A CFD Study of Thermodynamics and Efficiency Metrics in a Hydrogen-Fueled Micro Planar Combustor Housing Dual Heat-Recirculating Cylindrical Combustors for MTPV Applications

Abstract

:1. Introduction

2. Materials and Methods

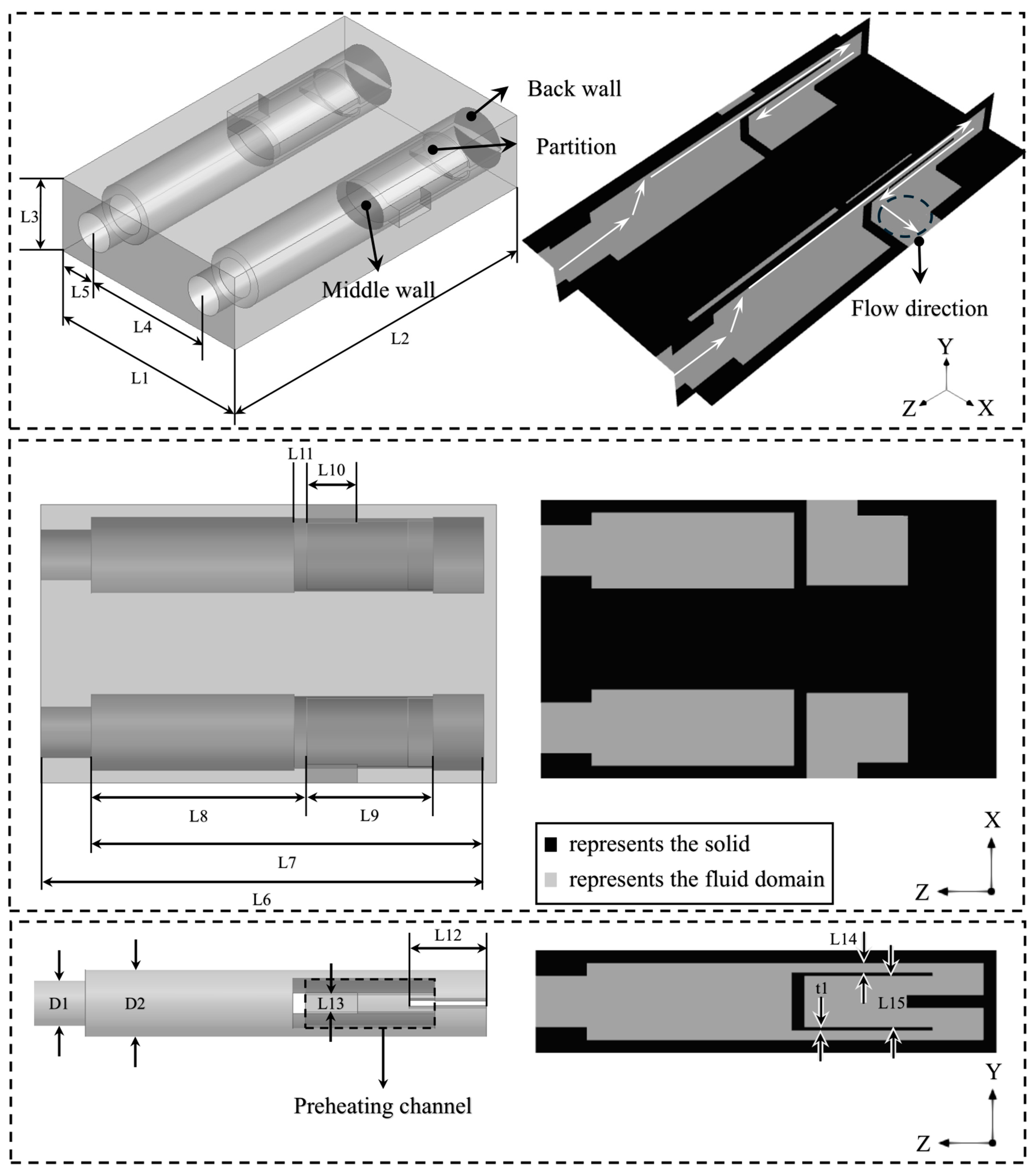

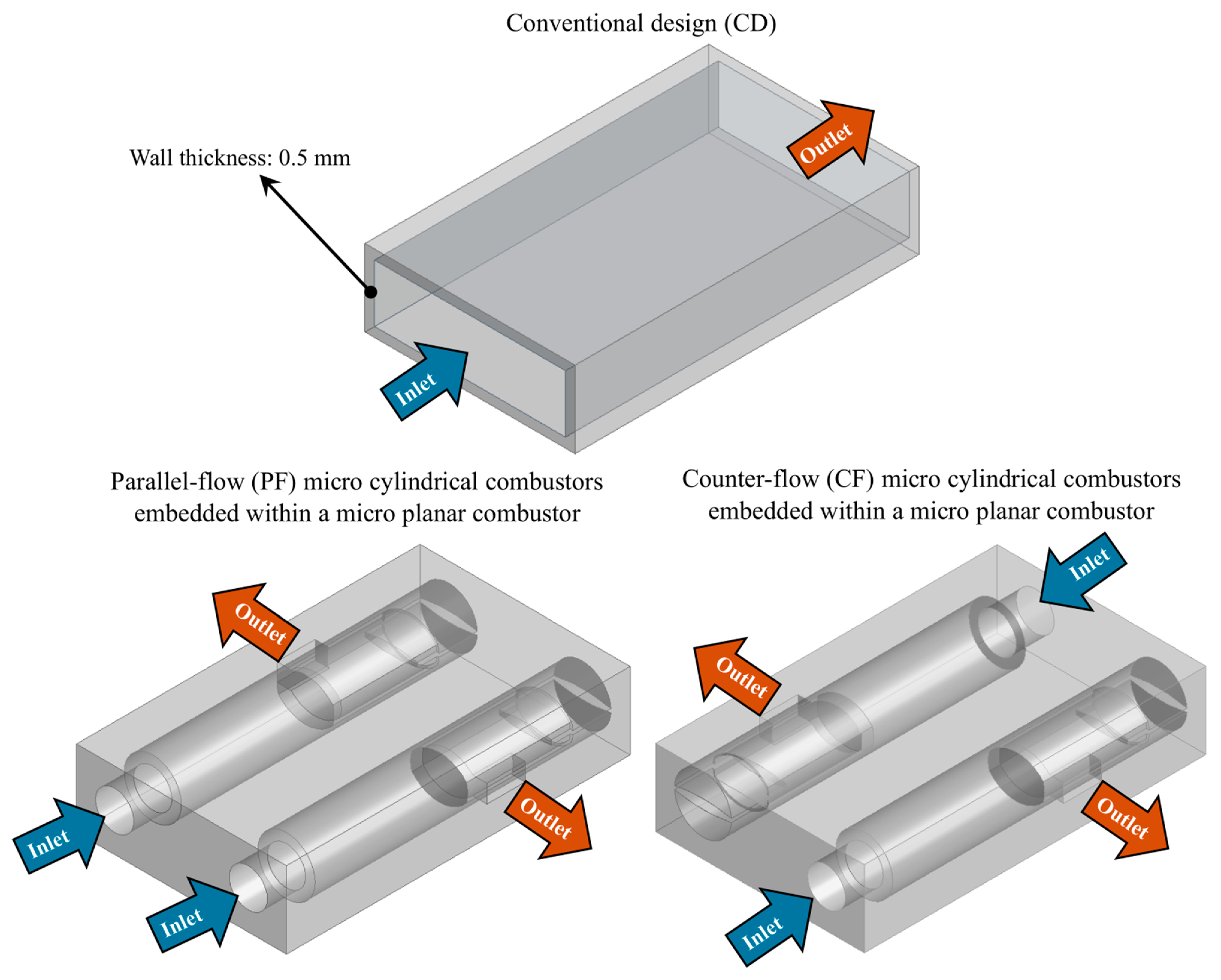

2.1. Geometric Model

2.2. Govering Equations

2.3. Numerical Setup and Boundary Conditions

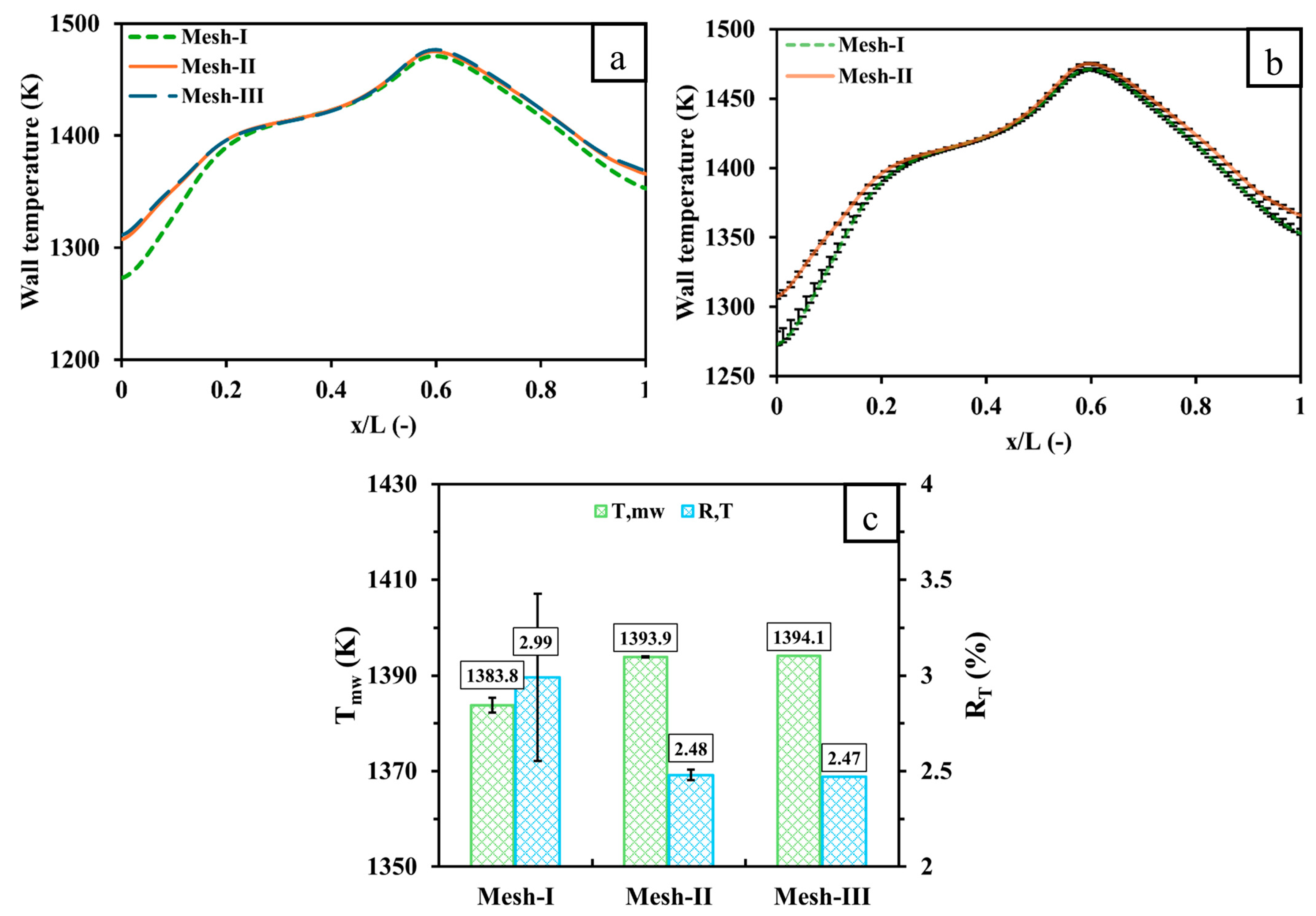

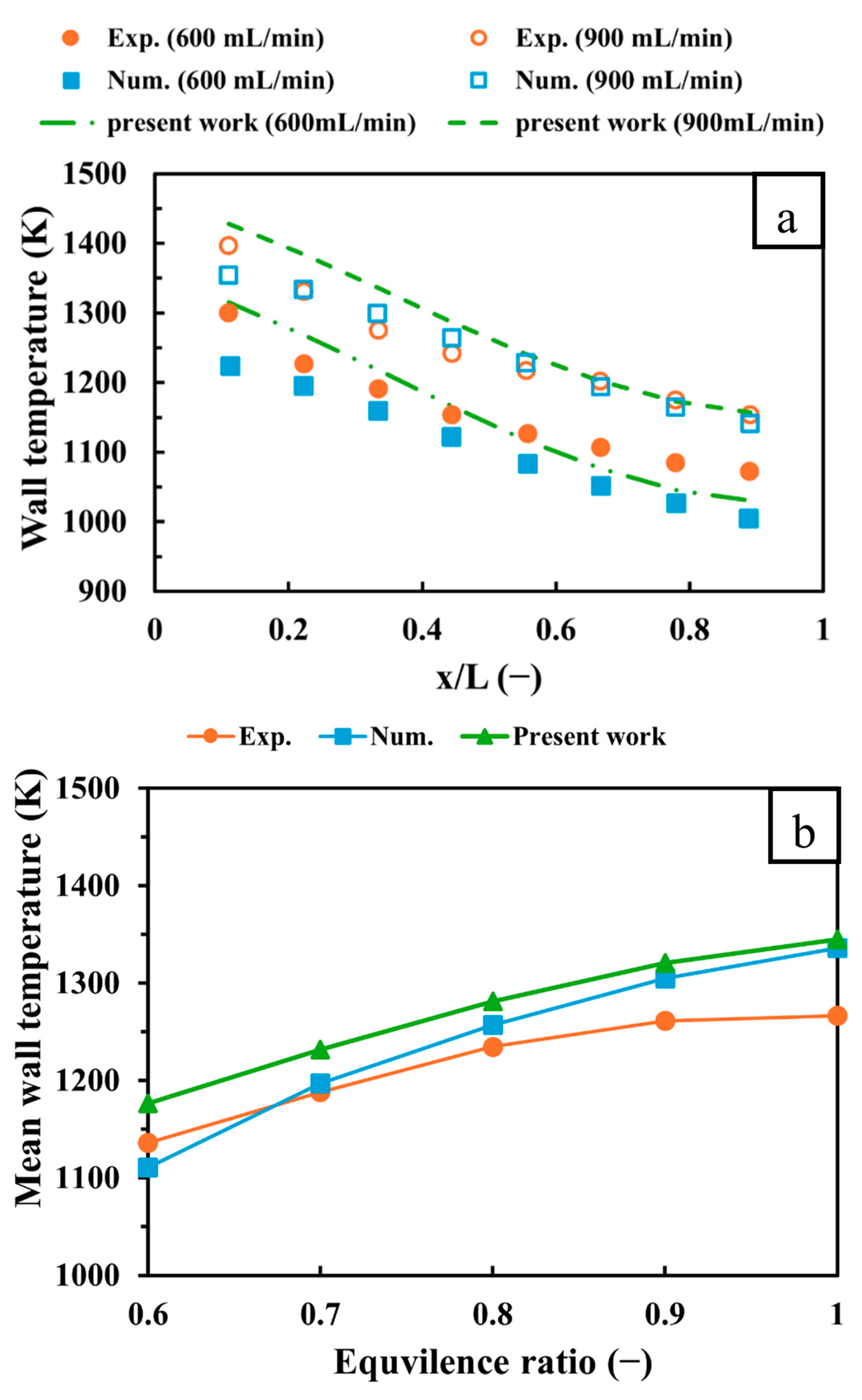

2.4. Grid Independence and Model Validation

3. Results

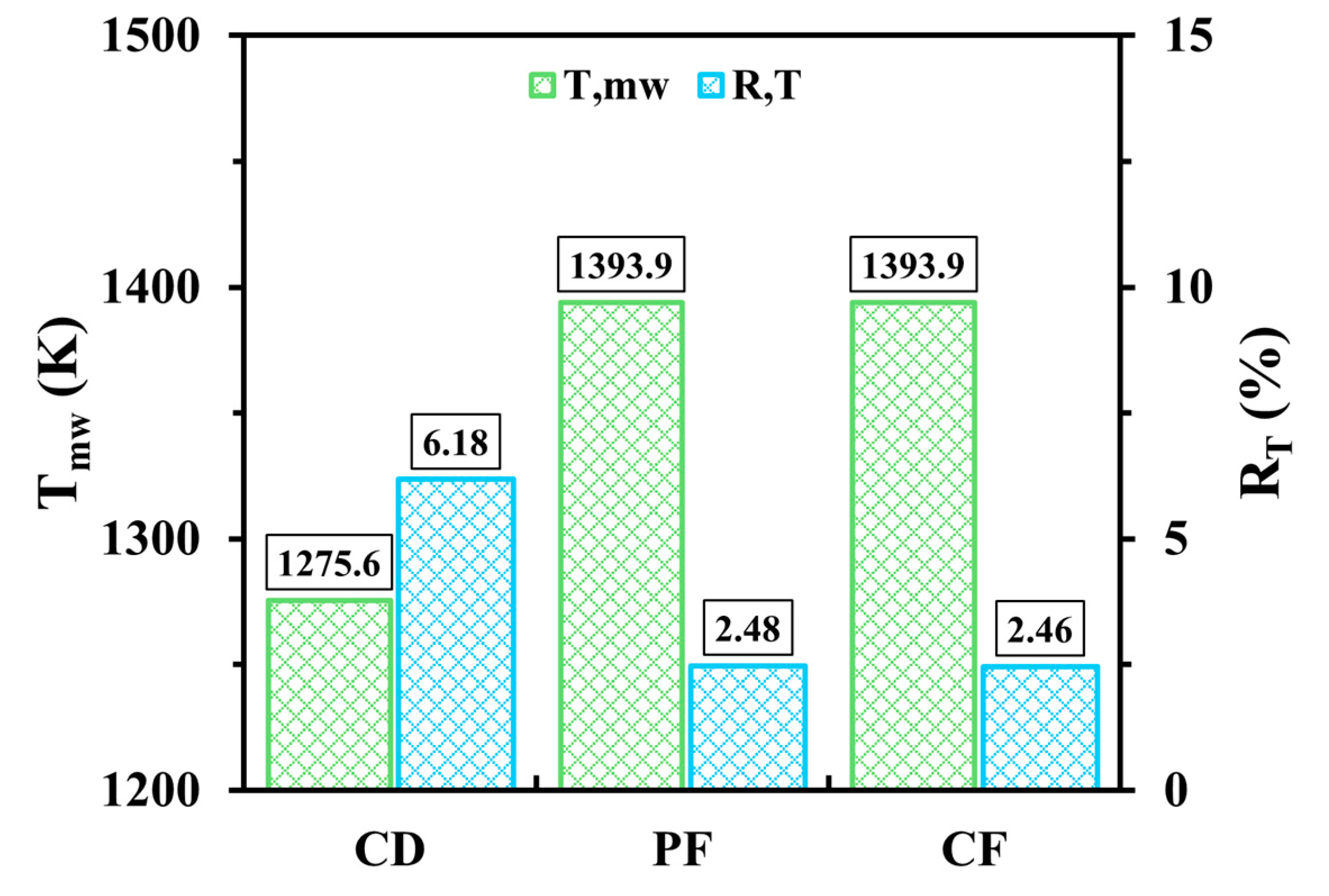

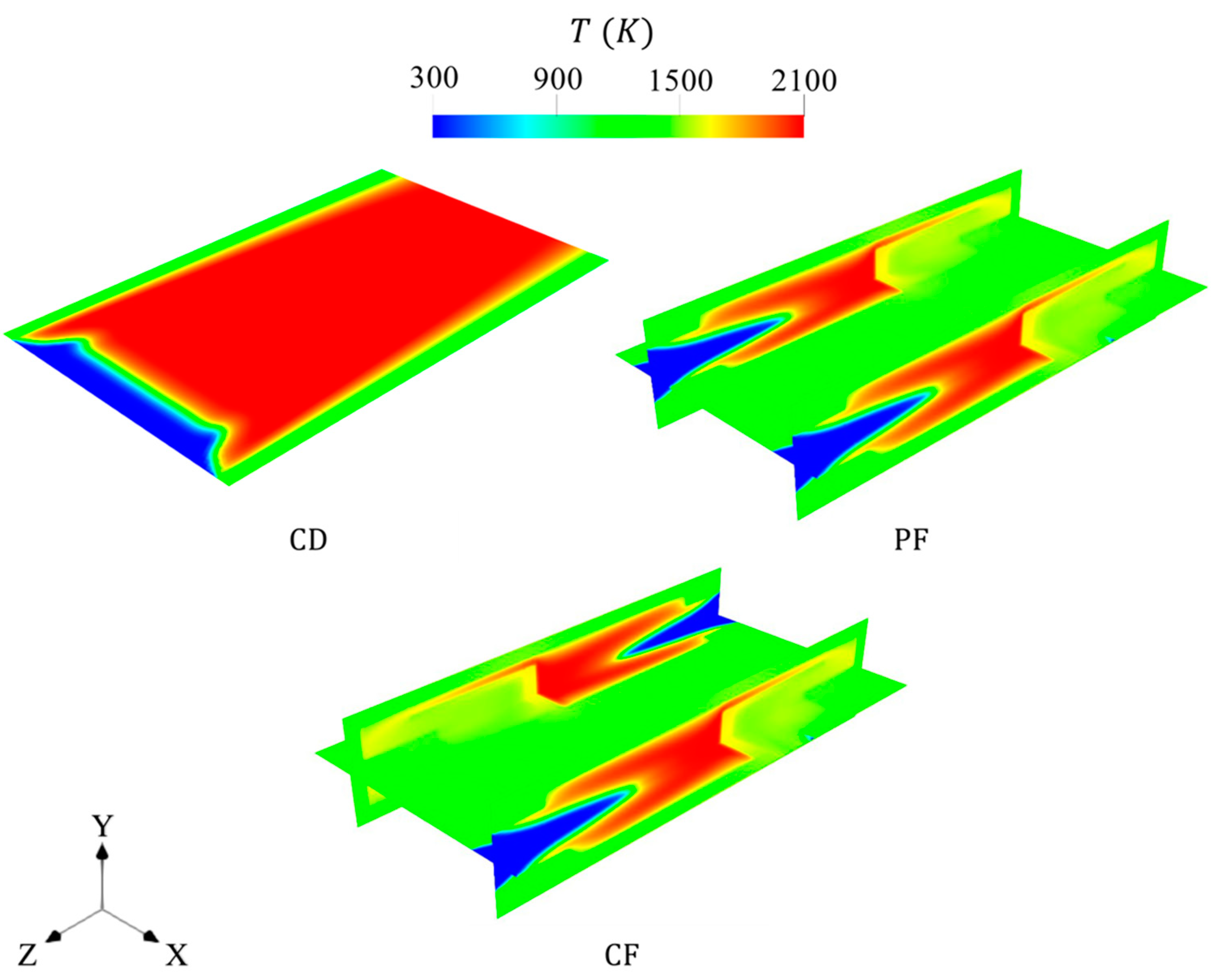

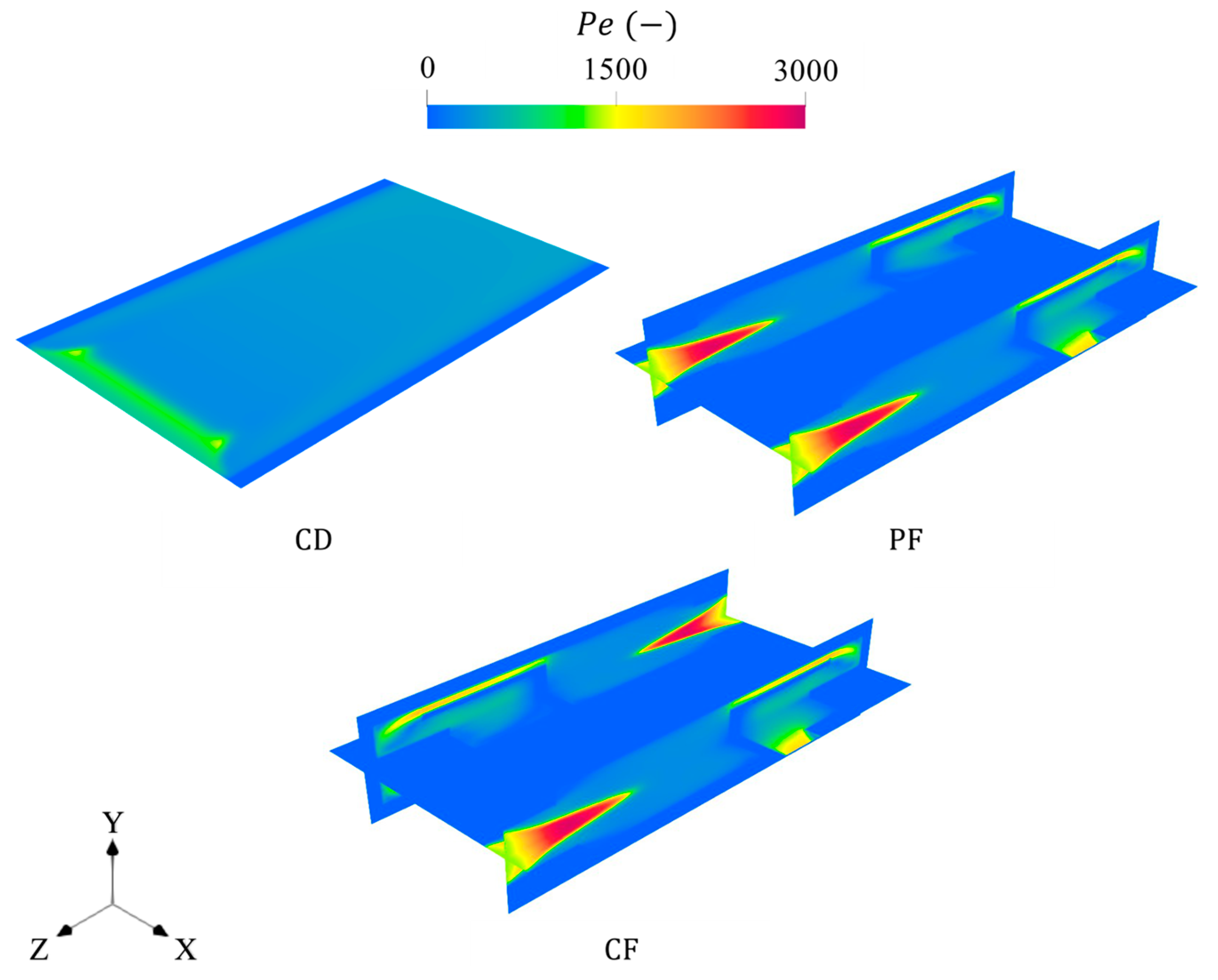

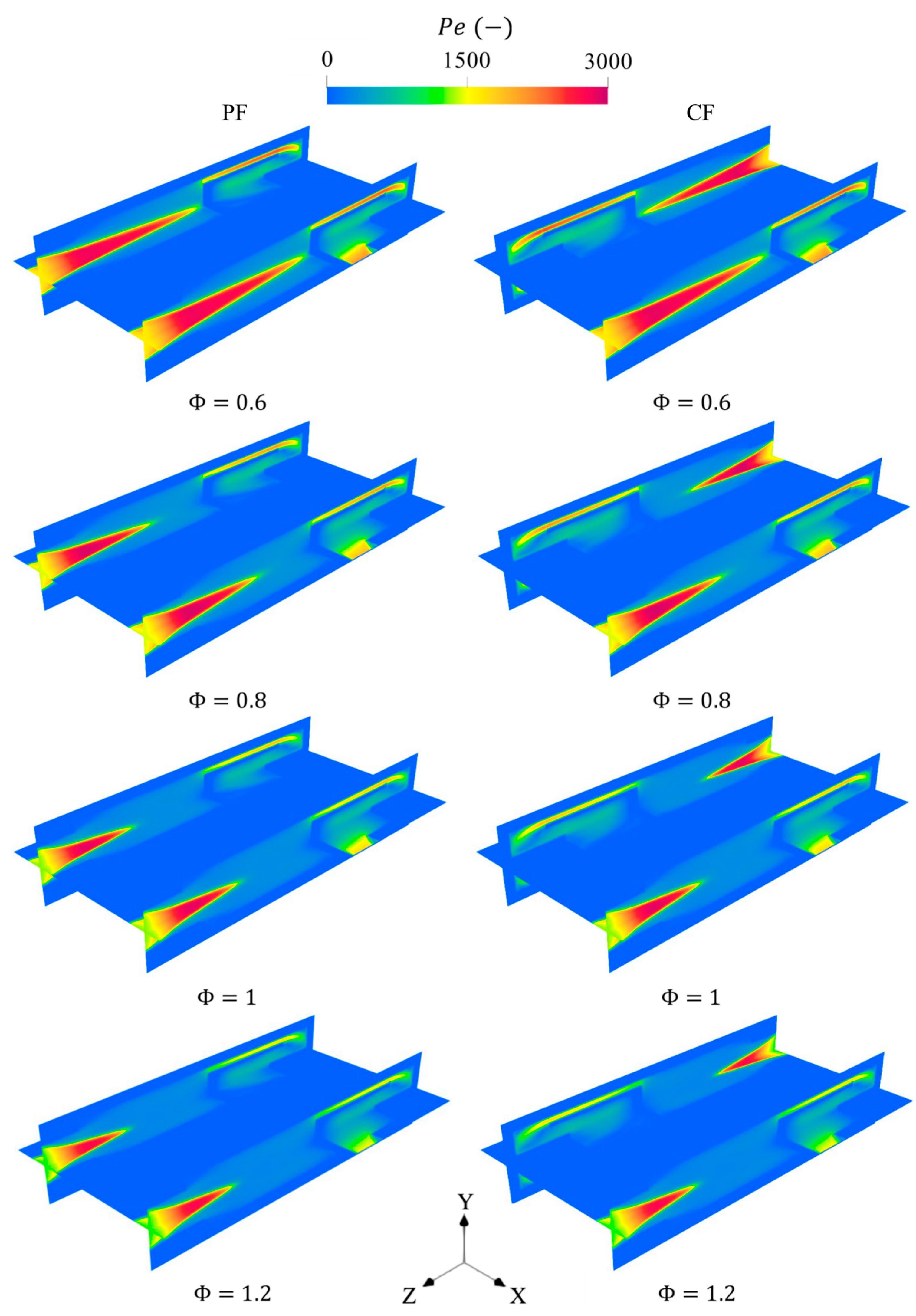

3.1. Effects of Two Micro Cylindrical Combustors Embedded Within a Micro Planar Combustor

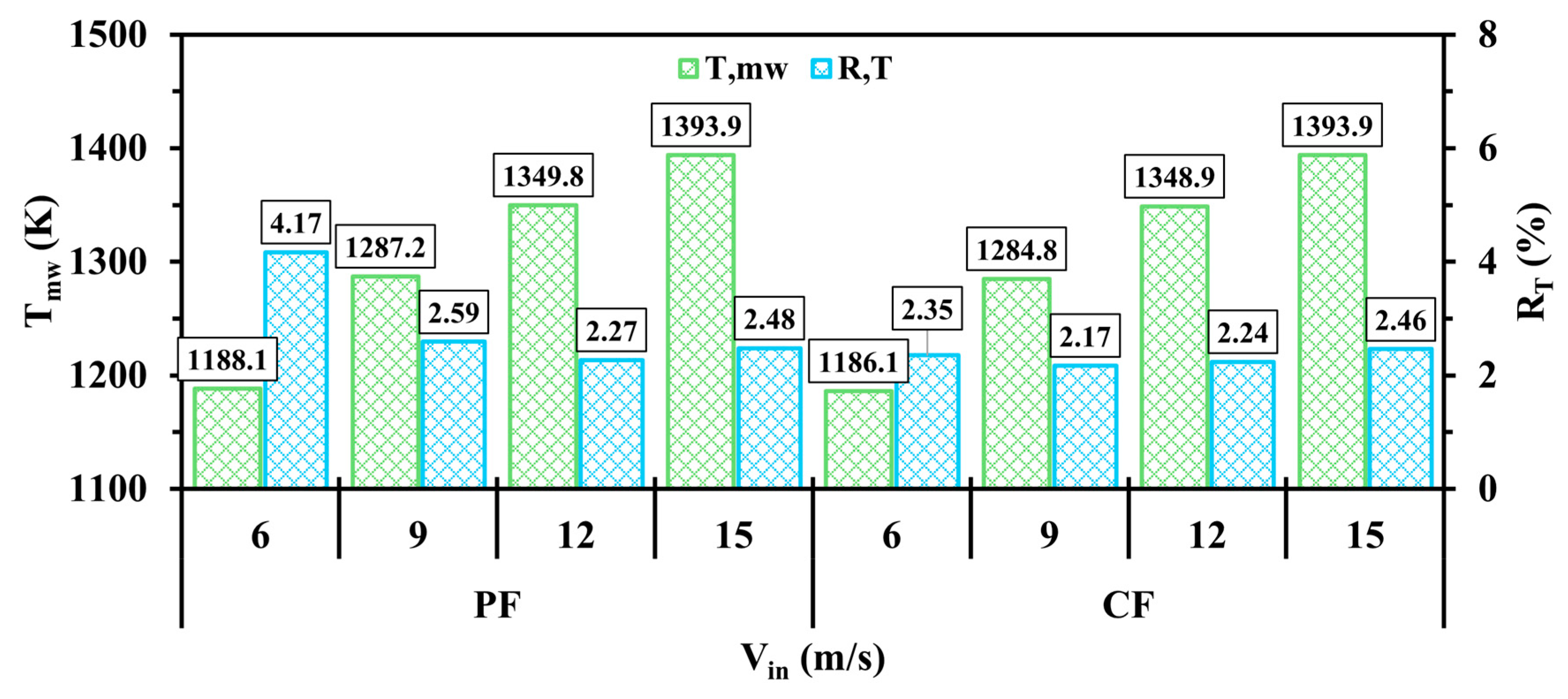

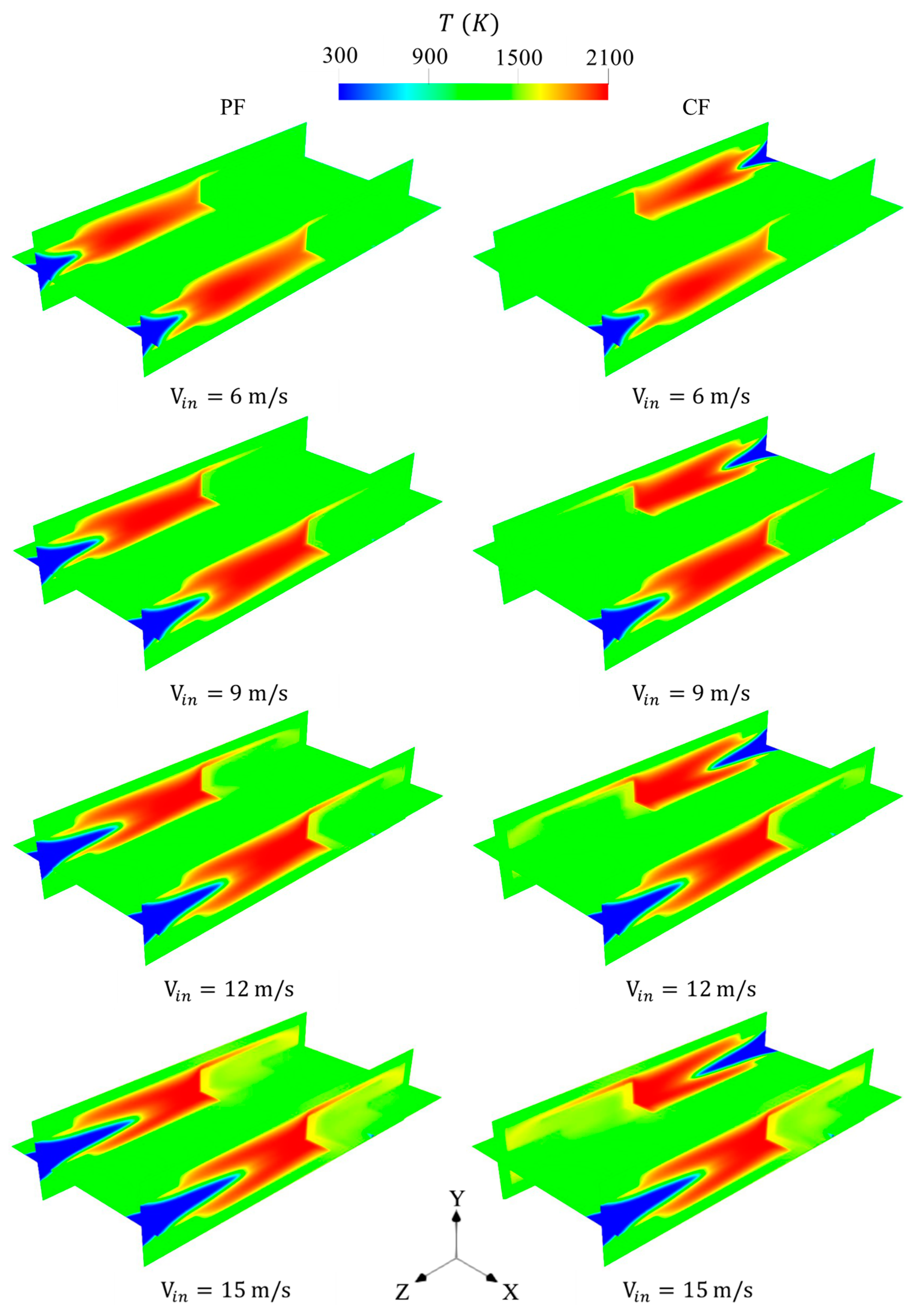

