Mimicking Marine Conditions to Improve Prodigiosin Yields in Bioreactor

Abstract

1. Introduction

2. Materials and Methods

2.1. Bacterial Strain

2.2. Cell Growth

2.3. Effect of Inoculum Concentration

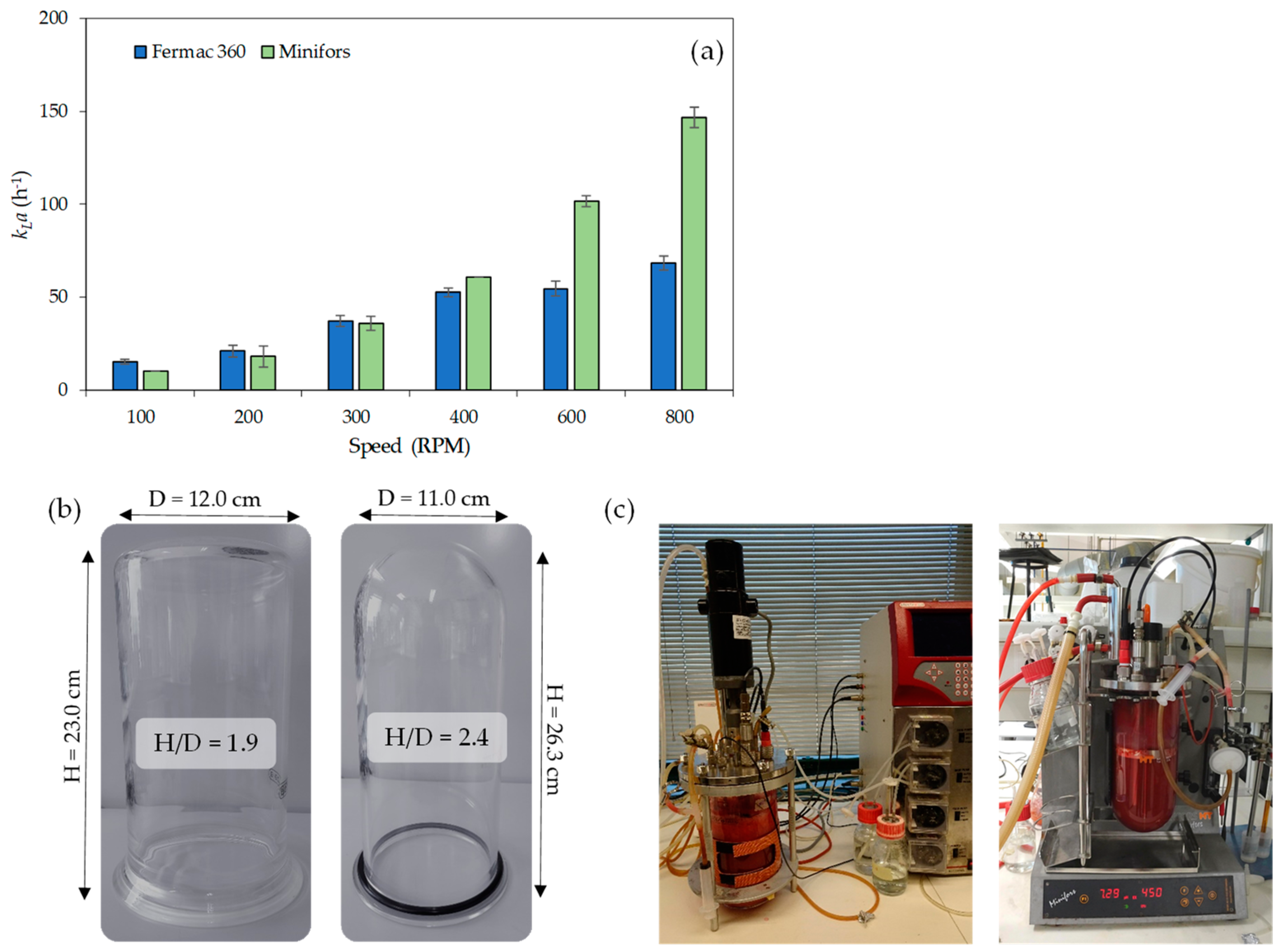

2.4. Bioreactors

2.4.1. kLa Determination

2.4.2. Bacterial Culture

- S1—Phase with low oxygen followed by an aerated phase applied in the bioreactor

- S2—Phase with low oxygen concentration between two aerated phases in the bioreactor

- S3—Aerobic conditions in the bioreactor and addition of fresh medium

- S4—Phase with low oxygen concentration between two aerobic phases in the inoculum

- S5—Low oxygen concentration in the inoculum, aerobic conditions in the bioreactor

