Study on Activation and Restructuring of Key Strata in Shallowly Buried Coal Seam Bearing Structure and Load Characteristics

Abstract

1. Introduction

2. Simulation Experiment Design for Activation and Recombination of Support Structures in Coal Seam Group Mining

2.1. Engineering Background

2.2. Similar Material Simulation Experiments

3. Analysis of Activation and Recombination of Key Strata Support Structures and Their Migration Characteristics

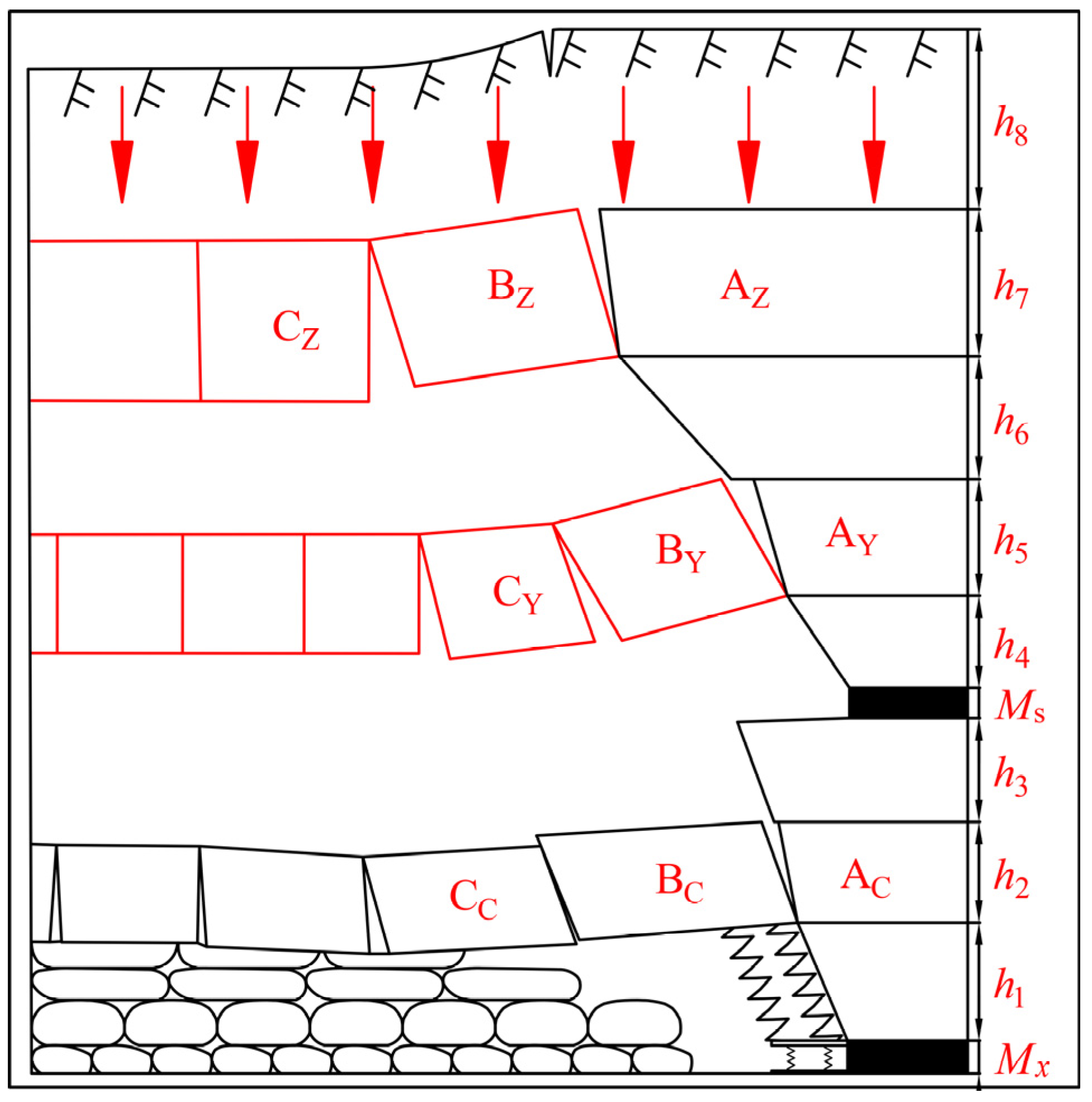

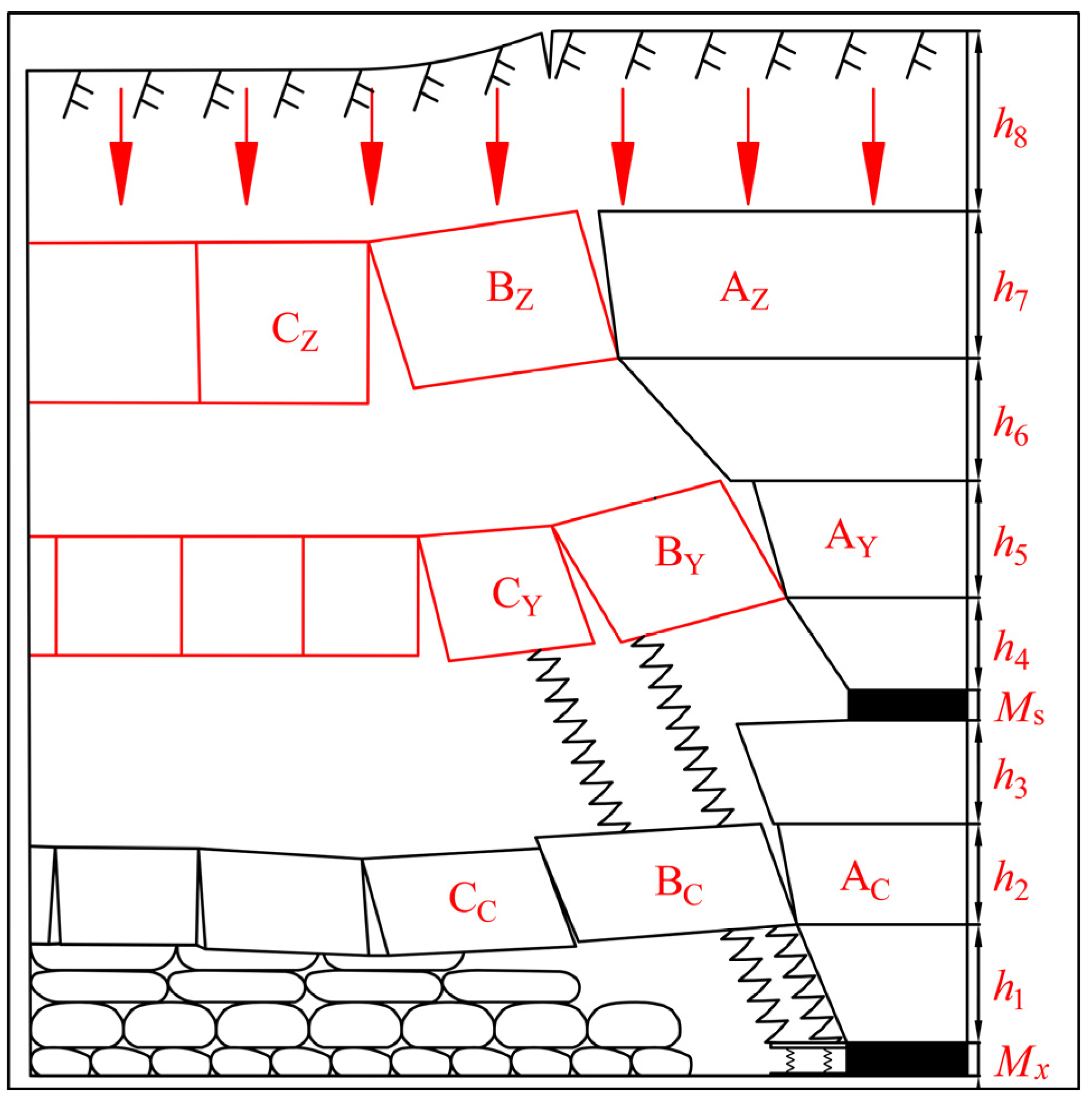

3.1. Fracture Characteristics of Key Strata during Shallow-Buried Coal Seam Mining

- (1)

