The Gas Production Characteristics of No. 3 Coal Seam Coalbed Methane Well in the Zhengbei Block and the Optimization of Favorable Development Areas

Abstract

1. Introduction

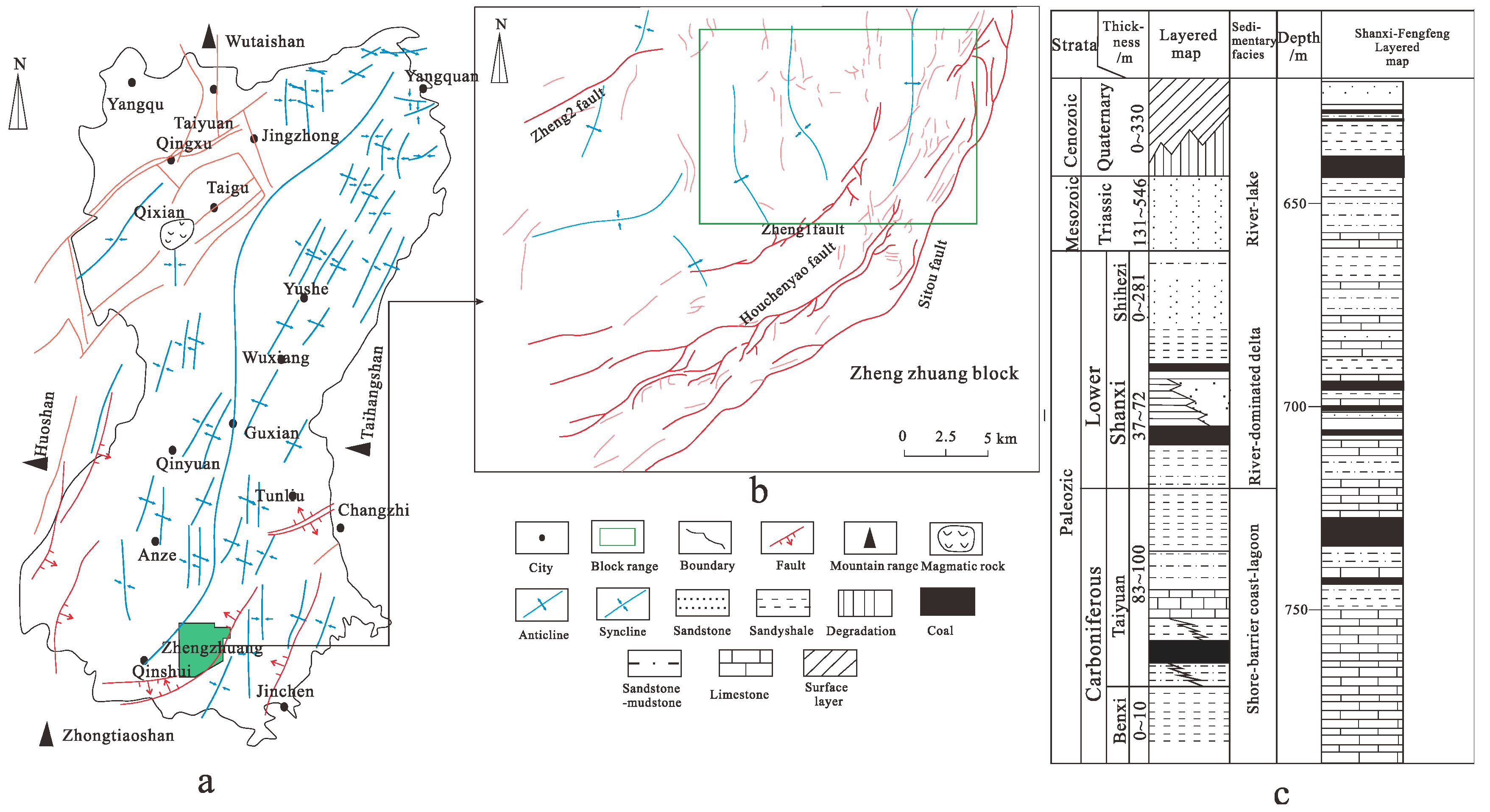

2. Geological Background

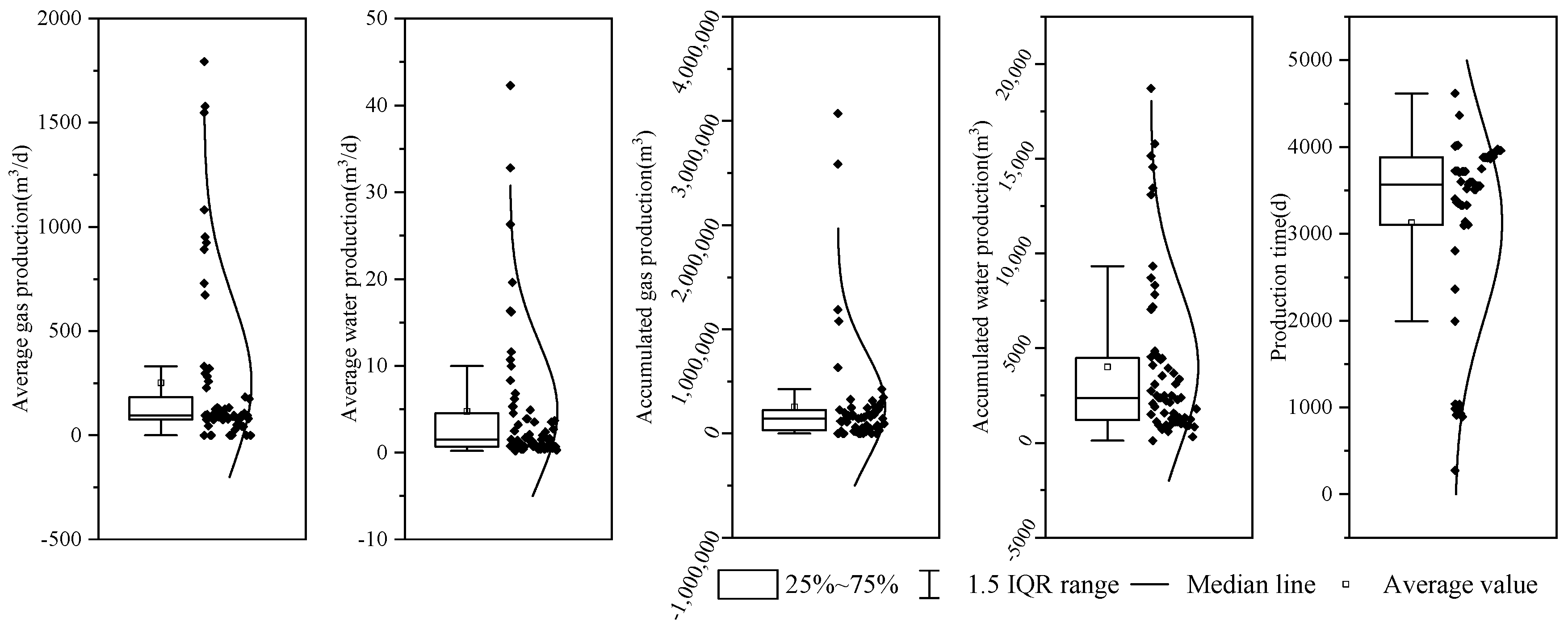

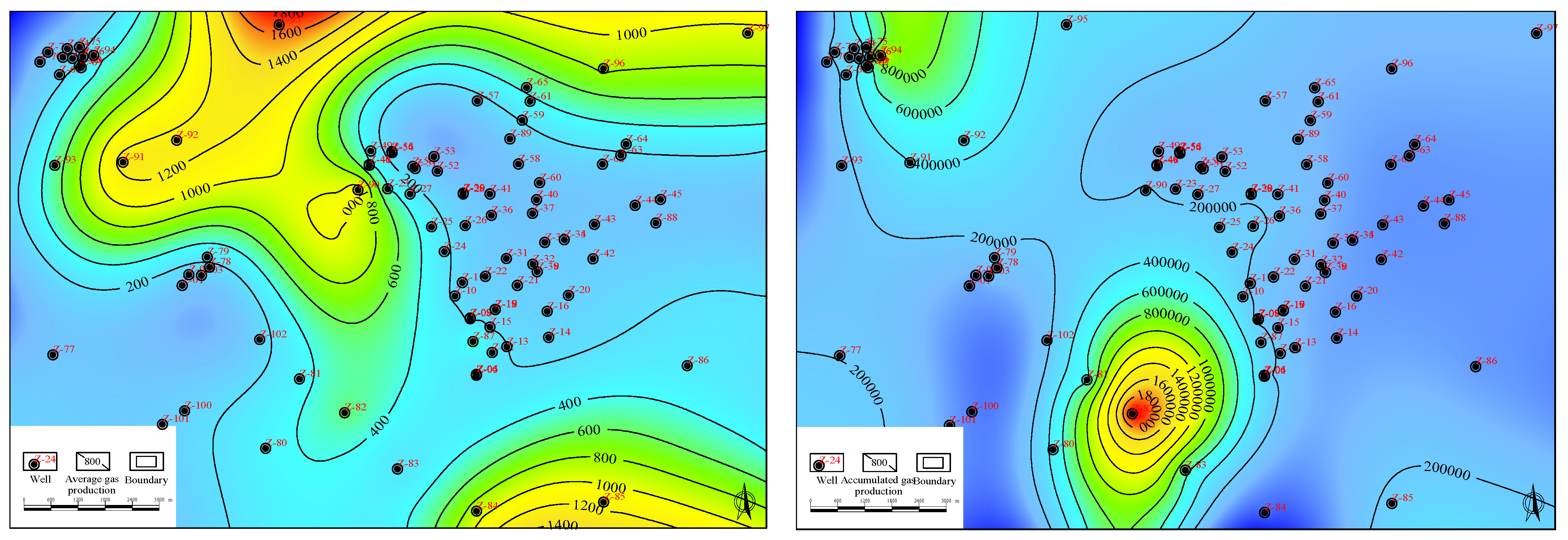

3. CBM Well Productivity Characteristics

4. Control Factors of CBM Well Productivity

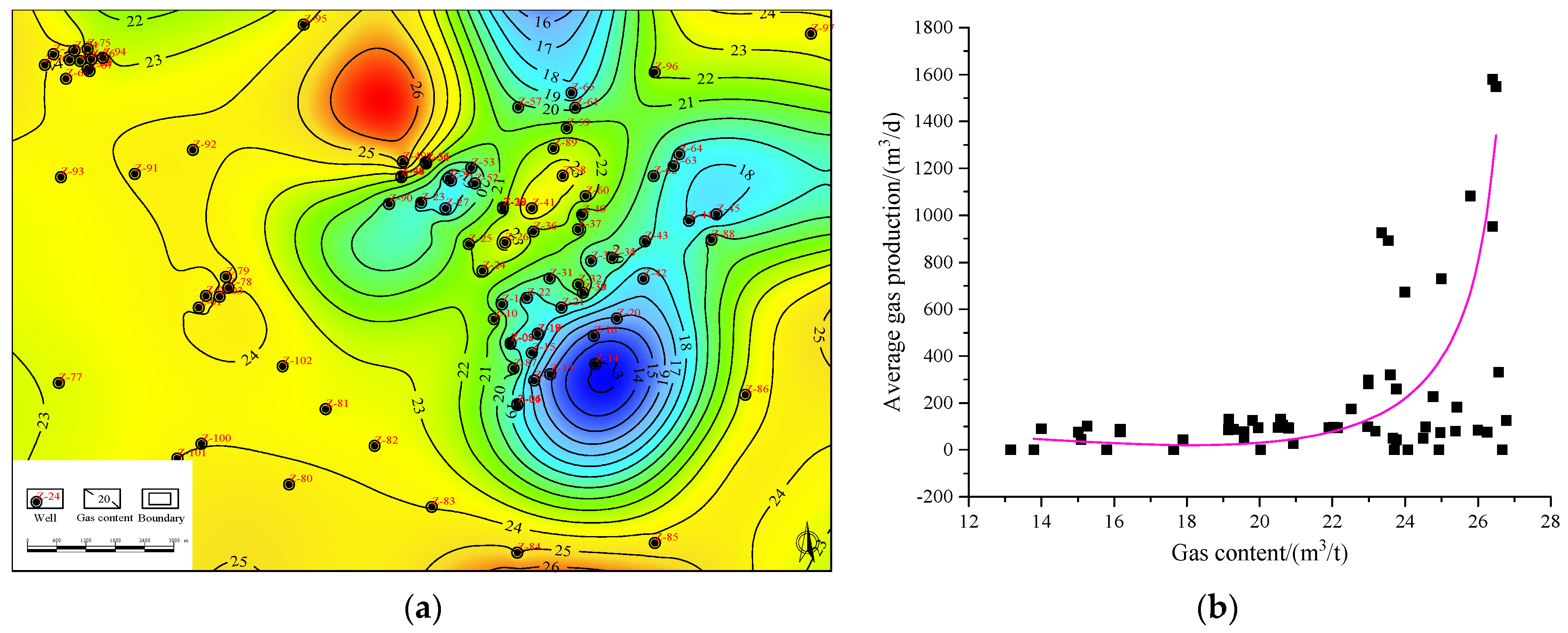

4.1. Gas-Bearing Enrichment Factors

4.1.1. Gas Content

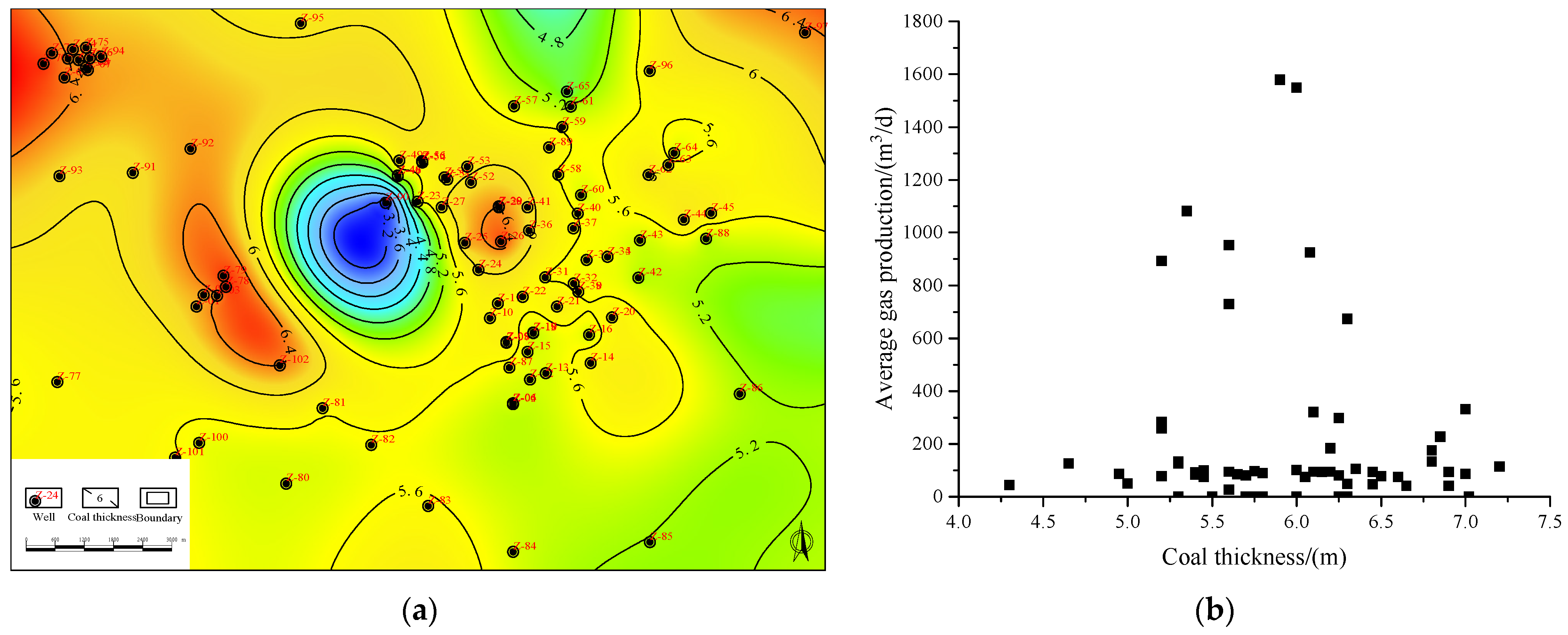

4.1.2. Coal Seam Thickness

4.1.3. Critical Desorption Pressure

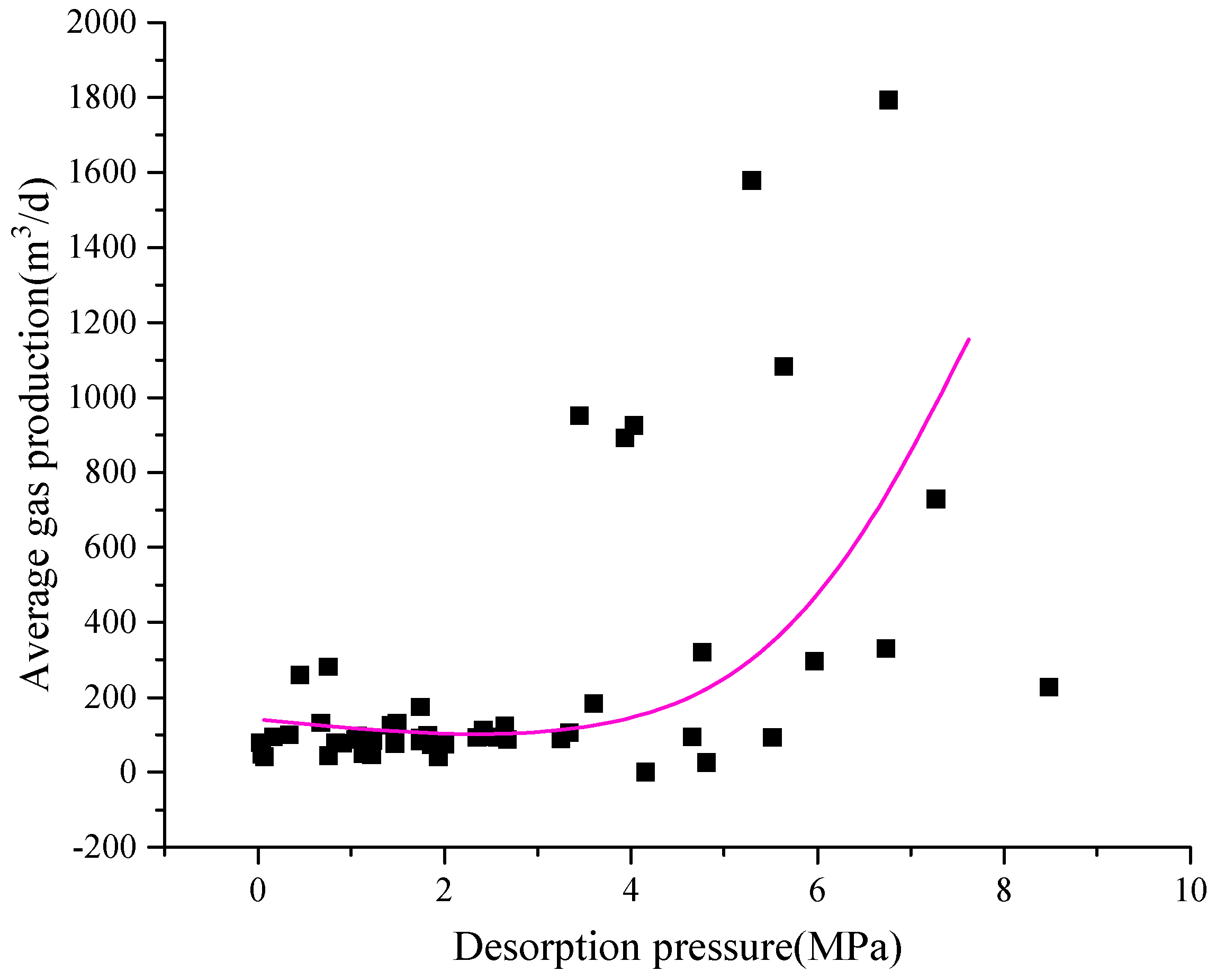

4.1.4. Fault Fractal Dimension

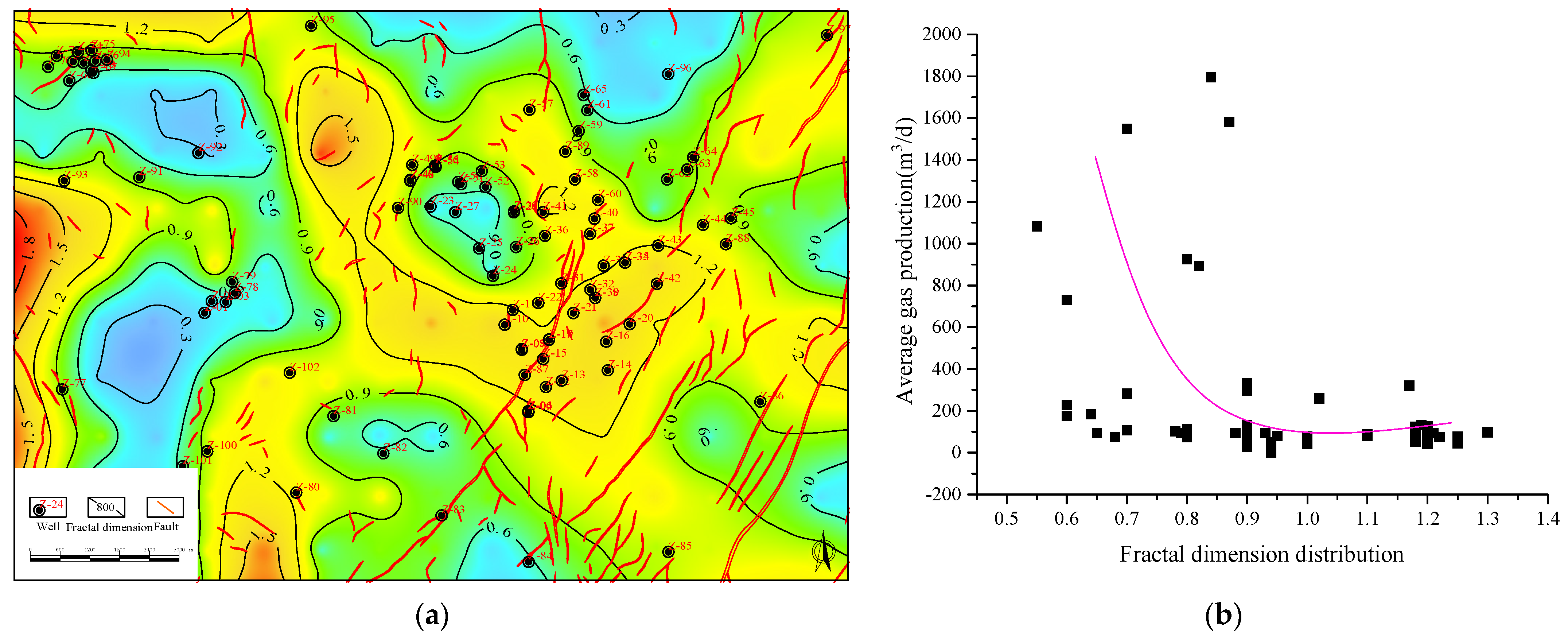

4.2. Permeability Factors

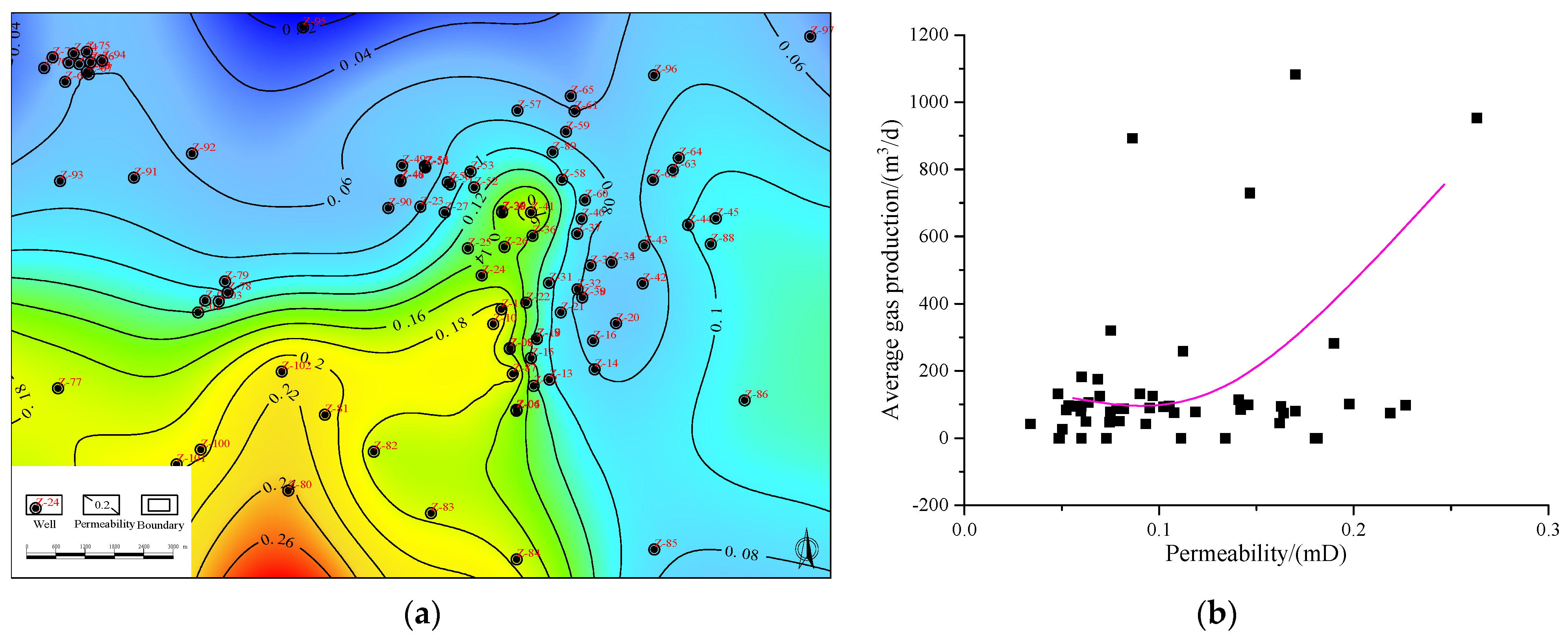

4.2.1. Permeability

4.2.2. Fracture Index

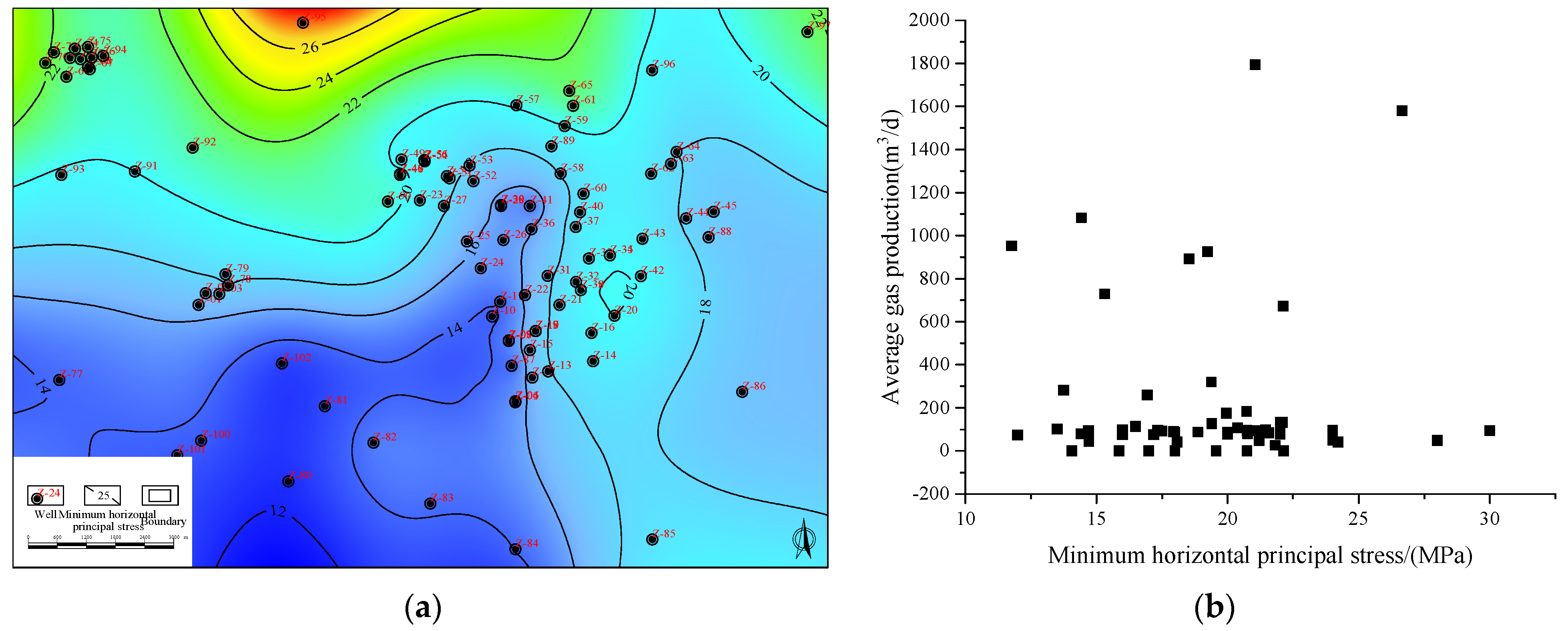

4.2.3. Minimum Horizontal Principal Stress

4.3. Favorable Fracturing Factors

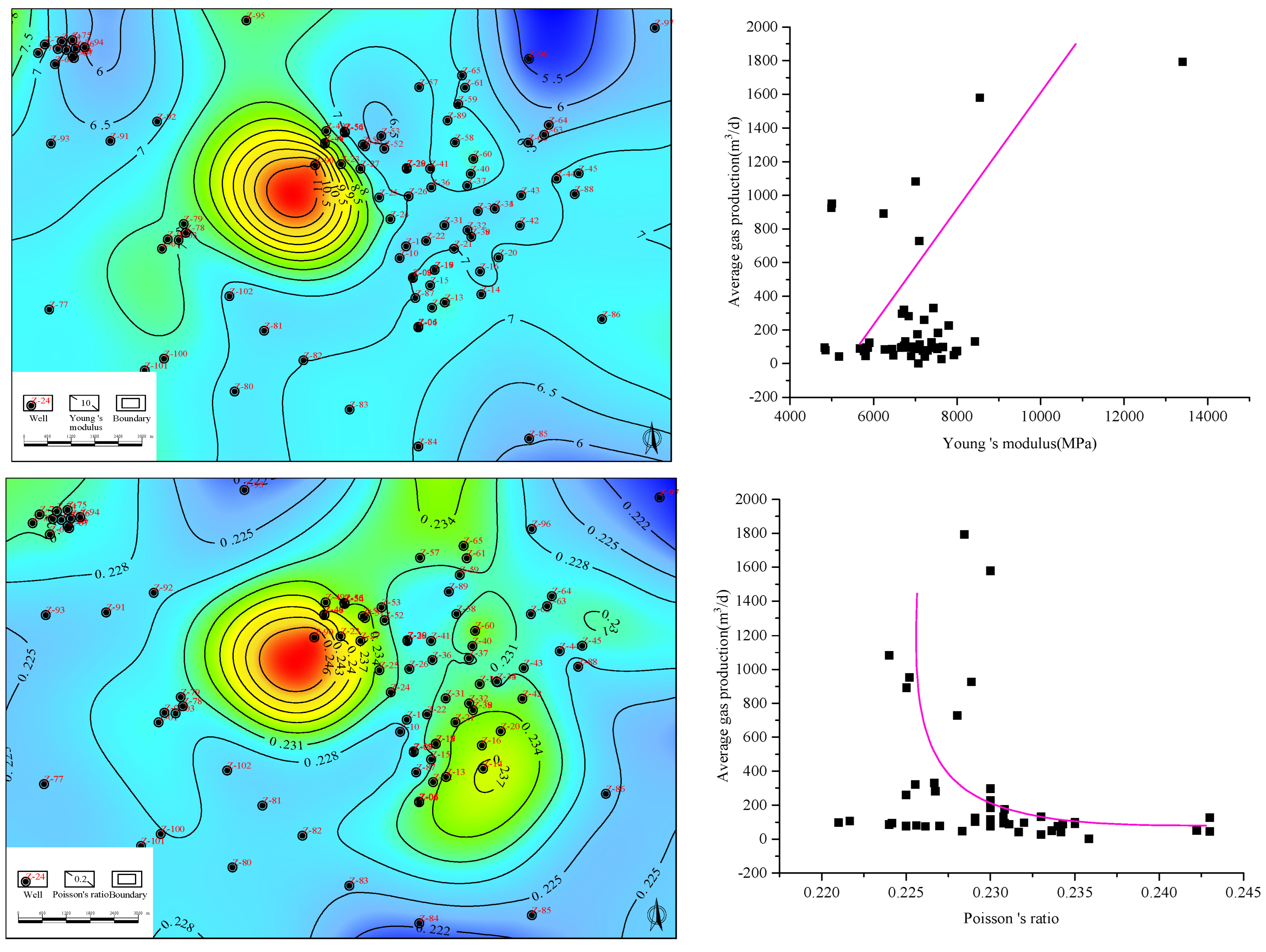

