Overview of Salt Cavern Oil Storage Development and Site Suitability Analysis

Abstract

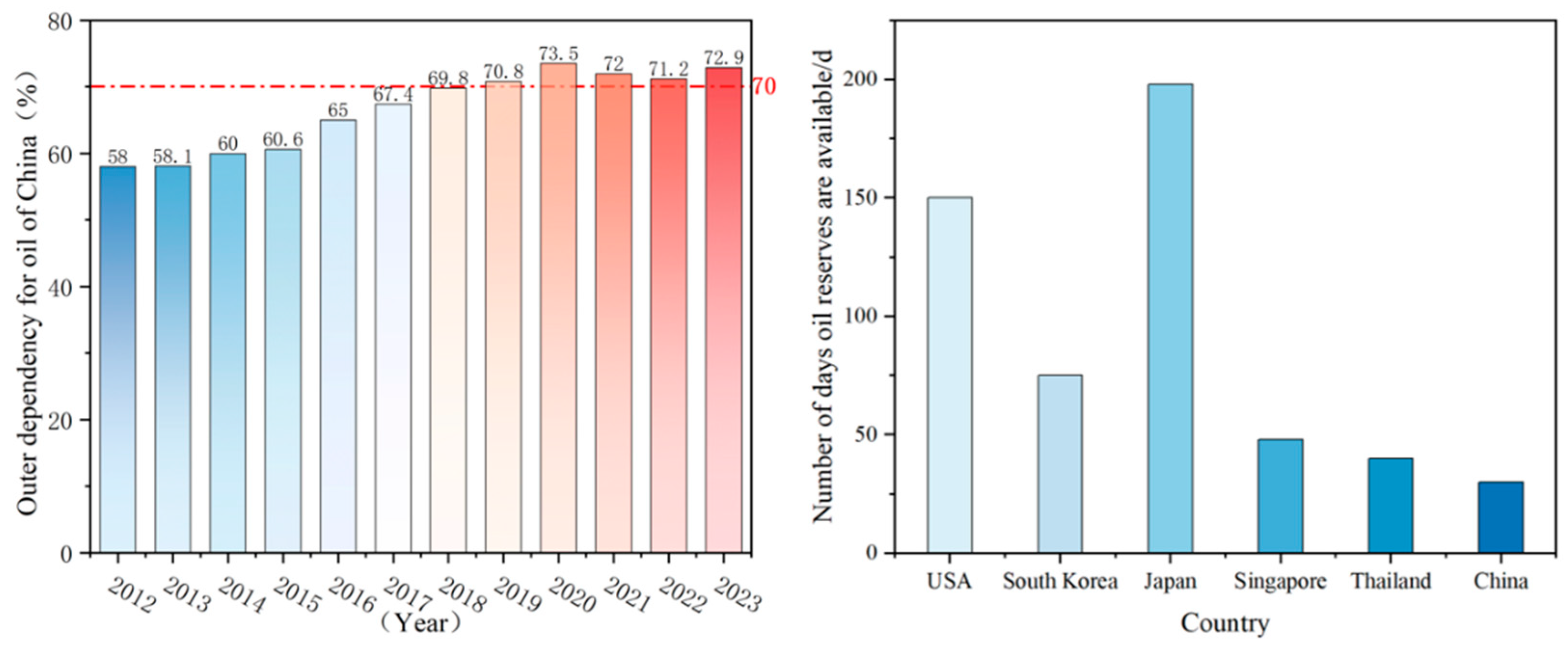

:1. Introduction

2. Current Status of Oil Storage Development in Salt Caverns at Home and Abroad

2.1. Current Situation of Salt Cavern Oil Storage Development in Foreign Countries

2.2. Development Status of Domestic Salt Cavern Oil Storage

3. Overview of the Development of Salt Cavern Oil Storage in China

3.1. Advantages of China’s Salt Cavern Storage for Strategic Petroleum Reserves

3.1.1. Technical Advantages

3.1.2. Resource Advantages

3.1.3. Transportation Advantages

3.2. Key Issues and Development Trends in China’s Strategic Petroleum Reserves

- ①

- Establishing methods and standards for screening existing cavities: Currently, China has a large number of existing cavern resources. Utilizing these existing cavities for oil storage conversion is more economical than creating new ones. However, these cavities vary greatly in shape. Determining the safe pillar distance and the appropriate shape for oil storage requires screening methods and standards [42,43,44].

- ②

- Engineering technology for converting oil storage caverns: Crude oil contains corrosive impurities that can corrode injection and production tubing, such as inorganic salts, sulfides, sulfur dioxide, and water. Additionally, the high concentration of chloride ions in brine accelerates corrosion. The stability of mudstone interlayers or cap rocks may also change when exposed to storage media. Determining the appropriate well structure to meet the functional requirements of oil storage caverns is crucial for construction quality and ensuring the storage facility can function effectively when needed.

- ③

- Injection and production operation technology for salt cavern storage: To maximize the functionality of constructed oil storage caverns, it is essential to manage the relationship between injection/production rates and cavity stability, maintain cavity stability at low pressures, and prevent crystallization blockages in the tubing due to contact with brine [45].

