Generative Artificial Intelligence in Adaptive Social Manufacturing: A Pathway to Achieving Industry 5.0 Sustainability Goals

Abstract

:1. Introduction

2. Literature Review

3. Theoretical Framework

4. Method

5. Results

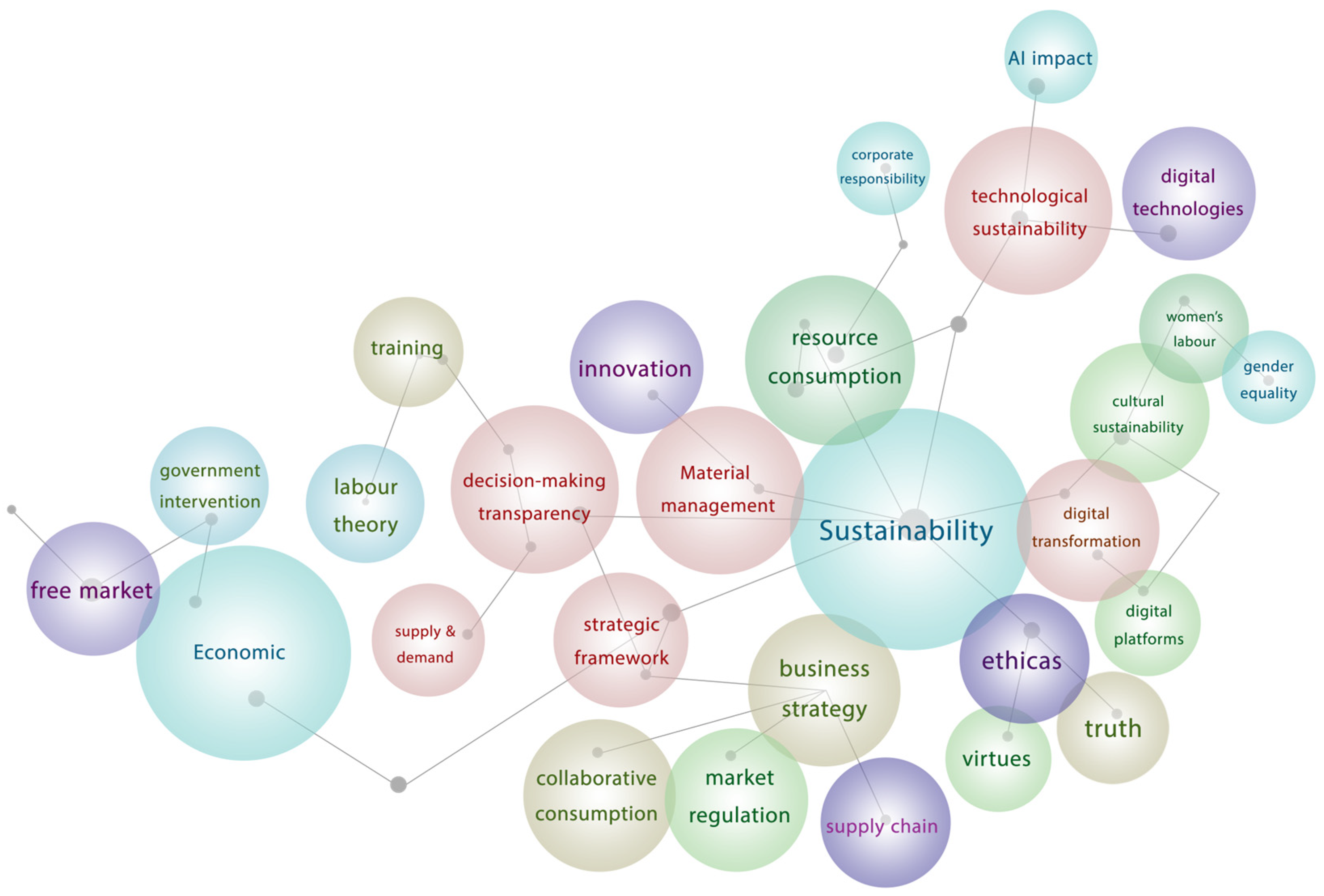

5.1. Content Analysis of Industry 5.0 Sustainability Goals

5.2. Expert Engagement and Validation

5.3. Evaluation Framework and Statistical Analysis

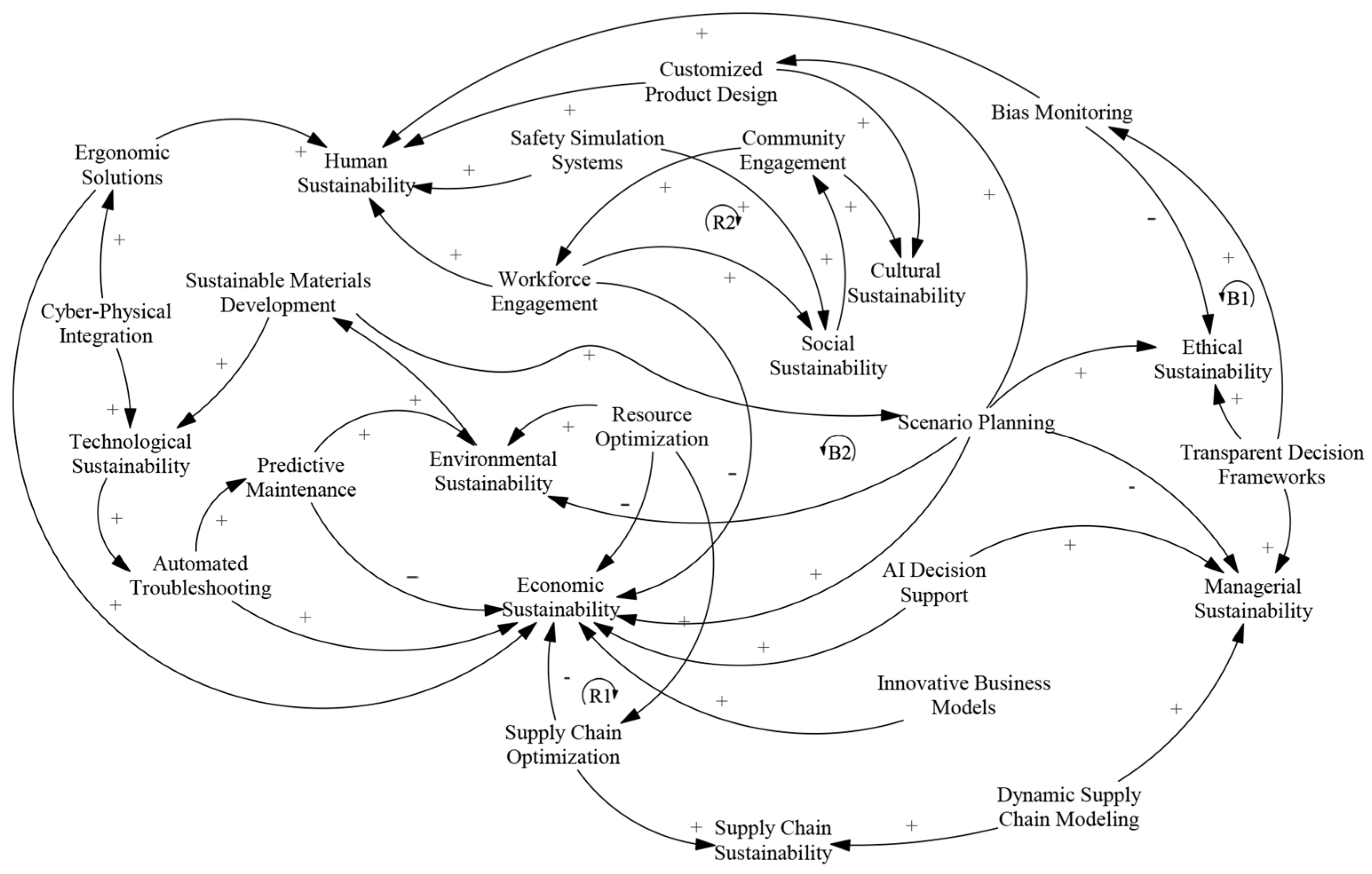

5.4. CLD

6. Discussion

7. Conclusions

- This research proposes a novel framework integrating GAI into adaptive social manufacturing systems, addressing current theoretical and practical gaps in Industry 5.0’s sustainability agenda.

- A rigorous, multi-stage methodology was implemented, comprising content analysis, multi-round expert validation (n = 130), MANOVA and Friedman tests, and causal system dynamics modeling to ensure methodological robustness and empirical depth.

