Abstract

In view of the limited applicability of traditional chemical flooding and binary composite flooding for heavy-oil reservoirs, branched-preformed particle gel (B-PPG) with excellent plugging performance was added to construct the B-PPG/SP (B-PPG/surfactant/polymer) composite system. Through sand pack flooding experiments, it has been proven that the synergistic effect between B-PPG and polymer can expand the swept area and increase the contact between the viscosity reducer and heavy oil, enabling the viscosity reducer to better exert emulsification and viscosity reduction effects. The synergistic effect between B-PPG, polymer and viscosity reducer can further expand the swept area and oil displacement efficiency, ultimately enhancing the heavy-oil recovery by 37.8%. Microscopic visualization flooding experiments proved that cluster remaining oil accounts for the largest proportion in the microscopic remaining oil in heavy oil. By adding B-PPG and polymers, cluster remaining oil can be effectively displaced, thereby significantly enhancing the heavy-oil recovery. And adding viscosity reducer to the composite system can effectively enhance the dispersed residual oil recovery within the swept area. The sand pack flooding experiments with different heavy-oil viscosity proved that the optimal oil viscosity of the B-PPG/SP composite system can reach 657.2 mPa·s, with an incremental oil recovery rate increase of 30.2%.

1. Introduction

With the development of the petroleum industry, the importance of heavy oil in the world’s hydrocarbon resources is increasing [1,2]. Due to the high viscosity and poor fluidity of heavy oil, conventional water flooding development suffers from high water–oil mobility and low swept area, resulting in low water flooding recovery [3,4]. Meanwhile, long-term water flooding development leads to changes in fluid properties, reservoir pore structure, and remaining oil distribution, making it more difficult to enhance heavy-oil recovery [5]. Based on the characteristics, the thermal recovery and cold recovery are adopted to reduce the heavy-oil viscosity and enhance heavy-oil recovery [6]. However, thermal recovery methods such as steam flooding and steam huff and puff have drawbacks such as high energy consumption, highly specific equipment conditions, and poor adaptability to heavy-oil reservoirs with thin and deep oil layers [7,8,9,10,11]. Therefore, thermal recovery is not suitable for deep and thin heavy-oil reservoirs.

The chemical flooding technology, as an important cold recovery method, has the advantages of low production cost, simple process flow, and low equipment requirements. And it has achieved good development results in oilfield applications [12,13,14]. At first, the chemical flooding technology applied to heavy-oil reservoirs only used a single chemical agent, such as polymer (polyacrylamide or partially hydrolyzed polyacrylamide), alkali and surfactant (petroleum Sulfonates). Previous studies [15,16] have demonstrated that alkali substances undergo saponification reactions with indigenous organic acids present in crude oil reservoirs, resulting in the in situ formation of surfactant species. These endogenously generated surfactants effectively stabilize oil-in-water (O/W) emulsions through interfacial activity. Furthermore, experimental evidence reveals that these in situ formed surfactants exhibit synergistic interactions with exogenously introduced synthetic surfactants, enabling the achievement of ultralow interfacial tension (IFT) values at oil–water interfaces. This combined surfactant system demonstrates superior performance in destabilizing viscous crude oil systems through multiple mechanisms, including emulsification, interfacial tension reduction, and fluidity improvement, thereby significantly augmenting the efficiency of enhanced heavy-oil recovery processes. Researcher [17,18,19] proved that surfactant exhibit superior emulsification capacity, enabling the disintegrated dispersion of viscous crude oil into stabilized oil-in-water (O/W) emulsion systems within brine formation and reducing the heavy-oil viscosity. At the same time, viscosity reducers can reduce the IFT between oil and water, thereby reducing the seepage resistance of heavy oil and enhancing oil recovery. A large number of studies [20,21] have confirmed that polymer (such as polyacrylamide) additives enhance recovery efficiency through dual mechanisms: (1) viscous fingering mitigation via aqueous phase viscosity augmentation, and (2) macroscopic sweep improvement through permeability-selective mobility control.

At present, with the development of chemical flooding in heavy oil exploitation, more and more experts and scholars are combining different oil displacement agents to form binary or ternary composite flooding systems, such as SA (surfactant/alkali) flooding, SP (surfactant/polymer) flooding and ASP (alkali/surfactant/polymer) flooding [22,23,24,25]. These systems further enhance heavy-oil recovery through the synergistic effect between different oil displacement agents.

However, there are many problems associated with different chemical flooding methods. In the process of oil displacement in chemical composite systems containing alkali, there will be problems such as low sweep efficiency and oil displacement efficiency caused by a large amount of alkali consumption, unsuitable mobility ratio, as well as scaling and viscosity fingering [26,27]. At the same time, the applicable range of heavy-oil viscosity using SP flooding technology is limited. In high heavy-oil-viscosity reservoirs, decreasing the water–oil mobility ratio by increasing the injection liquid viscosity cannot effectively expand the swept area [28,29,30]. Therefore, exploring new exploitation methods for heavy-oil reservoirs is of great significance for enhancing efficient development of heavy-oil reservoirs.

In the exploitation of heterogeneous oil reservoirs, a heterogeneous phase combination flooding system (HPCF) composed of the polymer, surfactant, and branched-preformed particle gel (B-PPG) was proposed. Preformed particle gel (PPG) can absorb water and swell to form soft solid particles [31]. By changing the profile through particle migration, selective permeability plugging, and viscoelastic deformation driven diversion, the sweep efficiency was significantly enhanced [32,33,34]. The B-PPG represents a structural advancement achieved through the incorporation of water-soluble linear branched chains into the PPG molecular architecture. These hydrophilic branches enhance colloidal stability through steric hindrance effects while synergistically improving aqueous phase viscosity and particulate suspension capacity [35,36,37]. The field pilot test of HPCF has been implemented in the Zhongyiqu Ng3 block, Gudao oil plant of the Shengli oilfield. The results of the field pilot test showed that the total daily oil production increased from 4.5 to 81.2 t/d, and the comprehensive water cut was decreased by 18.5% and oil recovery was increased by 3.5% [38]. However, there is few research on the application of B-PPG to heavy-oil reservoirs. Therefore, we propose a method to enhance heavy-oil recovery and the applicable viscosity range of chemical flooding by utilizing the plugging performance of B-PPG and the synergistic effect between B-PPG, polymers, and viscosity reducers.

In a previous study, a surfactant system with excellent oil displacement ability was screened for constructing the B-PPG/SP composite flooding system [18]. In this study, the ability of different oil displacement agents, different binary displacement, and B-PPG/SP composite flooding to enhance oil recovery was investigated and compared through macroscale and microscale flooding experiments to analyze the synergistic effect between polymers, viscosity reducers, and B-PPG. The mechanism of the B-PPG/SP composite system on enhancing heavy-oil recovery was clarified. At the same time, the influence of crude oil viscosity on the ability of B-PPG/SP composite system to enhance oil recovery was studied through sand-packed flooding experiments, and the applicable viscosity range of the system was clarified, providing a new method for enhancing heavy-oil reservoir recovery.

