Study on the Impact of Drilling Fluid Rheology on Pressure Transmission Within Micro-Cracks in Hard Brittle Shale

Abstract

1. Introduction

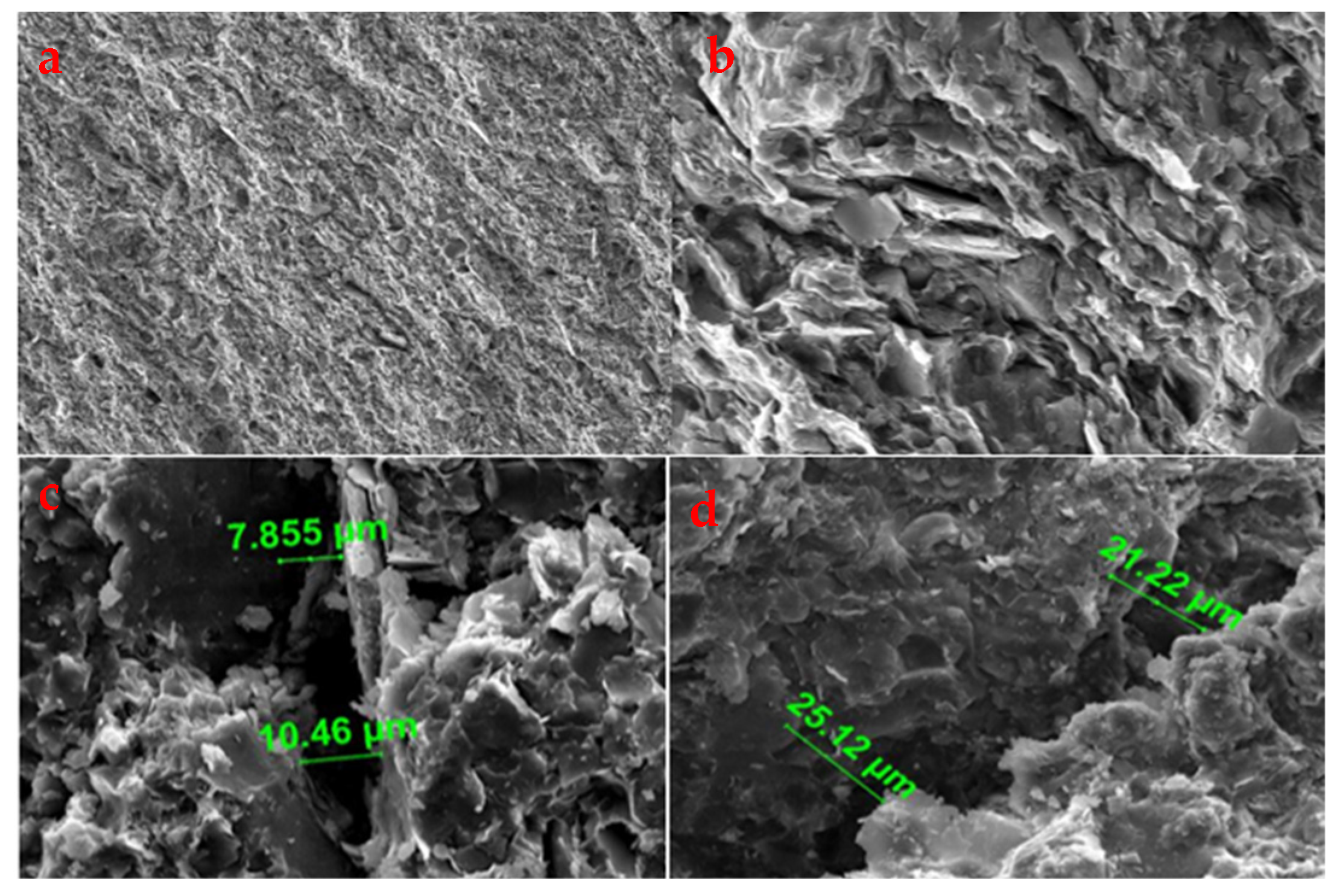

2. Microscopic Structural Characteristics of Hard Brittle Mud Shale

3. Numerical Simulation Methods

3.1. Flow Model in Fractures

- (1)

- The fracture geometry remains unchanged during the drilling fluid invasion, and fracture extension is neglected.

- (2)

- The drilling fluid displaces the formation fluid in a piston-like manner with a clear interface.

- (3)

- Fluid flow within the fracture is one-dimensional.