- The study identifies and prioritizes 17 high-impact GAI functions based on their contributions to nine validated sustainability dimensions, including environmental, economic, social, human, cultural, ethical, and managerial domains.

- Quantitative analysis reveals that functions such as DSCM, BMT, and ES consistently scored highest in terms of sustainability impact and strategic relevance.

- Through expert-driven construction of a CLD, the research uncovers reinforcing and balancing feedback loops among GAI functions and sustainability outcomes, illustrating the systemic nature of GAI-enabled sustainability.

- The findings demonstrate that leveraging GAI within adaptive manufacturing ecosystems requires a holistic approach, balancing technological advancement with ethical governance, human-centric design, and organizational resilience.

- By bridging theoretical constructs and real-world application, this study delivers a validated, scalable, and transferable roadmap for industries seeking to operationalize Industry 5.0 through responsible and sustainable GAI deployment.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Sustainability Dimension | Sources | Sources | |

| 1 | Environmental sustainability | 25 | 1. Ghobakhloo, M.; Iranmanesh, M.; Foroughi, B.; Tirkolaee, E.B.; Asadi, S.; Amran, A. Industry 5.0 implications for inclusive sustainable manufacturing: An evidence-knowledge-based strategic roadmap. J. Clean. Prod. 2023, 417, 138023. 2. Ghobakhloo, M.; Iranmanesh, M.; Mubarak, M.F.; Mubarik, M.; Rejeb, A.; Nilashi, M. Identifying industry 5.0 contributions to sustainable development: A strategy roadmap for delivering sustainability values. Sustain. Prod. Consum. 2022, 33, 716–737. 3. Van Erp, T.; Carvalho, N.G.P.; Gerolamo, M.C.; Gonçalves, R.; Rytter, N.G.M.; Gladysz, B. Industry 5.0: A new strategy framework for sustainability management and beyond. J. Clean. Prod. 2024, 461, 142271. 4. Agote-Garrido, A.; Martín-Gómez, A.M.; Lama-Ruiz, J.R. Manufacturing system design in industry 5.0: Incorporating sociotechnical systems and social metabolism for human-centered, sustainable, and resilient production. Systems 2023, 11, 537. 5. Gamberini, L.; Pluchino, P. Industry 5.0: A comprehensive insight into the future of work, social sustainability, sustainable development, and career. Aust. J. Career Dev. 2024, 33, 5–14. 6. Rame, R.; Purwanto, P.; Sudarno, S. Industry 5.0 and sustainability: An overview of emerging trends and challenges for a green future. Innov. Green Dev. 2024, 3, 100173. 7. Martini, B.; Bellisario, D.; Coletti, P. Human-centered and sustainable artificial intelligence in industry 5.0: Challenges and perspectives. Sustainability 2024, 16, 5448. 8. Dacre, N.; Yan, J.; Frei, R.; Al-Mhdawi, M.K.S.; Dong, H. Advancing sustainable manufacturing: A systematic exploration of industry 5.0 supply chains for sustainability, human-centricity, and resilience. Prod. Plan. Control 2024, 1–30. 9. Oyekunle, D.O.T.; Okwudili Matthew, U.; Bakare, K.M.; Fatai, L.O.; Asnui, O. Industry 5.0: A Paradigm Shift Towards Sustainability, Adaptability and Human-Centeredness. Self-Published Work, 2024. 10. Vyhmeister, E.; Castane, G.G. When Industry meets trustworthy AI: A systematic review of AI for Industry 5.0. arXiv 2024, arXiv:2403.03061. 11. Cao, H.; Söderlund, H.; Derspeisse, M.; Johansson, B. Exploring the current applications and potential of extended reality for environmental sustainability in manufacturing. arXiv 2023, arXiv:2312.17595. 12. Zeb, S.; Mahmood, A.; Khowaja, S.A.; Dev, K.; Hassan, S.A.; Qureshi, N.M.F.; Bellavista, P. Industry 5.0 is coming: A survey on intelligent nextG wireless networks as technological enablers. arXiv 2022, arXiv:2205.09084. 13. Varde, A.S.; Liang, J. Machine learning approaches in agile manufacturing with recycled materials for sustainability. arXiv 2023, arXiv:2303.08291. 14. Grabowska, S.; Saniuk, S.; Gajdzik, B. Industry 5.0: Improving humanization and sustainability of Industry 4.0. Scientometrics 2022, 127, 3117–3144. 15. Fraga-Lamas, P.; Fernández-Caramés, T.M.; da Cruz, A.M.R.; Lopes, S.I. An overview of blockchain for Industry 5.0: Towards human-centric, sustainable and resilient applications. IEEE Access 2024. 16. ElFar, O.A.; Chang, C.K.; Leong, H.Y.; Peter, A.P.; Chew, K.W.; Show, P.L. Prospects of Industry 5.0 in algae: Customization of production and new advance technology for clean bioenergy generation. Energy Convers. Manag. X 2021, 10, 100048. 17. Kasinathan, P.; Pugazhendhi, R.; Elavarasan, R.M.; Ramachandaramurthy, V.K.; Ramanathan, V.; Subramanian, S.; Alsharif, M.H. Realization of sustainable development goals with disruptive technologies by integrating industry 5.0, society 5.0, smart cities and villages. Sustainability 2022, 14, 15258. 18. Pizoń, J.; Witczak, M.; Gola, A.; Świć, A. Challenges of human-centered manufacturing in the aspect of industry 5.0 assumptions. IFAC-Pap. Online 2023, 56, 156–161. 19. Ali, I.; Nguyen, K.; Oh, I. Systematic literature review on Industry 5.0: Current status and future research directions with insights for the Asia Pacific countries. Asia Pac. Bus. Rev. 2025, 1–28. 20. Davim, J.P. Perceptions of Industry 5.0: Sustainability Perspective. BioResources 2025, 20, 1. 21. Adel, A. Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. J. Cloud Comput. 2022, 11, 40. 22. Reddy, C.K.K.; Anisha, P.R.; Khan, S.; Hanafiah, M.M.; Pamulaparty, L.; Mohana, R.M., Eds. Sustainability in Industry 5.0: Theory and Applications; CRC Press: Boca Raton, FL, USA, 2024. 23. Barata, J.; Kayser, I. Industry 5.0–Past, present, and near future. Procedia Comput. Sci. 2023, 219, 778–788. 24. Nahavandi, S. Industry 5.0—A human-centric solution. Sustainability 2019, 11, 4371. 25. Johri, P.; Singh, J.N.; Sharma, A.; Rastogi, D. Sustainability of coexistence of humans and machines: An evolution of industry 5.0 from industry 4.0. In Proceedings of the 2021 10th International Conference on System Modeling & Advancement in Research Trends (SMART), Moradabad, India, 17–18 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 410–414. |