2. Materials and Methods

2.1. Materials

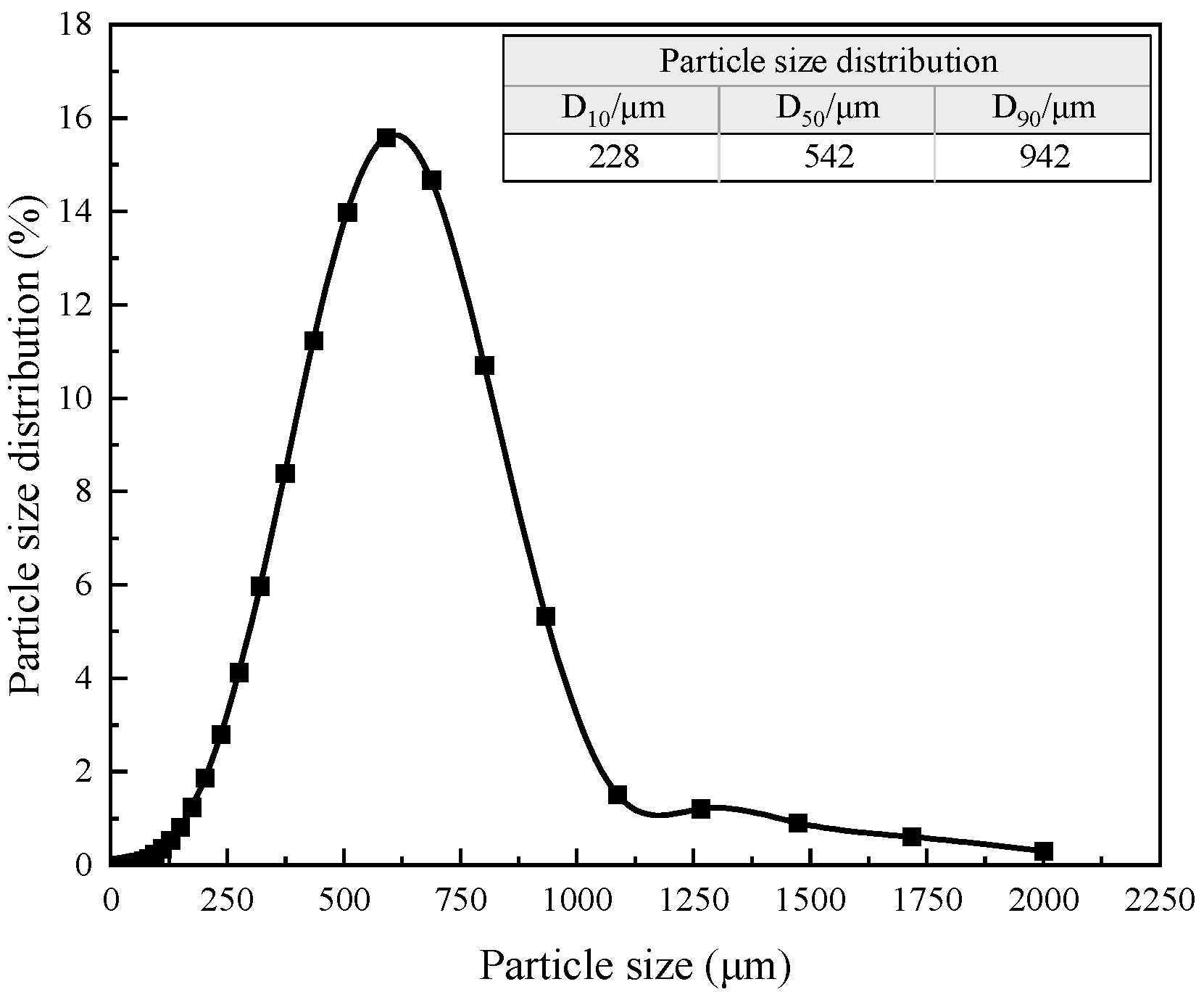

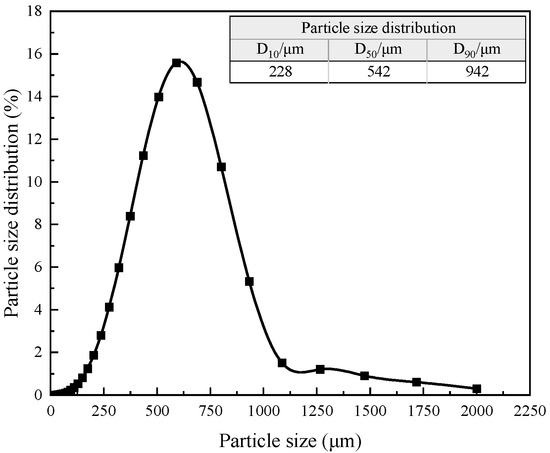

Degassed heavy oil from Shengli Oilfield was used as the oil phase, with a viscosity of 446 mPa·s and a density of 0.962 g·cm−3 at 70 °C. The oil used in the microscopic visual flooding experiment was a synthetic oil prepared by mixing the degassed heavy oil and kerosene, with a viscosity of 363.73 mPa·s at 30 °C. The mass ratio of heavy oil to kerosene is 10:1. The oil with different viscosities used in the sand-flooding experiment is a synthetic oil prepared by mixing degassed heavy oil and kerosene at 70 °C. This synthetic oil can better simulate the flooding process under real reservoir conditions. The experiment also featured a surfactant system Alkyl Polyglucoside and Linear Alkylbenzene Sulfonate Sodium Salt (APG1214/LAS-30, produced by Shandong Yousuo Chemical Technology Co., Ltd., Linxi, China) with excellent viscosity-reducing ability with an IFT of 0.15 mN·m−1 [18]. Branched-preformed particle gel (B-PPG) was provided by Shengli Oilfield. The size distribution of B-PPG is shown in Figure 1. Polymer (partially hydrolyzed polyacrylamide, HPAM) with a molecular weight of 30 million was provided by Shengli Oilfield. The brine adopted the composition of that from Gudong, Shengli Oilfield. The synthetic formation brine contained Ca2+ (292 mg/L), Mg2+ (65 mg/L), Na+(K+) (3667 mg/L), and Cl− (6583 mg/L). The B-PPG concentration used in the experiment was 1500 mg·L−1, the polymer concentration was 2000 mg·L−1, and the micro dynamic viscosity reducer concentration was 3000 mg·L−1.

Figure 1.

Particle size distribution of B-PPG.

2.2. Methods

2.2.1. Evaluation of Emulsifying Ability and Stability of Composited System

The shaker shaking method was used to evaluate the emulsifying ability of the viscosity reducer. The oscillation of the shaker would disrupt the oil–water interface and form relative flowing and shearing at the oil–water interface, offering a better simulation of the emulsification conditions of the reservoir [39]. The procedures of the oscillation method were as follows:

- (1)

- First, 15 mL crude oil was added into 35 mL of prepared viscosity reducer solution in a container.

- (2)

- Then, the sample bottle was placed in a constant-temperature shaker and then was oscillated for 3 min under different oscillation frequency from 0 to 250 r·min−1.

- (3)

- The emulsifying ability of viscosity reducers was determined by observing the state of oil and water in different systems with increasing oscillation frequency.

The emulsion prepared using a constant-temperature shaker at oscillatory frequencies of 250 r·min−1 for 3 min was poured into a test tube and then placed in a 70 °C constant-temperature water bath. Then, the oil–water interface position and the water separating volume from the emulsion were recorded at regular intervals for 120 min. The water separating rate was calculated using the following formula:

where f was the water-separating rate, a dimensionless quantity. Vw was the volume of water separation in mL. V0 was the volume of water initially used to prepare the emulsion (mL).

2.2.2. Sand Pack Flooding Experiment

To clarify the effect of different oil displacement agents on oil recovery and the applicable range of heavy-oil viscosity for B-PPG/SP composite system, the sand pack flooding experiments were conducted to compare the effects of different chemical agents and heavy-oil viscosity on oil recovery. The experimental processes are as follows:

- (1)

- Preparation of sand pack core: A sand pack core with permeability of 1.0 μm2 was made with 120 mesh quartz sand. Then, water flooding was conducted and the permeability of the sand pack was measured by Darcy’s law.

- (2)

- Heavy-oil saturation period: At 70 °C, the sand pack core was flooded with heavy oil at an injection rate of 0.1 mL·min−1 until the oil was complete at the production end. The original oil saturation of the sand pack was calculated based on the volume of water expelled. Then, the saturated sand pack was sealed in a 70 °C oven for 24 h.

- (3)

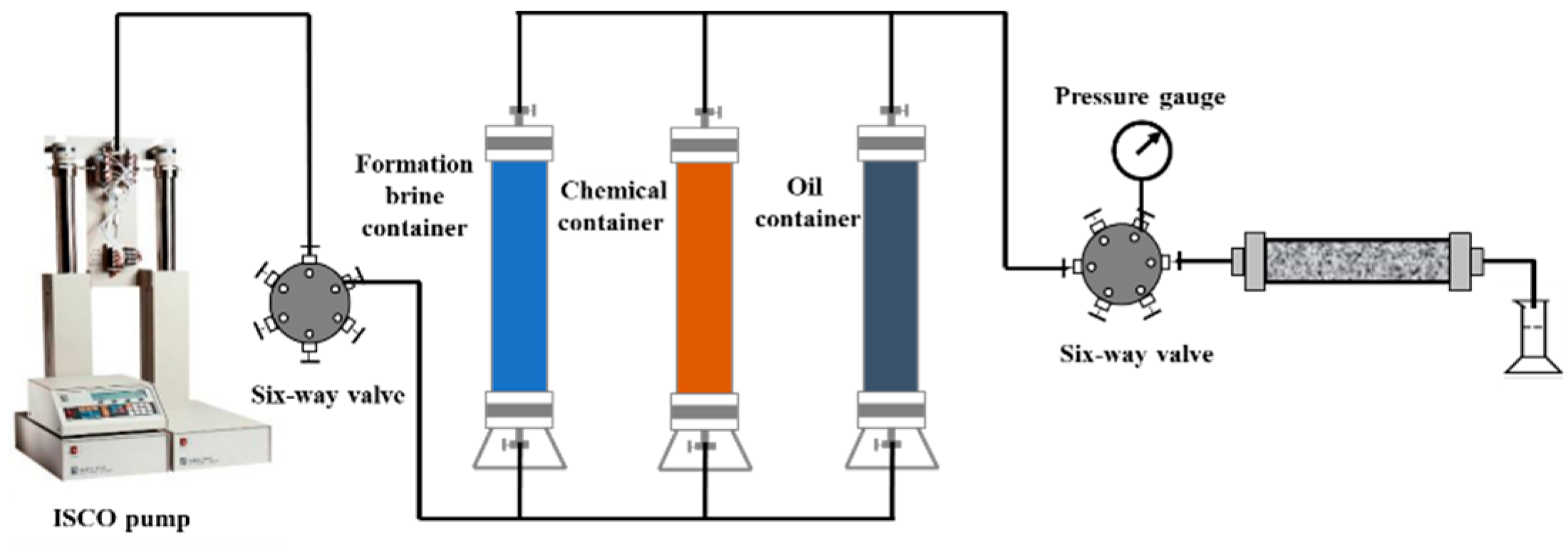

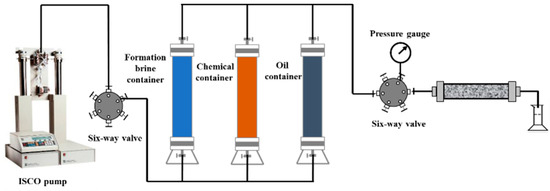

- Initial water flooding period: According to the flow chart of the oil displacement experiment, as shown in Figure 2, water flooding was conducted until the water reached the 95% cutoff rate with an injection rate of 0.3 mL·min−1.

Figure 2. Flow chart of sand pack flooding experiment.

Figure 2. Flow chart of sand pack flooding experiment. - (4)

- Chemical flooding and subsequent water flooding period: Then, 0.4 PV chemical slug was injected into the sand pack care and followed by subsequent water flooding until the water cut reached 98%. The injection pressure and volume of produced water was recorded during different flooding periods, and parameters such as water cut and oil recovery were calculated based on the oil and water volume of the produced liquid.

2.2.3. Microscopic Visualization Flooding Experiment

To clarify the EOR mechanism at pore scale, the microscopic visualization flooding experiments were conducted by using a microscopic visualization etching model to compare water flooding and different chemical flooding.

- (1)

- Heavy-oil saturation period: The synthetic oil was injected into the microscopic visualization model using a high-precision injection pump at an injection rate of 0.01 mL·min−1. The flow rate value was chosen to ensure complete flooding of the porous material without bubbles. Then, the saturated model was aged for 24 h.

- (2)

- Initial water flooding period. The water flooding was conducted until the water cutoff point reached 100% with an injection rate of 0.01 mL·min−1. And the distribution of remaining oil was recorded.

- (3)

- Chemical flooding period: The different chemical slugs were injected with injection rate of 0.01 mL·min−1 after water flooding until the water cutoff reached 100% again. And the distribution of the remaining oil was recorded.

- (4)

- The heavy-oil recovery and microscopic remaining oil proportion after different amounts of chemical flooding were calculated by Xitu image processing software (CIAS-WQT Micro displacement Dynamic Image Analysis System v3.0).

