A Full-Stage Productivity Equation for Constant-Volume Gas Reservoirs and Its Application

Abstract

1. Introduction

2. Mathematical Model

2.1. Darcy Equation

2.2. Material Balance Equation

2.3. Full-Stage Productivity Equation

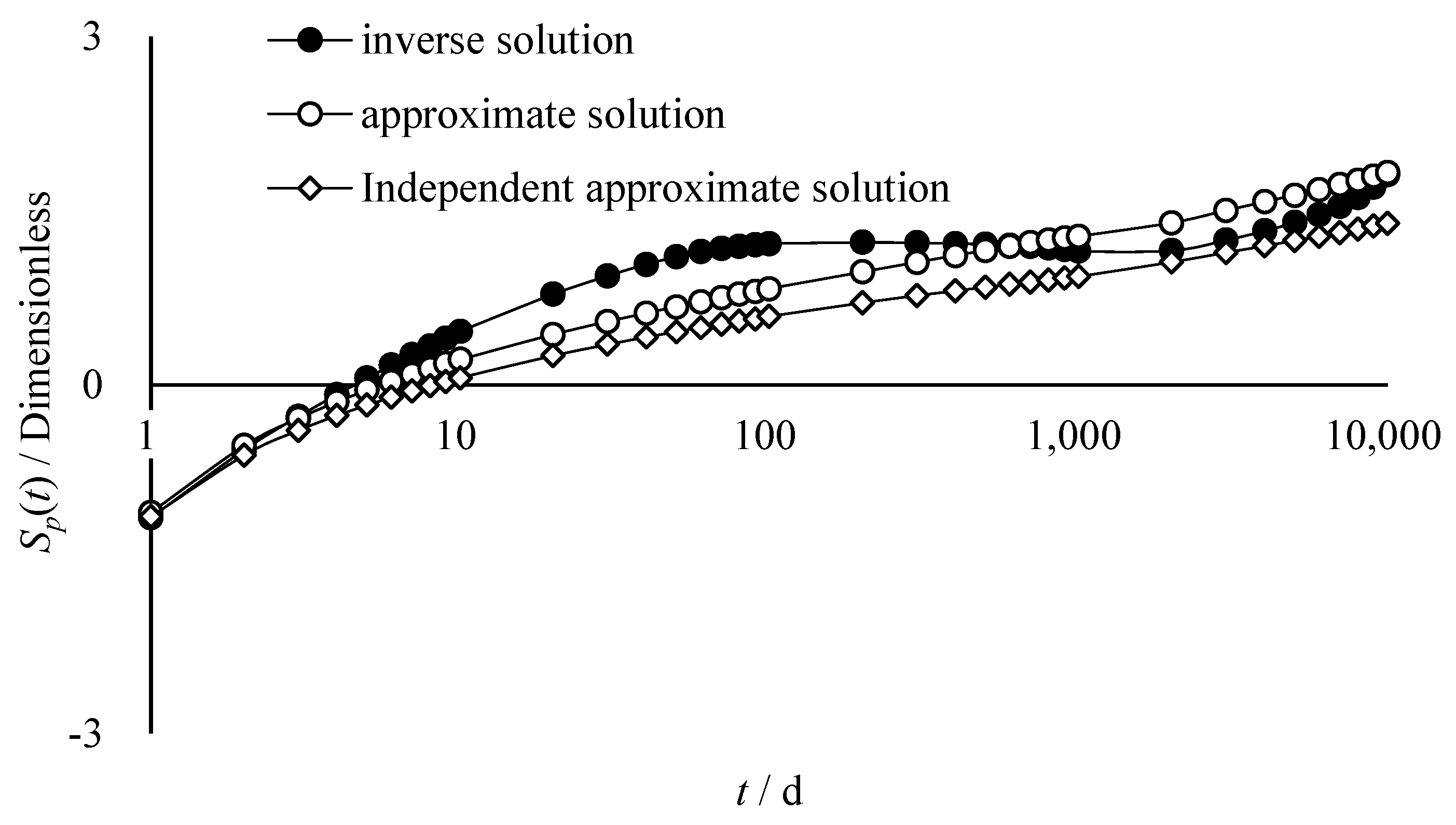

2.4. Pressure-Conversion Skin Factor

2.5. Open-Flow Capacity

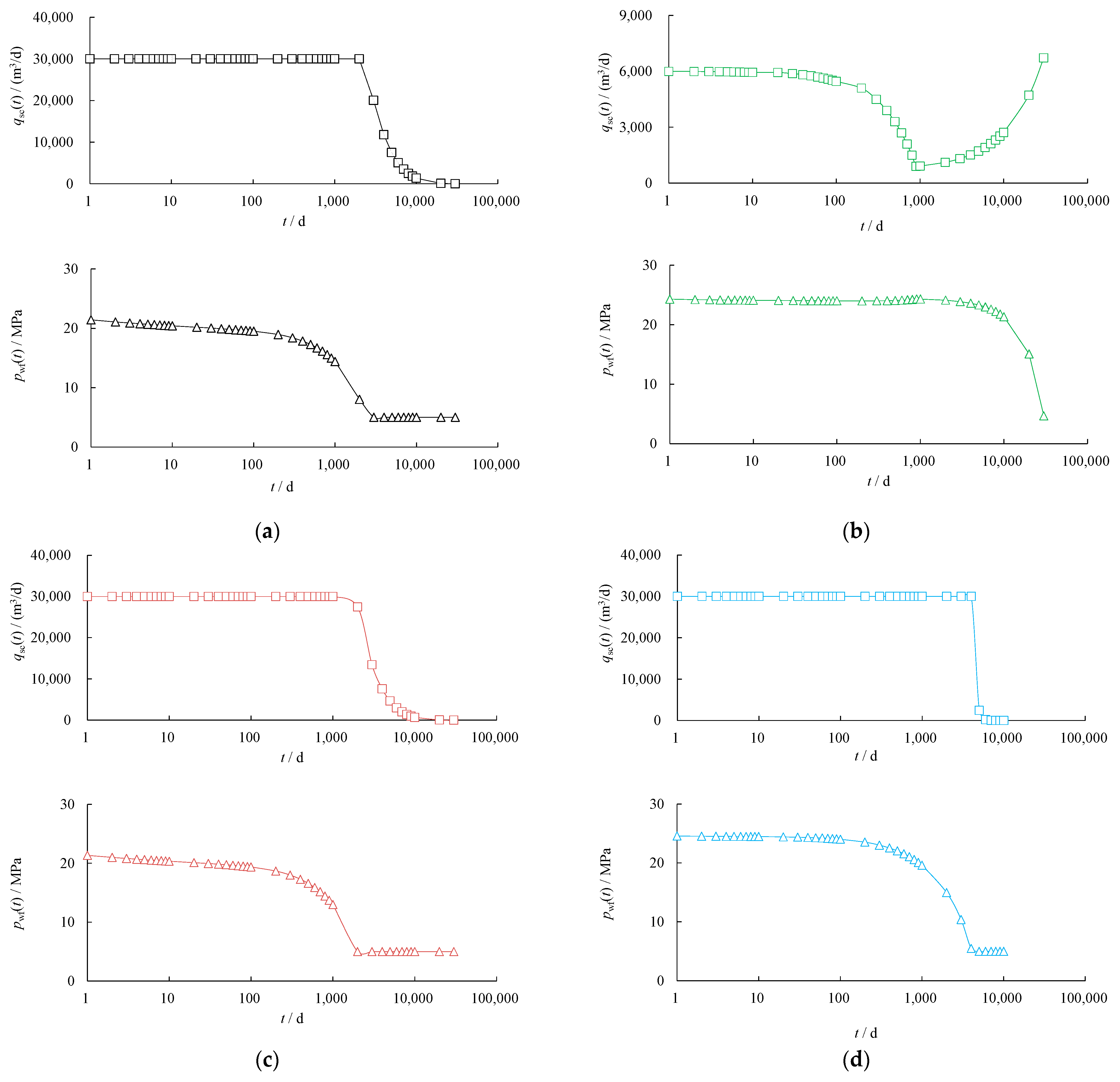