| 2 | Social sustainability | 17 articles | 1. Grybauskas, A.; Stefanini, A.; Ghobakhloo, M. Social sustainability in the age of digitalization: A systematic literature review on the social implications of industry 4.0. Technol. Soc. 2022, 71, 101997. 2. Saunila, M.; Nasiri, M.; Ukko, J.; Gastaldi, L. Managing social sustainability with IoT implementation: An Industry 5.0 perspective. Sustain. Dev. 2025. 3. Rane, N. ChatGPT and similar generative artificial intelligence (AI) for smart industry: Role, challenges and opportunities for industry 4.0, industry 5.0 and society 5.0. Challenges Oppor. Ind. 2023, 4. 4. Rehman, A.; Umar, T. Literature review: Industry 5.0. Leveraging technologies for environmental, social and governance advancement in corporate settings. Corp. Gov.: Int. J. Bus. Soc. 2025, 25, 229–251. 5. Asif, M.; Searcy, C.; Castka, P. ESG and Industry 5.0: The role of technologies in enhancing ESG disclosure. Technol. Forecast. Soc. Change 2023, 195, 122806. 6. Ruiz-de-la-Torre-Acha, A.; Guevara-Ramirez, W.; Río-Belver, R.M.; Borregan-Alvarado, J. Industry 5.0. The road to sustainability. In Proceedings of the International Symposium on Industrial Engineering and Automation, Cham, Switzerland, June 2023; Springer Nature: Cham, Switzerland, 2023; pp. 247–257. 7. Sindhwani, R.; Afridi, S.; Kumar, A.; Banaitis, A.; Luthra, S.; Singh, P.L. Can Industry 5.0 revolutionize the wave of resilience and social value creation? A multi-criteria framework to analyze enablers. Technol. Soc. 2022, 68, 101887. 8. Costa, E. Industry 5.0 and SDG 9: A symbiotic dance towards sustainable transformation. Sustain. Earth Rev. 2024, 7, 4. 9. Ali, I.; Nguyen, K.; Oh, I. Systematic literature review on Industry 5.0: Current status and future research directions with insights for the Asia Pacific countries. Asia Pac. Bus. Rev. 2025, 1–28. 10. Panza, L.; Bruno, G.; Lombardi, F. Integrating absolute sustainability and social sustainability in the digital product passport to promote industry 5.0. Sustainability 2023, 15, 12552. 11. Alojaiman, B. Technological modernizations in the Industry 5.0 era: A descriptive analysis and future research directions. Processes 2023, 11, 1318. 12. Narkhede, G.; Pasi, B.; Rajhans, N.; Kulkarni, A. Industry 5.0 and the future of sustainable manufacturing: A systematic literature review. Bus. Strategy Dev. 2023, 6, 704–723. 13. Ghobakhloo, M.; Mahdiraji, H.A.; Iranmanesh, M.; Jafari-Sadeghi, V. From Industry 4.0 digital manufacturing to Industry 5.0 digital society: A roadmap toward human-centric, sustainable, and resilient production. Inf. Syst. Front. 2024, 1–33. 14. Abualhija, S.; Masa’deh, R.E. ESG meets Industry 5.0: Systematic and bibliometric reviews of development trends, and future directions. In Big Data in Finance: Transforming the Financial Landscape; Springer: Cham, Switzerland, 2024; pp. 257. 15. Fernández-Miguel, A.; García-Muiña, F.E.; Jiménez-Calzado, M.; San Román, P.M.; del Hoyo, A.P.F.; Settembre-Blundo, D. Boosting business agility with additive digital molding: An Industry 5.0 approach to sustainable supply chains. Comput. Ind. Eng. 2024, 192, 110222. 16. Tromp, J.G.; Le, D.N.; Van Le, C., Eds. Emerging Extended Reality Technologies for Industry 4.0: Early Experiences with Conception, Design, Implementation, Evaluation and Deployment; John Wiley & Sons: Hoboken, NJ, USA, 2020. 17. Huang, S.; Wang, B.; Li, X.; Zheng, P.; Mourtzis, D.; Wang, L. Industry 5.0 and Society 5.0—Comparison, complementation and co-evolution. J. Manuf. Syst. 2022, 64, 424–428. |

| 3 | Economic sustainability | 10 articles | 1. Leng, J., Zhong, Y., Lin, Z., Xu, K., Mourtzis, D., Zhou, X., ... & Shen, W. Towards resilience in Industry 5.0: A decentralized autonomous manufacturing paradigm. Journal of Manufacturing Systems 2023, 71, 95–114. 2. Mohamed, M., & Gamal, A. Toward sustainable emerging economics based on industry 5.0: leveraging neutrosophic theory in appraisal decision framework. Neutrosophic systems with applications 2023, 1, 14–21. 3. Masoomi, B., Sahebi, I. G., Ghobakhloo, M., & Mosayebi, A. Do industry 5.0 advantages address the sustainable development challenges of the renewable energy supply chain?. Sustainable Production and Consumption 2023, 43, 94–112. 4. Ben Youssef, A., & Mejri, I. Linking digital technologies to sustainability through industry 5.0: A bibliometric analysis. Sustainability 2023, 15(9), 7465. 5. Sharma, M., Tomar, A., & Hazra, A. Edge computing for industry 5.0: Fundamental, applications and research challenges. IEEE Internet of Things Journal. 2024. 6. Musarat, M. A., Irfan, M., Alaloul, W. S., Maqsoom, A., & Ghufran, M. A review on the way forward in construction through industrial revolution 5.0. Sustainability 2023, 15(18), 13862. 7. Gomathi, L., Mishra, A. K., & Tyagi, A. K. (2023, April). Industry 5.0 for healthcare 5.0: Opportunities, challenges and future research possibilities. In 2023 7th International Conference on Trends in Electronics and Informatics (ICOEI) (pp. 204–213). IEEE. 8. Sharma, R., & Gupta, H. Leveraging cognitive digital twins in industry 5.0 for achieving sustainable development goal 9: An exploration of inclusive and sustainable industrialization strategies. Journal of Cleaner Production 2024, 448, 141364. 9. Xu, X., Lu, Y., Vogel-Heuser, B., & Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. Journal of manufacturing systems 2021, 61, 530–535. 10. Martín-Gómez, A. M., Agote-Garrido, A., & Lama-Ruiz, J. R. A framework for sustainable manufacturing: Integrating industry 4.0 technologies with industry 5.0 values. Sustainability 2024, 16(4), 1364. |

| 4 | Ethical sustainability | 10 articles | 1. Leng, J.; Zhong, Y.; Lin, Z.; Xu, K.; Mourtzis, D.; Zhou, X.; Shen, W. Towards resilience in Industry 5.0: A decentralized autonomous manufacturing paradigm. J. Manuf. Syst. 2023, 71, 95–114. 2. Mohamed, M.; Gamal, A. Toward sustainable emerging economics based on Industry 5.0: Leveraging neutrosophic theory in appraisal decision framework. Neutrosophic Syst. Appl. 2023, 1, 14–21. 3. Masoomi, B.; Sahebi, I.G.; Ghobakhloo, M.; Mosayebi, A. Do Industry 5.0 advantages address the sustainable development challenges of the renewable energy supply chain? Sustain. Prod. Consum. 2023, 43, 94–112. 4. Ben Youssef, A.; Mejri, I. Linking digital technologies to sustainability through Industry 5.0: A bibliometric analysis. Sustainability 2023, 15, 7465. 5. Sharma, M.; Tomar, A.; Hazra, A. Edge computing for Industry 5.0: Fundamental, applications and research challenges. IEEE Internet Things J. 2024. 6. Musarat, M.A.; Irfan, M.; Alaloul, W.S.; Maqsoom, A.; Ghufran, M. A review on the way forward in construction through Industrial Revolution 5.0. Sustainability 2023, 15, 13862. 7. Gomathi, L.; Mishra, A.K.; Tyagi, A.K. Industry 5.0 for Healthcare 5.0: Opportunities, challenges and future research possibilities. In Proceedings of the 2023 7th International Conference on Trends in Electronics and Informatics (ICOEI), Tirunelveli, India, 13–15 April 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 204–213. 8. Sharma, R.; Gupta, H. Leveraging cognitive digital twins in Industry 5.0 for achieving Sustainable Development Goal 9: An exploration of inclusive and sustainable industrialization strategies. J. Clean. Prod. 2024, 448, 141364. 9. Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. 10. Martín-Gómez, A.M.; Agote-Garrido, A.; Lama-Ruiz, J.R. A framework for sustainable manufacturing: Integrating Industry 4.0 technologies with Industry 5.0 values. Sustainability 2024, 16, 1364. |

| 5 | Technological sustainability | 8 articles | 1. Verma, D. Industry 5.0: A human-centric and sustainable approach to industrial development. Int. J. Soc. Relev. Concern 2024, 12, 5. 2. Alves, J.; Lima, T.M.; Gaspar, P.D. Is Industry 5.0 a human-centred approach? A systematic review. Processes 2023, 11, 193. 3. Aheleroff, S.; Huang, H.; Xu, X.; Zhong, R.Y. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2022, 2, 951643. 4. Sheikh, R.A.; Ahmed, I.; Faqihi, A.Y.A.; Shehawy, Y.M. Global perspectives on navigating Industry 5.0 knowledge: Achieving resilience, sustainability, and human-centric innovation in manufacturing. J. Knowl. Econ. 2024, 1–36. 5. Brückner, A.; Wölke, M.; Hein-Pensel, F.; Schero, E.; Winkler, H.; Jabs, I. Assessing Industry 5.0 readiness—Prototype of a holistic digital index to evaluate sustainability, resilience and human-centered factors. Int. J. Inf. Manag. Data Insights 2025, 5, 100329. 6. Yin, S.; Liu, L.; Mahmood, T. New trends in sustainable development for Industry 5.0: Digital green innovation economy. Green Low-Carbon Econ. 2024, 2, 269–276. 7. Lo, H.W.; Chan, H.W.; Lin, J.W.; Lin, S.W. Evaluating the interrelationships of Industry 5.0 development factors using an integration approach of Fermatean fuzzy logic. J. Oper. Intell. 2024, 2, 95–113. 8. Victor, N.; Maddikunta, P.K.R.; Mary, D.R.K.; Murugan, R.; Chengoden, R.; Gadekallu, T.R.; Paek, J. Remote sensing for agriculture in the era of Industry 5.0—A survey. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2024. |