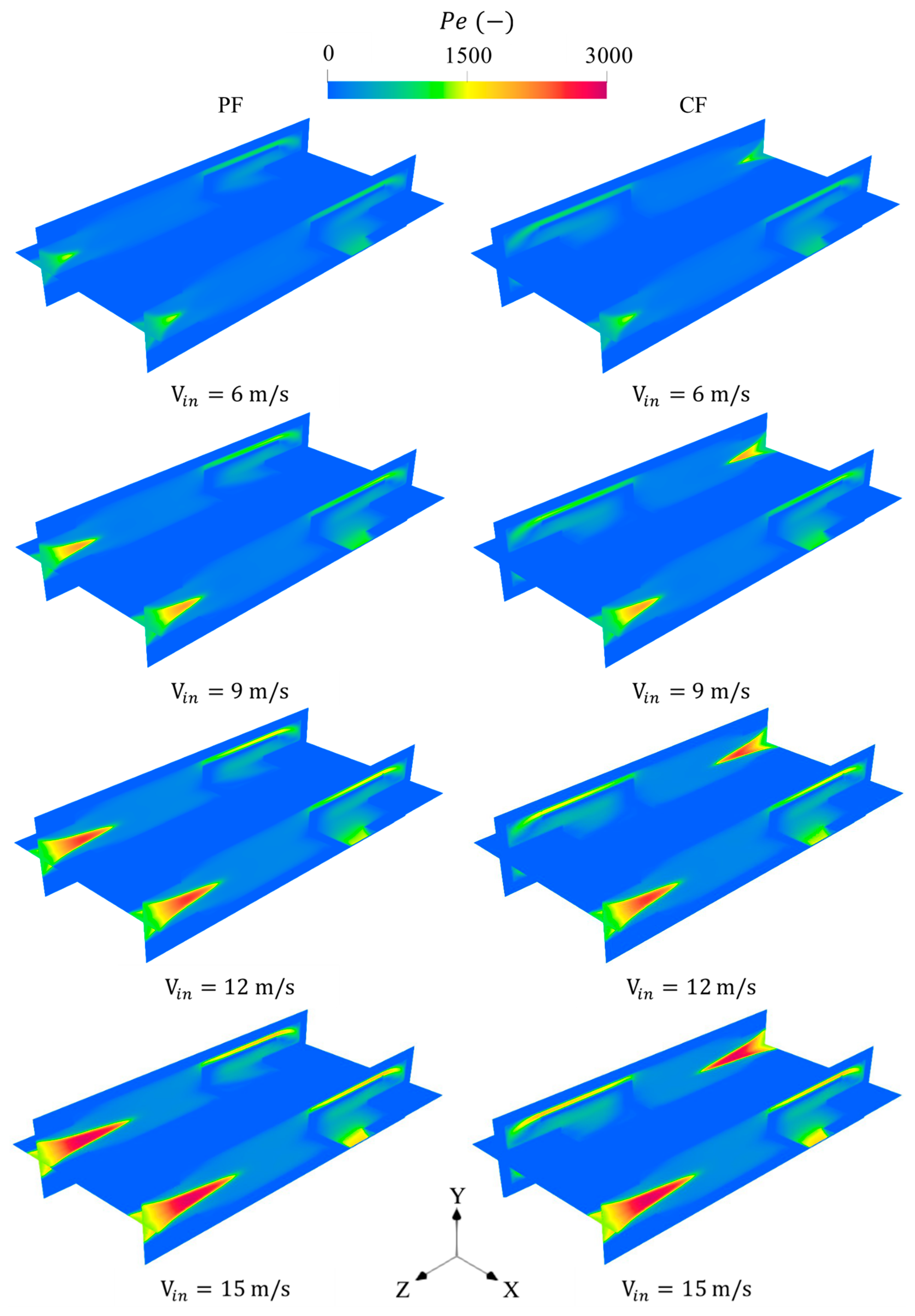

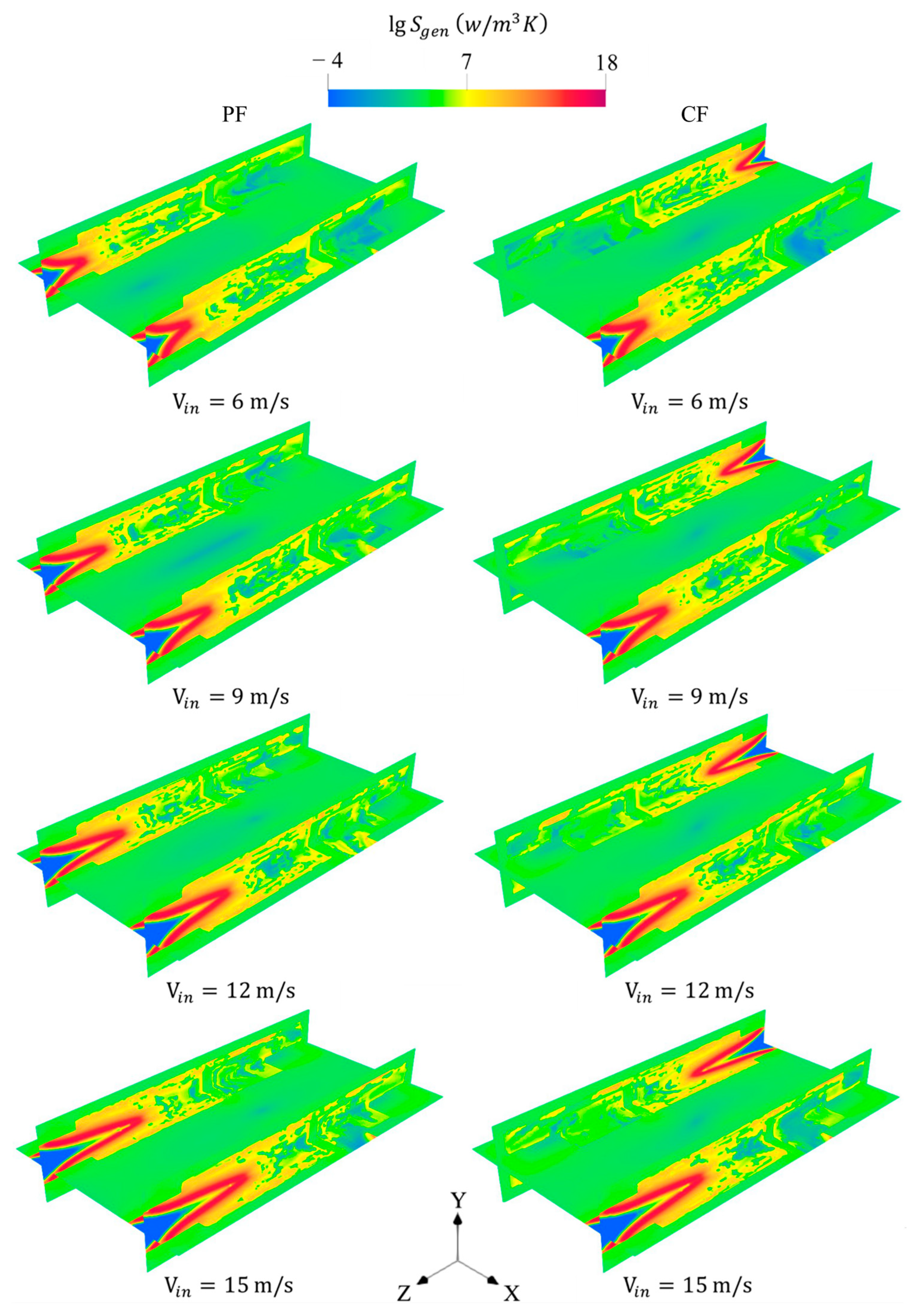

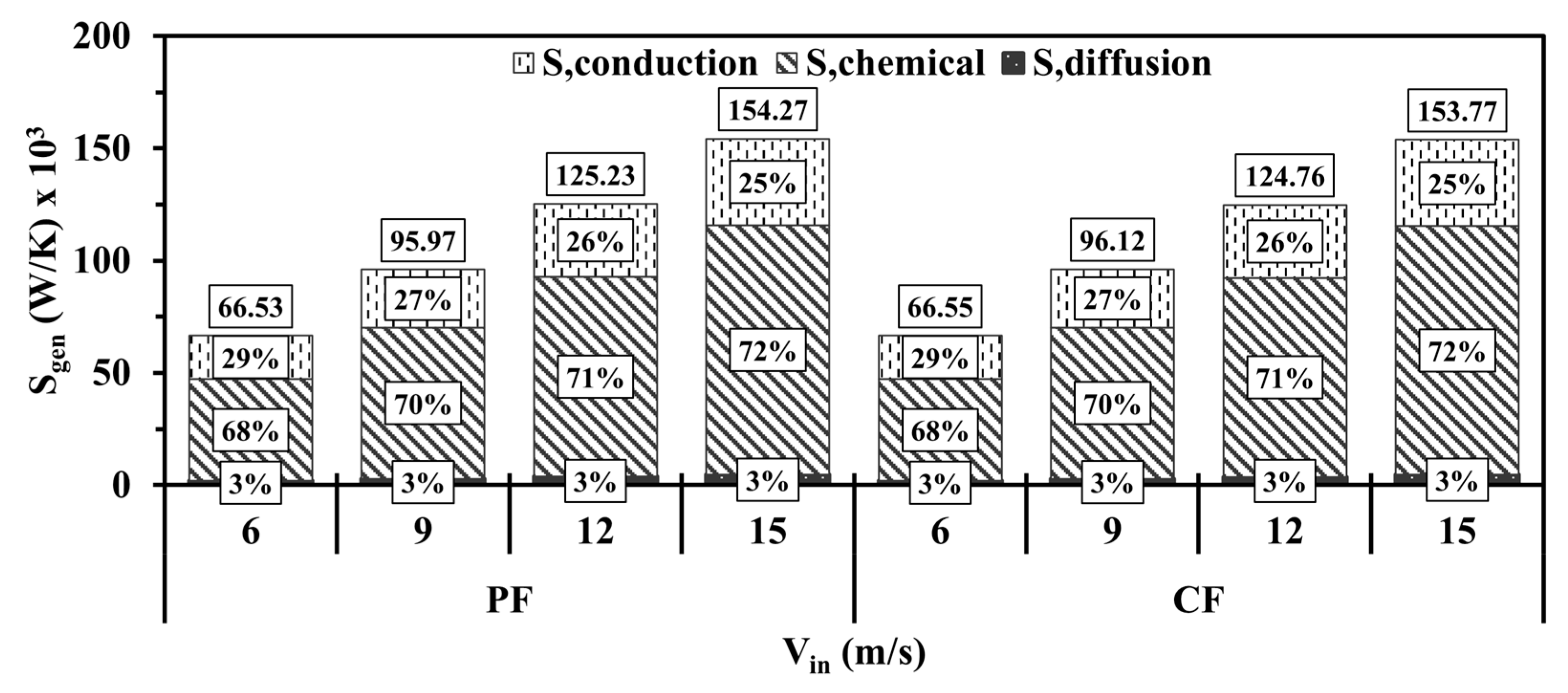

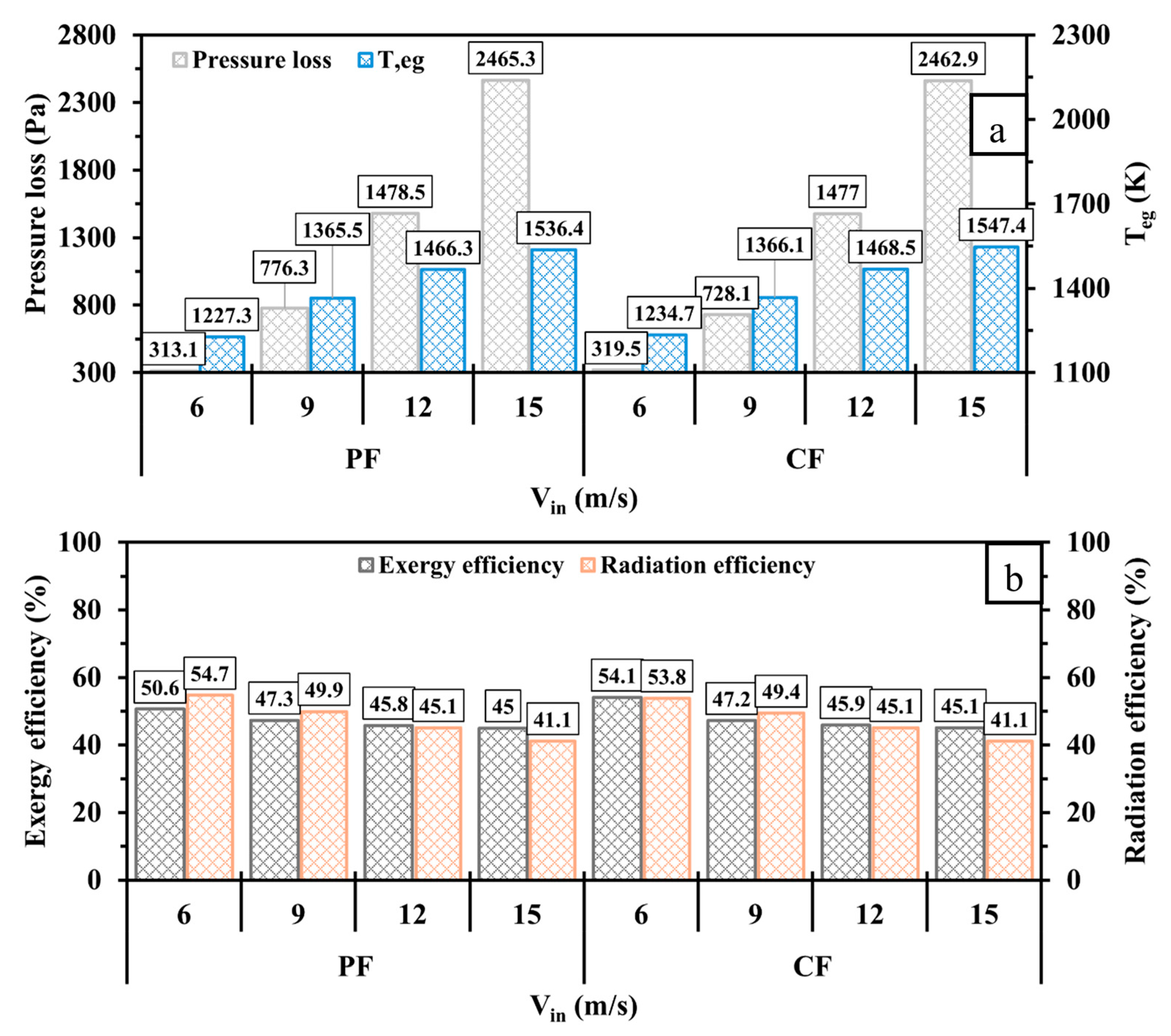

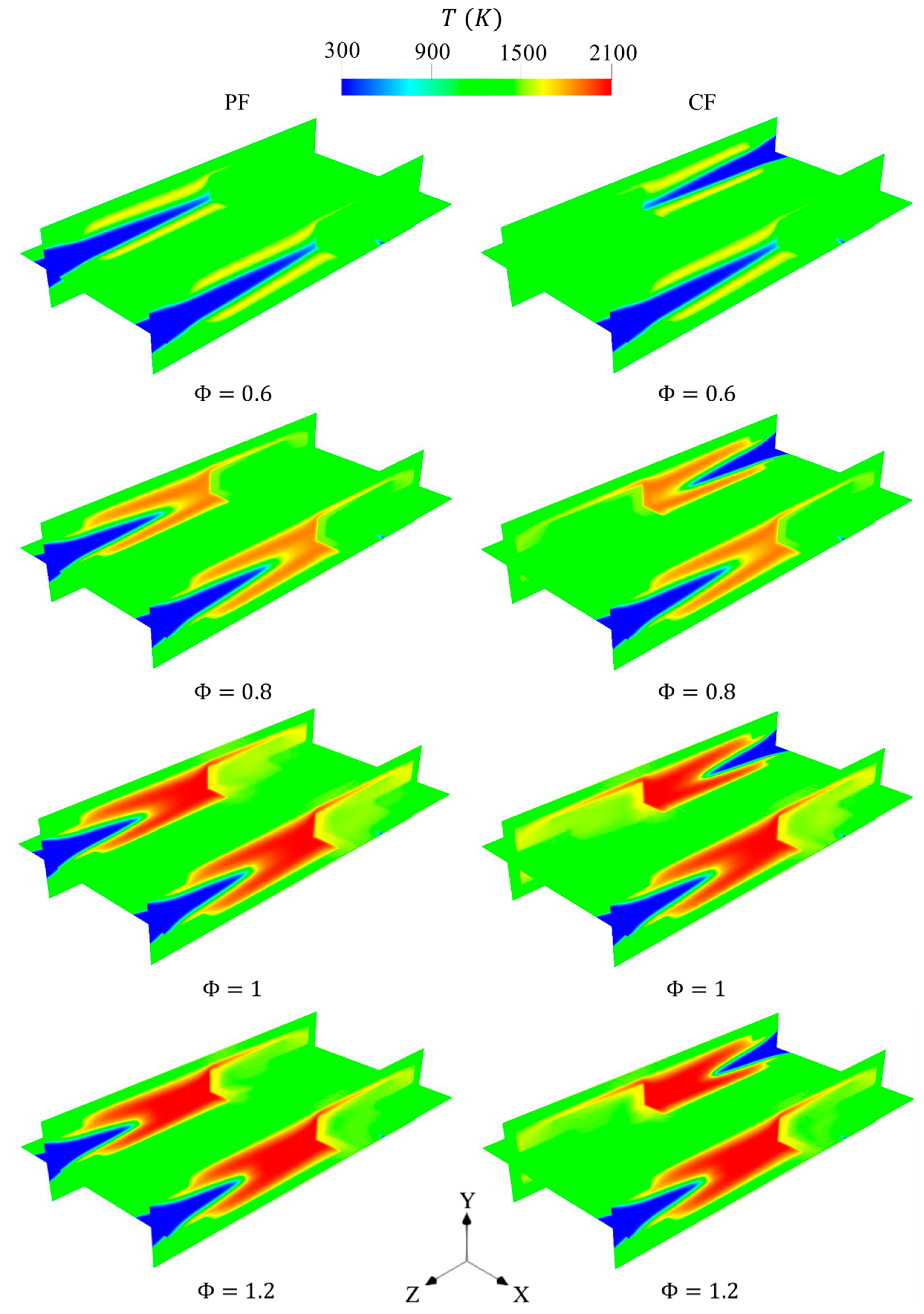

3.2. Effects of Inlet Velocity

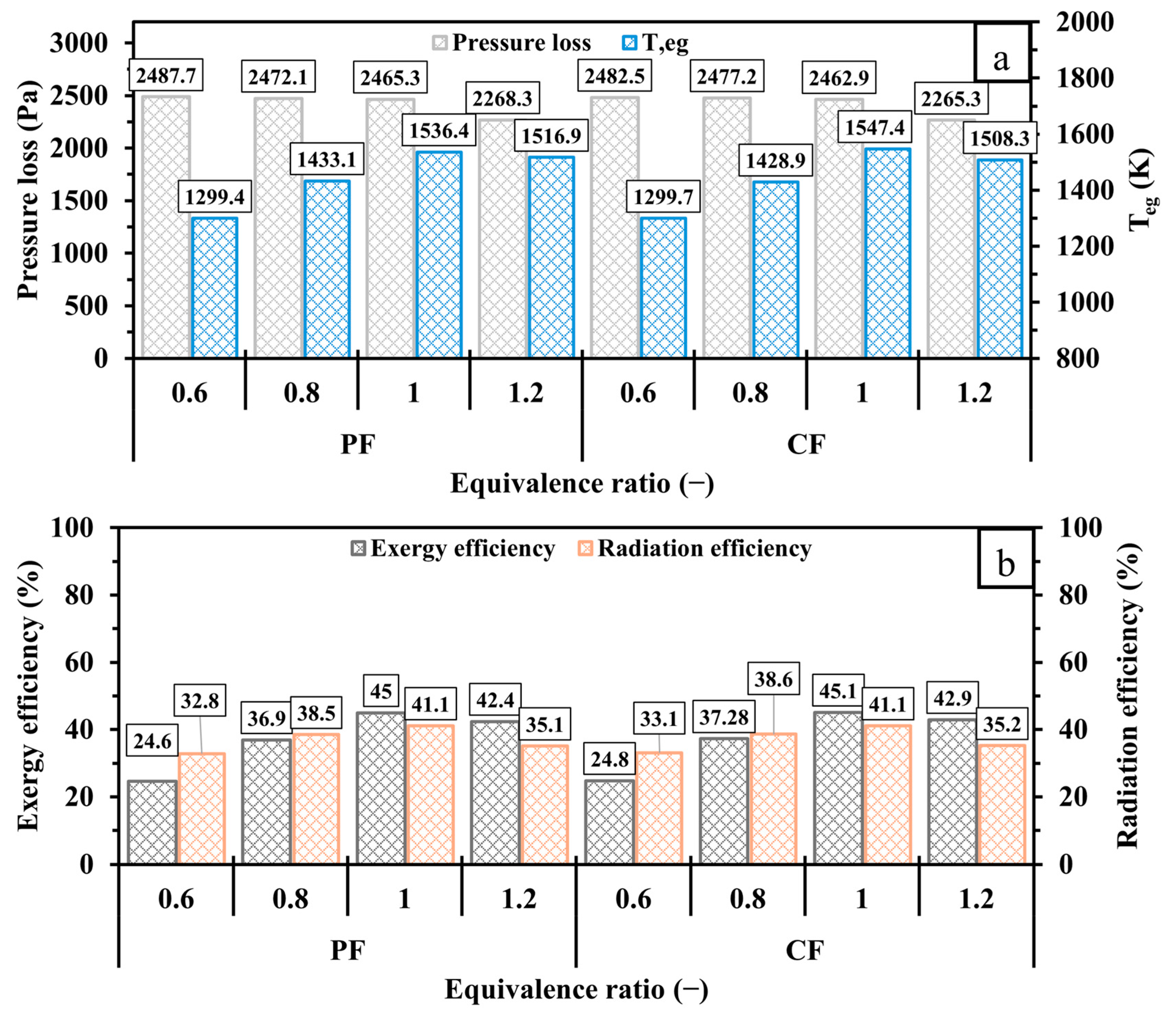

3.3. Effects of Inlet Equivalence Ratio

4. Conclusions

- The PF and CF structures significantly improve and compared to CD structure, indicating enhancements in the rate of absorption of heat produced by combustion by the external walls. This is confirmed by the greater variations in Pe number for the two former cases, implying that the advocation effects dominate over those of diffusion. It is noteworthy that both PF and CF result in pronounced increases in the magnitude of compared to the CD configuration, indicating high dissipations of energy. However, the PF