Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce

Abstract

:1. Introduction

2. The Need to Reduce Food Losses in the Postharvest Supply Chain of Fruits and Vegetables

3. Advanced Technologies for Quality Assessment in Postharvest Supply Chain: State-Of-The-Art

3.1. Application of Imaging Technology, Spectroscopy, Multi-Sensors, E-Nose, AIR, RFID and PTS in the Postharvest Supply Chain of Fruits and Vegetables

3.2. Application of Mathematical Modeling Techniques in the Postharvest Supply Chain of Fruits and Vegetables

4. Emerging Opportunities in Reducing Food Losses in the Postharvest Supply Chain

4.1. Application of IoT in the Postharvest Supply Chain of Fruits and Vegetables

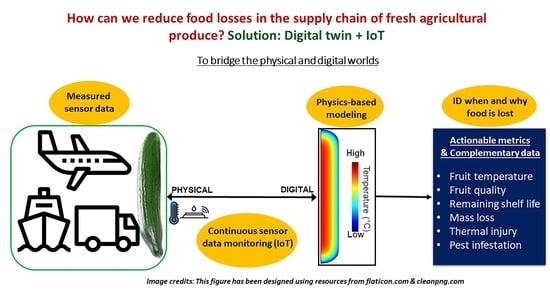

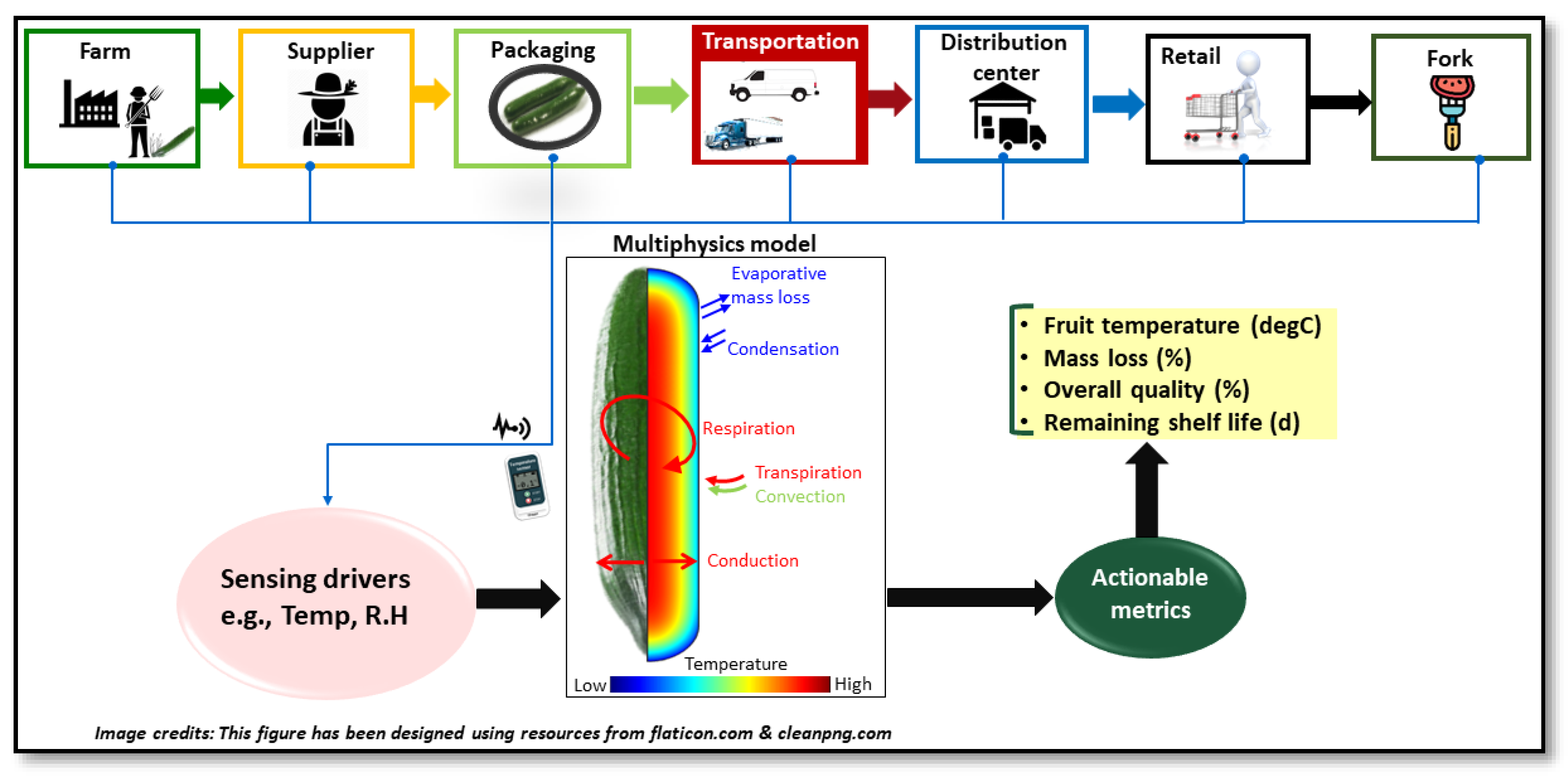

4.2. Digital Twin as an Advanced Tool in Reducing Food Losses in the Postharvest Supply Chain of Fruits and Vegetables

5. Future Opportunities to Reduce Food Losses in the Postharvest Supply Chain of Fruits and Vegetables

6. Conclusions

- Computer vision, hyperspectral imaging, multispectral imaging, spectroscopy, and X-ray imaging are already widely used in monitoring and optimizing the cold chain processes of fresh agricultural produce.

- The application of MM, MGS models, HMT models, SBM, SM, and KRM in improving the cold chain processes and evaluating the quality losses of fresh produce is well established. These models can help control and optimize the packaging and storage operations of fruits and vegetables in order to reduce quality losses.

- IoT is widely applied in monitoring and controlling the process conditions of fresh produce, enabling various stakeholders to implement proper decisions.

- Digital twins are significant in quantifying the quality evolution of fresh produce in each shipment and also predict the remaining shelf life days.

- There is a very huge potential for coupling digital twins with big data technologies (IoT devices, printed sensors, RFID, multi-sensors, soft sensors) to monitor, optimize, and make significant changes that will reduce food losses in the postharvest supply chain of fresh produce. However, such a system does not exist.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| FAO | Food and Agriculture Organization |

| AIR | Acoustic Impulse Response |

| CV | Computer Vision |

| HSI | Hyperspectral Imaging |

| MSI | Multispectral Imaging |

| CCD | Charge-Couple Device |

| SG | Savitsky–Golay |

| SNV | Standard Normal Variate |

| PCA | Principal Component Analysis |

| PLSR | Partial Least Squares Regression |

| MSC | Multiple Scatter Correction |

| PLS-DA | Partial Least Squares Discriminant Analysis |

| ANN | Artificial Neural Network |

| CNN | Convolutional Neural Networks |

| LDA | Linear Discriminant Analysis |

| kNN | k-Nearest Neighbors |

| CFS | Correlation-based Feature Subset Selection |

| GIA | Gini Impurity Algorithm |

| SFS | Sequential Forward Selection |

| BPNN | Backpropagation Neural Network |

| ELM | Extreme Learning Machine |

| SLR | Sparse Logistic Regression |

| CMS | Central Monitoring System |

| RTS | Real-Time analytic System |

| RFID | Radio Frequency Identification Tags |

| MSA | Multi-Sensors Analysis |

| SVM | Support Vector Machine |

| RBF | Radial Basis Function |

| LCA | Life Cycle Assessment |

| PTS | Printed Sensors |

| GA | Genetic Algorithm |

| SVR | Support Vector Regression |

| SNK | Student–Newman–Keuls |

| LS-SVM | Least Squares Support Vector Machines |

| RF | Random Forest |

| LW | Local Order |

| WSNs | Wireless Sensor Networks |

| ROC | Receiver Operating Characteristic |

| MM | Migration Models |

| MGS | Membrane Gas Separation |

| HMT | Heat and Mass Transfer |

| SBM | Structural Behavior Models |

| SM | Stochastic Models |

| KRM | Kinetics Rate Models |

| CO2 | Carbon Dioxide |

| O2 | Oxygen |

| N2 | Nitrogen |

| H2O | Water |

| FEA | Finite Element Analysis |

| MAP | Modified Atmosphere Packaging |

| 1-MCP | Methyl Cyclopropane |

| TR | Transpiration Rate |

| CFD | Computational Fluid Dynamic |

| VCP | Ventilated Corrugated Paperboard |

| IoT | Internet of Things |

| GPS | Global Positioning System |

| NN | Neural Networks |

| NCP | Nano-Composite based Packaging |

| CFD | Computational Fluid Dynamics |

References

- Coulomb, D. Refrigeration and cold chain serving the global food industry and creating a better future: Two key IIR challenges for improved health and environment. Trends Food Sci. Technol. 2008, 19, 413–417. [Google Scholar] [CrossRef]

- Shafiee-Jood, M.; Cai, X. Reducing Food Loss and Waste to Enhance Food Security and Environmental Sustainability. Environ. Sci. Technol. 2016, 50, 8432–8443. [Google Scholar] [CrossRef] [PubMed]

- Gustavsson, J.; Stage, J. Retail waste of horticultural products in Sweden. Resour. Conserv. Recycl. 2011, 55, 554–556. [Google Scholar] [CrossRef]

- Yahaya, S.; Ay, M. Review of Post-Harvest Losses of Fruits and Vegetables. Biomed. J. Sci. Tech. Res. 2019, 13, 10192–10200. [Google Scholar] [CrossRef]

- Onwude, D.; Hashim, N.; Janius, R.; Nawi, N.; Khalina, A. Modeling the thin-layer drying of fruits and vegetables—A review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef]

- Salehi, F.; Aghajanzadeh, S. Effect of dried fruits and vegetables powder on cakes quality: A review. Trends Food Sci. Technol. 2020, 95, 162–172. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, M.; Xu, B. Application of ultrasonic technology in postharvested fruits and vegetables storage: A review. Ultrason. Sonochem. 2020, 69, 105261. [Google Scholar] [CrossRef]