4.3.1. Young’s Modulus and Poisson’s Ratio

4.3.2. Schlumberger Ratio

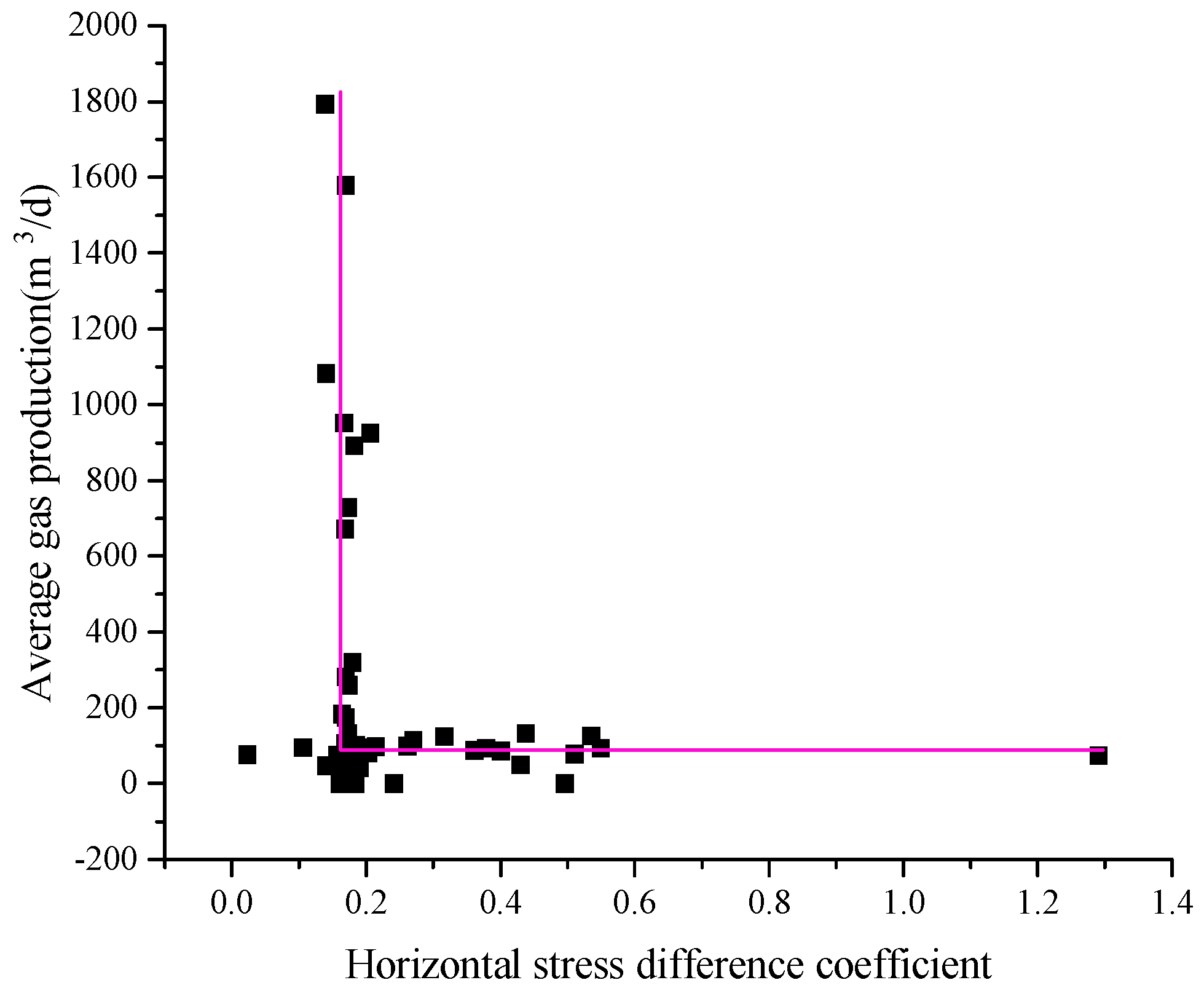

4.3.3. Horizontal Stress Difference Coefficient

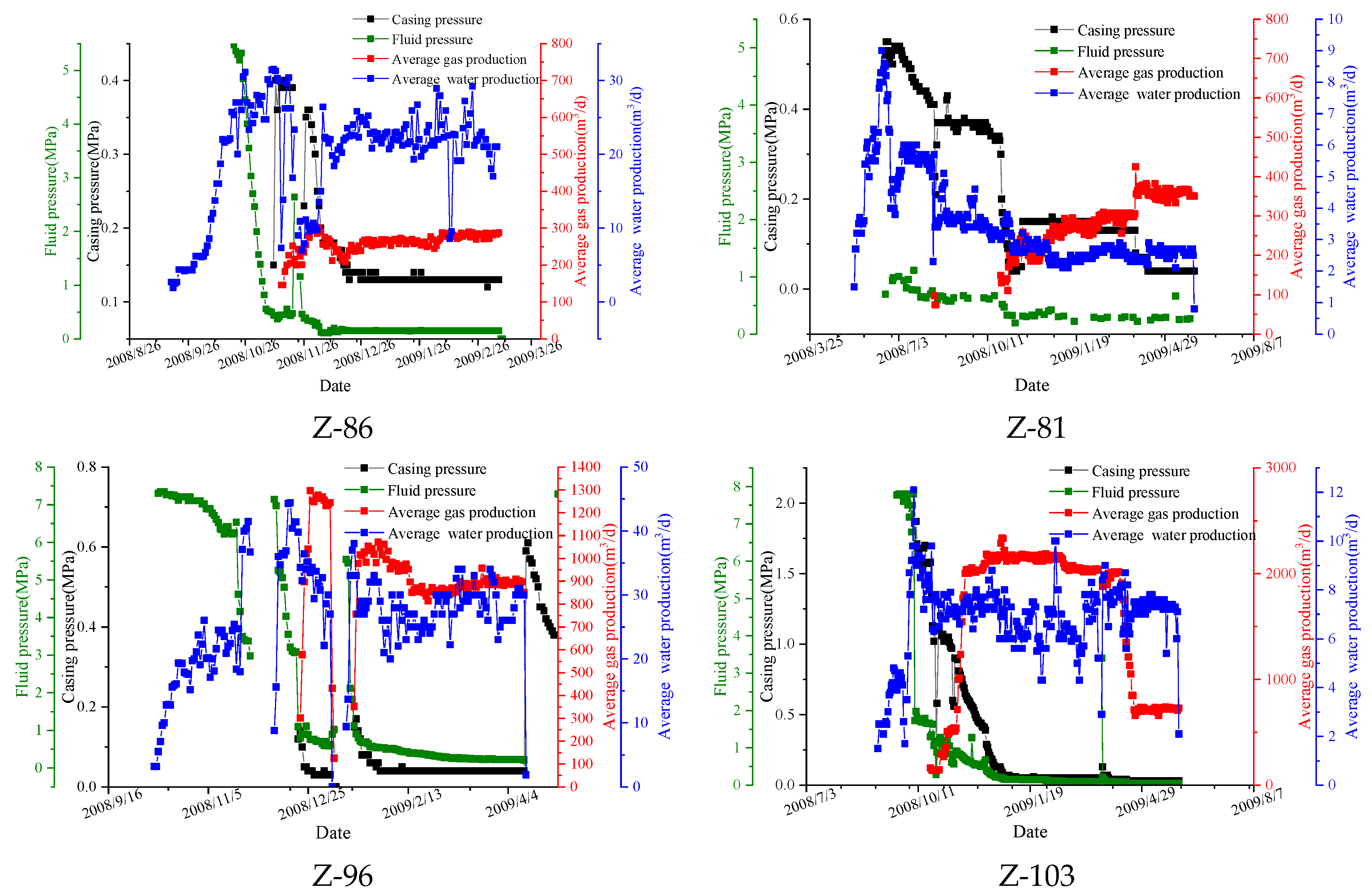

4.4. Control Factors of CBM Well Productivity Engineering

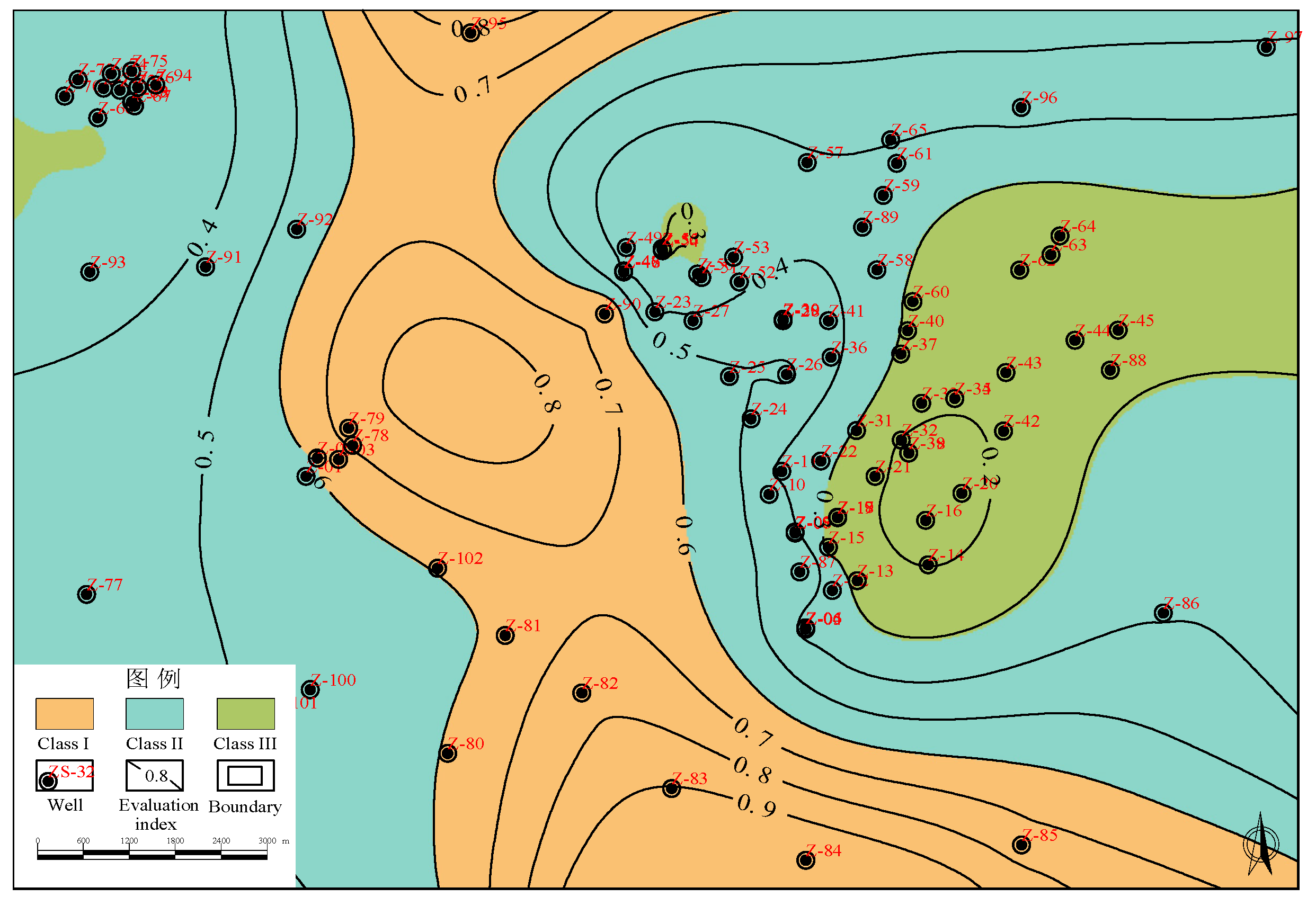

5. Prediction of Favorable Development Unit of CBM

5.1. Optimization Method of Favorable Area Development

- (1)

- Sample data normalization

- (2)

- Normalized data volume translation

- (3)

- Entropy weight calculation

5.2. Development Unit Division

6. Conclusions

- (1)

- The characteristics of CBM production in the Zhengbei block have been identified. The average gas production of CBM wells in the study area is between 0 and 1793 m3/d, with an average of 250.97 m3/d. Of the wells, 80% are lower than 500 m3/d, and there are fewer wells above 1000 m3/d. The highest points of average gas production and cumulative gas production are mainly concentrated in the northern, central, and southeastern parts of the block.

