Experimental Investigation on Active Heat Transfer Improvement in Double-Pipe Heat Exchangers

Abstract

:1. Introduction

2. Experimental Setup

3. Governing Equations

4. Ultrasonic Enhancement of Heat Transfer Mechanisms

4.1. Macroscopic Effects

4.2. Microscopic Effects

5. Results and Discussion

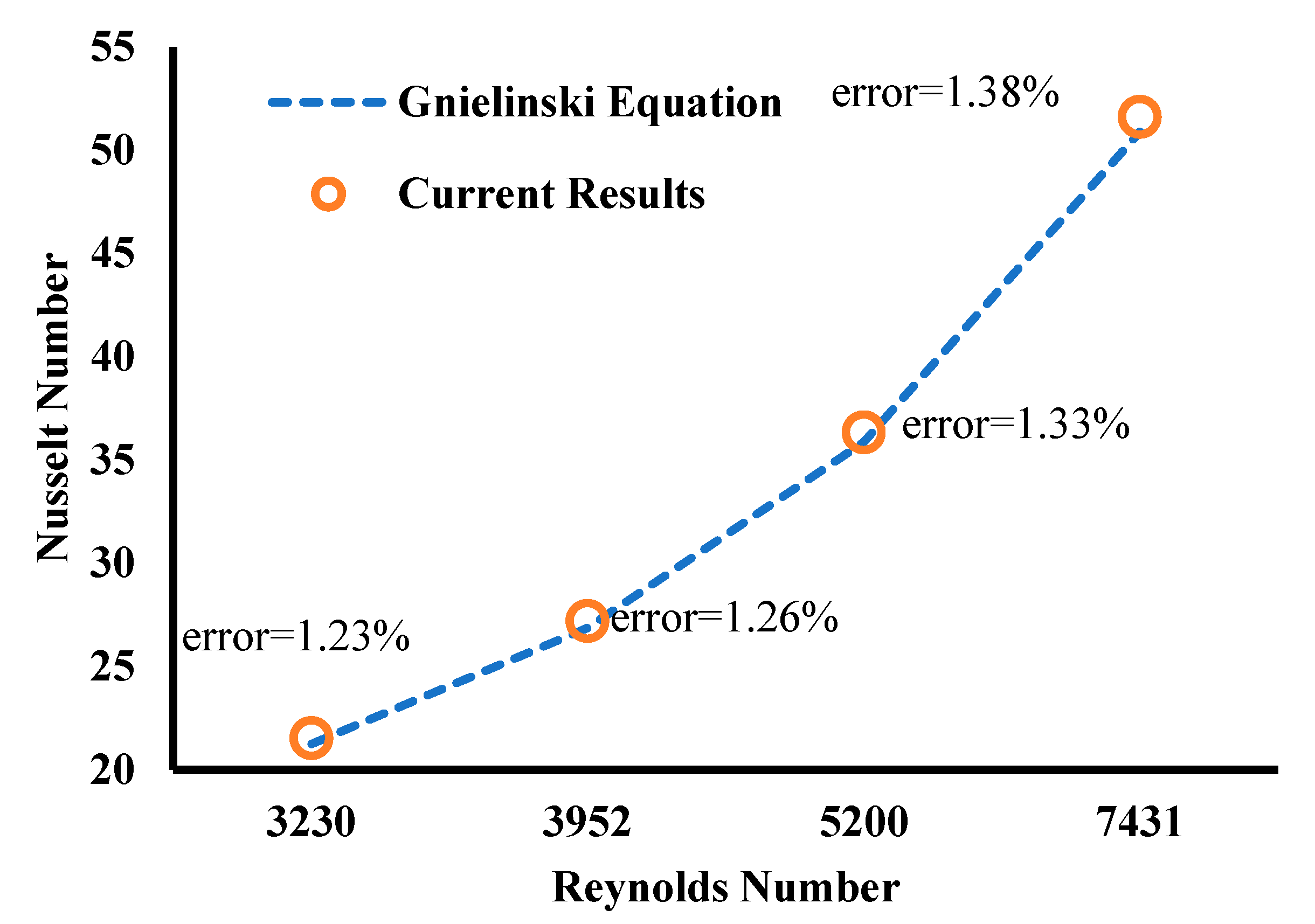

5.1. Validation Tests

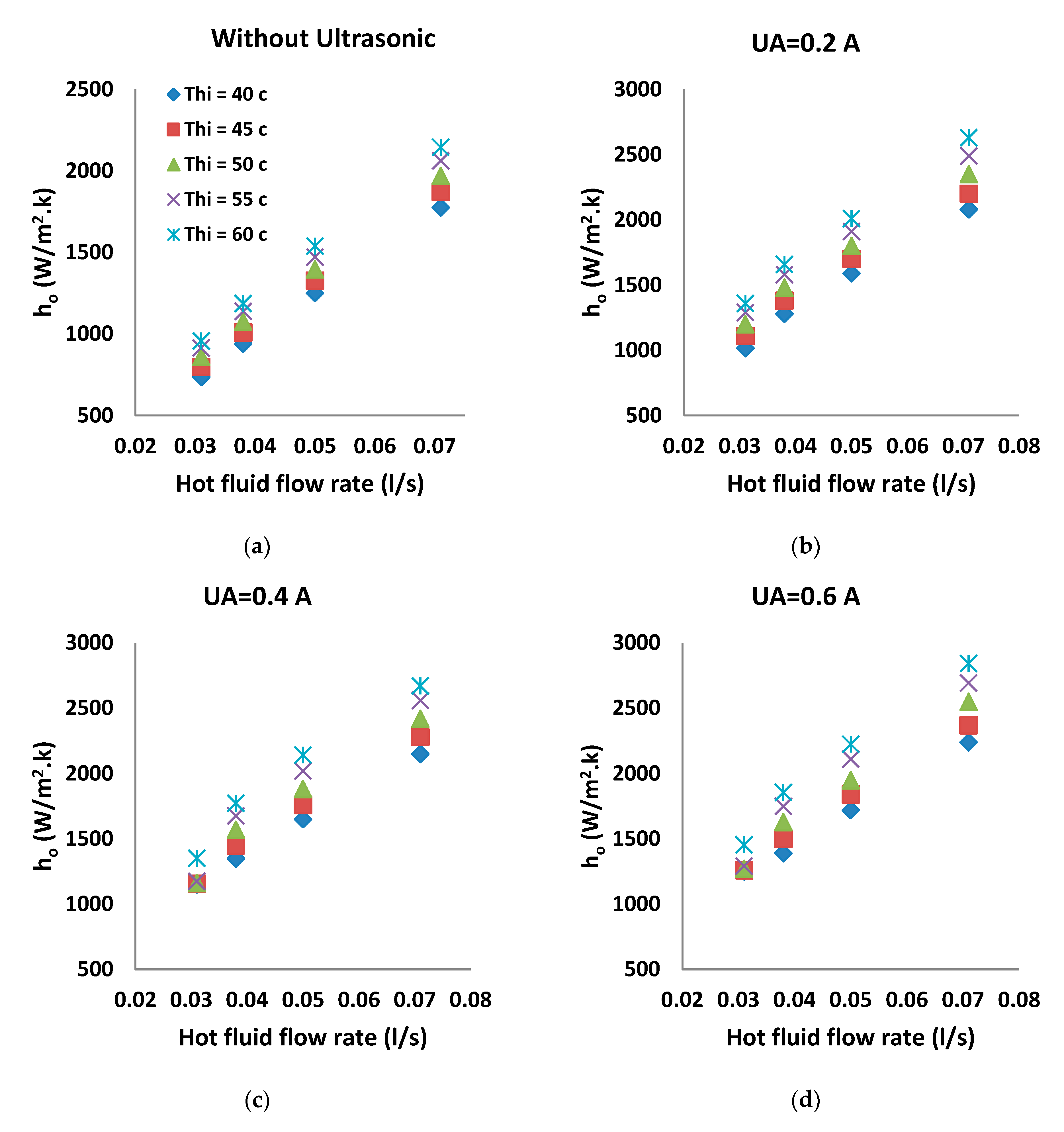

5.2. Variation of Convective Heat Transfer Coefficient