- Cömert, E.D.; Mogol, B.A.; Gökmen, V. Relationship between color and antioxidant capacity of fruits and vegetables. Curr. Res. Food Sci. 2020, 2, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.l.; Zhang, M. Trends in Development of Dried Vegetable Products as Snacks. Dry. Technol. 2012, 30, 448–461. [Google Scholar] [CrossRef]

- Liu, D.K.; Xu, C.C.; Guo, C.X.; Zhang, X.X. Sub-zero temperature preservation of fruits and vegetables: A review. J. Food Eng. 2019, 275, 109881. [Google Scholar] [CrossRef]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time–Temperature Management along the Food Cold Chain: A Review of Recent Developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef]

- Arah, I.K.; Ahorbo, G.K.; Anku, E.K.; Kumah, E.K.; Amaglo, H. Postharvest Handling Practices and Treatment Methods for Tomato Handlers in Developing Countries: A Mini Review. Adv. Agric. 2016, 2016, 6436945. [Google Scholar] [CrossRef] [Green Version]

- Raut, R.D.; Gardas, B.B.; Narwane, V.S.; Narkhede, B.E. Improvement in the food losses in fruits and vegetable supply chain—A perspective of cold third-party logistics approach. Oper. Res. Perspect. 2019, 6, 100117. [Google Scholar] [CrossRef]

- James, S.J.; James, C. The food cold-chain and climate change. Food Res. Int. 2010, 43, 1944–1956. [Google Scholar] [CrossRef]

- Defraeye, T.; Cronje, P.J.R.; Berry, T.; Opara, U.L.; East, A.; Hertog, M.L.A.T.M.; Verboven, P.; Nicolai, B.M. Towards integrated performance evaluation of future packaging for fresh produce in the cold chain. Trends Food Sci. Technol. 2015, 44, 201–225. [Google Scholar] [CrossRef]

- Thompson, J.F.; Mejia, D.C.; Singh, R.P. Energy Use of Commercial Forced-Air Coolers for Fruit. Appl. Eng. Agric. 2010, 26, 919–924. [Google Scholar] [CrossRef]

- Piljac-Žegarac, J.; Šamec, D. Antioxidant stability of small fruits in postharvest storage at room and refrigerator temperatures. Food Res. Int. 2011, 44, 345–350. [Google Scholar] [CrossRef]

- Chu, W.; Gao, H.; Chen, H.; Wu, W.-J.; Fang, X. Changes in Cuticular Wax Composition of Two Blueberry Cultivars during Fruit Ripening and Postharvest Cold Storage. J. Agric. Food Chem. 2018, 66, 2870–2876. [Google Scholar] [CrossRef]

- Fagundes, C.; Moraes, K.; Pérez-Gago, M.; Palou, L.; Maraschin, M.; Monteiro, A. Effect of active modified atmosphere and cold storage on the postharvest quality of cherry tomatoes. Postharvest Biol. Technol. 2015, 109, 73–81. [Google Scholar] [CrossRef]

- Hong, K.; Xie, J.; Zhang, L.; Sun, D.; Gong, D. Effects of chitosan coating on postharvest life and quality of guava (Psidium guajava L.) fruit during cold storage. Sci. Hortic. 2012, 144, 172–178. [Google Scholar] [CrossRef]

- Hu, Q.; Fang, Y.; Yang, Y.; Ma, N.; Zhao, L. Effect of nanocomposite-based packaging on postharvest quality of ethylene-treated kiwifruit (Actinidia deliciosa) during cold storage. Food Res. Int. 2011, 44, 1589–1596. [Google Scholar] [CrossRef]

- Jiang, T.; Feng, L.; Li, J. Changes in microbial and postharvest quality of shiitake mushroom (Lentinus edodes) treated with chitosan–glucose complex coating under cold storage. Food Chem. 2012, 131, 780–786. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, M.; Yang, H. Postharvest chitosan-g-salicylic acid application alleviates chilling injury and preserves cucumber fruit quality during cold storage. Food Chem. 2015, 174, 558–563. [Google Scholar] [CrossRef]

- Ghaani, M.; Cozzolino, C.A.; Castelli, G.; Farris, S. An overview of the intelligent packaging technologies in the food sector. Trends Food Sci. Technol. 2016, 51, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Müller, P.; Schmid, M. Intelligent Packaging in the Food Sector: A Brief Overview. Foods 2019, 8, 16. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Haass, R.; Dittmer, P.; Veigt, M.; Lütjen, M. Reducing food losses and carbon emission by using autonomous control—A simulation study of the intelligent container. Int. J. Prod. Econ. 2015, 164, 400–408. [Google Scholar] [CrossRef]

- Janjarasskul, T.; Suppakul, P. Active and intelligent packaging: The indication of quality and safety. Crit. Rev. Food Sci. Nutr. 2017, 58, 808–831. [Google Scholar] [CrossRef]

- Williams, H.; Wikström, F. Environmental impact of packaging and food losses in a life cycle perspective: A comparative analysis of five food items. J. Clean. Prod. 2011, 19, 43–48. [Google Scholar] [CrossRef]

- White, A.; Lockyer, S. Removing plastic packaging from fresh produce—What’s the impact? Nutr. Bull. 2020, 45, 35–50. [Google Scholar] [CrossRef]

- Bilstein, F. What Reduces Our Personal CO2 Footprint? We Have no Clue! 2019. Available online: https://www.linkedin.com/pulse/what-reduces-our-personal-co2-footprint-we-have-clue-frank-bilstein (accessed on 19 October 2020).

- Wynes, S.; A Nicholas, K. The climate mitigation gap: Education and government recommendations miss the most effective individual actions. Environ. Res. Lett. 2017, 12, 074024. [Google Scholar] [CrossRef] [Green Version]

- Hischier, R. Schwierige Suche Nach Plastikalternativen. Migros Mag. 2019. Available online: https://www.migrosmagazin.ch/schwierige-suche-nach-plastikalternativen (accessed on 19 October 2020).

- Conte, A.; Cappelletti, G.; Nicoletti, G.; Russo, C.; Del Nobile, M. Environmental implications of food loss probability in packaging design. Food Res. Int. 2015, 78, 11–17. [Google Scholar] [CrossRef]

- Gutierrez, M.M.; Meleddu, M.; Piga, A. Food losses, shelf life extension and environmental impact of a packaged cheesecake: A life cycle assessment. Food Res. Int. 2017, 91, 124–132. [Google Scholar] [CrossRef]

- Denkstatt. How Packaging Contributes to Food Waste Prevention. 2017. Available online: www.denkstatt.at (accessed on 19 October 2020).

- Duan, Y.; Wang, G.-B.; Fawole, O.A.; Verboven, P.; Zhang, X.-R.; Wu, D.; Opara, U.L.; Nicolai, B.; Chen, K. Postharvest precooling of fruit and vegetables: A review. Trends Food Sci. Technol. 2020, 100, 278–291. [Google Scholar] [CrossRef]

- Praeger, U.; Jedermann, R.; Sellwig, M.; Neuwald, D.A.; Hartgenbusch, N.; Borysov, M.; Truppel, I.; Scaar, H.; Geyer, M. Airflow distribution in an apple storage room. J. Food Eng. 2020, 269, 109746. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Carthy, U.M.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Villalba, J.I.R. New trends in cold chain monitoring applications—A review. Food Control 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste; FAO: Rome, Italy, 2011. [Google Scholar]

- Morris, K.J.; Kamarulzaman, N.H.; I Morris, K. Small-scale postharvest practices among plantain farmers and traders: A potential for reducing losses in rivers state, Nigeria. Sci. Afr. 2019, 4, e00086. [Google Scholar] [CrossRef]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef] [Green Version]

- Lundqvist, J.; de Fraiture, C.; Molden, D. Saving Water: From Field to Fork: Curbing Losses and Wastage in the Food Chain; Stockholm International Water Institute: Stockholm, Sweden, 2008. [Google Scholar]

- Bustos, C.A.; Moors, E.H. Reducing post-harvest food losses through innovative collaboration: Insights from the Colombian and Mexican avocado supply chains. J. Clean. Prod. 2018, 199, 1020–1034. [Google Scholar] [CrossRef] [Green Version]

- Santos, S.F.; Cardoso, R.D.C.V.; Borges, Í.M.P.; Almeida, E.A.C.; Andrade, E.S.; Dos Santos, S.F.; Ramos, L.D.C. Post-harvest losses of fruits and vegetables in supply centers in Salvador, Brazil: Analysis of determinants, volumes and reduction strategies. Waste Manag. 2019, 101, 161–170. [Google Scholar] [CrossRef]

- FAO. Food Wastage Footprint—Impacts on Natural Resources: Summary Report; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013. [Google Scholar]

- Sivakumar, D.; Wall, M.M. Papaya Fruit Quality Management during the Postharvest Supply Chain. Food Rev. Int. 2013, 29, 24–48. [Google Scholar] [CrossRef]

- Mampholo, B.M.; Sivakumar, D.; Thompson, A.K. Maintaining overall quality of fresh traditional leafy vegetables of Southern Africa during the postharvest chain. Food Rev. Int. 2015, 32, 400–416. [Google Scholar] [CrossRef]

- Bradford, K.J.; Dahal, P.; Van Asbrouck, J.; Kunusoth, K.; Bello, P.; Thompson, J.; Wu, F. The dry chain: Reducing postharvest losses and improving food safety in humid climates. Trends Food Sci. Technol. 2018, 71, 84–93. [Google Scholar] [CrossRef]

- Gordon, A.; Gordon, D. Food safety and quality systems implementation along value chains. In Food Safety and Quality Systems in Developing Countries; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 81–124. [Google Scholar]

- Canadian Food Inspection Agency. Food Safety Enhancement Program Manual; Canadian Food Inspection Agency: Ottawa, ON, Canada, 2014.