- (2)

- The average gas production is positively correlated with gas content, critical desorption pressure, permeability, Young’s modulus, and Schlumberger ratio, and negatively correlated with fracture index, fault fractal dimension, Poisson’s ratio, and horizontal stress difference coefficient. The correlation with coal thickness and minimum horizontal principal stress is poor.

- (3)

- The low-yield wells in the study area have the characteristics of multiple pump-stopping disturbances, unstable casing pressure control, and overly rapid depressurization in the single-phase flow stage. CBM wells have higher sand, pulverized coal, and water production. Compared with the roof and floor rock mechanics experiments, it is found that this may be caused by the small difference in compressive strength between the roof and floor and the small difference in Young’s modulus of the floor. The difference between the two high-yield wells is large, and the fracturing cracks are easy to control in the coal seam and extend along the layer.

- (4)

- The production control factors from strong to weak are as follows: critical desorption pressure, permeability, Schlumberger ratio, fault fractal dimension, Young’s modulus, horizontal stress difference coefficient, minimum horizontal principal stress, gas content, Poisson’s ratio, fracture index, coal seam thickness. On the plane, the type I development unit of the Zhengbei block is stripped and interspersed with the north and south of the block, and the type III development unit is mainly located in the east of the block and near the well Z-56. The comprehensive index is positively correlated with gas production, and the prediction results are accurate.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Bao, Y.; Hu, Y. Recent progress in improving the yield of microbially enhanced CBM production. Energy Rep. 2023, 9, 2810–2819. [Google Scholar] [CrossRef]