3.1.1. Pressure Distribution in the Drilling Fluid Area

3.1.2. Pressure Distribution in the Formation Fluid Area

3.2. Discrete Treatment of Flow Models

3.3. Boundary Conditions

3.4. Simulation Parameters

4. Simulation Result Analysis and Discussion

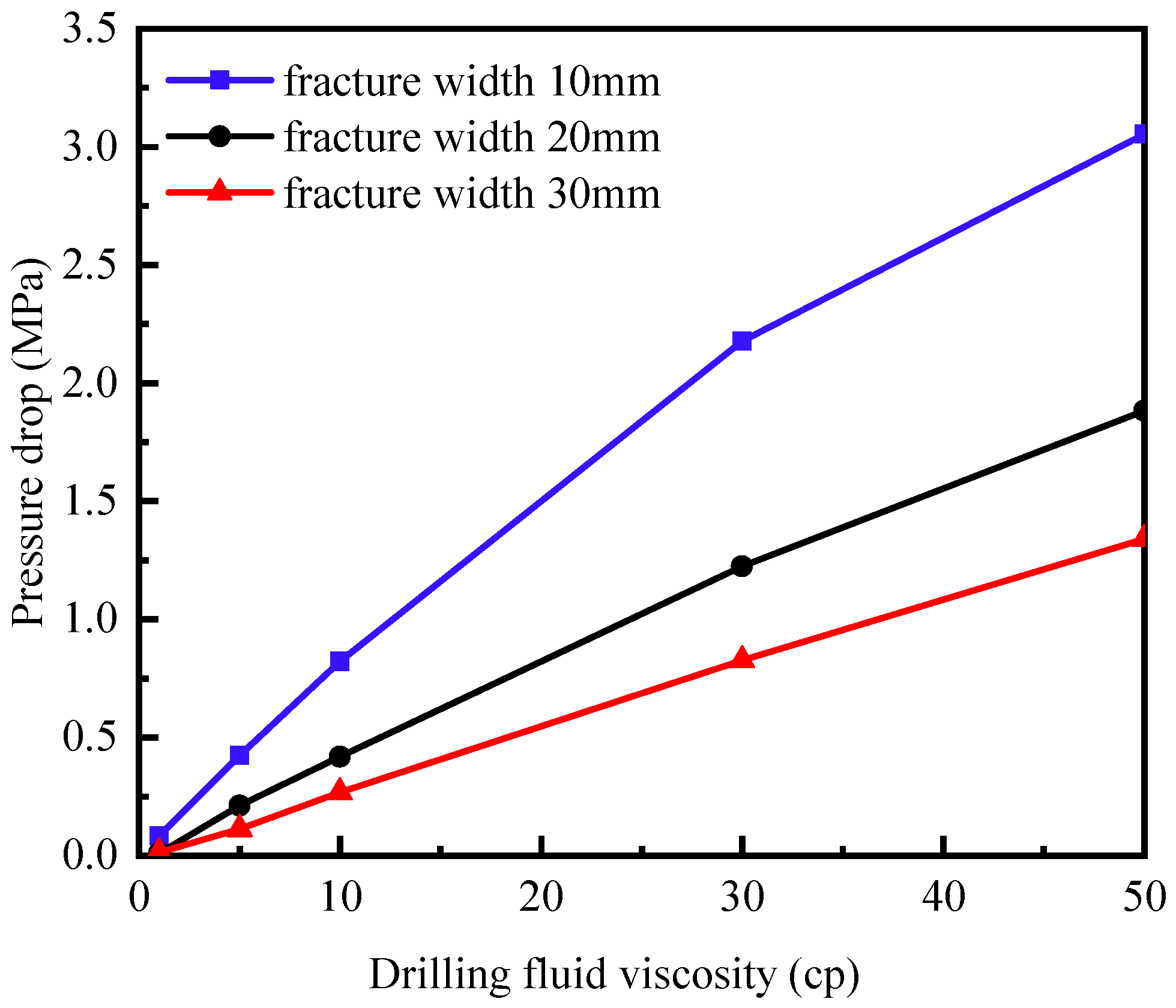

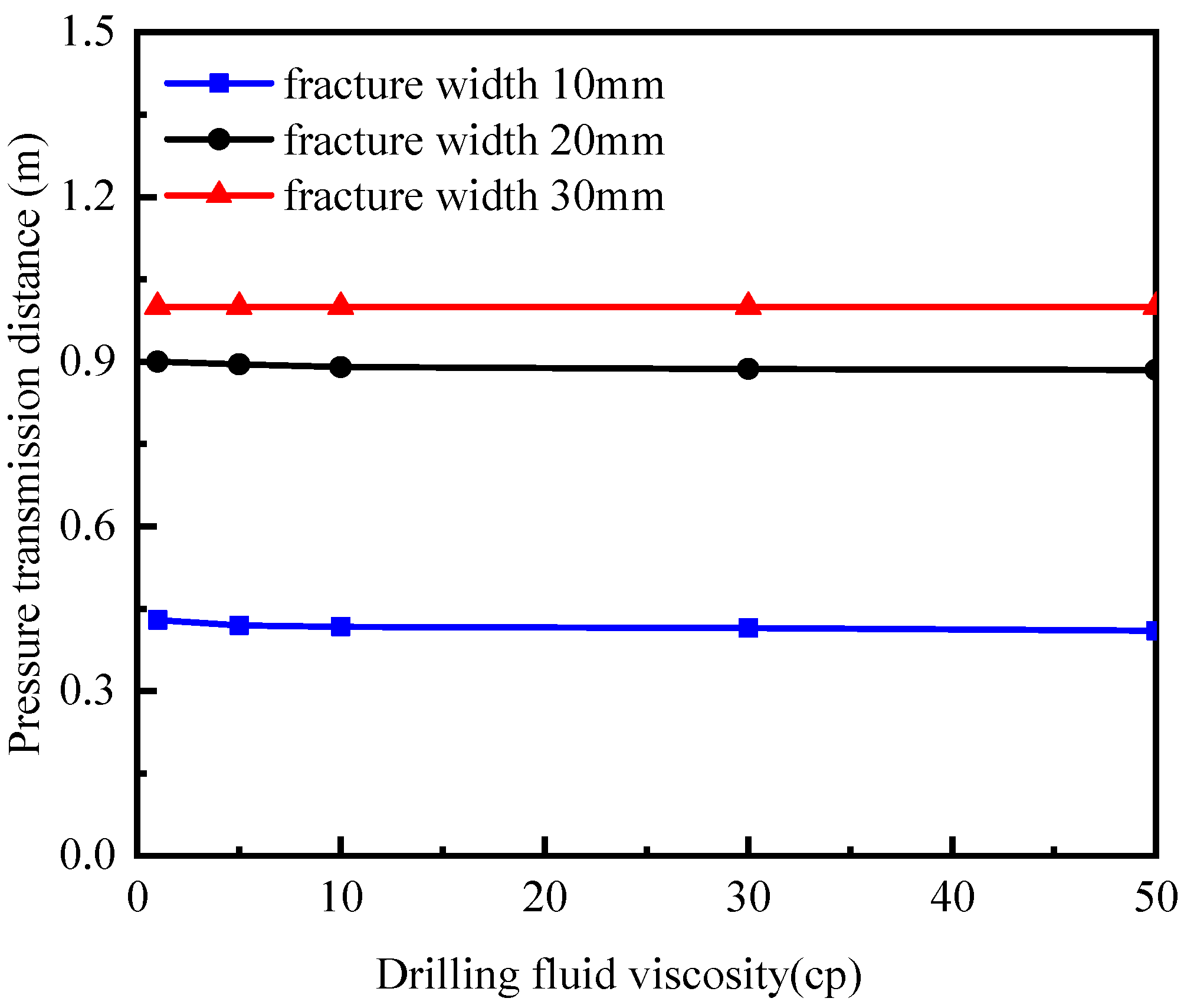