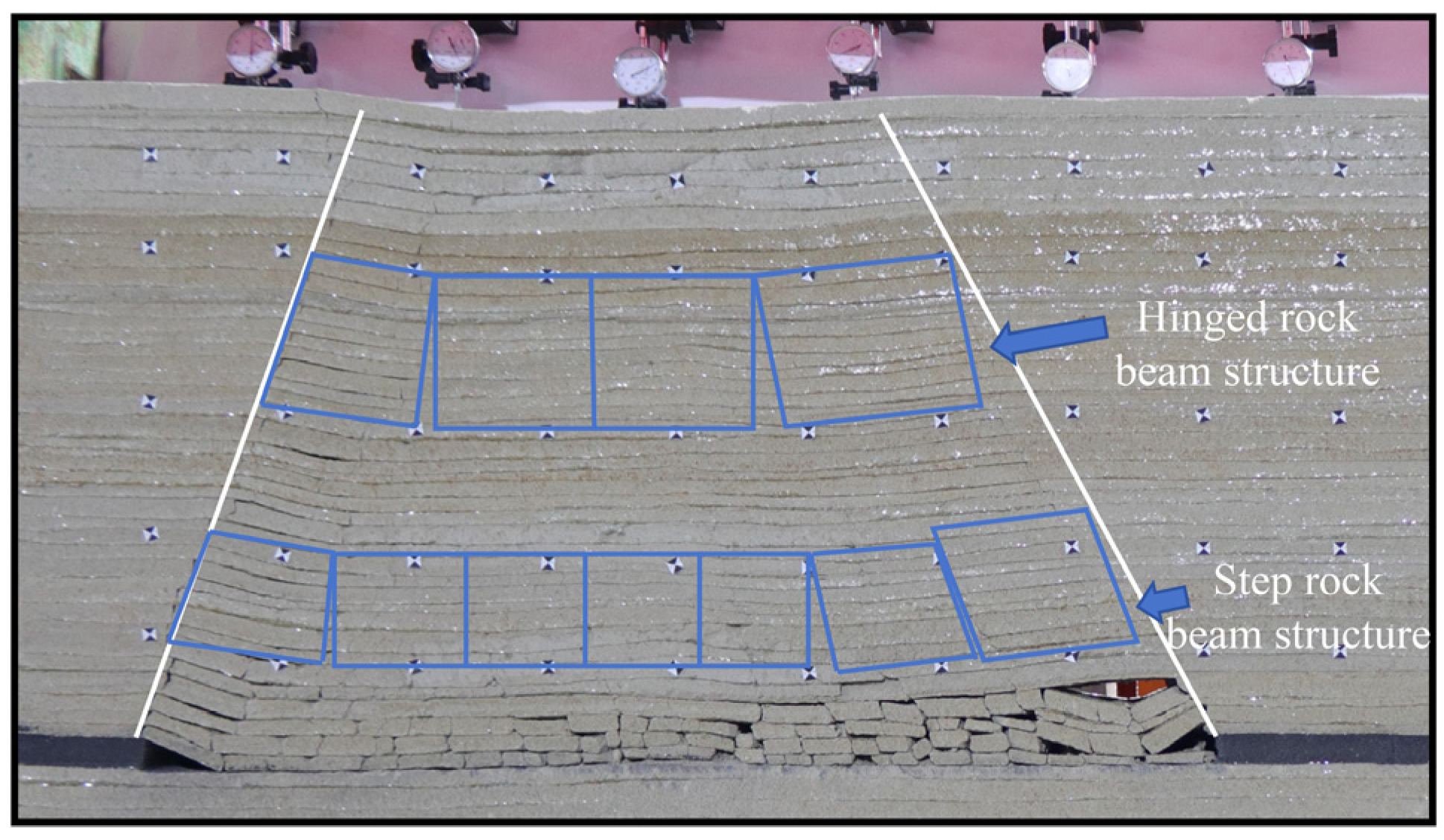

- Fracture characteristics of key strata during the extraction of the 1-2 coal seam

- (2)

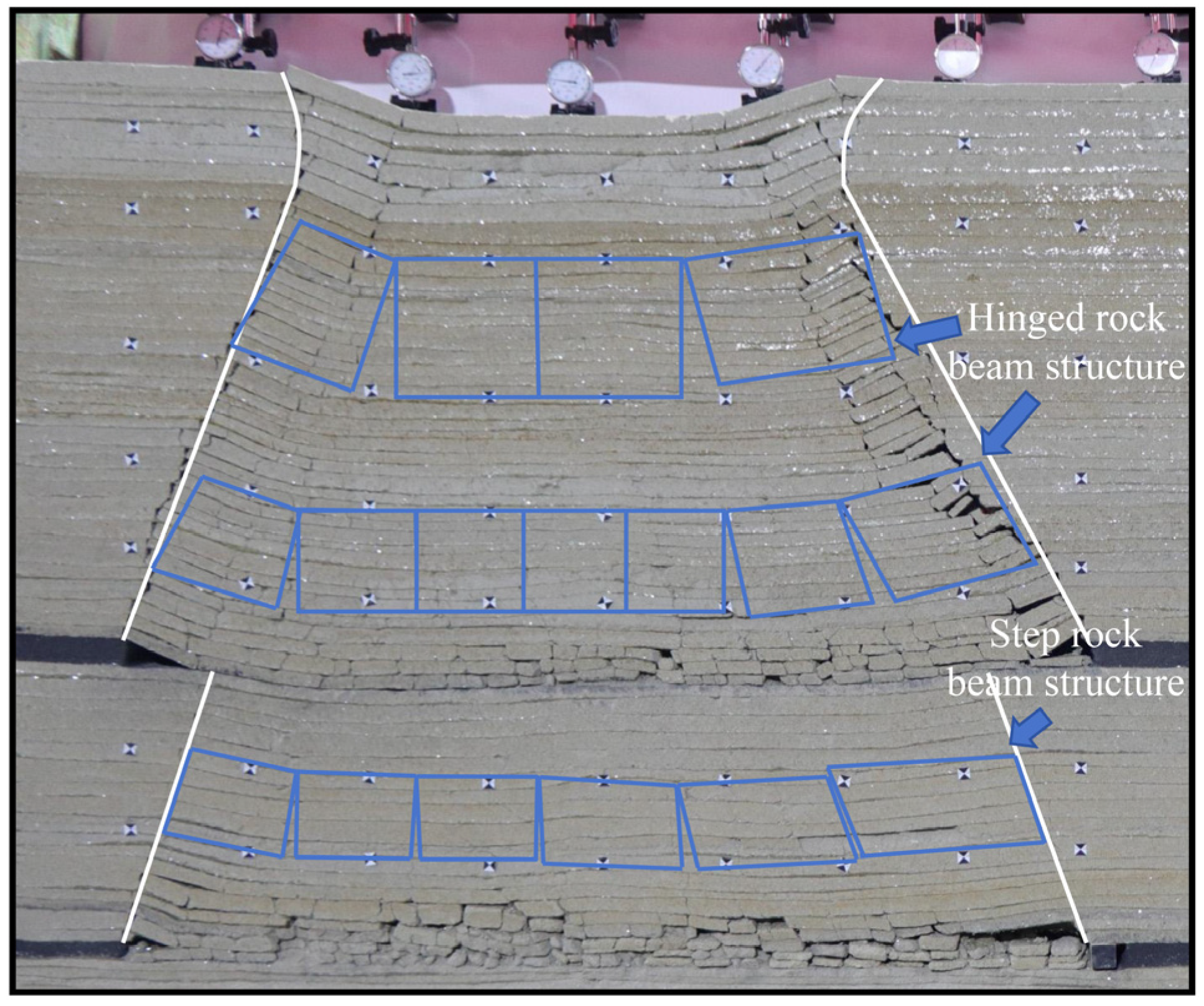

- Fracture characteristics of key strata during the extraction of the 2-2 coal seam