| 6 | Cultural sustainability | 8 articles | 1. Hsu, C.H.; Wu, J.Z.; Zhang, T.Y.; Chen, J.Y. Deploying Industry 5.0 drivers to enhance sustainable supply chain risk resilience. Int. J. Sustain. Eng. 2024, 17(1), 211–238. https://doi.org/10.1080/19397038.2023.2321124 2. Enang, E.; Bashiri, M.; Jarvis, D. Exploring the transition from techno-centric Industry 4.0 towards value-centric Industry 5.0: A systematic literature review. Int. J. Prod. Res. 2023, 61(22), 7866–7902. https://doi.org/10.1080/00207543.2023.2213791 3. Gomathi, L.; Mishra, A.K.; Tyagi, A.K. Industry 5.0 for Healthcare 5.0: Opportunities, challenges and future research possibilities. In Proceedings of the 2023 7th International Conference on Trends in Electronics and Informatics (ICOEI), Tirunelveli, India, 13–15 April 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 204–213. https://doi.org/10.1109/ICOEI54979.2023.1019084 4. Aheleroff, S.; Huang, H.; Xu, X.; Zhong, R.Y. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2022, 2, 951643. https://doi.org/10.3389/fmtec.2022.951643 5. Musarat, M.A.; Irfan, M.; Alaloul, W.S.; Maqsoom, A.; Ghufran, M. A review on the way forward in construction through Industrial Revolution 5.0. Sustainability 2023, 15, 13862. https://doi.org/10.3390/su151813862 6. Dacre, N.; Yan, J.; Frei, R.; Al-Mhdawi, M.K.S.; Dong, H. Advancing sustainable manufacturing: A systematic exploration of Industry 5.0 supply chains for sustainability, human-centricity, and resilience. Prod. Plan. Control 2024, 1–30. https://doi.org/10.1080/09537287.2024.2247211 7. Sharma, R.; Gupta, H. Leveraging cognitive digital twins in Industry 5.0 for achieving Sustainable Development Goal 9: An exploration of inclusive and sustainable industrialization strategies. J. Clean. Prod. 2024, 448, 141364. https://doi.org/10.1016/j.jclepro.2023.141364 8.ments foster the green transition pathways for Industry 5.0? A perspective toward carbon neutrality. Benchmarking: An Int. J. 2025, Article Pending. https://doi.org/10.1108/BJI-11-2023-0410 |

| 7 | Supply chain sustainability | 8 articles | 1. Lu, Y.; Zheng, H.; Chand, S.; Xia, W.; Liu, Z.; Xu, X.; Bao, J. Outlook on human-centric manufacturing towards Industry 5.0. J. Manuf. Syst. 2022, 62, 612–627. https://doi.org/10.1016/j.jmsy.2021.12.007 2. Abualhija, S.; Masa’deh, R.E. ESG meets Industry 5.0: Systematic and bibliometric reviews of development trends, and future directions. In Big Data in Finance: Transforming the Financial Landscape; Springer: Cham, Switzerland, 2024; pp. 257. 3. Narkhede, G.B.; Pasi, B.N.; Rajhans, N.; Kulkarni, A. Industry 5.0 and sustainable manufacturing: A systematic literature review. Benchmarking: An Int. J. 2025, 32(2), 608–635. https://doi.org/10.1108/BJI-02-2024-0351 4. Barros, D.; Fraga-Lamas, P.; Fernández-Caramés, T.M.; Lopes, S.I. A cost-effective thermal imaging safety sensor for industry 5.0 and collaborative robotics. In Proceedings of the International Conference on Intelligent Edge Processing in the IoT Era, Cham, Switzerland, 2022, pp. 3–15. Springer Nature Switzerland. https://doi.org/10.1007/978-3-030-92547-7_1 5. Karmaker, C.L.; Bari, A.M.; Anam, M.Z.; Ahmed, T.; Ali, S.M.; de Jesus Pacheco, D.A.; Moktadir, M.A. Industry 5.0 challenges for post-pandemic supply chain sustainability in an emerging economy. Int. J. Prod. Econ. 2023, 258, 108806. https://doi.org/10.1016/j.ijpe.2023.108806 6. Wang, X.; Wang, Y.; Yang, J.; Jia, X.; Li, L.; Ding, W.; Wang, F.Y. The survey on multi-source data fusion in cyber-physical-social systems: Foundational infrastructure for industrial metaverses and Industries 5.0. Inf. Fusion 2024, Article 102321. https://doi.org/10.1016/j.inffus.2023.102321 7. Dhayal, K.S.; Giri, A.K.; Agrawal, R.; Agrawal, S.; Samadhiya, A.; Kumar, A. Do the innovative technological advancements foster the green transition pathways for Industry 5.0? A perspective toward carbon neutrality. Benchmarking: An Int. J. 2025, Article Pending. https://doi.org/10.1108/BJI-11-2023-0410 8. Dwivedi, A.; Agrawal, D.; Jha, A.; Mathiyazhagan, K. Studying the interactions among Industry 5.0 and circular supply chain: Towards attaining sustainable development. Comput. Ind. Eng. 2022, 176, 108927. https://doi.org/10.1016/j.cie.2022.108927 |

| 8 | Human sustainability | 8 articles | 1. Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. A Literature Review of the Challenges and Opportunities of the Transition from Industry 4.0 to Society 5.0. Energies 2022, 15, 6276. https://doi.org/10.3390/en15176276. 2. Valette, E.; Haouzi, H.; Demesure, G. Industry 5.0 and its technologies: A systematic literature review upon the human place into IoT- and CPS-based industrial systems. Comput. Ind. Eng. 2023, 184, 109426. https://doi.org/10.1016/j.cie.2023.109426. 3. Youssef, A.; Mejri, I. Linking Digital Technologies to Sustainability through Industry 5.0: A bibliometric Analysis. Sustainability 2023, 15, 7465. https://doi.org/10.3390/su15097465. 4. Zhang, C.; Wang, Z.; Zhou, G.; Chang, F.; Jing, Y.; Cheng, W.; Ding, K.; Zhao, D. Towards new-generation human-centric smart manufacturing in Industry 5.0: A systematic review. Adv. Eng. Informatics 2023, 57, 102121. https://doi.org/10.1016/j.aei.2023.102121. 5. Murtaza, A.; Saher, A.; Zafar, M.; Moosavi, S.; Aftab, M.; Sanfilippo, F. Paradigm shift for predictive maintenance and condition monitoring from Industry 4.0 to Industry 5.0: A systematic review, challenges and case study. Results in Engineering 2024, Article 102935. https://doi.org/10.1016/j.rineng.2024.102935. 6. Ryvak, N. Industry 5.0: Transition to a sustainable and human-oriented industry. Socio-Economic Problems of the Modern Period of Ukraine 2022, 3, 7. https://doi.org/10.36818/2071-4653-2022-3-7. 7. Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. https://doi.org/10.3390/su12114674. 8. Castagnoli, R.; Cugno, M.; Maroncelli, S.; Cugno, A. A New Research Agenda for Human-Centric Manufacturing: A Systematic Literature Review. IEEE Trans. Eng. Manag. 2024, 71, 15236–15253. https://doi.org/10.1109/TEM.2024.3479775. |