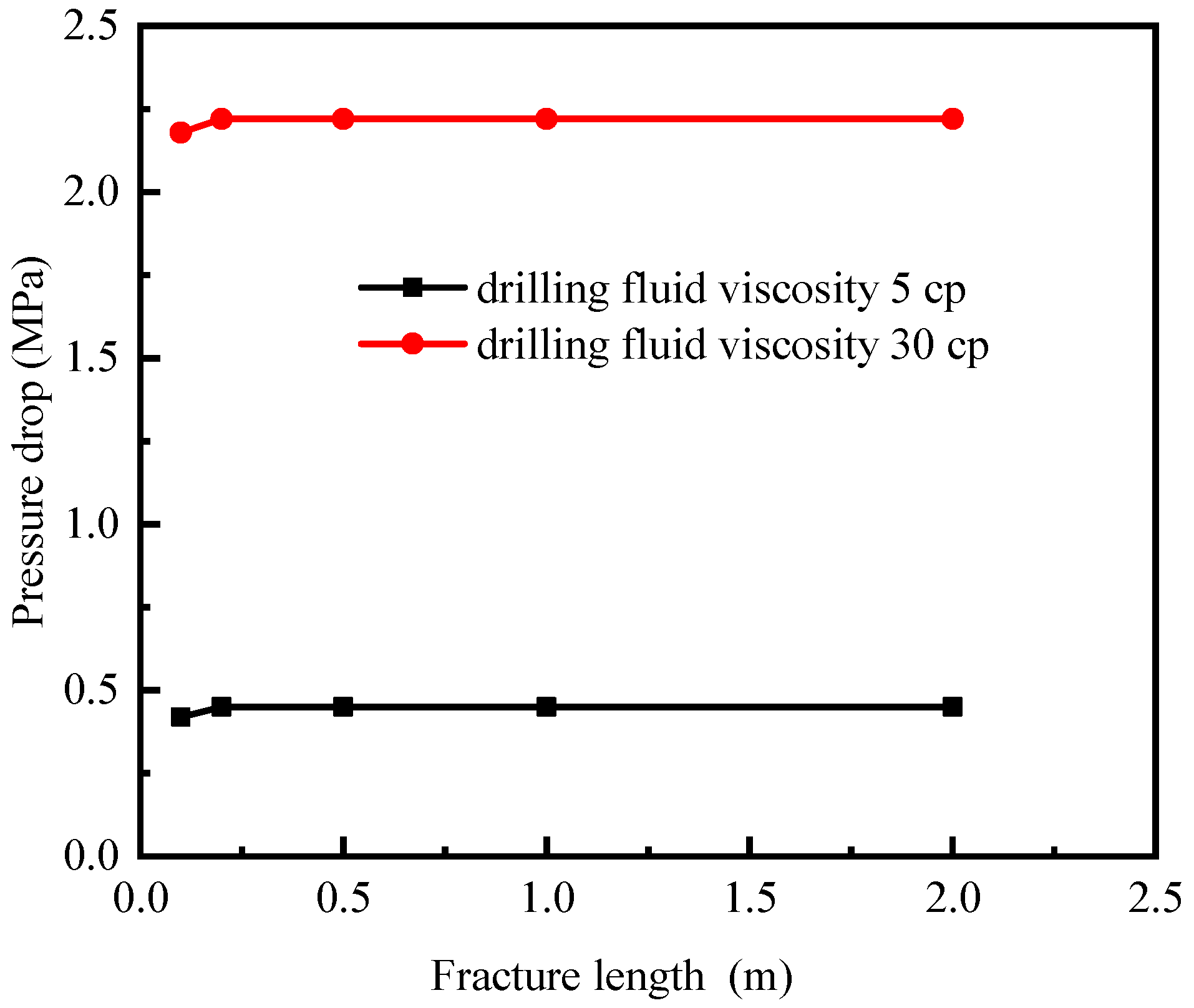

4.1. Influence of Drilling Fluid Viscosity

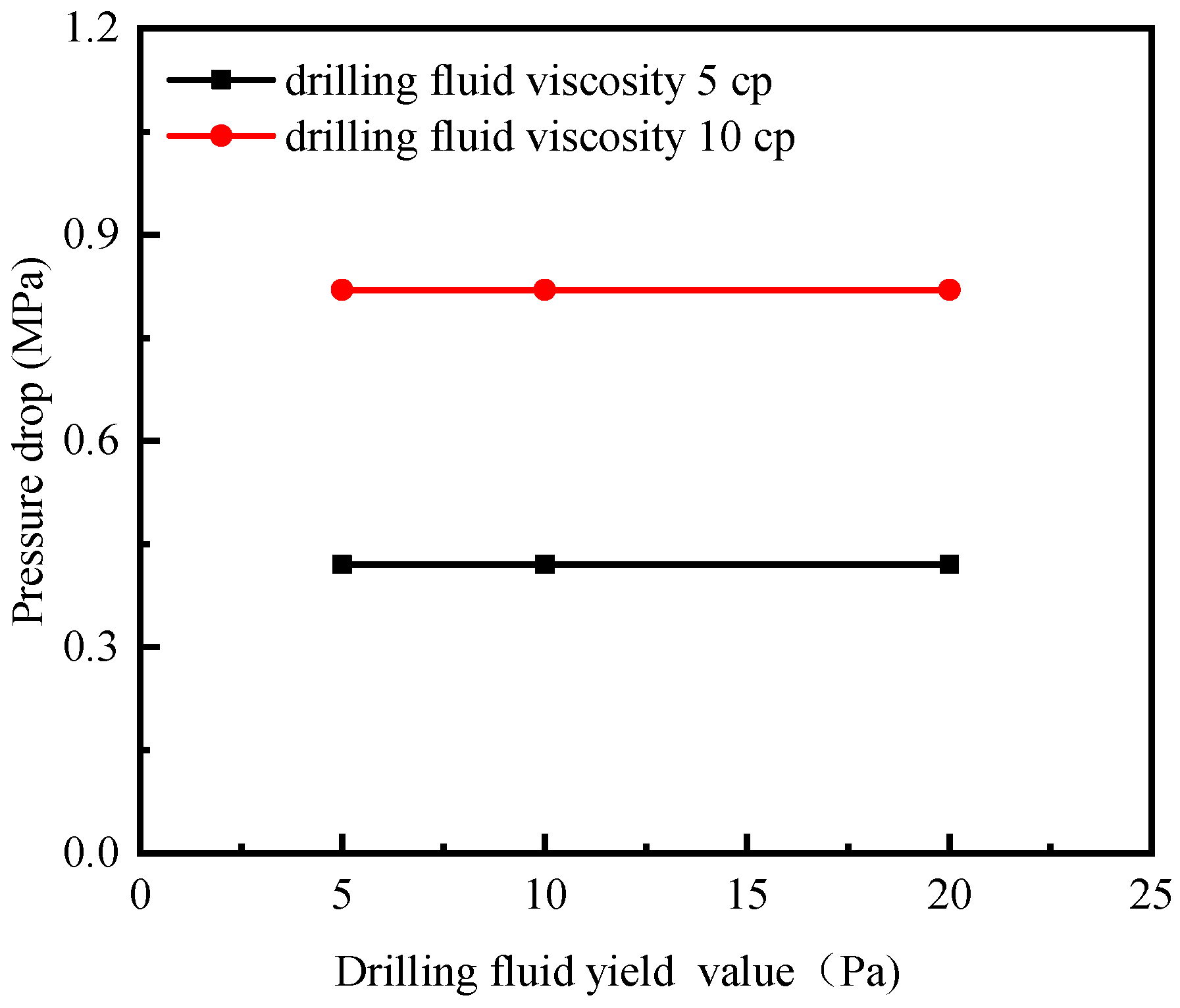

