The Influence of Parabolic Static Mixers on the Mixing Performance of Heavy Oil Dilution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Description of the Equipment

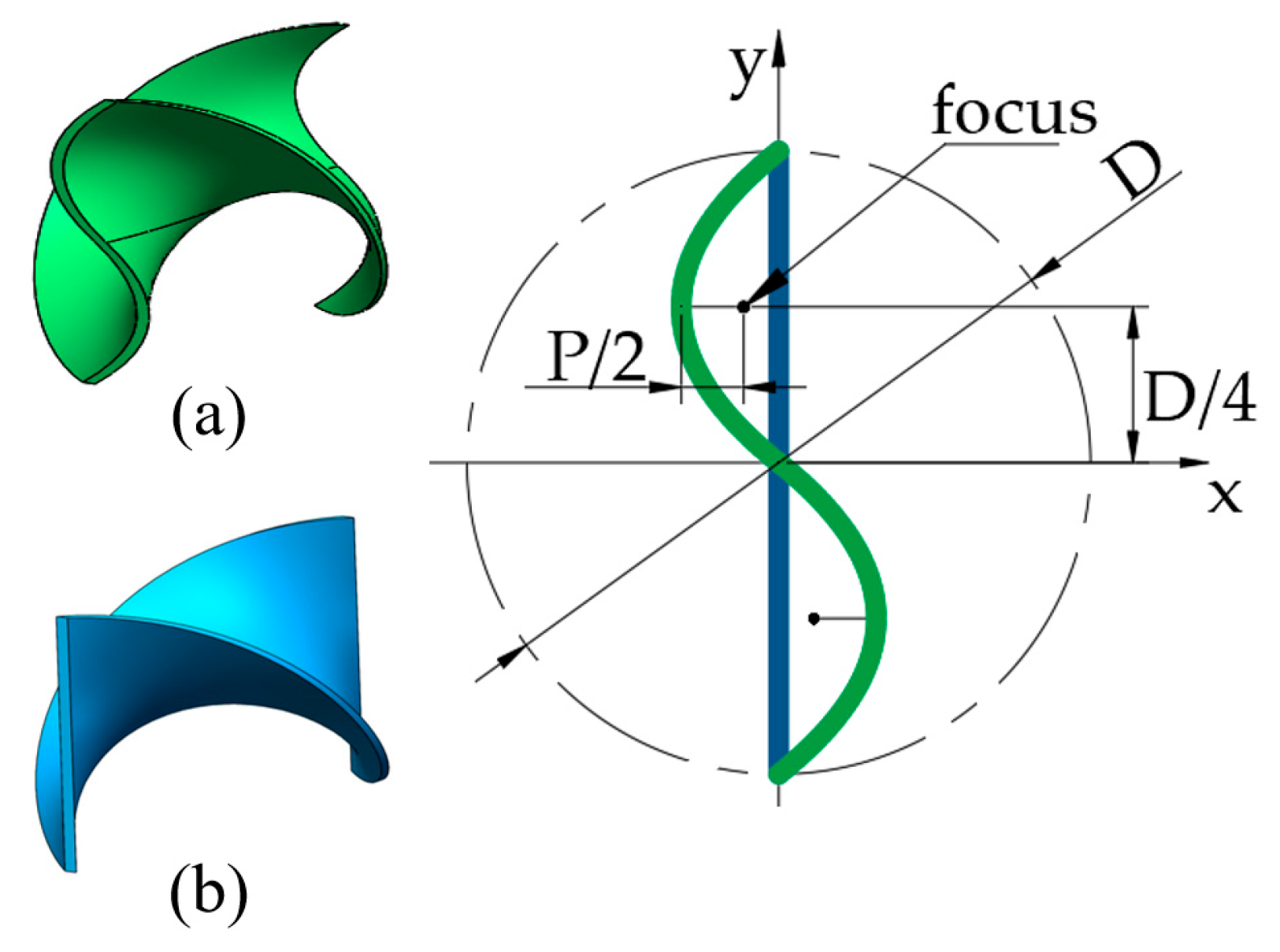

2.1.1. Design of the Parabolic Mixing Blade

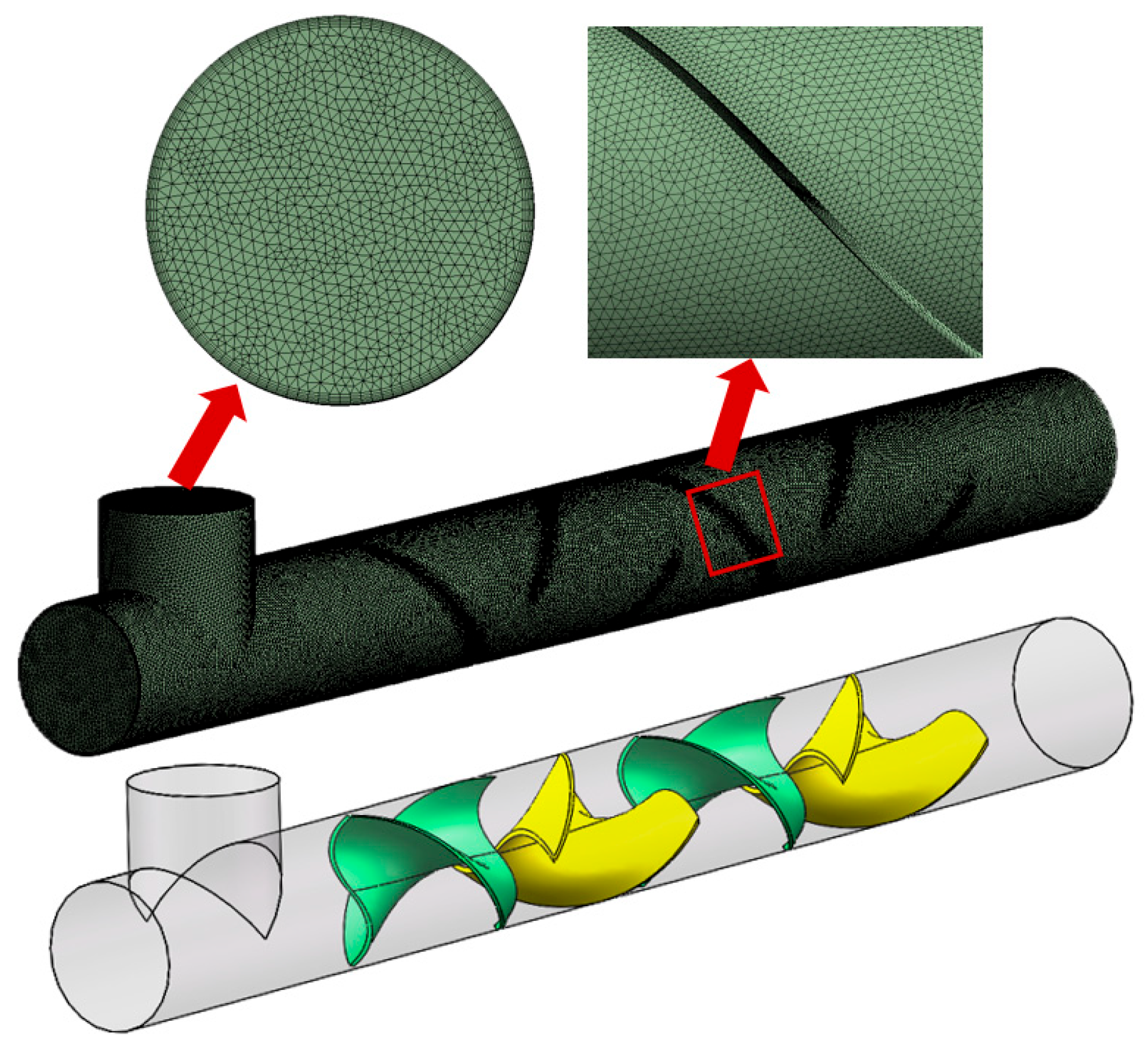

2.1.2. Geometric Model of Static Mixer

2.2. Evaluation Index

2.2.1. Mixing Effect

2.2.2. Pressure Drop

2.3. Numerical Simulation

2.3.1. Continuity Equation and Momentum Equation

2.3.2. Turbulence Model

2.3.3. Boundary Conditions and Solving Methods

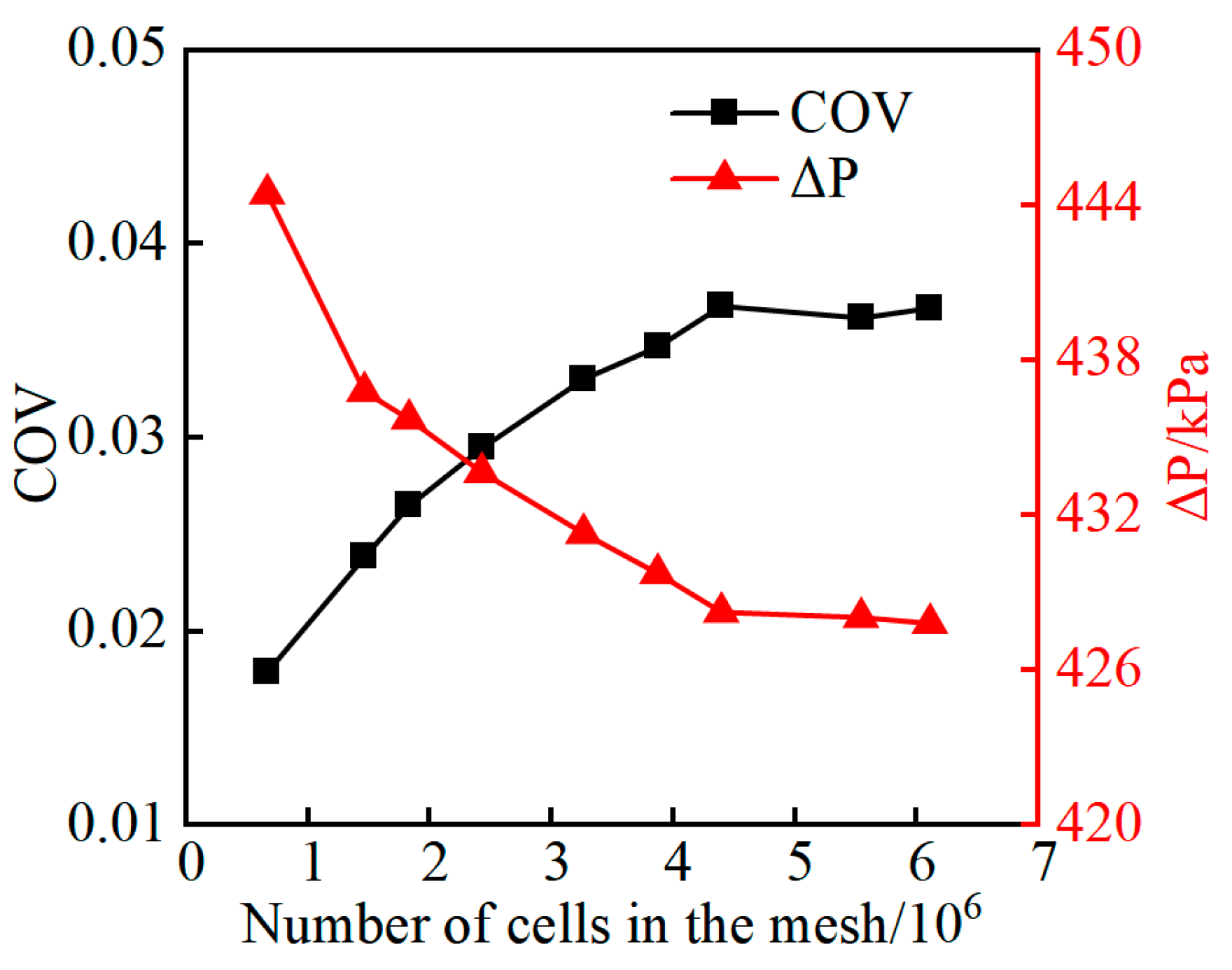

2.3.4. Mesh Independence Verification

2.3.5. Model Verification

3. Results and Discussion