4. Construction of Salt Cavern Oil Storage and Principles and Factors for Site Selection

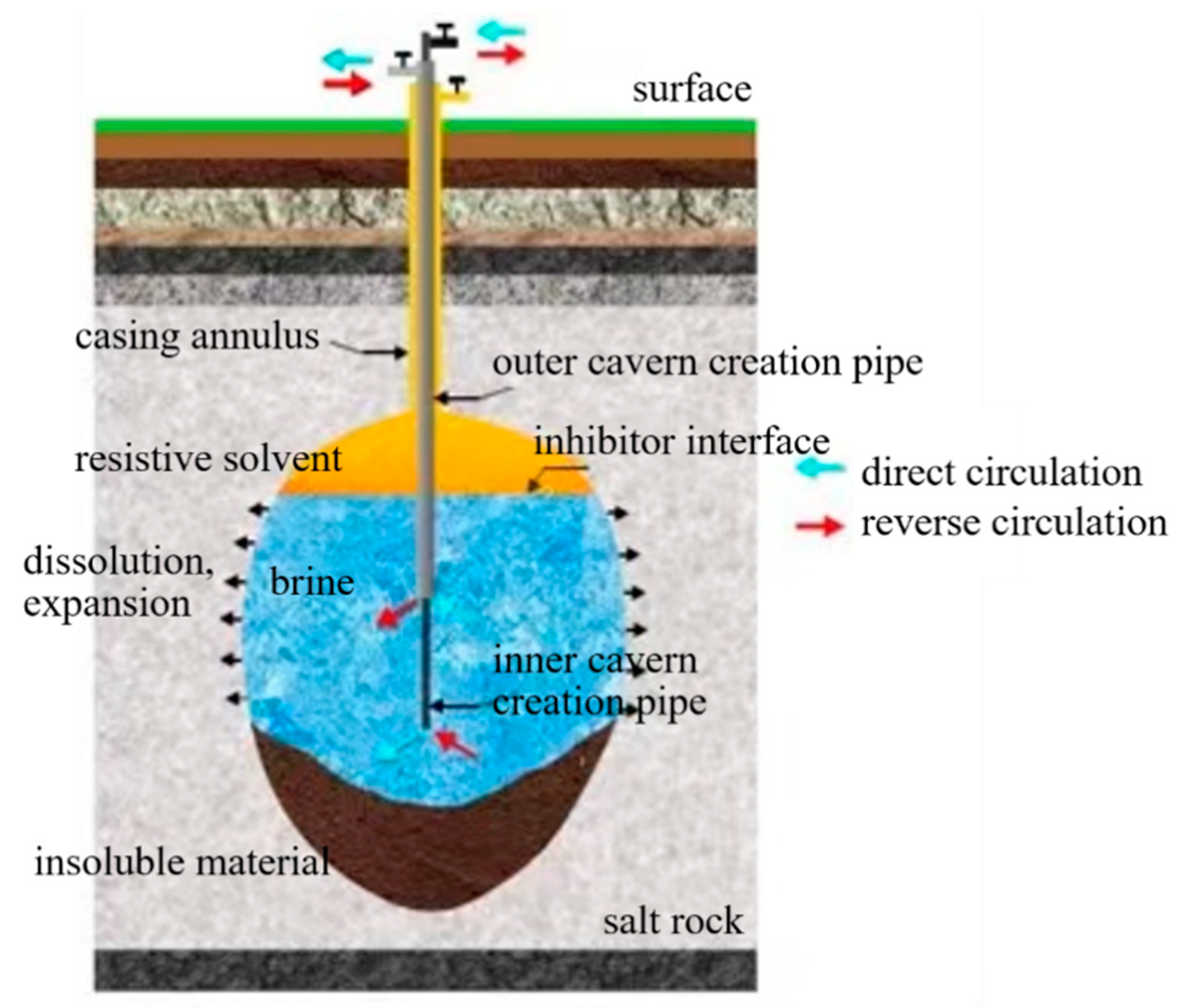

4.1. Construction of Salt Cavern Oil Storage

4.2. Basic Principles for the Site Selection of Salt Cavern Oil Storage

- ①

- Safety Principle

- ②

- Economic Principle

- ③

- Proximity Principle

- ④

- Strategic Principle

4.3. Influencing Factors for the Site Selection of Salt Cavern Oil Storage

- ①

- Structural Characteristics of the Mining Area

- ②

- Hydrological Characteristics of the Mining Area

- ③

- Sedimentary Characteristics of the Strata

- ④

- Characteristics of the Target Salt Layer and Interlayers

- ⑤

- Characteristics of the Roof and Floor Plates of the Salt Rock Layer

- ⑥

- Surface Factors

- ⑦

- Environmental Factors

5. Site Selection and Macro Suitability Assessment Method for Salt Cavern Storage

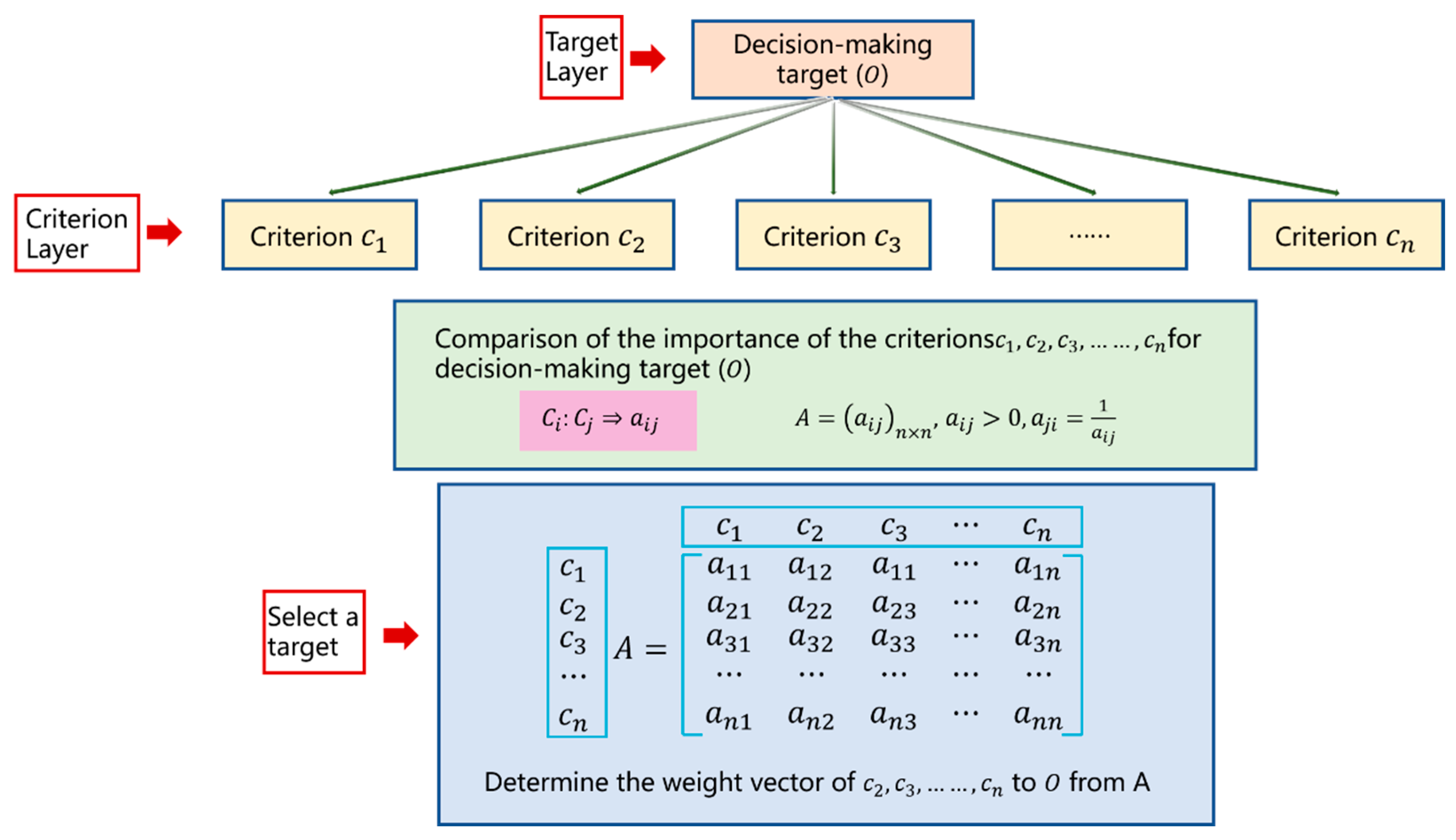

5.1. Theory of Analytical Hierarchy Process (AHP) Model Construction

- ①

- Structuring the Decision Elements

- ②

- Constructing the Judgment (Pairwise Comparison) Matrix

- ③

- Hierarchical Single Sorting and Consistency Test

- ④

- Overall Hierarchical Ranking and Its Consistency Check

5.2. Macro Suitability Assessment Method for Oil Storage

5.2.1. Establishment of the Evaluation System

5.2.2. Weight Calculation

5.2.3. Suitability Assessment

5.3. Engineering Application

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, X.; Shi, J.; Cao, G.; Yang, N.; Cui, M.; Jia, D.; Liu, H. Progress and prospects of oil and gas production engineering tech-nology in China. Pet. Explor. Dev. 2022, 49, 644–659. [Google Scholar] [CrossRef]

- Qiao, L.; Li, C.; Wang, Z.; Wang, X.; Guo, J. Seawater intrusion into an underground water-sealed oil storage cavern: Effects of water curtain system, hydraulic conductivity and dispersivity. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2022, 126, 104542. [Google Scholar] [CrossRef]

- Paik, I.; Leiby, P.; Jones, D.; Yokobori, K.; Bowman, D. Strategic oil stocks in the APEC region. In Proceedings of the 22nd IAEE Annual International Conference, Rome, Italy, 9–12 June 1999; International Association for Energy Economists: Rome, Italy, 1999. [Google Scholar]

- Molecke, M.A. Final State of the Strategic Petroleum Reserve (SPR) Weeks Island Mine; Sandia National Laboratories: Albuquerque, NM, USA, 2000; pp. 1–63.