5.3. Variation of Ultrasonic Power Levels

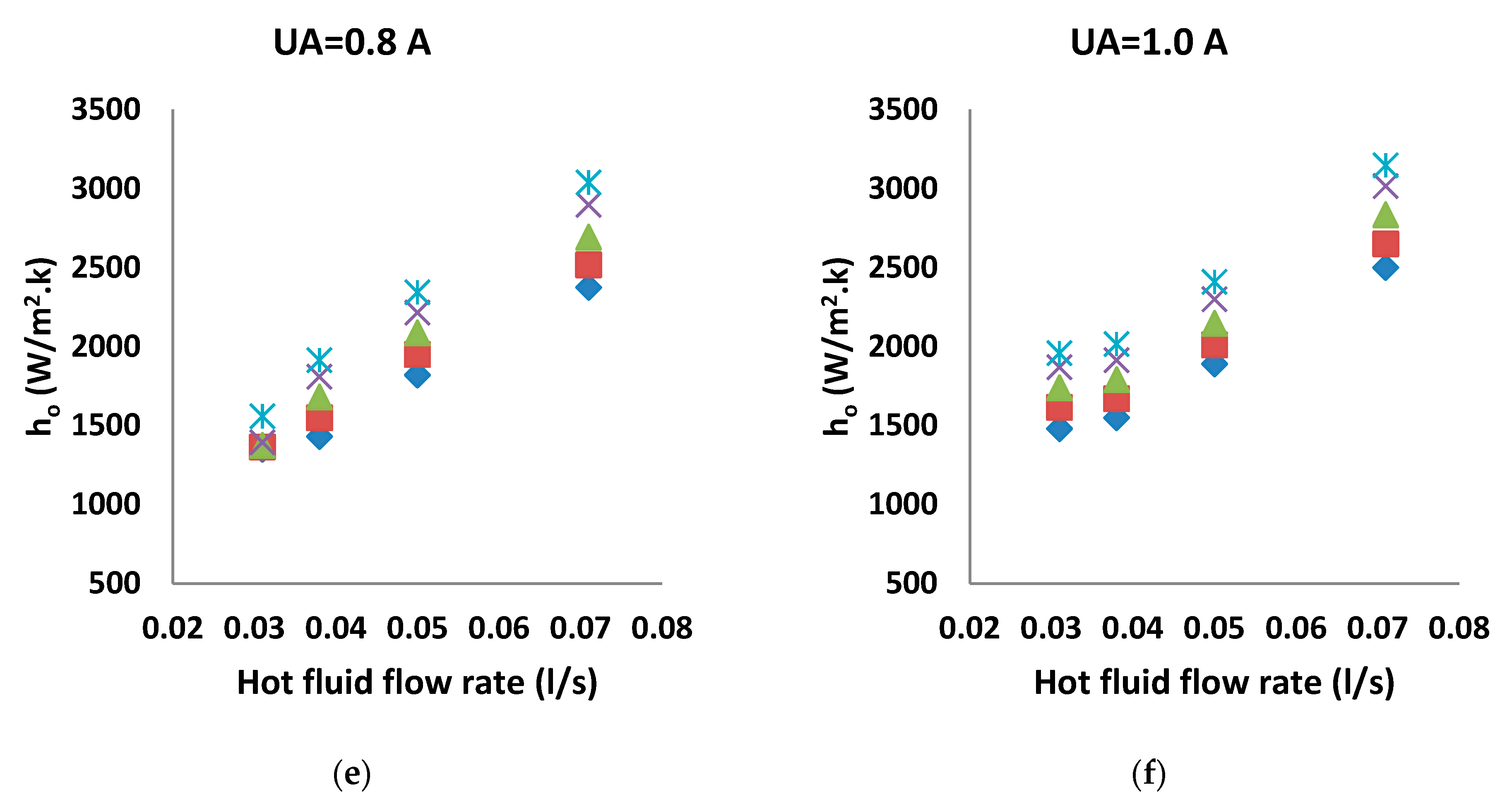

5.4. Variation of Heat Transfer Rate

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Declaration of AI and AI-Assisted Technologies in the Writing Process

References

- Omidi, M.; Farhadi, M.; Jafari, M. A comprehensive review on double pipe heat exchangers. Appl. Therm. Eng. 2017, 110, 1075–1090. [Google Scholar] [CrossRef]

- Musielak, G. Modeling of heat and mass transfer during ultrasound-assisted drying of a packed bed consisting of highly shrinkable material. Chem. Eng. Res. Des. 2018, 129, 25–33. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, M.; Mujumdar, A.S.; Zhong, Q.; Wang, Z. Effects of ultrasonic pretreatments on quality, energy consumption and sterilization of barley grass in freeze drying. Ultrason. Sonochem. 2018, 40, 333–340. [Google Scholar] [CrossRef] [PubMed]