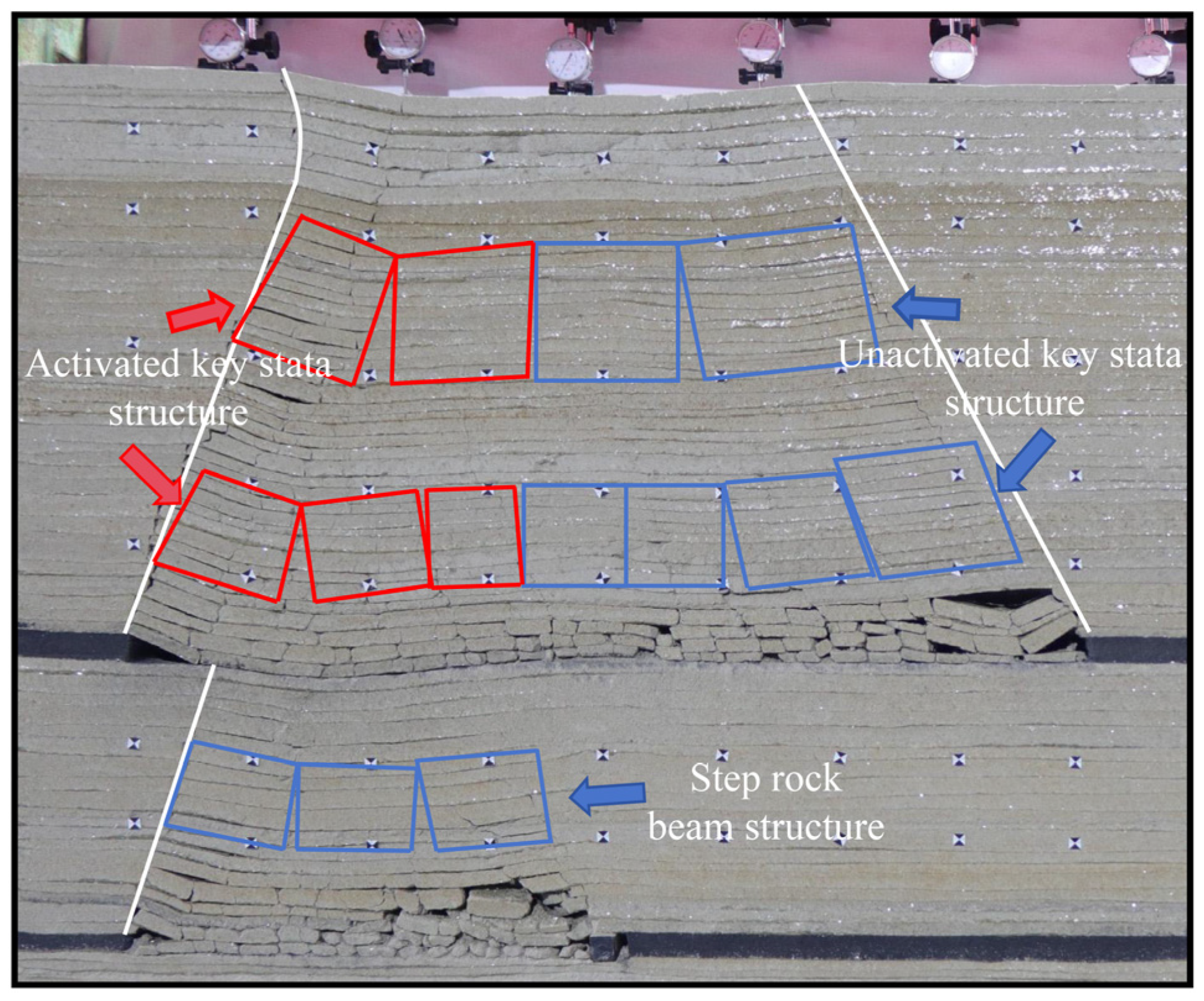

3.2. Activation Characteristics of Key Strata Support Structures

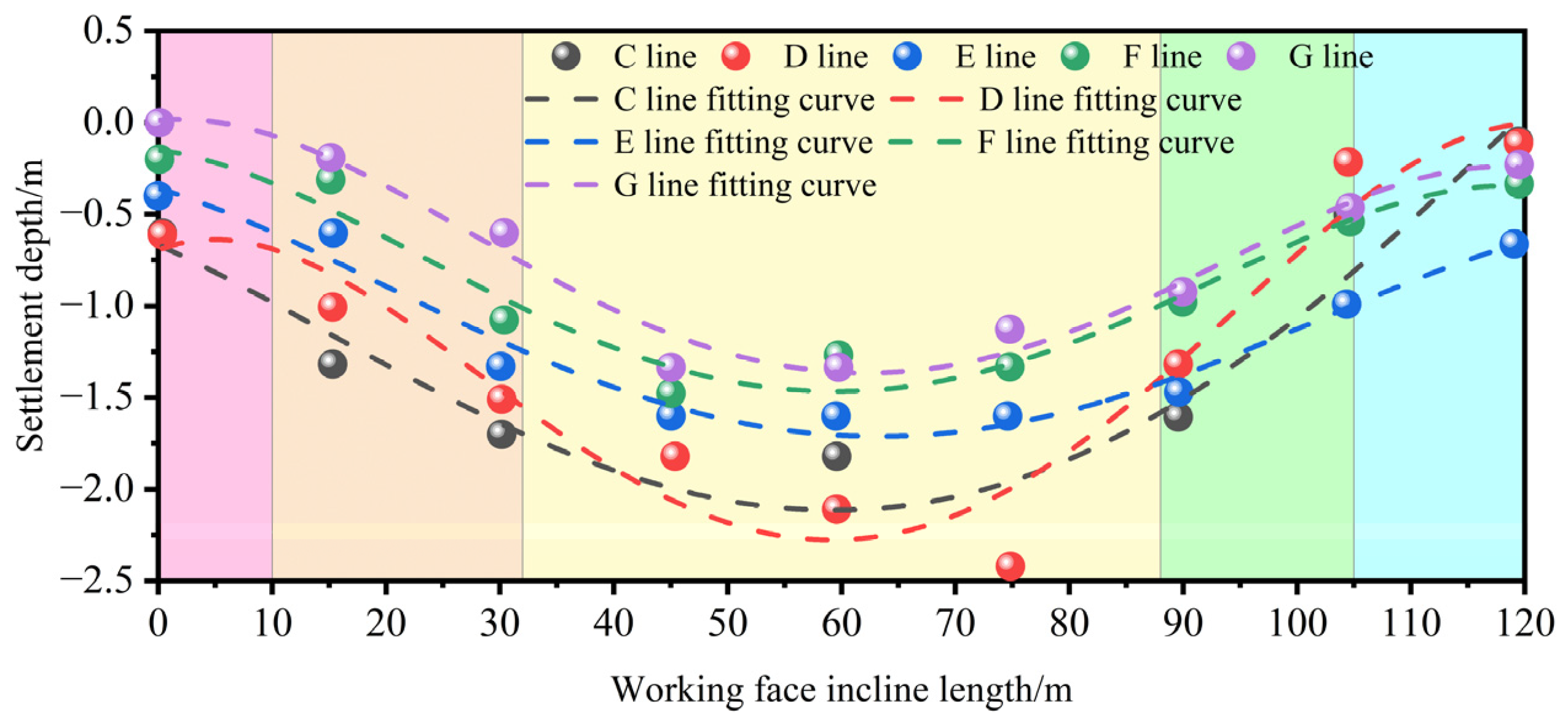

3.3. Movement Characteristics of Rock and Soil Layers in Shallow Coal Seam Group Mining

- (1)

- The characteristics of overburden movement due to coal seam mining

- (2)

- Characteristics of rock and soil layer movement in lower coal seam mining

4. Mechanical Mechanisms of Rolling Friction in Activated Key Strata Bearing Structures and Stability Assessment

4.1. Construction of Mechanical Models

4.2. Analysis of the Rolling Friction Mechanics in the Activation of Key Strata Bearing Structures

4.3. Stability Assessment of Activated Bearing Structures

5. Mechanical Characteristics of Activated and Restructured Key Strata Bearing Structures

5.1. Analysis of Non-Synchronous Migration Load Characteristics of Key Strata Bearing Structures

- (1)