- Grappe, J. UGS technology improvements: Some answers of the UGS industry to the evolution of gas markets. In Proceedings of the International Gas Union Research Conference, Paris, France, 8–10 October 2008; pp. 461–472. [Google Scholar]

- Silva, L.; Soares, C.G. Robust optimization model of an offshore oil production system for cost and pipeline risk of failure. Reliab. Eng. Syst. Saf. 2023, 232, 109052. [Google Scholar] [CrossRef]

- Zhu, Y. Research on Facilities of Strategic Petroleum Reserve; China University of Petroleum: Beijing, China, 2008. [Google Scholar]

- Zhao, K.; Liu, Y.; Li, Y.; Ma, H.; Hou, W.; Yu, C.; Liu, H.; Feng, C.; Yang, C. Feasibility analysis of salt cavern gas storage in extremely deep formation: A case study in China. J. Energy Storage 2022, 47, 103649. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Korzeniowski, W.; Poborska-Młynarska, K. Binding Capability of Ashes and Dusts from Municipal Solid Waste Incineration with Salt Brine and Geotechnical Parameters of the Cemented Samples. Arch. Min. Sci. 2018, 63, 903–918. [Google Scholar]

- Waldemar, K.; Katarzyna, P.M.; Krzysztof, S. The Idea of the Recovery of Municipal Solid Waste Incineration (MSWI) Residues in Kodawa Salt Mine S.A. by Filling the Excavations with Self-Solidifying Mixtures. Arch. Min. Sci. 2018, 63, 553–565. [Google Scholar]

- Hunsche, U. Uniaxial and triaxial creep and failure tests on rock: Experimental technique and interpretation. In Visco-Plastic Behaviour of Geomaterials; Springer: Vienna, Austria, 1994. [Google Scholar]

- Burgherr, P.; Eckle, P.; Hirschberg, S. Comparative assessment of severe accident risks in the coal, oil and natural gas chains. Reliab. Eng. Syst. Saf. 2012, 105, 97–103. [Google Scholar] [CrossRef]

- Tsvetkova, A. World experience of strategic reserves mineral. In Proceedings of the 3rd International Conference on Management–Economics–Ethics–Technology (MEET 2017), Gliwice, Poland, 21–22 September 2017. [Google Scholar]

- Zhang, D. A Study on China Strategic Petroleum Reserve; Wuhan University: Wuhan, China, 2014. [Google Scholar]

- Yuan, G.; Xia, Y.; Jin, G. Present state of underground storage and development trends in engineering technologies at home and abroad. Pet. Drill. Technol. 2017, 45, 8–14. [Google Scholar]

- Tillerson, J.R. Geomechanics Invetigations of SPR Crude Oil Storage Caverns; SAND-79-2031C; Sandia National Laboratories: Albuquerque, NM, USA, 1979.

