. Environ. Technol. 2009, 30, 329–336. [Google Scholar] [CrossRef]

- Hou, H.; Li, L.; Cho, Y.; de Figueiredo, P.; Han, A. Microfabricated Microbial Fuel Cell Arrays Reveal Electrochemically Active Microbes. PLoS ONE 2009, 4, e6570. [Google Scholar] [CrossRef]

- Park, D.-H.; Kim, B.-H. Growth Properties of the Iron-Reducing Bacteria, Shewanella Putrefaciens IR-1 and MR-1 Coupling to Reduction of Fe (III) to Fe (II). J. Microbiol. 2001, 39, 273–278. [Google Scholar]

- Pons, L.; Délia, M.; Basséguy, R.; Bergel, A. Electrochimica Acta Effect of the Semi-Conductive Properties of the Passive Layer on the Current Provided by Stainless Steel Microbial Cathodes. Electrochim. Acta 2011, 56, 2682–2688. [Google Scholar] [CrossRef]

- Liu, Z.; Li, H.; Liu, J.; Su, Z. Effects of Inoculation Strategy and Cultivation Approach on the Performance of Microbial Fuel Cell Using Marine Sediment as Bio-Matrix. J. Appl. Microbiol. 2008, 104, 1163–1170. [Google Scholar] [CrossRef] [PubMed]

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the Anaerobic Digestion of Agricultural Resources. Bioresour. Technol. 2008, 99, 7928–7940. [Google Scholar] [CrossRef] [PubMed]

- Rossi, R.; Fedrigucci, A.; Setti, L. Characterization of Electron Mediated Microbial Fuel Cell by Saccharomyces cerevisiae. Chem. Eng. Trans. 2015, 43, 337–342. [Google Scholar] [CrossRef]

- Ai, C.; Hou, S.; Yan, Z.; Zheng, X.; Amanze, C.; Chai, L.; Qiu, G.; Zeng, W. Recovery of Metals from Acid Mine Drainage by Bioelectrochemical System Inoculated with a Novel Exoelectrogen, Pseudomonas sp. E8. Microorganisms 2020, 8, 41. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Adhami, A.; Darvari, S.; Zirepour, A.; Oh, S.E. Microbial Fuel Cell as New Technol Ogy for Bioelectricity Generation: A Review. Alex. Eng. J. 2015, 54, 745–756. [Google Scholar] [CrossRef]

- Khalid, A.; Arshad, M.; Anjum, M.; Mahmood, T.; Dawson, L. The Anaerobic Digestion of Solid Organic Waste. Waste Manag. 2011, 31, 1737–1744. [Google Scholar] [CrossRef]

- Sun, R.; Xing, D.; Jia, J.; Liu, Q.; Zhou, A.; Bai, S.; Ren, N. Optimization of High-Solid Waste Activated Sludge Concentration for Hydrogen Production in Microbial Electrolysis Cells and Microbial Community Diversity Analysis. Int. J. Hydrogen Energy 2014, 39, 19912–19920. [Google Scholar] [CrossRef]

- Rojas-Flores, S.; De La Cruz-Noriega, M.; Benites, S.M.; Delfín-Narciso, D.; Luis, A.S.; Díaz, F.; Luis, C.C.; Moises, G.C. Electric Current Generation by Increasing Sucrose in Papaya Waste in Microbial Fuel Cells. Molecules 2022, 27, 5198. [Google Scholar] [CrossRef]

- Rezaei, F.; Richard, T.L.; Logan, B.E. Analysis of Chitin Particle Size on Maximum Power Generation, Power Longevity, and Coulombic Efficiency in Solid–Substrate Microbial Fuel Cells. J. Power Sources 2009, 192, 304–309. [Google Scholar] [CrossRef]

- Lee, Y.; Nirmalakhandan, N. Electricity Production in Membrane-Less Microbial Fuel Cell Fed with Livestock Organic Solid Waste. Bioresour. Technol. 2011, 102, 5831–5835. [Google Scholar] [CrossRef] [PubMed]

- Li, X.H.; Liang, D.W.; Bai, Y.X.; Fan, Y.T.; Hou, H.W. Enhanced H2 Production from Corn Stalk by Integrating Dark Fermentation and Single Chamber Microbial Electrolysis Cells with Double Anode Arrangement. Int. J. Hydrogen Energy 2014, 39, 8977–8982. [Google Scholar] [CrossRef]

- Sekoai, P.T.; Gueguim Kana, E.B. Semi-Pilot Scale Production of Hydrogen from Organic Fraction of Solid Municipal Waste and Electricity Generation from Process Effluents. Biomass Bioenergy 2014, 60, 156–163. [Google Scholar] [CrossRef]

- Karluvali, A.; Köroğlu, E.O.; Manav, N.; Çetinkaya, A.Y.; Özkaya, B. Electricity Generation from Organic Fraction of Municipal Solid Wastes in Tubular Microbial Fuel Cell. Sep. Purif. Technol. 2015, 156, 502–511. [Google Scholar] [CrossRef]