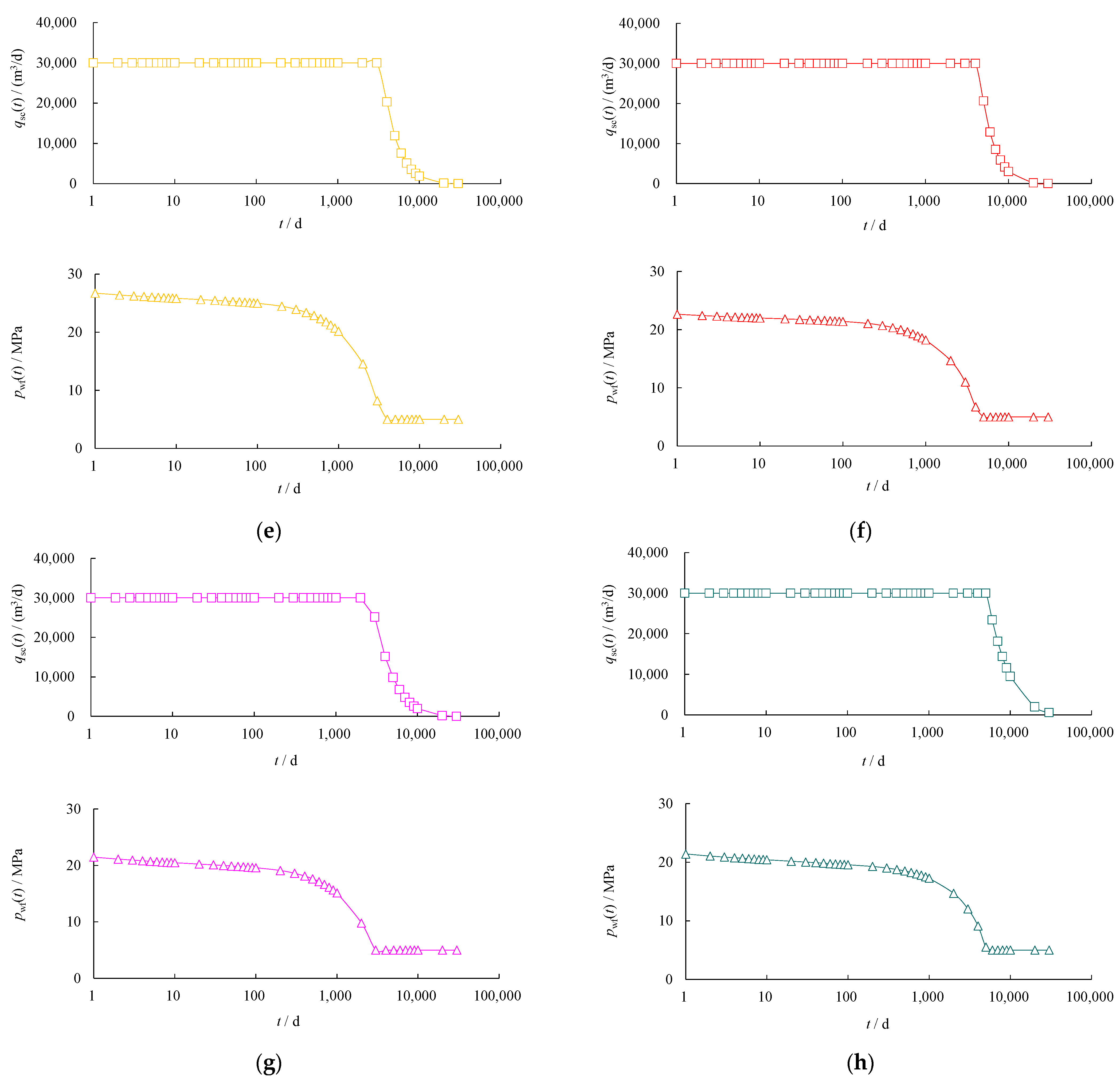

3. Model Validation

4. Application

5. Conclusions

- (1)

- For a fixed-volume gas reservoir, a full-stage productivity equation has been created; continuous production and pressure are not required during the derivation process. Except for adding the pressure-conversion skin, the relevant stage was expanded from the stable production stage to the full gas reservoir development stage, compared to the quasi-steady-state production equation. The full-stage production-capacity equation was solved by building approximative and independent solutions for the pressure-conversion skin without influencing the addition of non-Darcy terms and the wellbore pressure drop skin.

- (2)