- Gao, P.; Zhou, X.; Cheng, B.; Zhang, D.; Zhou, G. Study on heat and mass transfer of droplet cooling in ultrasound wave. Int. J. Heat Mass Transf. 2016, 107, 916–924. [Google Scholar] [CrossRef]

- Rostami, Z.; Rahimi, M.; Azimi, N. Using high-frequency ultrasound waves and nanofluid for increasing the efficiency and cooling performance of a PV module. Energy Convers. Manag. 2018, 160, 141–149. [Google Scholar] [CrossRef]

- Thomä, M.; Wagner, G.; Straß, B.; Wolter, B.; Benfer, S.; Fürbeth, W. Ultrasound enhanced friction stir welding of aluminum and steel: Process and properties of EN AW 6061/DC04-Joints. J. Mater. Sci. Technol. 2018, 34, 163–172. [Google Scholar] [CrossRef]

- Bouazaoui, O.; Chouaf, A. Characterization of Defects in Termite Welds Rails by Ultrasound Method. Procedia Eng. 2017, 181, 991–998. [Google Scholar] [CrossRef]

- Reuter, F.; Lauterborn, S.; Mettin, R.; Lauterborn, W. Membrane cleaning with ultrasonically driven bubbles. Ultrason. Sonochem. 2017, 37, 542–560. [Google Scholar] [CrossRef] [PubMed]

- Luján-Facundo, M.-J.; Mendoza-Roca, J.-A.; Cuartas-Uribe, B.; Álvarez-Blanco, S. Membrane fouling in whey processing and subsequent cleaning with ultrasounds for a more sustainable process. J. Clean. Prod. 2017, 143, 804–813. [Google Scholar] [CrossRef]

- Luo, X.; Cao, J.; Yan, H.; Gong, H.; Yin, H.; He, L. Study on separation characteristics of water in oil (W/O) emulsion under ultrasonic standing wave field. Chem. Eng. Process. Process Intensif. 2018, 123, 214–220. [Google Scholar] [CrossRef]

- Carletti, C.; De Blasio, C.; Miceli, M.; Pirone, R.; Westerlund, T. Ultrasonic enhanced limestone dissolution: Experimental and mathematical modeling. Chem. Eng. Process.—Process. Intensif. 2017, 118, 26–36. [Google Scholar] [CrossRef]

- Li, K.W.; Parker, J.D. Acoustical effects on free convective heat transfer from a horizontal wire. J. Heat Transf. 1967, 89, 277–278. [Google Scholar] [CrossRef]

- Bergles, A.; Newell, P. The influence of ultrasonic vibrations on heat transfer to water flowing in annuli. Int. J. Heat Mass Transf. 1965, 8, 1273–1280. [Google Scholar] [CrossRef]

- Kim, H.Y.; Kim, Y.G.; Kang, B.H. Enhancement of natural convection and pool boiling heat transfer via ultrasonic vibration. Int. J. Heat Mass Transf. 2004, 47, 2831–2840. [Google Scholar] [CrossRef]

- Loh, B.-G.; Hyun, S.; Ro, P.I.; Kleinstreuer, C. Acoustic streaming induced by ultrasonic flexural vibrations and associated enhancement of convective heat transfer. J. Acoust. Soc. Am. 2002, 111, 875–883. [Google Scholar] [CrossRef] [PubMed]

- Setareh, M.; Saffar-Avval, M.; Abdullah, A. Experimental and numerical study on heat transfer enhancement using ultrasonic vibration in a double-pipe heat exchanger. Appl. Therm. Eng. 2019, 159, 113867. [Google Scholar] [CrossRef]

- Komarov, S.; Hirasawa, M. Enhancement of gas phase heat transfer by acoustic field application. Ultrasonics 2003, 41, 289–293. [Google Scholar] [CrossRef] [PubMed]

- Monnot, A.; Boldo, P.; Gondrexon, N.; Bontemps, A. Enhancement of Cooling Rate by Means of High Frequency Ultrasound. Heat Transf. Eng. 2007, 28, 3–8. [Google Scholar] [CrossRef]

- Gondrexon, N.; Rousselet, Y.; Legay, M.; Boldo, P.; Le Person, S.; Bontemps, A. Intensification of heat transfer process: Improvement of shell-and-tube heat exchanger performances by means of ultrasound. Chem. Eng. Process.—Process. Intensif. 2010, 49, 936–942. [Google Scholar] [CrossRef]