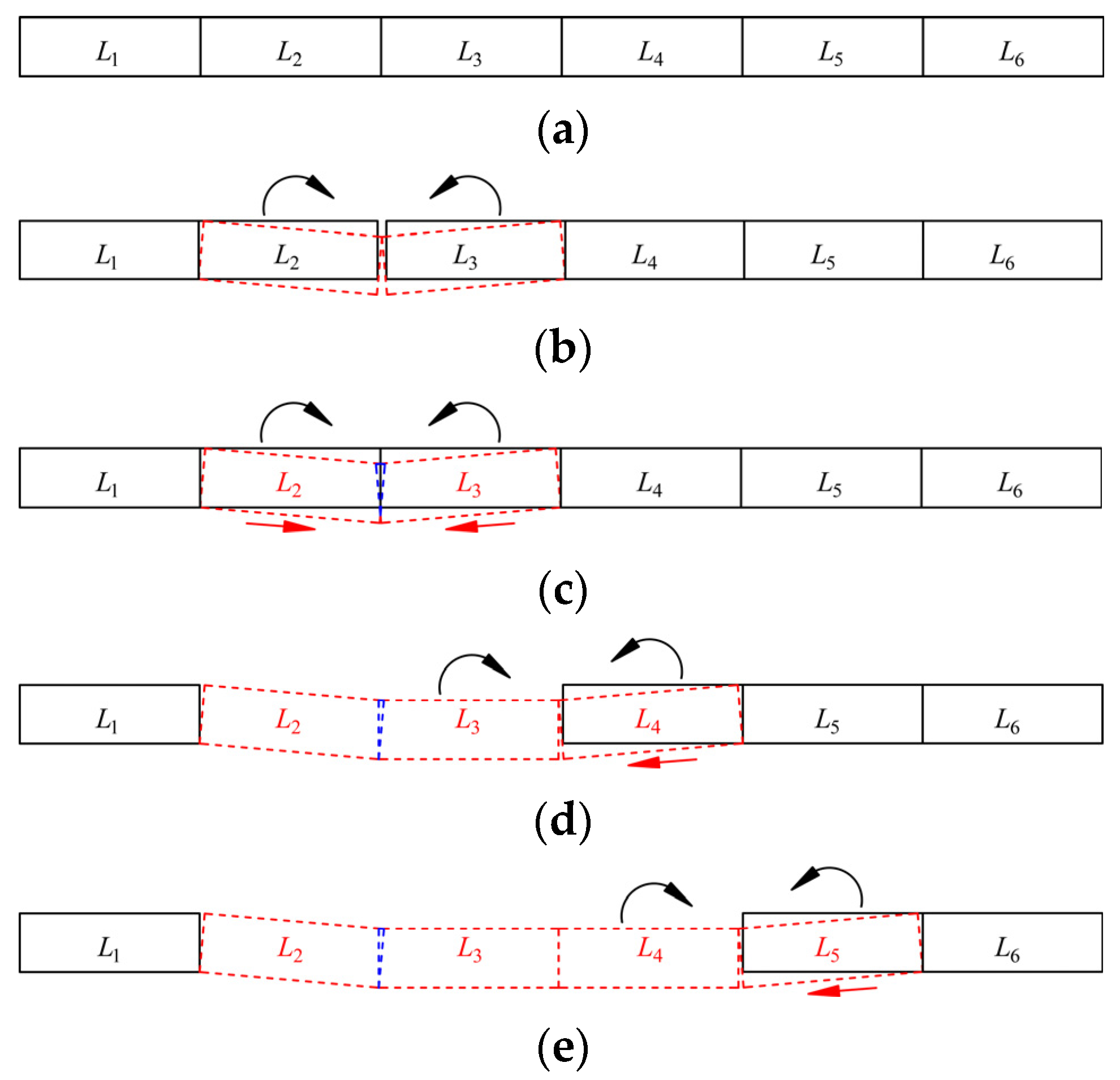

- Analysis of the key strata bearing structure without synchronous migration load mechanics model

- (2)

- Analysis of the key strata bearing structure instability load mechanics model

- (a)

- Stability of the sub-key strata

- (b)

- Instability of the sub-key strata

- (c)

- Simultaneous instability of sub-key strata and main key strata

5.2. Synchronous Migration Load Characteristics Analysis of Key Strata Bearing Structures

- (1)

- Analysis of the synchronous migration load mechanics model for sub-key strata activated bearing structures

- (2)

- Analysis of the synchronous migration load mechanics model for activated key strata bearing structures

5.3. Validation through Engineering Case Studies

6. Conclusions

- (1)

- Through physical similarity simulation, it was found that mining in the lower coal seam prompts the activation of overlying strata in the upper coal seam, forming a reorganized bearing structure that exerts a bearing effect on the overlying strata. At the initial stage of bearing structure activation, it presents as a V-shaped hinged arch, the blockiness of the immediate roof decreases, and the rock blocks tend to become spherical, which facilitates the transition of the sub-key strata from sliding friction to rolling friction.

- (2)

- Based on the rolling friction characteristics of the load-bearing structure, a mathematical model for calculating the rolling friction of the activated load-bearing structure of the key stratum was constructed. The coefficient of rolling friction for the key blocks of the subkey strata and the stability criterion of the load-bearing structure under rolling friction conditions were obtained. This facilitates a more precise theoretical calculation method for the structural effects of the load-bearing strata.

- (3)

- Drawing from the migration characteristics of bearing structures in coal seam groups, four types of mechanical models for key strata bearing structures were established: a key strata bearing structure without synchronous migration load mechanics model, a key strata bearing structure instability load mechanics model, a sub-key strata activated bearing structure with synchronous migration load mechanics model, and a key strata activated bearing structure with synchronous migration load mechanics model. Furthermore, load calculation formulas for these mechanical models were derived.

- (4)

