Study on the Mobilization Mechanisms of Microscopic Residual Oil in High-Water-Cut Sandstone Reservoirs

Abstract

:1. Introduction

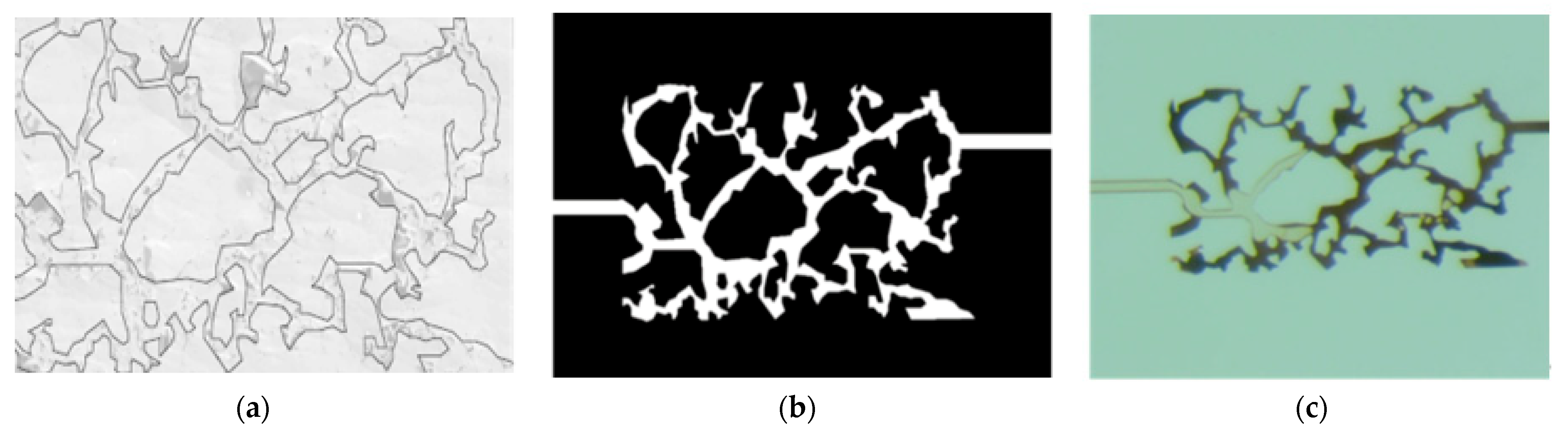

2. PDMS Microscopic Oil Displacement Model Observation Method

2.1. Experimental Principles

2.2. Quantification and Classification of Microscopic Residual Oil

2.3. Experimental Procedure

3. Quantitative Methods for Microscopic Residual Oil Mobilization Experiments

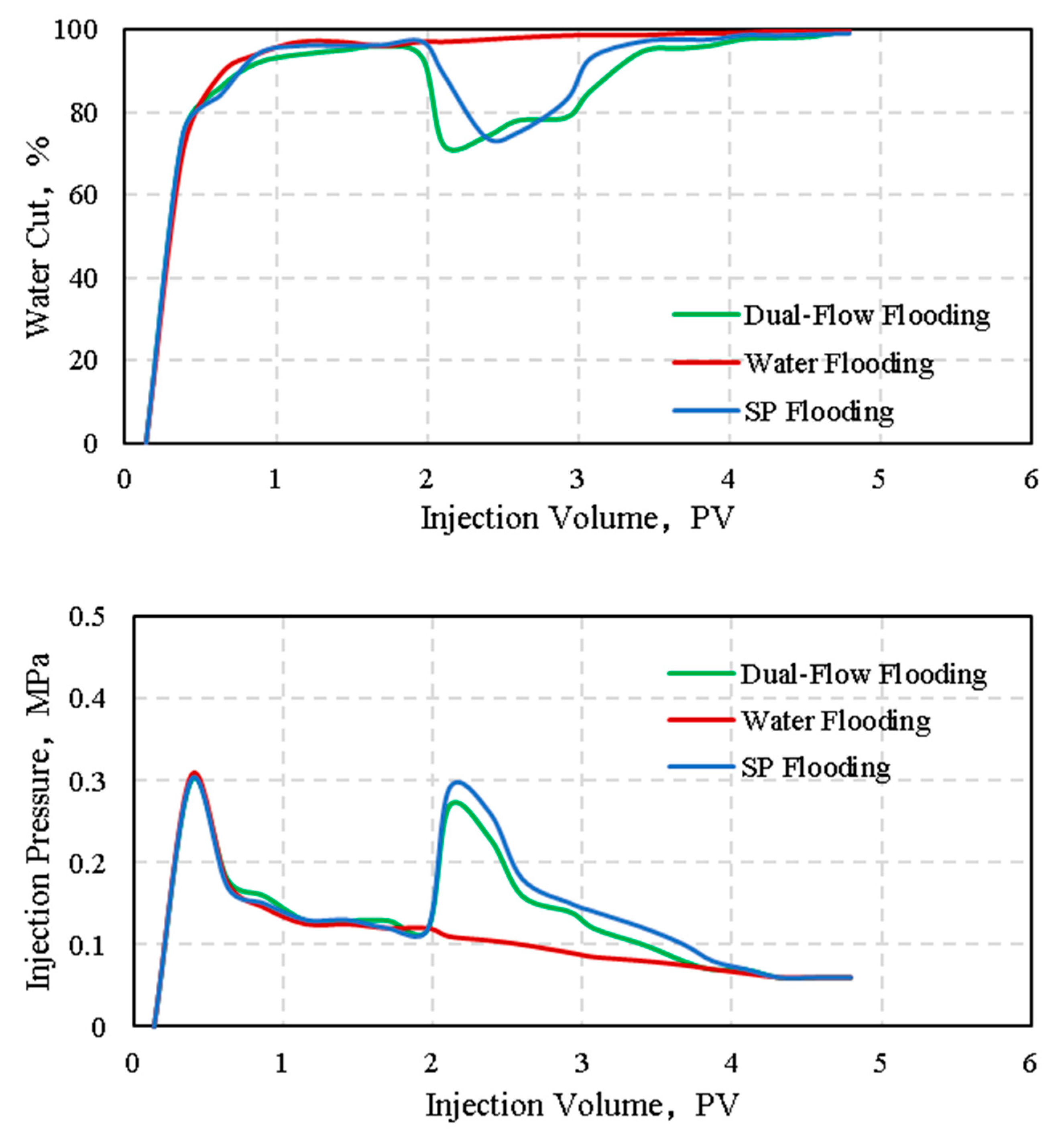

3.1. Differences in Microscopic Residual Oil Mobilization Effectiveness at Various Development Stages

3.2. Differences in Microscopic Residual Oil Mobilization Effectiveness with Various Chemical Agents

4. Analysis of Experimental Results