3. Results and Discussion

3.1. Evaluation of Emulsifying Ability and Stability

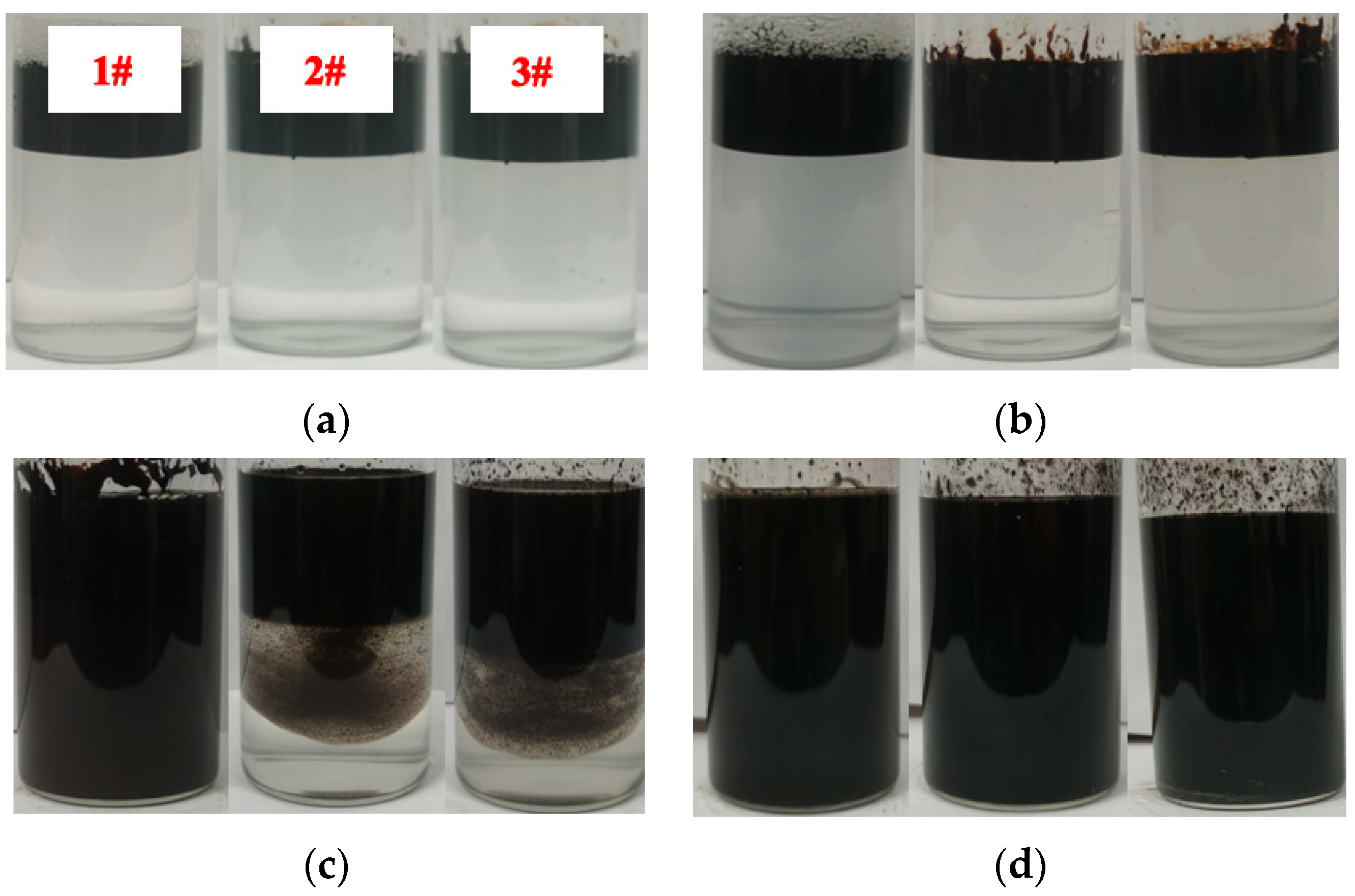

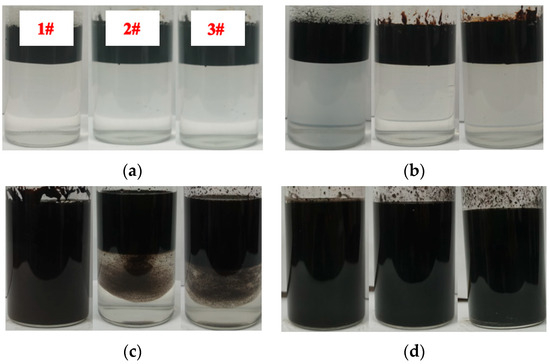

The emulsification ability of three systems was compared and evaluated by using a constant-temperature shaker, and the emulsification states of the three systems and crude oil at different oscillation frequencies were compared.

As shown in Figure 3, when the oscillation frequency increased to 150 r·min−1, the heavy oil was completely emulsified by 1#. Meanwhile, heavy oil was only partially emulsified by 2# and 3#, and due to the addition of polymer, the viscosity of the aqueous phase increased, resulting in an emulsion with clear phase boundaries. When the oscillation frequency increased to 180 r·min−1, the heavy oil in all three sample bottles was completely emulsified. It indicated that since the viscosity of 2# and 3# was higher than that of 1#, the required oscillation frequency for 2# and 3# was higher; that is, the external energy required to emulsify heavy oil was greater.

Figure 3.

Emulsification state of heavy oil and different composite systems under different oscillation frequencies (1# is a viscosity reducer/B-PPG system, 2# is a viscosity reducer/polymer system, and 3# is the B-PPG/SP composite system). (a) Initial state (b) oscillation frequencies of 100 r·min−1 (c) oscillation frequencies of 150 r·min−1, and (d) oscillation frequencies of 180 r·min−1.

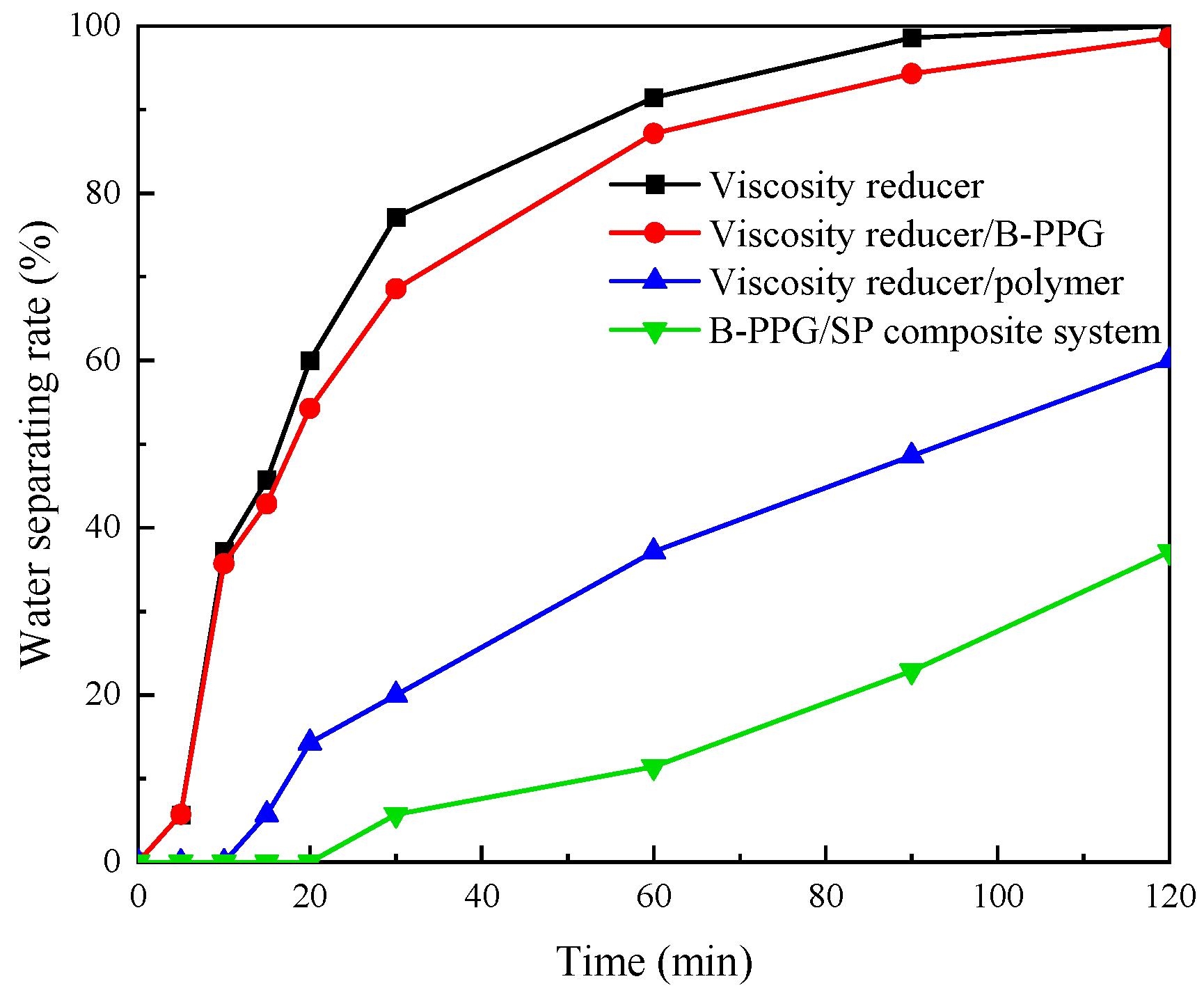

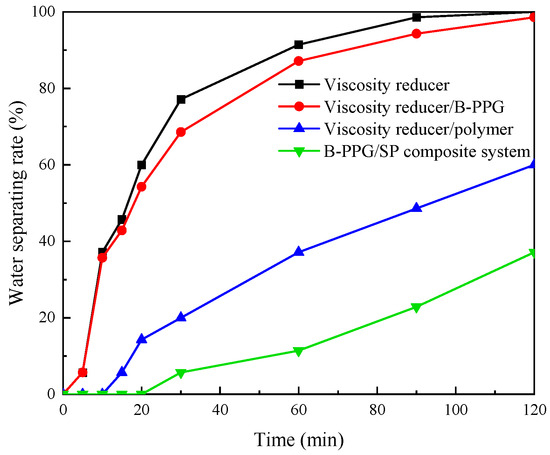

As shown in Figure 4, the emulsion formed by the B-PPG/SP composite system and heavy oil had the best emulsification stability, followed by the viscosity reducer/polymer system. This was attributed to the increase in solution viscosity, which made it more difficult for oil droplets to aggregate, resulting in the emulsion having better stability.

Figure 4.

Curves of the water-separating rate of emulsion formed by heavy oil and different composite systems.

3.2. The Sand Pack Flooding Experiment Results of Chemical Flooding

The sand pack flooding experiments were conducted to investigate the enhanced oil recovery ability of different oil displacement systems. And the ability and mechanism to enhance oil recovery can be recognized.