- Siripatrawan, U. Hyperspectral imaging for rapid evaluation and visualization of quality deterioration index of vacuum packaged dry-cured sausages. Sensors Actuators B Chem. 2018, 254, 1025–1032. [Google Scholar] [CrossRef]

- Dowlati, M.; De La Guardia, M.; Mohtasebi, S.S. Application of machine-vision techniques to fish-quality assessment. TrAC Trends Anal. Chem. 2012, 40, 168–179. [Google Scholar] [CrossRef]

- Feng, Y.Z.; Sun, D.-W. Determination of total viable count (TVC) in chicken breast fillets by near-infrared hyperspectral imaging and spectroscopic transforms. Talanta 2013, 105, 244–249. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Hosseinpour, S.; Ghasemi-Varnamkhasti, M. Computer vision technology for real-time food quality assurance during drying process. Trends Food Sci. Technol. 2014, 39, 76–84. [Google Scholar] [CrossRef]

- Martynenko, A. Computer Vision for Real-Time Control in Drying. Food Eng. Rev. 2017, 9, 91–111. [Google Scholar] [CrossRef]

- Zhang, H.; Li, D. Applications of computer vision techniques to cotton foreign matter inspection: A review. Comput. Electron. Agric. 2014, 109, 59–70. [Google Scholar] [CrossRef]

- Zhang, B.; Huang, W.; Li, J.; Zhao, C.; Fan, S.; Wu, J.; Liu, C. Principles, developments and applications of computer vision for external quality inspection of fruits and vegetables: A review. Food Res. Int. 2014, 62, 326–343. [Google Scholar] [CrossRef]

- Agudelo-Laverde, L.M.; Schebor, C.; Buera, M. Water content effect on the chromatic attributes of dehydrated strawberries during storage, as evaluated by image analysis. LWT-Food Sci. Technol. 2013, 52, 157–162. [Google Scholar] [CrossRef] [Green Version]

- Cubero, S.; Aleixos, N.; Moltó, E.; Gómez-Sanchis, J.; Blasco, J. Advances in Machine Vision Applications for Automatic Inspection and Quality Evaluation of Fruits and Vegetables. Food Bioprocess Technol. 2010, 4, 487–504. [Google Scholar] [CrossRef]

- Li, Y.; Tang, X.; Shen, Z.; Dong, J. Prediction of total volatile basic nitrogen (TVB-N) content of chilled beef for freshness evaluation by using viscoelasticity based on airflow and laser technique. Food Chem. 2019, 287, 126–132. [Google Scholar] [CrossRef]

- Sanaeifar, A.; Zakidizaji, H.; Jafari, A.; De La Guardia, M. Early detection of contamination and defect in foodstuffs by electronic nose: A review. TrAC Trends Anal. Chem. 2017, 97, 257–271. [Google Scholar] [CrossRef]

- Emana, B.; Afari-Sefa, V.; Nenguwo, N.; Ayana, A.; Kebede, D.; Mohammed, H. Characterization of pre- and postharvest losses of tomato supply chain in Ethiopia. Agric. Food Secur. 2017, 6, 87. [Google Scholar] [CrossRef] [Green Version]

- Pace, B.; Cefola, M.; Da Pelo, P.; Renna, F.; Attolico, G. Non-destructive evaluation of quality and ammonia content in whole and fresh-cut lettuce by computer vision system. Food Res. Int. 2014, 64, 647–655. [Google Scholar] [CrossRef] [PubMed]

- Fukuda, S.; Yasunaga, E.; Nagle, M.; Yuge, K.; Sardsud, V.; Spreer, W.; Müller, J. Modelling the relationship between peel colour and the quality of fresh mango fruit using Random Forests. J. Food Eng. 2014, 131, 7–17. [Google Scholar] [CrossRef]

- Cavallo, D.P.; Cefola, M.; Pace, B.; Logrieco, A.F.; Attolico, G. Non-destructive automatic quality evaluation of fresh-cut iceberg lettuce through packaging material. J. Food Eng. 2018, 223, 46–52. [Google Scholar] [CrossRef]

- Cavallo, D.P.; Cefola, M.; Pace, B.; Logrieco, A.F.; Attolico, G. Non-destructive and contactless quality evaluation of table grapes by a computer vision system. Comput. Electron. Agric. 2019, 156, 558–564. [Google Scholar] [CrossRef]

- Amigo, J.M.; Santos, C. Preprocessing of hyperspectral and multispectral images. Data Handl. Sci. Technol. 2020, 32, 37–53. [Google Scholar] [CrossRef]

- Marini, F.; Amigo, J.M. Unsupervised exploration of hyperspectral and multispectral images. Data Handl. Sci. Technol. 2020, 32, 93–114. [Google Scholar] [CrossRef]

- Nicolaï, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive measurement of fruit and vegetable quality by means of NIR spectroscopy: A review. Postharvest Biol. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

- Hashim, N.; Onwude, D.; Osman, M.S. Evaluation of Chilling Injury in Mangoes Using Multispectral Imaging. J. Food Sci. 2018, 83, 1271–1279. [Google Scholar] [CrossRef]

- Ruiz-Altisent, M.; Ruiz-Garcia, L.; Moreda, G.; Lu, R.; Hernandez-Sanchez, N.; Correa, E.; Diezma, B.; Nicolaï, B.; García-Ramos, J. Sensors for product characterization and quality of specialty crops—A review. Comput. Electron. Agric. 2010, 74, 176–194. [Google Scholar] [CrossRef] [Green Version]

- Lara, M.A.; Lleó, L.; Iglesias, B.D.; Roger, J.; Altisent, M.R. Monitoring spinach shelf-life with hyperspectral image through packaging films. J. Food Eng. 2013, 119, 353–361. [Google Scholar] [CrossRef] [Green Version]

- Taghizadeh, M.; Gowen, A.; Ward, P.; O’Donnell, C.P. Use of hyperspectral imaging for evaluation of the shelf-life of fresh white button mushrooms (Agaricus bisporus) stored in different packaging films. Innov. Food Sci. Emerg. Technol. 2010, 11, 423–431. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Y.R.; Wang, C.Y.; Chan, D.E.; Kim, M.S. Development of hyperspectral imaging technique for the detection of chilling injury in cucumbers; spectral and image analysis. Appl. Eng. Agric. 2006, 22, 101–111. [Google Scholar] [CrossRef]

- Rivera, N.V.; Gómez-Sanchis, J.; Chanona-Pérez, J.; Carrasco, J.J.; Millán-Giraldo, M.; Lorente, D.; Cubero, S.; Blasco, J. Early detection of mechanical damage in mango using NIR hyperspectral images and machine learning. Biosyst. Eng. 2014, 122, 91–98. [Google Scholar] [CrossRef]

- Panagou, E.Z.; Papadopoulou, O.; Carstensen, J.M.; Stamatiou, A. Potential of multispectral imaging technology for rapid and non-destructive determination of the microbiological quality of beef filets during aerobic storage. Int. J. Food Microbiol. 2014, 174, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Du, D.; Wang, J.; Wang, B.; Zhu, L.; Hong, X. Ripeness Prediction of Postharvest Kiwifruit Using a MOS E-Nose Combined with Chemometrics. Sensors 2019, 19, 419. [Google Scholar] [CrossRef] [Green Version]

- Al-Sanabani, D.G.A.; Solihin, M.I.; Pui, L.P.; Astuti, W.; Ang, C.K.; Hong, L.W. Development of non-destructive mango assessment using Handheld Spectroscopy and Machine Learning Regression. J. Phys. Conf. Ser. 2019, 1367, 012030. [Google Scholar] [CrossRef]

- Van de Looverbosch, T.; Bhuiyan, H.R.; Verboven, P.; Dierick, M.; Van Loo, D.; De Beenbouwer, J.; Sijbers, J.; Nicolaï, B. Nondestructive internal quality inspection of pear fruit by X-ray CT using machine learning. Food Control 2020, 113, 107170. [Google Scholar] [CrossRef]

- Einarsdottir, H. Image Analysis for X-ray Imaging of Food. Ph.D. Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2016. [Google Scholar]

- Ghasemi-Varnamkhasti, M.; Apetrei, C.; Lozano, J.; Anyogu, A. Potential use of electronic noses, electronic tongues and biosensors as multisensor systems for spoilage examination in foods. Trends Food Sci. Technol. 2018, 80, 71–92. [Google Scholar] [CrossRef]

- Fortuna, L.; Graziani, S.; Rizzo, A.; Xibilia, M.G. Soft Sensors for Monitoring and Control of Industrial Processes; Springer Science & Business Media: Berlin, Germany, 2007. [Google Scholar]

- Liu, Z.; Jia, X.; Xu, X. Study of shrimp recognition methods using smart networks. Comput. Electron. Agric. 2019, 165, 104926. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Li, Z.; Zhang, X.; Jemrić, T.; Wang, X. Quality Monitoring and Analysis of Xinjiang ‘Korla’ Fragrant Pear in Cold Chain Logistics and Home Storage with Multi-Sensor Technology. Appl. Sci. 2019, 9, 3895. [Google Scholar] [CrossRef] [Green Version]

- Feng, C.; Drummond, L.; Zhang, Z.; Sun, D.-W.; Wang, Q. Vacuum Cooling of Meat Products: Current State-of-the-Art Research Advances. Crit. Rev. Food Sci. Nutr. 2012, 52, 1024–1038. [Google Scholar] [CrossRef]

- Lashgari, M.; Maleki, A.; Amiriparian, J. Application of acoustic impulse response in discrimination of apple storage time using neural network. Int. Food Res. J. 2017, 24, 1075. [Google Scholar]

- Zou, Z.; Chen, Q.; Uysal, I.; Zheng, L. Radio frequency identification enabled wireless sensing for intelligent food logistics. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130313. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Ruiz-García, L.; Garcia-Hierro, J.; Villalba, J.I.R. Refrigerated Fruit Storage Monitoring Combining Two Different Wireless Sensing Technologies: RFID and WSN. Sensors 2015, 15, 4781–4795. [Google Scholar] [CrossRef] [Green Version]

- Grunow, M.; Piramuthu, S. RFID in highly perishable food supply chains—Remaining shelf life to supplant expiry date? Int. J. Prod. Econ. 2013, 146, 717–727. [Google Scholar] [CrossRef]

- Tian, F. An agri-food supply chain traceability system for China based on RFID & blockchain technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016. [Google Scholar] [CrossRef]