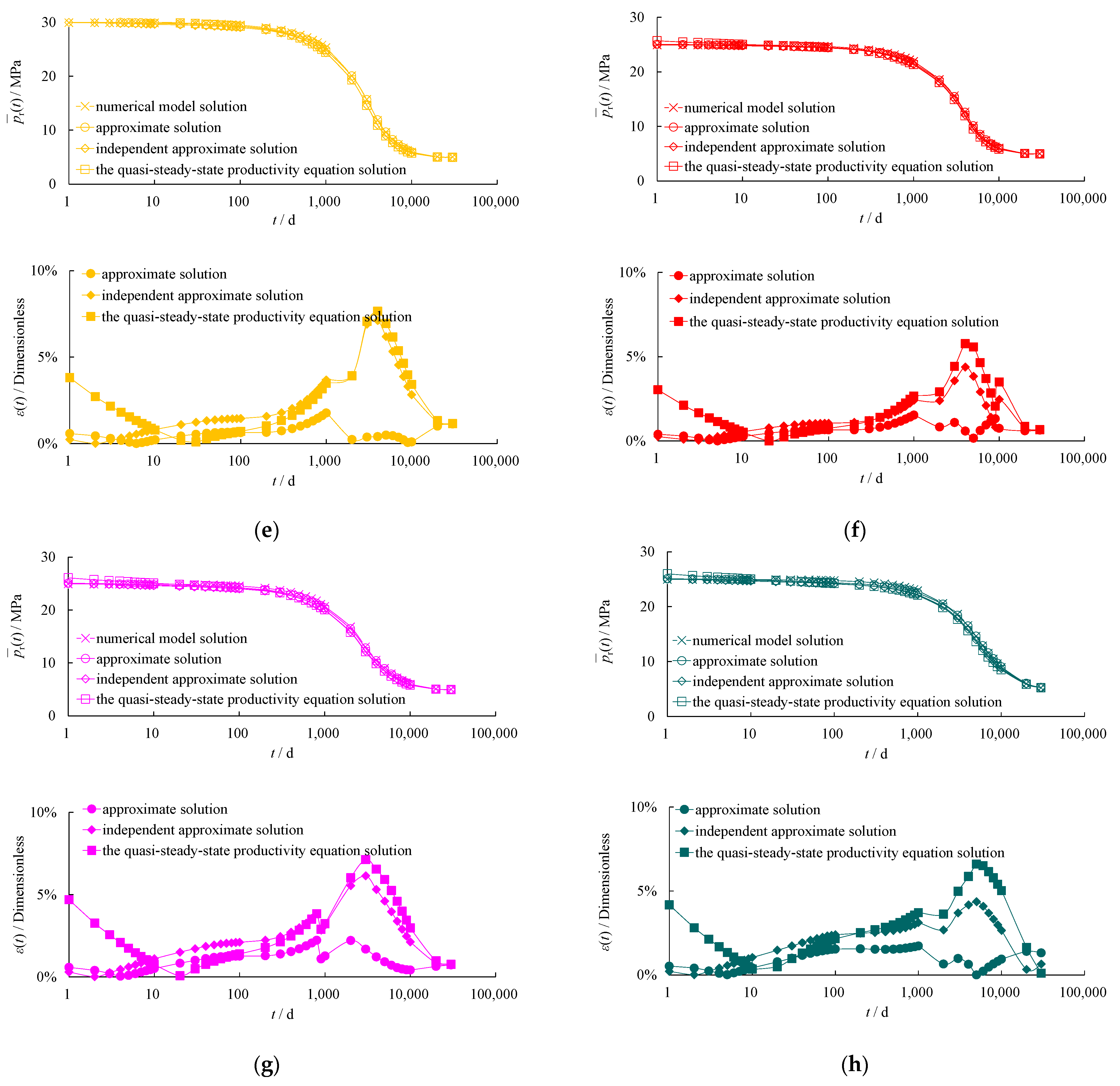

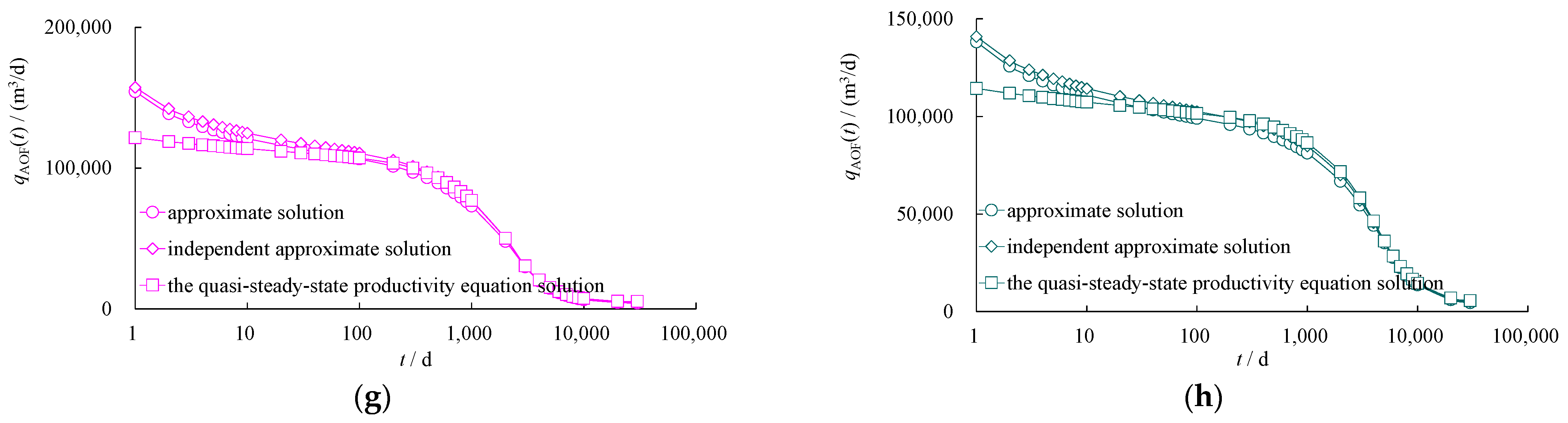

- The approximate solution and independent approximate solution of the pressure-conversion skin are the only sources of error in the full-stage productivity equation. The validation of the model reveals that the approximate and independent solutions of the average formation pressure consistently exhibited good accuracy under varying production systems and fundamental factors. In contrast, the approximate and independent solutions of the absolute open-flow rate nearly overlap. The application results show that the full-stage productivity equation also has relatively reliable accuracy compared to the corrected isochronous well testing. The comprehensive model validation and application results indicate that the full-stage productivity equation is not affected by production systems, and this applies to the entire stage of gas reservoir development.