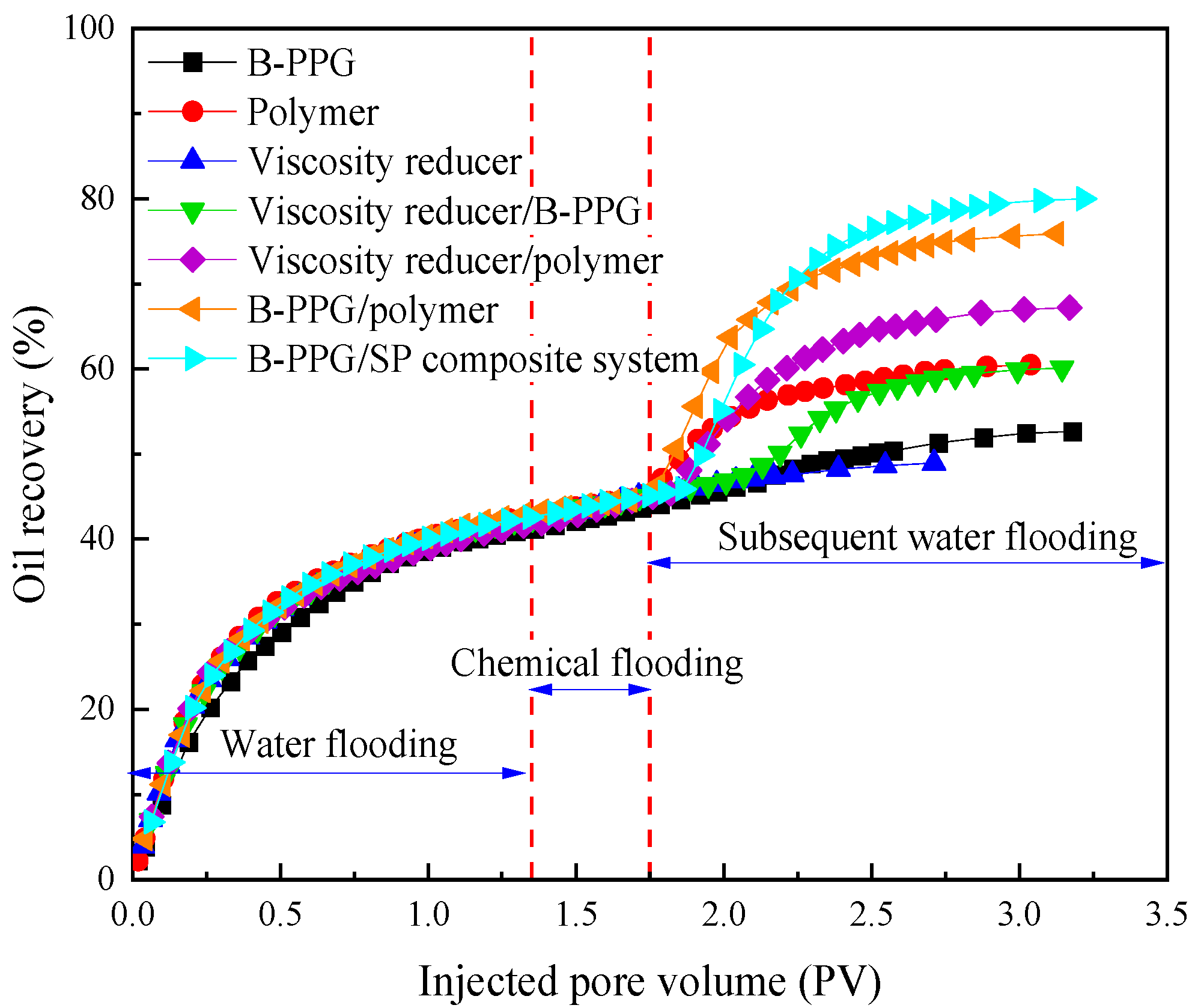

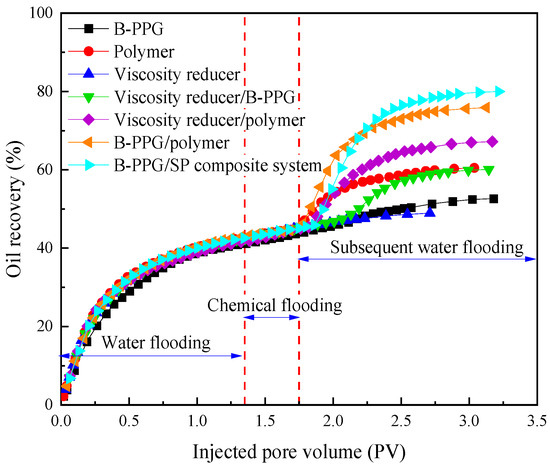

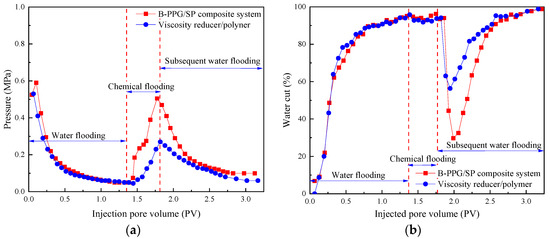

According to Table 1 and Figure 5, the water flooding recovery of all experiments was at the same level, while the incremental oil recovery varied due to the injection of different chemicals. The B-PPG/SP composite system had the best ability to enhance heavy-oil recovery. By injecting 0.4 PV B-PPG/SP composite into the system, the heavy-oil recovery increased from 42.2% to 80.0% with increments of 37.8%. The synergistic effect between viscosity reducer, B-PPG, and polymers effectively enhanced heavy-oil recovery.

Table 1.

Oil recoveries of different sand pack flooding experiments.

Figure 5.

Oil recovery curves of different flooding experiments.

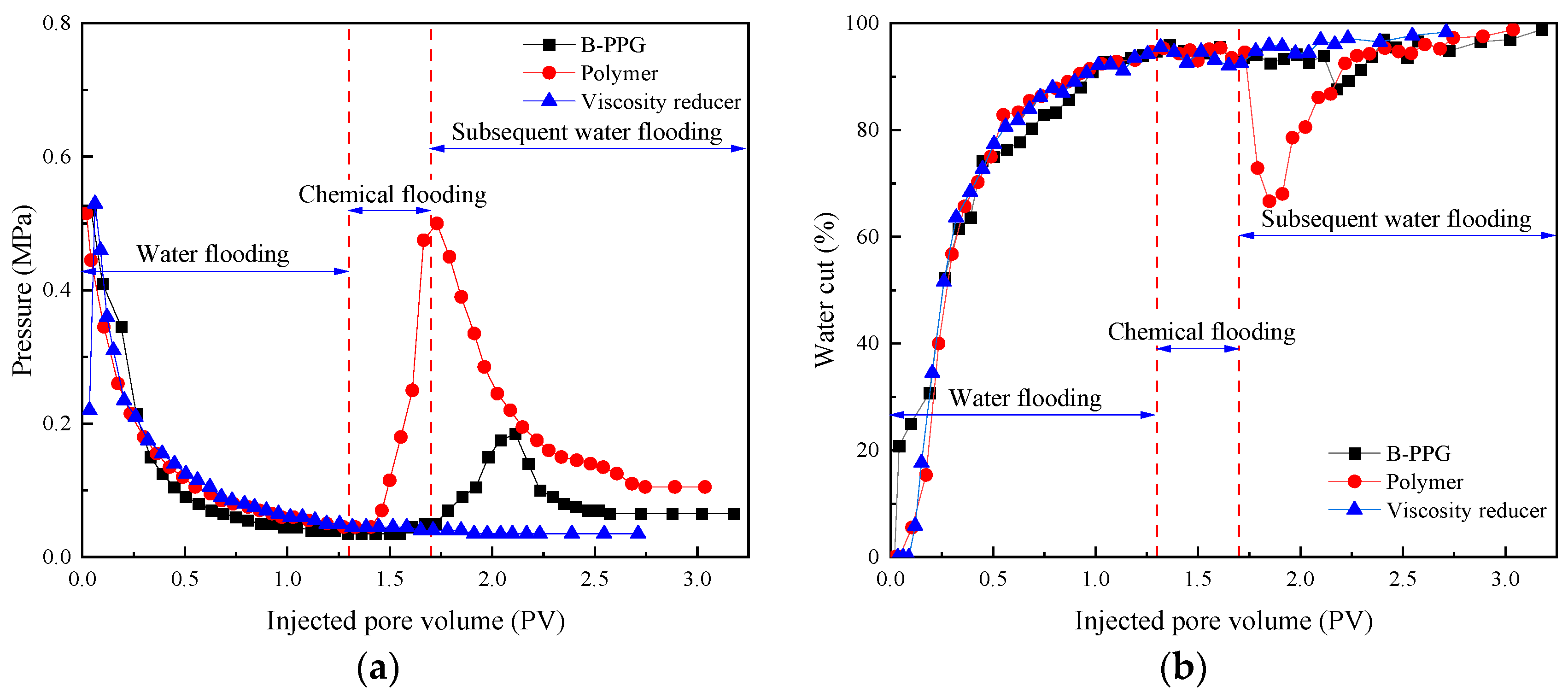

To further analyze the influence of different single-oil displacement agents on the EOR ability of the composite system, the pressure and water cut curves were analyzed, as follows.

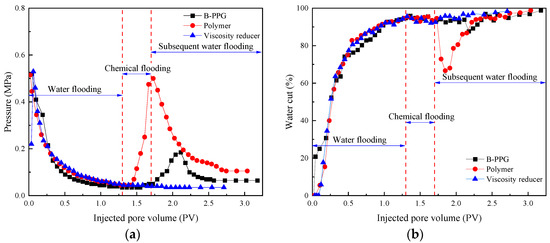

According to Figure 6, after water flooding, the pressure increase in polymer flooding was at its largest, while the viscosity reducer flooding was almost negligible. Meanwhile, compared to polymer flooding, the pressure increase and water cut decrease in B-PPG flooding lagged behind. Analysis suggested that both polymer flooding and B-PPG flooding enhanced heavy-oil recovery by expanding the swept area, which led to an increase in displacement pressure after water flooding. However, the mechanisms by which polymer flooding and B-PPG flooding improved the swept area were different. Polymers directly increased the viscosity of the water phase, increasing the flow resistance and expanding the swept area. B-PPG utilized its unique “partially crosslinked and partially branched” molecular structure to dynamically adjust and block the flow line in porous media through viscosity enhancement and elastic deformation properties, thereby expanding the swept area. The effect of polymer flooding on enhancing heavy-oil recovery was more significant due to B-PPG. In viscosity reducer flooding, most viscosity reducer flowed out along the advantageous channels formed after water flooding, failing to effectively emulsify heavy oil and reduce heavy-oil viscosity, resulting in a limited ability to enhance heavy-oil recovery.

Figure 6.

Oil displacement curves of single oil displacement agent flooding experiments. (a) Pressure curve and (b) water cut curve.

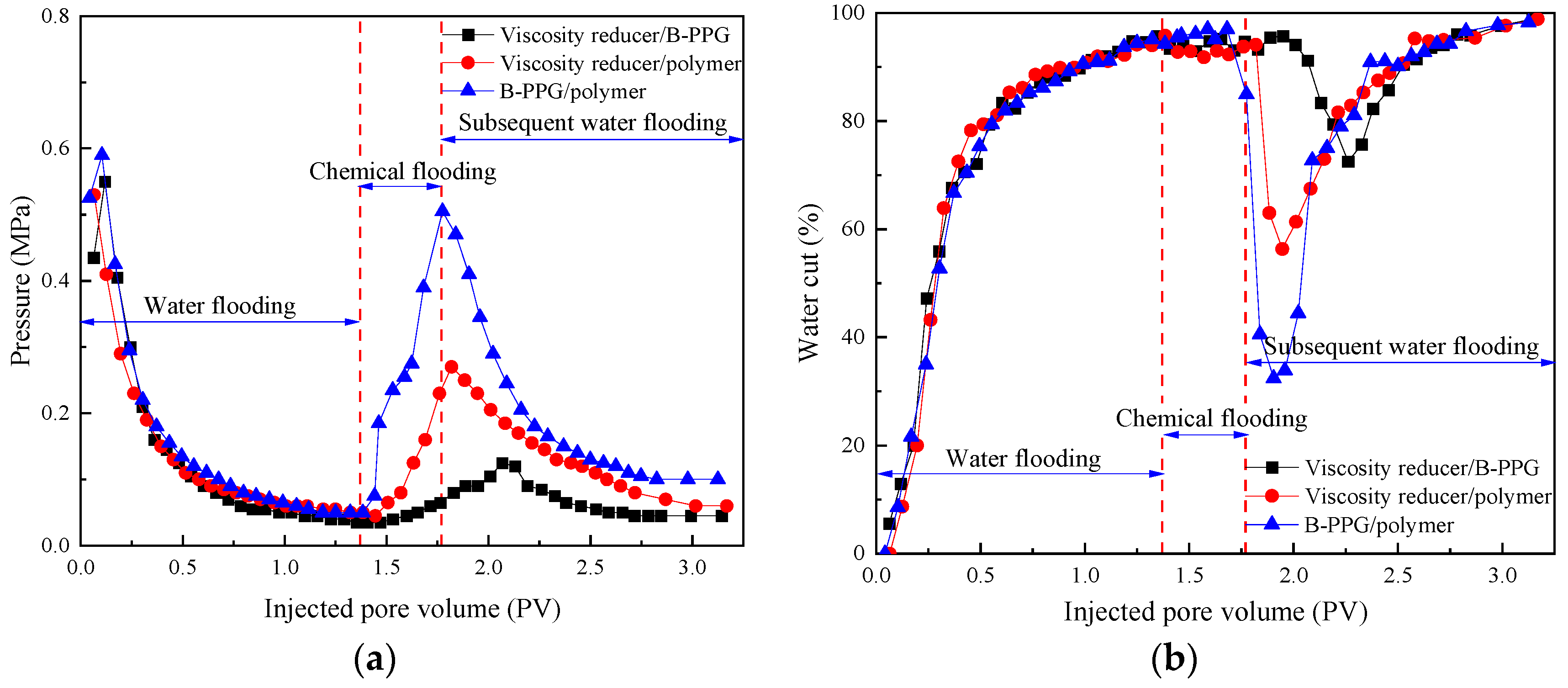

To further analyze the synergistic effect between different single-oil displacement agents, the pressure and water cut curves were analyzed, as follows.

