Numerical Simulation of Internal Flow Field in Optimization Model of Gas–Liquid Mixing Device

Abstract

1. Introduction

2. Methodology

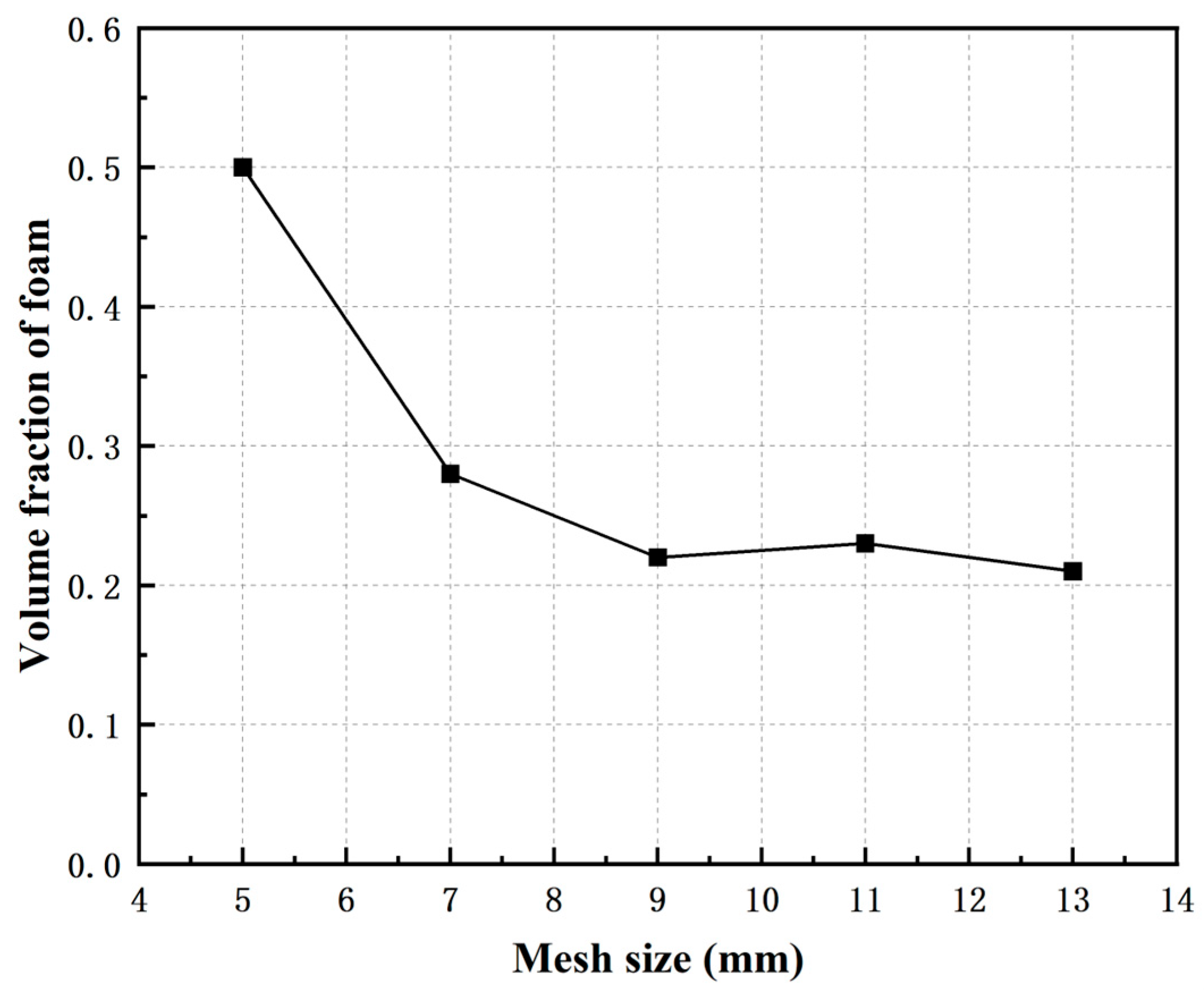

2.1. Numerical Methods

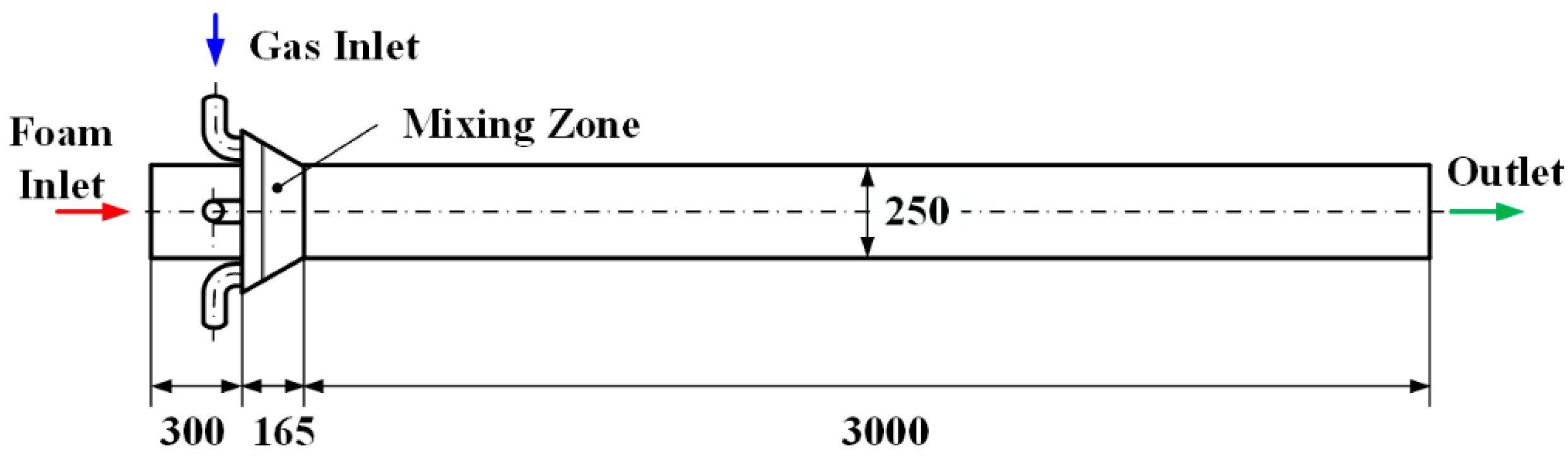

2.2. Experimental Setup

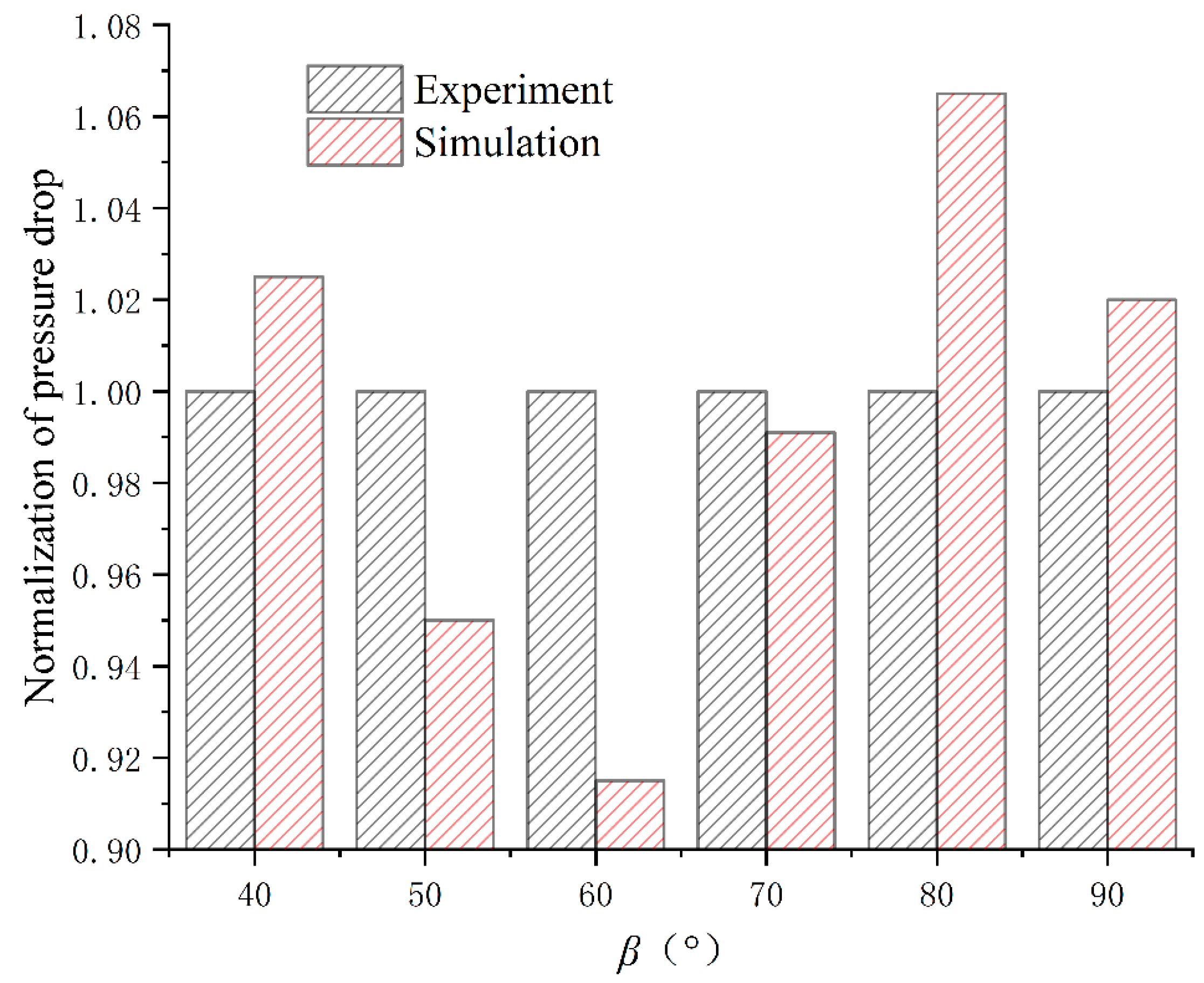

2.3. Simulation Model Verification

3. Results and Discussion

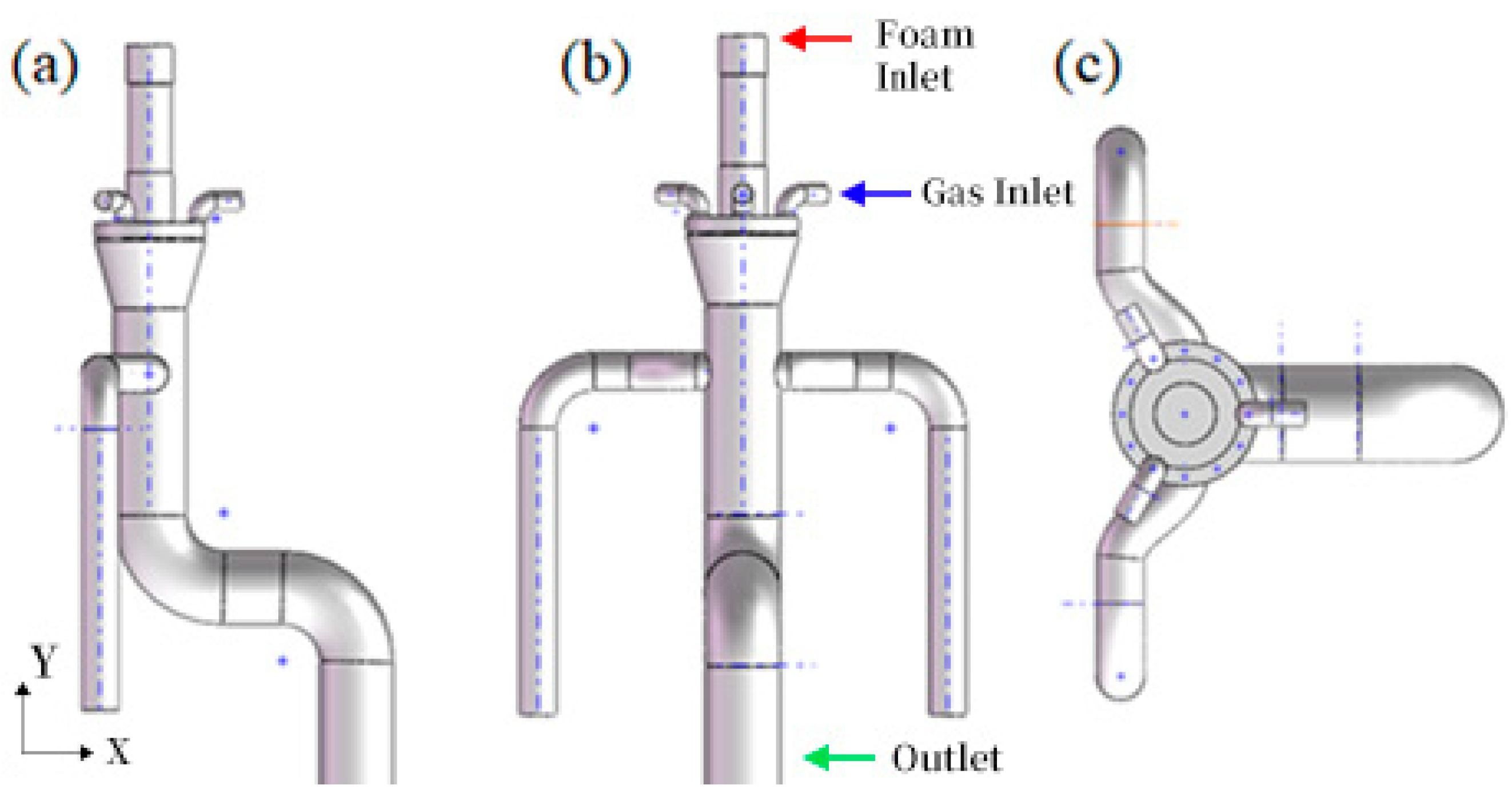

3.1. Numerical Simulation of the JP21/G2 Fire Truck

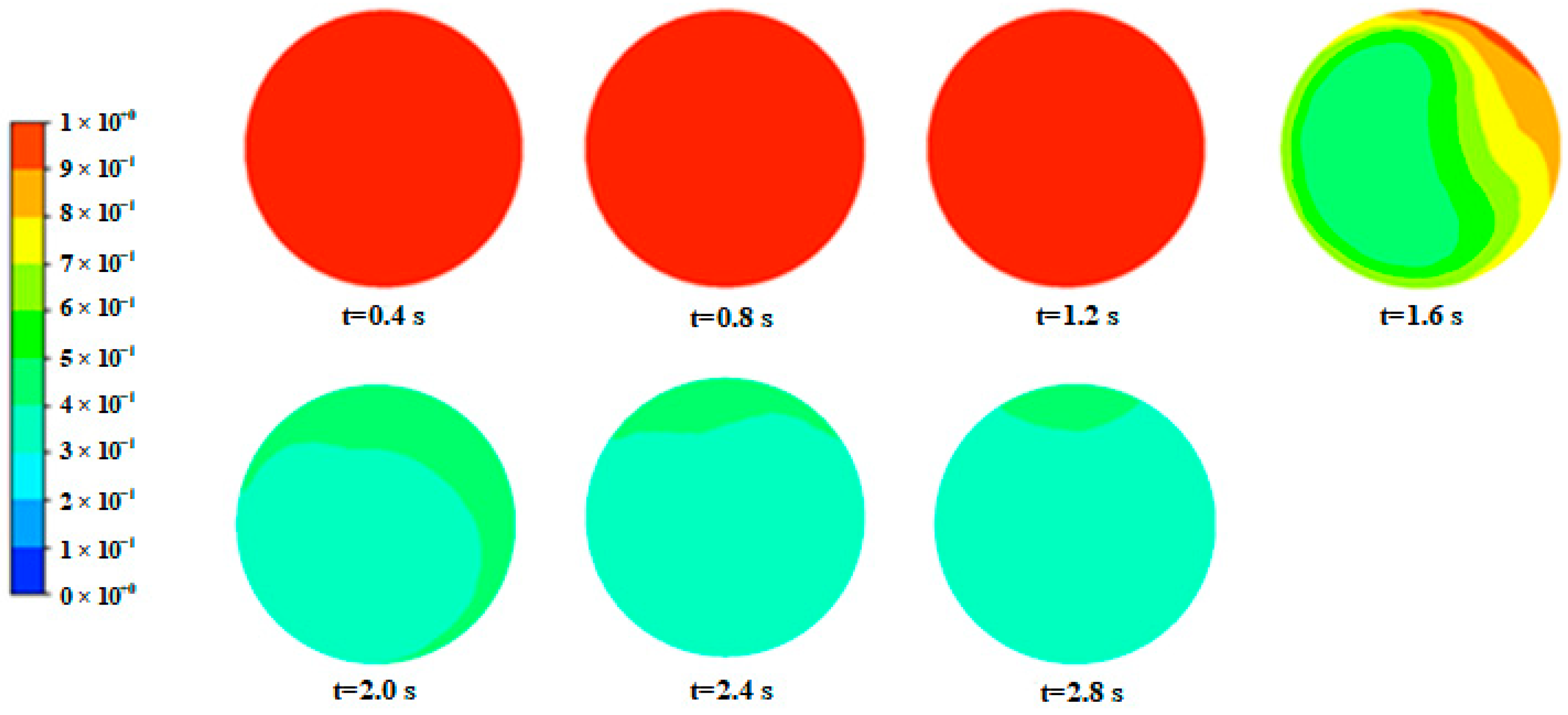

3.1.1. Changes in the Time Dimension of Mixing Effects

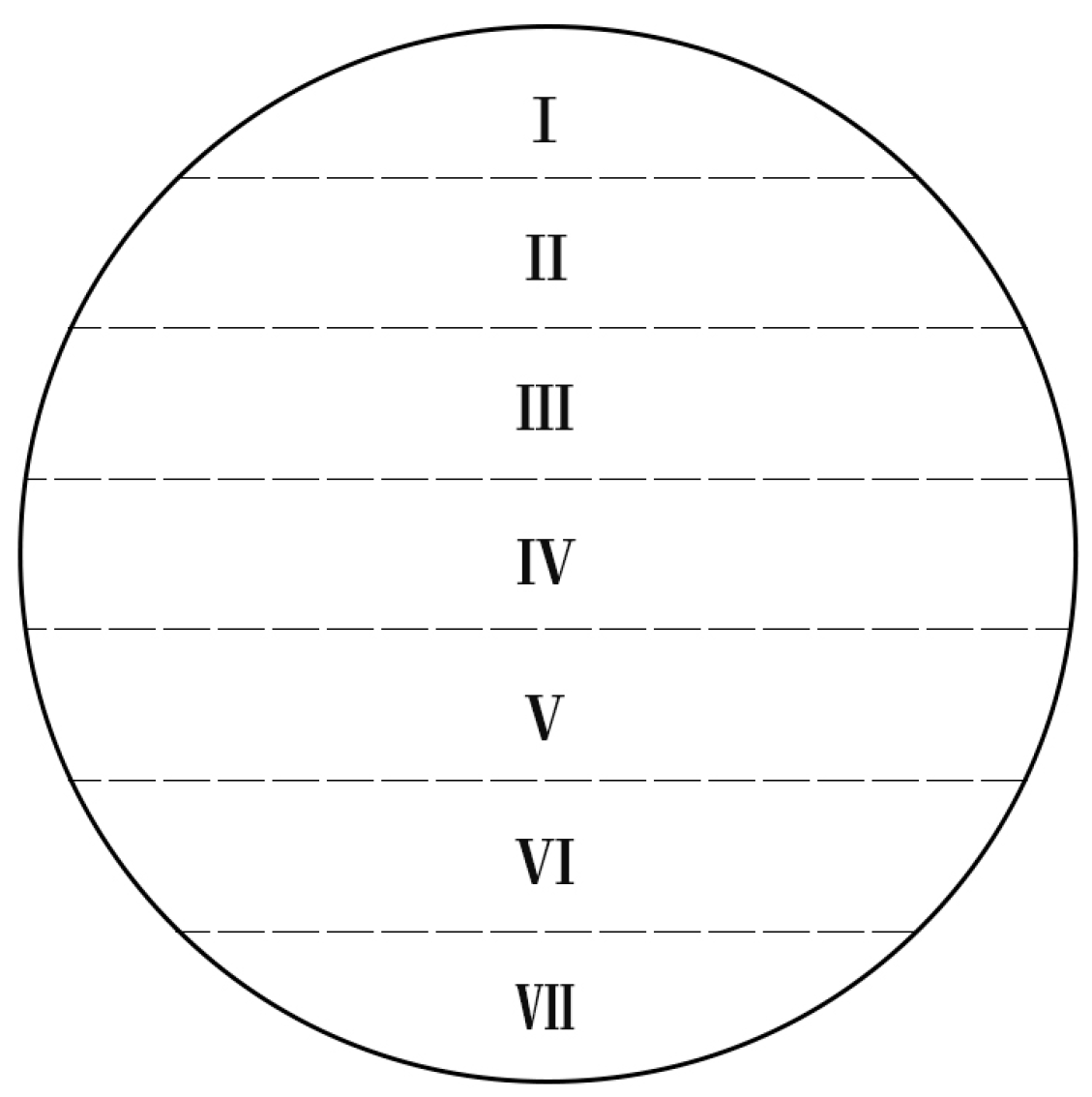

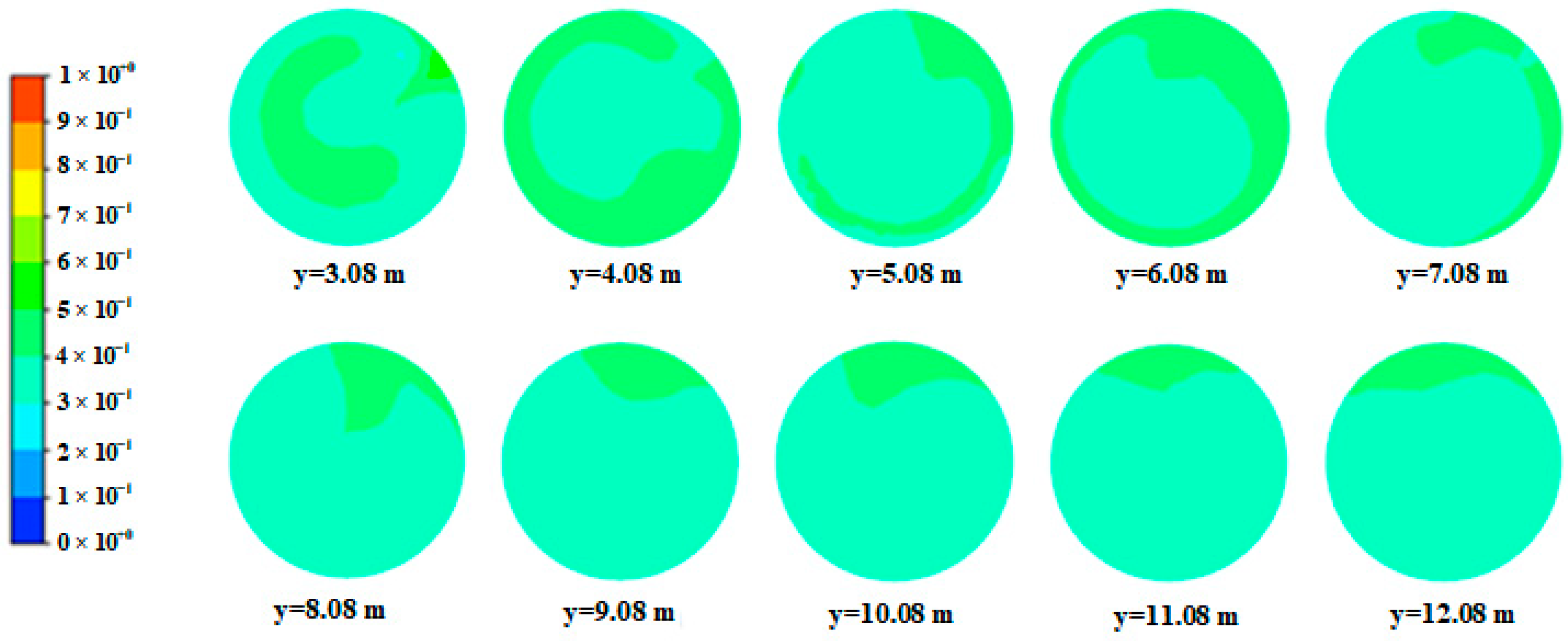

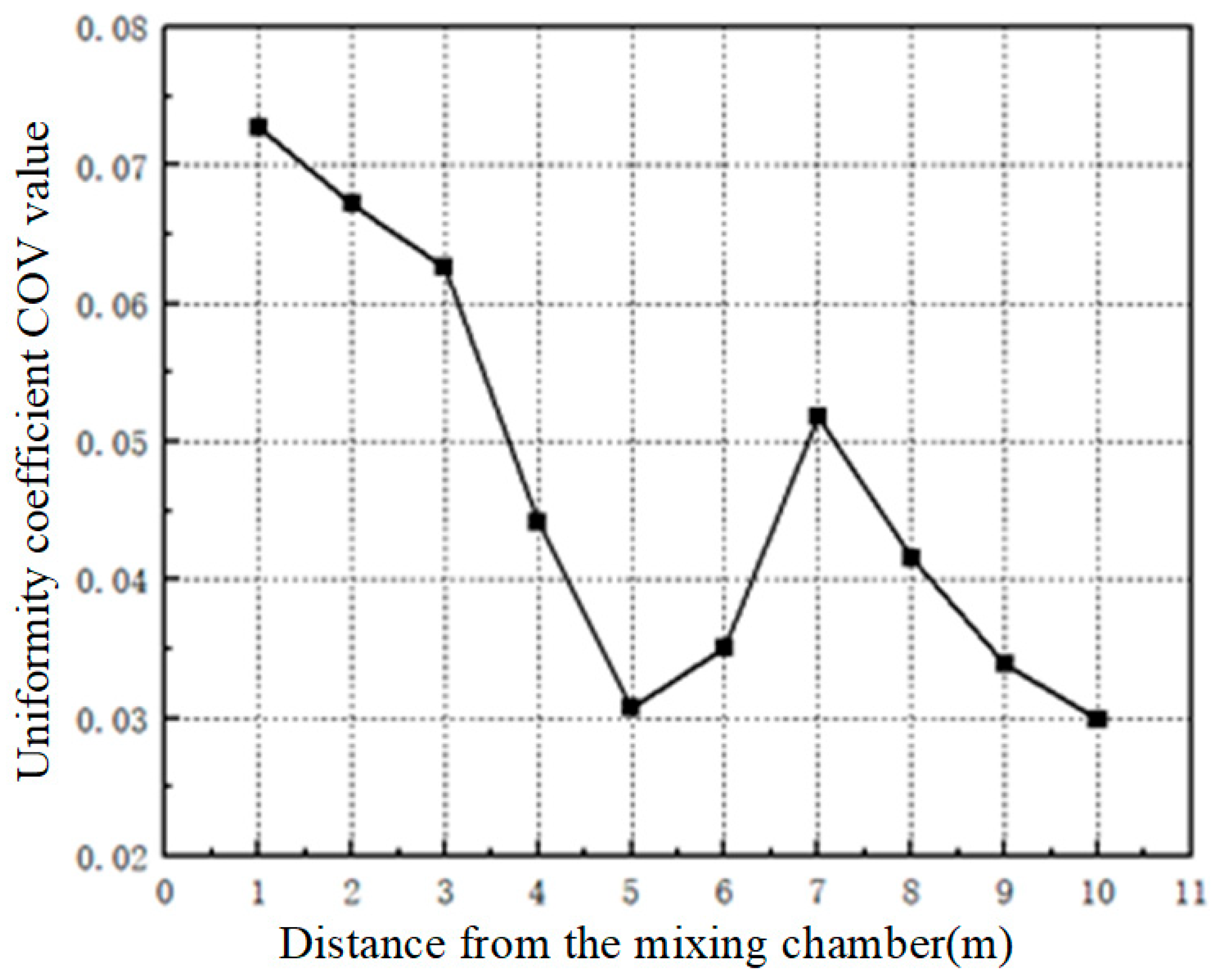

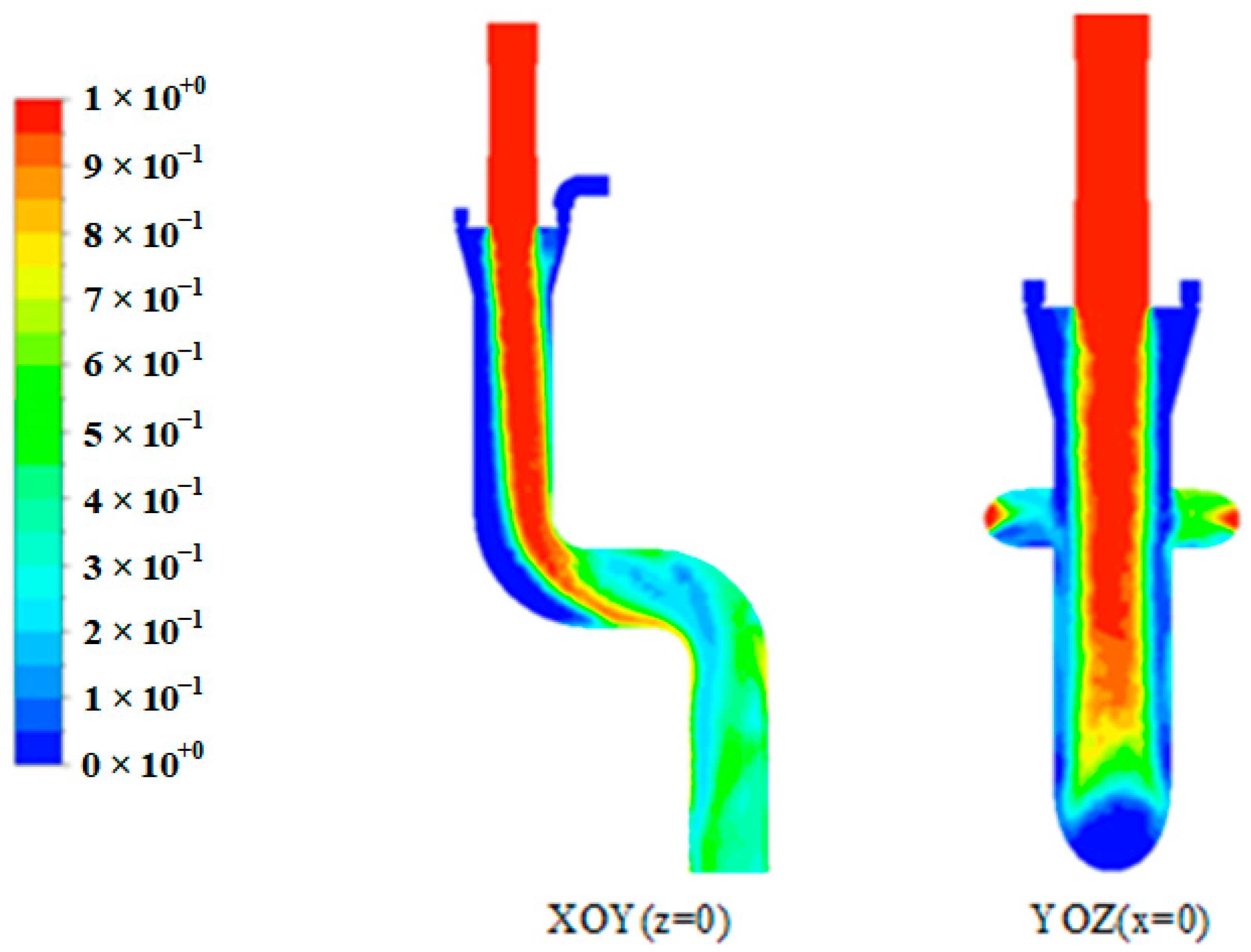

3.1.2. Variation Law of Liquid Phase Volume Fraction

3.1.3. Static Pressure Variation Pattern

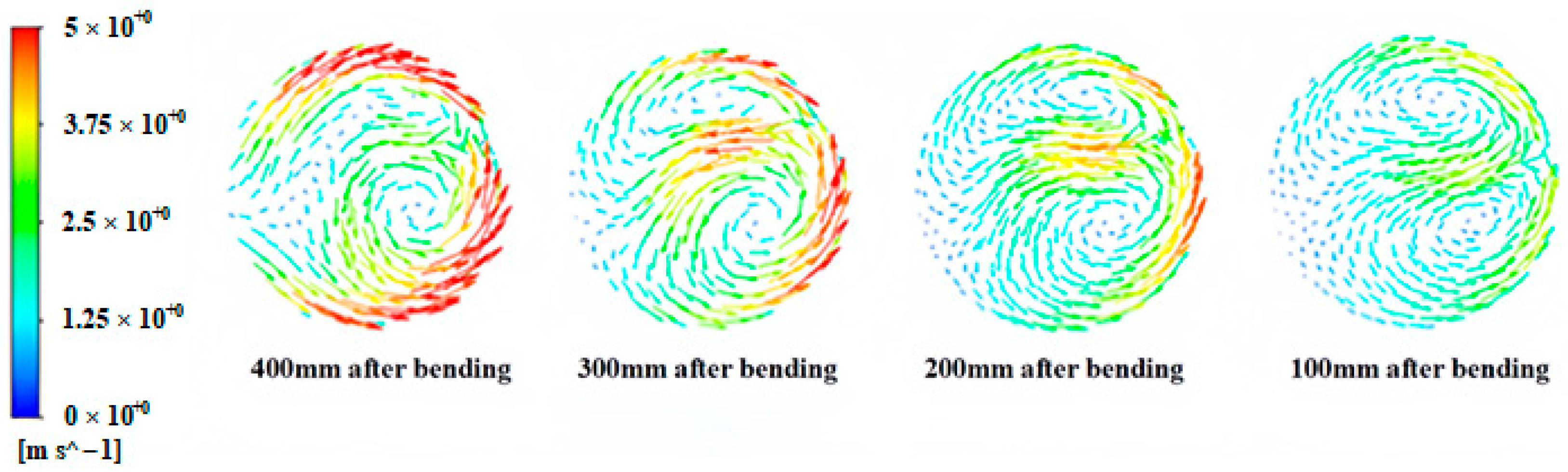

3.1.4. Speed Streamline

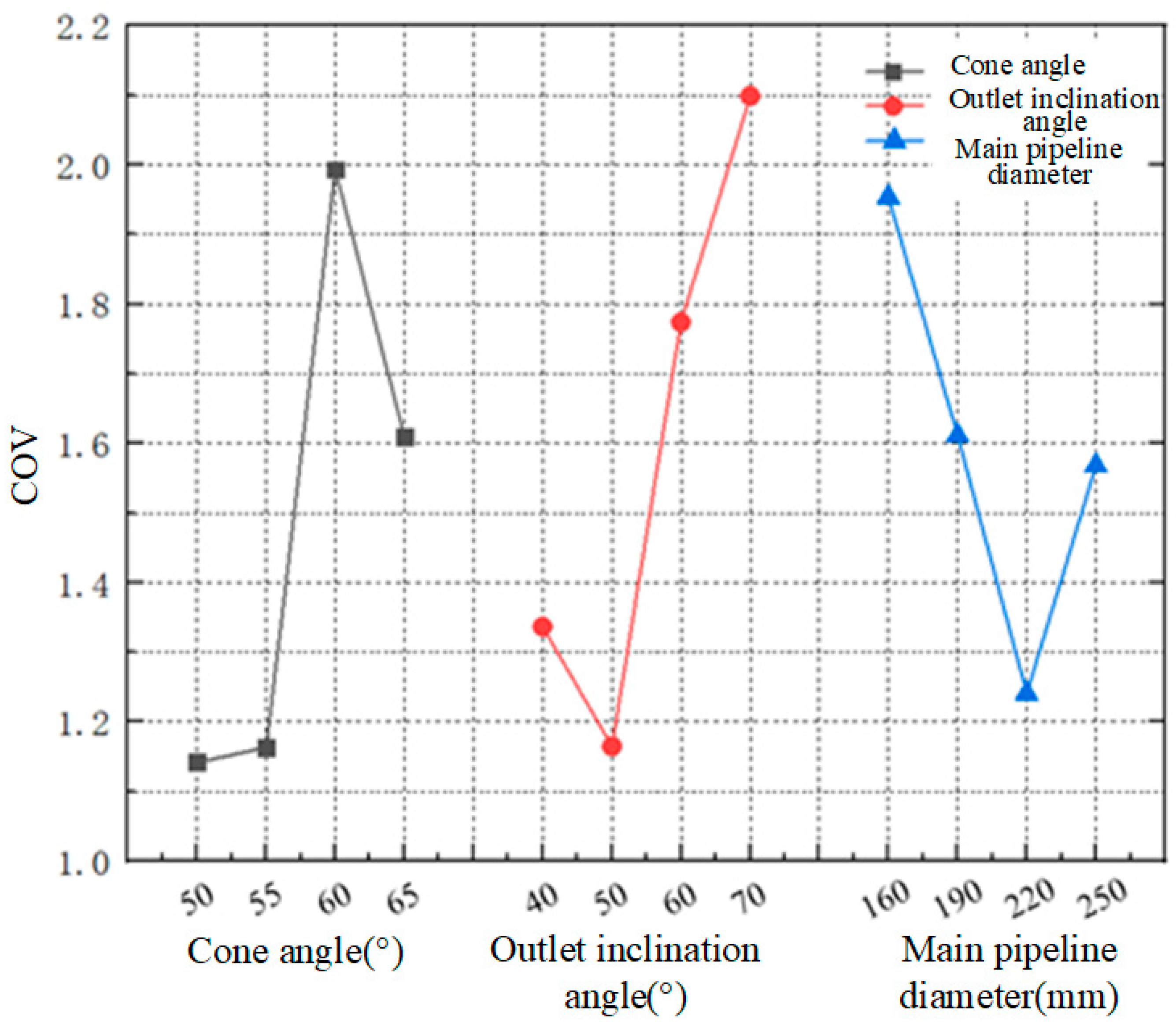

3.2. Orthogonal Experimental Design