- (3)

- The precision of the approximation answer is marginally greater overall, and the effect of various pressure-conversion skins on the entire stage production-capacity equation varies. The independent approximation solution eliminates the effect of the venting radius. It is advised to utilize the approximate pressure-conversion skin solution for computing parameters like the average formation pressure. It is advised to utilize the independent approximation solution of the pressure-conversion skin to determine the absolute open-flow rate.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, B.; Ghalambor, A. Natural Gas Engineering Handbook; Gulf Publishing Company: Houston, TX, USA, 2005; pp. 35–49. [Google Scholar]

- Guo, C.; Li, F.; Liu, H.; Xia, Z.; Liu, X.; Fan, H.; Liu, L. Analysis of quantitative relationship between gas offtake and plateau duration of natural gas reservoir. Acta Pet. Sin. 2009, 30, 908–911. [Google Scholar]

- Aminian, K.; Ameri, S.; Yussefabad, A.G. A simple and reliable method for gas well deliverability determination. In Proceedings of the SPE Eastern Regional Meeting, Lexington, KY, USA, 17–19 October 2007; SPE-111195-MS. SPE: Houston, TX, USA, 2007. [Google Scholar]

- Li, S. Natural Gas Engineering, 2nd ed.; Petroleum Industry Press: Beijing, China, 2000; pp. 85–95. [Google Scholar]

- Yang, J. Fundamentals of Gas Production Technology; Petroleum Industry Press: Beijing, China, 1992; pp. 44–58. [Google Scholar]

- Cheng, Y.; Guo, C.; Tan, C.; Chen, P.; Shi, H.; Xing, Y. Experimental analysis and deliverability calculation of abnormally pressured carbonate gas reservoir considering stress sensitivity. J. Pet. Explor. Prod. Technol. 2022, 12, 3105–3115. [Google Scholar] [CrossRef]

- Xiao, X.; Bi, Y.; Wang, X.; Gao, J.; Chang, Z.; Zhang, J. A new trinomial deliverability equation with consideration of stress sensitivity. Nat. Gas Geosci. 2014, 25, 767–770. [Google Scholar]

- Al-Attar, H.; Al-Zuhair, S. A general approach for deliverability calculations of gas wells. In Proceedings of the SPE North Africa Technical Conference and Exhibition, Marrakech, Morocco, 12–14 March 2008; SPE-111380-MS. SPE: Houston, TX, USA, 2008. [Google Scholar]

- Chen, Y. A simple method for determining absolute open flow rate of gas well. Nat. Gas Ind. 1987, 7, 59–63. [Google Scholar]

- Kalantariasl, A.; Farhadi, L.; Farzani, S.; Keshavarz, A. A new comprehensive dimensionless inflow performance relationship for gas wells. J. Pet. Explor. Prod. Technol. 2022, 12, 2257–2269. [Google Scholar] [CrossRef]

- Liang, H.; An, X.; Li, X. Principles for application of single point test and errors of deliverability evaluation of gas exploration well. Nat. Gas Ind. 2006, 26, 92–95. [Google Scholar]

- Zhuang, H. Dynamic Description and Well Test of Gas Reservoirs; Petroleum Industry Press: Beijing, China, 2004; pp. 45–49. [Google Scholar]

- Sun, H.; Meng, G.; Cao, W.; Su, X.; Liang, Z.; Zhang, R.; Zhu, S.; Wang, S. Applicable conditions of the binomial pressure method and pressure-squared method for gas well deliverability evaluation. Nat. Gas Ind. B 2020, 7, 397–402. [Google Scholar] [CrossRef]

- Tan, Y.; Lian, L.; Yan, M. Calculation of pseudo pressure for real gas. Gas Heat 1999, 19, 31–33. [Google Scholar]

- Tian, J.; Li, C.; Huang, S.; Li, D.; Jiang, Y. A new empirical formula of pseudo pressure calculation for real gas. Oil Drill. Prod. Technol. 2009, 31, 65–67. [Google Scholar]

- Li, C.; Li, X.; Gao, S.; Liu, H.; You, S.; Fang, F.; Shen, W. Experiment on gas-water two-phase seepage and inflow performance curves of gas wells in carbonate reservoirs: A case study of Longwangmiao Formation and Dengying Formation in Gaoshiti-Moxi block, Sichuan Basin, SW China. Pet. Explor. Dev. 2017, 44, 930–938. [Google Scholar] [CrossRef]

- Li, Y. An analysis of dimensionless IPR equations for gas wells. Nat. Gas Ind. 1995, 15, 48–53. [Google Scholar]

- Wang, C.; Li, Z.; Lai, F. A novel binomial deliverability equation for fractured gas well considering non-Darcy effects. J. Nat. Gas Sci. Eng. 2014, 20, 27–37. [Google Scholar] [CrossRef]

- Guo, P.; Wen, Y.; Wang, Z.; Ren, J.; Yang, L. An Unsteady-State Productivity Model and Main Influences on Low-Permeability Water-Bearing Gas Reservoirs at Ultrahigh Temperature/High Pressure. ACS Omega 2022, 7, 6601–6615. [Google Scholar] [CrossRef] [PubMed]