4.1. Distribution of Microscopic Residual Oil in the High-Water-Cut Stage after Water Flooding

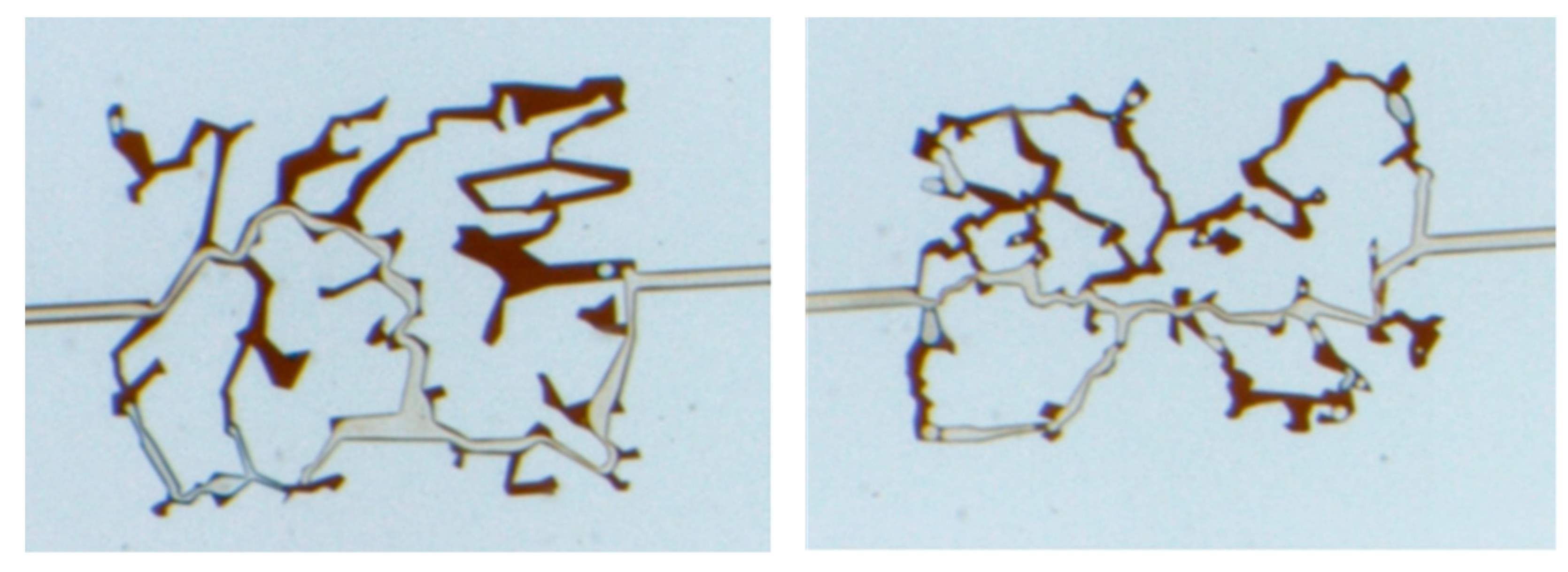

4.2. Mobilization of Microscopic Residual Oil after Different Chemical Flooding Methods

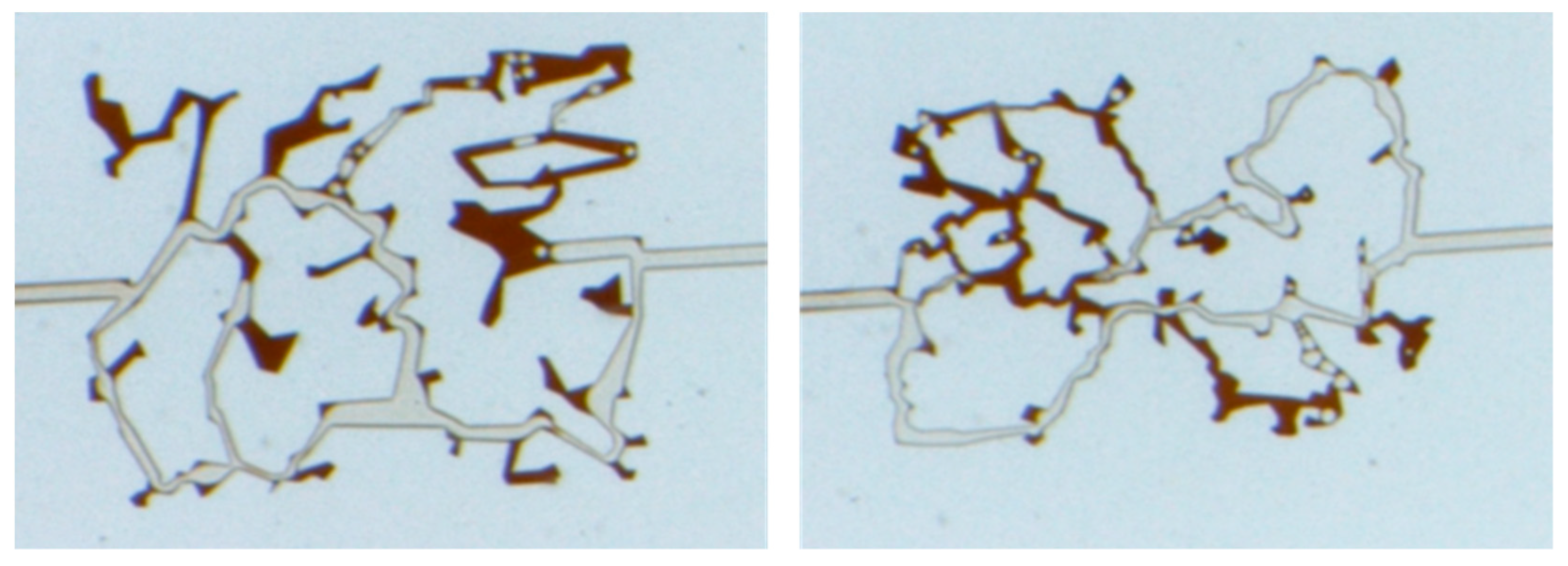

4.3. Mobilization of Microscopic Residual Oil after “Dual-Flow Flooding” Chemical Flooding

4.4. Differences in Microscopic Residual Oil Mobilization Among Various Systems

5. Conclusions

- (1)

- The PDMS oil displacement model uses polydimethylsiloxane (PDMS) as the model substrate, combined with laser etching technology, to create a microscopic displacement model on a 1:1 scale based on the actual pore structure of natural rock cores. The PDMS oil displacement model has a precision of 1 μm, making it closer to the pore throat size of natural sandstone. Through natural core data extraction, digital core modeling, and the 1:1 replication of the natural core pore throat structure, the model’s pore throat fidelity is significantly higher than that of traditional hand-etched glass models.

- (2)

- Microscopic residual oils can be categorized into four main types based on their occurrence state in porous media and different mobilization mechanisms: cluster-like, corner-like, pore surface film-like, and slit-like. The corner-like and cluster-like residual oils are mobilized by enhancing microscopic sweep efficiency, while the pore surface film-like and slit-like residual oils are mobilized by improving microscopic oil washing efficiency.

- (3)

- Different chemical flooding methods have distinct mobilization effects on various types of microscopic residual oil. Polymer solutions primarily enhance microscopic sweep efficiency with a secondary “pull and drag” oil washing effect, mainly mobilizing cluster-like and corner-like residual oils. Surfactant solutions focus on improving oil washing efficiency, but their low viscosity results in limited sweep efficiency, primarily mobilizing pore surface film-like and slit-like microscopic residual oil. Polymer–surfactant flooding solutions combine the characteristics of both polymer and surfactant solutions, effectively mobilizing all types of microscopic residual oil, although the solution cost is relatively high.

- (4)