- Pendyala, B.; Chaganti, S.R.; Lalman, J.A.; Heath, D.D. Optimizing the Performance of Microbial Fuel Cells Fed a Combination of Different Synthetic Organic Fractions in Municipal Solid Waste. Waste Manag. 2016, 49, 73–82. [Google Scholar] [CrossRef]

- Du, H.; Li, F. Enhancement of Solid Potato Waste Treatment by Microbial Fuel Cell with Mixed Feeding of Waste Activated Sludge. J. Clean. Prod. 2017, 143, 336–344. [Google Scholar] [CrossRef]

- Ren, N.; Wang, A.; Cao, G.; Xu, J.; Gao, L. Bioconversion of Lignocellulosic Biomass to Hydrogen: Potential and Challenges. Biotechnol. Adv. 2009, 27, 1051–1060. [Google Scholar] [CrossRef]

- Haghpanah, T.; Sobati, M.A.; Pishvaee. Multi-Objective Superstructure Optimization of a Microalgae Biorefinery Considering Economic and Environmental Aspects. Comput. Chem. Eng. 2022, 164, 107894. [Google Scholar] [CrossRef]

- Xu, D.; Tree, D.R.; Lewis, R.S. The Effects of Syngas Impurities on Syngas Fermentation to Liquid Fuels. Biomass Bioenergy 2011, 35, 2690–2696. [Google Scholar] [CrossRef]

- Liew, F.M.; Martin, M.E.; Tappel, R.C.; Heijstra, B.D.; Mihalcea, C.; Köpke, M. Gas Fermentation-A Flexible Platform for Commercial Scale Production of Low-Carbon-Fuels and Chemicals from Waste and Renewable Feedstocks. Front. Microbiol. 2016, 7, 694. [Google Scholar] [CrossRef]

- Silva, F.C.; Serafim, L.S.; Nadais, H.; Arroja, L.; Capela, I. Acidogenic Fermentation towards Valorisation of Organic Waste Streams into Volatile Fatty Acids. Chem. Biochem. Eng. Q. 2013, 27, 467–476. [Google Scholar]

- Abdeljaber, A.; Zannerni, R.; Masoud, W.; Abdallah, M.; Rocha-Meneses, L. Eco-Efficiency Analysis of Integrated Waste Management Strategies Based on Gasification and Mechanical Biological Treatment. Sustainability 2022, 14, 3899. [Google Scholar] [CrossRef]

- Guermoud, N.; Ouadjnia, F.; Abdelmalek, F.; Taleb, F.; Addou, A. Municipal Solid Waste in Mostaganem City (Western Algeria). Waste Manag. 2009, 29, 896–902. [Google Scholar] [CrossRef] [PubMed]

- Bolzonella, D.; Mıcoluccı, F.; Battısta, F.; Cavınato, C.; Gottardo, M.; Pıovesan, S.; Pavan, P. Producing Biohythane from Urban Organic Wastes. Waste Biomass Valorization 2020, 11, 2367–2374. [Google Scholar] [CrossRef]

- De Gisi, S.; Gadaleta, G.; Gorrasi, G.; La Mantia, F.P.; Notarnicola, M.; Sorrentino, A. The Role of (Bio)Degradability on the Management of Petrochemical and Bio-Based Plastic Waste. J. Environ. Manag. 2022, 310, 114769. [Google Scholar] [CrossRef]

- Maiti, D.; Ansari, I.; Rather, M.A.; Deepa, A. Comprehensive Review on Wastewater Discharged from the Coal-Related Industries—Characteristics and Treatment Strategies. Water Sci. Technol. 2019, 79, 2023–2035. [Google Scholar] [CrossRef]

- Bolognesi, S.; Cecconet, D.; Callegari, A.; Capodaglio, A.G. Bioelectrochemical Treatment of Municipal Solid Waste Landfill Mature Leachate and Dairy Wastewater as Co-Substrates. Environ. Sci. Pollut. Res. 2021, 28, 24639–24649. [Google Scholar] [CrossRef]

- Cheng, S.; Xing, D.; Call, D.F.; Logan, B.E. Direct Biological Conversion of Electrical Current into Methane by Electromethanogenesis. Environ. Sci. Technol. 2009, 43, 3953–3958. [Google Scholar] [CrossRef]

- Zhang, G.; Jiao, Y.; Lee, D.-J. A Lab-Scale Anoxic/Oxic-Bioelectrochemical Reactor for Leachate Treatments. Bioresour. Technol. 2015, 186, 97–105. [Google Scholar] [CrossRef]

- Zhang, G.; Jiao, Y.; Lee, D.J. Transformation of Dissolved Organic Matters in Landfill Leachate-Bioelectrochemical System. Bioresour. Technol. 2015, 191, 350–354. [Google Scholar] [CrossRef] [PubMed]

- Santoro, C.; Arbizzani, C.; Erable, B.; Ieropoulos, I. Microbial Fuel Cells: From Fundamentals to Applications. A Review. J. Power Sources 2017, 356, 225–244. [Google Scholar] [CrossRef] [PubMed]

- Prajapati, K.B.; Singh, R. Bio-Electrochemically Hydrogen and Methane Production from Co-Digestion of Wastes. Energy 2020, 198, 117259. [Google Scholar] [CrossRef]