and CF configurations save more thermal energy, as the values are reduced by 591 K and 580 K compared to the CD configuration, respectively, resulting in higher exergy and radiation efficiencies;

- Increasing leads to notably advanced values for PF and CF; however, reversing the direction of flow from one inlet in CF provides the optimal at a Vin of 9 m/s. Furthermore, the increase in shifts the onset of combustion further downstream, and significantly boosts the magnitude. It is important to highlight that the chemical entropy generation mechanism is escalated when approaching higher , suggesting intense combustion under such conditions. Nevertheless, altering the value from low to high increases and decreases the exergy and radiation efficiencies due to the low capacity of a combustor at the micro scale to utilize greater input powers;

- For both PF and CF test cases, the and the exergy and radiation efficiencies are improved when increasing from lean to stoichiometric, and are reduced under rich conditions, due to the low consumption rates of oxygen and hydrogen, respectively. This implies that the unity equivalence ratio optimizes the fuel and air ratio. Further, the vigorous chemistry in the highlighted case enhances and . In comparison with PF, CF shows relatively better in most states of owing to the equal amounts of thermal energy released from opposite sides of the micro combustor.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Total total energy of the fluid | |

| Peclet number | |

| Reaction net rate of production of species i | |

| Natural convection heat transfer coefficient | |

| Vector velocity | |

| Heat losses by radiation | |

| Heat losses by convection | |

| Effective thermal conductivity | |