- Based on site monitoring and the calculation formulas, it was determined that the load is greatest when the key strata bearing structure of the working face is synchronously migrated during retreat mining. The existing support models meet the site requirements, but monitoring of mining pressure should be intensified.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, F.L.; Liu, B.Q.; Lv, K.; Gao, A.; Song, J.Y. Classification and movement characteristics of overlying strata structure of coal seams group mining in Datong mining area. J. Min. Saf. Eng. 2023, 40, 972–982. [Google Scholar]

- Wang, B.F.; Jiang, J.Q.; Liu, X.S.; Liang, B.; Zhang, J. Analysis and application of sheared and fallen roof structure during shallowly buried fully mechanized mining under thick loose bed and thin base rock. Rock Soil Mech. 2023, 44, 3011–3021. [Google Scholar]

- Gu, D.Z.; Zhang, Y.; Cao, Z.G. Technical progress of water resource protection and utilization by coal mining in China. Coal Sci. Technol. 2016, 44, 1–7. [Google Scholar]

- Sun, Y.J.; Zhang, M.F.; Gao, S.; Xu, Z.M.; Shao, F.Y.; Jiang, S. Water preserved mining technology and practice in typical high intensity mining area of China. J. China Coal Soc. 2017, 42, 56–65. [Google Scholar]

- Islam, A.; Abdullah, R.A.; Ibrahim, I.S.; Lai, G.T.; Chaudry, M.H.; Junaid, M.; Iqbal, Z.; Jamal, N.; Aziz, A.F.A.; Salim, A. Effect of stress ratio K due to varying overburden topography on crack intensity of tunnel liner. J. Perform. Constr. Facil. 2023, 37, 04023026. [Google Scholar] [CrossRef]

- Malinowska, A.A.; Hejmanowski, R. The impact of deep underground coal mining on earth fissure occurrence. Acta Geodyn. Geomater. 2016, 13, 321–330. [Google Scholar] [CrossRef]

- Prakash, A.; Kumar, A.; Verma, A. Trait of subsidence under high rate of coal extraction by longwall mining: Some inferences. Sadhana-Acad. Proc. Eng. Sci. 2021, 46, 216. [Google Scholar] [CrossRef]

- Dyczko, A.; Malec, M.; Prostanski, D. The efficiency of longwall systems in the case of using different cutting technologies in the LW Bogdanka. Acta Montan. Slovaca 2020, 25, 504–516. [Google Scholar]

- Qian, M.G.; Miao, X.X.; Xu, J.L. Theoretical study of key stratum in ground control. J. China Coal Soc. 1996, 21, 225–230. [Google Scholar]

- Hou, Z.J. Study on application of combinatorial key stratum theory and parameters determining. J. China Coal Soc. 2001, 26, 611–615. [Google Scholar]