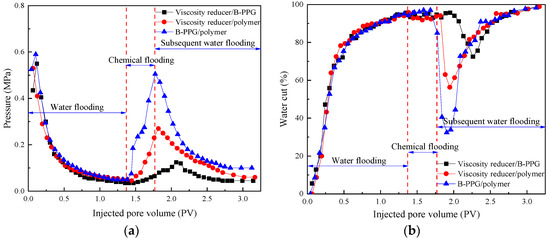

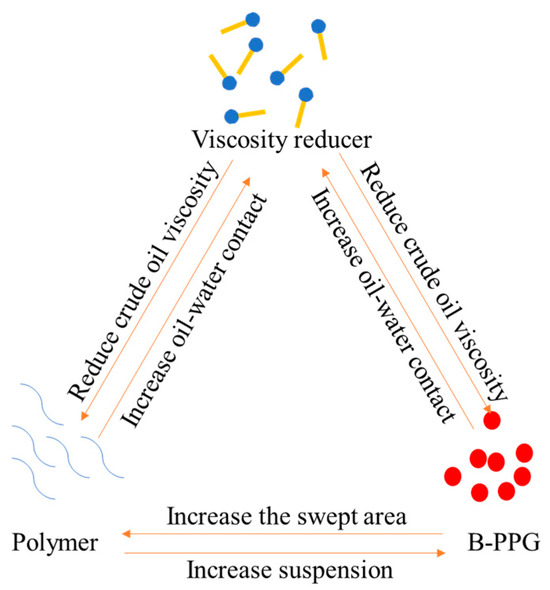

According to Figure 6 and Figure 7, by comparing viscosity reducer/B-PPG flooding and B-PPG flooding, the synergistic effect of viscosity reducer and B-PPG resulted in a decrease in the pressure of viscosity reducer/B-PPG flooding compared to B-PPG flooding after water flooding, while the heavy-oil recovery increased. B-PPG increased the contact between viscosity reducers and heavy oil by expanding the swept area. During the flow process, viscosity reducers can effectively emulsify heavy oil to form O/W emulsion, thereby reducing the flow resistance and enhancing heavy-oil recovery. The synergistic effect between viscosity reducers and polymers is similar to the synergistic effect between viscosity reducers and B-PPG. However, emulsions containing polymers have better stability, as shown in Figure 4.

Figure 7.

Oil displacement curves of different binary composite flooding experiments. (a) Pressure curve; (b) water cut curve.

By comparing B-PPG/polymer flooding with B-PPG flooding and polymer flooding, the synergistic effect of B-PPG and polymer resulted in an increase in pressure of B-PPG/polymer flooding after water flooding, while the heavy-oil recovery increased. During the B-PPG flooding, some B-PPG settled and accumulated near the injection end, and cannot enter the interior of the sand pack core. At the same time, polymer flooding had poor plugging of pore throats. Therefore, in the B-PPG/polymer composite system, due to the thickening and suspension performance of the polymer, the injectability of B-PPG was enhanced, allowing more B-PPG particles to enter the porous media, fully improving the formation heterogeneity, and continuously expanding the swept area. This also increased the displacement efficiency of the polymers on heavy oil during the displacement process, and ultimately enables B-PPG/polymer flooding to effectively enhance heavy-oil recovery by 33.0%.