| Local mass fraction of species i | |

| Source term of enthalpy | |

| Mixture thermal conductivity | |

| External wall surface area | |

| External wall area of cell i | |

| Diffusion flux of species (mol·m−2·s−1) | |

| Mass diffusion mechanism of entropy generation | |

| Chemical reaction of entropy generation | |

| Heat conduction of entropy generation | |

| Total entropy generation | |

| Entropy of species i at reference conditions | |

| Enthalpy of species i at reference conditions | |

| Inlet exergy (W) | |

| Uncounted exergy destruction (W) | |

| Total exergy losses | |

| Energy loss from the combustion exhaust gas | |

| Wall temperature uniformity | |

| Pressure (Pa) | |

| Atmospheric pressure | |

| Ti | Outer wall temperature of cell i |

| Exhaust gas temperature | |

| Area-weighted mean wall temperature | |

| Ambient temperature | |

| Temperature of external wall | |

| Gas constant | |

| Di | Mass diffusivity of species i |

| Specific heat capacity | |

| Velocity (m·s−1) | |

| Lower heating value | |

| Fuel mass flow rate | |

| Inlet stream mass flow rate | |

| Specific nthalpy of species j | |

| Greek letters | |

| Mixture gas density | |

| Viscous stress | |

| Reynolds stress | |

| Chemical potential of species i | |

| Mass fraction of species, i | |

| Exergy efficiency | |

| Radiation efficiency | |

| Stephan–Boltzmann constant | |

| Emissivity of the solid surface | |

| Thermal conductivity | |

| Production rate of species i | |

| Equivalence ratio | |

| Mole fraction of species, i |

References

- Chircov, C.; Grumezescu, A.M. Microelectromechanical Systems (MEMS) for Biomedical Applications. Micromachines 2022, 13, 164. [Google Scholar] [CrossRef]