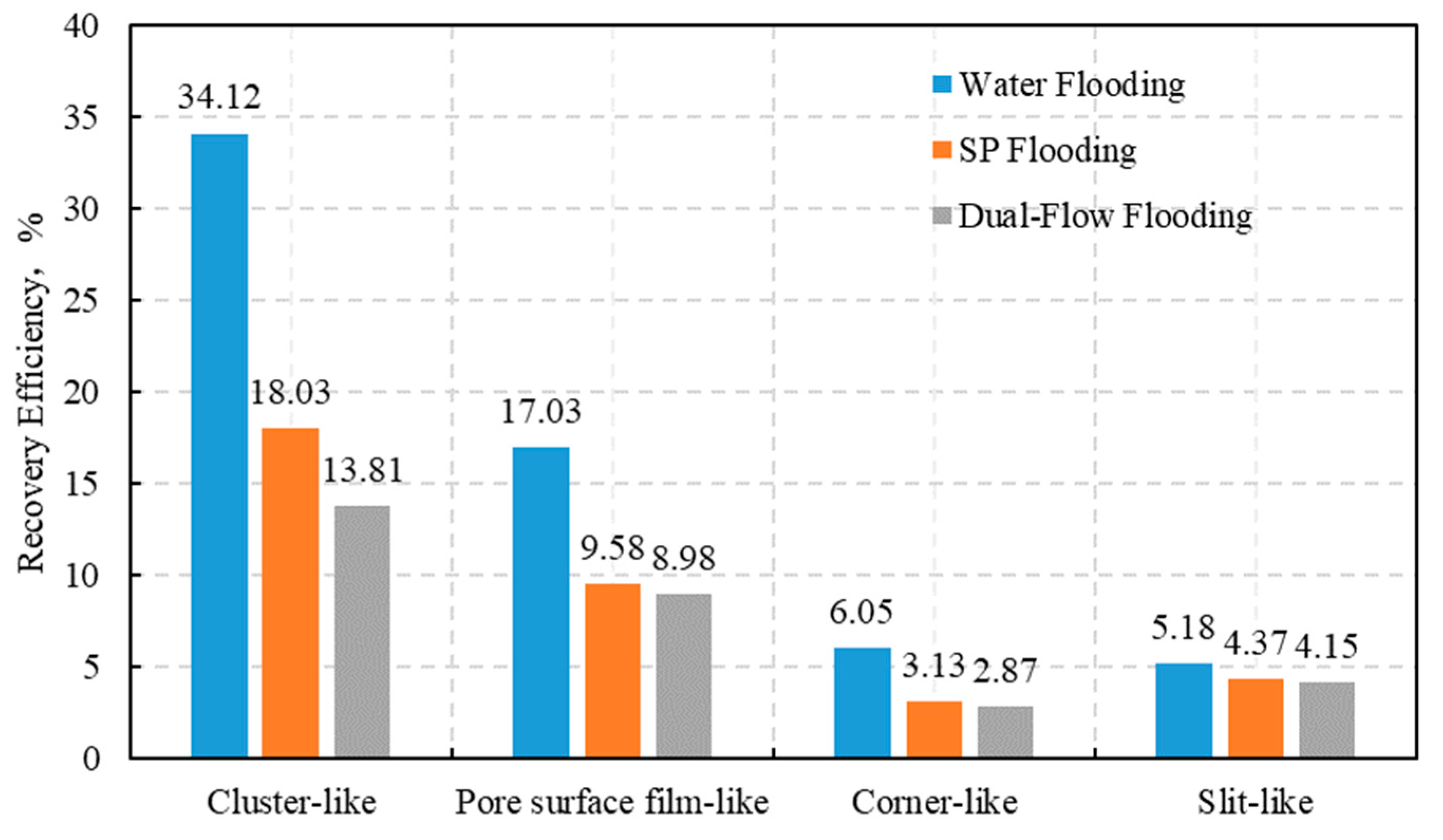

- SP flooding effectively mobilizes both cluster-like and pore surface film-like residual oil, with 47.16% of cluster-like residual oil and 43.74% of pore surface film-like residual oil being effectively mobilized. Corner-like and slit-like residual oils are also mobilized to some extent. On the basis of SP flooding, dual-mobility flooding further increases the mobilization of cluster-like residual oil by 12.37% and pore surface film-like residual oil by 3.52%. Although the rate of improvement slows compared to SP flooding, the development cost is reduced by 16.43% with the same slug size. Overall, dual-mobility flooding provides better development effectiveness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiong, A.; Cheng, G.; Li, D.; Ding, W.; Liu, Y.; Chen, G.; Yang, L.; Yuan, Y.; Zhu, Y.; Liu, L. Micropore Structure and Micro Residual Oil Distribution of Ultra-Low Permeable Reservoir: A Case Study of Chang 4+5 of Baibao Area, Wuqi Oilfield. J. Jilin Univ. Earth Sci. Ed. 2023, 53, 1338–1351. [Google Scholar]

- Zhou, Q.; Liu, J.; Zhang, D.; Li, C.; Xiao, Y.; Chen, G.; Lyu, C. Microscopic enrichment and porosity-permeability reduction mechanism of residual oil in tight sandstone reservoirs: An insight from Chang 8 Member, Yanchang Formation, Ordos Basin, China. J. Pet. Explor. Prod. Technol. 2024, 14, 1365–1393. [Google Scholar] [CrossRef]

- Liu, Y.; Pi, J.; Tong, K. Pore-Scale Experimental Investigation of the Residual Oil Formation in Carbonate Sample from the Middle East. Processes 2023, 11, 2289. [Google Scholar] [CrossRef]

- Liu, X.; Wang, J.; Ge, L.; Hu, F.; Li, C.; Li, X.; Yu, J.; Xu, H.; Lu, S.; Xue, Q. Pore-Scale Characterization of Tight Sandstone inYanchang Formation Ordos Basin China Using Micro-CT and SEM Imaging from Nm- to Cm-Scale. Fuel 2017, 209, 254–264. [Google Scholar] [CrossRef]