- Liao, Y.; Zhang, R.; Qian, J. Printed electronics based on inorganic conductive nanomaterials and their applications in intelligent food packaging. RSC Adv. 2019, 9, 29154–29172. [Google Scholar] [CrossRef] [Green Version]

- Lipińska, M.; Tomaszewska, M.; Kołożyn-Krajewska, D. Identifying Factors Associated with Food Losses during Transportation: Potentials for Social Purposes. Sustainability 2019, 11, 2046. [Google Scholar] [CrossRef] [Green Version]

- Badia-Melis, R.; Qian, J.P.; Fan, B.L.; Hoyos-Echevarria, P.; Ruiz-García, L.; Yang, X.T. Artificial Neural Networks and Thermal Image for Temperature Prediction in Apples. Food Bioprocess Technol. 2016, 9, 1089–1099. [Google Scholar] [CrossRef]

- Castell-Palou, A.; Simal, S. Heat pump drying kinetics of a pressed type cheese. LWT 2011, 44, 489–494. [Google Scholar] [CrossRef]

- Hertog, M.L.A.T.M.; Uysal, I.; McCarthy, U.; Verlinden, B.M.; Nicolaï, B.M. Shelf life modelling for first-expired-first-out warehouse management. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130306. [Google Scholar] [CrossRef]

- Wu, W.; Cronje, P.J.; Nicolai, B.; Verboven, P.; Opara, U.L.; Defraeye, T. Virtual cold chain method to model the postharvest temperature history and quality evolution of fresh fruit—A case study for citrus fruit packed in a single carton. Comput. Electron. Agric. 2018, 144, 199–208. [Google Scholar] [CrossRef]

- Song, Y.; Hu, Q.; Wu, Y.; Pei, F.; Kimatu, B.M.; Su, A.; Yang, W. Storage time assessment and shelf-life prediction models for postharvest Agaricus bisporus. LWT 2019, 101, 360–365. [Google Scholar] [CrossRef]

- Ktenioudaki, A.; O’Donnell, C.P.; Nunes, M.C.D.N. Modelling the biochemical and sensory changes of strawberries during storage under diverse relative humidity conditions. Postharvest Biol. Technol. 2019, 154, 148–158. [Google Scholar] [CrossRef]

- Zou, J.; Li, P. Modelling of litchi shelf life based on the entropy weight method. Food Packag. Shelf Life 2020, 25, 100509. [Google Scholar] [CrossRef]

- Ambaw, A.; Verboven, P.; Defraeye, T.; Tijskens, E.; Schenk, A.; Opara, U.L.; Nicolai, B.M. Porous medium modeling and parameter sensitivity analysis of 1-MCP distribution in boxes with apple fruit. J. Food Eng. 2013, 119, 13–21. [Google Scholar] [CrossRef] [Green Version]

- Delele, M.A.; Ngcobo, M.E.K.; Opara, U.L.; Meyer, C.J. Investigating the Effects of Table Grape Package Components and Stacking on Airflow, Heat and Mass Transfer Using 3-D CFD Modelling. Food Bioprocess Technol. 2012, 6, 2571–2585. [Google Scholar] [CrossRef]

- Kim, W.R.; Aung, M.M.; Chang, Y.S.; Makatsoris, H. Freshness Gauge based cold storage management: A method for adjusting temperature and humidity levels for food quality. Food Control. 2015, 47, 510–519. [Google Scholar] [CrossRef]

- Jedermann, R.; Praeger, U.; Geyer, M.; Lang, W. Remote quality monitoring in the banana chain. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130303. [Google Scholar] [CrossRef]

- Hoang, M.H.; Laguerre, O.; Moureh, J.; Flick, D.; Hoang, H. Heat transfer modelling in a ventilated cavity loaded with food product: Application to a refrigerated vehicle. J. Food Eng. 2012, 113, 389–398. [Google Scholar] [CrossRef]

- Defraeye, T.; Lambrecht, R.; Delele, M.; Ambaw, A.; Opara, U.L.; Cronje, P.J.; Verboven, P.; Nicolai, B. Forced-convective cooling of citrus fruit: Cooling conditions and energy consumption in relation to package design. J. Food Eng. 2014, 121, 118–127. [Google Scholar] [CrossRef]

- Laguerre, O.; Düret, S.; Hoang, H.; Guillier, L.; Flick, D. Simplified heat transfer modeling in a cold room filled with food products. J. Food Eng. 2015, 149, 78–86. [Google Scholar] [CrossRef]

- Escuela, G.; Hinze, T.; Dittrich, P.; Schuster, S. Modelling Modified Atmosphere Packaging for Fruits and Vegetables Using Membrane Systems. In Proceedings of the International Conference on Bio-inspired Systems and Signal Processing 2010, Valencia, Spain, 20–23 January 2010; pp. 306–311. [Google Scholar] [CrossRef]

- Ahsan, M.; Hussain, A. A comparison of numerical methods used to solve cross flow model for multicomponent membrane gas separation. World Appl. Sci. J. 2013, 22, 703–711. [Google Scholar] [CrossRef]

- Walawender, W.P.; Stern, S.A. Analysis of Membrane Separation Parameters. II. Counter-current and Cocurrent Flow in a Single Permeation Stage. Sep. Sci. 1972, 7, 553–584. [Google Scholar] [CrossRef]

- Szwast, M.; Szwast, Z. A Mathematical Model of Membrane Gas Separation with Energy Transfer by Molecules of Gas Flowing in a Channel to Molecules Penetrating this Channel from the Adjacent Channel. Chem. Process. Eng. 2015, 36, 151–169. [Google Scholar] [CrossRef] [Green Version]

- Xanthopoulos, G.; Koronaki, E.; Boudouvis, A. Mass transport analysis in perforation-mediated modified atmosphere packaging of strawberries. J. Food Eng. 2012, 111, 326–335. [Google Scholar] [CrossRef]

- Dehghannya, J.; Ngadi, M.; Vigneault, C. Mathematical modeling of airflow and heat transfer during forced convection cooling of produce considering various package vent areas. Food Control 2011, 22, 1393–1399. [Google Scholar] [CrossRef]

- Cevoli, C.; Fabbri, A. Heat transfer finite element model of fresh fruit salad insulating packages in non-refrigerated conditions. Biosyst. Eng. 2017, 153, 89–98. [Google Scholar] [CrossRef]

- Choi, S.J.; Burgess, G. Practical mathematical model to predict the performance of insulating packages. Packag. Technol. Sci. 2007, 20, 369–380. [Google Scholar] [CrossRef]

- De Cursi, E.S.; Sampaio, R. Introduction. In Uncertainty Quantification and Stochastic Modeling with Matlab; Elsevier Science: Amsterdam, The Netherlands, 2015; pp. 11–13. [Google Scholar] [CrossRef]

- Ho, Q.T.; Rogge, S.; Verboven, P.; Verlinden, B.E.; Nicolaï, B.M. Stochastic modelling for virtual engineering of controlled atmosphere storage of fruit. J. Food Eng. 2016, 176, 77–87. [Google Scholar] [CrossRef]

- Valentas, K.; Singh, R.P.; Rotstein, E. Handbook of Food Engineering Practice; Informa UK Limited: London, UK, 1997. [Google Scholar]

- Zülch, A.; Piringer, O. Measurement and modelling of migration from paper and board into foodstuffs and dry food simulants. Food Addit. Contam. Part A 2010, 27, 1306–1324. [Google Scholar] [CrossRef]

- Montanez, J.C.; Rodríguez, F.A.; Mahajan, P.V.; Frias, J. Modelling the gas exchange rate in perforation-mediated modified atmosphere packaging: Effect of the external air movement and tube dimensions. J. Food Eng. 2010, 97, 79–86. [Google Scholar] [CrossRef]

- Poças, M.F.; Oliveira, J.C.; Pereira, J.R.; Brandsch, R.; Hogg, T. Modelling migration from paper into a food simulant. Food Control 2011, 22, 303–312. [Google Scholar] [CrossRef] [Green Version]

- Xanthopoulos, G.; Mitropoulos, D.; Lambrinos, G. Estimation of Heat and Mass Transfer Coefficients During Air-Freezing of Cucumber. Int. J. Food Prop. 2012, 15, 221–235. [Google Scholar] [CrossRef]

- Pandey, S.K.; Goswami, T.K. Modelling perforated mediated modified atmospheric packaging of capsicum. Int. J. Food Sci. Technol. 2012, 47, 556–563. [Google Scholar] [CrossRef]

- Dehghannya, J.; Ngadi, M.; Vigneault, C. Transport phenomena modelling during produce cooling for optimal package design: Thermal sensitivity analysis. Biosyst. Eng. 2012, 111, 315–324. [Google Scholar] [CrossRef]

- Delele, M.A.; Ngcobo, M.; Getahun, S.; Chen, L.; Mellmann, J.; Opara, U.L. Studying airflow and heat transfer characteristics of a horticultural produce packaging system using a 3-D CFD model. Part I: Model development and validation. Postharvest Biol. Technol. 2013, 86, 536–545. [Google Scholar] [CrossRef]

- Chong, K.L.; Peng, N.; Yin, H.; Lipscomb, G.G.; Chung, T.-S.; Chung, T.-S. Food sustainability by designing and modelling a membrane controlled atmosphere storage system. J. Food Eng. 2013, 114, 361–374. [Google Scholar] [CrossRef]

- Ambaw, A.; Verboven, P.; Defraeye, T.; Tijskens, E.; Schenk, A.; Opara, U.L.; Nicolai, B. Effect of box materials on the distribution of 1-MCP gas during cold storage: A CFD study. J. Food Eng. 2013, 119, 150–158. [Google Scholar] [CrossRef]

- Sousa-Gallagher, M.J.; Mahajan, P.; Mezdad, T. Engineering packaging design accounting for transpiration rate: Model development and validation with strawberries. J. Food Eng. 2013, 119, 370–376. [Google Scholar] [CrossRef]

- Ambaw, A.; Verboven, P.; Delele, M.A.; Defraeye, T.; Tijskens, E.; Schenk, A.; Nicolaï, B.M.; Ambaw, A. CFD Modelling of the 3D Spatial and Temporal Distribution of 1-methylcyclopropene in a Fruit Storage Container. Food Bioprocess Technol. 2012, 6, 2235–2250. [Google Scholar] [CrossRef] [Green Version]