- S6—In-series bioreactors

2.5. Analytical Methods

2.5.1. Off-Line Quantification of Biomass (X) and Prodigiosin (P)

2.5.2. Lipid Analysis

2.5.3. At-Line Monitoring of Cell Viability and Product Production

2.6. Statistics

3. Results and Discussion

3.1. Assessing the Best Initial Inoculum Concentration

3.2. Fermentation Conditions

3.2.1. Effect of Stirring Speed

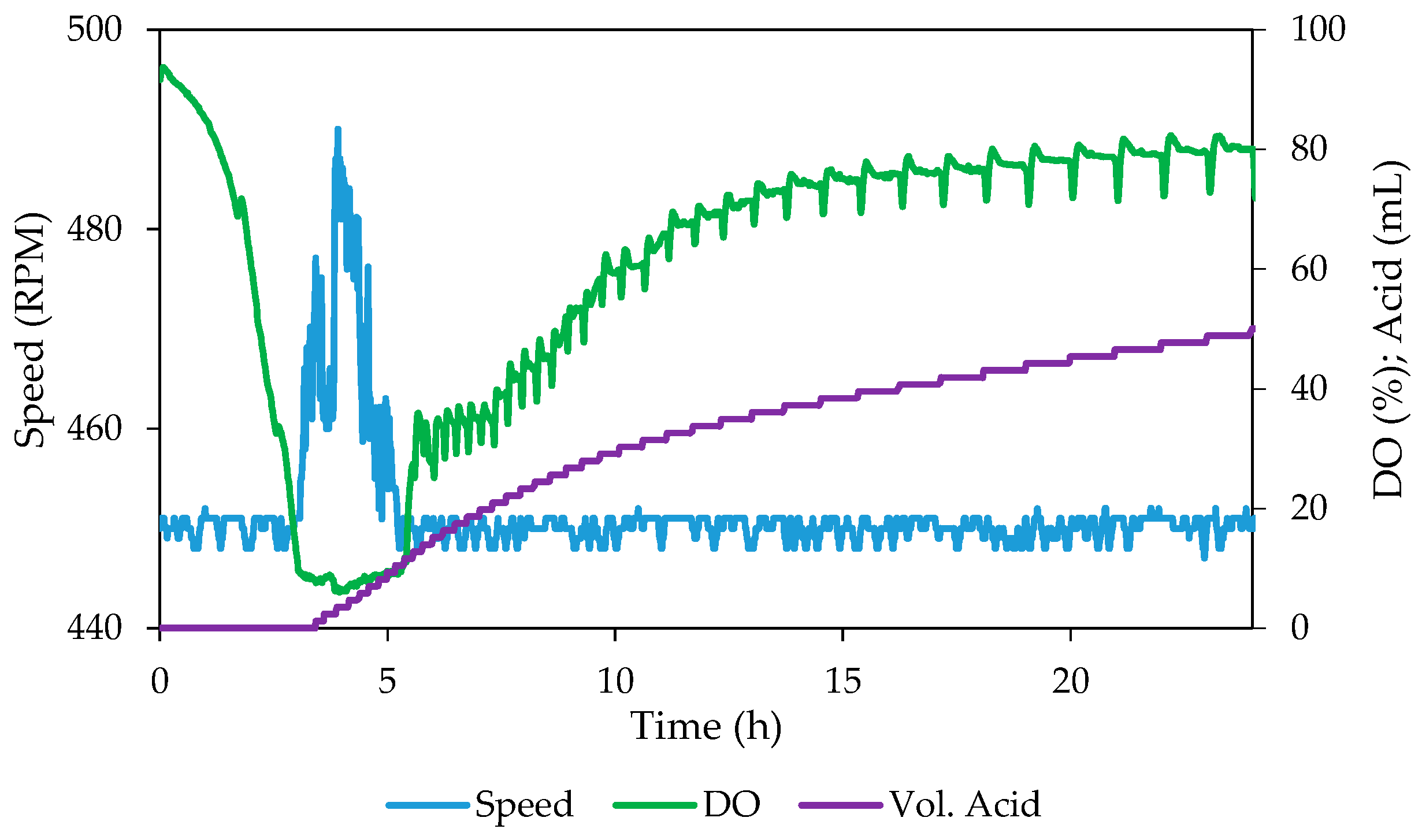

3.2.2. Applying Cascade Control to Maintain Oxygen Concentration

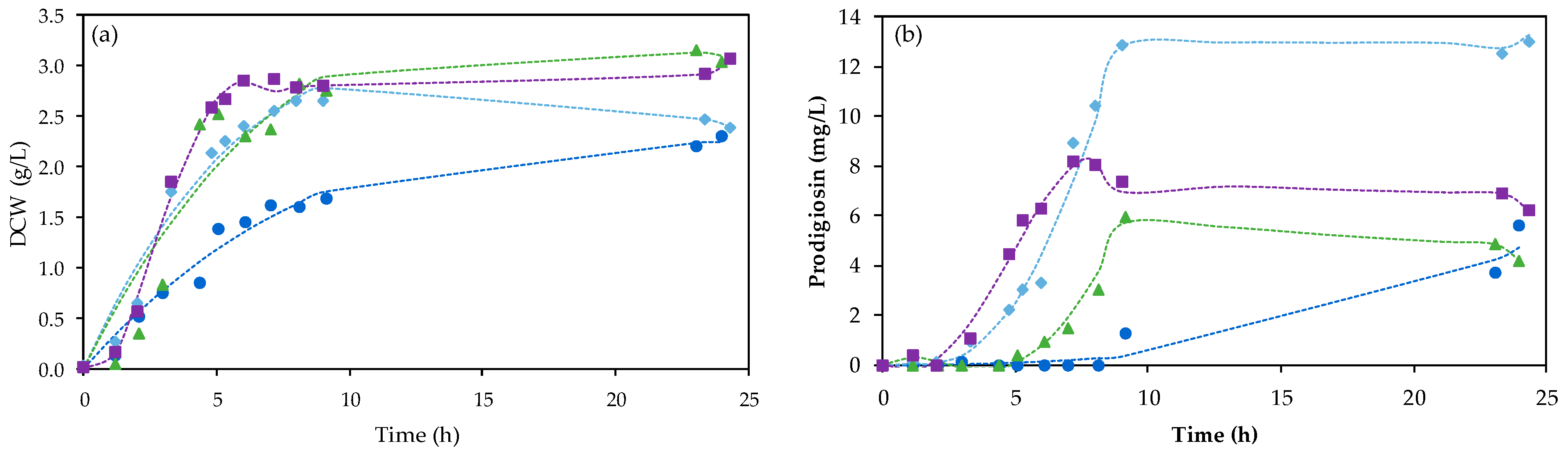

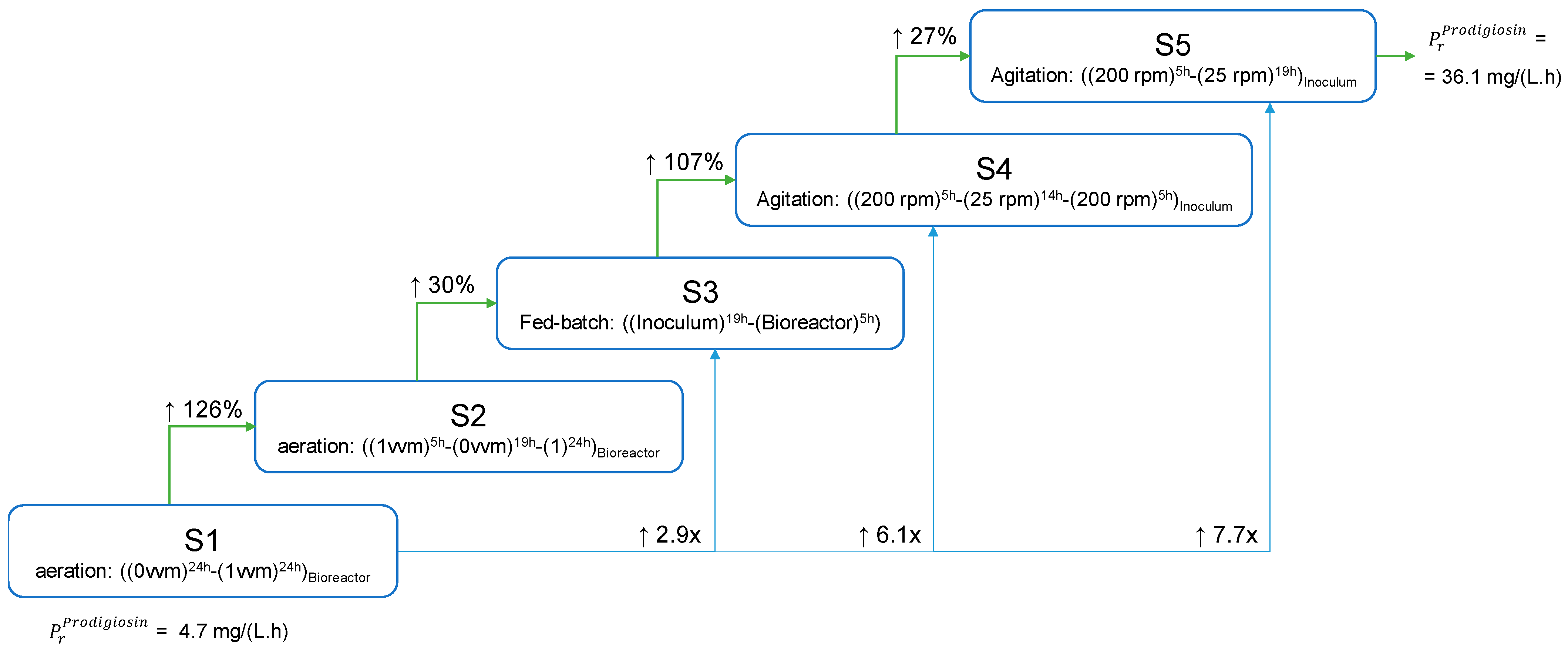