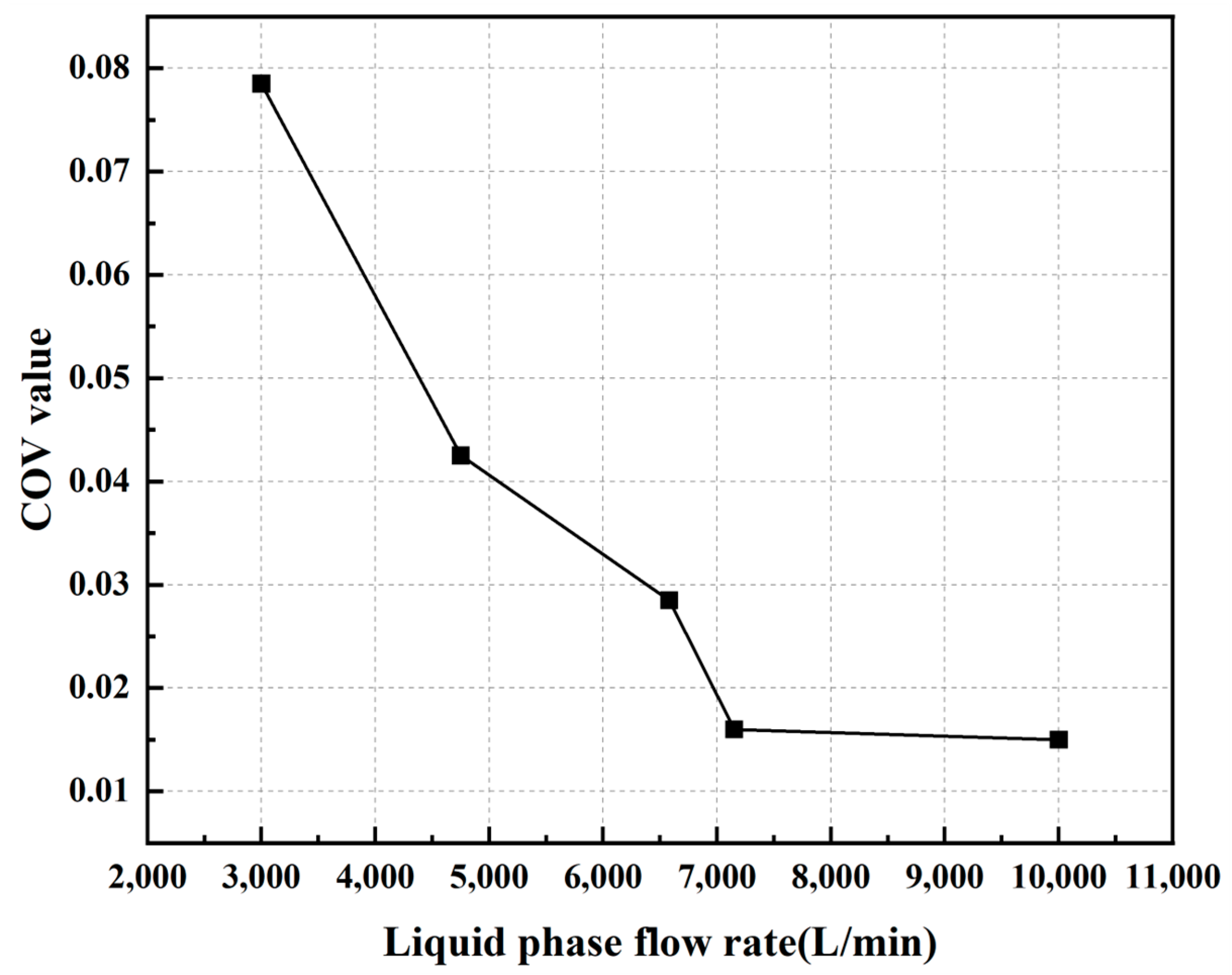

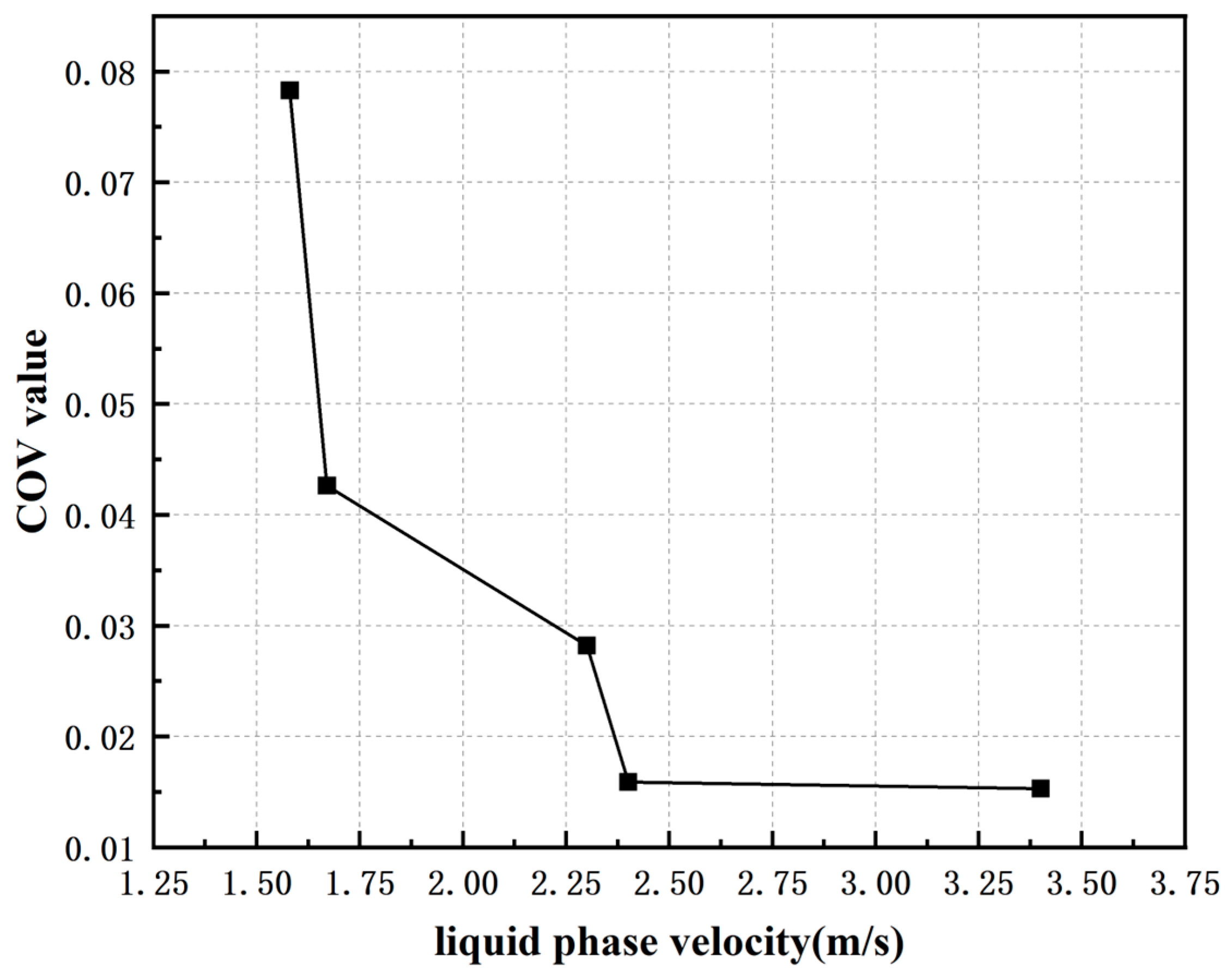

3.3. The Impact of Flow Rate on the Mixing Effect

3.3.1. Impact of Flow Rate on Optimal Pipe Diameter

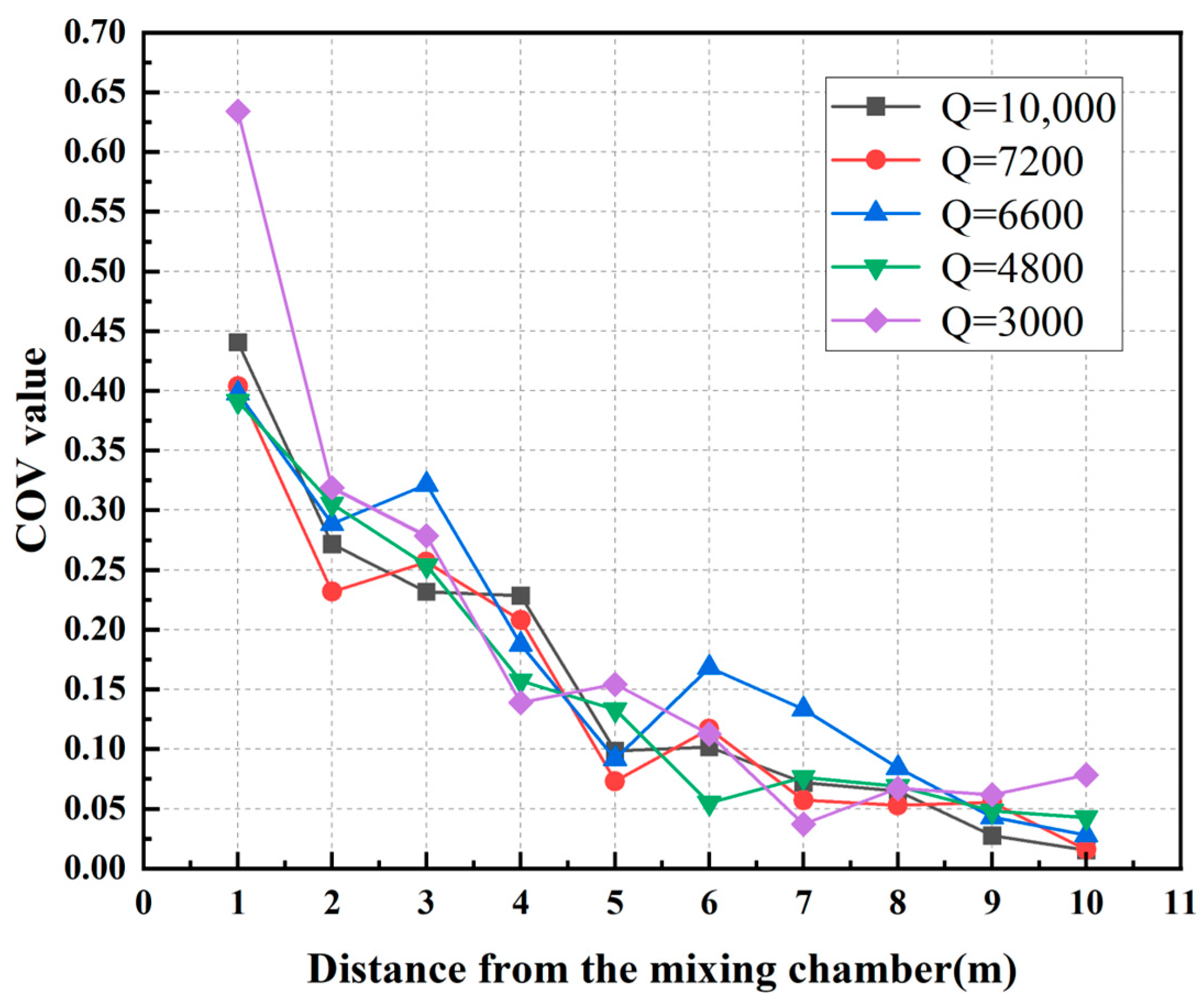

3.3.2. Impact of Flow Rate on the Shortest Mixing Distance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Georgiadis-Filikas, K.; Bakas, I.; Kontoleon, K. Statistical Analysis and Review of Fire Incidents Data of Greece, with Special Focus on Residential Cases 2000–2019. Fire Technol. 2022, 58, 3191–3233. [Google Scholar] [CrossRef]

- Luo, Y.; Li, Q.; Jiang, L.; Zhou, Y. Analysis of Chinese fire statistics during the period 1997–2017. Fire Safety J. 2021, 125, 103400. [Google Scholar] [CrossRef]

- Jin, G.; Wang, Q.; Zhu, C.; Feng, Y.; Huang, J.; Hu, X. Urban Fire Situation Forecasting: Deep sequence learning with spatio-temporal dynamics. Appl. Soft Comput. 2020, 97, 106730. [Google Scholar] [CrossRef]