- Leiby, P.N.; Bowman, D. The Value of Expanding the U.S. Strategic Petroleum Reserve; ORNL/TM-2000/179; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2000.

- Lord, D.L.; Checkai, D.; Eldredge, L.; Osborne, G. Pressure trending analysis to support cavern integrity monitoring at the U.S. Strategic petroleum reserve. In Proceedings of the Solution Mining Research Institute Technical Conference, San Antonio, TX, USA, 5–6 May 2014. [Google Scholar]

- Langer, M. Use of solution-mined caverns in salt for oil and gas storage and toxic waste disposal in Germany. Eng. Geol. 1993, 35, 183–190. [Google Scholar] [CrossRef]

- Davis, R.M. National strategic petroleum reserve. Science 1981, 213, 618–622. [Google Scholar] [CrossRef]

- Nilsen, B. Norwegian oil and gas storage in rock caverns—Technology based on experience from hydropower development. J. Rock Mech. Geotech. Eng. 2021, 13, 479–486. [Google Scholar] [CrossRef]

- Lin, L. Drawing on foreign experience to create a strategic petroleum reserve model with Chinese characteristics. Shandong Ind. Technol. 2013, 32, 18–19. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, L. Optimal selection of underground salt cavern oil storage site. Oil Gas Storage Transp. 2011, 30, 117–120. [Google Scholar]

- Li, J. China Has Built 9 Major Oil Reserve Bases. People’s Daily 2017, 70, 3–5. [Google Scholar]

- Yang, C.; Wang, T. Advance in deep underground energy storage. Chin. J. Rock Mechan-Ics Eng. 2022, 41, 1729–1759. [Google Scholar]

- Cyran, K. Insight into a Shape of Salt Storage Caverns. Arch. Min. Sci. 2020, 65, 363–398. [Google Scholar]

- Wang, Z.; Li, Y.; Zhang, L. Engineering geological conditions and feasibility analysis of under-ground gas storage in thin-layered salt rock. J. Eng. Geol. 2015, 23, 148–154. [Google Scholar]

- Liu, W.; Du, J.; Li, Q.; Shi, X.; Chen, J.; Yi, W.; He, T.; Li, D.; Dong, Y.; Jiang, D.; et al. Feasibility analysis on the utilization of TWH-caverns with sediment space for gas storage: A case study of Sanshui salt mine. J. Energy Storage 2023, 75, 109576. [Google Scholar] [CrossRef]

- Ding, G.; Xie, P. Salt cavern available for state strategic petroleum storage. Oil Gas Storage Transp. 2006, 25, 16–19. [Google Scholar]

- Liu, W.; Dong, Y.K.; Zhang, Z.X.; Li, L.; Jiang, D.Y.; Fan, J.Y.; Chen, J.; Zhang, X.; Wan, J.F.; Li, Z.Z. Optimization of operating pressure of hydrogen storage salt cavern in bedded salt rock with multi-interlayers. Int. J. Hydrogen Energy 2024, 58, 974–986. [Google Scholar] [CrossRef]

- Li, J.; Wan, J.; Liu, H.; Jurado, M.J.; He, Y.; Yuan, G.; Xia, Y. Stability Analysis of a Typical Salt Cavern Gas Storage in the Jintan Area of China. Energies 2022, 15, 4167. [Google Scholar] [CrossRef]

- Shi, X.L.; Yang, C.H.; Li, Y.P.; Li, J.L.; Ma, H.L.; Wang, T.T.; Guo, Y.T.; Chen, T.; Chen, J.; Liu, W.; et al. Development prospect of salt cavern gas storage and new research progress of salt cavern leaching in China. In Proceedings of the 51st U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 25–28 June 2017. [Google Scholar]

- Wu, W.; Xu, S.; Yang, C.; Bai, S. Testing studies on response behaviour of rock salt to impacting. Chin. J. Rock Mech. Eng. 2004, 23, 3613. [Google Scholar]

- Zhang, N.; Liu, X.; Zhang, Y.; Gu, H.; Yan, B.; Jia, Q.; Gao, X. Investigating the Mechanism of Land Subsidence Due to Water Network Integration at the Guangzhou Longgui Salt Mine and Its Impact on Adjacent Subway. Water 2024, 16, 1723. [Google Scholar] [CrossRef]

- Jiang, D.Y.; Ren, T.; Chen, J.; Ren, S.; Fan, X.Q.; Yang, C.H. Experimental study on mechanical characteristics of molded salt rock with weak interlayer. Chin. J. Rock Mech. Eng. 2012, 31, 1797–1803. [Google Scholar]

- Chen, W.; Tan, X.; Wu, G. Gas leakage assessment method of underground gas storage in multi-interlayer salt mine. Chin. J. Rock Mech. Eng. 2008, 28, 11–20. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Yin, H. Evaluation method for gas leakage in multi-layered salt rock underground storage. Rock Soil Mech. 2018, 40, 11–20. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; He, M.; Song, Z.; Feng, S.; Liu, X.; Zhang, Y. Long-term stability analysis and evaluation of horizontal salt cavern gas storage. J. Energy Storage 2023, 66, 107413. [Google Scholar] [CrossRef]