- Osisanya, S.O.; Ayokunle, A.T.; Ghosh, B.; Suboyin, A. A modified horizontal well productivity model for a tight gas reservoir subjected to non-uniform damage and turbulence. Energies 2021, 14, 8334. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Wang, X.; Zhou, W.; Zeng, X.; Liu, C.; Zhao, N.; Wang, L.; Wang, X.; Wang, W. Productivity analysis method for gas-water wells in abnormal overpressure gas reservoirs. Pet. Explor. Dev. 2017, 44, 258–262. [Google Scholar] [CrossRef]

- Kang, X.; Li, X.; Cheng, S. Evaluation of non-Darcy flow effect in gas well considering influence of flow boundary. J. China Univ. Pet. 2006, 30, 82–85. [Google Scholar]

- Xue, J.; Zhang, M.; Song, H.; Wang, H. Multiple-factor Estimation for Productivity of Low Permeability Gas Reservoir. Sci. Technol. Eng. 2020, 20, 3940–3945. [Google Scholar]

- Pan, Y.; Xu, Y.; Yang, Z.; Wang, C.; Liao, R. Shale gas productivity prediction model considering time-dependent fracture conductivity. Processes 2022, 10, 801. [Google Scholar] [CrossRef]

- Xu, B.; Li, X.; Yin, B. Influence of gas slippage on gas well productivity evaluation. Nat. Gas Ind. 2010, 30, 45–48. [Google Scholar]

- Yan, W.; Qi, Z.; Yuan, Y.; Li, J.; Huang, X. Productivity equation of low-permeability condensate gas well considering the influence of multiple factors. J. Pet. Explor. Prod. Technol. 2019, 9, 2997–3005. [Google Scholar] [CrossRef]

- Chen, F.; Duan, Y.; Wang, K. Productivity Model Study of Water-Bearing Tight Gas Reservoirs Considering Micro-to Nano-Scale Effects. Processes 2024, 12, 1499. [Google Scholar] [CrossRef]

- Li, M.; Xue, G.; Luo, B.; Yang, W. Pseudosteady-State Trinomial Deliverability Equation and Application of Low Permeability Gas Reservoir. Xinjiang Pet. Geol. 2009, 30, 593–595. [Google Scholar]

- Wu, K.; Li, X.; Yang, P.; Zhang, S. The Establishment of a Novel Deliverability Equation of Abnormal Pressure Gas Reservoirs Considering a Variable Threshold Pressure Drop. Pet. Sci. Technol. 2014, 32, 15–21. [Google Scholar] [CrossRef]

- Ghahri, P.; Alatefi, S.; Jamiolahmady, M. A new, accurate and simple model for calculation of horizontal well productivity in gas and gas condensate reservoirs. In Proceedings of the SPE Europec featured at EAGE Conference and Exhibition, Madrid, Spain, 1–4 June 2015; SPE-174345-MS. SPE: Houston, TX, USA, 2015. [Google Scholar]

- Xie, X.; Luo, K.; Song, W. A novel equation for modeling gas condensate well deliverability. Acta Pet. Sin. 2001, 22, 36–42. [Google Scholar]

- Ghahri, P.; Jamiolahmadi, M.; Alatefi, E.; Wilkinson, D.; Dehkordi, F.; Hamidi, H. A new and simple model for the prediction of horizontal well productivity in gas condensate reservoirs. Fuel 2018, 223, 431–450. [Google Scholar] [CrossRef]

- Song, H.; Liu, Q.; Yang, D.; Yu, M.; Lou, Y.; Zhu, W. Productivity equation of fractured horizontal well in a water-bearing tight gas reservoir with low-velocity non-Darcy flow. J. Nat. Gas Sci. Eng. 2014, 18, 467–473. [Google Scholar] [CrossRef]

- Yu, Q.; Jia, Y.; Liu, P.; Hu, X.; Hao, S. Rate transient analysis methods for water-producing gas wells in tight reservoirs with mobile water. Energy Geosci. 2024, 5, 100251. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, S.; Liu, H.; Ye, L.; Zhu, W.; An, W. Research on types of gas reservoirs divided by seepage capacity and their seepage mechanism, law and productivity. Energy Rep. 2023, 10, 2537–2550. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, T.; Zeng, B. Productivity performances of hydraulically fractured gas well. Acta Pet. Sin. 2003, 24, 65–68. [Google Scholar]

- Liu, S.; Xiong, S.; Weng, D.; Song, P.; Chen, R.; He, Y.; Liu, X.; Chu, S. Study on deliverability evaluation of staged fractured horizontal wells in tight oil reservoirs. Energies 2021, 14, 5857. [Google Scholar] [CrossRef]