- Luo, R.; Hui, D.; Miao, N.; Liang, C.; Wells, N. Global relationship of fire occurrence and fire intensity: A test of intermediate fire occurrence-intensity hypothesis. J. Geophys. Res. Biogeosci. 2017, 122, 1123–1136. [Google Scholar] [CrossRef]

- Guo, T.; Fu, Z. The fire situation and progress in fire safety science and technology in China. Fire Safety J. 2007, 42, 171–182. [Google Scholar] [CrossRef]

- Cheung, W.K.; Zeng, Y.; Lin, S.; Huang, X. Modelling carbon monoxide transport and hazard from smouldering for building fire safety design analysis. Fire Safety J. 2023, 140, 103895. [Google Scholar] [CrossRef]

- Bai, M.; Liu, Q. Evaluating Urban Fire Risk Based on Entropy-Cloud Model Method Considering Urban Safety Resilience. Fire 2023, 6, 62. [Google Scholar] [CrossRef]

- Hulse, L.M.; Galea, E.R.; Thompson, O.F.; Wales, D. Perception and recollection of fire hazards in dwelling fires. Safety Sci. 2020, 122, 104518. [Google Scholar] [CrossRef]

- Chaos, M. Determination of Separation Distances Inside Large Buildings. Fire Technol. 2017, 53, 249–281. [Google Scholar] [CrossRef]