- Percy, J.J.; Kanthamani, S. Revolutionizing Wireless Communication: A Review Perspective on Design and Optimization of RF MEMS Switches. Microelectron. J. 2023, 139, 105891. [Google Scholar] [CrossRef]

- Bai, S.; Ding, R.; Chirarattananon, P. A Micro Aircraft with Passive Variable-Sweep Wings. IEEE Robot. Autom. Lett. 2022, 7, 4016–4023. [Google Scholar] [CrossRef]

- Ding, J.; E, J.; Cai, L.; Luo, B.; Li, J. Development of a Reaction Mechanism of Hydrogen Production through Rich Methane-Acetylene Blending in a Porous Medium Micro-Combustor. Energy Convers. Manag. 2025, 325, 119360. [Google Scholar] [CrossRef]

- Song, L.; Zhang, S.; Wang, Q.; Chen, W.; Liu, B.; Zhao, Y.-D. Light-Controlled Microbots Gathering as a Sterilization Platform for Highly Efficient Capturing, Concentrating and Killing Targeted Bacteria. Chem. Eng. J. 2022, 435, 135067. [Google Scholar] [CrossRef]

- Tang, A.; Cai, T.; Li, C.; Zhou, C.; Gao, L. Flame Visualization and Spectral Analysis of Combustion Instability in a Premixed Methane/Air-Fueled Micro-Combustor. Energy 2024, 294, 130793. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, D.; Sun, D.; Semlitsch, B. Electrical Power, Energy Efficiency, NO and CO Emissions Investigations of an Ammonia/Methane-Fueled Micro-Thermal Photovoltaic System with a Reduced Chemical Reaction Mechanism. Energy 2024, 305, 132248. [Google Scholar] [CrossRef]

- Cai, S.; Yang, W.; Ding, Y.; Zeng, Q.; Wan, J. Hydrogen-Air Premixed Combustion in a Novel Micro Disc-Burner with an Annular Step. Fuel 2022, 313, 123015. [Google Scholar] [CrossRef]

- Cai, L.; E, J.; Li, J.; Ding, J.; Luo, B. A Comprehensive Review on Combustion Stabilization Technologies of Micro/Meso-Scale Combustors for Micro Thermophotovoltaic Systems: Thermal, Emission, and Energy Conversion. Fuel 2023, 335, 126660. [Google Scholar] [CrossRef]

- E, J.; Mei, Y.; Feng, C.; Ding, J.; Cai, L.; Luo, B. A Review of Enhancing Micro Combustion to Improve Energy Conversion Performance in Micro Power System. Int. J. Hydrogen Energy 2022, 47, 22574–22601. [Google Scholar] [CrossRef]

- Amani, E.; Daneshgar, A.; Hemmatzade, A. A Novel Combined Baffle-Cavity Micro-Combustor Configuration for Micro-Thermo-Photo-Voltaic Applications. Chin. J. Chem. Eng. 2020, 28, 403–413. [Google Scholar] [CrossRef]

- He, Z.; Yan, Y.; Fang, R.; Ou, Z.; Zhang, Z.; Yang, Z.; Zhang, Z. Numerical Investigation of a Novel Micro Combustor with a Central and Bilateral Slotted Blunt Body. Int. J. Hydrogen Energy 2021, 46, 23564–23579. [Google Scholar] [CrossRef]

- Kaisare, N.S.; Di Sarli, V. The Effect of Catalyst Placement on the Stability of a U-Bend Catalytic Heat-Recirculating Micro-Combustor: A Numerical Investigation. Catalysts 2021, 11, 1560. [Google Scholar] [CrossRef]

- Yan, Y.; Wu, G.; Huang, W.; Zhang, L.; Li, L.; Yang, Z. Numerical Comparison Study of Methane Catalytic Combustion Characteristic between Newly Proposed Opposed Counter-Flow Micro-Combustor and the Conventional Ones. Energy 2019, 170, 403–410. [Google Scholar] [CrossRef]

- Yilmaz, H. Investigation of Combustion and Emission Performance of a Micro Combustor: Effects of Bluff Body Insertion and Oxygen Enriched Combustion Conditions. Int. J. Hydrogen Energy 2019, 44, 25985–25999. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, Q.; Fan, B.; Long, L.; Quaye, E.K.; Pan, J. Effect of Multiple Bluff Bodies on Hydrogen/Air Combustion Characteristics and Thermal Properties in Micro Combustor. Int. J. Hydrogen Energy 2023, 48, 4064–4072. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, C.; Wu, G.; Feng, S.; Yang, Z. Numerical Study on Methane/Air Combustion Characteristics in a Heat-Recirculating Micro Combustor Embedded with Porous Media. Int. J. Hydrogen Energy 2022, 47, 20999–21012. [Google Scholar] [CrossRef]

- Li, J.; Xiao, H.; Li, Q.; Shi, J. Heat Recirculation and Heat Losses in Porous Micro-Combustors: Effects of Wall and Porous Media Properties and Combustor Dimensions. Energy 2021, 220, 119772. [Google Scholar] [CrossRef]

- Nauman, M.; Pan, J.; Lu, Q.; Zhang, Y.; Liu, C.; Li, F.; Quaye, E.K. Analyzing the Combustion Characteristics of Premixed Methane-Oxygen with Different Hydrogen Addition Ratios in a Catalytic Micro-Combustor. J. Energy Inst. 2024, 114, 101655. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, D.; Becker, S. Thermal Performances Investigation on an Ammonia-Fuelled Heat-Recirculating Micro-Combustor with Reduced Chemical Mechanism. Appl. Therm. Eng. 2024, 236, 121685. [Google Scholar] [CrossRef]

- Ni, S.; Zhao, D.; Wu, W.; Guan, Y. NOx Emission Reduction Reaction of Ammonia-Hydrogen with Self-Sustained Pulsating Oscillations. Therm. Sci. Eng. Prog. 2020, 19, 100615. [Google Scholar] [CrossRef]

- Cai, L.; E, J.; Zhao, D. Numerical Investigation on NOx Emissions and Thermal Performance of Hydrogen/Ammonia Fueled Micro-Combustors with Periodic Wall Structures. Renew. Energy 2025, 241, 122347. [Google Scholar] [CrossRef]

- Nieto-Londoño, C.; Silva-López, W.; Gómez-Velásquez, N. Numerical Assessment of the Combustion of Methane–Hydrogen–Air Mixtures in Micro-Scale Conditions. Processes 2025, 13, 794. [Google Scholar] [CrossRef]

- Dai, C.; Zuo, W.; Li, Q.; Zhou, K.; Huang, Y.; Zhang, G.; E, J. Energy Conversion Efficiency Improvement Studies on the Hydrogen-Fueled Micro Planar Combustor with Multi-Baffles for Thermophotovoltaic Applications. Energy 2024, 313, 134099. [Google Scholar] [CrossRef]

- Li, J.; E, J.; Ding, J.; Cai, L.; Luo, B. Investigation on Thermophotovoltaic Performance Enhancement of the Hydrogen Fueled Micro Combustors with the Center-Cleared Twisted Tapes for Micro-Thermophotovoltaic System. Appl. Therm. Eng. 2025, 264, 125483. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, Q.; Fan, B.; Chen, W.; Jiang, C.; Pan, J.; Jia, R. Study on the Non-Premixed Combustion Characteristics and Exergy Analysis of H2/Air in Vase-Shaped Micro Combustor. Appl. Therm. Eng. 2023, 233, 121104. [Google Scholar] [CrossRef]

- Sheykhbaglou, S.; Dimitriou, P. Numerical Analysis of Combustion and Thermal Performance of a Bluff-Body and Swirl-Stabilized Micro-Combustor with Premixed NH3/H2/Air Flames. Energies 2025, 18, 780. [Google Scholar] [CrossRef]

- Tang, A.; Pan, J.; Yang, W.; Xu, Y.; Hou, Z. Numerical Study of Premixed Hydrogen/Air Combustion in a Micro Planar Combustor with Parallel Separating Plates. Int. J. Hydrogen Energy 2015, 40, 2396–2403. [Google Scholar] [CrossRef]

- Su, Y.; Cheng, Q.; Song, J.; Si, M. Numerical Study on a Multiple-Channel Micro Combustor for a Micro-Thermophotovoltaic System. Energy Convers. Manag. 2016, 120, 197–205. [Google Scholar] [CrossRef]

- Kang, X. Micro/Mesoscale Combustion Based Portable Power Generating System. Ph.D. Thesis, The University of Queensland, Brisbane, QLD, Australia, 2017. [Google Scholar]

- Almutairi, F. A Numerical Study on Key Thermal Parameters and NOx Emissions of a Hydrogen-Fueled Double-Channel Outlet Micro Cylindrical Combustor Employing a Heat-Recirculating Configuration for Thermophotovoltaic Applications. Processes 2024, 12, 1848. [Google Scholar] [CrossRef]

- ANSYS Fluent User’s Guide; Release 23.2; ANSYS, Inc.: Canonsburg, PA, USA, 2023.