- Hou, Z.J. Study on key stratum in shallow seam. J. China Coal Soc. 1999, 24, 25–29. [Google Scholar]

- Huang, Q.X.; Qian, M.G.; Shi, P.W. Structural analysis of main roof stability during periodic weighting in longwall face. J. China Coal Soc. 1999, 24, 581–585. [Google Scholar]

- Huang, Q.X. Ground pressure behavior and definition of shallow seams. Chin. J. Rock Mech. Eng. 2002, 21, 1174–1177. [Google Scholar]

- Huang, Q.X.; Huang, K.J.; Zhao, M.Y. Research on roof structure and support resistance during first periodic weighting in shallow group coal seams. J. Min. Saf. Eng. 2018, 35, 940–944. [Google Scholar]

- Shi, J.X.; Hou, Z.J.; He, Z.F. The law of ground pressure manifestation in shallow buried working faces. Mine Press. Roof Manag. 1992, 2, 33–37+79–81. [Google Scholar]

- Li, S.G.; Shi, P.; Qian, M.G. Study on the dynamic distribution characteristics of overlying rock mining fracture elliptical throw zone. Mine Press. Roof Manag. 1999, Z1, 44–46. [Google Scholar]

- Huang, Q.X.; Cao, J.; He, Y.P.; Wang, B.Q.; Miao, Y.P.; Li, J. Classification of shallow buried close seams group and support resistance determination. J. Min. Saf. Eng. 2018, 35, 1177–1184. [Google Scholar]

- Ren, Y.F. Presentation and verification of “cantilever beam-articulated rock beam” composite structure in shallow buried working face. J. China Coal Soc. 2019, 44 (Suppl. S1), 1–8. [Google Scholar]

- Zhang, J.; He, Y.F. Research on the fracture evolution law and combined bearing structure load of shallow buried coal seam group. Coal Sci. Technol. 2023, 51, 65–76. [Google Scholar]

- Xu, J.L.; Xuan, D.Y.; Zhu, W.B.; Wang, X.Z. Partial backflling coal mining technology based on key strata control. J. Min. Strat. Control. Eng. 2019, 1, 69–76. [Google Scholar]

- Guo, G.L.; Li, H.Z.; Zha, J.F. Research status and countermeasures of coordinated development of coal mining and cultivated land protection in the plain coal-cropland overlapped areas. Coal Sci. Technol. 2023, 51, 416–426. [Google Scholar]

- Guo, W.B.; Bai, E.H.; Zhao, G.B. Current status and progress on overburden and surface damage and prevention technology of high-intensity mining. J. China Coal Soc. 2020, 45, 509–523. [Google Scholar]

- Zhang, J.; He, Y.F.; Yang, T.; Bai, W.Y.; Wu, J.J. Coevolution mechanism and branch of pillar-overburden fissures in shallow coal seam mining. Energy Sci. Eng. 2023, 11, 1630–1642. [Google Scholar] [CrossRef]

- Jiránková, E.; Waclawik, P.; Nemcik, J. Assessment of models to predict surface subsidence in the czech part of the upper silesian coal basin-case study. Acta Geodyn. Geomater. 2020, 17, 469–484. [Google Scholar] [CrossRef]

- Klishin, V.I.; Fryanov, V.N.; Pavlova, L.D.; Opruk, G.Y. Modeling top coal disintegration in thick seams in longwall top coal caving. J. Min. Sci. 2020, 15, 247–256. [Google Scholar] [CrossRef]

- Zhu, C.; Yuan, Y.; Chen, Z.; Liu, Z.; Yuan, C. Study of the stability control of the rock surrounding double-key strata recovery roadways in shallow seams. Adv. Civ. Eng. 2019, 2019, 9801637. [Google Scholar] [CrossRef]

- Szurgacz, D. Analysis of the pressure increase in the hydraulic cylinder of the longwall powered roof support during use. Appl. Sci. 2022, 12, 8806. [Google Scholar] [CrossRef]

- Su, W.; Zheng, B.; Jiang, P. Study on anchor cable instead of single hydraulic prop support in advance support of deep roadway. Adv. Civ. Eng. 2021, 2021, 6644832. [Google Scholar] [CrossRef]

- Ning, J.; Wang, J.; Tan, Y.; Xu, Q. Mechanical mechanism of overlying strata breaking and development of fractured zone during close-distance coal seam group mining. Int. J. Min. Sci. Technol. 2020, 30, 207–215. [Google Scholar] [CrossRef]

- Mehrabi, A.; Derakhshani, R.; Nilfouroushan, F.; Rahnamarad, J.; Azarafza, M. Spatiotemporal subsidence over Pabdana coal mine Kerman province, central Iran using time-series of Sentinel-1 remote sensing imagery. Episodes 2023, 46, 19–33. [Google Scholar] [CrossRef]

- Hossain, M.I.S.; Alam, M.S.; Biswas, P.K.; Rana, M.S.; Sultana, M.S. Integrated satellite imagery and electrical resistivity analysis of underground mine-induced subsidence and associated risk assessment of Barapukuria coal mine, Bangladesh. Environ. Earth Sci. 2023, 82, 537. [Google Scholar] [CrossRef]

- Yi, S.; Zhang, Y.; Yi, H.; Li, X.; Wang, X.; Wang, Y.; Chu, T. Study on the instability activation mechanism and deformation law of surrounding rock affected by water immersion in goafs. Water 2022, 14, 3250. [Google Scholar] [CrossRef]

- Frith, R.; Reed, G. Limitations and potential design risks when applying empirically derived coal pillar strength equations to real-life mine stability problems. Int. J. Min. Sci. Technol. 2019, 29, 17–25. [Google Scholar] [CrossRef]