| 9 | Managerial sustainability | 10 articles | 1. Piccarozzi, M.; Silvestri, C.; Aquilani, B.; Silvestri, L. Is this a new story of the ‘Two Giants’? A systematic literature review of the relationship between industry 4.0, sustainability and its pillars. Technol. Forecast. Soc. Change 2022, 177, 121511. https://doi.org/10.1016/j.techfore.2022.121511. 2. Mouazen, A.; Hernández-Lara, A.; Chahine, J.; Halawi, A. Triple bottom line sustainability and Innovation 5.0 management through the lens of Industry 5.0, Society 5.0 and Digitized Value Chain 5.0. Eur. J. Innov. Manag. 2025, 28. https://doi.org/10.1108/ejim-04-2024-0339. 3. Shet, S.; Pereira, V. Proposed managerial competencies for Industry 4.0—Implications for social sustainability. Technol. Forecast. Soc. Change 2021, 173, 121080. https://doi.org/10.1016/j.techfore.2021.121080. 4. Borchardt, M.; Pereira, G.; Milan, G.; Scavarda, A.; Nogueira, E.; Poltosi, L. Industry 5.0 Beyond Technology: An Analysis Through the Lens of Business and Operations Management Literature. Organizacija 2022, 55, 305–321. https://doi.org/10.2139/ssrn.4111659. 5. Birkel, H.; Müller, J. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2021, 289, 125612. https://doi.org/10.1016/j.jclepro.2020.125612. 6. Nayeri, S.; Sazvar, Z.; Heydari, J. Towards a responsive supply chain based on the industry 5.0 dimensions: A novel decision-making method. Expert Syst. Appl. 2022, 213, 119267. https://doi.org/10.1016/j.eswa.2022.119267. 7. Bag, S.; Telukdarie, A.; Pretorius, J.; Gupta, S. Industry 4.0 and supply chain sustainability: Framework and future research directions. Benchmarking 2018, 25, 2349–2377. https://doi.org/10.1108/BIJ-03-2018-0056. 8. De Mendonça Santos, A.; Sant’Anna, Â. Industry 4.0 technologies for sustainability within small and medium enterprises: A systematic literature review and future directions. J. Clean. Prod. 2024, 372, 143023. https://doi.org/10.1016/j.jclepro.2024.143023. 9. Smuts, H.; Van Der Merwe, A. Knowledge Management in Society 5.0: A Sustainability Perspective. Sustainability 2022, 14, 6878. https://doi.org/10.3390/su14116878. 10. Psarommatis, F.; May, G.; Azamfirei, V. Envisioning maintenance 5.0: Insights from a systematic literature review of Industry 4.0 and a proposed framework. J. Manuf. Syst. 2023, 70, 113–129. https://doi.org/10.1016/j.jmsy.2023.04.009. |

References

- Totlani, K. The evolution of generative artificial intelligence: Implications for the media and film industry. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 973–980. [Google Scholar] [CrossRef]

- Kanbach, D.K.; Heiduk, L.; Blueher, G.; Schreiter, M.; Lahmann, A. The GenAI is out of the bottle: Generative artificial intelligence from a business model innovation perspective. Rev. Manag. Sci. 2024, 18, 1189–1220. [Google Scholar] [CrossRef]

- Liu, Y. Implications of generative artificial intelligence for the development of the media industry. Adv. Eng. Innov. 2023, 1, 28–35. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Fathi, M.; Iranmanesh, M.; Vilkas, M.; Grybauskas, A.; Amran, A. Generative artificial intelligence in manufacturing: Opportunities for actualizing Industry 5.0 sustainability goals. J. Manuf. Technol. Manag. 2024, 35, 94–121. [Google Scholar] [CrossRef]

- Cioffi, R.; Travaglioni, M.; Piscitelli, G.; Petrillo, A.; Felice, F. Artificial intelligence and machine learning applications in smart production: Progress, trends, and directions. Sustainability 2020, 12, 492. [Google Scholar] [CrossRef]

- Waltersmann, L.; Kiemel, S.; Stuhlsatz, J.; Sauer, A.; Miehe, R. Artificial intelligence applications for increasing resource efficiency in manufacturing companies—A comprehensive review. Sustainability 2021, 13, 6689. [Google Scholar] [CrossRef]

- Mondal, S.; Goswami, S. Rise of intelligent machines: Influence of artificial intelligence on mechanical engineering innovation. Spectr. Eng. Manag. Sci. 2024, 2, 46–55. [Google Scholar] [CrossRef]

- Bilgram, V.; Laarmann, F. Accelerating innovation with generative AI: AI-augmented digital prototyping and innovation methods. IEEE Eng. Manag. Rev. 2023, 51, 18–25. [Google Scholar] [CrossRef]

- Bécue, A.; Gama, J.; Brito, P. AI’s effect on innovation capacity in the context of Industry 5.0: A scoping review. Artif. Intell. Rev. 2024, 57, 10864. [Google Scholar] [CrossRef]

- Kulkarni, N.; Bansal, S. Revolutionizing manufacturing: The integral role of AI and computer vision in shaping future industries. J. Glob. Econ. Bus. Financ. 2024, 6, 5–10. [Google Scholar] [CrossRef]

- Jun, L.; Jiang, X.; Shi, M.; Yang, Y. Impact of artificial intelligence on manufacturing industry global value chain position. Sustainability 2024, 16, 1341. [Google Scholar] [CrossRef]

- Burki, A.; Mafaz, M.; Ahmad, Z.; Zulfaka, A.; Isa, M. Artificial intelligence and environmental sustainability: Insights from PLS-SEM on resource efficiency and carbon emission reduction. Opsearch Am. J. Open Res. 2024, 3, 277–288. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, S. Artificial intelligence and carbon emissions in manufacturing firms: The moderating role of green innovation. Processes 2023, 11, 2705. [Google Scholar] [CrossRef]

- Santhanam, A. Systematic literature review on artificial intelligence and sustainable practices in the apparel industry. J. Inform. Educ. Res. 2024, 4, 1712. [Google Scholar] [CrossRef]

- Judijanto, L.; Winarko, T.; Tahir, U.; Vandika, A.; Sarungallo, A. The effect of AI-based technology implementation, green energy sustainability, and product innovation on economic growth of the manufacturing industry in Indonesia. West Sci. Nat. Technol. 2024, 2, 153–163. [Google Scholar] [CrossRef]

- Guo, W.; Jiang, P. An investigation on establishing small- and medium-sized enterprises communities under the environment of social manufacturing. Concurr. Eng. 2018, 26, 251–264. [Google Scholar] [CrossRef]

- Zanella, R.M.; Frazzon, E.M.; Uhlmann, I.R. Social manufacturing: From the theory to the practice. Braz. J. Oper. Prod. Manag. 2022, 19, 1–21. [Google Scholar] [CrossRef]

- Awan, U.; Kraslawski, A.; Huiskonen, J. Governing interfirm relationships for social sustainability: The relationship between governance mechanisms, sustainable collaboration, and cultural intelligence. Sustainability 2018, 10, 4473. [Google Scholar] [CrossRef]

- Fraile, F.; Sanchis, R.; Poler, R.; Ortiz, A. Reference models for digital manufacturing platforms. Appl. Sci. 2019, 9, 4433. [Google Scholar] [CrossRef]

- Tran, N.H.; Park, H.S.; Nguyen, Q.V.; Hoang, T.D. Development of a smart cyber-physical manufacturing system in the Industry 4.0 context. Appl. Sci. 2019, 9, 3325. [Google Scholar] [CrossRef]

- Hughes, R.T.; Zhu, L.; Bednarz, T. Generative adversarial networks–enabled human–artificial intelligence collaborative applications for creative and design industries: A systematic review of current approaches and trends. Front. Artif. Intell. 2021, 4, 604234. [Google Scholar] [CrossRef] [PubMed]

- Munteanu, S.; Cărbune, V. Design of specialized hardware architectures for Industry 4.0. In Electronics, Communications and Computing; Technnica-TUTM: Chisinau, Moldova, 2023; pp. 244–246. [Google Scholar]

- Mageto, J. Current and future trends of information technology and sustainability in logistics outsourcing. Sustainability 2022, 14, 7641. [Google Scholar] [CrossRef]

- Fareed, A.; De Felice, F.; Forcina, A.; Petrillo, A. Role and applications of advanced digital technologies in achieving sustainability in multimodal logistics operations: A systematic literature review. Sustain. Futures 2024, 8, 100278. [Google Scholar] [CrossRef]

- Saqib, Z.; Qin, L. Investigating Effects of Digital Innovations on Sustainable Operations of Logistics: An Empirical Study. Sustainability 2024, 16, 5518. [Google Scholar] [CrossRef]

- Sharma, V.; Raut, R.; Govindarajan, U.; Narkhede, B. Advancements in urban logistics toward smart, sustainable reforms in developing enabling technologies and markets. Kybernetes 2021, 51, 1038–1061. [Google Scholar] [CrossRef]

- Kotsiopoulos, T.; Michailidis, P.; Ziogou, C.; Alexopoulos, N.; Bouloumpasis, I.; Tzovaras, D. Machine learning and deep learning in smart manufacturing: The smart grid paradigm. Comput. Sci. Rev. 2021, 40, 100341. [Google Scholar] [CrossRef]

- Agote-Garrido, A.; Martín-Gómez, A.M.; Lama-Ruiz, J.R. Manufacturing system design in Industry 5.0: Incorporating sociotechnical systems and social metabolism for human-centered, sustainable, and resilient production. Systems 2023, 11, 537. [Google Scholar] [CrossRef]

- Wang, H.; Liu, M.; Shen, W. Industrial-generative pre-trained transformer for intelligent manufacturing systems. IET Collab. Intell. Manuf. 2023, 5, e12078. [Google Scholar] [CrossRef]