- Xuan, Z. Research on China’s salt mine resources and salt chemical industry areas. Lake Salt Res. 1996, Z1, 69–72. [Google Scholar]

- Li, W.; Ding, G.; Zhang, Y. Feasibility of underground oil reserve in China. Petrochem. Technol. Econ. 2002, 19, 14–18. [Google Scholar]

- Li, J. Using salt beds to build underground gas storages with salt caves. Nat. Gas Ind. 2004, 24, 119–121. [Google Scholar]

- Yang, C.H.; Liang, W.G.; Wei, D.H.; Yang, H.J. Investigation on possibility of energy storage in salt rock in China. Chin. J. Rock Mech. Eng. 2005, 24, 4409. [Google Scholar]

- Park, B.Y.; Ehgartner, B.L. Sensitivity of Storage Field Performance to Geologic and Cavern Design Parameters in Salt Domes. In Proceedings of the 44th U.S. Rock Mechanics Symposium and 5th U.S.—Canada Rock Mechanics Symposium, Salt Lake City, UT, USA, 27–30 June 2010. [Google Scholar]

- Park, B.Y.; Ehgartner, B.L.; Herrick, C.G. Allowable Pillar to Diameter Ratio for Strategic Petroleum Reserve Caverns. In Proceedings of the 45th U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 26–29 June 2011. [Google Scholar]

- Wei, X.; Shi, X.; Li, Y.; Li, P.; Ban, S.; Zhao, K.; Ma, H.; Liu, H.; Yang, C. A comprehensive feasibility evaluation of salt cavern oil energy storage system in China. Appl. Energy 2023, 351, 121807. [Google Scholar] [CrossRef]

- Yang, C.; Jing, W.; Daemen, J.J.; Zhang, G.; Du, C. Analysis of major risks associated with hydrocarbon storage caverns in bedded salt rock. Reliab. Eng. Syst. Saf. 2013, 113, 94–111. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, Z. Cementing technology for Jintan salt cavern underground gas storage. Pet. Drill. Technol. 2006, 34, 3. [Google Scholar]

- Liu, X.; Zhao, N.; Yang, X.; Hen, Z. Application of high water absorption temporary plugging completion fluid in Hutubi gas storage well completion. Pet. Drill. Technol. 2013, 41, 6. [Google Scholar]

- Cyran, K.; Kowalski, M. Shape Modelling and Volume Optimisation of Salt Caverns for Energy Storage. Appl. Sci. 2021, 11, 423. [Google Scholar] [CrossRef]

- Bruno, M.; Dorfmann, L.; Han, G.; Lao, K.; Young, J. 3D geomechanical analysis of multiple caverns in bedded salt. In Proceedings of the SMRI Fall 2005 Meeting, Nancy, France, 1–5 October 2005. [Google Scholar]

- Ding, G. Demand and challenges of underground gas storage in China. Nat. Gas Ind. 2011, 31, 90–93+131. [Google Scholar]

- Wan, J.; Meng, T.; Li, J.; Liu, W. Energy storage salt cavern construction and evaluation technology. Adv. Geo-Energy Res. 2023, 9, 141–145. [Google Scholar] [CrossRef]

- Gou, Y.; Bai, S.; Jia, J.; Li, K.; Li, F.; Ran, L. Feasibility analysis of single well and double cavity in the salt-cavern gas storage with thick sandwiches. Oil Drill. Prod. Technol. 2020, 42, 449–453. [Google Scholar]

- Jing, W.; Yang, C.; Li, Y.; Yang, C. Research on the feasibility of Jintan salt cavern as an underground gas storage site. Nat. Gas Ind. 2005, 25, 118–120. [Google Scholar]

- Lux, K.H. Gebirsmechanischer Entwurf und Felderfahrungen im Salzkavernenbau: Ein Beitrag zur Entwicklung von Prognosemodellen für den Hohlraumbau im duktilen Salzgebirge; Ferdinand Enke: Stuttgart, Germany, 1984. [Google Scholar]

- Fu, J.; Wang, X.; Ding, M.M.; Yang, G.B.; Zhang, S.Y.; Liu, B.S.; Chen, C. Research on Construction and Operation Parameters of an Underground Oil Storage in Depleted Salt Caverns in the East of China. Presented at the SPE Europec Featured at 82nd EAGE Conference and Exhibition, Amsterdam, The Netherlands, 18–21 October 2021. [Google Scholar] [CrossRef]

- Pan, J. China’s Energy Resources Issues and Construction of the State Petroleum Strategic Reserve. Oil Gas Storage Transp. 2004, 23, 1–3. [Google Scholar]

- Yang, Y. Feasibility Analysis on Using Underground Cavern as State Oil Strategic Reserves. OGST 2004, 23, 22–24. [Google Scholar]

- Song, H.; Zhu, S.; Li, J.; Wang, Z.; Li, Q.; Ning, Z. Design Criteria for the Construction of Energy Storage Salt Cavern Considering Economic Benefits and Resource Utilization. Sustainability 2023, 15, 6870. [Google Scholar] [CrossRef]

- Xia, X.; Liu, Y. A Brief Discussion on the Construction of Underground Oil Reservoirs in China. Pet. Plan. Des. 2004, 15, 26–27. [Google Scholar]

- Liu, Y.; Li, Y.; Ma, H.; Shi, X.; Zheng, Z.; Dong, Z.; Zhao, K. Detection and Evaluation Technologies for Using Existing Salt Caverns to Build Energy Storage. Energies 2022, 15, 9144. [Google Scholar] [CrossRef]