- Ehibor, L.; Ohenhen, L.; Oloyede, B.; Adetoyi, G.; Amaechi, T.; Olajide, O.; Kaka, A.; Woyengidiripre, A. Gas Condensate Well Deliverability Model, a Field Case Study of a Niger Delta Gas Condensate Reservoir. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 1–3 August 2022; 212043-MS. SPE: Houston, TX, USA, 2022. [Google Scholar]

- Liu, Y.; Li, X.; Kang, X. Determination of reasonable pressure difference for condensate gas reservoir. Acta Pet. Sin. 2006, 27, 85–88. [Google Scholar]

- Ogunrewo, O.; Herens, T.; Gringarten, A.C. Well deliverability forecasting of gas condensate and volatile oil wells below saturation pressure. In Proceedings of the SPE Europec featured at EAGE Conference and Exhibition, London, UK, 1–13 June 2013; SPE-164869-MS. SPE: Houston, TX, USA, 2013. [Google Scholar]

- Wang, W.; Lei, X.; Lu, R.; Chen, J.; He, Z. Regional productivity prediction technology for abnormal high temperature and high pressure gas reservoirs in western south China sea. Earth Sci. 2019, 44, 2636–2642. [Google Scholar]

- Wang, F.; Liu, S.; Jia, Y.; Gao, A.; Su, K.; Liu, Y.; Du, J.; Wang, L. Production forecasting methods for different types of gas reservoirs. Energy Geosci. 2024, 5, 100296. [Google Scholar] [CrossRef]

- Du, X.; Zhang, Y.; Zhou, C.; Su, Y.; Li, Q.; Li, P.; Lu, Z.; Xian, Y.; Lu, D. A novel method for determining the binomial deliverability equation of fractured caved carbonate reservoirs. J. Pet. Sci. Eng. 2022, 208, 109496. [Google Scholar] [CrossRef]

- Hu, J.; Yang, S.; Wang, B.; Yan, Y.; Deng, H.; Zhao, X. Trinomial capacity equation for horizontal wells in deep carbonate gas reservoirs: Case study of Dengying Formation in Anyue Gas Field, Sichuan Basin. Nat. Gas Geosci. 2023, 34, 1112–1122. [Google Scholar]

- Li, Y.; Feng, Y.; Li, X.; Zhong, J.; Wang, W. Productivity performance of open hole horizontal gas well for low permeability gas reservoirs. Pet. Sci. Technol. 2024, 42, 169–189. [Google Scholar] [CrossRef]

- Wei, B.; Nie, X.; Zhang, Z.; Ding, J.; Shayireatehan, R.; Ning, P.; Deng, D.; Cao, Y. Productivity Equation of Fractured Vertical Well with Gas–Water Co-Production in High-Water-Cut Tight Sandstone Gas Reservoir. Processes 2023, 11, 3123. [Google Scholar] [CrossRef]

- Zhu, W.; Song, H.; He, D.; Wang, M.; Jia, A.; Hu, Y. Low-velocity non-Darcy gas seepage model and productivity equationsof low-permeability wate-|bearing gas reservoirs. Nat. Gas Geosci. 2008, 19, 685–689. [Google Scholar]

- Zeng, D.; Zhang, Q.; Li, T.; Su, Y.; Zhang, R.; Zhang, C.; Peng, S. Key technologies for long-period high and stable production of the Puguang high-sulfur gas field, Sichuan Basin. Nat. Gas Ind. 2023, 43, 65–75. [Google Scholar]

- Li, G.; Wu, X.; Llt, Y.; Yang, J. Full life-circle production and elfect evaluation of Panzhuang coalbed meth-ane wells in 0inshui Basin. J. China Coal Soc. 2020, 45, 894–903. [Google Scholar]

- Gao, S.; Liu, H.; Ye, L.; Hu, Z.; An, W. Physical simulation experiment and numerical inversion of the full life cycle of shale gas well. Acta Pet. Sin. 2018, 39, 435–444. [Google Scholar] [CrossRef]

- Mehrdad, V.; Rasa, S.; Saeid, J.; Saeed, S. Development of a dynamic model for drilling fluid’s filtration: Implications to prevent formation damage. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 26–28 February 2014; SPE-168151-MS. SPE: Houston, TX, USA, 2014. [Google Scholar]

- Salehi, S.; Hussmann, S.; Karimi, M.; Ezeakacha, C.; Tavanaei, A. Profiling drilling fluid’s invasion using scanning electron microscopy: Implications for bridging and wellbore strengthening effects. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Galveston, TX, USA, 10–11 September 2014; SPE-170315-MS. SPE: Houston, TX, USA, 2014. [Google Scholar]

- Ezeakacha, C.P.; Salehi, S.; Hayatdavoudi, A. Experimental study of drilling fluid’s filtration and mud cake evolution in sandstone formations. J. Energy Resour. Technol. 2017, 139, 022912. [Google Scholar] [CrossRef]