3.3. Fermentation Strategies to Mimick Sampling Site Conditions

3.4. Assessing the Best Fermentation Conditions

3.5. In-Series Strategy to Enhance Prodigiosin Production (S6)

3.6. kLa Maintenance Conditions from BI to BE

3.7. At-Line Analytical Techniques to Assess the Biological Condition of Cells and Prodigiosin Presence

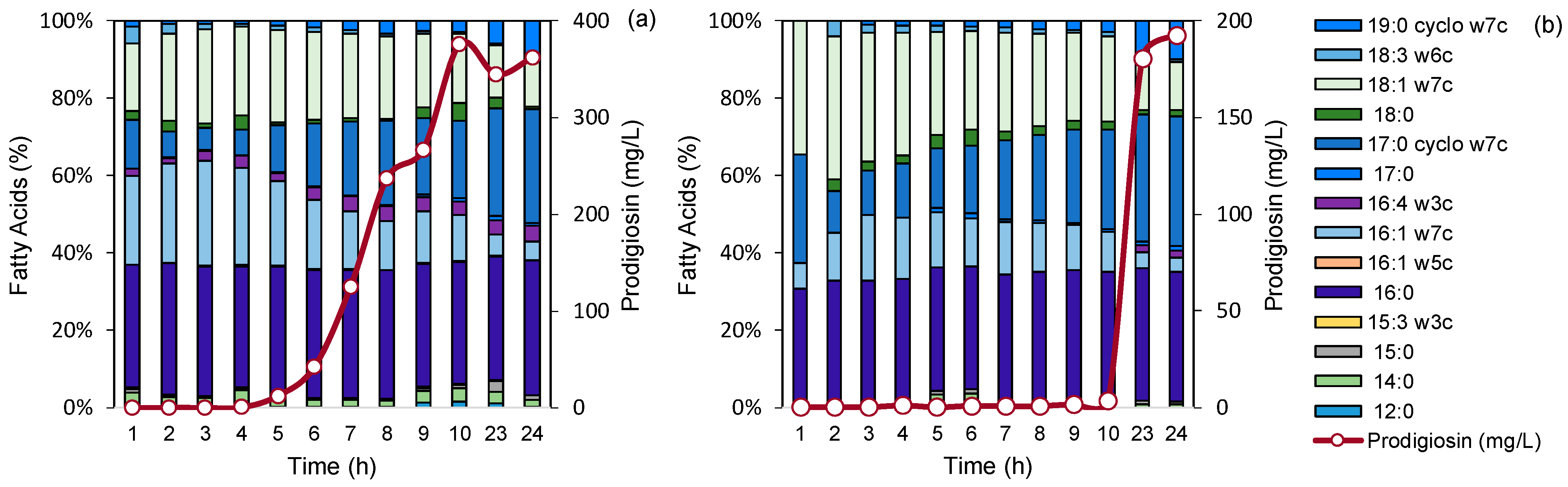

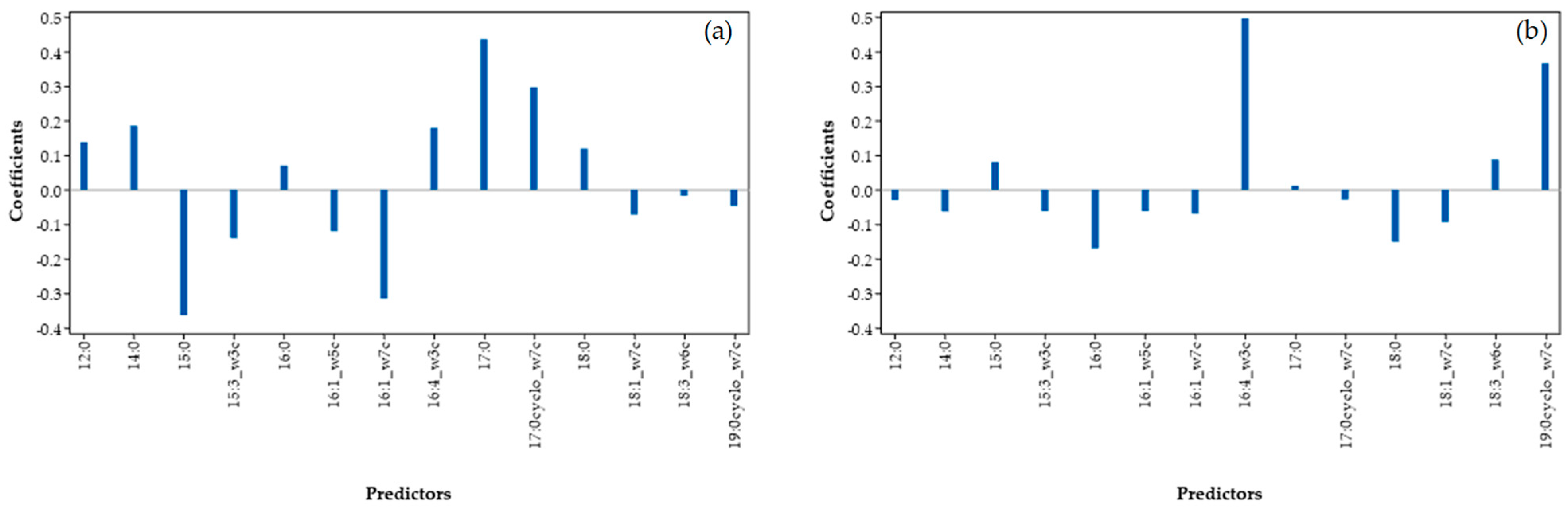

3.7.1. Analysis of Cell Lipids

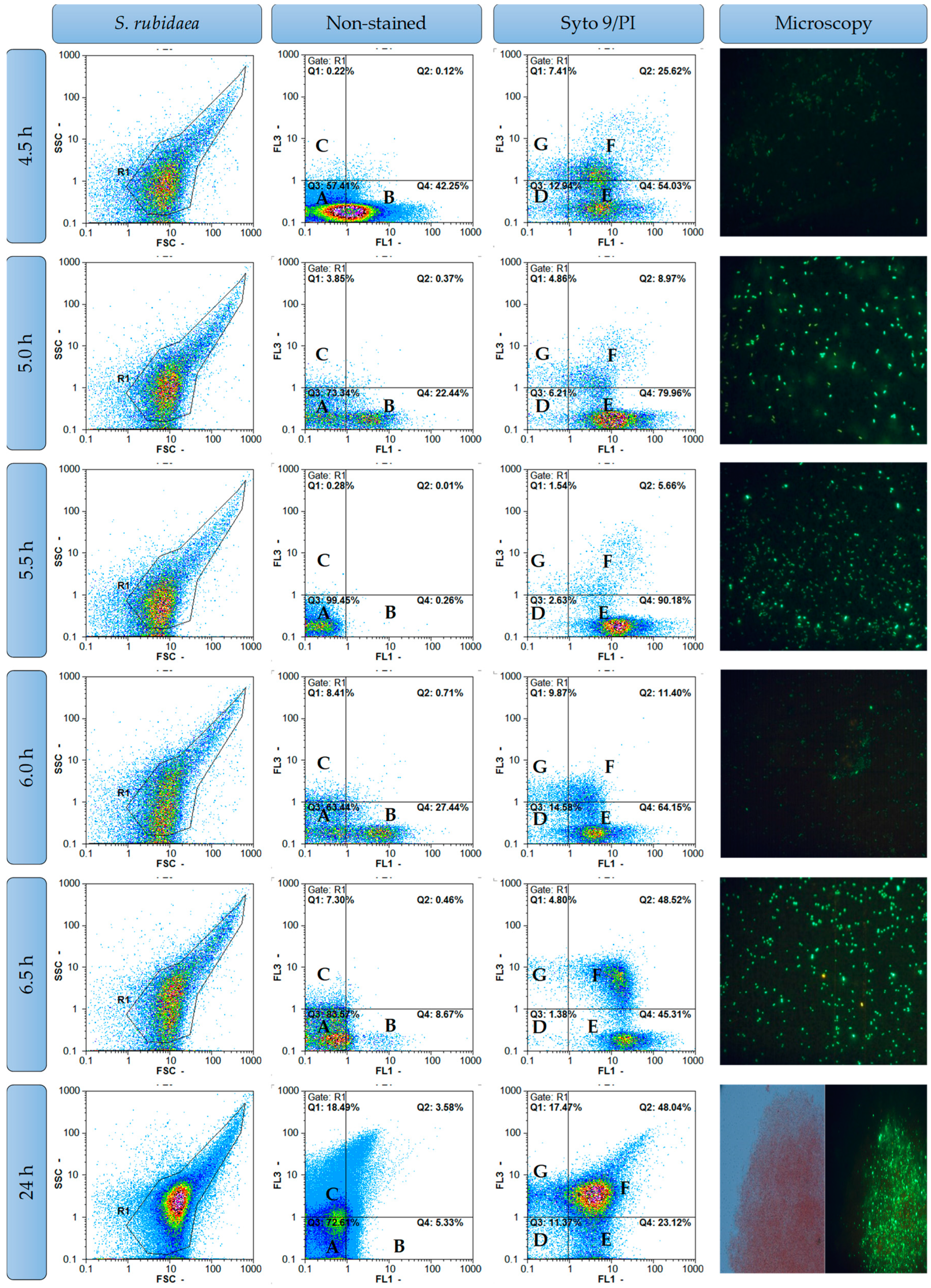

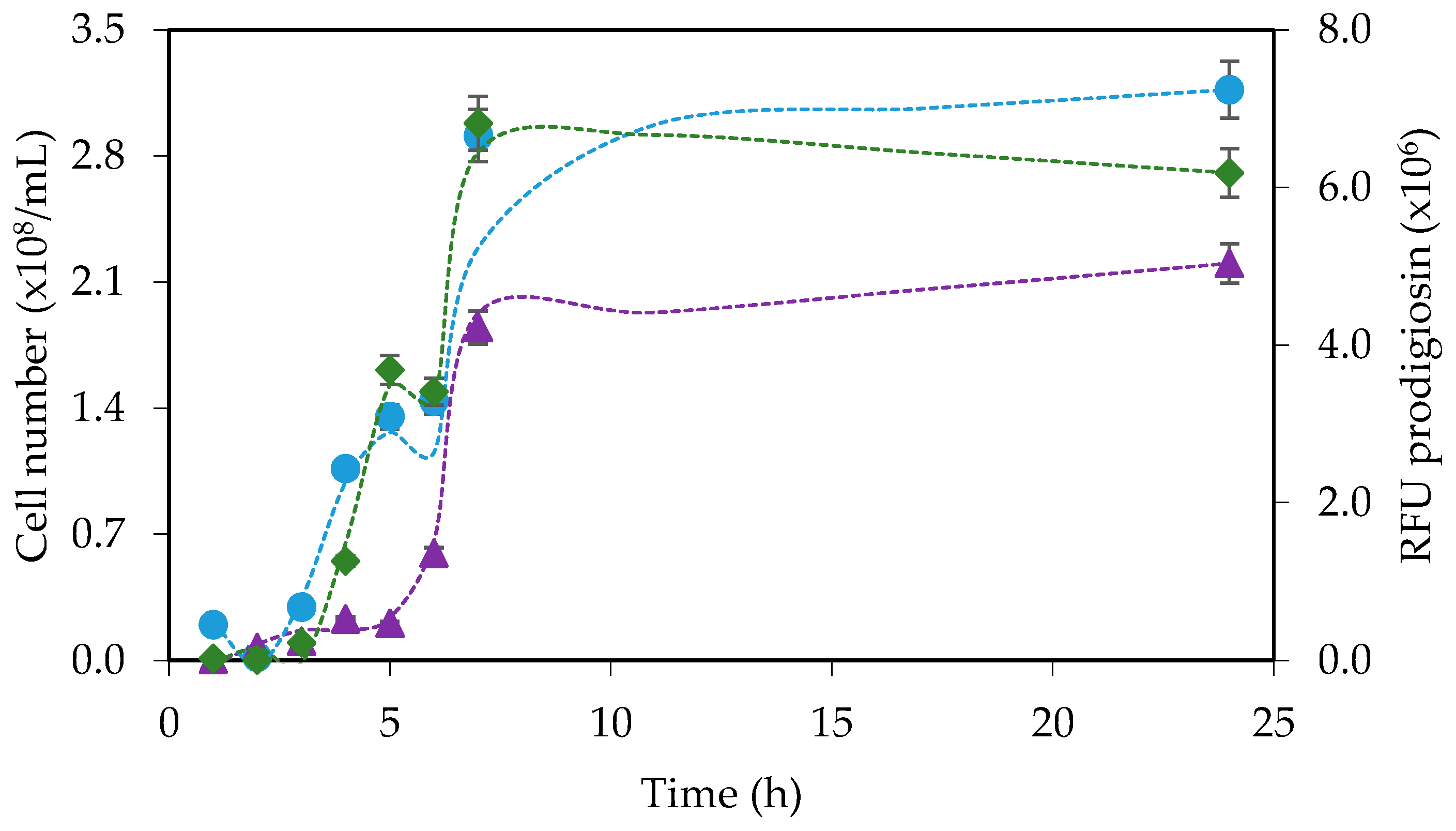

3.7.2. Flow Cytometry