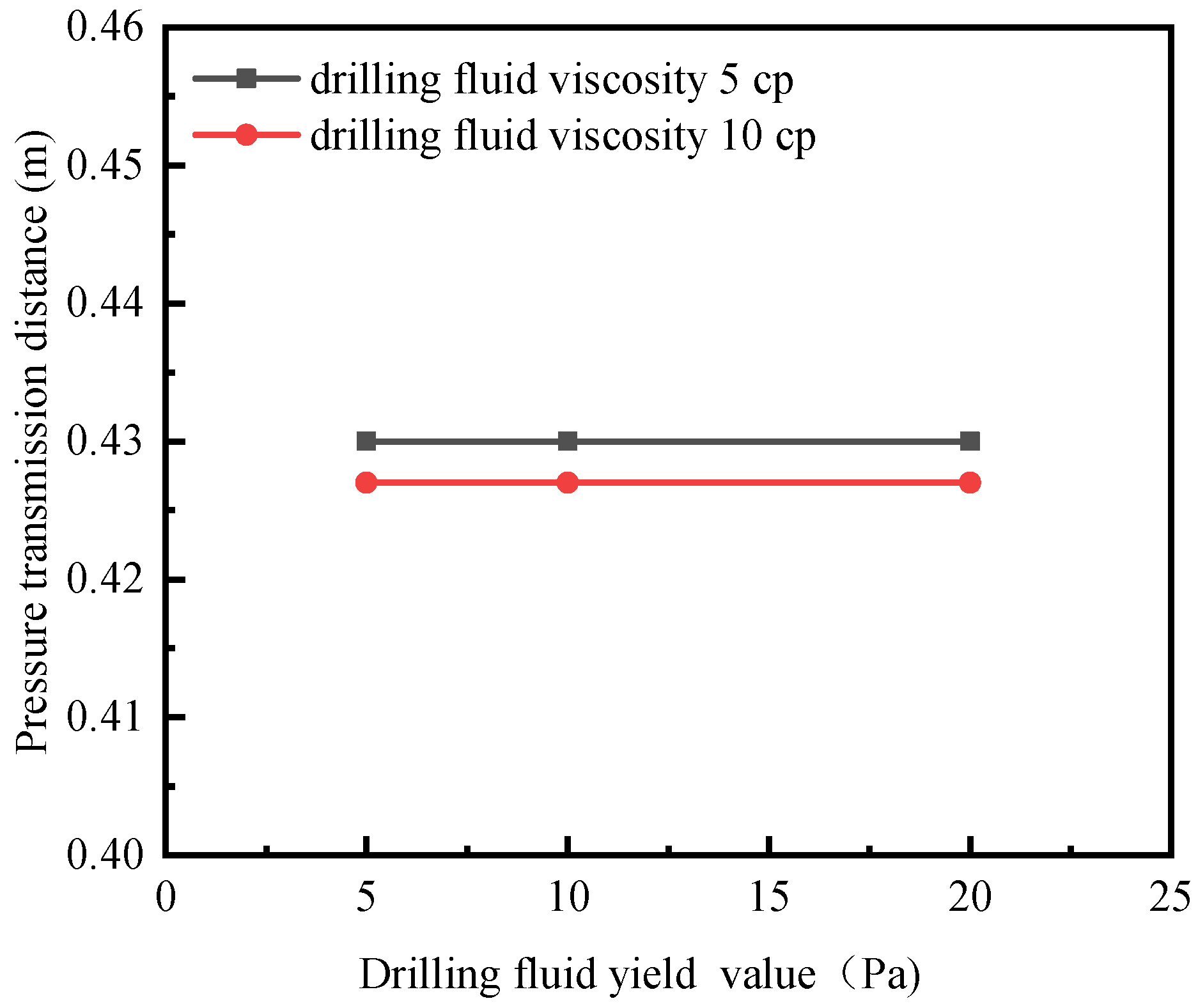

4.2. Influence of Drilling Fluid Yield

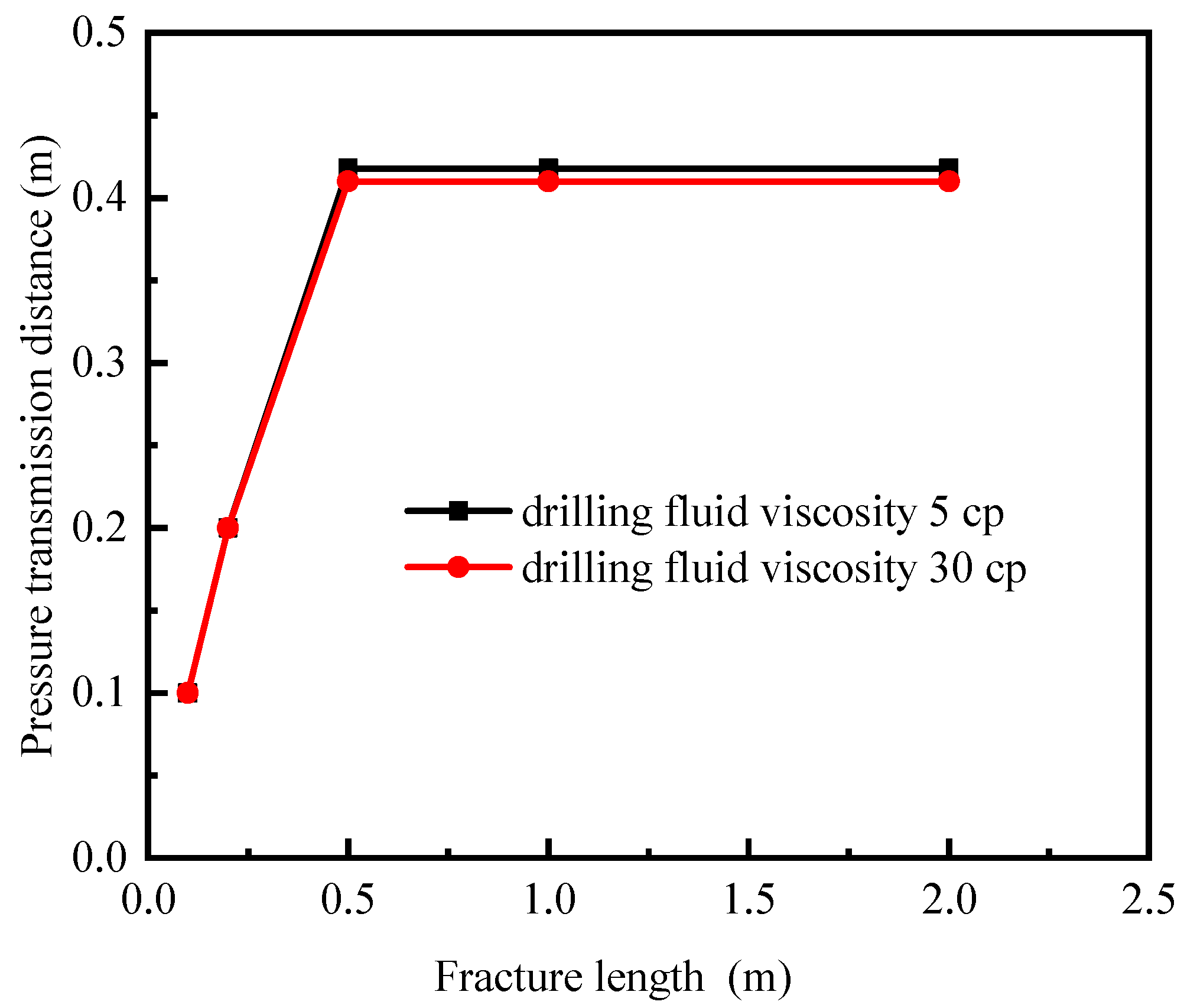

4.3. Influence of Crack Length L

5. Conclusions

- (1)