- Cheng, L.; Li, S.; Ma, L.; Li, M.; Ma, X. Fire spread simulation using GIS: Aiming at urban natural gas pipeline. Safety Sci. 2015, 75, 23–35. [Google Scholar] [CrossRef]

- Wang, B.; Li, W.; Lai, G.; Chang, N.; Chen, F.; Bai, Y.; Liu, X. Forest Fire Spread Hazard and Landscape Pattern Characteristics in the Mountainous District, Beijing. Forests 2023, 14, 2139. [Google Scholar] [CrossRef]

- Jiao, Q.; Fan, M.; Tao, J.; Wang, W.; Liu, D.; Wang, P. Forest Fire Patterns and Lightning-Caused Forest Fire Detection in Heilongjiang Province of China Using Satellite Data. Fire 2023, 6, 166. [Google Scholar] [CrossRef]

- Ma, W.; Feng, Z.; Cheng, Z.; Chen, S.; Wang, F. Identifying Forest Fire Driving Factors and Related Impacts in China Using Random Forest Algorithm. Forests 2020, 11, 507. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Qi, S. Forest fire hazard during 2000–2016 in Zhejiang province of the typical subtropical region, China. Nat. Hazards 2018, 94, 975–977. [Google Scholar] [CrossRef]

- Grishin, A.M.; Filkov, A.I. A deterministic-probabilistic system for predicting forest fire hazard. Fire Safety J. 2011, 46, 56–62. [Google Scholar] [CrossRef]

- Yin, H.; Kong, F.; Li, X. RS and GIS-based forest fire risk zone mapping in da hinggan mountains. Chinese Geogr. Sci. 2004, 14, 251–257. [Google Scholar] [CrossRef]

- Chen, F.; Xu, T.; Hou, G.; Huang, J.; Zhu, G.; Deng, T.; Jiang, Z.; Wang, Z. Efficiency and mechanism of fire suppression through pneumatic sandblasting firefighting. Case Stud. Therm. Eng. 2023, 49, 103361. [Google Scholar] [CrossRef]

- Wang, W.; He, S.; He, T.; You, T.; Parker, T.; Wang, Q. Suppression behavior of water mist containing compound additives on lithium-ion batteries fire. Process Saf. Environ. 2022, 161, 476–487. [Google Scholar] [CrossRef]

- Sheng, Y.; Xue, M.; Ma, L.; Zhao, Y.; Wang, Q.; Liu, X. Environmentally Friendly Firefighting Foams Used to Fight Flammable Liquid Fire. Fire Technol. 2021, 57, 2079–2096. [Google Scholar] [CrossRef]