- She, Y.; Zhang, C.; Mahardika, M.A.; Patmonoaji, A.; Hu, Y.; Matsushita, S.; Suekane, T. Pore-Scale Study of in-Situ Surfactant Flooding with Strong Oil Emulsification in Sandstone Based on X-ray Microtomography. J. Ind. Eng. Chem. 2021, 98, 247–261. [Google Scholar] [CrossRef]

- Panahi, H.; Kobchenko, M.; Renard, F.; Mazzini, A.; Scheibert, J.; Dysthe, D.; Jamtveit, B.; Malthe-Sorenssen, A.; Meakin, P. 4D synchrotron X-ray-tomography study of the formation of hydrocarbon-migration pathways in heated organic-rich shale. SPE J. 2013, 18, 366–377. [Google Scholar] [CrossRef]

- Yakimov, A.S.; Pryazhnikov, A.I.; Pryazhnikov, M.I.; Skorobogatova, A.D.; Minakov, A.V. Plasma Surface Modification of PDMS-Glass Microfluidic Chips for Oil Recovery Studies. Appl. Sci. 2023, 13, 6365. [Google Scholar] [CrossRef]

- Jia, B.; Xian, C.; Tsau, J.S.; Zuo, X.; Jia, W. Status and Outlook of Oil Field Chemistry-Assisted Analysis during the Energy Transition Period. Energy Fuel 2022, 36, 12917–12945. [Google Scholar] [CrossRef]

- Olabode, O.; Dike, H.; Olaniyan, D.; Oni, B.; Faleye, M. Experimental Investigation of the Effect of Surfactant–Polymer Flooding on Enhanced Oil Recovery for Medium Crude Oil. Polymers 2024, 16, 1674. [Google Scholar] [CrossRef]

- Awelewa, K.; Ogunkunle, F.; Olabode, O.; Oni, B.; Abraham, D.; Adeleye, S.; Ifeanyi, S. Dataset on modelling natural surfactant adsorption derived from non-edible seed oil (linseed oil) on sandstone reservoir rock. Data Brief 2023, 50, 109578. [Google Scholar] [CrossRef]

- Olabode, O.; Oni, B.; Dike, H.; Akinsanya, O.; Ajidahun, J.; Olaniyan, D. Investigating the effect of salt concentration on oil recovery during guar gum polymer flooding: A simulation study. Results Eng. 2024, 22, 102269. [Google Scholar] [CrossRef]

- Olabode, O.; Akinsanya, O.; Daramola, O.; Sowunmi, A.; Osakwe, C.; Benjamin, S.; Samuel, I. Effect of Salt Concentration on Oil Recovery during Polymer Flooding: Simulation Studies on Xanthan Gum and Gum Arabic. Polymers 2023, 15, 4013. [Google Scholar] [CrossRef] [PubMed]

- Tananykhin, D.S.; Struchkov, I.A.; Khormali, A.; Roschin, P.V. Investigation of the influences of asphaltene deposition on oilfield development using reservoir simulation. Pet. Explor. Dev. 2022, 49, 1138–1149. [Google Scholar] [CrossRef]

- Cheng, B.; Li, J.; Jiang, S.; Lu, C.; Su, H.; Yu, F.; Jiang, H. Pore-Scale Investigation of Microscopic Remaining Oil Variation Characteristic in Different Flow Rates Using Micro-CT. Energies 2021, 14, 3057. [Google Scholar] [CrossRef]

- Li, J.; Gao, Y.; Jiang, H.; Liu, Y.; Dong, H. Pore-Scale Imaging of the Oil Cluster Dynamic during Drainage and Imbibition Using in Situ X-Ray Microtomography. Geofluids 2018, 2018, 7679607. [Google Scholar] [CrossRef]

- Yin, D.; Zhang, X. Study on Micro Pore Structure Characteristics of Yangdachengzi Oil Layer in Chaoyanggou Oilfield. J. Petrochem. Univ. 2021, 34, 39–45. [Google Scholar]

- Hawthorne, S.B.; Miller, D.J.; Grabanski, C.B. Volumetric Swelling of Bakken Crude Oil with Carbon Dioxide and Hydrocarbon Gases at 110 °C and Pressures of up to 34.5 Megapascals. Energy Fuels 2022, 36, 9091–9100. [Google Scholar] [CrossRef]