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Islan, G.A.; Rodenak-Kladniew, B.; Noacco, N.; Duran, N.; Castro, G.R. Prodigiosin: A promising biomolecule with many potential biomedical applications. Bioengineered 2022, 13, 14227–14258. [Google Scholar] [CrossRef] [PubMed]

- Srilekha, V.; Krishna, G.; Sreelatha, B.; Jagadeesh Kumar, E.; Rajeshwari, K.V.N. Prodigiosin: A fascinating and the most versatile bioactive pigment with diverse applications. Syst. Microbiol. Biomanuf. 2023, 4, 66–76. [Google Scholar] [CrossRef]

- Anwar, M.M.; Albanese, C.; Hamdy, N.M.; Sultan, A.S. Rise of the natural red pigment ‘prodigiosin’ as an immunomodulator in cancer. Cancer Cell Int. 2022, 22, 419. [Google Scholar] [CrossRef]

- Luna, G.M. Biotechnological potential of marine microbes. In Springer Handbook of Marine Biotechnology; Kim, S.K., Ed.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 651–661. [Google Scholar]

- Debashish, G.; Malay, S.; Barindra, S.; Joydeep, M. Marine enzymes. In Marine Biotechnology I. Advances in Biochemical Engineering/Biotechnology; Ulber, R., Le Gal, Y., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; Volume 96, pp. 189–218. ISBN 3540256598. [Google Scholar]