- Du, S.; Wang, M.; Yang, J.; Zhao, Y.; Wang, J.; Yue, M.; Xie, C.; Song, H. An enhanced prediction framework for CBM production incorporating deep learning and transfer learning. Energy 2023, 282, 128877. [Google Scholar] [CrossRef]

- Wang, G.; Qin, Y.; Xie, Y. Geochemical Characteristics of Coal in the Taiyuan Formation in the Center and North of the Xishan Coalfield. Energies 2022, 15, 8025. [Google Scholar] [CrossRef]

- Li, H.; Lau, H.; Huang, S. China’s CBM development: A review of the challenges and opportunities in subsurface and surface engineering. J. Pet. Sci. Eng. 2018, 166, 621–635. [Google Scholar] [CrossRef]

- Zhang, C.; Li, M.; Feng, S.; Hu, Q.; Qiao, M.; Wu, D.; Yu, J.; Li, K. Reservoir properties and gas production difference between No.15 coal and No.3 coal in Zhengzhuang Block, southern Qinshui Basin. Coal Geol. Explor. 2022, 50, 145–153. [Google Scholar]

- Zhu, Q.; Li, Z.; Li, Z.; Wang, S.; Sun, R.; Wang, Y.; Xiao, Y.; Wang, J.; Wang, J.; Guan, X. Practice and cognition of efficient CBM development under complex geological Practice and cognition of efficient CBM development under complex geological. Coal Geol. Explor. 2023, 51, 131–138. [Google Scholar]