- Zhang, C.; Oostrom, M.; Wietsma, T.W.; Grate, J.W.; Warner, M.G. Influence of Viscous and Capillary Forces on Immiscible Fluid Displacement: Pore-Scale Experimental Study in a Water-Wet Micromodel Demonstrating Viscous and Capillary Fingering. Energy Fuels 2011, 25, 3493–3505. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, X.; Liu, X.; Wang, K. The friction factor of the fracture-matrix system considering the effects of free flow, seepage flow, and roughness. J. Hydrol. 2024, 628, 130602. [Google Scholar] [CrossRef]

- Jafarian, K.; Kayhani, M.H.; Nazari, M.; Ghorbanbakhsh, B.; Shokri, N. WAG injection in porous media: A microfluidic analysis. Chem. Eng. Res. Des. 2023, 193, 649–659. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, J.; Yin, D.; Cheng, X.; Jiang, N. Relative permeability measurement of coal microchannels using advanced microchip technology. Fuel 2022, 312, 122633. [Google Scholar] [CrossRef]

- Zou, H.B.; Kang, H.W.; Slim, A.C.; Neild, A. Pore-scale multiple-contact miscibility measurements in a microfluidic chip. Lab Chip 2020, 20, 3582–3590. [Google Scholar] [CrossRef]

- Omran, M.; Akarri, S.; Torsaeter, O. The Effect of Wettability and Flow Rate on Oil Displacement Using Polymer-Coated Silica Nanoparticles: A Microfluidic Study. Processes 2020, 8, 991. [Google Scholar] [CrossRef]

- Meng, Q.B.; Xu, S.; Cai, J.C. Microscopic Studies of Immiscible Displacement Behavior in Interconnected Fractures and Cavities. J. Energy Resour. Technol. 2019, 141, 092901. [Google Scholar] [CrossRef]

- Khorshidian, H.; James, L.A.; Butt, S.D. Demonstrating the effect of hydraulic continuity of the wetting phase on the performance of pore network micromodels during gas assisted gravity drainage. J. Pet. Sci. Eng. 2018, 165, 375–387. [Google Scholar] [CrossRef]

- Yin, D.D.; Li, Y.Q.; Zhao, D.F. Utilization of produced gas of CO2 flooding to improve oil recovery. J. Energy Inst. 2014, 87, 289–296. [Google Scholar] [CrossRef]

- Shen, H.; Gu, Y.Q. Periodic characteristic of effectiveness on surfactant/polymer (SP) flooding. Xinjiang Oil Gas 2006, 30, 71–74. [Google Scholar]

- Shi, L.T.; Ye, Z.B.; Zhang, Z.; Zhou, C.J.; Zhu, S.S.; Guo, Z.D. Necessity and feasibility of improving the residual resistance factor of polymer flooding in heavy oil reservoirs. Pet. Sci. 2010, 7, 251–256. [Google Scholar] [CrossRef]

- Wang, H.Y.; Cao, X.L.; Zhang, A.M. Development and application of dilute surfactant-polymer flooding system for Shengli Oilfield. J. Pet. Sci. Eng. 2009, 65, 45–50. [Google Scholar]

- Chen, M.; Dai, J.; Liu, X.; Kuang, Y.; Wang, Z.; Gou, S.; Qin, M.; Li, M. Effect of displacement rates on fluid distributions and dynamics during water flooding in tight oil sandstone cores from nuclear magnetic resonance (NMR). J. Pet. Sci. Eng. 2020, 184, 106588. [Google Scholar] [CrossRef]

- Liu, Y.G.; Liu, C.L.; Li, Y.Y. Experimental study of an amphiphilic graphene oxide based nanofluid for chemical enhanced oil recovery of heavy oil. New J. Chem. 2023, 47, 1945–1953. [Google Scholar] [CrossRef]

- Liu, R.; Lu, J.; Pu, W.; Xie, Q.; Lu, Y.; Du, D.; Yang, X. Synergetic effect between in-situ mobility control and micro-displacement for chemical enhanced oil recovery (CEOR) of a surface-active nanofluid. J. Pet. Sci. Eng. 2021, 205, 108983. [Google Scholar] [CrossRef]