- Aydin, B.; Selvi, E.; Tao, J.; Starek, M. Use of Fire-Extinguishing Balls for a Conceptual System of Drone-Assisted Wildfire Fighting. Drones 2019, 3, 17. [Google Scholar] [CrossRef]

- Deng, B.; Lu, L.; Qian, X.; Kang, Q.; Fu, L. Research on the influence of driving gas types in compound jet on extinguishing the pool fire. J. Hazard. Mater. 2019, 363, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Yuan, F.; Cui, Z.; Lin, J. Experimental and Numerical Study on Flow Resistance and Bubble Transport in a Helical Static Mixer. Energies 2020, 13, 1228. [Google Scholar] [CrossRef]

- Jia, X.; Che, B.; Jing, G.; Zhang, C. Air-Bubble Induced Mixing: A Fluidic Mixer Chip. Micromachines 2020, 11, 195. [Google Scholar] [CrossRef] [PubMed]

- Hashemi, N.; Ein-Mozaffari, F.; Upreti, S.R.; Hwang, D.K. Experimental investigation of the bubble behavior in an aerated coaxial mixing vessel through electrical resistance tomography (ERT). Chem. Eng. J. 2016, 289, 402–412. [Google Scholar] [CrossRef]

- Dietrich, N.; Poncin, S.; Midoux, N.; Li, H.Z. Bubble formation dynamics in various flow-focusing microdevices. Langmuir 2008, 24, 13904–13911. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Wang, H.; Wang, L.; Li, L.; Cai, C.; Zhu, J. The Law of Gas–Liquid Shear Mixing under the Synergistic Effect of Jet Stirring. Processes 2023, 11, 2531. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, J.; Li, W.; Li, W.; Zhang, J. Investigation of gas-liquid mass transfer and power consumption characteristics in jet-flow high shear mixers. Chem. Eng. J. 2021, 411, 128580. [Google Scholar] [CrossRef]

- Amiri, T.Y.; Moghaddas, J.S.; Moghaddas, Y. A jet mixing study in two phase gas–liquid systems. Chem. Eng. Res. Des. 2011, 89, 352–366. [Google Scholar] [CrossRef]

- Hou, J.; Qian, G.; Zhou, X. Gas–liquid mixing in a multi-scale micromixer with arborescence structure. Chem. Eng. J. 2011, 167, 475–482. [Google Scholar] [CrossRef]