- Chaix, E.; Broyart, B.; Couvert, O.; Guillaume, C.; Gontard, N.; Guillard, V. Mechanistic model coupling gas exchange dynamics and Listeria monocytogenes growth in modified atmosphere packaging of non respiring food. Food Microbiol. 2015, 51, 192–205. [Google Scholar] [CrossRef]

- Castellanos, D.A.; Cerisuelo, J.P.; Hernandez-Muñoz, P.; Herrera, A.; Gavara, R. Modelling the evolution of O2 and CO2 concentrations in MAP of a fresh product: Application to tomato. J. Food Eng. 2016, 168, 84–95. [Google Scholar] [CrossRef]

- Castellanos, D.A.; Herrera, D.R.; Herrera, A.O. Modelling water vapour transport, transpiration and weight loss in a perforated modified atmosphere packaging for feijoa fruits. Biosyst. Eng. 2016, 151, 218–230. [Google Scholar] [CrossRef]

- Fadiji, T.; Coetzee, C.; Opara, U.L. Compression strength of ventilated corrugated paperboard packages: Numerical modelling, experimental validation and effects of vent geometric design. Biosyst. Eng. 2016, 151, 231–247. [Google Scholar] [CrossRef]

- Fadiji, T.S.; Berry, T.M.; Opara, U.L. Investigating the Mechanical Properties of Paperboard Packaging Material for Handling Fresh Produce under Different Environmental Conditions: Experimental Analysis and Finite Element Modelling Investigating the Mechanical Properties of Paperboard Packaging. J. Appl. Packag. Res. 2017, 9, 1–32. [Google Scholar]

- Gruyters, W.; Verboven, P.; Diels, E.; Rogge, S.; Smeets, B.; Ramon, H.; Defraeye, T.; Nicolaï, B.M. Modelling Cooling of Packaged Fruit Using 3D Shape Models. Food Bioprocess Technol. 2018, 11, 2008–2020. [Google Scholar] [CrossRef]

- Han, J.W.; Qian, J.-P.; Zhao, C.-J.; Yang, X.; Fan, B.-L. Mathematical modelling of cooling efficiency of ventilated packaging: Integral performance evaluation. Int. J. Heat Mass Transf. 2017, 111, 386–397. [Google Scholar] [CrossRef]

- Fadiji, T.; Ambaw, A.; Coetzee, C.J.; Berry, T.M.; Opara, U.L. Application of finite element analysis to predict the mechanical strength of ventilated corrugated paperboard packaging for handling fresh produce. Biosyst. Eng. 2018, 174, 260–281. [Google Scholar] [CrossRef]

- Wu, W.; Defraeye, T. Identifying heterogeneities in cooling and quality evolution for a pallet of packed fresh fruit by using virtual cold chains. Appl. Therm. Eng. 2018, 133, 407–417. [Google Scholar] [CrossRef]

- Getahun, S.; Ambaw, A.; Delele, M.; Meyer, C.J.; Opara, U.L. Experimental and Numerical Investigation of Airflow Inside Refrigerated Shipping Containers. Food Bioprocess Technol. 2018, 11, 1164–1176. [Google Scholar] [CrossRef]

- Kolodziejczyk, M.; Smierciew, K.; Gagan, J.; Butrymowicz, D. Numerical Modelling of Heat and Mass Transfer in Vegetables Cold Storage. Procedia Eng. 2016, 157, 279–284. [Google Scholar] [CrossRef] [Green Version]

- Marques, A.C.; Davies, G.; Evans, J.; Maidment, G.; Wood, I. Theoretical modelling and experimental investigation of a thermal energy storage refrigerator. Energy 2013, 55, 457–465. [Google Scholar] [CrossRef]

- Broeze, J.; Guo, X.; Axmann, H.; Vollebregt, M. A Systemic Approach for Trade-Off Analysis of Food Loss Reduction and Greenhouse Gas Emissions; CCAFS: Wageningen, The Netherlands, 2019. [Google Scholar]

- Pinheiro, J.; Alegria, C.; Abreu, M.; Gonçalves, E.M.; Silva, C.L. Kinetics of changes in the physical quality parameters of fresh tomato fruits (Solanum lycopersicum, cv. ‘Zinac’) during storage. J. Food Eng. 2013, 114, 338–345. [Google Scholar] [CrossRef]

- Aiello, G.; La Scalia, G.; Micale, R. Simulation analysis of cold chain performance based on time–temperature data. Prod. Plan. Control. 2011, 23, 468–476. [Google Scholar] [CrossRef]

- Gonalves, E.M.; Abreu, M.; Brandão, T.R.; Silva, C.L. Degradation kinetics of colour, vitamin C and drip loss in frozen broccoli (Brassica oleracea L. ssp. Italica) during storage at isothermal and non-isothermal conditions. Int. J. Refrig. 2011, 34, 2136–2144. [Google Scholar] [CrossRef]

- Guo, P.; Han, M.; Cao, N.; Shen, Y. The Research on Innovative Application of E-Commerce in IoT Era. In Proceedings of the 2017 IEEE International Conference on Computational Science and Engineering (CSE) and IEEE International Conference on Embedded and Ubiquitous Computing (EUC), Institute of Electrical and Electronics Engineers (IEEE), Guangzhou, China, 21–24 July 2017; Volume 2, pp. 410–413. [Google Scholar]

- Singh, S.; Singh, N. Internet of Things (IoT): Security challenges, business opportunities & reference architecture for E-commerce. In Proceedings of the 2015 International Conference on Green Computing and Internet of Things (ICGCIoT) 2015, Delhi, India, 8–10 October 2015; pp. 1577–1581. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, C.; Chen, C.; Huang, G.Q. Big Data Analytics for Physical Internet-based intelligent manufacturing shop floors. Int. J. Prod. Res. 2015, 55, 2610–2621. [Google Scholar] [CrossRef]

- Grgić, K.; Speh, I.; Hedi, I. A web-based IoT solution for monitoring data using MQTT protocol. In Proceedings of the 2016 International Conference on Smart Systems and Technologies (SST), Osijek, Croatia, 12–14 October 2016; pp. 249–253. [Google Scholar] [CrossRef]

- Zhamanov, A.; Sakhiyeva, Z.; Suliyev, R.; Kaldykulova, Z. IoT smart campus review and implementation of IoT applications into education process of university. In Proceedings of the 2017 13th International Conference on Electronics, Computer and Computation (ICECCO), Piscataway, NJ, USA, 28–29 November 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Bagheri, M.; Movahed, S.H. The Effect of the Internet of Things (IoT) on Education Business Model. In Proceedings of the 2016 12th International Conference on Signal-Image Technology & Internet-Based Systems (SITIS), Naples, Italy, 28 November–1 December 2016; pp. 435–441. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Lo, D.C.-T.; Xie, Y.; Lartigue, J. Integrating Internet of Things (IoT) into STEM undergraduate education: Case study of a modern technology infused courseware for embedded system course. In Proceedings of the 2016 IEEE Frontiers in Education Conference (FIE), Eire, PA, USA, 12–15 October 2016; Institute of Electrical and Electronics Engineers (IEEE): New York, NY, USA, 2016; pp. 1–9. [Google Scholar]

- Mezghani, E.; Exposito, E.; Drira, K. A Model-Driven Methodology for the Design of Autonomic and Cognitive IoT-Based Systems: Application to Healthcare. IEEE Trans. Emerg. Top. Comput. Intell. 2017, 1, 224–234. [Google Scholar] [CrossRef]

- Amato, A.; Coronato, A. An IoT-Aware architecture for smart healthcare coaching systems. Proc. Int. Conf. Adv. Inf. Netw. Appl. AINA 2017, 2, 1027–1034. [Google Scholar] [CrossRef]

- Doukas, C.; Maglogiannis, I. Bringing IoT and Cloud Computing towards Pervasive Healthcare. In Proceedings of the 2012 Sixth International Conference on Innovative Mobile and Internet Services in Ubiquitous Computing, Palermo, Italy, 4–6 July 2012; pp. 922–926. [Google Scholar] [CrossRef]

- Kim, S.; Kim, S. A multi-criteria approach toward discovering killer IoT application in Korea. Technol. Forecast. Soc. Chang. 2016, 102, 143–155. [Google Scholar] [CrossRef]

- Amendola, S.; Lodato, R.; Manzari, S.; Occhiuzzi, C.; Marrocco, G. RFID Technology for IoT-Based Personal Healthcare in Smart Spaces. IEEE Internet Things J. 2014, 1, 144–152. [Google Scholar] [CrossRef]

- Lee, B.M.; Ouyang, J. Intelligent Healthcare Service by using Collaborations between IoT Personal Health Devices. Int. J. Bio Sci. Bio Technol. 2014, 6, 155–164. [Google Scholar] [CrossRef]

- Farahani, B.; Firouzi, F.; Chang, V.; Badaroglu, M.; Constant, N.; Mankodiya, K. Towards fog-driven IoT eHealth: Promises and challenges of IoT in medicine and healthcare. Future Gener. Comput. Syst. 2018, 78, 659–676. [Google Scholar] [CrossRef] [Green Version]

- Shenoy, J.; Pingle, Y. IOT in Agriculture. In Proceedings of the 2016 3rd International Conference on Computing for Sustainable Global Development (INDIACom), New Delhi, India, 16–18 March 2016; pp. 1456–1458. [Google Scholar]

- Brewster, C.; Roussaki, I.; Kalatzis, N.; Doolin, K.; Ellis, K. IoT in Agriculture: Designing a Europe-Wide Large-Scale Pilot. IEEE Commun. Mag. 2017, 55, 26–33. [Google Scholar] [CrossRef]

- Pang, Z.; Chen, Q.; Han, W.; Zheng, L. Value-centric design of the internet-of-things solution for food supply chain: Value creation, sensor portfolio and information fusion. Inf. Syst. Front. 2012, 17, 289–319. [Google Scholar] [CrossRef]

- Naeem, H. Detection of Malicious Activities in Internet of Things Environment Based on Binary Visualization and Machine Intelligence. Wirel. Pers. Commun. 2019, 108, 2609–2629. [Google Scholar] [CrossRef]