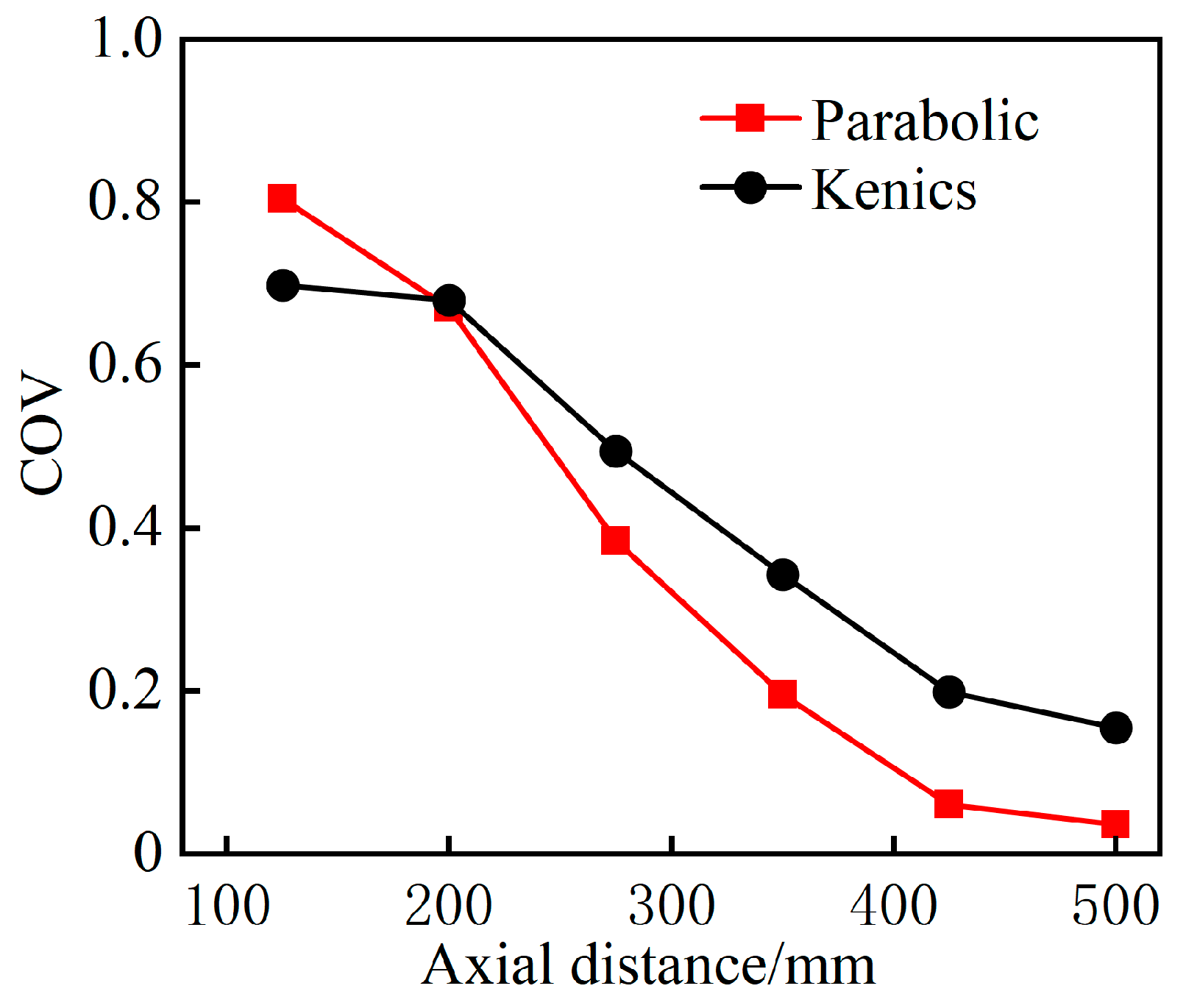

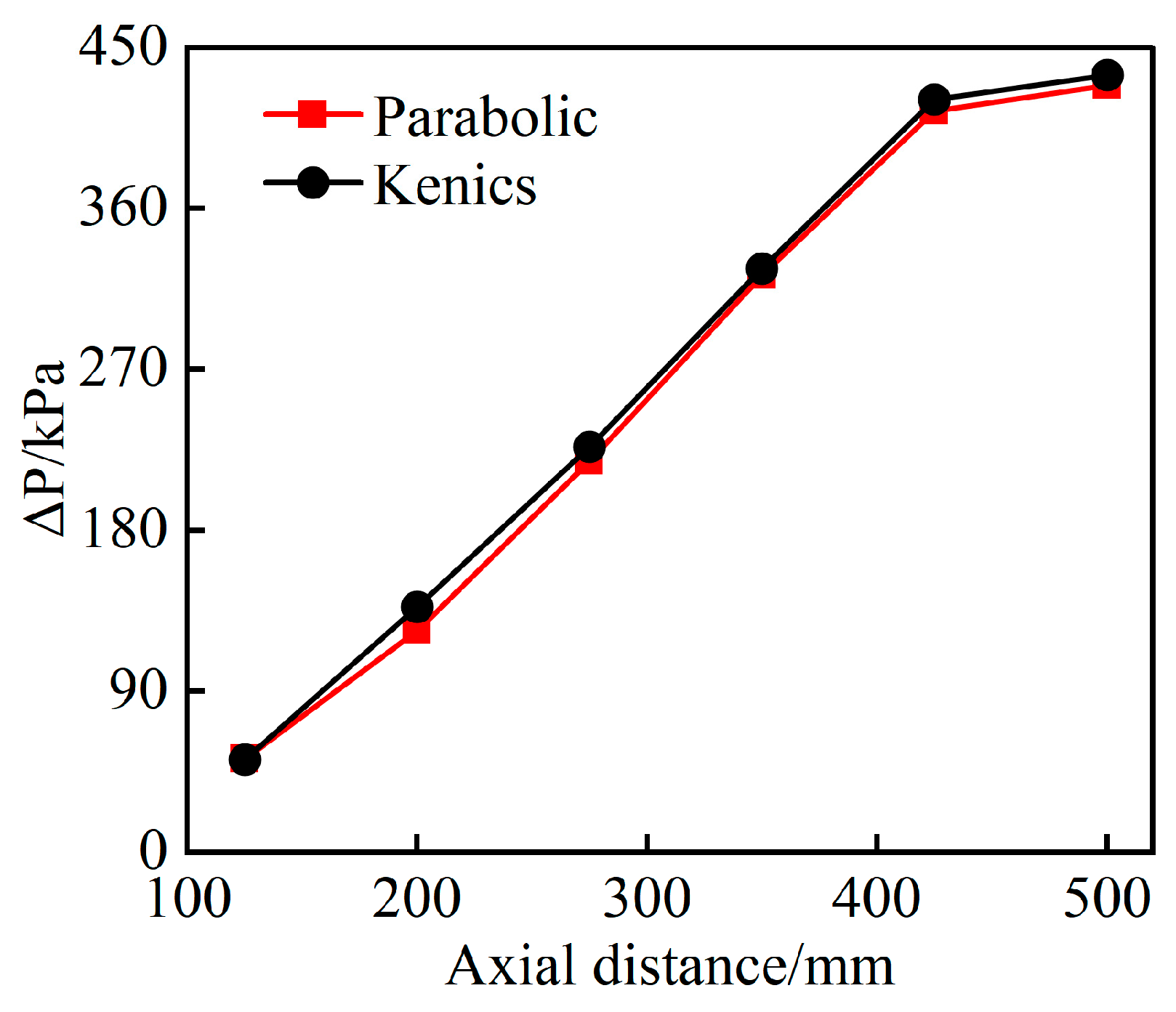

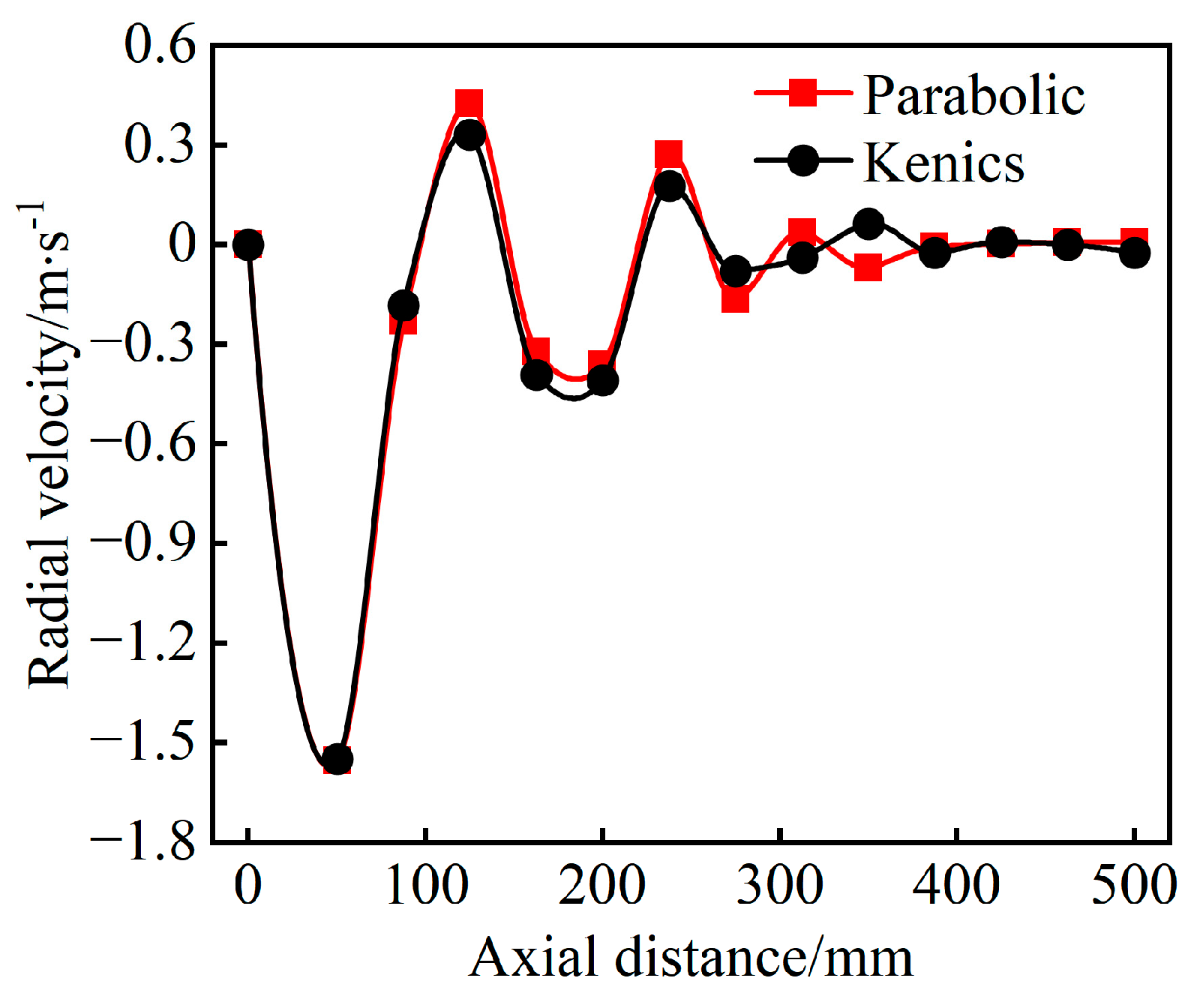

3.1. Comparison of Mixing Performance of Static Mixers

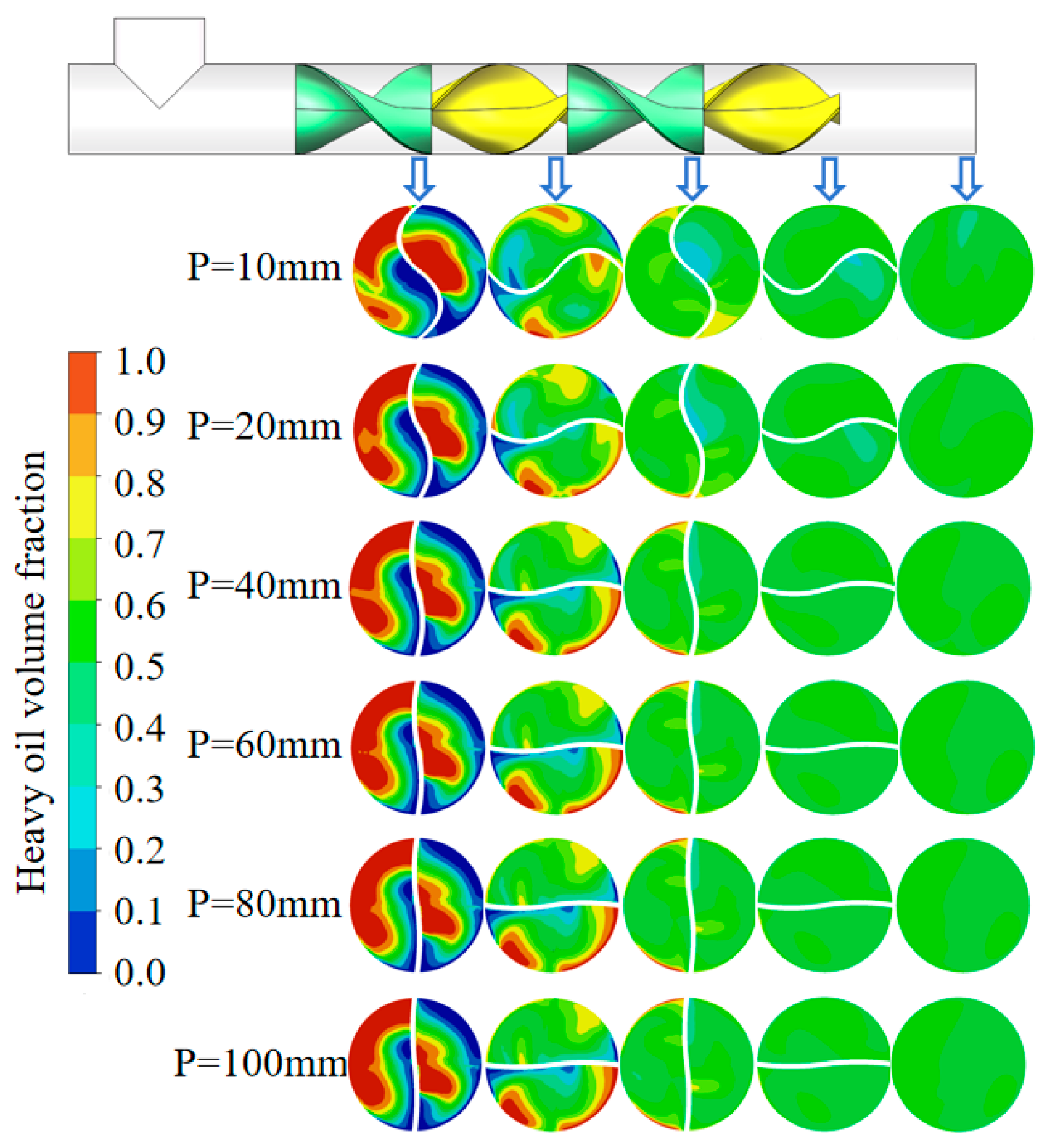

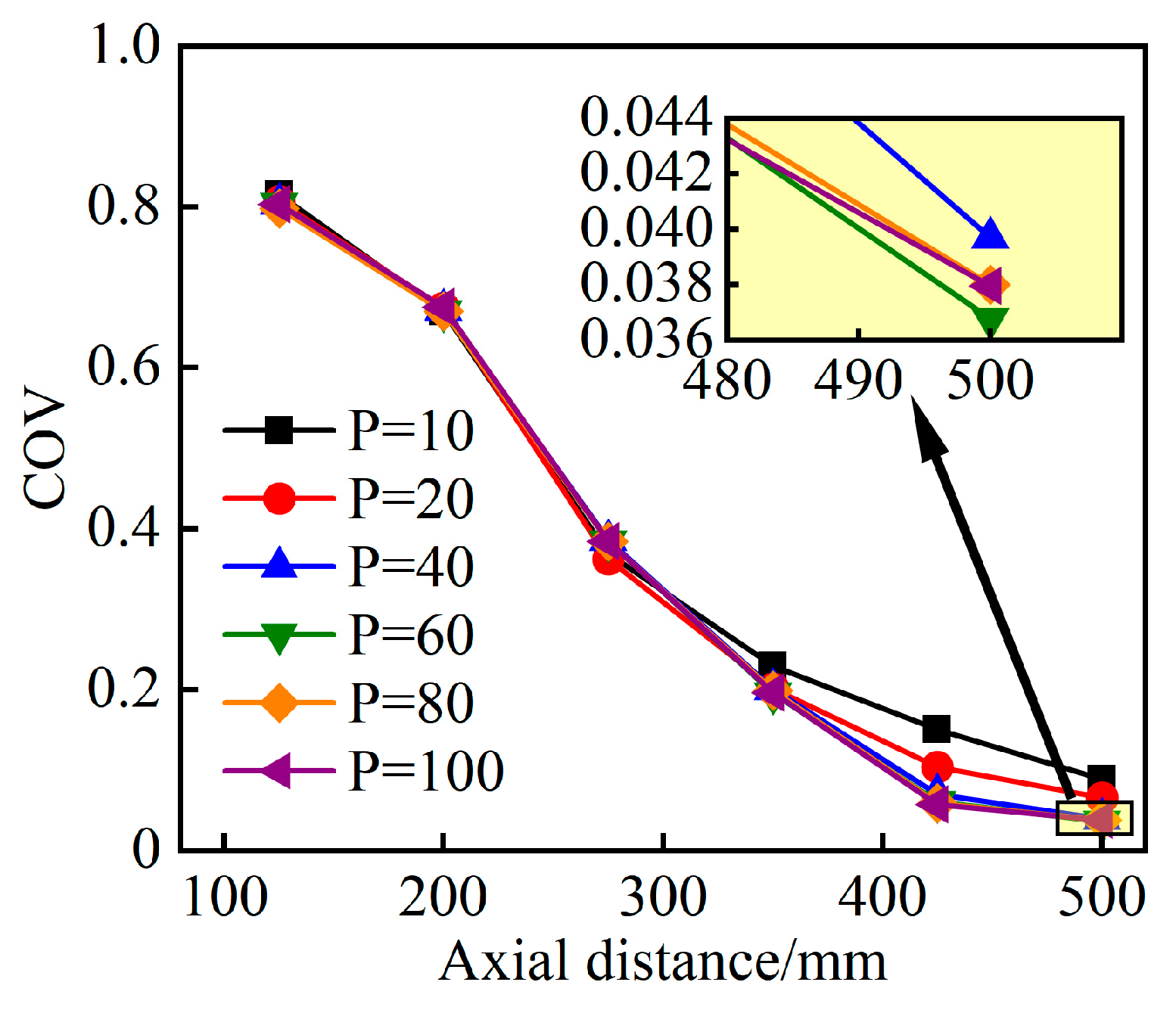

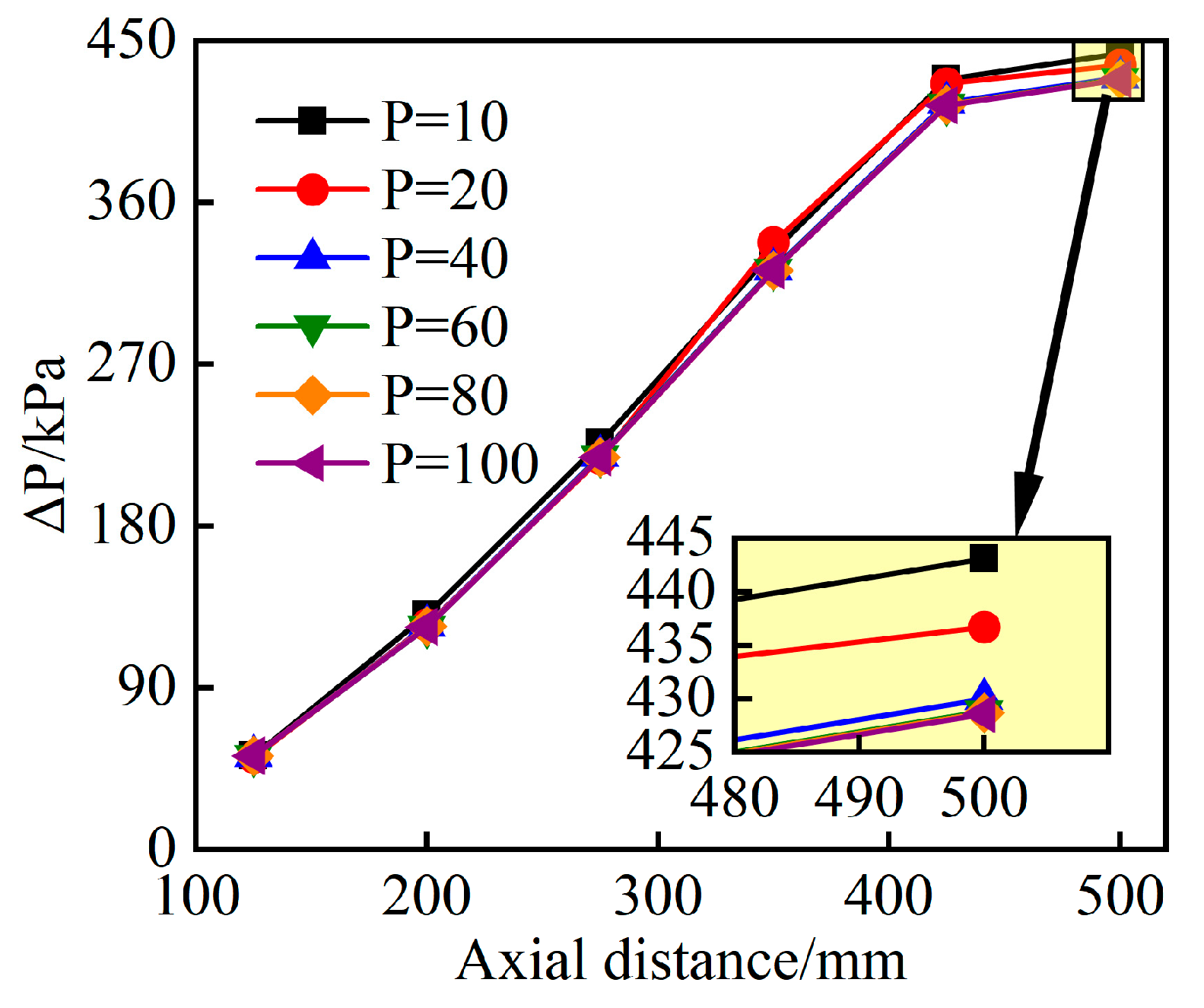

3.2. Influence of Focal Length P on Mixing Performance

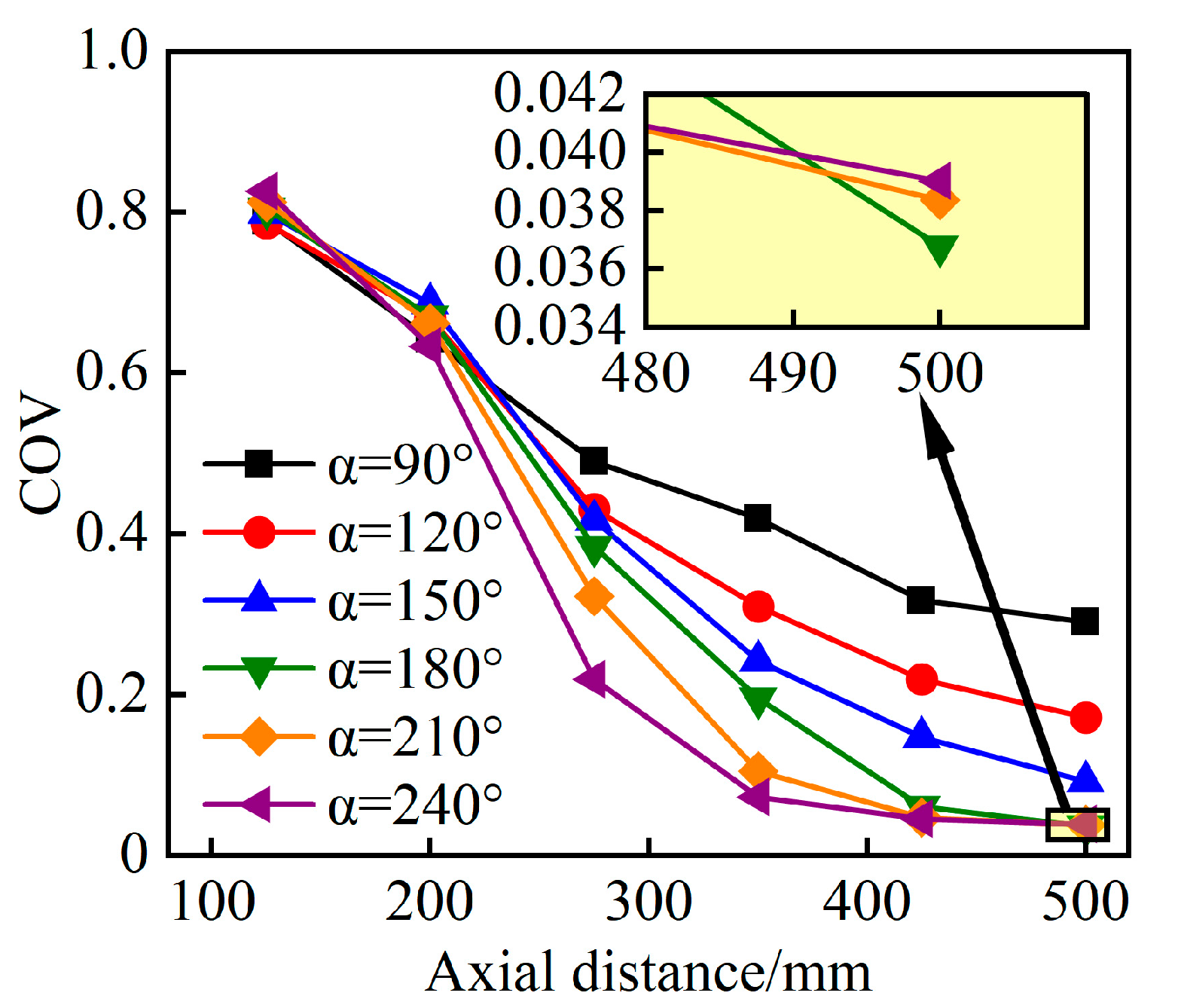

3.3. Influence of Torsion Angle α on Mixing Performance

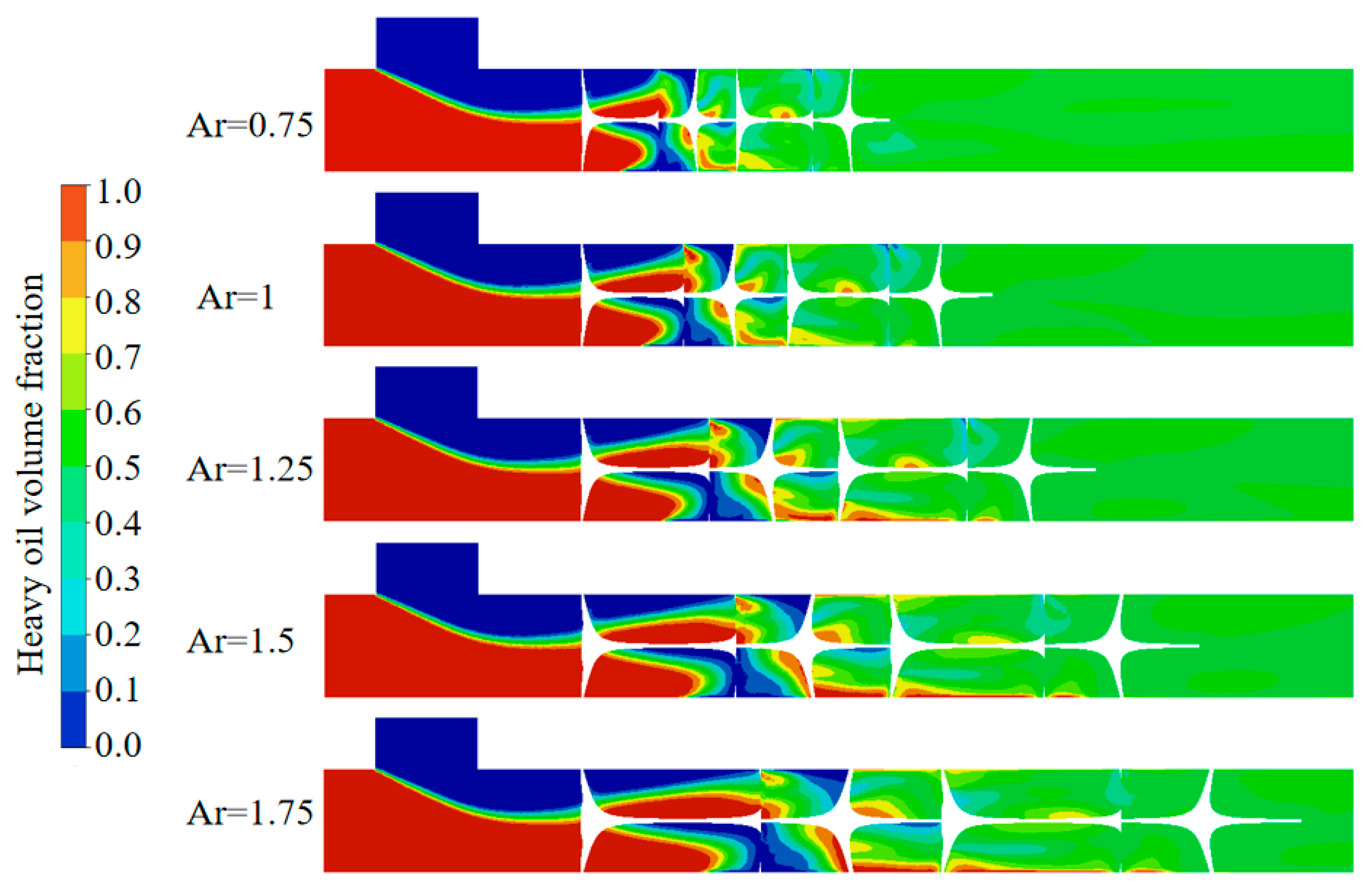

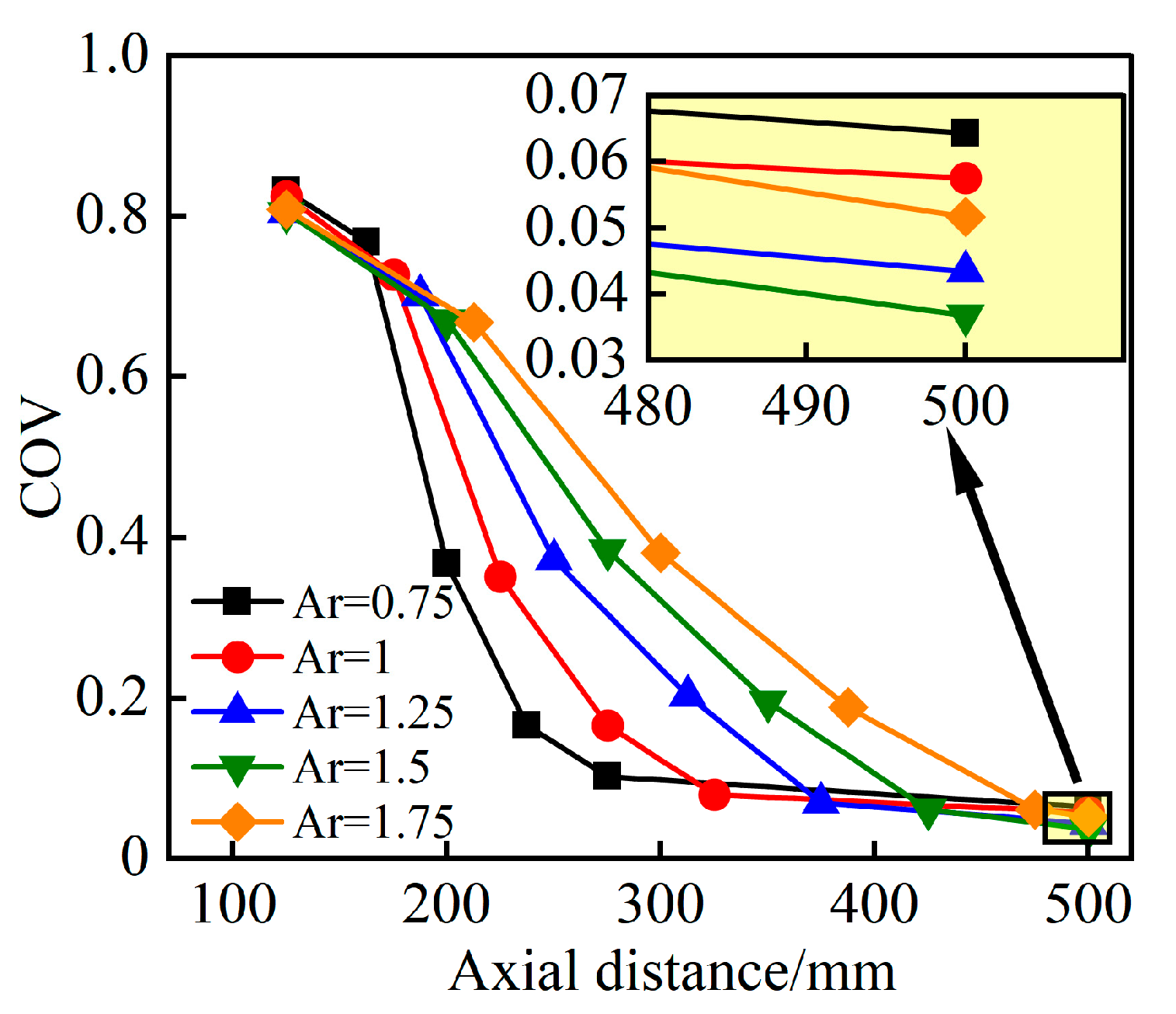

3.4. Influence of Length-to-Diameter Ratio Ar on Mixing Performance

4. Conclusions