- Yang, Q.; Jin, S. Exploring the impact of digital transformation on manufacturing environment, social responsibility, and corporate governance performance: The moderating role of top management teams. Sustainability 2024, 16, 4342. [Google Scholar] [CrossRef]

- Rajesh, R. Industry 5.0: Analyzing the challenges in implementation using grey influence analysis. J. Enterp. Inf. Manag. 2023, 36, 1349–1371. [Google Scholar] [CrossRef]

- Ghadge, A.; Kara, M.E.; Moradlou, H.; Goswami, M. The impact of Industry 4.0 implementation on supply chains. J. Manuf. Technol. Manag. 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Jamil, M.; Mehmood, W.; Aslam, A. Sustainability education in Pakistan: A qualitative content analysis of the 10th grade Pakistan Studies textbook. Voyag. J. Educ. Stud. 2024, 4, 80–95. [Google Scholar] [CrossRef]

- Hu, X.; Chong, H. Environmental sustainability of off-site manufacturing: A literature review. Eng. Constr. Archit. Manag. 2019, 28, 332–350. [Google Scholar] [CrossRef]

- Jayarathna, C.; Agdas, D.; Dawes, L.; Miska, M. Exploring sector-specific sustainability indicators: A content analysis of sustainability reports in the logistics sector. Eur. Bus. Rev. 2021, 34, 321–343. [Google Scholar] [CrossRef]

- Rashed, A.; Rashdan, S.; Ali-Mohamed, A. Towards effective environmental sustainability reporting in the large industrial sector of Bahrain. Sustainability 2021, 14, 219. [Google Scholar] [CrossRef]

- Martins, F.; Batalhão, A.; Ahokas, M.; Liboni, L.; Cezarino, L. Rethinking sustainability in cocoa supply chain in light of SDG disclosure. Sustain. Account. Manag. Policy J. 2023, 14, 258–286. [Google Scholar] [CrossRef]

- Amaya, N.; López-Santamaría, M.; Acosta, Y.; Hinestroza, M. A step-by-step method to classify corporate sustainability practices based on the signaling theory. MethodsX 2021, 8, 101538. [Google Scholar] [CrossRef]

- Crocco, E.; Broccardo, L.; Alofaysan, H.; Agarwal, R. Sustainability reporting in carbon-intensive industries: Insights from a cross-sector machine learning approach. Bus. Strateg. Environ. 2024, 33, 7201–7215. [Google Scholar] [CrossRef]

- Hess, J. A multi-level analysis of sustainability practices in Ghana: Examining the timber, cocoa, and gold mining industries. Int. J. Organ. Anal. 2021, 30, 760–777. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Bonilla, S.H.; Silva, H.R.O.; da Silva, M.T.; Gonçalves, R.F.; Sacomano, J.B. Industry 4.0 and sustainability implications: A scenario-based analysis of the impacts and challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Morovati Sharif Abadi, A.; Kazemi, F.; Salehi, M.; Ghahfarokhi, H.M. Supply chain management in the information age (An analysis of research trends in the field of information flow in the supply chain). Iran. J. Inf. Process. Manag. 2024, 39, 1477–1505. [Google Scholar]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Adenigbo, A.J. Analysis of air cargo traffic at airports in Nigeria and Ghana. J. Sustain. Dev. Transp. Logist. 2023, 8, 23–42. [Google Scholar] [CrossRef]

- Sira, M. Generative AI takes centre stage: Revolutionizing productivity and reshaping industries. Syst. Saf. Hum.-Tech. Facil.-Environ. 2023, 5, 57–65. [Google Scholar] [CrossRef]

- Duong, C.D. A serial mediation model of the linkage between entrepreneurial education, self-efficacy, attitudes and intentions: Does gender matter? A multi-group analysis. Horiz. Int. J. Learn. Futures 2023, 31, 174–195. [Google Scholar] [CrossRef]

- Oluwagbenro, M.B. Generative AI: Definition, concepts, applications, and future prospects. Authorea Prepr. 2024. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Critical components of Industry 5.0 towards a successful adoption in the field of manufacturing. J. Ind. Integr. Manag. 2020, 5, 327–348. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, X.; Wang, Y.; Zhao, H. Industry convergence and value innovation: A bibliometric analysis and systematic review. Kybernetes 2023, 52, 4576–4610. [Google Scholar] [CrossRef]

- Aldoseri, A.; Al-Khalifa, K.N.; Hamouda, A.M. AI-powered innovation in digital transformation: Key pillars and industry impact. Sustainability 2024, 16, 1790. [Google Scholar] [CrossRef]

- Kamble, R.; Wankhade, L. System dynamics model to improve productivity in manufacturing industries. Int. J. Prod. Qual. Manag. 2021, 32, 23. [Google Scholar] [CrossRef]

- Ojsteršek, R.; Buchmeister, B. The impact of manufacturing flexibility and multi-criteria optimization on the sustainability of manufacturing systems. Symmetry 2020, 12, 157. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhao, L.; Gao, Y.; Sun, M.; Li, J. Evaluating performance of innovation resource allocation in industrial enterprises: An improved two-stage DEA model. Technol. Anal. Strateg. Manag. 2024, 36, 2624–2646. [Google Scholar] [CrossRef]

- Sylvia, E.; Sunitiyoso, Y. A system dynamic model for Indonesian petrochemical industry emission reduction. Int. J. Energy Sect. Manag. 2023, 18, 1–25. [Google Scholar] [CrossRef]

- Huilu, Y.; Dong, S.; Li, F. A system dynamics approach to eco-industry system effects and trends. Pol. J. Environ. Stud. 2019, 28, 1469–1482. [Google Scholar] [CrossRef]

- Xiong, G.-Y.; Zhu, Q.-L.; Wang, Y.-Z.; Huang, Y.-Q.; Jiang, P.-Y. A case study in social manufacturing: From social manufacturing to social value chain. Machines 2022, 10, 978. [Google Scholar] [CrossRef]

- Ding, K.; Jiang, P.-Y. Social sensors (S2ensors): A kind of hardware-software-integrated mediators for social manufacturing systems under mass individualization. Chin. J. Mech. Eng. 2017, 30, 1150–1161. [Google Scholar] [CrossRef]

- Sari, M.; Herianto, H.; Dharma, I.; Tontowi, A. Integrated production system on social manufacturing: A simulation study. Manag. Syst. Prod. Eng. 2022, 30, 230–237. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Ma, Q.; Fan, S.; Jin, H.; Liu, H.; Liu, H. A social sustainability assessment model for manufacturing company based on s-lca. Int. J. Sustain. Dev. Plan. 2019, 14, 172–182. [Google Scholar] [CrossRef]

- Chi, Y.; Fang, Y.; Liu, J. Research on the motivation and path simulation of collaborative agglomeration of Chinese culture and tourism industries based on system dynamics. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Susanty, A.; Puspitasari, N.B.; Fachreza, A. Measuring the performance of SMEs during the pandemic situation using system dynamic. Kybernetes 2023, 52, 2538–2567. [Google Scholar] [CrossRef]

- Guillén-Yparrea, N.; Hernández-Rodríguez, F. Unveiling generative AI in higher education: Insights from engineering students and professors. In Proceedings of the 2024 IEEE Global Engineering Education Conference (EDUCON), Kos Island, Greece, 8–11 May 2024; IEEE: New York, NY, USA, 2024; pp. 1–5. [Google Scholar]

- Zhao, J.; Xi, Q.; Wang, S.; Wang, S. Improving the partial-load fuel economy of 4-cylinder SI engines by combining variable valve timing and cylinder-deactivation through double intake manifolds. Appl. Therm. Eng. 2018, 141, 245–256. [Google Scholar] [CrossRef]

- Sharma, K.; Kumar, R.; Kumar, A.; Balabantaray, S.; Arora, M. A digital ecosystem for sustainable fruit supply chain in Uttarakhand: A comprehensive review. Environ. Dev. Sustain. 2024, 26, 13217–13252. [Google Scholar] [CrossRef]

- Farooq, M.A.; Gao, S.; Hassan, M.A.; Huang, Z.; Rasheed, A.; Hearne, S.; Li, X.; Li, H. Artificial intelligence in plant breeding. Trends Genet. 2024, 40, 891–908. [Google Scholar] [CrossRef]

- Sohn, K.; Berthelot, D.; Carlini, N.; Zhang, Z.; Zhang, H.; Raffel, C.; Cubuk, E.D.; Kurakin, A.; Li, C.-L. Fixmatch: Simplifying semi-supervised learning with consistency and confidence. Adv. Neural Inf. Process. Syst. 2020, 33, 596–608. [Google Scholar]