- There are numerous micro-fractures in hard and brittle shale, typically sized between 0.5 μm and 30 μm, which serve as the primary flow channels for the filtrate. The micro-fracture sizes in hard and brittle shale are generally larger than 0.1 μm, and the fluid flow within them falls under micro-flow, which produces a micro-flow effect. However, the Navier–Stokes equations and their no-slip boundary conditions remain applicable.

- (2)

- The influence of drilling fluid rheological properties on pressure transmission in fractures around the wellbore in hard and brittle shale can be divided into two aspects: When the fracture width is equal to the fracture length, an increase in drilling fluid viscosity leads to a rapid increase in pressure drop (ΔP), while the pressure transmission distance decreases slowly. This indicates that drilling fluid viscosity has a significant impact on the pore pressure around the wellbore but a relatively smaller effect on the pressure transmission distance. When the drilling fluid viscosity is equivalent to the fracture width and length, an increase in the drilling fluid yield point results in a slow and minimal decrease in pressure drop (ΔP), while the pressure transmission distance remains largely unchanged. This suggests that within a reasonable range of drilling fluid yield points, the yield point has little influence on the pore pressure or pressure transmission distance around the wellbore.

- (3)

- Under reasonable drilling fluid rheological parameters, increasing parameters such as drilling fluid viscosity will reduce the rise in pore pressure around the wellbore in hard and brittle shale formations. This reduction in pore pressure also lowers the collapse pressure required to maintain vertical wellbore stability, which is beneficial for improving the stability of wellbores in hard and brittle shale formations.

6. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, H. Coordinated development of shale gas benefit exploitation and ecological environmental conservation in China: A mini review. Front. Ecol. Evol. 2023, 11, 1232395. [Google Scholar] [CrossRef]

- Zou, C.; Dong, D.; Wang, Y.; Li, X.; Hung, J.; Wang, S.; Guan, Q.; Zhang, C.; Wang, H.; Liu, H.; et al. Shale gas in China: Characteristics, challenges and prospects (I). Pet. Explor. Dev. 2015, 42, 753–767. [Google Scholar] [CrossRef]

- Zou, C.; Dong, D.; Wang, Y.; Li, X.; Hung, J.; Wang, S.; Guan, Q.; Zhang, C.; Wang, H.; Liu, H.; et al. Shale gas in China: Characteristics, challenges and prospects (II). Pet. Explor. Dev. 2016, 43, 182–196. [Google Scholar] [CrossRef]

- Sun, J.; Lu, C.; Li, Z.; Ouyang, G.; Cao, X.; Zhou, F. Characteristics of stress distribution and microseismic activity in rock parting occurrence area. J. Min. Strat. Control Eng. 2021, 3, 043518. [Google Scholar]

- Jin, Y.; Zhang, Y.; Lu, Y. Progress and reflections on the microcrack growth mechanism of hard-brittle shale under chemical-mechanical couplings. Pet. Sci. Bull. 2023, 5, 577–587. [Google Scholar]

- Fjaer, E.; Holt, R.M.; Horsrud, P.; Raaen, A.M. Petroleum Related Rock Mechanics; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Li, H.; Zhu Deng, J.; Zhang, Y.; Li, Z.; Li, X. Study and Application of Wellbore Stability in Offshore Drilling: A case study of Well A-1. Sci. Technol. Eng. 2022, 22, 16007–16015. [Google Scholar]

- Lal, M. Shale stability: Drilling fluid interaction and shale strength. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 20–22 April 1999; SPE-54356-MS. SPE: Dallas, TX, USA, 1999. [Google Scholar]

- Van Oort, E. On the physical and chemical stability of shales. J. Pet. Sci. Eng. 2003, 38, 213–235. [Google Scholar] [CrossRef]

- Schoenball, M.; Sahara, D.P.; Kohl, T. Time-dependent brittle creep as a mechanism for time-delayed wellbore failure. Int. J. Rock Mech. Min. Sci. 2014, 70, 400–406. [Google Scholar] [CrossRef]

- Zoback, M.D. Reservoir Geomechanics; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Xiao, Z.; Jia, S.; Qi, X.; Dai, Y.; Lv, F.; Jia, L.; Wen, C. Hydraulic-mechanical-chemical coupling evaluation for progressive failure of hard brittle shale wellbore. J. Cent. South Univ. (Sci. Technol.) 2019, 50, 2464–2480. [Google Scholar]

- Ewy, R.T. Practical approaches for addressing shale testing challenges associated with permeability, capillarity and brine interactions. Geomech. Energy Environ. 2018, 14, 3–15. [Google Scholar] [CrossRef]