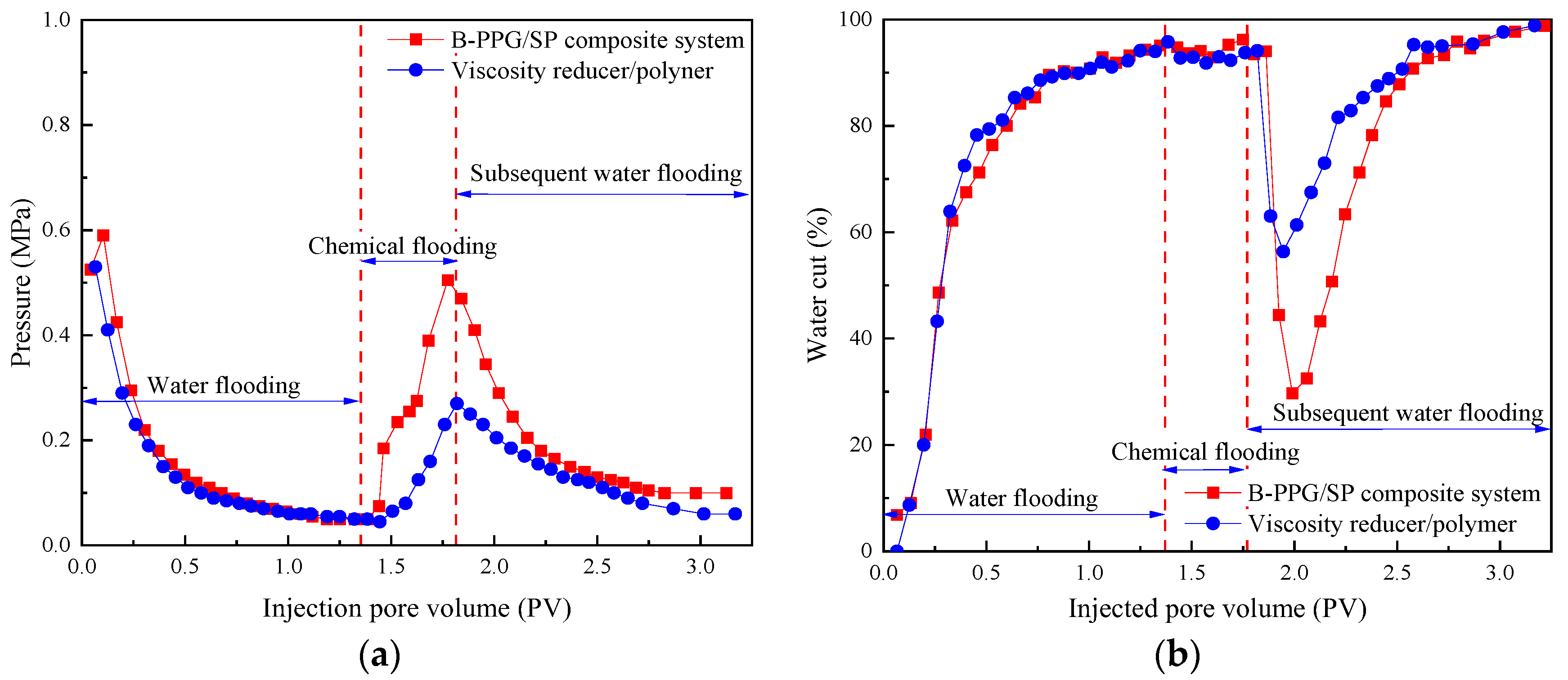

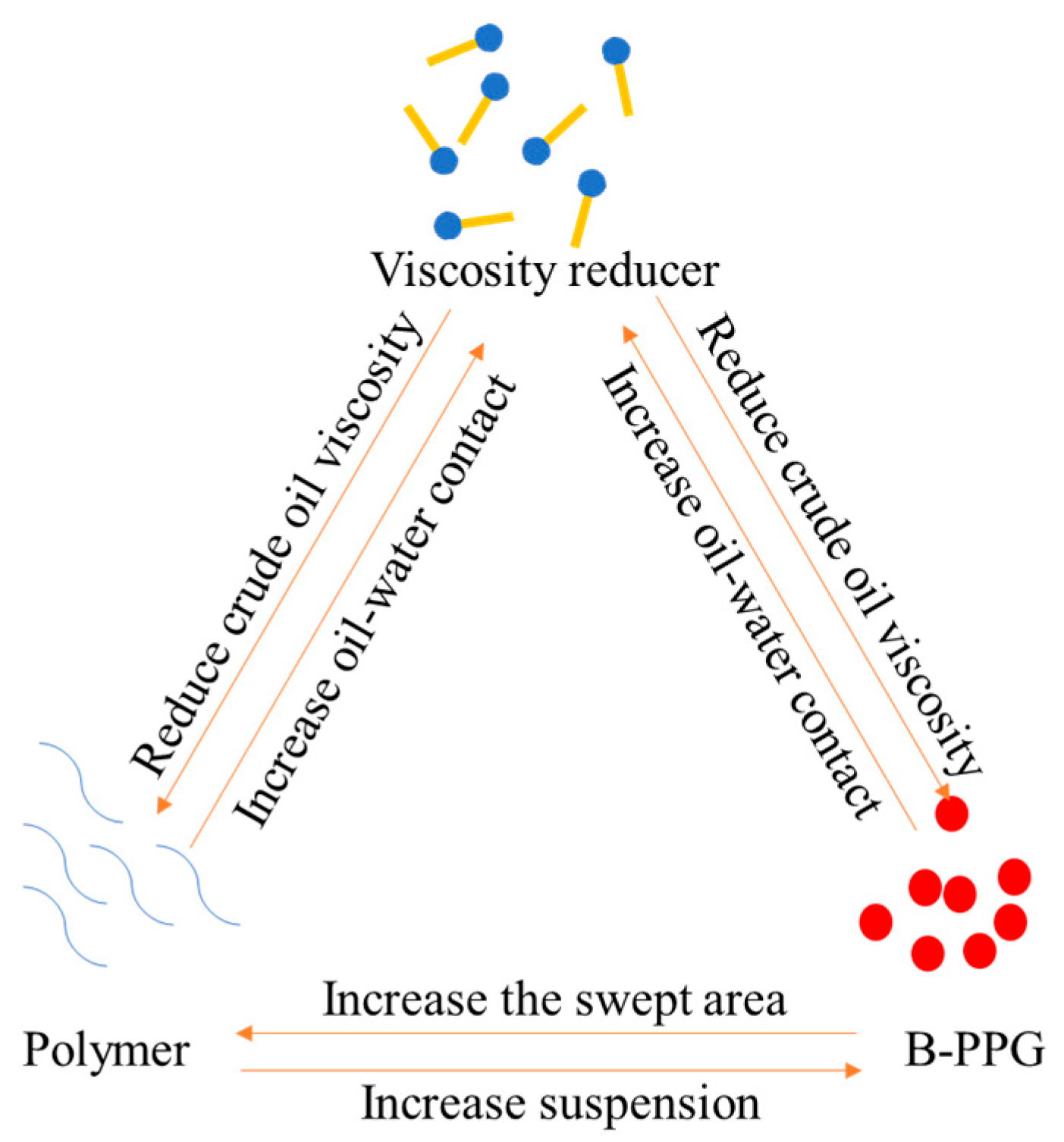

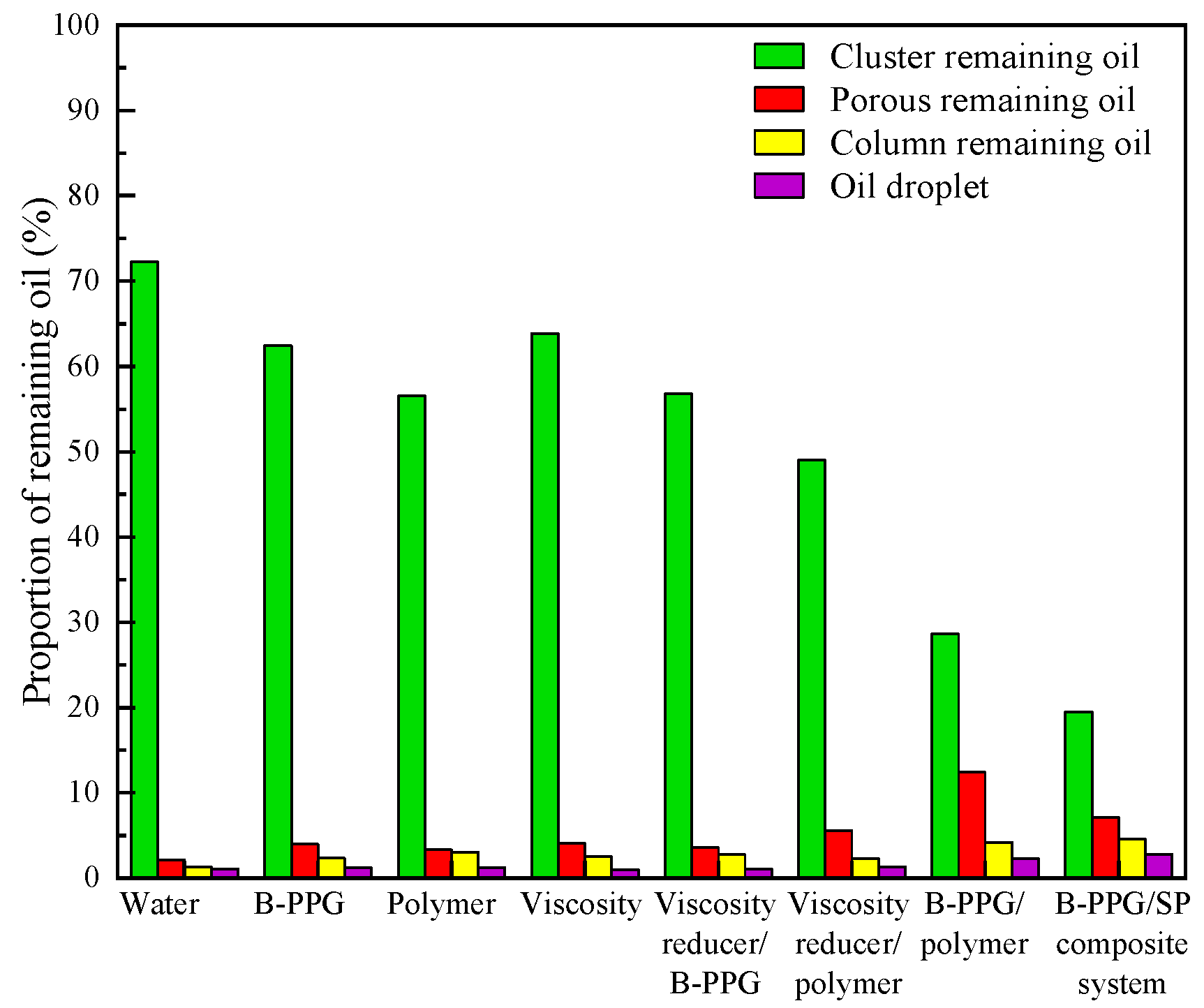

According to Figure 8 and Figure 9, adding B-PPG to the SP system can significantly increase the swept area and reduce water content, effectively enhancing heavy-oil recovery by 37.8%. The thickening performance of polymers increased the injectability and suspension performance of B-PPG, enhanced the plugging performance of B-PPG, and at the same time, the plugging performance of B-PPG further enhanced the displacement efficiency of polymers and expanded swept area. This synergistic effect increased the contact between viscosity reducers and heavy oil in the B-PPG/SP composite system, better exerting the effect of emulsification and viscosity reduction. The synergistic effect between the viscosity reducer, B-PPG, and polymer enhances the interaction between each component, further reducing the oil–water viscosity ratio, expanding the swept area, and effectively enhancing heavy-oil recovery.

Figure 8.

Oil displacement curves of SP system and B-PPG/SP system flooding experiments. (a) Pressure curve; (b) water cut curve.

Figure 9.

Schematic diagram of the synergistic effect between viscosity reducer, polymer, and B-PPG.

3.3. The Microscopic Visualization Flooding Experiment Results

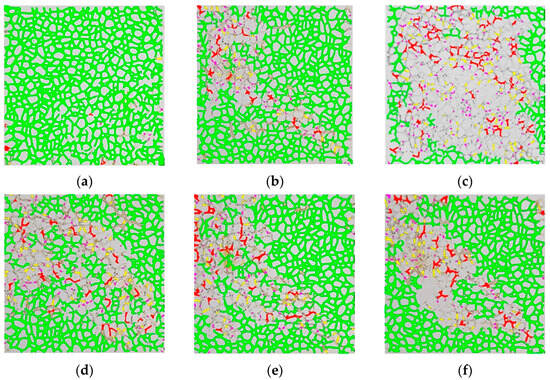

The flooding experiment was conducted to investigate the remaining oil distribution in porous media by using a microscopic visualization etching model. It was also conducted to clarify the utilization mechanism of the different oil displacement systems for remaining oil in ordinary heavy-oil reservoirs.