- European Commission: Information Society and Media. Internet of Things in 2020: A Roadmap for the Future. Internet Things 2020, 22, 97–114. [Google Scholar]

- Dlodlo, N.; Kalezhi, J. The internet of things in agriculture for sustainable rural development. In Proceedings of the 2015 IEEE International Conference on Emerging Trends in Networks and Computer Communications (ETNCC), Windhoek, Namibia, 17–20 May 2015; pp. 13–18. [Google Scholar]

- Tsang, Y.P.; Choy, K.; Wu, C.; Ho, G.; Lam, H.; Tang, V. An intelligent model for assuring food quality in managing a multi-temperature food distribution centre. Food Control 2018, 90, 81–97. [Google Scholar] [CrossRef]

- Verdouw, C.; Kruize, J.W. Digital twins in farm management: Illustrations from the FIWARE accelerators SmartAgriFood and Fractals. In Proceedings of the 7th Asian-Australasian Conference on Precision Agriculture, Hamilton, New Zealand, 16 October 2017; pp. 1–5. [Google Scholar]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2017, 57, 4719–4742. [Google Scholar] [CrossRef] [Green Version]

- Tzounis, A.; Katsoulas, N.; Bartzanas, T.; Kittas, C. Internet of Things in agriculture, recent advances and future challenges. Biosyst. Eng. 2017, 164, 31–48. [Google Scholar] [CrossRef]

- Ramundo, L.; Taisch, M.; Terzi, S. State of the art of technology in the food sector value chain towards the IoT. In Proceedings of the 2016 IEEE 2nd International Forum on Research and Technologies for Society and Industry Leveraging a better tomorrow (RTSI), Piscataway, NJ, USA, 7–9 September 2016; pp. 1–6. [Google Scholar]

- Popa, A.; Hnatiuc, M.; Paun, M.; Geman, O.; Hemanth, D.J.; Dorcea, D.; Son, L.H.; Ghita, S. An Intelligent IoT-Based Food Quality Monitoring Approach Using Low-Cost Sensors. Symmetry 2019, 11, 374. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zhao, L.; Qian, C. Modeling of an IoT-enabled supply chain for perishable food with two-echelon supply hubs. Ind. Manag. Data Syst. 2017, 117, 1890–1905. [Google Scholar] [CrossRef]

- Ghoshal, G. Recent Trends in Active, Smart, and Intelligent Packaging for Food Products; Elsevier Inc.: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Porat, R.; Lichter, A.; Terry, L.A.; Harker, R.; Buzby, J. Postharvest losses of fruit and vegetables during retail and in consumers’ homes: Quantifications, causes, and means of prevention. Postharvest Biol. Technol. 2018, 139, 135–149. [Google Scholar] [CrossRef] [Green Version]

- Fuertes, G.; Soto, I.; Carrasco, R.R.; Vargas, M.; Sabattin, J.; Lagos, C. Intelligent Packaging Systems: Sensors and Nanosensors to Monitor Food Quality and Safety. J. Sens. 2016, 2016, 4046061. [Google Scholar] [CrossRef] [Green Version]

- Sohail, M.; Sun, D.-W.; Zhu, Z. Recent developments in intelligent packaging for enhancing food quality and safety. Crit. Rev. Food Sci. Nutr. 2018, 58, 2650–2662. [Google Scholar] [CrossRef]

- Borchert, N.B.; Kerry, J.P.; Papkovsky, D.B. A CO2 sensor based on Pt-porphyrin dye and FRET scheme for food packaging applications. Sensors Actuators B Chem. 2013, 176, 157–165. [Google Scholar] [CrossRef]

- Xiao, X.; Fu, Z.; Zhang, X.; Cheng, J.; Yang, M. Battery-free wireless sensor system with compressed sensing for table grapes cold chain. Comput. Electron. Agric. 2019, 163, 104869. [Google Scholar] [CrossRef]

- Maksimović, M.; Vujović, V.; Omanović-Mikličanin, E. Application of internet of things in food packaging and transportation. Int. J. Sustain. Agric. Manag. Inform. 2015, 1, 333. [Google Scholar] [CrossRef]

- Nukala, R.; Panduru, K.; Shields, A.; Riordan, D.; Doody, P.; Walsh, J. Internet of Things: A review from ‘Farm to Fork’. In Proceedings of the 2016 27th IEEE Irish Signals and Systems Conference (ISSC), Derry, Ireland, 21–22 June 2016; pp. 1–6. [Google Scholar]

- Bassi, A.; Bauer, M.; Fiedler, M.; Kranenburg, R.V. Enabling Things to Talk; Springer-Verlag GmbH: Berlin, Germany, 2013. [Google Scholar]

- Verboven, P.; Verboven, P.; Defraeye, T.; Datta, A.K.; Nicolai, B. Digital twins of food process operations: The next step for food process models? Curr. Opin. Food Sci. 2020, 35, 79–87. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Uhlemann, T.H.J.; Schock, C.; Lehmann, C.; Freiberger, S.; Steinhilper, R. The Digital Twin: Demonstrating the Potential of Real Time Data Acquisition in Production Systems. Procedia Manuf. 2017, 9, 113–120. [Google Scholar] [CrossRef]

- Defraeye, T.; Tagliavini, G.; Wu, W.; Prawiranto, K.; Schudel, S.; Kerisima, M.A.; Verboven, P.; Bühlmann, A. Digital twins probe into food cooling and biochemical quality changes for reducing losses in refrigerated supply chains. Resour. Conserv. Recycl. 2019, 149, 778–794. [Google Scholar] [CrossRef]

- Tagliavini, G.; Defraeye, T.; Carmeliet, J. Multiphysics modeling of convective cooling of non-spherical, multi-material fruit to unveil its quality evolution throughout the cold chain. Food Bioprod. Process. 2019, 117, 310–320. [Google Scholar] [CrossRef]

- Furio, A.; Landi, G.; Altavilla, C.; Sofia, D.; Iannace, S.; Sorrentino, A.; Neitzert, H.C. Light irradiation tuning of surface wettability, optical, and electric properties of graphene oxide thin films. Nanotechnology 2016, 28, 54003. [Google Scholar] [CrossRef]

- Cuello, J. Our Fresh-Produce Supply Chain after COVID-19: How vertical farming can play a key role. Resour. Mag. 2020, 27, 10–12. [Google Scholar]

| S/N | Technology | Cold Chain Operation | Purpose | Food Type | Statistical Approach | Significant Results | Reference |

|---|---|---|---|---|---|---|---|

| 1. | Imaging technology hyperspectral Imaging | Packaging and storage | To study the image characteristics of vegetables acquired during packaging and storage | Spinach | SG, SNV, PCA | The arterial images were able to sense the aging of the leaves | [72] |

| 2. | Imaging technology hyperspectral Imaging | Packaging | To study the refrigeration conditions of vegetables during packaging | Mushrooms | PLS, PLSR, MSC, PLS-DA | This method suggested an effective packaging solution to extend shelf life and prevent food losses of mushrooms during storage. | [73] |

| 3. | Imaging technology multispectral imaging technology | Storage | To monitor and evaluate agro-food spoilage during storage | - | PLS-D | The spoiled food was predicted with an overall classification rate of 91.8% | [76] |

| 4. | Imaging technology hyperspectral image | Storage | To explore the potential for the detection of chilling induced damage in fruits and vegetables | Cucumber | PCA | An overall classification rate of 90% | [74] |

| 5. | Imaging technology computer vision system | Storage | To evaluate the effect of hydration degree during storage | Strawberry | PCA | Lighter appearance up to 75% | [58] |

| 6. | Imaging technology machine vision systems | Storage | To monitor the quality change of food during storage | Orange | ANN, CART, CNN, LDA, kNN | An overall classification rate of 91.5% | [59] |

| 7. | Imaging technology NIR hyperspectral image | Storage | To study the mechanical damage in fruits | Mango | CFS, GIA, SFS, SLR, LDA, kNN | Accuracy of 97.9% | [75] |

| 8. | Imaging technology X-ray CT | Storage | To preserve the quality of fresh fruit during the supply chain and long-term storage | Pear | SVM, FEA | The X-ray computed tomography successfully detected the internal disorder severity of pear fruit with classification accuracies ranging between 90% and 95% | [79] |

| 9. | Imaging technology computer vision | Storage | To develop a shelf life prediction model for postharvest handling of fruits and vegetables | Grape | RBF, NN | The method found the prediction accuracy of R2 0.91 | [60] |

| 10. | Imaging technology computer vision | Storage | To study changes in color features of fruits during storage and to evaluate the use of image analysis technique as a rapid and nondestructive method | Banana | RBF, SVR, ANN | The computer vision technology with SVR of color parameters provided a useful model for prediction of the quality indices of bananas | [61] |

| 11. | Imaging technology computer vision | Storage | To provide an application designed for embedded devices such as mobile Android smartphones to objectivize the measurements using machine vision | Tomato and zucchini | HA | The proposed method successfully achieved by predicting the quality characteristics of the products during cold storage | [62] |

| 12. | Imaging technology computer vision system | Storage | To develop a computer vision system to predict the quality levels of vegetables during storage | Lettuce | SNK | The color information measured by the computer vision system achieved nondestructively to evaluate the quality level of iceberg lettuce with R2 of 0.77 | [63] |

| 13 | Imaging technology computer vision | Storage | To demonstrate the applicability of Random Forests (RF) for estimating the internal qualities of fruits based on peel color | Mango | RF | The relationship between peel color and fruit quality was strongly found in different storage temperatures with a correlation coefficient up to 0.98 | [64] |

| 14. | Imaging technology X-ray | Storage | To design a methodology for sorting fruits with X-ray image processing and pattern recognition techniques | Kiwifruits | NN, LDA | The model built with LDA predicted the columella firmness in kiwifruit with a 94.6% | [11] |

| 15. | Imaging technology thermography | Packaging | To study the temperature distribution on a pallet of fruits during plastic boxes and cardboard packaging | Apples | ANN | Thermal imaging showed the cardboard boxes to be a better packaging material for apples compared to plastic boxes | [93] |

