Reconstruction of the Municipal Wastewater-Treatment Plant According to the Principles of Aerobic Granular Sludge Cultivation

Abstract

:1. Introduction

2. Materials and Methods

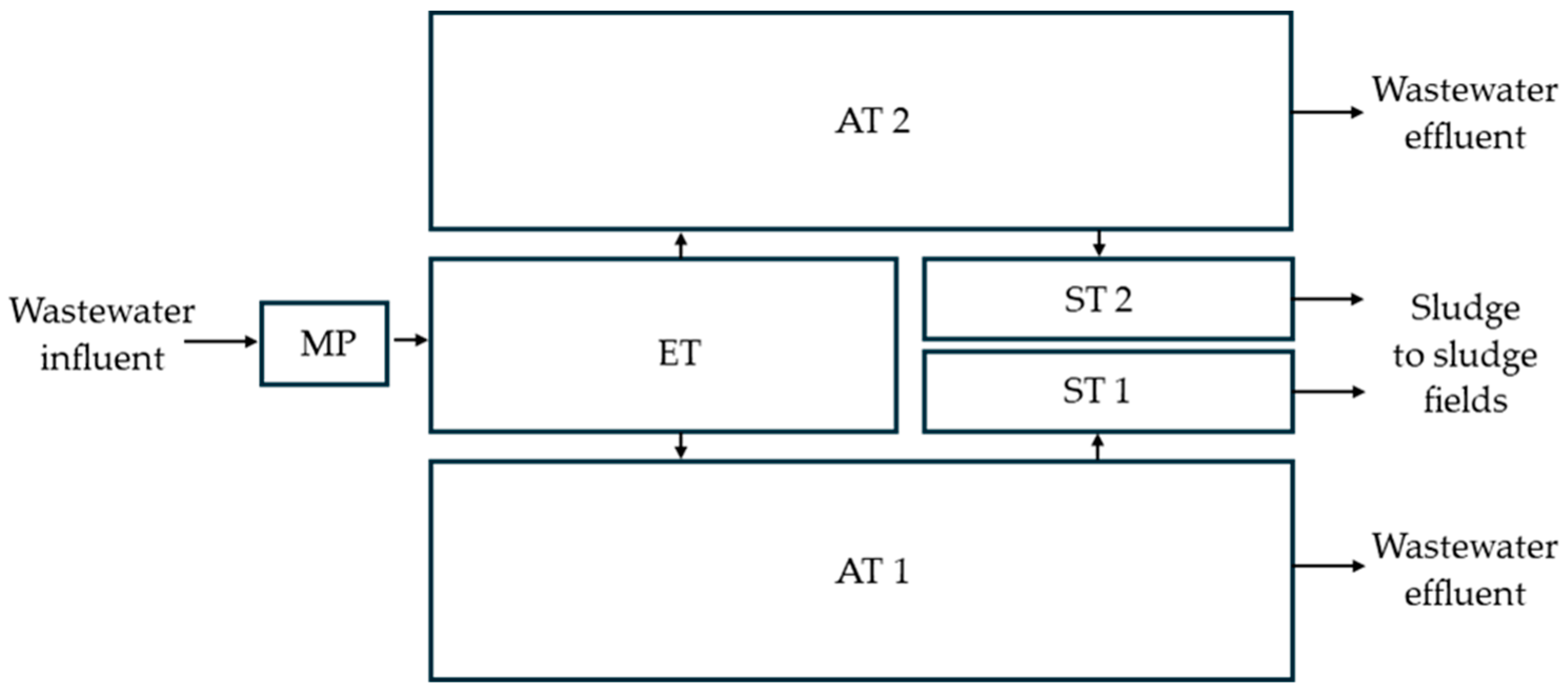

2.1. Technology of the Reconstructed WWTP

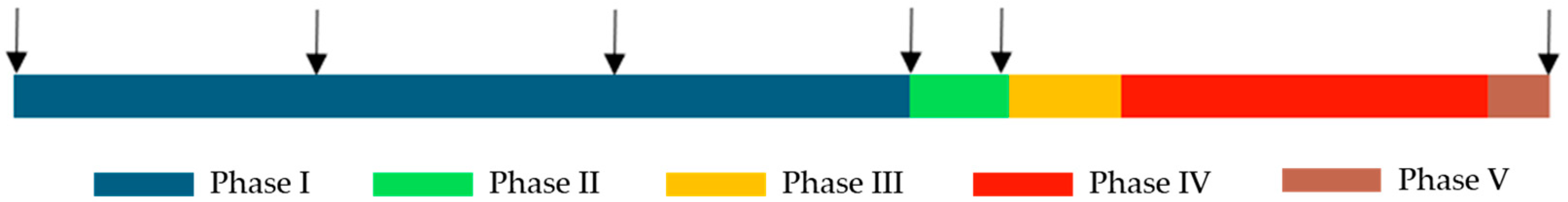

- Phase I—aeration;

- Phase II—intermittent aeration (the period of aeration interruption and aeration alternates several times);

- Phase III—sedimentation;

- Phase IV—filling wastewater into the lower part of the sludge bed while simultaneously discharging purified water (upper overflow into the drain)—fill-and-draw running;

- Phase V—sludge removal from the upper part of the sludge bed into the storage tanks.