- Jia, H.; Hu, Q.; Fan, B.; Mao, C.; Zhang, Q. Causes for low CBM production of vertical wells and efficient development tech-nology in northern Zhengzhuang Block in Qinshui Basin. Coal Geol. Explor. 2021, 49, 34–42. [Google Scholar]

- Wang, M.; Zhu, Y.; Li, W.; Zhong, H.; Wang, Y. Tectonic evolution and reservoir formation of CBM in Zhengzhuang block of Qinshui basin. J. China Univ. Min. Technol. 2012, 41, 425–431. [Google Scholar]

- Chen, L.; Hou, Y.; Yao, Y.; Yang, Y.; Zhong, L.; Xie, N. Study on heterogeneity of coal reservoir in Zhengzhuang Block of south Qinshui Basin. Coal Sci. Technol. 2016, 44, 147–153. [Google Scholar]

- Zhang, J.; Feng, Q.; Zhang, X.; Hu, Q.; Wen, S.; Chen, D.; Zhai, Y.; Yan, X. Multi-fractured horizontal well for improved coalbed methane production in eastern Ordos basin, China: Field observations and numerical simulations. J. Pet. Sci. Eng. 2020, 194, 107488. [Google Scholar] [CrossRef]

- Han, S.; Sang, S.; Duan, P.; Xu, A.; Zhang, J.; Xiang, W. Modified assessment method of CO2 geologic storage capacity in deep coal and its application in the Zhengzhuang Block, Qinshui Basin. J. China Univ. Min. Technol. 2023, 52, 772–788. [Google Scholar]

- Lu, X.; Zhang, Y.; Zhou, Q.; Wang, X.; Lu, X.; Han, Y. Characteristics of In-situ Stress Field in Zhengzhuang Block and Its influence on CBM Development. China CBM 2019, 16, 14–18. [Google Scholar]

- Yao, Y.; Wang, H.; Yang, Y.; Liu, D.; Lu, X.; Cao, L. Evaluation of the hydro-fracturing potential for CBM reservoir: A case study of Zhengzhuang CBM field. Coal Geol. Explor. 2021, 49, 119–129. [Google Scholar]

- Qiu, F.; Liu, J.; Cai, Y.; Liu, D.; Sun, F. Mechanical property evaluation of coal bed and favorable area prediction of coalbedmethane (CBM) development based on well logging: A case study of No. 3 coal bed in Zhengzhuang Block, southern Qinshui Basin. Coal Geol. Explor. 2023, 51, 46–56. [Google Scholar]