| 16. | Imaging technology hyperspectral imaging systems | Storage | To develop a feature selection technique in classifying problems for detecting rottenness in tropical fruits | Citrus fruits | ROC, NN | Hyperspectral images found the classification success rate of around 89% for detecting the rottenness in citrus fruits | [75] |

| 17. | Imaging technology multispectral Imaging | Storage | To evaluate chilling injury in fruits during storage using multispectral imaging | Mangoes | LS-SVM, PCA | The statistical results demonstrated significant changes in the reference quality properties of samples before and after storage | [70] |

| 18. | Imaging technology computer vision systems | Packaging | To evaluate the quality of vegetables nondestructively using computer vision during packaging | Iceberg lettuce | CNN | The CNNs method was able to identify the lettuce quality with an accuracy of 86% | [65] |

| 19. | Imaging technology computer vision systems | Storage | To evaluate fruit quality nondestructively by computer vision | Grapes | RF | The system achieved a cross-validation classification accuracy up to 92% which support its capability of powerfully, flexibly, and continuously monitoring the quality of the complete production along the whole supply chain | [66] |

| 20. | Visible/shortwave near-infrared spectroscopy | Storage | To establish optimal spectral models for the assessment of fruits in actual production and therefore obtain early warning information of mechanical injuries during storage | Peach | GA | The optimal spectral model through the GA-PLS method found prediction accuracy ranges from 0.89 to 0.91 of the mechanical injuries of peaches during storage | [77] |

| 21. | Handheld spectroscopy | Storage | To develop a nondestructive assessment of fruit quality using handheld micro NIR spectroscopic device | Mango | SVM, PLS | The proposed method was able to detect the mango fruit quality during the storage with prediction accuracy up to 96% | [78] |

| 22. | Multi-sensor technology | Transportation and storage | To provide decision support to quality change and control | Pear | BPNN | The results indicated that this method could improve the accuracy of continuous sensor data acquisition | [83] |

| 23. | Multi-sensor technology | Storage | To monitor and improve the data accuracy of sensory and physiological quality attributes of fruits during cold storage | Korla fragrant pear | BPNN | The multi-sensors technology including temperature, relative humidity, O2, CO2, and ethylene sensors improved the accuracy of data acquisition for gas content, pH, firmness, and total soluble solids | [84] |

| 24. | Electronic nose | Storage | To investigate the reliability and validity of using the electronic nose to evaluate the quality and freshness of vegetables after high-pressure argon treatments | Cherry tomatoes | ELM, PLS | The results demonstrated E-nose technology combined with ELM provided a reliable and valid method for evaluating the quality and freshness of cherry tomatoes during cold storage with fitting correlation coefficients (R2 > 0.95) | [85] |

| 25. | Acoustic impulse response | Storage | To apply for apple classification nondestructively | Apple | ANN | The accuracy was 84.9% and 84.7% for Golden Delicious and Red Delicious, respectively | [86] |

| S/N | Technology | Cold Chain Operation | Purpose | Food Type | Significant Results | Reference |

|---|---|---|---|---|---|---|

| 1. | Membrane gas separation modeling | Packaging | To predict changes in fresh produce on molecular level based on changes in environmental conditions; to reduce losses | Apple | A membrane-based model can be used to abstract packaging for different fruit and vegetables; respiration of the process is considered important in modeling, and also environmental biological and technical factors; quality (taste, texture, color, appearance) is based on some subjective consumer evaluation | [107] |

| 2. | Migration modeling | Packaging—paper and board | Deepened understanding of migrants from paper and board into foodstuffs | Tomato | Migration rate from paper and board to food at low temperatures is small compared to plastic material. For modeling, paper and board can be regarded as a two-layer system | [134] |

| 3. | Membrane gas separation modeling | Packaging | To study the effect of external turbulence on the gas exchange rate; to develop a mathematical model to predict the effect of tube dimensions | Carrots | Different hydrodynamic condition affects the gas exchange rate in PM-MAP (perforation-mediated modified atmosphere packaging); the effect of temp, air velocity, and tube diameter on O2 and CO2 | [135] |

| 4. | Kinetic modeling | Storage | To predict the remaining shelf-life after storage; to predict dipp loss (zero-order), vitamin C (first-order), color (zero and first order) food quality | Broccoli | The model only looked at temperature effect on shelf life and adequately predicted the shelf life based on a 50% threshold of vitamin C loss at −18°C | [144] |

| 5. | Migration modeling | Packaging migration controlled by diffusion | To use the Weibull distribution model to quantify migration in food packaging systems | - | Migration depends on the type of contact, food stimulant, type of paper, chemical nature of migrant in a paper, temperature and time of contact; migration is faster in paper than in plastics and involves the simultaneous transfer into food and also to the atmosphere | [136] |

| 6. | Heat and mass transfer modeling | Packaging; storage | To quantify the impact of ventilation vent on temperature distribution of product | - | Decreasing the number of vents increased the cooling uniformity; the model, based on velocity and temperature simulation can be used as a design tool to provide homogenous temperature distribution to reduce food losses | [112] |

| 7. | Heat and mass transfer modeling | Packaging | To predict O2, CO2, N2, and H2O concentrate in perforation-mediated polymeric packages; transport of O2, CO2, N2, and H2O was modeled using Maxwell Stefan equation for gas and Fick’s law for diffusion through the micro-perforated package | Strawberries | The model result suggests an improvement in material properties, especially with regard to the permeability of polymeric packaging film; the model predicted a packaging with 30 µm thickness, 6 micro-perforation of 50 µm diameter each as the most suitable | [137] |

| 8. | Heat and mass transfer modeling—based on compartments | Transport; storage | To predict temperature distribution during transport and storage of fruits and vegetables | Spinach, apricots, and peaches | The model adequately predicted the maximum and minimal load temperature distribution with lower computational time compared to CFD simulation | [104] |

| 9. | Membrane gas separation modeling (Michaelis–Menten kinetic model + mass transfer model) | Packaging; storage | To describe the evolution of MAP of capsicum using a mathematical model; to quantify the performance of different packaging under the dynamic condition of use | Capsicums | Temperature and perforation have a significant effect on MAP conditions of capsicum; the combined model adequately predicted O2 and CO2 under different storage conditions | [118] |

| 10. | Heat and mass transfer modeling | Packaging; storage | To assess the sensitivity of produce cooling uniformity and cooling time with respect to the packaging vent design | - | Increase in the number of vents increased cooling uniformity and reduce cooling time | [119] |

| 11 | Stochastic modeling (Monte Carlo simulations) + kinetic modeling | Storage; transportation | To estimate the expected fraction of perished products | Peaches | The simulation study predicted a fraction of 8.00% perished products based on a 100.00% quality threshold. The model quantifies thereof. | [143] |

| 12. | Heat and mass transfer modeling | Packaging | To develop a 3D heat and mass transfer model of a fresh food produce packaging system to predict airflow and heat transfer characteristics | Citrus | Airflow, temperature, and turbulence property distribution inside a single product are nonuniform; good correlation between air velocity and temperature; the accuracy of the model depends on geometry, thermal, physical, and chemical properties of the package, the cooling air, and the produce | [120] |

| 13. | Membrane gas separation modeling | Packaging; storage; transportation | To develop a mathematical model to investigate the effect of stage cut on the gas separation performance of hollow fiber membrane modules | Avocado | The model utilizes pure gas permeances of membrane material to predict the mixed gas separation performance; the performance of gas separation declines over time as they age with exposure to pressure, temperature, and contaminant loading | [121] |

| 14. | Kinetic modeling | Storage | To evaluate the impact of storage conditions on vegetable color, firmness, weight loss, and phenolic content; to investigate the kinetics of quality parameters alterations of stored vegetables | Tomato | Fractional kinetic model fitted adequately well with experimental data; Arrhenius model describes well the temperature effect on all factors studied | [142] |

| 15. | Migration modeling | Packaging; storage | To study the influence of box material and plastic cover on the distribution of 1-MCP (methyl cyclopropane) in cold storage to delay ripening of fruit | Apple | Diffusion, convection, and adsorption were modeled to simulate the temporal distributions of 1-MCP inside a storage container, boxes, and fruits; the plastic cover does not affect the adsorption of 1-MCP; wooden boxes notably adsorbed 1-MCP from the treatment atmosphere and may reduce the efficacy | [122] |

| 16. | Kinetic modeling | Packaging | To investigate the impact of temperature and relative humidity on fruit transpiration rate (TR); to develop a prediction model for quantifying TR; to integrate TR model into engineering packaging design and quantify | Strawberries | Temperature and relative humidity have a significant impact on the transpiration rate of strawberries; increase in relative humidity increases TR; decreasing temperature decreases TR; the model predicted the water vapor barrier properties required for maintaining optimal relative humidity inside package | [123] |

| 17. | Heat and mass transfer modeling | Storage | To model the airflow and temperature distribution in a natural connection thermal energy storage refrigerator; to determine the performance of the refrigerator with different phase change material (PCM) vertical-horizontal | - | Horizontal PCM configuration produces lower compartment temperatures than a vertical configuration; combining horizontal and vertical configuration gives better design performance | [140] |

| 18. | Migration modeling | Packaging; storage | To study the diffusion, convection and adsorption of 1-MCP gas in cold stores; to understand the mechanism of 3D distribution of 1-MCP | Apple | The model demonstrated the absence of significant spatial variation of 1-MCP gas in a container; diffusion–convection in air and diffusion–adsorption in the product | [124] |

| 19. | Heat and mass transfer modeling | Packaging | To develop a porous medium model was develop on volume averaging of transport equations of momentum and 1-MCP in air and product | Apple | The velocity field in and around the stack was well reproduced by the porous medium model; the porosity, skin mass transfer coefficient, and specific surface area strongly affected the simulation process | [100] |

| 20. | Heat and mass transfer modeling | Packaging (bunch carry bag and plastic liners) | To determine the effect of the packaging component and box stacking on airflow, heat, and mass transfer rate | Grape | The use of carry bag resulted in an increase in the cooling time; the addition of plastic liner over the bunch carry bag increased cooling time; moisture loss was most prevented using nonperforated liners; CFD simulation determined optimum table grape packaging and costing procedure | [101] |