- Vasheghani, F.M.; Foroughi, S.; Norouzi, S.; Jamshidi, S. Mechanistic study of fines migration in porous media using lattice Boltzmann method coupled with rigid body physics engine. J. Energy Resour. Technol. 2019, 141, 123001. [Google Scholar] [CrossRef]

| Number | Set-Up | ε(t)max of (t) | ε(t)avg of (t) | ||||

|---|---|---|---|---|---|---|---|

| Approximate Solution | Independent Approximate Solution | The Quasi-Steady-State Productivity Equation Solution | Approximate Solution | Independent Approximate Solution | The Quasi-Steady-State Productivity Equation Solution | ||

| Model 1 | Fix production before fixing pressure | 1.95% | 3.27% | 6.46% | 0.72% | 1.48% | 2.71% |

| Model 2 | Reduce production before increasing it | 3.56% | 0.77% | 5.50% | 0.23% | 0.15% | 0.51% |

| Model 3 | Sgi = 80% | 1.93% | 3.18% | 7.77% | 0.73% | 1.21% | 2.54% |

| Model 4 | K = 10 × 10−3 μm2 | 2.04% | 1.73% | 2.73% | 0.32% | 0.27% | 0.49% |

| Model 5 | pi = 30 MPa | 1.78% | 7.11% | 7.65% | 0.59% | 2.22% | 2.39% |

| Model 6 | h = 15 m | 1.54% | 4.38% | 5.77% | 0.66% | 1.35% | 1.82% |

| Model 7 | φ = 8% | 2.22% | 6.14% | 7.12% | 0.97% | 2.27% | 2.61% |

| Model 8 | re = 900 m | 1.73% | 4.36% | 6.60% | 0.94% | 2.10% | 2.80% |

| Parameter | Well A | Well B | Parameter | Well A | Well B |

|---|---|---|---|---|---|

| rw/m | 0.108 | 0.108 | re/m | 23.74 | 483.93 |

| μi/mPa.s | 0.02059 | 0.02161 | pwf(1)/MPa | 23.736 | 23.323 |

| Zi | 0.96540 | 0.97202 | qsc(1)/(m3/d) | 8864 | 50,450 |

| pi/MPa | 27.233 | 27.551 | t/d | 26 | 637 |

| T/K | 376.59 | 360.06 | pwf(t)/MPa | 22.859 | 17.780 |

| K/10−3 μm2 | 0.357 | 1.15 | μwf(t)/mPa.s | 0.02059 | 0.01776 |

| h/m | 5.6 | 6.7 | Zwf(t) | 0.96406 | 0.92752 |

| φ | 4.07% | 8.20% | S | −0.09 | −2.85 |

| Sgi | 73.01% | 75.90% | qsc(t)/(m3/d) | 10,079 | 46,154 |

| Parameter | Solution Method | Well A | Relative Error | Well B | Relative Error |

|---|---|---|---|---|---|

| /MPa | Test result | 27.005 | / | 22.260 | / |

| Approximate solution | 27.960 | 3.54% | 21.777 | −2.17% | |

| Independent approximate solution | 27.951 | 3.50% | 21.386 | −3.92% | |

| the quasi-steady-state productivity equation solution | 29.737 | 10.11% | 23.422 | 5.22% | |

| qAOF(t)/(m3/d) | Test result | 33,585.27 | / | 175,495.43 | / |

| Approximate solution | 36,054.94 | 7.35% | 163,799.28 | −6.66% | |

| Independent approximate solution | 36,125.61 | 7.56% | 183,294.24 | 4.44% | |

| the quasi-steady-state productivity equation solution | 25,844.08 | −23.05% | 112,304.79 | −36.01% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Cheng, S.; Wu, K.; Xin, C.; Song, J.; Zhang, T.; Xie, X.; Zhao, Z. A Full-Stage Productivity Equation for Constant-Volume Gas Reservoirs and Its Application. Processes 2024, 12, 1855. https://doi.org/10.3390/pr12091855

Zhang L, Cheng S, Wu K, Xin C, Song J, Zhang T, Xie X, Zhao Z. A Full-Stage Productivity Equation for Constant-Volume Gas Reservoirs and Its Application. Processes. 2024; 12(9):1855. https://doi.org/10.3390/pr12091855

Chicago/Turabian StyleZhang, Lei, Shiying Cheng, Keliu Wu, Cuiping Xin, Jiaxuan Song, Tao Zhang, Xiaofei Xie, and Zidan Zhao. 2024. "A Full-Stage Productivity Equation for Constant-Volume Gas Reservoirs and Its Application" Processes 12, no. 9: 1855. https://doi.org/10.3390/pr12091855

APA StyleZhang, L., Cheng, S., Wu, K., Xin, C., Song, J., Zhang, T., Xie, X., & Zhao, Z. (2024). A Full-Stage Productivity Equation for Constant-Volume Gas Reservoirs and Its Application. Processes, 12(9), 1855. https://doi.org/10.3390/pr12091855