- Luo, H.; Jenkins, P.E.; Ren, Z. Concurrent Desalination and Hydrogen Generation Using Microbial Electrolysis and Desalination Cells. Environ. Sci. Technol. 2011, 45, 340–344. [Google Scholar] [CrossRef]

- Ma, L.; Chen, N.; Feng, C.; Yao, Y.; Wang, S.; Wang, G.; Su, Y.; Zhang, Y. Enhanced Cr(VI) Reduction in Biocathode Microbial Electrolysis Cell Using Fenton-Derived Ferric Sludge. Water Res. 2022, 212, 118144. [Google Scholar] [CrossRef] [PubMed]

- FP7|CORDIS|European Commission. Final Report Summary—PLANTPOWER (PlantPower—Living Plants in Microbial Fuel Cells for Clean, Renewable, Sustainable, Efficient, in situ Bioenergy Production). Available online: https://cordis.europa.eu/project/id/226532/reporting (accessed on 2 August 2023).

- Durruty, I.; Bonanni, P.S.; González, J.F.; Busalmen, J.P. Evaluation of Potato-Processing Wastewater Treatment in a Microbial Fuel Cell. Bioresour. Technol. 2012, 105, 81–87. [Google Scholar] [CrossRef]

- Sevda, S.; Jyoti Sarma, P.; Mohanty, K.; Sreekrishnan, T.R.; Pant, D. Microbial Fuel Cell Technology for Bioelectricity Generation from Wastewaters. In Waste to Wealth; Energy, Environment, and Sustainability; Springer: Berlin/Heidelberg, Germany, 2018; pp. 237–258. [Google Scholar] [CrossRef]

- Hamelers, H.V.M.; Ter Heijne, A.; Sleutels, T.H.J.A.; Jeremiasse, A.W.; Strik, D.P.B.T.B.; Buisman, C.J.N. New Applications and Performance of Bioelectrochemical Systems. Appl. Microbiol. Biotechnol. 2010, 85, 1673–1685. [Google Scholar] [CrossRef]

- Bolognesi, S.; Bañeras, L.; Perona-Vico, E.; Capodaglio, A.G.; Balaguer, M.D.; Puig, S. Carbon Dioxide to Bio-Oil in a Bioelectrochemical System-Assisted Microalgae Biorefinery Process. Sustain. Energy Fuels 2022, 6, 150–161. [Google Scholar] [CrossRef]

| Characteristic | Description |

|---|---|

| Composition | Can include organic and inorganic materials |

| Physical State | Neither liquid nor gas, exists in a solid form |

| Volume | Takes up physical space and has volume |

| Density | Varies depending on the types of materials present |

| Biodegradability | Organic waste is biodegradable; inorganic waste is not |

| Odor | Organic waste can produce unpleasant odors as it decomposes |

| Pest Attraction | Organic waste can attract pests like rodents and insects |

| Flammability | Some materials are highly flammable |

| Volume Reduction | Can be reduced using methods like compaction or shredding |

| Aesthetic Impact | Improperly managed waste can cause visual pollution |

| Landfill Potential | Materials that cannot be recycled may end up in landfills |

| Health and Environmental Risk | Presence of hazardous materials poses risks |

| Recyclability | Many components can be recycled and reused |

| Solid Waste Material | Potential Applications or Benefits of BES |

|---|---|

| Food Scraps | - Direct conversion to electricity using MFCs. |

| - Waste treatment and reduction. | |

| Potential for bioproducts or value-added chemicals. | |

| Agricultural Residues | Electricity generation |

| Nutrient recovery | |

| Reduction in waste volume | |

| Organic Sludges | Hydrogen production |

| Value-added chemical production | |

| Waste valorization | |

| Sewage Sludge | Electricity or hydrogen production |

| Efficient waste treatment | |

| Removal of pollutants | |

| Lignocellulosic Waste | Electricity generation |

| Biohydrogen or biogas production | |

| Potential for biofuels | |

| Industrial Waste | Conversion to electricity or valuable chemicals |

| Resource recovery | |

| Landfill Leachate | Electricity generation |

| Landfill leachate treatment | |

| Reduction in environmental impact |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maddirala, S.; Bhadra, S.; Mozumder, M.S.I.; Garlapati, V.K.; Sevda, S. Advancements in Bioelectrochemical Systems for Solid Organic Waste Valorization: A Comprehensive Review. Processes 2024, 12, 805. https://doi.org/10.3390/pr12040805

Maddirala S, Bhadra S, Mozumder MSI, Garlapati VK, Sevda S. Advancements in Bioelectrochemical Systems for Solid Organic Waste Valorization: A Comprehensive Review. Processes. 2024; 12(4):805. https://doi.org/10.3390/pr12040805

Chicago/Turabian StyleMaddirala, Shivani, Sudipa Bhadra, Md. Salatul Islam Mozumder, Vijay Kumar Garlapati, and Surajbhan Sevda. 2024. "Advancements in Bioelectrochemical Systems for Solid Organic Waste Valorization: A Comprehensive Review" Processes 12, no. 4: 805. https://doi.org/10.3390/pr12040805