- Comparative analysis reveals that the mixing performance of the parabolic static mixer is significantly different from that of the traditional Kenics static mixer. The parabolic blade considerably improves radial velocity fluctuations and enhances turbulent kinetic energy, thereby promoting both radial and axial mixing of heavy oil and light oil. Consequently, the coefficient of concentration variance (COV) of the parabolic static mixer can be reduced to 0.036. This results in nearly complete mixing of heavy oil and light oil, while the pressure drop (∆P) is also slightly reduced.

- As P increases, the path resistance correspondingly decreases, leading to a reduction in the pressure drop (∆P) and thereby enhancing the mixing effect of the parabolic static mixer. However, when P is excessively high, the curvature of the parabola decreases, which weakens the swirling effect of the mixed fluid. The parameter P has little influence on the ΔP of the parabolic static mixer, so the COV is used as the main evaluation index. Considering all factors, the parabolic static mixer with P = 60 mm exhibits the best mixing performance.

- As α increases, the swirl intensity rises, leading to a decrease in the COV of the parabolic static mixer. However, when α becomes excessively large, the torsion angle of the mixed fluid increases over the same distance, resulting in a rise in ∆P and a decrease in axial velocity, thereby weakening the mixing performance at the outlet of the mixer. In order to ensure good mixing effect and a minimum pressure drop, comprehensive analysis shows that the parabolic static mixer with α = 180° has the best mixing performance.

- Different Ar values significantly influence the mixing process of parabolic static mixers. The smaller Ar is, the faster the COV decreases, resulting in a shorter axial distance to reach a stable state. However, excessively small Ar values can cause a sharp increase in ∆P over a short distance due to blade swirl and shear action, significantly increasing energy consumption and adversely affecting the mixing