- Ni, S.; Zhao, D.; Sellier, M.; Li, J.; Chen, X.; Li, X.; Cao, F.; Li, W. Thermal Performances and Emitter Efficiency Improvement Studies on Premixed Micro-Combustors with Different Geometric Shapes for Thermophotovoltaics Applications. Energy 2021, 226, 120298. [Google Scholar] [CrossRef]

- Yang, X.; Yu, B.; Peng, X.; Zhou, H. Investigation of Thermal Performance and Energy Conversion in a Novel Planar Micro-Combustor with Four-Corner Entrances for Thermo-Photovoltaic Power Generators. J. Power Sources 2021, 515, 230625. [Google Scholar] [CrossRef]

- Kuo, C.H.; Ronney, P.D. Numerical Modeling of Non-Adiabatic Heat-Recirculating Combustors. Proc. Combust. Inst. 2007, 31, 3277–3284. [Google Scholar] [CrossRef]

- Shih, T.-H.; Liou, W.W.; Shabbir, A.; Yang, Z.; Zhu, J. A New K-ϵ Eddy Viscosity Model for High Reynolds Number Turbulent Flows. Comput. Fluids 1995, 24, 227–238. [Google Scholar] [CrossRef]

- Zhao, H.; Zhao, D.; Becker, S.; Zhang, Y. NO Emission and Enhanced Thermal Performances Studies on Counter-Flow Double-Channel Hydrogen/Ammonia-Fuelled Microcombustors with Oval-Shaped Internal Threads. Fuel 2023, 341, 127665. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Sotoudeh, F.; Jun, D.; Lee, B.J.; Esfahani, J.A.; Karimi, N. On the Effects of NH3 Addition to a Reacting Mixture of H2/CH4 under MILD Combustion Regime: Numerical Modeling with a Modified EDC Combustion Model. Fuel 2022, 326, 125096. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D.; Karimi, N. Optimizing Thermal Performance and Exergy Efficiency in Hydrogen-Fueled Meso-Combustors by Applying a Bluff-Body. J. Clean. Prod. 2021, 311, 127573. [Google Scholar] [CrossRef]

- Yang, W.M.; Chua, K.J.; Pan, J.F.; Jiang, D.Y.; An, H. Development of Micro-Thermophotovoltaic Power Generator with Heat Recuperation. Energy Convers. Manag. 2014, 78, 81–87. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D. Effects of Fuel Composition and Wall Thermal Conductivity on Thermal and NOx Emission Performances of an Ammonia/Hydrogen-Oxygen Micro-Power System. Fuel Process. Technol. 2020, 209, 106527. [Google Scholar] [CrossRef]

- Li, J.; Huang, J.; Chen, X.; Zhao, D.; Shi, B.; Wei, Z.; Wang, N. Effects of Heat Recirculation on Combustion Characteristics of N-Heptane in Micro Combustors. Appl. Therm. Eng. 2016, 109, 697–708. [Google Scholar] [CrossRef]

- He, Z.; Yan, Y.; Zhao, T.; Feng, S.; Li, X.; Zhang, L.; Zhang, Z. Heat Transfer Enhancement and Exergy Efficiency Improvement of a Micro Combustor with Internal Spiral Fins for Thermophotovoltaic Systems. Appl. Therm. Eng. 2021, 189, 116723. [Google Scholar] [CrossRef]

- Fan, Y.; Schlick, C.P.; Umbanhowar, P.B.; Ottino, J.M.; Lueptow, R.M. Modelling Size Segregation of Granular Materials: The Roles of Segregation, Advection and Diffusion. J. Fluid Mech. 2014, 741, 252–279. [Google Scholar] [CrossRef]

- Figueroa, A.; Meunier, P.; Cuevas, S.; Villermaux, E.; Ramos, E. Chaotic Advection at Large Péclet Number: Electromagnetically Driven Experiments, Numerical Simulations, and Theoretical Predictions. Phys. Fluids 2014, 26, 013601. [Google Scholar] [CrossRef]

- Ni, S.; Zhao, D.; Zhu, X. Heat Transfer and Entropy Production Evaluation on Premixed Hydrogen/Air-Fuelled Micro-Combustors with Internal Threads. Fuel 2021, 303, 121325. [Google Scholar] [CrossRef]

- Sun, Y.; Zhao, D.; Ni, S.; David, T.; Zhang, Y. Entropy and Flame Transfer Function Analysis of a Hydrogen-Fueled Diffusion Flame in a Longitudinal Combustor. Energy 2020, 194, 116870. [Google Scholar] [CrossRef]

- Sahoo, B.B.; Saha, U.K.; Sahoo, N. Diagnosing the Effects of Pilot Fuel Quality on Exergy Terms in a Biogas Run Dual Fuel Diesel Engine. Int. J. Exergy 2012, 10, 77–93. [Google Scholar] [CrossRef]

- Stepanov, V.S. Chemical Energies and Exergies of Fuels. Energy 1995, 20, 235–242. [Google Scholar] [CrossRef]

- Tong, J.; Cai, T. Enhancing Thermal Performance, Exergy and Thermodynamics Efficiency of Premixed Methane/Air Micro-Planar Combustor in Micro-Thermophotovoltaic Systems. Energies 2023, 16, 118. [Google Scholar] [CrossRef]

- Peng, Q.; Yang, W.; E, J.; Li, Z.; Xu, H.; Fu, G.; Li, S. Investigation on H2/Air Combustion with C3H8 Addition in the Combustor with Part/Full Porous Medium. Energy Convers. Manag. 2021, 228, 113652. [Google Scholar] [CrossRef]

- Ismail, B.C.; Urmila, G.H.I.A.; Patrick, J.R.; Christopher, J.F.; Hugh, C.; Raad, P.E. Procedure for Estimation and Reporting of Uncertainty Due to Discretization in CFD Applications. J. Fluids Eng. 2008, 130, 078001. [Google Scholar]

- Rong, H.; Zhao, D.; Cai, T.; Becker, S. Enhancing Thermal and Exergy Performances in a CO2-Free Micro-Combustor with Reverse Flow Double-Channel Outlet Structure. Appl. Therm. Eng. 2023, 233, 121180. [Google Scholar] [CrossRef]

- Yang, W.; Chou, S.; Shu, C.; Xue, H.; Li, Z. Effect of Wall Thickness of Micro-Combustor on the Performance of Micro-Thermophotovoltaic Power Generators. Sens. Actuators A Phys. 2005, 119, 441–445. [Google Scholar]

- Zuo, W.; Zhang, Y.; Li, Q.; Li, J.; He, Z. Numerical Investigations on Hydrogen-Fueled Micro-Cylindrical Combustors with Cavity for Micro-Thermophotovoltaic Applications. Energy 2021, 223, 120098. [Google Scholar] [CrossRef]

| Variables | Value (mm) | |||

|---|---|---|---|---|

| CD | PF | CF | ||

| Length | L1 | 11 | 11 | 11 |

| L2 | 18 | 18 | 18 | |

| L3 | 4 | 4 | 4 | |

| L4 | NA | 7 | 7 | |

| L5 | NA | 2 | 2 | |

| L6 | NA | 17.5 | 17.5 | |

| L7 | NA | 15.5 | 15.5 | |

| L8 | NA | 8.5 | 8.5 | |

| L9 | NA | 5 | 5 | |

| L10 | NA | 2 | 2 | |

| L11 | NA | 0.5 | 0.5 | |

| L12 | NA | 3 | 3 | |

| L13 | NA | 0.94 | 0.94 | |

| L14 | NA | 0.4 | 0.4 | |

| L15 | NA | 1.95 | 1.95 | |

| Diameter | D1 | NA | 2 | 2 |

| D2 | NA | 3 | 3 | |

| Thickness | t1 | NA | 0.125 | 0.125 |

| Reactions | (m kmol s) | (J/mol) | |

|---|---|---|---|

| 1. O2 + H = OH + O | 5.10 1013 | −0.82 | 6.91 107 |

| 2. H2 + O = OH + H | 1.80 107 | 1.00 | 3.70 107 |

| 3. H2 + OH = H2O + H | 1.20 106 | 1.30 | 1.52 107 |

| 4. OH + OH = H2O + O | 6.00 106 | 1.30 | 0.00 |

| 5. H2 + O2 = OH + OH | 1.70 1010 | 0.00 | 2.0 108 |

| 6. H + OH + M = H2O + M a | 7.50 1017 | −2.60 | 0.00 |

| 7. O2 + M = O + O + M | 1.90 108 | 0.50 | 4.001 108 |

| 8. H2 + M = H + H + M b | 2.20 109 | 0.50 | 3.877 108 |

| 9. H + O2 + M = HO2 + M c | 2.10 1012 | −1.00 | 0.00 |

| 10. H + O2 + O2 = HO2 + O2 | 6.70 1013 | −1.42 | 0.00 |

| 11. H + O2 + N2 = HO2 + N2 | 6.70 1013 | −1.42 | 0.00 |

| 12. HO2 + H = H2 + O2 | 2.50 1010 | 0.00 | 2.90 106 |

| 13. HO2 + H = OH + OH | 2.50 1011 | 0.00 | 7.90 106 |

| 14. HO2 + O = OH + O2 | 4.80 1010 | 0.00 | 4.20 106 |

| 15. HO2 + OH = H2O + O2 | 5.00 1010 | 0.00 | 4.20 106 |

| 16. HO2 + HO2 = H2O2 + O2 | 2.00 109 | 0.00 | 0.00 |

| 17. H2O2 + M = OH + OH + M | 1.30 1014 | 0.00 | 1.905 108 |

| 18. H2O2 + H = H2 + HO2 | 1.70 109 | 0.00 | 1.57 107 |

| 19. H2O2 + OH = H2O + HO2 | 1.0 1010 | 0.00 | 7.50 106 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almutairi, F. A CFD Study of Thermodynamics and Efficiency Metrics in a Hydrogen-Fueled Micro Planar Combustor Housing Dual Heat-Recirculating Cylindrical Combustors for MTPV Applications. Processes 2025, 13, 1142. https://doi.org/10.3390/pr13041142

Almutairi F. A CFD Study of Thermodynamics and Efficiency Metrics in a Hydrogen-Fueled Micro Planar Combustor Housing Dual Heat-Recirculating Cylindrical Combustors for MTPV Applications. Processes. 2025; 13(4):1142. https://doi.org/10.3390/pr13041142

Chicago/Turabian StyleAlmutairi, Faisal. 2025. "A CFD Study of Thermodynamics and Efficiency Metrics in a Hydrogen-Fueled Micro Planar Combustor Housing Dual Heat-Recirculating Cylindrical Combustors for MTPV Applications" Processes 13, no. 4: 1142. https://doi.org/10.3390/pr13041142

APA StyleAlmutairi, F. (2025). A CFD Study of Thermodynamics and Efficiency Metrics in a Hydrogen-Fueled Micro Planar Combustor Housing Dual Heat-Recirculating Cylindrical Combustors for MTPV Applications. Processes, 13(4), 1142. https://doi.org/10.3390/pr13041142