- Roychaudhuri, B.; Tsotsis, T.T.; Jessen, K. Shale-fluid interactions during forced lmbibition and flow-back. J. Pet. Sci. Eng. 2019, 172, 443–453. [Google Scholar] [CrossRef]

- Abdullah, A.H.; Ridha, S.; Mohshim, D.F.; Yusuf, M.; Kamyab, H.; Krishna, S.; Maoinser, M.A. A comprehensive review of nanoparticles: Effect on water-based drilling fluids and wellbore stability. Chemosphere 2022, 308, 136274. [Google Scholar] [CrossRef]

- Luo, J.; Xu, S.; Wu, X. Influence of silicate base drilling fluid on wellbore stability of shale. Drill. Fluid Complet. Fluid 2006, 23, 17–20. [Google Scholar]

- Yao, R.; Jiang, G.; Li, W.; Zhang, H. Research and Application of Permitted Rheological Parameter Control Window of Drilling Fluid. Sci. Technol. Eng. 2013, 13, 1671–1815. [Google Scholar]

- Yamamoto, K.; Shioya, Y.; Uryu, N. Discrete element approach for the wellbore instability of laminated and fissured rocks. In Proceedings of the SPE/ISRM Rock Mechanics Conference, Irving, TX, USA, 20–23 October 2002; SPE-78181-MS. SPE: Dallas, TX, USA, 2002. [Google Scholar]

- Roshan, H. Three Dimensional Non-Linear Anisotropic Thermo-Chemo-Poro-Elastoplastic Modelling of Borehole Stability in Chemically Active Rocks; UNSW: Sydney, Australia, 2011. [Google Scholar]

- Kong, Y.; Han, F.; Yao, L.; Zhang, G.; Liu, J. Simulation and application of shale fracture width immersed in drilling fluid. Oil Drill. Prod. Technol. 2014, 36, 41–46. [Google Scholar]

- Song, S.; Wu, Y.; Fu, Y.; Liu, D.; Zhou, P. Experimental study on shear mechanical properties of anchored rock mass under impact load. J. Min. Strat. Control. Eng. 2021, 3, 043034. [Google Scholar]

- Gholami, R.; Elochukwu, H.; Fakhari, N.; Sarmadivaleh, M. A review on borehole instability in active shale formations: Interactions, mechanisms and inhibitors. Earth-Sci. Rev. 2018, 177, 2–13. [Google Scholar] [CrossRef]

- Lee, H.; Ong, S.H.; Azeemuddin, M.; Goodman, H. A wellbore stability model for formations with anisotropic rock strengths. J. Pet. Sci. Eng. 2012, 96, 109–119. [Google Scholar] [CrossRef]

- Nguyen, V.X.; Abousleiman, Y.N. The porochemothermoelastic coupled solutions of stress and pressure with applications to wellbore stability in chemically active shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009; SPE-124422-MS. SPE: Dallas, TX, USA, 2009. [Google Scholar]

- Xu, C.; Liu, J.; Tian, Y.; Xiao, W.; Xu, T.; Cai, W. Research on mechanism and treating methods of wellbore instability in fractured and hard brittle mudstone. Drill. Fluid Complet. Fluid 2013, 30, 13–16. [Google Scholar]

- Jia, L.; Chen, M.; Tan, Q.; Sun, Z.; Wu, S. Key Factors for Inhibiting Fracture Propagation during Leakage Control under Pressure. Pet. Drill. Tech. 2016, 44, 49–56. [Google Scholar] [CrossRef]

- Cheng, C.; Bunger, A.P. Optimizing fluid viscosity for systems of multiple hydraulic fractures. AIChE J. 2019, 65, e16564. [Google Scholar] [CrossRef]

- Zhao, H.; Fan, S.; Lian, S.; Li, S.; Cheng, X.; Ke, D. Study on high temperature resistant weak gel anti gas invasion drilling fluid system in Shunbei oil and gas field. Drill. Fluid Complet. Fluid 2023, 40, 332–339. [Google Scholar]

- Gholami, R.; Raza, A.; Rabiei, M.; Fakhari, N.; Balasubramaniam, P.; Rasouli, V.; Nagarajan, R. An approach to improve wellbore stability in active shale formations using nanomaterials. Petroleum 2021, 7, 24–32. [Google Scholar] [CrossRef]

- Li, M.; Xu, J.; Pei, D.; Su, K.; Wang, L. Evaluation of Aminated Nano-Silica as a Novel Shale Stabilizer to Improve Wellbore Stability. Materials 2024, 17, 1776. [Google Scholar] [CrossRef] [PubMed]

- Mao, H.; Yang, Y.; Zhang, H.; Zheng, J.; Zhong, Y. Conceptual design and methodology for rheological control of water-based drilling fluids in ultra-high temperature and ultra-high pressure drilling applications. J. Pet. Sci. Eng. 2020, 188, 106884. [Google Scholar] [CrossRef]

- Rodrigues, R.K.; Martins, S.d.F.C.; Naccache, M.F.; de Souza Mendes, P.R. Rheological modifiers in drilling fluids. J. Non-Newton. Fluid Mech. 2020, 286, 104397. [Google Scholar] [CrossRef]

- Zheng, D.; Miska, S.; Ozbayoglu, E.; Zhang, J. Combined experimental and well log study of anisotropic strength of shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 16–18 October 2023; D031S046R003. SPE: Dallas, TX, USA, 2023. [Google Scholar]

- Zheng, D.; Miska, S.; Ziaja, M.; Zhang, J. Study of anisotropic strength properties of shale. AGH Drill. Oil Gas 2019, 36, 93–112. [Google Scholar] [CrossRef]