2.2. Analyses

2.3. Tests for Nitrification and Denitrification Activity

3. Results and Discussion

3.1. Status of the WWTP before Reconstruction

| p | m | |

| COD | ≤120 mg/L | 150 mg/L |

| BOD5 | ≤25 mg/L | 45 mg/L |

| SS | ≤25 mg/L | 50 mg/L |

| N-NH4 | ≤20 mg/L | 40 mg/L |

| N-NH4 | ≤30 mg/LZ1 | 40 mg/LZ1 |

| Year | BOD5 (mg/L) | COD (mg/L) | SS (mg/L) | N-NH4 (mg/L) |

|---|---|---|---|---|

| Influent | ||||

| 2016 | 664 | 1246 | 643 | 100 |

| 2017 | 665 | 1246 | 1073 | 157 |

| 2018 | 629 | 1152 | 882 | 98 |

| Average | 653 | 1214 | 866 | 118 |

| Effluent | ||||

| 2016 | 43 | 219 | 52 | 90 |

| 2017 | 274 | 608 | 229 | 94 |

| 2018 | 57 | 247 | 69 | 77 |

| Average | 125 | 358 | 116 | 87 |

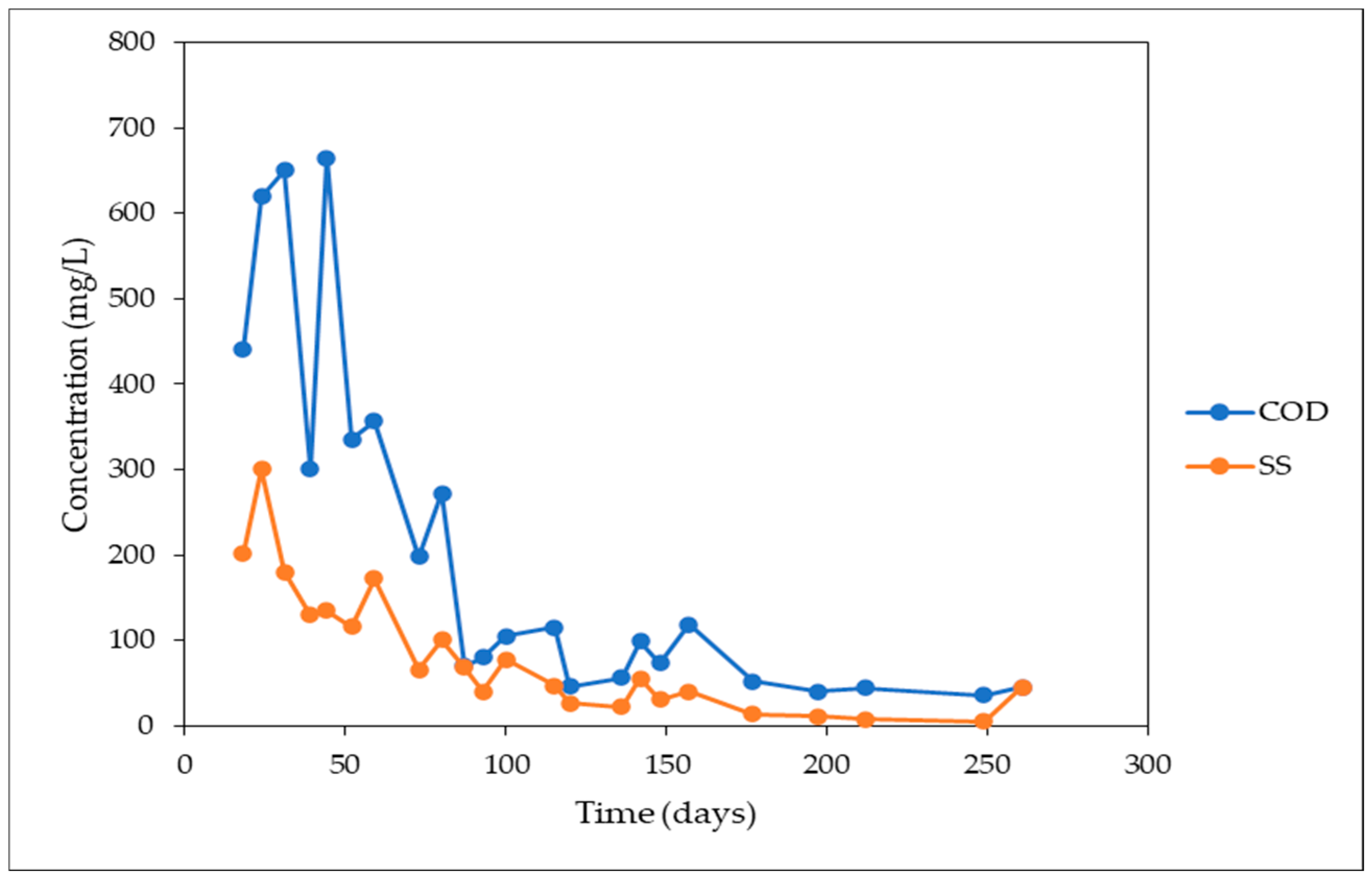

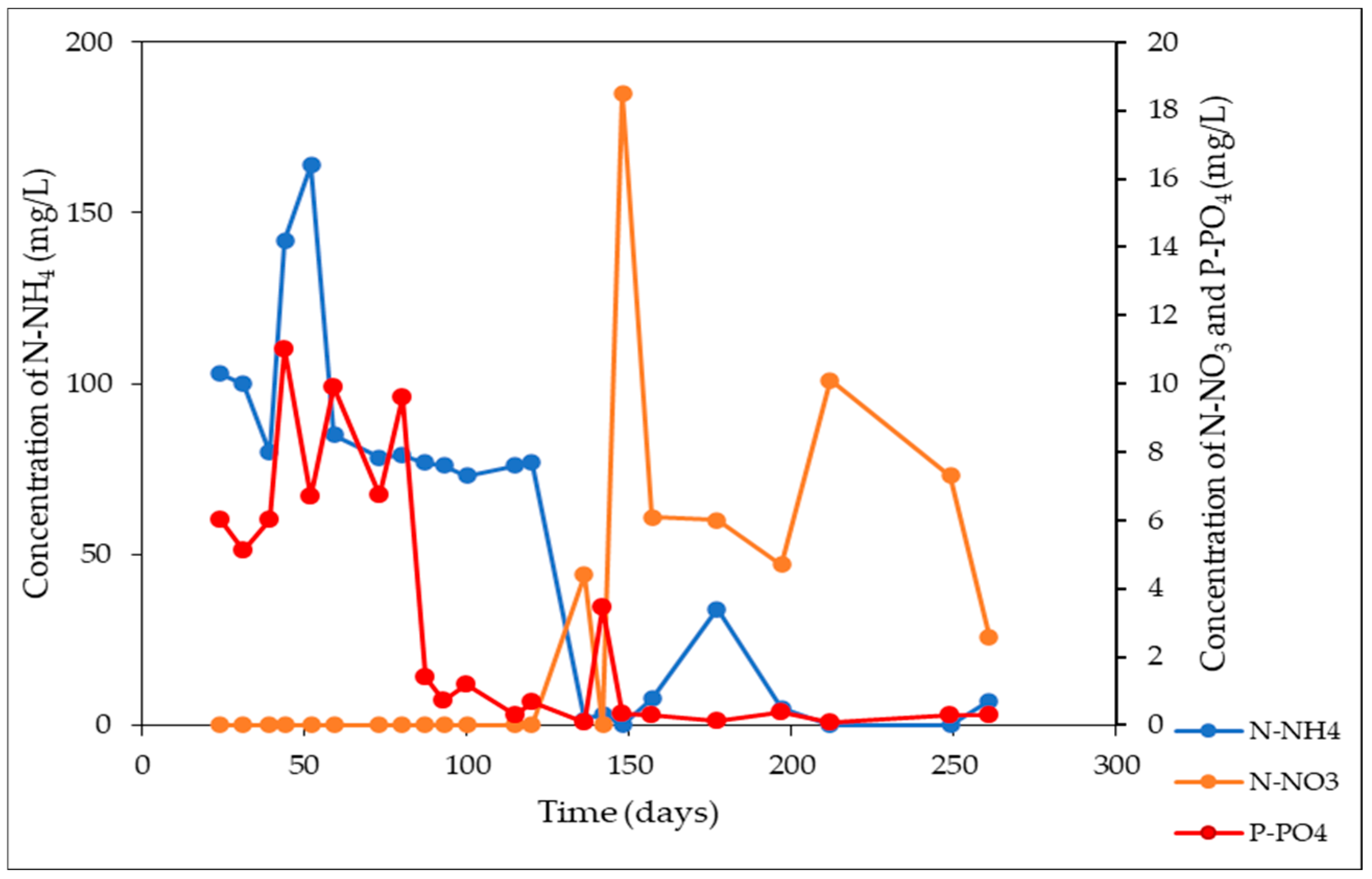

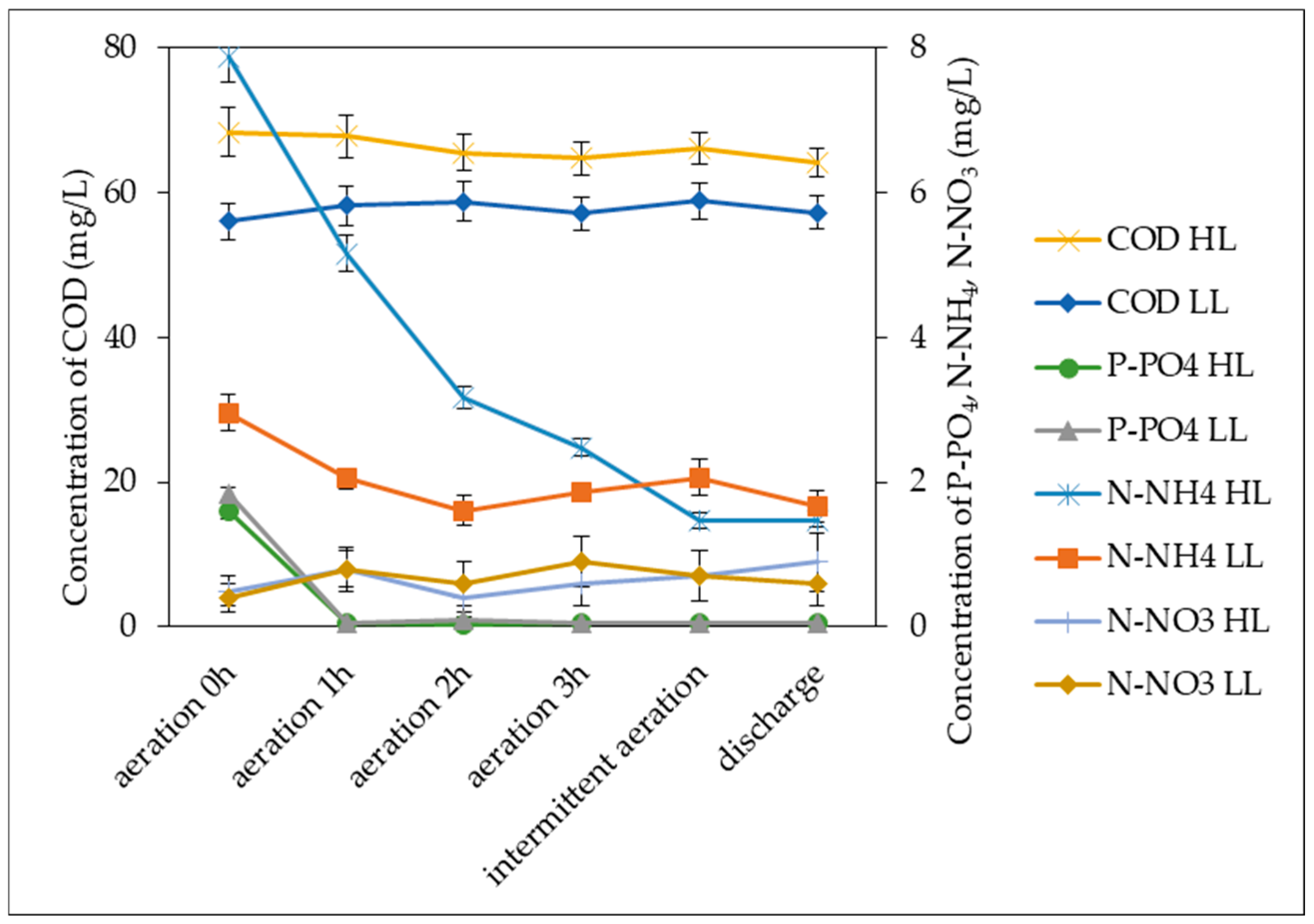

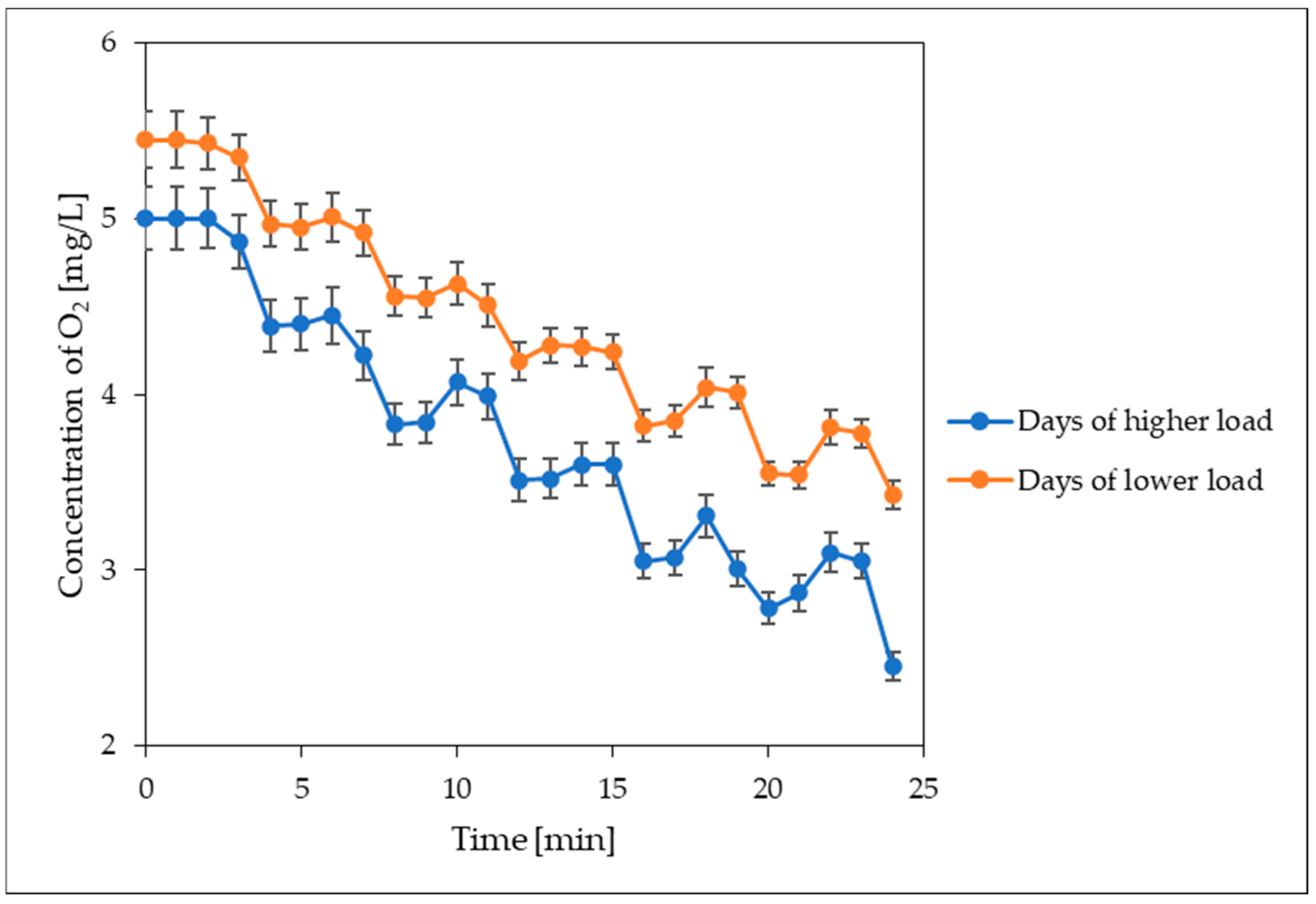