- Ferrer, M.; Méndez-García, C.; Bargiela, R.; Chow, J.; Alonso, S.; García-Moyano, A.; Bjerga, G.E.K.; Steen, I.H.; Schwabe, T.; Blom, C.; et al. Decoding the ocean’s microbiological secrets for marine enzyme biodiscovery. FEMS Microbiol. Lett. 2019, 366, 1–7. [Google Scholar] [CrossRef] [PubMed]

- de Carvalho, C.C.C.R.; Fernandes, P. Production of metabolites as bacterial responses to the marine environment. Mar. Drugs 2010, 8, 705–727. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Arends, J.B.A.; Van de Wiele, T.; Boon, N. Bioreactor technology in marine microbiology: From design to future application. Biotechnol. Adv. 2011, 29, 312–321. [Google Scholar] [CrossRef] [PubMed]

- Lang, S.; Hüners, M.; Lurtz, V. Bioprocess engineering data on the cultivation of marine prokaryotes and fungi. Adv. Biochem. Eng. Biotechnol. 2005, 97, 29–62. [Google Scholar] [CrossRef]

- Pereira, R.F.S.; Ferreira, M.J.; Oliveira, M.C.; Serra, M.C.; de Carvalho, C.C.C.R. Isolation and characterization of a Serratia rubidaea from a shallow water hydrothermal vent. Mar. Drugs 2023, 21, 599. [Google Scholar] [CrossRef]

- Pereira, R.F.S.; de Carvalho, C.C.C.R. Improving bioprocess conditions for the production of prodigiosin using a marine Serratia rubidaea strain. Mar. Drugs 2024, 22, 142. [Google Scholar] [CrossRef]

- Nikita, S.; Mishra, S.; Gupta, K.; Runkana, V.; Gomes, J.; Rathore, A.S. Advances in bioreactor control for production of biotherapeutic products. Biotechnol. Bioeng. 2023, 120, 1189–1214. [Google Scholar] [CrossRef]

- de Mello, A.F.M.; de Souza Vandenberghe, L.P.; Herrmann, L.W.; Letti, L.A.J.; Burgos, W.J.M.; Scapini, T.; Manzoki, M.C.; de Oliveira, P.Z.; Soccol, C.R. Strategies and engineering aspects on the scale-up of bioreactors for different bioprocesses. Syst. Microbiol. Biomanuf. 2024, 4, 365–385. [Google Scholar] [CrossRef]

- Wehrs, M.; Tanjore, D.; Eng, T.; Lievense, J.; Pray, T.R.; Mukhopadhyay, A. Engineering robust production microbes for large-scale cultivation. Trends Microbiol. 2019, 27, 524–537. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, C.J.C.; de Carvalho, C.C.C.R. Rhodococcus erythropolis cells adapt their fatty acid composition during biofilm formation on metallic and non-metallic surfaces. FEMS Microbiol. Ecol. 2015, 91, fiv135. [Google Scholar] [CrossRef]

- Kunitsky, C.; Osterhout, G.; Sasser, M. Identification of microorganisms using fatty acid methyl ester (FAME) analysis and the MIDI Sherlock Microbial Identification System. Encycl. Rapid Microbiol. Methods 2006, 3, 1–17. [Google Scholar]

- Robertson, J.; McGoverin, C.; Vanholsbeeck, F.; Swift, S. Optimisation of the protocol for the LIVE/DEAD®BacLightTM bacterial viability kit for rapid determination of bacterial load. Front. Microbiol. 2019, 10, 801. [Google Scholar] [CrossRef]

- Marques, M.P.C.; Walshe, K.; Doyle, S.; Fernandes, P.; de Carvalho, C.C.C.R. Anchoring high-throughput screening methods to scale-up bioproduction of siderophores. Process Biochem. 2012, 47, 416–421. [Google Scholar] [CrossRef][Green Version]

- Pereira, R.F.S.; de Carvalho, C.C.C.R. Optimization of multiparameters for increased yields of cytochrome B5 in bioreactors. Molecules 2021, 26, 4148. [Google Scholar] [CrossRef] [PubMed]

- Heinemann, B.; Howard, A.J.; Palocz, H.J. Influence of dissolved oxygen levels on production of l-asparaginase and prodigiosin by Serratia marcescens. Appl. Microbiol. 1970, 19, 800–804. [Google Scholar] [CrossRef]

- Kobayashi, N.; Ichikawa, Y. Decrease in respiration activity related to prodigiosin synthesis in Serratia marcescens. Microbology Immunol. 1985, 29, 301–308. [Google Scholar] [CrossRef]

- Han, R.; Xiang, R.; Li, J.; Wang, F.; Wang, C. High-level production of microbial prodigiosin: A review. J. Basic Microbiol. 2021, 61, 506–523. [Google Scholar] [CrossRef]

- Seborg, D.E.; Edgar, T.F.; Mellichamp, D.A.; Francis, J.D., III. Process Dynamics and Control, 4th ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2016; ISBN 978-1-119-28591-5. [Google Scholar]

- Buckland, B.C. The translation of scale in fermentation processes: The impact of computer process control. Nat. Biotechnol. 1984, 2, 875–883. [Google Scholar] [CrossRef]

- Molland, A.F. Marine engines and auxiliary machinery. In The Maritime Engineering Reference Book, A Guide to Ship Design, Construction and Operation; Butterworth-Heinemann—Elsevier: Oxford, UK, 2008; pp. 344–482. ISBN 978-0-7506-8987-8. [Google Scholar]

- Junker, B.H. Scale-up methodologies for Escherichia coli and yeast fermentation processes. J. Biosci. Bioeng. 2004, 97, 347–364. [Google Scholar] [CrossRef]

- Baquero, F.; Coque, T.M.; Galán, J.C.; Martinez, J.L. The origin of niches and species in the bacterial world. Front. Microbiol. 2021, 12, 657986. [Google Scholar] [CrossRef]