- Khopkar, A.R.; Kasat, G.R.; Pandit, A.B.; Ranade, V.V. CFD simulation of mixing in tall gas–liquid stirred vessel: Role of local flow patterns. Chem. Eng. Sci. 2006, 61, 2921–2929. [Google Scholar] [CrossRef]

- Meroney, R.N.; Colorado, P.E. CFD simulation of mechanical draft tube mixing in anaerobic digester tanks. Water Res. 2009, 43, 1040–1050. [Google Scholar] [CrossRef]

- Liu, Y.; Mitchell, T.; Upchurch, E.R.; Ozbayoglu, E.M.; Baldino, S. Investigation of Taylor bubble dynamics in annular conduits with counter-current flow. Int. J. Multiphas Flow 2024, 170, 104626. [Google Scholar] [CrossRef]

- Liu, Y.; Ozbayoglu, E.M.; Upchurch, E.R.; Baldino, S. Computational fluid dynamics simulations of Taylor bubbles rising in vertical and inclined concentric annuli. Int. J. Multiph. Flow 2023, 159, 104333. [Google Scholar] [CrossRef]

- Xu, L.; Yu, B.; Wang, C.; Jiang, H.; Liu, Y.; Chen, R. Particle-resolved CFD simulations of local bubble behaviors in a mini-packed bed with gas–liquid concurrent flow. Chem. Eng. Sci. 2022, 254, 117631. [Google Scholar] [CrossRef]

- Ning, J.; Jin, Z.; Xu, X. A partition-coupled Eulerian–Lagrangian method for large-deformation simulation of compressible fluid. Phys. Fluids 2022, 34, 116102. [Google Scholar] [CrossRef]

- Gómez-Pastora, J.; González-Fernández, C.; Fallanza, M.; Bringas, E.; Ortiz, I. Flow patterns and mass transfer performance of miscible liquid-liquid flows in various microchannels: Numerical and experimental studies. Chem. Eng. J. 2018, 344, 487–497. [Google Scholar] [CrossRef]

- Shao, N.; Gavriilidis, A.; Angeli, P. Flow regimes for adiabatic gas–liquid flow in microchannels. Chem. Eng. Sci. 2009, 64, 2749–2761. [Google Scholar] [CrossRef]

- Hu, J.; Li, W.; Chi, X.; Wang, N. Study on the Effect of Structural Parameters of Volume Control Tank on Gas–Liquid Mass Transfer. Energies 2023, 16, 4991. [Google Scholar] [CrossRef]

- Van Reeuwijk, M.; Sookhak Lari, K. Asymptotic solutions for turbulent mass transfer at high Schmidt number. Proc. R. Soc. A Math. Phys. Eng. Sci. 2012, 468, 1676–1695. [Google Scholar] [CrossRef]

- Vijiapurapu, S.; Cui, J. Performance of turbulence models for flows through rough pipes. Appl. Math. Model. 2010, 34, 1458–1466. [Google Scholar] [CrossRef]

- Mohammed, H.I.; Giddings, D.; Walker, G.S. CFD simulation of a concentrated salt nanofluid flow boiling in a rectangular tube. Int. J. Heat. Mass. Tran. 2018, 125, 218–228. [Google Scholar] [CrossRef]

- Fan, Z.; Liu, D.; Pan, S.; Ma, J.; Chen, X. Spreading dynamics of the viscous droplet impacting on a spherical particle. Phys. Fluids 2023, 35, 023311. [Google Scholar] [CrossRef]

- Wang, W.; Lin, F.; Wei, X.; Zou, J. Antibubble formation by a single drop impact on a free surface. Phys. Fluids 2021, 33, 042107. [Google Scholar] [CrossRef]

- Zhou, Y.; Chang, H.; Qi, T. Gas–liquid two-phase flow in serpentine microchannel with different wall wettability. Chinese J. Chem. Eng. 2017, 25, 874–881. [Google Scholar] [CrossRef]

- Sun, B.; Lu, Y.; Liu, Q.; Fang, H.; Zhang, C.; Zhang, J. Experimental and Numerical Analyses on Mixing Uniformity of Water and Saline in Pipe Flow. Water 2020, 12, 2281. [Google Scholar] [CrossRef]

| Foam Agent | Compressed Air | |

|---|---|---|

| Flow Q (L/min) | 10,000 | 50,000 |

| Pressure P (MPa) | 1 | 1.1 |

| Hydraulic diameter D (mm) | 250 | 60 |

| Density ρ (kg/m3) | 1010 | 13.072 |

| Dynamic viscosity μ (kg/(m·s)) | 0.0187 | 1.82 10−5 |

| Speed v (m/s) | 3.397 | 98.294 |

| Evaluating Indicator | Evaluation Criterion |

|---|---|

| Liquid phase volume fraction contour | The more vortices there are, the more thorough the mixing of the two phases is; the more uniform the size of the vortex, the better |

| Pressure drop before and after mixing chamber | The smaller the pressure drop value, the less energy consumption it indicates |

| Uniformity coefficient COV value | The smaller the COV value, the better the fluid uniformity and the value drops to 0.05, reaching the industrial standard |

| Liquid phase velocity streamline | The sparser and more uniform the streamline distribution, the higher the mixing stability |

| Number | Mixer Cone Angle (°)/A | Air Inlet Angle (°)/B | Main Pipeline Diameter (mm)/C | Uniformity Index COV Coefficient |

|---|---|---|---|---|

| 1 | 50 | 40 | 160 | 0.2745 |

| 2 | 50 | 50 | 190 | 0.18148 |

| 3 | 50 | 60 | 220 | 0.291 |

| 4 | 50 | 70 | 250 | 0.3946 |

| 5 | 55 | 40 | 190 | 0.3352 |

| 6 | 55 | 50 | 160 | 0.4409 |

| 7 | 55 | 60 | 250 | 0.394 |

| 8 | 55 | 70 | 220 | 0.4601 |

| 9 | 60 | 40 | 220 | 0.3614 |

| 10 | 60 | 50 | 250 | 0.4141 |

| 11 | 60 | 60 | 160 | 0.606 |

| 12 | 60 | 70 | 190 | 0.6116 |

| 13 | 65 | 40 | 250 | 0.36524 |

| 14 | 65 | 50 | 220 | 0.1282 |

| 15 | 65 | 60 | 190 | 0.4828 |

| 16 | 65 | 70 | 160 | 0.6325 |

| Analyze Parameters | A | B | C |

|---|---|---|---|

| 1.14158 | 1.33634 | 1.9539 | |

| 1.6302 | 1.16468 | 1.61108 | |

| 1.9931 | 1.7738 | 1.2407 | |

| 1.60874 | 2.0988 | 1.56794 | |

| 1.3032 | 1.7858 | 3.81773 | |

| 2.65755 | 1.35648 | 2.59558 | |

| 3.97245 | 3.15908 | 1.53934 | |

| 2.58804 | 4.405 | 2.45843 | |

| 0.09141 | 0.13769 | 0.06387 | |

| 0.03047 | 0.046 | 0.02129 | |

| Proportion of (%) | 31.168 | 47.054 | 21.778 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Zhang, J.; Ji, Y.; Zhou, J.; Hu, W. Numerical Simulation of Internal Flow Field in Optimization Model of Gas–Liquid Mixing Device. Processes 2024, 12, 1707. https://doi.org/10.3390/pr12081707

Chen H, Zhang J, Ji Y, Zhou J, Hu W. Numerical Simulation of Internal Flow Field in Optimization Model of Gas–Liquid Mixing Device. Processes. 2024; 12(8):1707. https://doi.org/10.3390/pr12081707

Chicago/Turabian StyleChen, Hongyu, Jie Zhang, Yun Ji, Jiawei Zhou, and Weibo Hu. 2024. "Numerical Simulation of Internal Flow Field in Optimization Model of Gas–Liquid Mixing Device" Processes 12, no. 8: 1707. https://doi.org/10.3390/pr12081707

APA StyleChen, H., Zhang, J., Ji, Y., Zhou, J., & Hu, W. (2024). Numerical Simulation of Internal Flow Field in Optimization Model of Gas–Liquid Mixing Device. Processes, 12(8), 1707. https://doi.org/10.3390/pr12081707