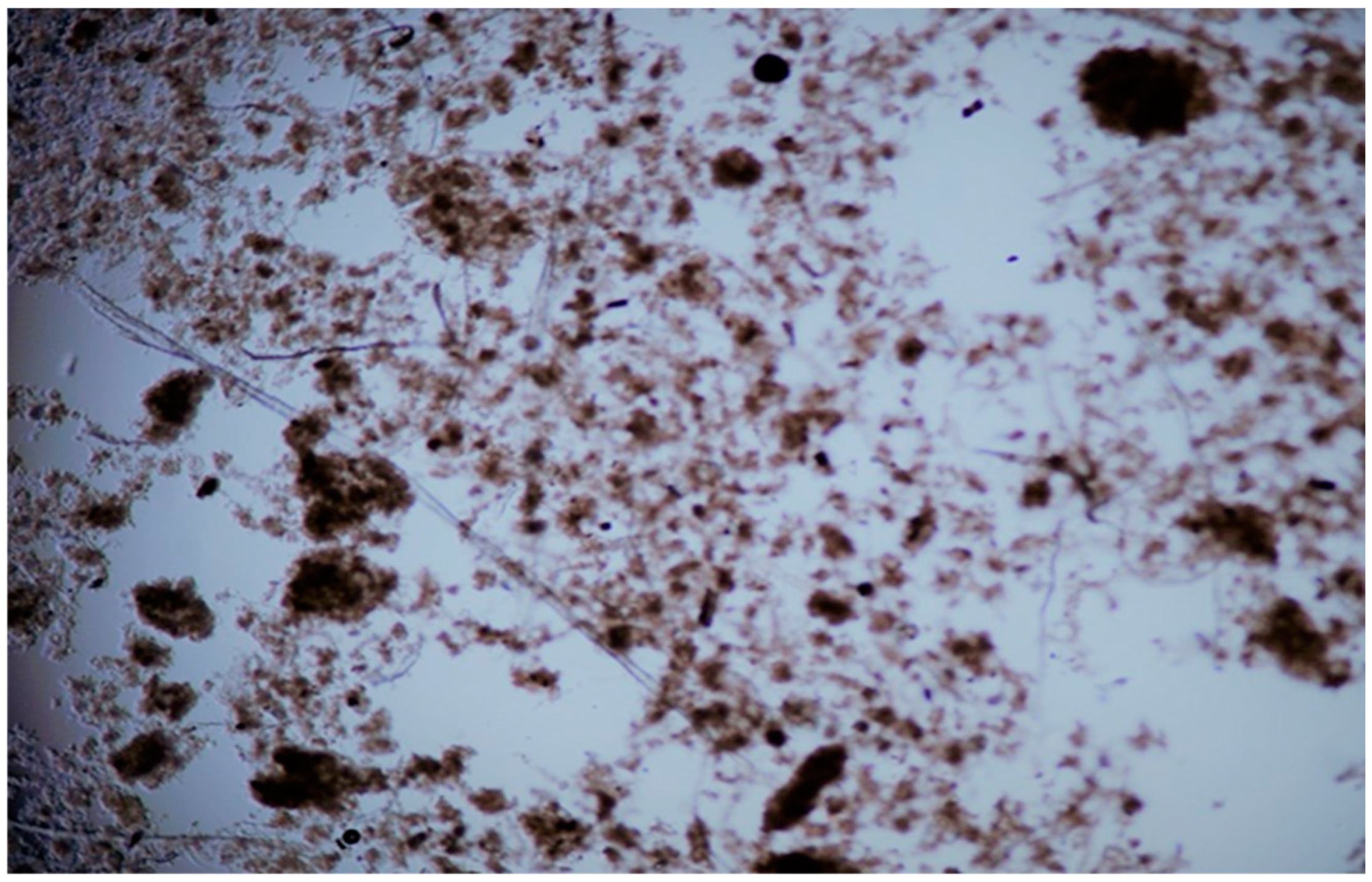

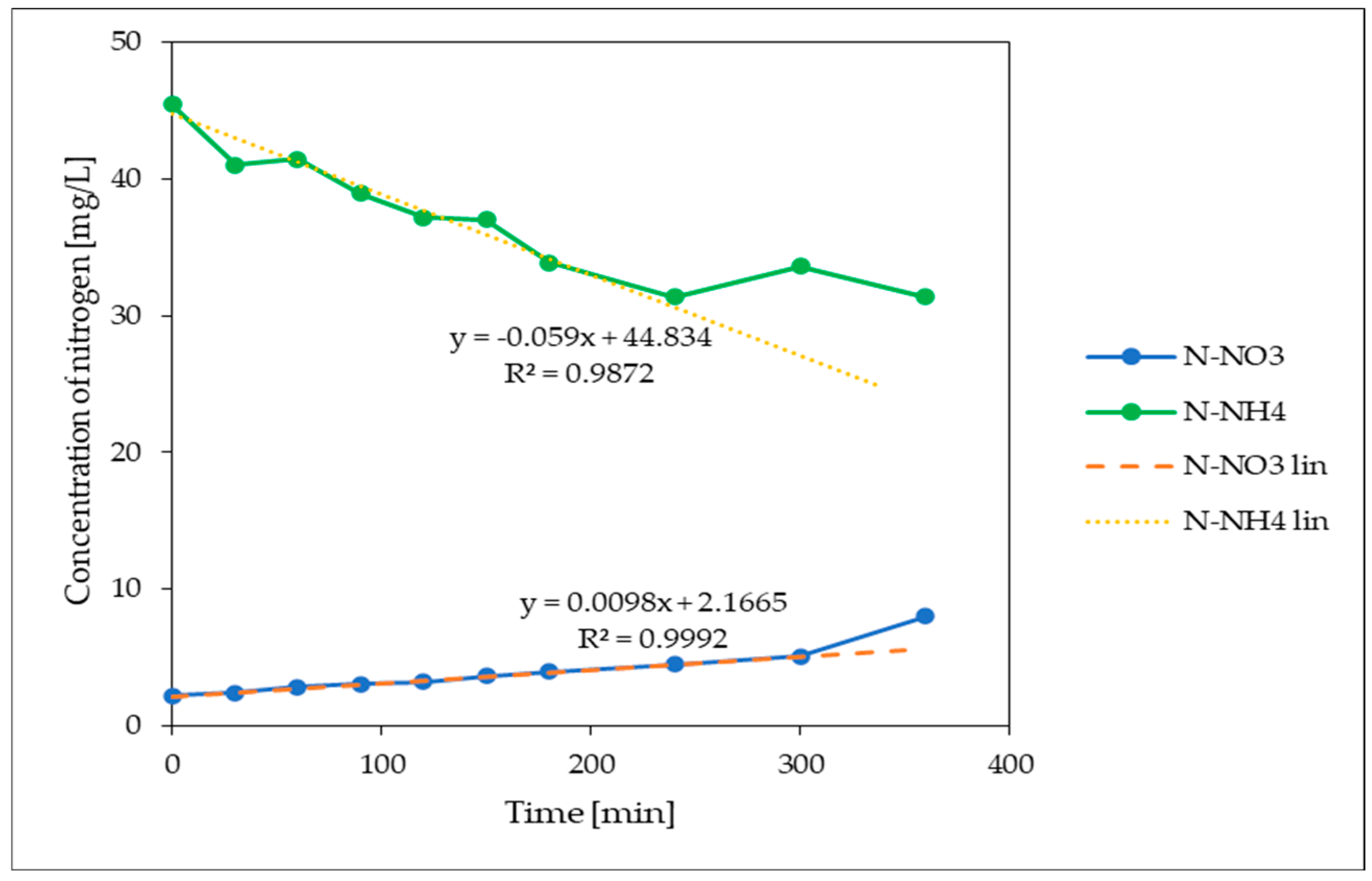

3.2. Operational Measurements at the WWTP after Reconstruction

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- de Kreuk, M.K.; Pronk, M.; van Loosdrecht, M.C.M. Formation of Aerobic Granules and Conversion Processes in an Aerobic Rranular Sludge Reactor at Moderate and Low Temperatures. Water Res. 2005, 39, 4476–4484. [Google Scholar] [CrossRef] [PubMed]

- de Kreuk, M.K.; Kishida, N.; van Loosdrecht, M.C.M. Aerobic Granular Sludge–State of the Art. Water Sci. Technol. 2007, 55, 75–81. [Google Scholar] [CrossRef]

- Weber, S.D.; Ludwig, W.; Schleifer, K.H.; Fried, J. Microbial Composition and Structure of Aerobic Granular Sewage Biofilms. Appl. Environ. Microbiol. 2007, 73, 6233–6240. [Google Scholar] [CrossRef] [PubMed]

- Pronk, M.; Kreuk, M.K.; de Bruin, B.; Kamminga, P.; Kleerebezem, R.; van Loosdrecht, M.C.M. Full Scale Performance of the Aerobic Granular Sludge Process for Sewage Treatment. Water Res. 2015, 84, 207–217. [Google Scholar] [CrossRef] [PubMed]

- de Sousa Rollemberg, S.L.; Mendes Barros, A.R.; Milen Firmino, P.I.; Bezerra dos Santos, A. Aerobic Granular Sludge: Cultivation Parameters and Removal Mechanisms. Bioresour. Technol. 2018, 270, 678–688. [Google Scholar] [CrossRef]