- Legay, M.; Simony, B.; Boldo, P.; Gondrexon, N.; Le Person, S.; Bontemps, A. Improvement of heat transfer by means of ultrasound: Application to a double-tube heat exchanger. Ultrason. Sonochem. 2011, 19, 1194–1200. [Google Scholar] [CrossRef]

- Legay, M.; Le Person, S.; Gondrexon, N.; Boldo, P.; Bontemps, A. Performances of two heat exchangers assisted by ultrasound. Appl. Therm. Eng. 2012, 37, 60–66. [Google Scholar] [CrossRef]

- Delouei, A.A.; Sajjadi, H.; Atashafrooz, M.; Hesari, M.; Hamida, M.B.B.; Arabkoohsar, A. Louvered fin-and-flat tube compact heat exchanger under ultrasonic excitation. Fire 2023, 6, 13. [Google Scholar] [CrossRef]

- Delouei, A.A.; Sajjadi, H.; Ahmadi, G. Ultrasonic Vibration Technology to Improve the Thermal Performance of CPU Water-Cooling Systems: Experimental Investigation. Water 2022, 14, 4000. [Google Scholar] [CrossRef]

- Delouei, A.A.; Sajjadi, H.; Ahmadi, G. The Effect of Piezoelectric Transducer Location on Heat Transfer Enhancement of an Ultrasonic-Assisted Liquid-Cooled CPU Radiator. Iran. J. Sci. Technol. Trans. Mech. Eng. 2024, 48, 239–252. [Google Scholar] [CrossRef]

- Hedeshi, M.; Jalali, A.; Arabkoohsar, A.; Delouei, A.A. Nanofluid as the working fluid of an ultrasonic-assisted double-pipe counter-flow heat exchanger. J. Therm. Anal. Calorim. 2023, 148, 8579–8591. [Google Scholar] [CrossRef]

- Tafarroj, M.M.; Delouei, A.A.; Hajjar, A.; Ben Hamida, M.B.; Izadi, M. MLP and optimized FCM-ANFIS models proposed for inlet turbulent flow under ultrasonic vibration. J. Therm. Anal. Calorim. 2023, 148, 13995–14009. [Google Scholar] [CrossRef]

- Esfandyari, M.; Delouei, A.A.; Jalai, A. Optimization of ultrasonic-excited double-pipe heat exchanger with machine learning and PSO. Int. Commun. Heat Mass Transf. 2023, 147, 106985. [Google Scholar] [CrossRef]

- Dhanalakshmi, N.P.; Nagarajan, R.; Sivagaminathan, N.; Prasad, B.V.S.S.S. Acoustic enhancement of heat transfer in furnace tubes. Chem. Eng. Process. Process Intensif. 2012, 59, 36–42. [Google Scholar] [CrossRef]

- Legay, M.; Gondrexon, N.; Le Person, S.; Boldo, P.; Bontemps, A. Enhancement of Heat Transfer by Ultrasound: Review and Recent Advances. Int. J. Chem. Eng. 2011, 2011, 670108. [Google Scholar] [CrossRef]

- Hosseinian, A.; Isfahani, A.H.M.; Shirani, E. Experimental investigation of surface vibration effects on increasing the stability and heat transfer coefficient of MWCNTs-water nanofluid in a flexible double pipe heat exchanger. Exp. Therm. Fluid Sci. 2018, 90, 275–285. [Google Scholar] [CrossRef]

- Rafati, M.; Hamidi, A.; Niaser, M.S. Application of nanofluids in computer cooling systems (heat transfer performance of nanofluids). Appl. Therm. Eng. 2012, 45, 9–14. [Google Scholar] [CrossRef]

- Delouei, A.A.; Naeimi, H.; Sajjadi, H.; Atashafrooz, M.; Imanparast, M.; Chamkha, A.J. An active approach to heat transfer enhancement in indirect heaters of city gate stations: An experimental modeling. Appl. Therm. Eng. 2024, 237, 121795. [Google Scholar] [CrossRef]

- Nazari, M.; Ashouri, M.; Kayhani, M.H.; Tamayol, A. Experimental study of convective heat transfer of a nanofluid through a pipe filled with metal foam. Int. J. Therm. Sci. 2015, 88, 33–39. [Google Scholar] [CrossRef]