- Xie, N.; Yao, Y.; Yang, Y.; Chen, Y. Fracturing effect factors analysis of CBM appraisal wells in Zhengzhuang Block. Coal Sci. Technol. 2016, 44 (Suppl. S1), 180–185. [Google Scholar]

- Li, C.; Yang, Z.; Chen, J.; Sun, H. Prediction of Critical Desorption Pressure of Coalbed Methane in Multi-coal Seams Reservoir of Medium and High Coal Rank: A Case Study of Eastern Yunnan and Western Guizhou, China. Nat. Resour. Res. 2022, 31, 1443–1461. [Google Scholar] [CrossRef]

- Li, Q.; Shen, J.; Hu, H.; Ji, X. Research on the Control of CBM Well Reservoir Geological Engineering Characteristics on Productivity. Geol. J. China Univ. 2023, 29, 644–656. [Google Scholar]

- Liu, J.; Zhu, G.; Liu, Y.; Chao, W.; Du, J.; Yang, Q.; Mi, H.; Zhang, S. Breakthrough, future challenges and countermeasures of deep CBM in the eastern margin of Ordos Basin:a case study of Linxing-Shenfu block. Acta Pet. Sin. 2023, 44, 1827–1839. [Google Scholar]

- Zhang, S.; Peng, X. Calculation method of critical desorption pressure in undersaturated CBM reservoirs. Pet. Reserv. Eval. Dev. 2022, 12, 589–595. [Google Scholar]

- Tang, D.; Zhao, J.; Xu, H.; Li, Z.; Tao, S.; Li, S. Material and energy dynamic balance mechanism in middle-high rank CBM systems. J. China Coal Soc. 2016, 41, 40–48. [Google Scholar]

- Wang, H.; Wang, Q.; Huang, L.; Wang, C.; Cui, W. Intelligent decision-making system for integrated geological and engineering of deep coalbed methane development. Energy Fuels 2023, 37, 13976–13984. [Google Scholar] [CrossRef]

- Shen, J.; Qin, Y.; Li, Y.; Yang, Y.; Ju, W.; Yang, C.; Wang, G. In situ stress field in the FZ Block of Qinshui Basin, China: Implications for the permeability and coalbed methane production. J. Pet. Sci. Eng. 2018, 170, 744–754. [Google Scholar] [CrossRef]

- Pan, J.; He, H.; Li, G.; Wang, X.; Hou, Q.; Liu, L.; Cheng, N. Anisotropic strain of anthracite induced by different phase CO2 injection and its effect on permeability. Energy 2023, 284, 128619. [Google Scholar] [CrossRef]

- Meng, F.; Wong, L.; Zhou, H. Rock brittleness indices and their applications to different fields of rock engineering: A review. J. Rock Mech. Geotech. Eng. 2021, 13, 221–247. [Google Scholar] [CrossRef]

- Liao, S.; Hu, J.; Zhang, Y. Investigation on the influence of multiple fracture interference on hydraulic fracture propagation in tight reservoirs. J. Pet. Sci. Eng. 2022, 211, 110160. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, K.; Zhou, S.; Tang, S.; Zhang, S.; Yan, X. Yi Y., Dang F., Zhu W. lnfluence of geological factors on hydraulic fracturing effect of CBM wells in Shizhuangnan Block, Qinshui Basin in Shizhuangnan Block, Qinshui Basin. J. China Coal Soc. 2020, 45, 2636–2645. [Google Scholar]

- Su, X.; Wang, Q.; Yu, S.; Zhao, W.; Wang, X.; Bi, C.; Chen, M.; Wang, Y.; Sun, C.; Fu, H.; et al. Integrated development technology path for deep coal measure gas based on low-negative carbon emission reduction. Acta Pet. Sin. 2023, 44, 1931–1948. [Google Scholar]

- Ni, X.; Ao, X.; Liang, X.; Ai, L.; Xu, G.; Liu, D. Quantitative ldentification of Coal Structure Based on Schlumberger Ratio and Crack Index. Saf. Coal Mines 2017, 48, 144–146. [Google Scholar]

- Song, M.; Liu, Z.; Zhang, X.; Wang, Y.; Li, J.; Yang, F. Fractability evaluation of tight sandstone reservoirs based on improved entropy analytic hierarchy process: Taking the Jurassic reservoirs of Well Z109 in the Junggar Basin as an example. J. Geomech. 2019, 25, 509–517. [Google Scholar]

- Zhang, C.; Li, M.; Hu, Q.; Jia, H.; Li, K.; Wang, Q.; Yang, R. Moderately deep coalbed methane reservoirs in the southern Qinshui Basin: Characteristics and technical strategies for exploitation. Coal Geol. Explor. 2024, 52, 122–133. [Google Scholar]

- Wang, K.; Tang, S.; Zhang, S.; Yang, N.; Xi, Z.; Zhang, Q.; Wang, J. Discussion on the causes of abnormally high-water production of CBM wells under the control of structural conditions and hydraulic fracturing. J. China Coal Soc. 2021, 46 (Suppl. S2), 849–861. [Google Scholar]

| Item | Information Entropy Value | Information Utility Value | Weight (%) | Item | Information Entropy Value | Information Utility Value | Weight (%) |

|---|---|---|---|---|---|---|---|

| Permeability | 0.932 | 0.068 | 15 | Critical desorption pressure | 0.922 | 0.078 | 17.247 |

| Young’s modulus | 0.956 | 0.044 | 9.754 | Fracture index | 0.992 | 0.008 | 1.854 |

| Schlumberger ratio | 0.936 | 0.064 | 14.25 | Poisson ratio | 0.978 | 0.022 | 4.866 |

| Coal seam thickness | 0.993 | 0.007 | 1.542 | Diversity factor | 0.962 | 0.038 | 8.486 |

| Minimum principal stress | 0.966 | 0.034 | 7.535 | Fault fractal dimension | 0.94 | 0.06 | 13.215 |

| Gas content | 0.972 | 0.028 | 6.251 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Hu, Q.; Liu, C.; Jia, H.; Sang, G.; Wu, D.; Li, K.; Wang, Q. The Gas Production Characteristics of No. 3 Coal Seam Coalbed Methane Well in the Zhengbei Block and the Optimization of Favorable Development Areas. Processes 2024, 12, 2018. https://doi.org/10.3390/pr12092018

Zhang C, Hu Q, Liu C, Jia H, Sang G, Wu D, Li K, Wang Q. The Gas Production Characteristics of No. 3 Coal Seam Coalbed Methane Well in the Zhengbei Block and the Optimization of Favorable Development Areas. Processes. 2024; 12(9):2018. https://doi.org/10.3390/pr12092018

Chicago/Turabian StyleZhang, Cong, Qiujia Hu, Chunchun Liu, Huimin Jia, Guangjie Sang, Dingquan Wu, Kexin Li, and Qian Wang. 2024. "The Gas Production Characteristics of No. 3 Coal Seam Coalbed Methane Well in the Zhengbei Block and the Optimization of Favorable Development Areas" Processes 12, no. 9: 2018. https://doi.org/10.3390/pr12092018

APA StyleZhang, C., Hu, Q., Liu, C., Jia, H., Sang, G., Wu, D., Li, K., & Wang, Q. (2024). The Gas Production Characteristics of No. 3 Coal Seam Coalbed Methane Well in the Zhengbei Block and the Optimization of Favorable Development Areas. Processes, 12(9), 2018. https://doi.org/10.3390/pr12092018