- Nancharaiah, Y.V.; Sarvajith, M. Aerobic Granular Sludge Process: A Fast Growing Biological Treatment for Sustainable Wastewater Treatment. Curr. Opin. Environ. Sci. Health 2019, 12, 57–65. [Google Scholar] [CrossRef]

- Dangcong, P.; Bernet, M.; Delgenes, J.P.; Moletta, R. Aerobic Granular Sludge—A Case Report. Water Res. 1999, 33, 890–893. [Google Scholar] [CrossRef]

- Nancharaiah, Y.V.; Kiran Kumar Reddy, G. Mechanisms of Granulation and Biotechnological Applications. Bioresour. Technol. 2018, 247, 1128–1143. [Google Scholar] [CrossRef]

- Winkler, M.K.H.; Bassin, J.P.; Kleerebezem, R.; de Bruin, L.M.M.; van den Brand, T.P.H.; van Loosdrecht, M.C.M. Selective Sludge Removal in a Segregated Aerobic Granular Biomass System as a Strategy to Control PAO-GAO Competition at High Temperatures. Water Res. 2011, 45, 3291–3299. [Google Scholar] [CrossRef]

- Liu, Y.; Tay, J.H. The Essential Role of Hydrodynamic Shear Force in the Formation of Biofilm and Granular Sludge. Water Res. 2002, 36, 1653–1665. [Google Scholar] [CrossRef]

- Sarma, S.J.; Tay, J.H.; Chu, A. Finding Knowledge Gaps in Aerobic Granulation Technology. Trends Biotechnol. 2017, 35, 66–78. [Google Scholar] [CrossRef] [PubMed]

- Niermans, R.; Giesen, A.; van Loosdrecht, M.; de Buin, B. Full-scale Experiences with Aerobic Granular Biomass Technology for Treatment of Urban and Industrial Wastewater. Proc. Water Environ. Fed. 2014, 19, 2347–2357. [Google Scholar] [CrossRef]

- Li, J.; Ding, L.B.; Cai, A.; Huang, G.X.; Horn, H. Aerobic Sludge Granulation in a Full-scale Sequencing Batch Reactor. BioMed Res. Int. 2014, 2014, 268789. [Google Scholar] [CrossRef] [PubMed]

- APHA/AWWA/WEF. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2017. [Google Scholar]

- Morgan, G.; Hamza, R.A. Cultivation of Nitrifying and Nitrifying-Denitrifying Aerobic Granular Sludge for Sidestream Treatment of Anaerobically Digested Sludge Centrate. Processes 2022, 10, 1687. [Google Scholar] [CrossRef]

- Li, D.; Wang, Z.; Yang, Y.; Liu, H.; Fang, S.; Liu, S. Research Status and Development Trend of Wastewater Treatment Technology and Its Low Carbonization. Appl. Sci. 2023, 13, 1400. [Google Scholar] [CrossRef]

- Hou, Y.; Gan, C.; Chen, R.; Chen, Y.; Yuan, S.; Chen, Y. Structural Characteristics of Aerobic Granular Sludge and Factors That Influence Its Stability: A Mini Review. Water 2021, 13, 2726. [Google Scholar] [CrossRef]

- Ekholm, J.; Persson, F.; de Blois, M.; Modin, O.; Gustavsson, D.J.I.; Pronk, M.; van Loosdrecht, M.C.M.; Wilén, B.M. Microbiome structure and function in parallel full-scale aerobic granular sludge and activated sludge processes. Appl. Microbiol. Biotechnol. 2024, 108, 334. [Google Scholar] [CrossRef] [PubMed]

- Layer, M.; Villodres, M.G.; Hernandez, A.; Reynaert, E.; Morgenroth, E.; Derlon, N. Limited simultaneous nitrification-denitrification (SND) in aerobic granular sludge systems treating municipal wastewater: Mechanisms and practical implications. Water Res. X 2020, 7, 100048. [Google Scholar] [CrossRef]

- Carter, J.A. Bioaugmentation with Sidestream Granular Sludge for Nitrification in Activated Sludge. Master’s Thesis, Washington University, Washington, DC, USA, 2020. [Google Scholar]

- Yuan, X.; Gao, D. Effect of dissolved oxygen on nitrogen removal and process control in aerobic granular sludge reactor. J. Hazard. Mater. 2010, 178, 1041–1045. [Google Scholar] [CrossRef]

- Feng, Q.; Cao, J.; Chen, L.; Guo, C.; Tan, J.; Xu, H. Simultaneous nitrification and denitrification at variable C/N ratio in aerobic granular sequencing batch reactors. J. Food Agric. Environ. 2011, 9, 1135–1140. [Google Scholar]

- Figdore, B.A.; Stensel, H.D.; Winkler, M.K.H. Comparison of different aerobic granular sludge types for activated sludge nitrification bioaugmentation potential. Bioresour. Technol. 2018, 251, 189–196. [Google Scholar] [CrossRef] [PubMed]

- Figdore, B.A.; Winkler, M.K.H.; Stensel, H.D. Bioaugmentation with Nitrifying Granules in Low-SRT Flocculent Activated Sludge at Low Temperature. Water Environ. Res. 2017, 90, 343–354. [Google Scholar] [CrossRef] [PubMed]