| 21. | Heat and mass transfer modeling | Storage; packaging | To evaluate the performance of corrugated fiberboard, Supervent, Ecopack re-usable plastic container; to check the influence of airflow rate and cooling | Citrus | With respect to cooling, Eco-pack showed lower convective heat transfer rate but cooled in a uniform way, which improves fruit quality | [105] |

| 22. | Membrane gas separation modeling | Packaging | To predict the shelf life of MAP systems | - | The model was able to predict the mass transfer phenomena for O2 and CO2 and also the microbial growth in the food system | [125] |

| 23. | Kinetic model | Storage | To describe the product time–temperature history along the cold chain; the model considered front and rear air circulation in the cold room | Apples | The model adequately predicted cooling rate, the temperature at different positions, and weight loss; the model has a short CPU computational time (<1 s) when compared to CFD models. This enabled a rapid evaluation of input parameters such as air temperature | [106] |

| 24. | Stochastic modeling | Storage | To evaluate the quality of perishable foods using a generic algorithm + center of gravity model; to estimate the environmental level | Fruits | The algorithm adequately predicted temperature and humidity levels; the algorithm was integrated to gauge the use of RFID (radio frequency identification) and sensors for real-time information gathering | [102] |

| 25. | Stochastic modeling | Transport; storage | To estimate the heat generation and also the cooling efficiency during cold transport and storage chain | Banana | 10% accuracy for the heat of respiration and cooling efficiency was reached after 4–7.5 days of transport | [103] |

| 26. | Membrane gas separation modeling | Packaging; storage | To describe product respiration and gas exchange through package using Michaelis–Menten kinetics + Fick’s equation; taking into account diffusive gas permeation through packaging film and perforation respiration rate and storage temperature | Tomato | The model adequately predicted the required package surface area and perforation diameter to achieve a specific O2 concentration in the headspace; the model can be used to set a specific equilibrium concentration of O2 and CO2 by modifying the configuration of the package | [126] |

| 27. | Membrane gas separation modeling | Packaging | To develop describe the evolution of water vapor, O2, and CO2 in packaging headspace, weight loss, and condensation of water in a MAP system | Feijoa fruits | The model adequately predicted weight loss and relative humidity in the MAP system | [127] |

| 28. | Structural behavior modeling | Packaging | To develop a validated structural behavior model to predict the compression strength of a ventilated paperboard carton | - | The model adequately predicted the compression strength of a ventilated corrugated paperboard (VCP) packaging; the effect of vent area, vent height, and buckling load on the performance of VCP were adequately quantified by the model | [128] |

| 29. | Heat and mass transfer modeling | Storage | To model the airflow, heat, and mass transfer in the storage chamber of Chinese cabbage; to predict the velocity, temperature, and relative humidity distribution | Cabbage | The model gave qualitative insight into the flow patterns in the cold room; the model adequately predicted temperature in the bulk and relative humidity of the air | [139] |

| 30. | Stochastic modeling | Packaging; storage | To model the gas exchange in pear fruit taking the effect of biological variability | Pears | The model predicted that O2 and CO2 gas profiles inside the fruit were highly impacted by diffusivity, maximal respiration rate, and morphology of fruit; the model was used to analyze the incidence of fermentation at reduced O2 levels during controlled atmosphere storage | [116] |

| 31. | Structural behavior modeling | Packaging | To simulate the compression of paper and paperboard packaging material for food using finite element analysis (FEA) | - | The developed FEA model accurately predicted the incident buckling load of the corrugated paperboard; the modulus of elasticity was observed to be sensitive to the environmental conditions; the model can adequately be used to optimize corrugated paperboard packages | [129] |

| 32. | Heat and mass transfer modeling | Packaging | To develop a more accurate model for describing the cooling process of freshly harvested apples and pears | Apples; pears | The model was able to describe the cooling behavior and uniformity of fruits in fiberboard boxes; there was large variability in convective heat transfer coefficients from the apples and pear filling; the fruit shape affects the model accuracy | [130] |

| 33. | Heat and mass transfer modeling | Packaging | To develop a 3D HMT model to quantify cooling behavior of 10 different carton designs based on cooling rate, energy consumption, uniformity, weight loss, and chilling injury of apples | Apples | The model adequately quantified the effect of airflow, and packaging design on the product quality; vent area, shape and number of vent have less impact on the fruit cooling; homogeneity and symmetry of packaging vent positions have more impact on the fruit cooling rate; the model proposed airflow velocity between 0.4 and 1.0 m/s | [131] |

| 34. | Structural behavior modeling | Packaging | To develop a validated structural behavior model to study the structural behavior of VCP packages by considering the geometrical nonlinearities of the packages | Fruits and vegetables | The model accurately predicted the compression strength of the corrugated paperboard, control package, and standard vent package; compression strength of the standard vent packages was found to be linearly affected by paperboard liner thickness; increasing and decreasing the baseline liner thickness of the standard vent package by 80% resulted in an increase and decrease in compression strength by about 15% and 19%, respectively; from the contact FEA model, maximum Von Mises stress was produced at the corners of the package; Von Mises stress was significantly affected by the coefficient of friction | [132] |

| 35. | Heat and mass transfer modeling | Storage; transport | To investigate the airflow distribution inside two types of refrigerated shipping containers (T-bar floor and flat floor) used for transporting fresh fruit handling | The airflow distribution in the two container designs was markedly different. Good agreement was found between measured and predicted values of air velocities. The reefer with T-bar floor design exhibited a noticeable reduction of air recirculation zone and enhanced uniform vertical air movement compared to the reefer with flat floor design | [138] | |

| 36. | Kinetic modeling | Storage | To examine the effect of relative humidity (RH) conditions on the shelf life of strawberries including both the sensory and nutritional quality; to study the kinetics of sensory and chemical changes occurring in strawberries during storage by comparing three kinetic models; to examine and predict through modeling the waste that would occur depending on the storage conditions | Strawberries | Weight loss significantly increased when storage RH decreased; the weight loss was correlated with the changes that occurred in visual appearance and chemical properties. Overall appearance (i.e., the average score of color and shriveling), was modeled with a zero-order kinetics model for the various RH conditions; lower RH increased the rate of appearance deterioration thereby reducing the remaining shelf life of strawberries. The Weibull model adequately fitted the chemical properties data and it was found to be an important tool in describing the changes that occur with varying storage conditions | [98] |

| 37. | Stochastic modeling | Whole chain | To develop an Agro-Chain Greenhouse gas emissions calculator (ACGE calculator) to calculate the percentage of food losses per chain stage | Cut vegetables | The ACGE calculator can be applied for understanding the impacts of different operations along a postharvest cold chain and for analyzing chain configuration scenarios: such as weighing impacts of the operations/impacts along the chain, comparison between various options for supplying a specific food component, and comparing a reference scenario with an ‘improved scenario’; low temperature in the cold chain may result in extended retail shelf life and a lower percentage of losses, but will cost more energy; application of protective packaging leads to a reduction of losses, but at the cost of the packaging | [141] |

| 38. | Heat and mass transfer modeling | Transportation; storage; packaging | To obtain more insight into the cooling process and quality evolution of fruits parked in ventilated cartons in a pallet | Citrus | Fruits packed in downstream cartons exhibited lower cooling heterogeneity compared with those in upstream cartons. Precooling reduced quality loss by 23% | [133] |

| S/N | Technology | Cold Chain Operation | Purpose | Food Type | Significant Results | Reference |

|---|---|---|---|---|---|---|

| 1. | Internet of Things | Transportation | To build an intelligent model for food quality monitoring and control in a multi-temperature distribution center | Food | The food spoilage rate of food reduced during transportation due to the real-time food quality monitoring and control using an intelligent model | [165] |

| 2. | Internet of Things | Transportation | To improve transport efficiency in order to save the fruits from spoilage | Fruits | IoT system in a truck refrigerator adequately used to monitor the quality condition of fruits during transport | [20] |

| 3. | Internet of Things | Packaging, storage, and transportation | To monitor food quality and safety | Fruits and vegetables | IoT obtain real-time food traceability and monitoring data to control the logistic and process parameters causing quality loss | [178] |

| 4. | Internet of Things | Packaging, storage, and transportation | To reduce the food losses during the food chains since 50% is lost | Agro-food | IoT used to automate the packaging system with proper tracking and monitor the temperature of the produce at cold storage and during transportation | [159] |

| 5. | Internet of Things | Transportation | To monitor the temperature changes and inefficient management during transportation as the insufficient temperature can pose a high risk to food quality | Fruit and vegetables | Application of IoT in food chains facilitated safety, intelligence, and deliver quick decisions | [179] |

| 6. | Digital twin | Storage; transport | To develop a digital twin for the cold chain shipment of fruits | Mango | Based on measured environmental conditions, the impact of shipment duration, heat of respiration, airspeed and delivery air temperature history on quality of mango for different transport pathways was easily quantified using a digital twin | [184] |

| 7. | Digital twin | All chain | To gain a better insight into how fruits behave under convective cooling | Mango | At low speeds, a more uniform cooling can be achieved and thereby a more homogeneous quality decay within the mango; digital twin was able to evaluate the heterogeneity of the temperature field and identified the zones with the highest temperature inside the product, which can be valuable information for the placement of temperature probes | [185] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onwude, D.I.; Chen, G.; Eke-emezie, N.; Kabutey, A.; Khaled, A.Y.; Sturm, B. Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce. Processes 2020, 8, 1431. https://doi.org/10.3390/pr8111431

Onwude DI, Chen G, Eke-emezie N, Kabutey A, Khaled AY, Sturm B. Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce. Processes. 2020; 8(11):1431. https://doi.org/10.3390/pr8111431

Chicago/Turabian StyleOnwude, Daniel I., Guangnan Chen, Nnanna Eke-emezie, Abraham Kabutey, Alfadhl Yahya Khaled, and Barbara Sturm. 2020. "Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce" Processes 8, no. 11: 1431. https://doi.org/10.3390/pr8111431

APA StyleOnwude, D. I., Chen, G., Eke-emezie, N., Kabutey, A., Khaled, A. Y., & Sturm, B. (2020). Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce. Processes, 8(11), 1431. https://doi.org/10.3390/pr8111431