- Kayhani, M.H.; Soltanzadeh, H.; Heyhat, M.M.; Nazari, M.; Kowsary, F. Experimental study of convective heat transfer and pressure drop of TiO2/water nanofluid. Int. Commun. Heat Mass Transf. 2012, 39, 456–462. [Google Scholar] [CrossRef]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

- Zarembo, L.K. Acoustic streaming. In High-Intensity Ultrasonic Fields; Rozenberg, L.D., Ed.; Plenum Press: New York, NY, USA, 1971. [Google Scholar]

- Eckart, C. Vortices and Streams Caused by Sound Waves. Phys. Rev. B 1948, 73, 68–76. [Google Scholar] [CrossRef]

- Ashokkumar, M. The characterization of acoustic cavitation bubbles—An overview. Ultrason. Sonochem. 2011, 18, 864–872. [Google Scholar] [CrossRef]

- Yuan, M.; Li, C.; Ge, J.; Xu, Q.; Li, Z. Study on the Motion Characteristics of Solid Particles in Fine Flow Channels by Ultrasonic Cavitation. Micromachines 2022, 13, 1196. [Google Scholar] [CrossRef]

- Xiao, J. Thermoacoustic heat transportation and energy transformation Part 2: Isothermal wall thermoacoustic effects. Cryogenics 1995, 35, 21–26. [Google Scholar] [CrossRef]

- Cai, J.; Huai, X.; Liang, S.; Li, X. Augmentation of natural convective heat transfer by acoustic cavitation. Front. Energy Power Eng. China 2010, 4, 313–318. [Google Scholar] [CrossRef]

- Fairbanks, H.V. Influence of ultrasound upon heat transfer systems. In Proceedings of the Ultrasonics Symposium, New Orleans, LA, USA, 26–28 September 1979; pp. 384–387. [Google Scholar]

- Legay, M.; Allibert, Y.; Gondrexon, N.; Boldo, P.; Le Person, S. Experimental investigations of fouling reduction in an ultrasonically-assisted heat exchanger. Exp. Therm. Fluid Sci. 2013, 46, 111–119. [Google Scholar] [CrossRef]

- Fu, Y.; Bian, B.; Liu, Y.; Zhang, L.; Li, M.; Wen, J.; Xu, G. Airside heat transfer analysis using Wilson plot method of three analogous serpentine tube heat exchangers for aero-engine cooling. Appl. Therm. Eng. 2024, 248, 123238. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, X.; Liu, B.; Zhao, L.; Cheng, Q.; Wang, Z. Analysis of the main influencing factors of waste heat utilization effectiveness in the tank storage receiving process of waxy crude oil under dynamic liquid level conditions. Renew. Energy 2024, 228, 120707. [Google Scholar] [CrossRef]

- Gnielinski, V. New equations for heat and mass transfer in turbulent pipe and channel flow. Int. Chem. Eng. 1976, 16, 359–368. [Google Scholar]

- Petukhov, B.S. Advances in Heat Transfer; Irvine, T.F., Hartnett, J.P., Eds.; Academic Press: New York, NY, USA, 1970. [Google Scholar]

| Tco (°C) | Tho (°C) | Qc (W) | Qh (W) | PUS (W) | Qloss (W) | Error (%) |

|---|---|---|---|---|---|---|

| 26.7 | 45.6 | 1289 | 1300 | 0 | −10 | 0.01 |

| 28.7 | 45.1 | 1668 | 1447 | 240 | −19 | 2.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jalali, A.; Amiri Delouei, A.; Zaertaraghi, M.R.; Amiri Tavasoli, S. Experimental Investigation on Active Heat Transfer Improvement in Double-Pipe Heat Exchangers. Processes 2024, 12, 1333. https://doi.org/10.3390/pr12071333

Jalali A, Amiri Delouei A, Zaertaraghi MR, Amiri Tavasoli S. Experimental Investigation on Active Heat Transfer Improvement in Double-Pipe Heat Exchangers. Processes. 2024; 12(7):1333. https://doi.org/10.3390/pr12071333

Chicago/Turabian StyleJalali, A., A. Amiri Delouei, M. R. Zaertaraghi, and S. Amiri Tavasoli. 2024. "Experimental Investigation on Active Heat Transfer Improvement in Double-Pipe Heat Exchangers" Processes 12, no. 7: 1333. https://doi.org/10.3390/pr12071333