- Carvalho, M.d.R.; Mateus, A.; Nunes, J.C.; Carvalho, J.M. Chemistry of the Ferraria thermal water, S. Miguel Island, Azores: Mixing and precipitation processes. Environ. Earth Sci. 2011, 64, 539–547. [Google Scholar] [CrossRef]

- Wallenstein, F.M.; Couto, R.P.; Torrão, D.F.; Neto, A.I.; Rodrigues, A.S.; Wilkinson, M. Intertidal rocky shore seaweed communities subject to the influence of shallow water hydrothermal activity in São Miguel (Azores, Portugal). Helgol. Mar. Res. 2013, 67, 535–543. [Google Scholar] [CrossRef]

- Macedo, F.L.W.F.M. Rocky Shore Macroalgae Communities of the Azores (Portugal) and the British Isles: A Comparison for the Development of Ecological Quality Assessment Tools. Ph.D. Thesis, Heriot-Watt University, Edinburgh, Scotland, 2011. [Google Scholar]

- Caldeira, R.M.A.; Reis, J.C. The Azores confluence zone. Front. Mar. Sci. 2017, 4, 37. [Google Scholar] [CrossRef]

- Instituto Hidrográfico da Marinha Portuguesa. Available online: https://www.hidrografico.pt/ (accessed on 24 May 2024).

- Converti, A.; Sommariva, C.; Borghi, M.; Ferraiolo, G. The effects of mixing on bioprocesses. Concentration distributions and mechanical shear stress. Bioprocess Eng. 1993, 9, 183–189. [Google Scholar] [CrossRef]

- Nienow, A.W. Hydrodynamics of stirred bioreactors. Appl. Mech. Rev. 1998, 51, 3–32. [Google Scholar] [CrossRef]

- Sánchez Pérez, J.A.; Rodríguez Porcel, E.M.; Casas López, J.L.; Fernández Sevilla, J.M.; Chisti, Y. Shear rate in stirred tank and bubble column bioreactors. Chem. Eng. J. 2006, 124, 1–5. [Google Scholar] [CrossRef]

- Nadal-Rey, G.; McClure, D.D.; Kavanagh, J.M.; Cornelissen, S.; Fletcher, D.F.; Gernaey, K.V. Understanding gradients in industrial bioreactors. Biotechnol. Adv. 2021, 46, 107660. [Google Scholar] [CrossRef] [PubMed]

- Robertson, B.R.; Button, D.K.; Koch, A.L. Determination of the biomasses of small bacteria at low concentrations in a mixture of species with forward light scatter measurements by flow cytometry. Appl. Environ. Microbiol. 1998, 64, 3900–3909. [Google Scholar] [CrossRef]

- Wållberg, F.; Sundström, H.; Ledung, E.; Hewitt, C.J.; Enfors, S.O. Monitoring and quantification of inclusion body formation in Escherichia coli by multi-parameter flow cytometry. Biotechnol. Lett. 2005, 27, 919–926. [Google Scholar] [CrossRef] [PubMed]

- de Carvalho, C.C.C.R.; Caramujo, M.J. The various roles of fatty acids. Molecules 2018, 23, 36. [Google Scholar] [CrossRef] [PubMed]

- Sikkema, J.; De Bont, J.A.M.; Poolman, B. Mechanisms of membrane toxicity of hydrocarbons. Microbiol. Rev. 1995, 59, 201–222. [Google Scholar] [CrossRef] [PubMed]

- de Carvalho, C.C.C.R. Adaptation of Rhodococcus erythropolis cells for growth and bioremediation under extreme conditions. Res. Microbiol. 2012, 163, 125–136. [Google Scholar] [CrossRef]

- McGoverin, C.; Robertson, J.; Jonmohamadi, Y.; Swift, S.; Vanholsbeeck, F. Species dependence of SYTO 9 staining of bacteria. Front. Microbiol. 2020, 11, 545419. [Google Scholar] [CrossRef]

- Stiefel, P.; Schmidt-Emrich, S.; Maniura-Weber, K.; Ren, Q. Critical aspects of using bacterial cell viability assays with the fluorophores SYTO9 and propidium iodide. BMC Microbiol. 2015, 15, 36. [Google Scholar] [CrossRef]

- Shi, L.; Günther, S.; Hübschmann, T.; Wick, L.Y.; Harms, H.; Müller, S. Limits of propidium iodide as a cell viability indicator for environmental bacteria. Cytom. Part A 2007, 71, 592–598. [Google Scholar] [CrossRef]

| Stirring Speed (rpm) | Measured DO (%) | µmax (h−1) | td (h) | PrDCW (mg/(L.h)) | PrProduct (mg/(L.h)) |

|---|---|---|---|---|---|

| 100 | 0–80 | 1.26 ± 0.22 | 0.55 ± 0.03 | 95.3 | 0.23 |

| 200 | 0–90 | 1.16 ± 0.21 | 0.60 ± 0.03 | 104.4 | 0.54 |

| 300 | 11–96 | 1.23 ± 0.22 | 0.56 ± 0.03 | 136.2 | 0.21 |

| 400 | 47–97 | 1.31 ± 0.24 | 0.53 ± 0.03 | 123.9 | 0.30 |

| Bioreactor | µmax (h−1) | td (h) | PrDCW (mg/(L.h)) | PrProduct (mg/(L.h)) | [X] (g) | [P] (mg) | Ypx (mg/g) |

|---|---|---|---|---|---|---|---|

| BE | 0.63 ± 0.04 | 1.1 ± 0.06 | 117.8 | 15.03 | 4.02 | 541.3 | 134.5 |

| BE * | 0.29 ± 0.04 | 2.43 | 73.2 | 1.64 | 2.63 | 59.0 | 22.4 |

| BI | 0.28 ± 0.04 | 2.5 ± 0.35 | 50.9 | 8.02 | 1.83 | 288.6 | 157.6 |

| BI * | 0.24 ± 0.04 | 2.88 | 69.1 | 0.22 | 1.99 | 6.30 | 3.2 |

| Strategy | Inoculum (medium = 0.12 L, except *) | Reactor (medium = 1.32 L) | ||||