- Wang, J. Carbon-nanotube based electrochemical biosensors: A review. Electroanalysis 2005, 17, 7–14. [Google Scholar] [CrossRef]

- Farsi, M.; Ahmadi, H.; Saeed, N. Deployment techniques in wireless sensor networks, coverage and connectivity: A survey. IEEE Access 2019, 7, 28940–28954. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, H.; Liu, Y.; Sun, Y.; Wang, L. Digital twin-based opti-state control method for a synchronized production operation system. Robot. Comput.-Integr. Manuf. 2020, 63, 101892. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Delving deep into rectifiers: Surpassing human-level performance on ImageNet classification. In Proceedings of the IEEE International Conference on Computer Vision, Santiago, Chile, 11–18 December 2015; IEEE: New York, NY, USA, 2015; pp. 1026–1034. [Google Scholar]

- Han, L.; Li, Y.; Wang, H.; Xu, X. System dynamics modeling and simulation for global energy-economy-politics system. In Proceedings of the 2017 IEEE Conference on Energy Internet and Energy System Integration (EI2), Beijing, China, 26–28 November 2017; IEEE: New York, NY, USA, 2017; pp. 1–6. [Google Scholar]

- Hwang, Y.-L.; Truong, V.-T. Dynamic analysis and control of multi-body manufacturing systems based on Newton–Euler formulation. Int. J. Comput. Methods 2015, 12, 1550007. [Google Scholar] [CrossRef]

- Wei, S.; Yang, Z.; Cui, B.; Li, X. System dynamics simulation model for assessing socio-economic impacts of different levels of environmental flow allocation in the Weihe River Basin, China. Eur. J. Oper. Res. 2012, 221, 248–265. [Google Scholar] [CrossRef]

- Amirkhizi, P.J.; Pedrammehr, S.; Pakzad, S.; Asady, Z.; Arogbonlo, A.; Asadi, H. Emerging Synergies: Industry 5.0 Integration of Complex Systems. In Proceedings of the 2024 IEEE International Systems Conference (SysCon), Denver, CO, USA, 22–25 April 2024; IEEE: New York, NY, USA, 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Wang, K.; Ying, Z.; Goswami, S.; Yin, Y.; Zhao, Y. Investigating the role of artificial intelligence technologies in the construction industry using a Delphi-ANP-TOPSIS hybrid MCDM concept under a fuzzy environment. Sustainability 2023, 15, 11848. [Google Scholar] [CrossRef]

- Ahmad, T.; Zhang, D.; Huang, C.; Zhang, H.; Dai, N.; Song, Y.; Chen, H. Artificial intelligence in sustainable energy industry: Status quo, challenges and opportunities. J. Clean. Prod. 2021, 289, 125834. [Google Scholar] [CrossRef]

- Dmitrieva, E.; Balmiki, V.; Bhardwaj, N.; Kumar, K.; Sharma, A.; Shruthi, C. Security and privacy in AI-driven Industry 5.0: Experimental insights and threat analysis. In BIO Web of Conferences; EDP Sciences: Paris, France, 2024; Volume 86, p. 01097. [Google Scholar] [CrossRef]

- Giri, F.; Chaparro, T. Unveiling the blackbox within ESG ratings’ blackbox: Toward a framework for analyzing AI adoption and its impacts. Bus. Strat. Dev. 2024, 7, 70038. [Google Scholar] [CrossRef]

- Eang, M.; Clarke, A.; Ordonez-Ponce, E. The roles of multinational enterprises in implementing the United Nations Sustainable Development Goals at the local level. BRQ Bus. Res. Q. 2022, 26, 79–97. [Google Scholar] [CrossRef]

| Sustainability Dimension | Definition and Characteristics | Sources | |

|---|---|---|---|

| 1 | Environmental sustainability | Focuses on reducing carbon emissions, resource recycling, and supply chain management to minimize environmental impacts. | 25 articles |

| 2 | Social sustainability | Emphasizes enhancing employee welfare, fostering social responsibility, and supporting community development. | 17 articles |

| 3 | Economic sustainability | Involves cost reduction, productivity enhancement, and the development of flexible business models. | 10 articles |

| 4 | Ethical sustainability | Addresses equitable resource distribution and transparency in decision-making processes. | 10 articles |

| 5 | Technological sustainability | Highlights the role of advanced technologies, such as the IoT and big data, in improving efficiency and reducing environmental impact. | 8 articles |

| 6 | Cultural sustainability | Aims to preserve cultural identity and local values within production processes. | 8 articles |

| 7 | Supply chain sustainability | Focuses on ensuring transparency in supply chains and managing product life cycles effectively. | 8 articles |

| 8 | Human sustainability | Relates to improving employee health and safety and fostering secure and healthy work environments. | 8 articles |

| 9 | Managerial sustainability | Highlights the development of sustainable management strategies and international cooperation across supply chains. | 10 articles |

| Sustainability Dimension | Expert Feedback | Action Taken | Final Validated Sustainability Dimension | Agreement Score (Mean ± SD/Cohen’s Kappa) | |

|---|---|---|---|---|---|

| 1 | Environmental sustainability | Clear and highly relevant | No change | Environmental sustainability (EnS) | 4.7 ± 0.5/0.82 |

| 2 | Social sustainability | Clear and highly relevant | No change | Social sustainability (SoS) | 4.5 ± 0.6/0.79 |

| 3 | Economic sustainability | Clear and highly relevant | No change | Economic sustainability (EcS) | 4.6 ± 0.4/0.81 |

| 4 | Ethical sustainability | Clear and highly relevant | No change | Ethical sustainability (EthS) | 4.6 ± 0.5/0.80 |

| 5 | Technological sustainability | Clear and highly relevant | No change | Technological sustainability (TS) | 4.8 ± 0.3/0.85 |

| 6 | Cultural sustainability | Clear and highly relevant | No change | Cultural sustainability (CS) | 4.3 ± 0.6/0.77 |

| 7 | Supply chain sustainability | Clear and highly relevant | No change | Supply chain sustainability (SCS) | 4.5 ± 0.5/0.79 |

| 8 | Human sustainability | Clear and highly relevant | No change | Human sustainability (HS) | 4.5 ± 0.6/0.79 |

| 9 | Environmental sustainability | Clear and highly relevant | No change | Managerial sustainability (MS) | 4.4 ± 0.5/0.78 |

| Groups | Raters | Rated Items | Observed Agreement (%) | Expected Agreement (%) | Kappa Coefficient (κ) | SE | 95% Confidence Interval (CI) | Interpretation |