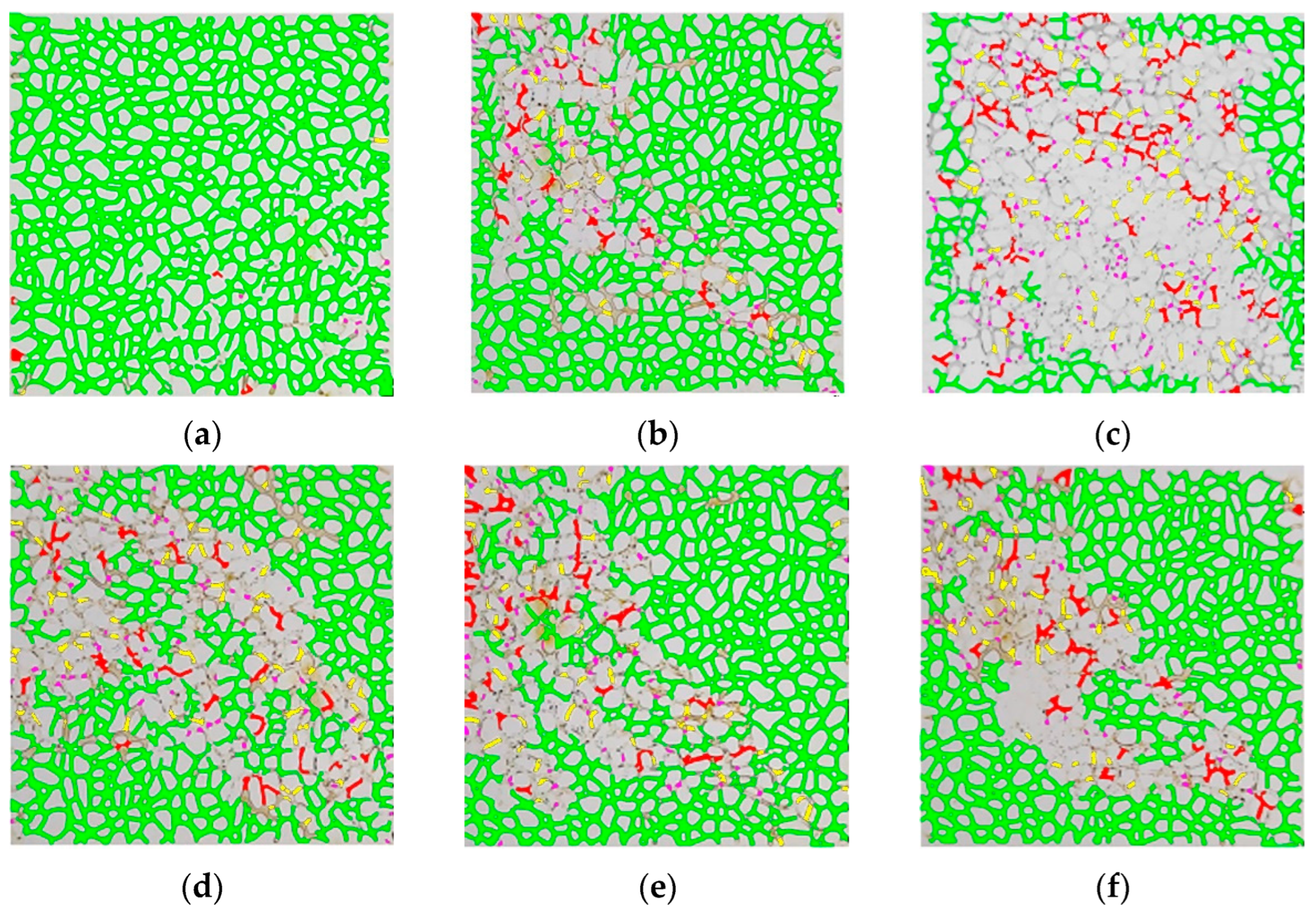

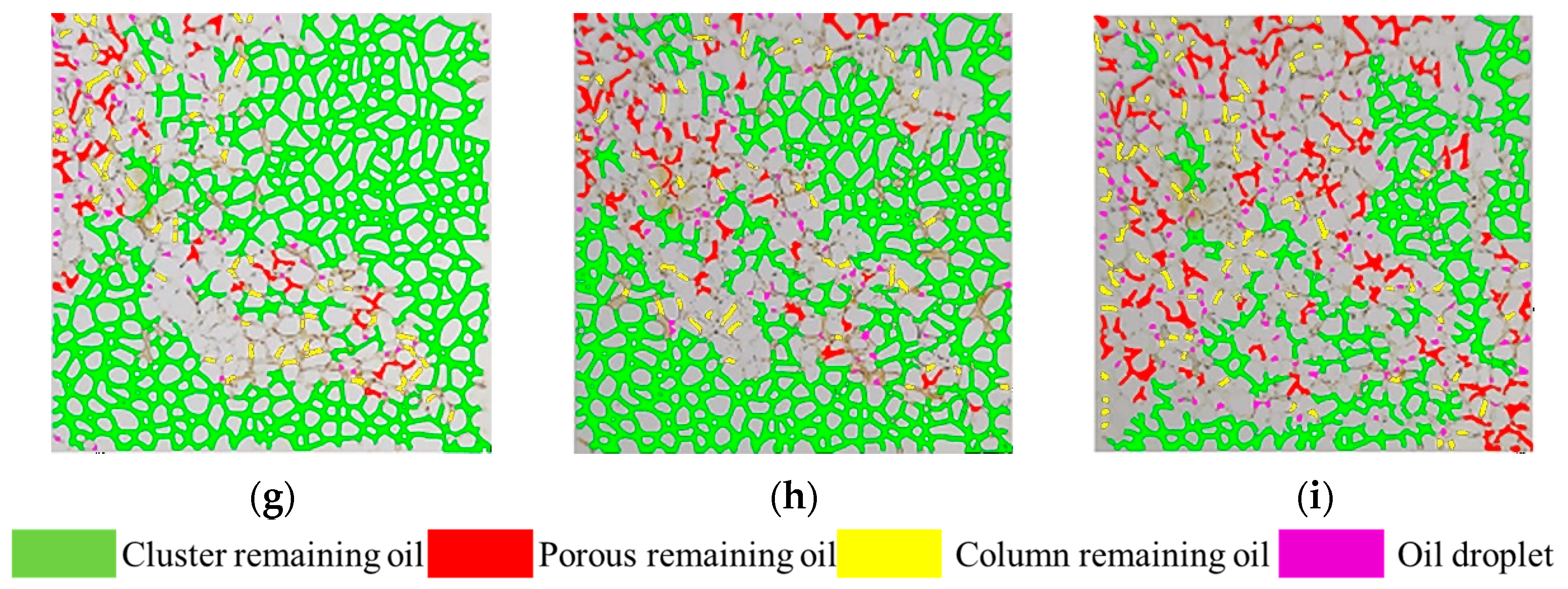

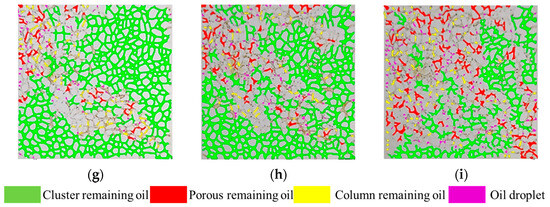

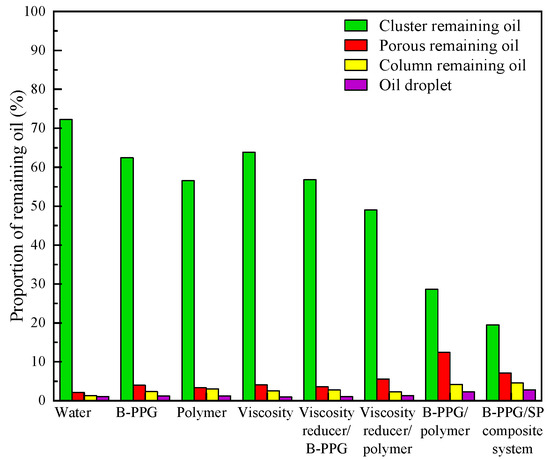

From Table 2 and Figure 10, due to the high viscosity of heavy oil, the water flooding recovery was low and the proportion of clusters of remaining oil was the highest. According to Figure 11, B-PPG/polymer flooding and B-PPG/SP composite flooding can effectively displace cluster remaining oil and increase the oil recovery. Therefore, for low-recovery heavy-oil reservoirs, expanding the swept area to displace cluster remaining oil is the most effective method of enhancing heavy-oil recovery. However, by increasing the swept area and utilizing the cluster remaining oil, some of the cluster remaining oil will transform into dispersed remaining oil, such as column remaining oil and oil droplets. Therefore, in order to further enhance heavy-oil recovery, it is necessary to consider utilizing the dispersed remaining oil.

Table 2.

Oil recoveries of different microscopic visualization flooding experiments.

Figure 10.

Remaining oil distribution at the end of different chemical flooding periods. (a) Initial state; (b) water flooding; (c) B-PPG/SP composite flooding; (d) B-PPG flooding; (e) polymer flooding; (f) viscosity reducer flooding; (g) viscosity reducer/B-PPG flooding; (h) viscosity reducer/polymer flooding; (i) B-PPG/polymer flooding.

Figure 11.

Microscopic remaining oil proportion at the end of different chemical flooding.

Meanwhile, compared with single-chemical-agent flooding and other binary composite flooding, B-PPG/polymer flooding resulted in a larger swept area but also a higher proportion of dispersed remaining oil. Compared with B-PPG/polymer flooding, after the B-PPG/SP composite system flooding, not only did the proportion of porous remaining oil decrease, but the proportion of cluster remaining oil also further decreased, while the proportion of column and droplet oil did not change much. This indicated that adding viscosity reducers to the oil displacement system, through the synergistic effect of viscosity reducers with B-PPG and polymers, can further increase the oil displacement efficiency within the swept area, thereby increasing the heavy-oil recovery.

3.4. The Applicable Range of Heavy-Oil Viscosity in the B-PPG/SP Composite System

The sand pack flooding experiments were conducted using seven heavy oils with different viscosities to clarify the effect of heavy-oil viscosity on enhancing heavy-oil recovery in the B-PPG/SP system. The viscosity of the heavy oil used in this experiment was measured at 70 °C and a shear rate of 6·s−1.

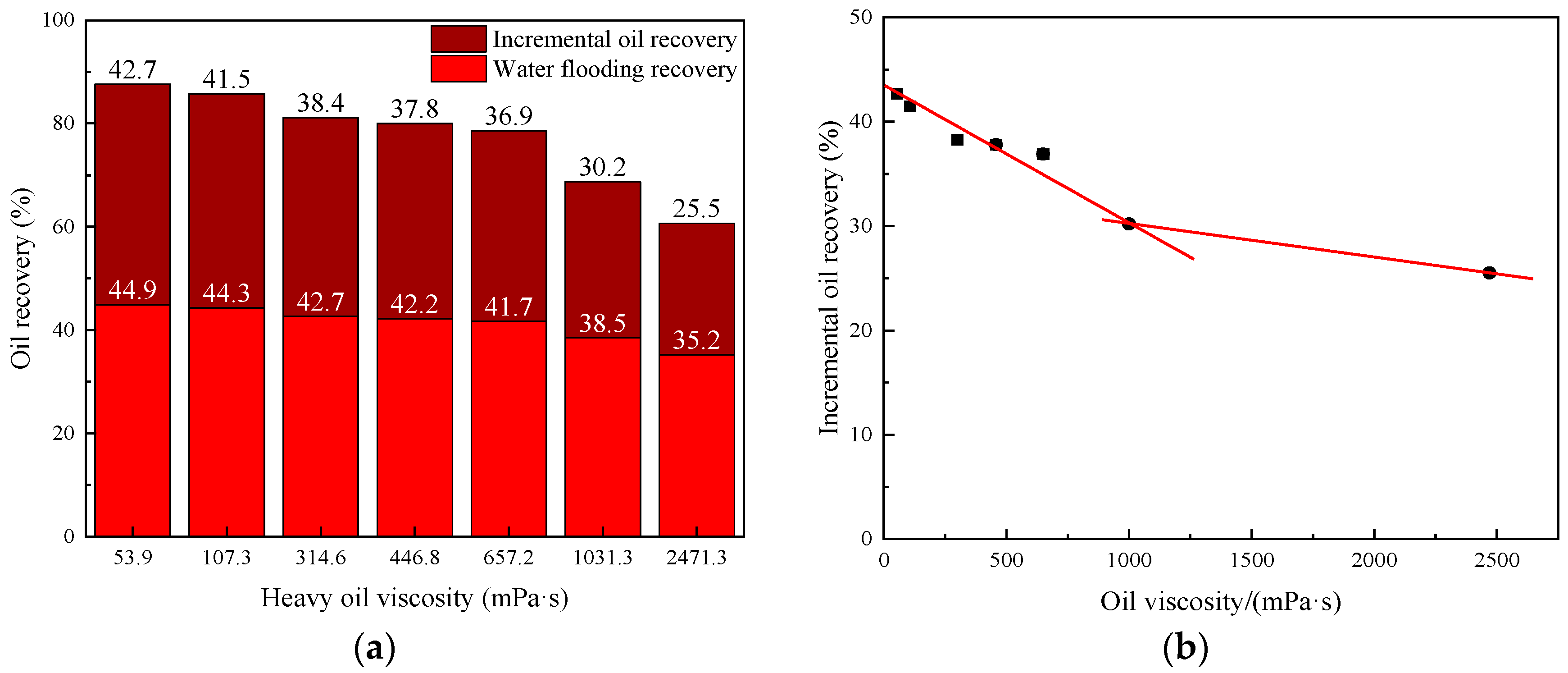

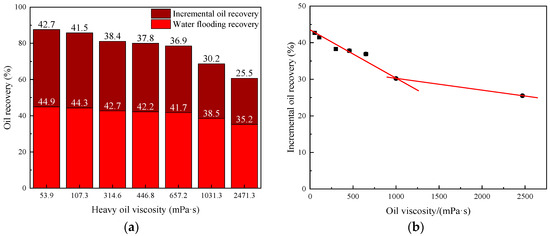

From Figure 12 and Table 3, at the stage of water flooding, as the heavy-oil viscosity increased, the water flooding recovery decreased. This indicated that the higher the heavy-oil viscosity, the higher the oil–water viscosity ratio during water flooding, the lower the water flooding recovery. After water flooding, as the heavy-oil viscosity increased, the effect of the B-PPG/SP composite system on enhancing the heavy-oil recovery began to decrease. When the heavy-oil viscosity exceeded 1031.3 mPa·s, the decrease in incremental oil recovery slowed down. When the viscosity of crude oil was 657.2 mPa·s, the incremental oil recovery was 36.9%, but when the viscosity increased to 1031.3 mPa·s, the incremental oil recovery was 30.2%, and the decrease was significant. The B-PPG/SP composite system could increase the viscosity of the injection liquid, reduce the water–oil viscosity ratio, and expand the sweeping efficiency. But when the viscosity was too high, the ability of the composite system flooding to expand the sweeping efficiency was limited, and the effect of enhancing oil recovery would decrease.

Figure 12.

Comparison of oil recovery of B-PPG/SP composite system flooding experiments with different heavy oil viscosities. (a) Recovery and increment oil recovery of B-PPG/SP flooding experiments oil with different oil viscosities; (b) Relationship between incremental oil recovery and oil viscosity of B-PPG/SP flooding experiment.

Table 3.

Oil recoveries of B-PPG/SP composite flooding experiments with different heavy oil viscosities.

4. Conclusions

In this study, based on sand pack flooding experiments and microscopic visualization flooding experiments, the synergistic effect between polymers, viscosity reducers, and B-PPG and the applicable heavy-oil viscosity range of B-PPG/SP composite flooding system were explored. Some conclusions can be drawn as follows:

- (1)

- The thickening performance of polymers can increase the injectability of B-PPG, thereby increasing its plugging performance. The synthetic effect of B-PPG and polymer can expand the swept area and the contact between the viscosity reducer and heavy oil. The increase in contact area between viscosity reducers and heavy oil enables the viscosity reducer to better exert emulsification and viscosity reduction effects, thereby reducing the viscosity crude oil. This further reduces the oil–water viscosity ratio and expands the swept area. The synergistic effect between B-PPG, polymer, and viscosity reducer can further expand the swept area and oil displacement efficiency, ultimately enhancing the heavy-oil recovery by 37.8%.

- (2)

- In the proportion of microscopic remaining oil in heavy oil, the proportion of clustered residual oil is particularly high. Therefore, adding B-PPG and polymers to expand the swept area and displace the cluster remaining oil is the most effective method to enhance heavy-oil recovery. The viscosity reducer can effectively displace the dispersed remaining oil within the swept area, thereby further enhancing the oil displacement efficiency.