- Song, K.; Tao, J.; Lyu, X.; Xu, Y.; Liu, S.; Wang, Z.; Liu, H.; Zhang, Y.; Fu, H.; Meng, E.; et al. Recent Advances in Polymer Flooding in China. Molecules 2022, 27, 6978. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Guo, H.; Li, Y.; Song, K. Recent advances of surfactant-polymer (SP) flooding enhanced oil recovery field tests in China. Geofluids 2020, 2020, 8286706. [Google Scholar] [CrossRef]

- Forgiarini, A.M.; Marquez, R.; Salager, J.-L. Formulation improvements in the applications of surfactant–oil–water systems using the HLDN approach with extended surfactant structure. Molecules 2021, 26, 3771. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Feng, Y. Dependence of intrinsic viscosity and molecular size on molecular weight of partially hydrolyzed polyacrylamide. J. Appl. Polym. Sci. 2021, 138, 50850. [Google Scholar] [CrossRef]

- Li, Z.; Espinoza, D.N.; Balhoff, M.T. Simulation of polymer injection in granular media: Implications of fluid-driven fractures, water quality, and undissolved polymers on polymer injectivity. SPE J. 2023, 28, 289–300. [Google Scholar] [CrossRef]

| Experiment No. | Residual Oil after Water Flooding, % | Cluster-Like, % | Pore Surface Film-Like, % | Corner-Like, % | Slit-Like, % |

|---|---|---|---|---|---|

| Yang11-7 | 58.98 | 31.13 | 16.33 | 5.18 | 4.23 |

| Yang19-9 | 65.77 | 37.11 | 21.73 | 8.92 | 8.13 |

| Average | 62.38 | 34.12 | 17.03 | 6.05 | 5.18 |

| Experiment No. | Residual Oil after Water Flooding, % | Cluster-Like, % | Pore Surface Film-Like, % | Corner-Like, % | Slit-Like, % |

|---|---|---|---|---|---|

| Yang 11-7 | 31.77 | 16.09 | 8.79 | 2.68 | 3.77 |

| Yang 19-9 | 38.45 | 19.97 | 10.37 | 3.58 | 4.97 |

| Average | 35.11 | 18.03 | 9.58 | 3.13 | 4.37 |

| Experiment No. | Residual Oil after Water Flooding, % | Cluster-Like, % | Pore Surface Film-Like, % | Corner-Like, % | Slit-Like, % |

|---|---|---|---|---|---|

| Yang 11-7 | 27.88 | 12.77 | 7.73 | 2.21 | 3.78 |

| Yang 19-9 | 31.74 | 14.85 | 10.23 | 3.53 | 4.52 |

| Average | 29.81 | 13.81 | 8.98 | 2.87 | 4.15 |

| Experimental Content | Viscosity, mPa·s | Water Flooding Recovery Factor, % | Chemical Flooding Recovery Factor, % | Ultimate Recovery Factor, % | Cost per Cubic Meter of Liquid, CNY |

|---|---|---|---|---|---|

| Water flooding | -- | 32.77 | -- | 36.45 | -- |

| SP flooding | 57 | 33.07 | 57.31 | 62.26 | 122 |

| Dual-flow flooding | 56 | 33.71 | 57.91 | 69.01 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, C.; Wang, X.; Zhao, J.; Zhang, J.; Wu, X.; Wang, W.; Yan, X. Study on the Mobilization Mechanisms of Microscopic Residual Oil in High-Water-Cut Sandstone Reservoirs. Processes 2024, 12, 1608. https://doi.org/10.3390/pr12081608

Sun C, Wang X, Zhao J, Zhang J, Wu X, Wang W, Yan X. Study on the Mobilization Mechanisms of Microscopic Residual Oil in High-Water-Cut Sandstone Reservoirs. Processes. 2024; 12(8):1608. https://doi.org/10.3390/pr12081608

Chicago/Turabian StyleSun, Chen, Xiaoyan Wang, Jian Zhao, Jin Zhang, Xing Wu, Wei Wang, and Xi Yan. 2024. "Study on the Mobilization Mechanisms of Microscopic Residual Oil in High-Water-Cut Sandstone Reservoirs" Processes 12, no. 8: 1608. https://doi.org/10.3390/pr12081608