- Jing, G.; He, J.; Chen, J.; Zhou, D.; Wang, X.; Liu, J.; Qi, D. Potential Analysis of Huai’an Salt Cavern Oil Storage. Oil Gas Storage Transp. 2017, 36, 875–882. [Google Scholar]

- Tan, Y.; Song, C. Analysis of Key Technical Points for Using Salt Caverns for Strategic Petroleum Storage. Oil Gas Storage Transp. 2008, 27, 1–4. [Google Scholar]

- Chen, J.; Tan, Y.; Yu, Q. Key Points in the Planning and Design of Underground Gas Storage. Oil Gas Storage Transp. 2001, 20, 13–16. [Google Scholar]

- Wang, T.; Yang, C.; Ma, H.; Daemen, J.J.K.; Wu, H. Safety evaluation of gas storage caverns located close to a tectonic fault. J. Nat. Gas Sci. Eng. 2015, 23, 281–293. [Google Scholar] [CrossRef]

- Walder, J.; Nur, A. Permeability measurement by the pulse-decay method: Effects of poroelastic phenomena and non-linear pore pressure diffusion. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1986, 23, 225–232. [Google Scholar] [CrossRef]

- Gu, H.; Lai, X.; Tao, M.; Momeni, A.; Zhang, Q. Dynamic mechanical mechanism and optimization approach of roadway surrounding coal water infusion for dynamic disaster prevention. Measurement 2023, 223, 113639. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.P.; Ge, X.B.; Shi, X.L.; Xue, T.F. Simulating brine transport in strata of a bedded salt cavern storage with a Fluid–Solid Coupling Model. Eng. Geol. 2020, 271, 105595. [Google Scholar] [CrossRef]

- Yang, C.; Chen, F.; Zeng, Y. Investigation on reep damage constitutive theory of salt rock. Chin. J. Rock Mech. Eng. 2002, 3, 1602–1604. [Google Scholar] [CrossRef]

- Gao, R.; Kuang, T.; Meng, X.; Huo, B. Effects of ground fracturing with horizontal fracture plane on rock breakage characteristics and mine pressure control. Rock Mech. Rock Eng. 2021, 54, 3229–3243. [Google Scholar] [CrossRef]

- Gao, R.; Bai, D.; Yu, B.; Tai, Y.; Meng, X.; Zhang, W. Ground fracturing of multi-strata for strong ground pressure control in extra-thick coal seams with hard roofs: Numerical simulation and case study. Eng. Fract. Mech. 2024, 303, 110129. [Google Scholar] [CrossRef]

- Zhu, D.; Yu, B.; Wang, D.; Zhang, Y. Fusion of finite element and machine learning methods to predict rock shear strength parameters. J. Geophys. Eng. 2024, 21, 1183–1193. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, D.; Feng, G.; Chi, M. Modelling method of heterogeneous rock mass and DEM investigation of seepage characteristics. Géoméch. Geophys. Geo-Energy Geo-Resour. 2024, 10, 1–22. [Google Scholar] [CrossRef]

- Wei, L.; Jie, C.; Deyi, J.; Xilin, S.; Yinping, L.; Daemen, J.J.K.; Chunhe, Y. Tightness and suitability evaluation of abandoned salt caverns served as hydrocarbon energies storage under adverse geological conditions (AGC). Appl. Energy 2016, 178, 703–720. [Google Scholar] [CrossRef]

- Ge, X.; Li, Y.; Shi, X.; Ma, H.; Wang, K.; Yin, H. Dynamics and enhanced stability properties of slender leaching tubings in salt cavern storage with a Y-type manifold fitted at free downstream end. J. Energy Storage 2021, 43, 103170. [Google Scholar] [CrossRef]

- Hoffman, E.L. Effects of Cavern Spacing on the Performance and Stability of Gas-Filled Storage Caverns; SAND-92-2545; Sandia National Laboratories: Albuquerque, NM, USA, 1993.

- Hoffman, E.L. Effects of Cavern Depth on Surface Subsidence and Storage Loss of Oil-Filled Caverns; SAND-92-0053; Sandia National Laboratories: Albuquerque, NM, USA, 1992.

- Hoffman, E.L.; Ehgartner, B.L. Using Three Dimensional Structural Simulations to Study the Interactions of Multiple Excavations in Salt; SAND-97-1017C; Sandia National Laboratories: Albuquerque, NM, USA, 1998.

- Yang, C.; Daemen, J.J.K.; Yin, J.H. Experimental investigation of creep behavior of salt rock. Int. J. Rock Mech. Min. Sci. 1999, 36, 233–242. [Google Scholar] [CrossRef]

- Huang, M.; Liu, W.; Shi, X. Engineering Geology Characteristics of Jintan Salt Mine. Soil Eng. Found. 2014, 28, 92–95. [Google Scholar]

- Ding, L. Research on estimation of slope stability based on improved grey correlation analysis and analytic hierarchy process. Rock Soil Mech. 2011, 32, 3437–3441. [Google Scholar]

- Haghiri, M.; Raeisi, N.; Azizi, R.; Shabani, K.; Ghadiri, M. Evaluation of karst aquifer development and karst water resource potential using fuzzy logic model (FAHP) and analysis hierarchy process (AHP): A case study, North of Iran. Carbonates Evaporites 2024, 39, 11. [Google Scholar] [CrossRef]

- Zhai, Y.; Cao, W.; Wang, J.; Zhang, Y. Slope Stability Fuzzy Evaluation Method Based on Uncertain Analytic Hierarchy Process. Rock Soil Mech. 2011, 32, 539–543. [Google Scholar] [CrossRef]