performance. Considering all factors, the parabolic static mixer with Ar = 1.5 exhibits the best mixing performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gateau, P.; Hénaut, I.; Barré, L.; Argillier, J.F. Heavy oil dilution. Oil Gas Sci. Technol. 2004, 59, 503–509. [Google Scholar] [CrossRef]

- Gao, X.D.; Dong, P.C.; Cui, J.W.; Gao, Q.C. Prediction Model for the Viscosity of Heavy Oil Diluted with Light Oil Using Machine Learning Techniques. Energies 2022, 15, 2297. [Google Scholar] [CrossRef]

- Wang, Q.X.; Zhang, W.; Wang, C.; Han, X.D.; Wang, H.Y.; Zhang, H. Microstructure of Heavy Oil Components and Mechanism of Influence on Viscosity of Heavy Oil. ACS Omega 2023, 8, 10980–10990. [Google Scholar] [CrossRef]

- Hasan, S.W.; Ghannam, M.T.; Esmail, N. Heavy crude oil viscosity reduction and rheology for pipeline transportation. Fuel 2010, 89, 1095–1100. [Google Scholar] [CrossRef]

- Martinez-Palou, R.; Mosqueira, M.d.L.; Zapata-Rendon, B.; Mar-Juarez, E.; Bernal-Huicochea, C.; Clavel-Lopez, J.d.l.C.; Aburto, J. Transportation of heavy and extra-heavy crude oil by pipeline: A review. J. Pet. Sci. Eng. 2011, 75, 274–282. [Google Scholar] [CrossRef]

- Thakur, R.K.; Vial, C.; Nigam, K.D.P.; Nauman, E.B.; Djelveh, G. Static mixers in the process industries—A review. Chem. Eng. Res. Des. 2003, 81, 787–826. [Google Scholar] [CrossRef]