- Jiang, J.Q.; Wu, Q.L.; Qu, H. Characteristic of mining stress evolution and activation of the reverse fault below the hard-thick strata. J. China Coal Soc. 2015, 40, 267–277. [Google Scholar]

- Smoliński, A.; Malashkevych, D.; Petlovanyi, M.; Rysbekov, K.; Lozynskyi, V.; Sai, K. Research into impact of leaving waste rocks in the mined-out space on the geomechanical state of the rock mass surrounding the longwall face. Energies 2023, 15, 9522. [Google Scholar] [CrossRef]

- Malashkevych, D.; Petlovanyi, M.; Sai, K.; Zubko, S. Research into the coal quality with a new selective mining technology of the waste rock accumulation in the mined-out area. Min. Miner. Depos. 2022, 16, 103–114. [Google Scholar] [CrossRef]

- Huang, Q.X.; Wang, X.J.; Hu, J.; Zhou, H.F.; Li, J.; He, Y.P. Activated roof structure and dynamic load of support under goaf oflow-buried close coal seams in loess hilly area. J. Min. Saf. Eng. 2023, 40, 983–990. [Google Scholar]

- Li, S.L. Study on misspacing of close distance cooperative mining of upper and lower coal seams based on stable pressure zone theory. Coal Sci. Technol. 2022, 50 (Suppl. S2), 44–49. [Google Scholar]

| Number | Lithology | Thickness (m) | Model Thickness (cm) | Tensile Strength (MPa) | Compressive Strength (MPa) | Bulk Modulus (MPa) | Volumetric Weight (kN·m−3) | Rock Type |

|---|---|---|---|---|---|---|---|---|

| 20 | Loess | 18.1 | 18 | 0.089 | 0.42 | 1134 | 16.3 | Loose loess layer |

| 19 | Siltstone | 16.63 | 16.5 | 2.1 | 31.2 | 738 | 23.4 | Main key strata |

| 18 | Medium-grained sandstone | 5.08 | 5 | 2.42 | 28.4 | 1487 | 23.8 | Interval rock strata |

| 17 | Mudstone | 2.66 | 2.5 | 1.33 | 13.2 | 733 | 27.6 | |

| 16 | Fine-grained sandstone | 1.6 | 1.5 | 1.95 | 28.6 | 1536 | 23.2 | |

| 15 | Siltstone | 4.93 | 5 | 2.3 | 32.1 | 756 | 24.1 | |

| 14 | Coarse-grained sandstone | 10.77 | 11 | 2.54 | 26.4 | 1433 | 22.8 | Sub-key strata |

| 13 | Mudstone | 1.2 | 1.5 | 1.29 | 12.9 | 752 | 28.1 | No. 1-2 coal immediate roof |

| 12 | Fine-grained sandstone | 1.23 | 1.5 | 1.94 | 27.9 | 1531 | 23.0 | |

| 11 | Medium-grained sandstone | 0.53 | 0.5 | 2.33 | 27.3 | 1494 | 23.4 | |

| 10 | Fine-grained sandstone | 3.7 | 4 | 1.87 | 28.3 | 1548 | 23.5 | |

| 9 | Siltstone | 4.65 | 4.5 | 2.2 | 29.8 | 746 | 23.1 | |

| 8 | No. 1-2 coal seam | 2.95 | 3 | 0.37 | 12.4 | 614 | 13.2 | |

| 7 | Siltstone | 3.92 | 4 | 2.4 | 28.9 | 782 | 24.3 | Interlayer rock |

| 6 | Fine-grained sandstone | 8 | 8 | 1.98 | 27.4 | 1621 | 23.3 | |

| 5 | Medium-grained sandstone | 8.02 | 8 | 2.45 | 28.4 | 1453 | 24.6 | Interlayer key strata |

| 4 | Siltstone | 6.23 | 6.5 | 2.3 | 29.8 | 744 | 23.4 | No. 2-2 coal immediate roof |

| 3 | Siltstone | 7.41 | 7.5 | 2.2 | 28.7 | 752 | 24.2 | |

| 2 | No. 2-2 coal seam | 3.3 | 3.5 | 0.34 | 12.6 | 625 | 13.4 | |

| 1 | Mudstone | 1.21 | 1 | 1.32 | 13.1 | 758 | 28.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Zhang, J.; Liu, H.; Yang, T.; Sun, J. Study on Activation and Restructuring of Key Strata in Shallowly Buried Coal Seam Bearing Structure and Load Characteristics. Processes 2024, 12, 1257. https://doi.org/10.3390/pr12061257

He Y, Zhang J, Liu H, Yang T, Sun J. Study on Activation and Restructuring of Key Strata in Shallowly Buried Coal Seam Bearing Structure and Load Characteristics. Processes. 2024; 12(6):1257. https://doi.org/10.3390/pr12061257

Chicago/Turabian StyleHe, Yifeng, Jie Zhang, Hui Liu, Tao Yang, and Jianping Sun. 2024. "Study on Activation and Restructuring of Key Strata in Shallowly Buried Coal Seam Bearing Structure and Load Characteristics" Processes 12, no. 6: 1257. https://doi.org/10.3390/pr12061257

APA StyleHe, Y., Zhang, J., Liu, H., Yang, T., & Sun, J. (2024). Study on Activation and Restructuring of Key Strata in Shallowly Buried Coal Seam Bearing Structure and Load Characteristics. Processes, 12(6), 1257. https://doi.org/10.3390/pr12061257