- Vaidya, O.S.; Kumar, S. Analytic hierarchy process: An overview of applications. Eur. J. Oper. Res. 2006, 169, 1–29. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Abrahamsen, E.B.; Milazzo, M.F.; Selvik, J.T.; Asche, F.; Abrahamsen, H.B. Prioritising investments in safety measures in the chemical industry by using the Analytic Hierarchy Process. Reliab. Eng. Syst. Saf. 2020, 198, 106811. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, C.; Hu, B. Analysis of Factors Influencing Brand Competitiveness of Beijing Vegetable Cooperatives Based on Analytic Hierarchy Process. North. Hortic. 2020, 44, 155–164. [Google Scholar]

- Zhao, X. Performance Evaluation of Dealers Based on Analytic Hierarchy Model. Mark. Mod. 2009, 38, 21–23. [Google Scholar]

- Wei, X.; Shi, X.; Li, Y. Optimization of engineering for the salt cavern oil storage (SCOS) during construction in China. Geoenergy Sci. Eng. 2024, 233, 212567. [Google Scholar] [CrossRef]

- Wu, W.; Hou, Z.; Yang, C. Investigation on Evaluating Criteria of Stabilities for Energy (Petroleum and Natural Gas) Storage Caverns in Rock Salt. Chin. J. Rock Mech. Eng. 2005, 24, 9. [Google Scholar]

- Yin, X.; Yang, C.; Li, Y. Influence of mudstone interlayer on stability of oil storage in laminated salt rock. Rock Soil Mech. 2006, 27, 344–348. [Google Scholar]

- Yin, X.; Yang, C.; Chen, J. Numerical simulation research on long-term stability of gas storage in Jintan salt mine. Rock Soil Mech. 2006, 27, 869–874. [Google Scholar]

- Zhao, X. Project Risk Management. Soc. Sci. 2005, S1, 391–392. [Google Scholar]

| Oil Storage Bases | Total Storage Capacity () | Remarks |

|---|---|---|

| Zhoushan | Surface storage bases | |

| Zhoushan Expansion | Surface storage bases | |

| Zhenhai | Surface storage bases | |

| Dalian | Surface storage bases | |

| Huangdao | Surface storage bases | |

| Dushanzi | Surface storage bases | |

| Lanzhou | Surface storage bases | |

| Tianjin | Surface storage bases | |

| Huangdao national oil reserve cavern | Underground storage bases |

| Scale | Meaning of Importance Comparison |

|---|---|

| 1 | and are equally important |

| 3 | is slightly more important than |

| 5 | is moderately more important than |

| 7 | is strongly more important than |

| 9 | is extremely more important than |

| 2, 4, 6, 8 | Intermediate values between the adjacent judgments |

| 1, 1/2, …, 1/9 | compared to in the reverse order of the above comparisons |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| RI | 0 | 0 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

| Level A | A1 | A2 | …… | Am | Total Ranking of Level B | |

|---|---|---|---|---|---|---|

| Level B | a1 | a2 | …… | am | ||

| B1 | b11 | b12 | …… | b1m | ||

| B2 | b21 | b22 | …… | b2m | ||

| …… | …… | …… | …… | …… | …… | |

| Bn | bn1 | bn2 | …… | bnm | ||

| Indicator | Relation to | Indicator | Relation to | Indicator | Relation to | Indicator | Relation to | Indicator | Relation to |

|---|---|---|---|---|---|---|---|---|---|

| Same 1 | Same-slightly more 2 | Slightly more 3 | Slightly more 3 | More 5 | |||||

| Same-slightly less 1/2 | Same 1 | Same-slightly more 2 | Same-slightly more 2 | Slightly more-more 4 | |||||

| Slightly less 1/3 | Same-slightly less 1/2 | Same 1 | Same 1 | Slightly more 3 | |||||

| Slightly less 1/3 | Same-slightly less 1/2 | Same 1 | Same 1 | Slightly more 3 | |||||

| Less 1/5 | Slightly less-less 1/4 | Slightly less 1/3 | Slightly less 1/3 | Same 1 |

| Goal Layer | Criterion Layer | Criterion Layer Weight | Evaluation Layer | Evaluation Layer Weight | Weight Relative to Goal Layer (Criterion Layer Weight Evaluation Layer Weight) |

|---|---|---|---|---|---|

| The suitability assessment for the site selection and construction of salt cavern storage | Macro-regional geological characteristics | 0.3918 | Regional tectonic characteristics Regional sedimentary characteristics Regional hydrological characteristics | 0.3333 0.3333 0.3333 | 0.1306 0.1306 0.1306 |

| Basic Geological Characteristics of the Mining Area | 0.2439 | Characteristics of rock layer distribution Interbedded distribution characteristics Average grade of ore body | 0.4000 0.4000 0.2000 | 0.0976 0.0976 0.0488 | |

| Basic characteristics of the salt layer for cavern construction | 0.1425 | Insoluble matter content of salt layer and interlayer Depth of the salt roof Interbedded salt layer thickness ratio | 0.5396 0.2969 0.1635 | 0.0769 0.0423 0.0233 | |

| Roof and floor characteristics of the salt layer | 0.1425 | Mechanical properties of roof and floor Pore and seepage characteristics of roof and floor Characteristics of fracture development of roof and floor | 0.3333 0.3333 0.3333 | 0.0475 0.0475 0.0475 | |

| surface factors | 0.0793 | Distance to the pier and oil pipelines Population and building density | 0.7500 0.2500 | 0.0595 0.0198 |

| Suitability | Best | Suitable | Average | Poor | |

|---|---|---|---|---|---|

| Evaluation Index | 10 | 8 | 6 | 4 | |

| Macro-regional geological characteristics | Regional tectonic characteristics | Seismic activity is very weak, no active faults within 1 km of the storage area | Seismic activity is weak, no active faults within 300–1000 m of the storage area | No major historical earthquakes recently, no active faults within 300–1000 m of the storage area | Recent major historical earthquakes, or recent major historical earthquakes present |