|---|---|---|---|---|---|---|

| S1 | 20 h, 200 rpm | 24 h, 100 rpm, 0 vvm | 24 h, 450–600 rpm, 1 vvm | |||

| S2 | 20 h, 200 rpm | 5 h, 450–600 rpm, 1 vvm | 19 h, 100 rpm, 0 vvm | 24 h, 450–600 rpm, 1 vvm | ||

| S3 | 19 h, 200 rpm, 0.12 L | 5 h, 200 rpm, 0.12 L + 0.6 L MB + S* | 24 h, 450–600 rpm, 1 vvm | |||

| S4 | 5 h, 200 rpm | 14 h, 25 rpm | 5 h, 200 rpm | 24 h, 450–600 rpm, 1 vvm | ||

| S5 | 5 h, 200 rpm | 19 h, 25 rpm | 24 h, 450–600 rpm, 1 vvm | |||

| Strategy | µmax (h−1) | td (h) | PrDCW (mg/L.h) | PrProduct (mg/L.h) | [X] (g) | [P] (mg) | Ypx (mg/g) |

|---|---|---|---|---|---|---|---|

| S1 | 0.45 ± 0.02 | 1.6 ± 0.08 | 114.4 | 4.7 | 11.0 | 448.2 | 40.7 |

| S2 | 0.36 ± 0.16 | 2.2 ± 0.83 | 43.7 | 10.6 | 2.4 | 583.7 | 242.1 |

| S3 | 0.27 ± 0.04 | 2.6 ± 0.34 | 51.5 | 13.8 | 1.5 | 398.5 | 267.4 |

| S4 | 0.40 ± 0.11 | 1.8 ± 0.53 | 73.6 | 28.5 | 2.3 | 802.0 | 350.5 |

| S5 | 1.39 ± 0.03 | 0.5 ± 0.01 | 62.7 | 36.1 | 1.8 | 1066.2 | 588.2 |

| Conditions | µmax (h−1) | td (h) | PrDCW (mg/L.h) | PrProduct (mg/L.h) | [X] (g) | [P] (mg) | Ypx (mg/g) |

|---|---|---|---|---|---|---|---|

| DO 30% 450–600 rpm | 0.34 ± 0.13 | 2.2 ± 0.87 | 144.3 | 11.2 | 4.2 | 323.8 | 77.8 |

| DO 50% 450–600 rpm | 0.64 ± 0.05 | 1.1 ± 0.09 | 186.4 | 19.9 | 5.4 | 577.9 | 107.2 |

| DO 40% 450–600 rpm pH 5.0–8.0 | 0.56 ± 0.23 | 1.3 ± 0.55 | 139.0 | 9.5 | 4.00 | 273.7 | 68.3 |

| DO 40% 200–600 rpm Aerated inoculum | 0.55 ± 0.04 | 1.2 ± 0.08 | 135.0 | 20.3 | 3.91 | 595.3 | 150.3 |

| DO 40% 200–600 rpm Inoculum as S5 | 0.32 ± 0.06 | 2.2 ± 0.46 | 166.0 | 16.2 | 4.79 | 468.1 | 97.7 |

| Inoculum Bioreactor | Production Bioreactor | System (Both Bioreactors) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Strategy | µmax (h−1) | td (h) | µmax (h−1) | td (h) | PrDCW (mg/L.h) | PrProduct (mg/L.h) | [X] (g) | [P] (mg) | Ypx (mg/g) |

| S6a | 0.46 ± 0.05 | 1.5 ± 0.06 | 0.36 ± 0.02 | 1.9 ± 0.23 | 104.8 | 32.0 | 3.76 | 802.4 | 305.1 |

| S6b | 0.57 ± 0.17 | 1.2 ± 0.56 | 0.20 ± 0.09 | 3.4 ± 1.01 | 215.8 | 22.6 | 5.02 | 630.5 | 104.9 |

| S6c | 0.57 ± 0.17 | 1.2 ± 0.56 | 0.02 ± 0.001 | 30.3 ± 1.51 | 204.6 | 30.5 | 5.92 | 879.5 | 149.2 |

| Conditions | µmax (h−1) | td (h) | PrDCW (mg/L.h) | PrProduct (mg/L.h) | [X] (g) | [P] (mg) | Ypx (mg/g) |

|---|---|---|---|---|---|---|---|

| cascade mode off | 0.48 ± 0.02 | 1.4 ± 0.07 | 77.9 | 7.08 | 2.24 | 203.9 | 91.0 |

| 2 control loops in cascade mode | 0.87 ± 0.04 | 0.8 ± 0.04 | 107.3 | 5.61 | 3.10 | 161.7 | 52.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira, R.F.S.; de Carvalho, C.C.C.R. Mimicking Marine Conditions to Improve Prodigiosin Yields in Bioreactor. Processes 2024, 12, 1794. https://doi.org/10.3390/pr12091794

Pereira RFS, de Carvalho CCCR. Mimicking Marine Conditions to Improve Prodigiosin Yields in Bioreactor. Processes. 2024; 12(9):1794. https://doi.org/10.3390/pr12091794

Chicago/Turabian StylePereira, Ricardo F. S., and Carla C. C. R. de Carvalho. 2024. "Mimicking Marine Conditions to Improve Prodigiosin Yields in Bioreactor" Processes 12, no. 9: 1794. https://doi.org/10.3390/pr12091794

APA StylePereira, R. F. S., & de Carvalho, C. C. C. R. (2024). Mimicking Marine Conditions to Improve Prodigiosin Yields in Bioreactor. Processes, 12(9), 1794. https://doi.org/10.3390/pr12091794