- Liu, C.-W.; Wei, H.-B.; Li, Z.-M. Numerical Simulation of the Influence of Swirl Mixer on Effect of Blending Dilute Oil through Oil Tube. Sci. Technol. Eng. 2012, 12, 3848–3851. [Google Scholar] [CrossRef]

- Fei, X. Simulation Study on Flow in Xinjiang Heavy Oil Mixed with Dilute Riser. Master Thesis, Southwest Petroleum University, Chengdu, China, 2014. [Google Scholar]

- Wang, X.; Zhao, C.; Han, W.; Zhou, Y. Numerical Simulation of the Down Hole Static Mixer for Heavy Oil Thin Mixing. J. Chongqing Univ. Sci. Technol. 2015, 17, 50–53+84. [Google Scholar] [CrossRef]

- Li, Q.; Peng, Y.; Huang, Z.; Qiu, C.; Jin, Y.; Wang, N. Numerical Simulation of the Downhole Dynamic Mixer for Heavy Oil Thin Mixing. China Pet. Mach. 2014, 42, 72–76. [Google Scholar] [CrossRef]

- Shi, C.W.; Yang, W.; Chen, J.B.; Sun, X.P.; Chen, W.Y.; An, H.Y.; Duo, Y.L.; Pei, M.Y. Application and mechanism of ultrasonic static mixer in heavy oil viscosity reduction. Ultrason. Sonochem. 2017, 37, 648–653. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, Z.-H.; Gao, D.-X.; Ren, H.-T.; Tang, Y.-X. Design and mixing performance research of core tube heavy oil mixing and diluting mixer. Chin. J. Eng. Des. 2018, 25, 510–517. [Google Scholar] [CrossRef]

- Zheng, L.; Lan, D.; Yang, Z.Y. Research on numerical simulation of the casing pipe blending lightoil for heavy oil dilution wells. Chin. J. Hydrodyn. 2018, 33, 609–617. [Google Scholar] [CrossRef]

- Wan, J.; Lin, R.; Ge, Y.; Dai, B.; Chen, X.; Huang, S.; Wang, L.; Liu, E. Numerical simulation of the effect of kenics type static mixer on the homogenization effect of water-cut crude oil. Chem. Eng. Oil Gas. 2024, 53, 83–89. [Google Scholar]

- Rahimi, M. The effect of impellers layout on mixing time in a large-scale crude oil storage tank. J. Pet. Sci. Eng. 2005, 46, 161–170. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Meng, H. CFD-PBM numerical simulation on the breakup and coalescence process of dispersed phase droplet in Kenics static mixer. Chin. J. Process Eng. 2021, 21, 935–943. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, P.; Liu, L. Influence of the Arrangement Angle of the Blade on the Mixing Effect of the Three-Spiral Static Mixer. Plastics 2023, 52, 87–91. [Google Scholar]

- Tang, Y.; Xie, L.; Zhu, S.; Xu, J.; Xiang, S. Effect of perforation on mixing performance of perforated Kenics static mixer. Petrochem. Technol. 2024, 53, 670–677. [Google Scholar] [CrossRef]

- Meng, L.C.; Gao, X.F.; Wang, D.W.; Liu, Y.; Wang, R.J.; Hu, B.S.; Tang, M.; Zhang, S.F. Experimental study on energy consumption characteristics of rotational-perforated static mixers. Can. J. Chem. Eng. J. Chem. Eng. 2023, 101, 6656–6671. [Google Scholar] [CrossRef]

- Deng, M.; Zhou, C.; Zhang, Y.; Ren, H.; Li, H. Research of the Heavy Oil Mixer with Helical-jet Mode. In Proceedings of the 2019 6th International Conference on Machinery, Mechanics, Materials, and Computer Engineering (MMMCE 2019), Hohhot, China, 27–28 July 2019; p. 9. [Google Scholar]

- Chen, H.Y.; Zhang, J.; Ji, Y.; Zhou, J.W.; Hu, W.B. Numerical Simulation of Internal Flow Field in Optimization Model of Gas-Liquid Mixing Device. Processes 2024, 12, 1707. [Google Scholar] [CrossRef]

- Wang, Y.; Han, H.; Liang, Z.; Yang, H.; Li, F.; Zhang, W.; Zhao, Y. Analysis of the Effect of Structural Parameters on the Internal Flow Field of Composite Curved Inlet Body Hydrocyclone. Processes 2024, 12, 2654. [Google Scholar] [CrossRef]

- Liu, Y.H.; Gao, M.M.; Huang, Z.B.; Wang, H.F.; Yuan, P.Q.; Xu, X.R.; Yang, J.Y. Numerical Simulation of the Mixing and Salt Washing Effects of a Static Mixer in an Electric Desalination Process. Processes 2024, 12, 883. [Google Scholar] [CrossRef]

- Chen, G.H.; Liu, Z.L. Numerical Research of Pressure Drop in Kenics Static Mixer. In Proceedings of the 4th International Conference on Manufacturing Science and Engineering (ICMSE 2013), Dalian, China, 30–31 March 2013; pp. 547–550. [Google Scholar]

- Brazhenko, V.; Qiu, Y.B.; Mochalin, I.; Zhu, G.G.; Cai, J.C.; Wang, D.Y. Study of hydraulic oil filtration process from solid admixtures using rotating perforated cylinder. J. Taiwan Inst. Chem. Eng. 2022, 141, 104578. [Google Scholar] [CrossRef]

| Fluid | Density/(kg/m3) | Viscosity/(Pa·s) |

|---|---|---|

| Heavy oil | 950.1 | 4.488 |

| Light oil | 932.5 | 0.08421 |

| Blade Type | COV | ∆P/kPa | Maximum Radial Velocity/m·s−1 | Maximum Turbulent Kinetic Energy/m2·s−2 |

|---|---|---|---|---|

| parabolic | 0.036 | 428.9 | 0.43 | 7.43 |

| Kenics | 0.15 | 434.6 | 0.33 | 7.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hua, J.; Yuan, H.; Deng, W.; Wang, T.; Jeremiah, E.N.; Yu, Z. The Influence of Parabolic Static Mixers on the Mixing Performance of Heavy Oil Dilution. Processes 2025, 13, 1125. https://doi.org/10.3390/pr13041125

Hua J, Yuan H, Deng W, Wang T, Jeremiah EN, Yu Z. The Influence of Parabolic Static Mixers on the Mixing Performance of Heavy Oil Dilution. Processes. 2025; 13(4):1125. https://doi.org/10.3390/pr13041125

Chicago/Turabian StyleHua, Jian, Hong Yuan, Wanquan Deng, Tieqiang Wang, Ebong Nathan Jeremiah, and Zekun Yu. 2025. "The Influence of Parabolic Static Mixers on the Mixing Performance of Heavy Oil Dilution" Processes 13, no. 4: 1125. https://doi.org/10.3390/pr13041125

APA StyleHua, J., Yuan, H., Deng, W., Wang, T., Jeremiah, E. N., & Yu, Z. (2025). The Influence of Parabolic Static Mixers on the Mixing Performance of Heavy Oil Dilution. Processes, 13(4), 1125. https://doi.org/10.3390/pr13041125