- Zheng, D.; Ozbayoglu, E.; Miska, S.; Zhang, J. Experimental study of anisotropic strength properties of shale. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Atlanta, GA, USA, 25–28 June 2023; ARMA-2023-0128. ARMA: Alexandria, VA, USA, 2023. [Google Scholar]

- Suo, Y.; Li, Z.H.; Fu, X.F.; Zhang, C.-C. Comprehensive study of hydraulic fracturing in shale oil reservoirs comprising shale–sandstone transitions. Phys. Fluids 2024, 36, 077161. [Google Scholar] [CrossRef]

- Suo, Y.; Zhao, Y.J.; Fu, X.F.; Fu, X.F.; He, W.Y.; Pan, Z. Study on fracture propagation behavior of deep high-temperature shale gas based on the modified MERR criterion. Theor. Appl. Fract. Mech. 2024, 131, 104352. [Google Scholar] [CrossRef]

- Rafieepour, S.; Zheng, D.; Miska, S.; Ozbayoglu, E.; Takach, N.; Yu, M.; Zhang, J. Combined experimental and well log evaluation of anisotropic mechanical properties of shales: An application to wellbore stability in bakken formation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 27–29 October 2020; D021S015R006. SPE: Dallas, TX, USA, 2020. [Google Scholar]

- Zheng, D.; Turhan, C.; Wang, N.; Wu, C.; Ashok, P.; van Oort, E. Prioritizing wells for repurposing or permanent abandonment based on generalized well integrity risk analysis. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Galveston, TX, USA, 5–7 March 2024; D021S018R001. SPE: Dallas, TX, USA, 2024. [Google Scholar]

- Suo, Y.; Li, F.; He, W.; Fu, X.; Pan, Z.; Feng, F.; Zhao, W. Invasion of drilling fluid into laminated shale model. Chin. J. Eng. 2024, 46, 547–555. [Google Scholar] [CrossRef]

- Bear, J. Dynamics of Fluids in Porous Media; Courier Corporation: Washington, DC, USA, 2013. [Google Scholar]

- American Petroleum Institute. API Recommended Practice 13B-1: Recommended Practice for Field Testing of Water-Based Drilling Fluids; API: Washington, DC, USA, 2009. [Google Scholar]

| Well Number | Well Depth (m) | Funnel Viscosity (s) | Density (g/cm3) | Hole Expansion Rate (%) |

|---|---|---|---|---|

| QG1 | 2740–2790 | 36 | 1.27 | 48.21 |

| 2790–2840 | 38 | 1.33 | 29.68 | |

| 2840–2890 | 56 | 1.35 | 16.11 | |

| 3190–3257 | 82 | 1.37 | 6.65 | |

| QN8 | 2900–2950 | 31 | 1.22 | 71.37 |

| 2950–3000 | 32 | 1.24 | 64.42 | |

| 3200–3250 | 35 | 1.28 | 72.83 | |

| 3250–3300 | 45 | 1.3 | 48.21 | |

| 3300–3350 | 58 | 1.34 | 23.68 | |

| 3350–3400 | 72 | 1.35 | 15.16 | |

| GS9 | 3063–3163 | 86 | 1.36 | 7.29 |

| 3163–3213 | 105 | 1.38 | 4.21 | |

| 3413–3463 | 45 | 1.42 | 20.42 | |

| 3363–3413 | 43 | 1.41 | 22.37 | |

| GS18 | 3078–3103 | 40 | 1.26 | 132.56 |

| 3103–3123 | 44 | 1.27 | 86.04 | |

| 3123–3153 | 53 | 1.27 | 64.98 | |

| 3153–3253 | 62 | 1.28 | 29.53 | |

| 3253–3463 | 73 | 1.28 | 18.03 | |

| GS69 | 3273–3373 | 84 | 1.28 | 8.84 |

| 3723–3773 | 58 | 1.45 | 6.53 | |

| GS7-1 | 3175–3225 | 90 | 1.26 | 6.97 |

| T30-22 | 3237–3297 | 27 | 1.28 | 92.13 |

| 3177–3237 | 25 | 1.27 | 139.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, W.; Zheng, Y.; Wang, W.; Jiang, G.; Sun, J.; Ma, C. Study on the Impact of Drilling Fluid Rheology on Pressure Transmission Within Micro-Cracks in Hard Brittle Shale. Processes 2025, 13, 1339. https://doi.org/10.3390/pr13051339

Shan W, Zheng Y, Wang W, Jiang G, Sun J, Ma C. Study on the Impact of Drilling Fluid Rheology on Pressure Transmission Within Micro-Cracks in Hard Brittle Shale. Processes. 2025; 13(5):1339. https://doi.org/10.3390/pr13051339

Chicago/Turabian StyleShan, Wenjun, Yuxuan Zheng, Wei Wang, Guancheng Jiang, Jinsheng Sun, and Chengyun Ma. 2025. "Study on the Impact of Drilling Fluid Rheology on Pressure Transmission Within Micro-Cracks in Hard Brittle Shale" Processes 13, no. 5: 1339. https://doi.org/10.3390/pr13051339

APA StyleShan, W., Zheng, Y., Wang, W., Jiang, G., Sun, J., & Ma, C. (2025). Study on the Impact of Drilling Fluid Rheology on Pressure Transmission Within Micro-Cracks in Hard Brittle Shale. Processes, 13(5), 1339. https://doi.org/10.3390/pr13051339