- (3)

- When the viscosity of crude oil was 657.2 mPa·s, the incremental oil recovery was 36.9%. When the heavy-oil viscosity exceeded 1031.3 mPa·s, the incremental oil recovery declined to 30.2% and was stabilized. The B-PPG/SP composite system can effectively expand the applicable range of heavy-oil viscosity in ordinary heavy-oil reservoirs.

Author Contributions

Y.Y.: Conceptualization, Methodology, Data curation, Investigation, and Writing—original draft. H.H.: Conceptualization, Validation; Visualization, and Writing—review and editing. H.P.: Investigation, Data curation, Software. W.Z.: Investigation, Data curation, and Software. W.K.: Data curation and Investigation. X.Z.: Data curation and Investigation. C.J.: Data curation and Investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, Z.; Wang, H.; Blackbourn, G.; Ma, F.; He, Z.; Wen, Z.; Wang, Z.; Yang, Z.; Luan, T.; Wu, Z. Heavy oils and oil sands: Global distribution and resource assessment. Acta Geol. Sin. 2019, 93, 199–212. [Google Scholar] [CrossRef]

- Guo, K.; Li, H.; Yu, Z. In-situ heavy and extra-heavy oil recovery: A review. Fuel 2016, 185, 886–902. [Google Scholar] [CrossRef]

- Alvarado, V.; Manrique, E. Enhanced Oil Recovery: An Update Review. Energies 2010, 3, 1529–1575. [Google Scholar] [CrossRef]

- Zhao, Q.; Guo, L.; Huang, Z.; Chen, L.; Jin, H.; Wang, Y. Experimental investigation on enhanced oil recovery of extra heavy oil by supercritical water flooding. Energy Fuels 2018, 32, 1685–1692. [Google Scholar] [CrossRef]

- Deng, R.; Dong, J.; Dang, L. Numerical simulation and evaluation of residual oil saturation in waterflooded reservoirs. Fuel 2025, 384, 134018. [Google Scholar] [CrossRef]

- Larisa, A.S.; Sergey, O.I. Effect of enhanced oil recovery on the composition and rheological properties of heavy crude oil. J. Pet. Sci. Eng. 2021, 203, 108641. [Google Scholar]

- Mai, A.; Bryan, J.; Goodarzi, N.; Kantzas, A. Insights into Non-Thermal Recovery of Heavy Oil. J. Can. Pet. Technol. 2009, 48, 27–35. [Google Scholar] [CrossRef]

- Guo, C.; Qu, F.; Liu, Y.; Nian, X.; Chen, Z.; Zou, Y. Numerical Simulation of Steam Injection for Heavy Oil Thermal Recovery. Energy Procedia 2017, 105, 3936–3946. [Google Scholar]

- Mandal, A.; Keka, O. Enhanced Oil Recovery: Mechanisms, Technologies and Feasibility Analyses; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Zhao, D.; Wang, J.; Gates, I. Thermal recovery strategies for thin heavy oil reservoirs. Fuel 2014, 117, 431–441. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, F.; Wu, Y.; Liu, G.; Li, X.; Su, H.; Zhu, Z. Overview of emulsified viscosity reducer for enhancing heavy oil recovery. IOP Conf. Ser. Mater. Sci. Eng. 2019, 479, 012009. [Google Scholar] [CrossRef]

- Yaser, A.; Meysam, H.; Behzad, V.; Asghar, G. Applications of nanoparticles during chemical enhanced oil recovery: A review of mechanisms and technical challenges. J. Mol. Liq. 2024, 415, 126287. [Google Scholar]

- Ahmadi, M.; Shadizadeh, S. Nano-surfactant flooding in carbonate reservoirs: A mechanistic study. Eur. Phys. J. Plus 2017, 132, 246. [Google Scholar] [CrossRef]

- Jia, H.; Zhou, H.; Jia, C.; Zeng, P.; Zhang, F.; Xie, M. Controlled synthesis of gold nanorings with structural defects assisted by elastic induction of mixed surfactants. CrystEngComm 2015, 17, 6053–6058. [Google Scholar] [CrossRef]

- Dong, M.; Liu, Q.; Li, A. Displacement mechanisms of enhanced heavy oil recovery by alkaline flooding in a micromodel. Particuology 2012, 10, 298–305. [Google Scholar] [CrossRef]

- Pei, H.; Zhang, G.; Ge, J.; Jin, L.; Ma, C. Potential of alkaline flooding to enhance heavy oil recovery through water-in-oil emulsification. Fuel 2013, 104, 284–293. [Google Scholar] [CrossRef]

- He, H.; Ning, W.; Pei, H.; Chen, R.; Tian, Y.; Liu, Y.; Zuo, Q. Insights into Enhanced Oil Recovery by Viscosity Reduction Combination Flooding System for Conventional Heavy Oil Reservoir. Processes 2025, 13, 618. [Google Scholar] [CrossRef]

- He, H.; Yang, Y.; Liu, H.; Zhang, X.; Fu, J.; Hu, J. Insights into the preparation and mechanism of Non-Alkali viscosity reducer for enhancing heavy oil recovery under Low-Shear condition. J. Mol. Liq. 2024, 410, 125601. [Google Scholar] [CrossRef]

- Lemahieu, G.; Ontiveros, J.; Souza, N.; Molinier, V.; Aubry, J. Fast and accurate selection of surfactants for enhanced oil recovery by dynamic Salinity-Phase-Inversion (SPI). Fuel 2021, 289, 119928. [Google Scholar] [CrossRef]

- Wang, F.; Xu, H.; Liu, Y.; Jiang, Y.; Wu, C. Experimental Study on the Enhanced Oil Recovery Mechanism of an Ordinary Heavy Oil Field by Polymer Flooding. ACS Omega 2023, 8, 14089–14096. [Google Scholar] [CrossRef]

- Gao, C. Scientific research and field applications of polymer flooding in heavy oil recovery. J. Pet. Explor. Prod. Technol. 2011, 1, 65–70. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, G.; Ge, J.; Jiang, P.; Tang, J.; Liu, Y. Research of the heavy oil displacement mechanism by using alkaline/surfactant flooding system. Colloids Surf. A Physicochem. Eng. Asp. 2013, 434, 63–71. [Google Scholar] [CrossRef]

- Denney, D. Enhanced Heavy-Oil Recovery by Alkali/Surfactant Flooding. J. Pet. Technol. 2008, 60, 91–93. [Google Scholar] [CrossRef]

- Ding, M.; Wang, Y.; Yuan, F.; Zhao, H.; Li, Z. A comparative study of the mechanism and performance of surfactant- and alkali-polymer flooding in heavy-oil recovery. Chem. Eng. Sci. 2020, 219, 115603. [Google Scholar] [CrossRef]

- Fu, L.; Zhang, G.; Ge, J.; Liao, K.; Pei, H.; Jiang, P.; Li, X. Study on organic alkali-surfactant-polymer flooding for enhanced ordinary heavy oil recovery. Colloids Surf. A Physicochem. Eng. Asp. 2016, 508, 230–239. [Google Scholar] [CrossRef]

- Ding, B.; Zhang, G.; Ge, J.; Liu, X. Research on Mechanisms of Alkaline Flooding for Heavy Oil. Energy Fuels 2010, 24, 6346–6352. [Google Scholar] [CrossRef]

- Liu, Q.; Dong, M.; Ma, S.; Tu, Y. Surfactant enhanced alkaline flooding for Western Canadian heavy oil recovery. Colloids Surf. A Physicochem. Eng. Asp. 2007, 293, 63–71. [Google Scholar] [CrossRef]

- Wu, Z.; Yue, X.; Cheng, T.; Yu, J.; Yang, H. Effect of viscosity and interfacial tension of surfactant–polymer flooding on oil recovery in high-temperature and high-salinity reservoirs. J. Pet. Explor. Prod. Technol. 2014, 4, 9–16. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y.; Ding, M.; Mao, D.; Chen, M.; Han, Y.; Liu, Y.; Xue, X. Effects of viscosification, ultra-low interfacial tension, and emulsification on heavy oil recovery by combination flooding. J. Mol. Liq. 2023, 380, 121698. [Google Scholar] [CrossRef]

- Xue, X.; Zhu, S.; Ma, X.; Zhang, S.; Yang, S.; Huang, Z.; Xu, M.; Huang, H. Enhancing heavy-oil displacement efficiency through viscoelasticity of polymer solution by investigating the viscosity limit of crude oil: An experimental study. Energy Sci. Eng. 2024, 12, 2493–2504. [Google Scholar] [CrossRef]

- Goudarzi, A.; Zhang, H.; Varavei, A.; Taksaudom, P.; Hu, Y.; Delshad, M.; Bai, B.; Sepehrnoori, K. A laboratory and simulation study of preformed particle gels for water conformance control. Fuel 2015, 140, 502–513. [Google Scholar] [CrossRef]

- Kang, W.; Shao, S.; Yang, H.; Chen, C.; Hou, X.; Huang, Z.; Zhao, H.; Aidarova, S.; Gabdullin, M. The effect of stepwise increasing of water injection rates on enhanced oil recovery after preformed particle gel treatment. J. Pet. Sci. Eng. 2019, 182, 106239. [Google Scholar] [CrossRef]

- Farasat, A.; Sefti, M.; Sadeghnejad, S.; Saghafi, H. Mechanical entrapment analysis of enhanced preformed particle gels (PPGs) in mature reservoirs. J. Pet. Sci. Eng. 2017, 157, 441–450. [Google Scholar] [CrossRef]

- Saghafi, H. Retention characteristics of enhanced preformed particle gels (PPGs) in porous media: Conformance control implications. J. Pet. Sci. Eng. 2018, 166, 962–968. [Google Scholar] [CrossRef]

- Xu, L.; Qiu, Z.; Gong, H.; Zhu, C.; Sang, Q.; Li, Y.; Dong, M. Synergy of microbial polysaccharides and branched-preformed particle gel on thickening and enhanced oil recovery. Chem. Eng. Sci. 2019, 208, 115138. [Google Scholar] [CrossRef]

- Pi, Y.; Liu, J.; Cao, R.; Liu, L.; Ma, Y.; Gu, X.; Li, X.; Fan, X.; Zhao, M. Visualized Study on a New Preformed Particle Gels (PPG) +Polymer System to Enhance Oil Recovery by Oil Saturation Monitoring Online Flooding Experiment. Gels 2023, 9, 81. [Google Scholar] [CrossRef] [PubMed]

- Pi, Y.; Su, Z.; Cao, R.; Li, B.; Liu, J.; Fan, X.; Zhao, M. Experimental Study on Enhanced Oil Recovery of PPG/ASP Heterogeneous System after Polymer Flooding. Gels 2023, 9, 427. [Google Scholar] [CrossRef]

- Sun, H. Application of pilot test for well pattern adjusting heterogeneous combination flooding after polymer flooding-case of Zhongyiqu Ng3 block, Gudao oilfield. Pet. Geol. Recovery Effic. 2014, 21, 1–4+111. [Google Scholar]

- Ding, M.; Wang, Y.; Li, Z.; Zhong, D.; Yuan, F.; Zhu, Y. The role of IFT and emulsification in recovering heavy oil during S/SP flooding. J. Ind. Eng. Chem. 2019, 77, 198–208. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).