|---|---|---|---|---|---|---|---|---|

| 1 | 26 | 50 | 85 | 60 | 0.625 | 0.045 | 0.537–0.713 | Substantial agreement |

| 2 | 26 | 50 | 90 | 65 | 0.714 | 0.042 | 0.632–0.796 | Substantial agreement |

| 3 | 26 | 50 | 92 | 70 | 0.733 | 0.040 | 0.654–0.812 | Substantial agreement |

| 4 | 26 | 50 | 88 | 62 | 0.684 | 0.043 | 0.600–0.768 | Substantial agreement |

| 5 | 26 | 50 | 87 | 61 | 0.667 | 0.044 | 0.581–0.753 | Substantial agreement |

| GAI Applications | Mean | SD | Skewness | Kurtosis |

|---|---|---|---|---|

| PM | 3.41 | 1.139 | −0.058 | −1.042 |

| ROA | 3.42 | 1.289 | −0.482 | −0.814 |

| SMD | 3.12 | 1.314 | 0.004 | −1.077 |

| WETP | 3 | 1.479 | −0.002 | −1.44 |

| CET | 3.2 | 1.271 | −0.124 | −0.901 |

| SCO | 3.04 | 1.347 | −0.184 | −1.171 |

| IBM | 2.81 | 1.295 | 0.28 | −1.07 |

| TDF | 3.11 | 1.389 | −0.01 | −1.329 |

| BMT | 3.54 | 1.343 | −0.542 | −0.882 |

| CPSI | 3.34 | 1.126 | −0.47 | −0.293 |

| AT | 3.09 | 1.529 | 0.0154 | −1.512 |

| CPD | 3.07 | 1.313 | 0.023 | −1.08 |

| DSCM | 3.09 | 1.551 | 0.033 | −1.527 |

| SSS | 3.61 | 1.253 | 0.237 | −1.121 |

| ES | 3.22 | 1.511 | −0.191 | −1.403 |

| AIDSS | 3.14 | 1.161 | 0.178 | −0.658 |

| SPT | 2.88 | 1.266 | 0.14 | −1.021 |

| Variable | Kolmogorov–Smirnov Statistics | Shapiro–Wilk Test | ||||

|---|---|---|---|---|---|---|

| Test Statistics | df | p-Value | Test Statistics | df | p-Value | |

| PM | 3.41 | 1170 | 0 | −0.058 | 1170 | 0 |

| ROA | 3.42 | 1170 | 0 | −0.482 | 1170 | 0 |

| SMD | 3.12 | 1170 | 0 | 0.004 | 1170 | 0 |

| WETP | 3 | 1170 | 0 | −0.002 | 1170 | 0 |

| CET | 3.2 | 1170 | 0 | −0.124 | 1170 | 0 |

| SCO | 3.04 | 1170 | 0 | −0.184 | 1170 | 0 |

| IBM | 2.81 | 1170 | 0 | 0.28 | 1170 | 0 |

| TDF | 3.11 | 1170 | 0 | −0.01 | 1170 | 0 |

| BMT | 3.54 | 1170 | 0 | −0.542 | 1170 | 0 |

| CPSI | 3.34 | 1170 | 0 | −0.47 | 1170 | 0 |

| AT | 3.09 | 1170 | 0 | 0.0154 | 1170 | 0 |

| CPD | 3.07 | 1170 | 0 | 0.023 | 1170 | 0 |

| DSCM | 3.09 | 1170 | 0 | 0.033 | 1170 | 0 |

| SSS | 3.61 | 1170 | 0 | 0.237 | 1170 | 0 |

| ES | 3.22 | 1170 | 0 | −0.191 | 1170 | 0 |

| AIDSS | 3.14 | 1170 | 0 | 0.178 | 1170 | 0 |

| SPT | 2.88 | 1170 | 0 | 0.14 | 1170 | 0 |

| Test | Measure | F | Hypothesis df | Error df | p-Value |

|---|---|---|---|---|---|

| Spillover effect | 7.073 | 516.986 | 136 | 9216 | 0 |

| Lande and Wilks | 0 | 832.631 | 136 | 8359.751 | 0 |

| Hotelling effect | 106.715 | 897.075 | 136 | 9146 | 0 |

| Largest Root Effect | 28751 | 1948.3 | 17 | 1152 | 0 |

| Variable | TS | EthS | EcS | SS | EnS | CS | SCS | HS | MS | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Ranking | Mean | Ranking | Mean | Ranking | Mean | Ranking | Mean | Ranking | Mean | Ranking | Mean | Ranking | Mean | Ranking | Mean | Ranking | |

| AIDSS | 13.06 | 4 | 8.41 | 9 | 12.43 | 4 | 6.03 | 11 | 7.68 | 11 | 15.02 | 1 | 8.42 | 11 | 8.79 | 8 | 2.51 | 14 |

| AT | 12.92 | 6 | 4.37 | 15 | 12.17 | 6 | 5.54 | 13 | 14.7 | 3 | 2.35 | 17 | 14.95 | 4 | 12.58 | 4 | 2.33 | 16 |

| BMT | 2.52 | 15 | 8.38 | 10 | 12.64 | 3 | 15.49 | 1 | 11.59 | 5 | 14.79 | 4 | 8.55 | 10 | 15.21 | 3 | 5.08 | 12 |

| CET | 2.38 | 17 | 8.51 | 8 | 7.93 | 10 | 13.03 | 4 | 7.77 | 10 | 14.9 | 2 | 5.05 | 14 | 8.13 | 11 | 14.75 | 3 |

| CPD | 9.09 | 9 | 1.57 | 17 | 15.17 | 2 | 9.18 | 10 | 4.3 | 14 | 14.82 | 3 | 8.56 | 9 | 4.61 | 14 | 11.6 | 6 |

| CPSI | 9.45 | 8 | 12.1 | 7 | 7.88 | 11 | 13 | 5 | 7.51 | 12 | 11.83 | 6 | 2.47 | 15 | 8.45 | 10 | 15.02 | 1 |

| DSCM | 5.33 | 13 | 15.28 | 3 | 2 | 16 | 15.4 | 3 | 2.02 | 16 | 4.88 | 13 | 12.05 | 5 | 15.32 | 2 | 8.04 | 10 |

| ES | 15.89 | 1 | 4.67 | 12 | 7.99 | 9 | 9.34 | 8 | 15.01 | 2 | 2.53 | 15 | 2.46 | 16 | 12.54 | 5 | 14.75 | 3 |

| IBM | 13.38 | 3 | 15.34 | 2 | 4.52 | 12 | 5.79 | 12 | 1.88 | 17 | 8.33 | 9 | 11.92 | 7 | 4.88 | 13 | 5.12 | 11 |

| PM | 15.77 | 2 | 12.26 | 6 | 8.28 | 8 | 5.41 | 14 | 11.43 | 7 | 8 | 11 | 14.98 | 3 | 5.05 | 12 | 8.29 | 8 |

| ROA | 13.02 | 5 | 15.38 | 1 | 4.23 | 14 | 2.52 | 17 | 7.78 | 9 | 11.28 | 8 | 11.98 | 6 | 8.46 | 9 | 14.84 | 2 |

| SCO | 8.87 | 11 | 4.62 | 13 | 2.11 | 15 | 9.5 | 7 | 11.37 | 8 | 11.91 | 5 | 15.07 | 1 | 2.18 | 16 | 11.77 | 4 |

| SMD | 9.51 | 7 | 8.36 | 11 | 15.25 | 1 | 9.2 | 9 | 4.43 | 13 | 5.23 | 12 | 2.46 | 16 | 15.58 | 1 | 11.67 | 5 |

| SPT | 8.88 | 10 | 4.5 | 14 | 8.44 | 7 | 2.6 | 16 | 4.27 | 15 | 11.54 | 7 | 15.03 | 2 | 4.53 | 15 | 11.58 | 7 |

| SSS | 2.5 | 16 | 12.53 | 4 | 4.4 | 13 | 12.79 | 6 | 11.55 | 6 | 8.27 | 10 | 5.14 | 13 | 2.12 | 17 | 5.06 | 13 |

| TDF | 5.35 | 12 | 12.36 | 5 | 15.25 | 1 | 2.7 | 15 | 15.02 | 1 | 4.85 | 14 | 5.23 | 12 | 12.31 | 6 | 8.16 | 9 |

| WETP | 5.07 | 14 | 4.35 | 16 | 12.29 | 5 | 15.47 | 2 | 14.69 | 4 | 2.45 | 16 | 8.66 | 8 | 12.26 | 7 | 2.43 | 15 |

| Expert Group | Participants No. | Observed Agreement (%) | Cohen’s Kappa (κ) | Standard Error (SE) | 95% Confidence Interval (CI) | Interpretation |

|---|---|---|---|---|---|---|

| 1 | 12 | 85 | 0.72 | 0.039 | 0.644–0.796 | Substantial agreement |

| 2 | 12 | 90 | 0.76 | 0.037 | 0.689–0.831 | Substantial agreement |

| 3 | 12 | 92 | 0.81 | 0.35 | 0.742–0.878 | Almost perfect agreement |

| 4 | 12 | 88 | 0.74 | 0.38 | 0.669–0.811 | Substantial agreement |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jourabchi Amirkhizi, P.; Pedrammehr, S.; Pakzad, S.; Shahhoseini, A. Generative Artificial Intelligence in Adaptive Social Manufacturing: A Pathway to Achieving Industry 5.0 Sustainability Goals. Processes 2025, 13, 1174. https://doi.org/10.3390/pr13041174

Jourabchi Amirkhizi P, Pedrammehr S, Pakzad S, Shahhoseini A. Generative Artificial Intelligence in Adaptive Social Manufacturing: A Pathway to Achieving Industry 5.0 Sustainability Goals. Processes. 2025; 13(4):1174. https://doi.org/10.3390/pr13041174

Chicago/Turabian StyleJourabchi Amirkhizi, Parisa, Siamak Pedrammehr, Sajjad Pakzad, and Ahad Shahhoseini. 2025. "Generative Artificial Intelligence in Adaptive Social Manufacturing: A Pathway to Achieving Industry 5.0 Sustainability Goals" Processes 13, no. 4: 1174. https://doi.org/10.3390/pr13041174

APA StyleJourabchi Amirkhizi, P., Pedrammehr, S., Pakzad, S., & Shahhoseini, A. (2025). Generative Artificial Intelligence in Adaptive Social Manufacturing: A Pathway to Achieving Industry 5.0 Sustainability Goals. Processes, 13(4), 1174. https://doi.org/10.3390/pr13041174