| Regional sedimentary characteristics | Marine sedimentation, thick salt dome, thickness ≥ 400 m | Marine sedimentation, thick salt dome, thickness 150~400 m | Marine sedimentation, thick salt dome, thickness 100~150 m | Marine sedimentation, thick salt dome, thickness < 100 m | |

| Regional hydrological characteristics | Ample surface fresh water close to the site, salt mine layer isolated from groundwater system | Ample surface fresh water close to the site, salt mine layer isolated from groundwater system | Ample surface fresh water at a distance, salt mine layer isolated from groundwater system | Lack of surface fresh water, or salt mine layer connected to groundwater system | |

| Basic Geological Characteristics of the Mining Area | Characteristics of rock layer distribution | Salt mine distribution area ≥ 100 km2 | Salt mine distribution area 50~100 km2 | Salt mine distribution area 20~50 km2 | Salt mine distribution area < 20 km2 |

| Interbedded distribution characteristics | Small thickness and very few interlayers within and between layers | More interlayers but small thickness | Numerous thin interlayers, occasionally thick interlayers > 10 m | Numerous thick interlayers | |

| Average grade of ore body | ≥85% | 70~85% | 50~70% | <50% | |

| Basic characteristics of the salt layer for cavern construction | Insoluble matter content of salt layer and interlayer | Insoluble content < 5%, overall solubility > 90% | Insoluble content 5~10%, overall solubility 75~90% | Insoluble content 10~15%, overall solubility 60~75% | Insoluble content > 15%, overall solubility < 60% |

| Depth of the salt roof | 800~1500 m | 1500~2500 m | 600~800 m or >2500 m | <600 m | |

| Interbedded salt layer thickness ratio | <5% | 5~20% | 20~40% | >40% | |

| Roof and floor characteristics of the salt layer | Mechanical properties of roof and floor | Hard rock, thickness ≥ 100 m, uniaxial strength ≥ 60 MPa | Hard rock, thickness 50~100 m, uniaxial strength 40~60 Mpa | Medium hard rock, thickness 30~50 m, uniaxial strength 20~40 Mpa | Soft rock or thickness <30 m, uniaxial strength < 20 Mpa |

| Pore and seepage characteristics of roof and floor | Porosity < 5%, permeability < 10−3 mD | Porosity 5~10%, permeability 10−3~10−1 mD | Porosity 10~20%, permeability 10−1~10 mD | Porosity > 20%, permeability > 10 mD | |

| Characteristics of fracture development of roof and floor | Good integrity, no fracture development | Good integrity, few fractures | Fractures developed but not through-going | Numerous through-going fractures | |

| surface factors | Distance to the pier and oil pipelines | ≤30 km | 30~65 km | 65~100 km | >100 km |

| Population and building density | Population density < 10 persons/km2, buildings < 5% | Population density 10~50 persons/km2, buildings < 5~15% | Population density50~100 persons/km2, buildings < 15~30% | Population density ≥ 100 persons/km2, buildings ≥ 30% |

| Suitability Rating | Best Site | Suitable Site | Generally Suitable Site | Unsuitable Site |

|---|---|---|---|---|

| Indicator Score | 9 < P ≤ 10 | 7 < P ≤ 9 | 5 < P ≤ 7 | P ≤ 5 |

| Suitability | Best | Suitable | Average | Poor | |

|---|---|---|---|---|---|

| Evaluation Index | 10 | 8 | 6 | 4 | |

| Macro-regional geological characteristics | Regional tectonic characteristics | Seismic activity is very weak, no active faults within 1 km of the storage area | — | — | — |

| Regional sedimentary characteristics | — | Marine sedimentation, thick salt dome, thickness 150~400 m | — | — | |

| Regional hydrological characteristics | Ample surface fresh water close to the site, salt mine layer isolated from groundwater system | — | — | — | |

| Basic Geological Characteristics of the Mining Area | Characteristics of rock layer distribution | — | Salt mine distribution area 50~100 km2 | — | — |

| Interbedded distribution characteristics | — | More interlayers but small thickness | — | — | |

| Average grade of ore body | ≥85% | — | — | — | |

| Basic characteristics of the salt layer for cavern construction | Insoluble matter content of salt layer and interlayer | — | Insoluble content 5~10%, overall solubility 75~90% | — | — |

| Depth of the salt roof | 800~1500 m | — | — | — | |

| Interbedded salt layer thickness ratio | — | 5~20% | — | — | |

| Roof and floor characteristics of the salt layer | Mechanical properties of roof and floor | — | Hard rock, thickness 50~100 m, uniaxial strength 40~60 Mpa | — | — |

| Pore and seepage characteristics of roof and floor | — | — | Porosity 10~20%, permeability 10−1~10 mD | — | |

| Characteristics of fracture development of roof and floor | — | Good integrity, few fractures | — | — | |

| surface factors | Distance to the pier and oil pipelines | ≤30,000 m | — | — | — |

| Population and building density | — | — | — | Population density ≥ 100/km2, buildings ≥ 30% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, N.; Gao, X.; Yan, B.; Zhang, Y.; Ji, S.; Shi, X. Overview of Salt Cavern Oil Storage Development and Site Suitability Analysis. Processes 2024, 12, 1709. https://doi.org/10.3390/pr12081709

Zhang N, Gao X, Yan B, Zhang Y, Ji S, Shi X. Overview of Salt Cavern Oil Storage Development and Site Suitability Analysis. Processes. 2024; 12(8):1709. https://doi.org/10.3390/pr12081709

Chicago/Turabian StyleZhang, Nan, Xinrong Gao, Baoxu Yan, Yun Zhang, Songtao Ji, and Xilin Shi. 2024. "Overview of Salt Cavern Oil Storage Development and Site Suitability Analysis" Processes 12, no. 8: 1709. https://doi.org/10.3390/pr12081709