- Harremoës, P.; Sinkjær, O. Kinetic interpretation of nitrogen removal in pilot scale experiments. Water Res. 1995, 29, 899–905. [Google Scholar] [CrossRef]

- Fan, X.; Urbain, V.; Qian, Y.; Manem, J. Nitrification and mass balance with a membrane bioreactor for municipal wastewater treatment. Water Sci. Technol. 1996, 34, 129–136. [Google Scholar]

- Grana, M.; Catenacci, A.; Ficara, E. Denitrification Capacity of Volatile Fatty Acids from Sludge Fermentation: Lab-Scale Testing and Full-Scale Assessment. Fermentation 2024, 10, 25. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Wang, R.; He, J.; Huang, Y.; Hang, Z.; Chen, X.; Li, Z. Managing stability of aerobic granules by coordinating diameter and denitrification. Sci. Total Environ. 2024, 906, 167795. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, B.; An, Q.; Zhang, P. The influence of different nitrate concentrations on aerobic sludge granulation and the role of extracellular polymeric substances. J. Environ. Manag. 2023, 348, 119226. [Google Scholar] [CrossRef]

| Parameter | Aerobic Sludge | |

|---|---|---|

| Activated/Suspended | Granulated | |

| Shape | Irregular | Regular and spherical |

| Average size | <0.2 mm | 0.2–5.0 mm |

| Sedimentation rate | Lower settling rates <10 m/h | Higher settling rates >10 m/h |

| SVI 1 | SVI5 2 > SVI30 3 | SVI5 ≈ SVI30 |

| Degree of compactness and density | Low | High |

| Layered structure or coexistence of aerobic, anoxic and anaerobic microenvironment | Minimum options for anaerobic zones | Aerobic, anaerobic and anoxic zones predominate |

| EPS 4 | Lower content of EPS | High content of EPS |

| Tolerance to toxic compounds | Lower tolerance to toxic pollutants | Higher tolerance to toxic pollutants |

| Ability to withstand impact pollution | Weak | Good |

| BOD5 (mg/L) | COD (mg/L) | SS (mg/L) | N-NH4 (mg/L) | P-PO4 (mg/L) |

|---|---|---|---|---|

| Higher load | ||||

| 760 ± 55.6 | 1 390 ± 102.2 | 880 ± 143.4 | 140 ± 18.2 | 16 ± 1.9 |

| Lower load | ||||

| 530 ± 53.4 | 1 050 ± 82.3 | 640 ± 94.1 | 95 ± 11.4 | 10 ± 1.2 |

| vN (mg/g·h) | Conditions | Reference |

|---|---|---|

| Aerobic suspended sludge | ||

| 1.5 | at 2 mg O2/L | [19] |

| 1.2–1.4 | at Xb 8.6–14.4 g/L | [20] |

| 1.506 | at 1 mg O2/L | [21] |

| 3.57 | at 4.5 mg O2/L | |

| 1.802 | at C/N = 20 | [22] |

| Aerobic granulated sludge | ||

| 31.25 | Pure nitrifying culture | [23] |

| 5.83 | Nitri. and denitri. sludge with biol. remov. of P | |

| 29.8 | Pure nitrifying culture | [24] |

| 40.36 | Pure nitrifying culture | [15] |

| 6.86 | Nitri. and denitri. sludge with biol. remov. of P | |

| 2.22 | Nitri. and denitri. sludge with biol. remov. of P | In this study |

| vD (mg/g·h) | Conditions | Reference |

|---|---|---|

| Aerobic suspended sludge | ||

| 0.80–0.90 | 7 °C | [25] |

| 0.97–2.50 | Membrane reactor | [26] |

| 1.00–2.20 | Pure volatile fatty acids | [27] |

| Aerobic granulated sludge | ||

| 0.697–0.775 | At C/N = 20–10 | [22] |

| 0.51 | Small AGS diameter < 200 µm | [28] |

| 2.24 | Medium AGS diameter 200–400 µm | |

| 5.48 | Large AGS diameter > 400 µm | |

| 2.93 | Xb 4 g/L | [29] |

| 0.93 | SBR | In this study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hutňan, M.; Jankovičová, B.; Jajcaiová, L.; Sammarah, M.; Kratochvíl, K.; Šoltýsová, N. Reconstruction of the Municipal Wastewater-Treatment Plant According to the Principles of Aerobic Granular Sludge Cultivation. Processes 2024, 12, 1782. https://doi.org/10.3390/pr12091782

Hutňan M, Jankovičová B, Jajcaiová L, Sammarah M, Kratochvíl K, Šoltýsová N. Reconstruction of the Municipal Wastewater-Treatment Plant According to the Principles of Aerobic Granular Sludge Cultivation. Processes. 2024; 12(9):1782. https://doi.org/10.3390/pr12091782

Chicago/Turabian StyleHutňan, Miroslav, Barbora Jankovičová, Lenka Jajcaiová, Mikhael Sammarah, Karol Kratochvíl, and Nikola Šoltýsová. 2024. "Reconstruction of the Municipal Wastewater-Treatment Plant According to the Principles of Aerobic Granular Sludge Cultivation" Processes 12, no. 9: 1782. https://doi.org/10.3390/pr12091782