Abstract

This paper provides a fundamental and critical review of biomass application as renewable reductant in integrated ferroalloy reduction process. The basis for the review is based on the current process and product quality requirement that bio-based reductants must fulfill. The characteristics of different feedstocks and suitable pre-treatment and post-treatment technologies for their upgrading are evaluated. The existing literature concerning biomass application in ferroalloy industries is reviewed to fill out the research gaps related to charcoal properties provided by current production technologies and the integration of renewable reductants in the existing industrial infrastructure. This review also provides insights and recommendations to the unresolved challenges related to the charcoal process economics. Several possibilities to integrate the production of bio-based reductants with bio-refineries to lower the cost and increase the total efficiency are given. A comparison of challenges related to energy efficient charcoal production and formation of emissions in classical kiln technologies are discussed to underline the potential of bio-based reductant usage in ferroalloy reduction process.

1. Introduction

Charcoal is one of the first man-made products which has been used for millennia. First application of charcoal were found from about 30,000 to 35,000 BC [1], and its first usage in metallurgy can be dated to about 6000 BC for copper production [2] respectively to about 1800 BC initiating the Iron Age [3]. Charcoal enabled high energy intense processes, such as glass production and metal smelting [4] and was used as the major energy source in industrial processes until the industrial revolution, when is was replaced by coal and its derivatives. Nowadays, charcoal is used as a fuel for heating and barbecue, and is considered as a reductant for ferrosilicon processes in Norway and Brazil [5]. However, metallurgical production continues to rely on fossil-based reductants due to limited knowledge of charcoal properties and high costs.

The global production of charcoal increased from 40.5 million tonnes in 2002 [6] to 53.2 million tons in 2018 [7], in which about two third were produced in Africa. Fuelwood and charcoal generate between 2 to 7% of global greenhouse gas (GHG) emissions, mainly caused by deforestation, and combustion-related pollutants [7]. Brazil is the largest producer of charcoal with an annual average production of 6.5 million tons between 1993–2017 [8,9]. It was reported that about 50% of charcoal were produced from planted Eucalyptus wood [10]. Over the last decades, charcoal production shifted from primary to secondary forestry, reducing anthropogenic CO emissions by deforestation [8,11]. Large amounts of Brazil’s charcoal are used in the metallurgical industry that consumes about 10 million tons of charcoal per year and replaces fossil fuels for pig-iron (30%), steel (15%) and ferroalloy (98%) production [8]. In Europe, the production of charcoal from wood has almost vanished in the last centuries [12], leading to the charcoal import from countries like Brazil, Nigeria or Tunisia.

The metallurgical industry in one of the most energy intensive industrial sectors. About 10% of the annual anthropogenic CO emissions are ascribable the direct and indirect GHG emissions from metallurgical industry [13,14,15]. These emissions are mainly produced by carbothermal reduction processes, such as blast furnaces (BF), electric arc furnaces (EAF) and submerged arc furnaces (SAF), and by power production. About 1 billion tons of metallurgical coal are consumed in global steel industry [14]. About half of it was used to produce 350 million tons of coke used in metallurgical processes [16]. The consumption of raw materials is highly dependent on the final product and used furnace type. For example, the consumption of reducing agents increases from 500–550 kg per metric ton high carbon ferrochrome (HC FeCr) in closed furnaces to 550–700 kg per metric ton in open furnaces, whereas only 410–500 kg per metric ton of high carbon ferromanganese (HC FeMn) are required in closed furnaces [17].

On average, special materials and high quality steels are composed of about 3% ferroalloys [17]. The ferroalloy industry refers to iron alloys with a high portion of additional elements, such as aluminium, chromium, manganese or silicon. Ferroalloys were initially produced in small-scale blast furnaces in the second half of the 19th century [17]. The scale of production increased with the introduction of electric arc furnaces, in which the major production nowadays takes place. The electrical consumption is in the range of 3000 to 3500 kWh per metric ton of ferroalloy, respectively up to 7000 to 8000 kWh per metric ton of high-silicon ferroalloy [17]. The electrical resistance of the charge material is used to heat the hearth of the electric furnace, in which a higher resistivity enables a deeper electrode tip position in the furnace [18]. Simulation have shown that a lower electrode tip positions can decrease current through the burden by about one third [19], improving the temperature profile inside the smelter.

Bio-based reductants have potential to replace the reductants made from fossil-based materials in metallurgy [20,21]. Between 800 and 1200 kg of wet woodchips and about 10% charcoal have been used for the silicon production in the EU countries [22,23]. The current demand of sustainable carbon for ferroalloy production is smaller than the production of charcoal, whereas the markets and quality of charcoal are very diverse. The production and usage of charcoal can have a socioeconomic impact on different regions and should be considered beside the technical requirements for metallurgical application. The Food and Agriculture Organization of the United Nations summarized the main sustainable development goals for charcoal to poverty reduction, food security and nutrition, health and availability of clean water, sustainable energy and sustainable forest management to ensure the conservation of biodiversity [7]. Some kilns used for the charcoal production do not include off-gas cleaning systems and Thus, can release unburned by-products to the environment. These emissions are composed of particulate matter (PM), volatile organic compounds (VOC) and combustion products. Volatile pyrolysis products can be reduced by at least 80% by using an afterburner [24], in which the CO emissions from the process are increased. Modern technologies produce charcoal continuously or semi-continuously, in which the off-gases are combusted or recirculated to provide the energy for the pyrolysis process [1,25]. However, only limited improvements have been made for these technologies over the last decades. Thus, charcoal production should be based on a sustainable forestry with concomitant reduction in CO emissions.

Norway has a significant potential of forest-based resources due to the high ratio of hydro-power in their energy supply and the availability of unexploited forests [26]. Biocarbon in combination with carbon capture and storage (CCS) is intended to reduce the CO emissions from Norwegian metallurgical industry by 6.8 million tons CO-equivalence per year in 2050 [27,28]. To substitute the fossil fuel carbon reductants in the ferroalloy industry, biocarbon reductants with specific chemical, mechanical, and electrical properties are required [18,23]. In this review, current technologies and the resulting properties of charcoal are discussed to understand (i) how bio-based reductants can replace fossil fuel-based carbon and (ii) how charcoal production routes can be improved to enable an economical production in Europe.

2. The Process Chain of Renewable Reductants

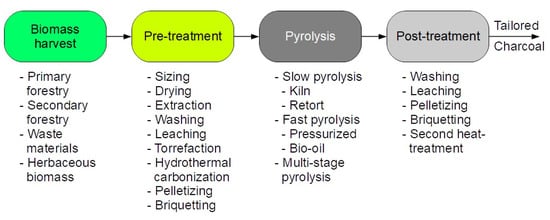

The properties of carbon reductants are crucial for a stable operation of SAF [16,18]. Differences in chemical and physical properties compared to fossil fuel based reductants could lead to a range of technical challenges for the bioreductant use in ferroalloy production. Currently used fossil fuel reductants generally provide a high mechanical stability and low gas reactivity. The fixed carbon content of fossil fuel reductants is expected to be larger than 85%, whereas ash content should be less than 12%. Ash constituents such as alkali and alkali earth metals, phosphorous and sulfur should be low to minimize catalytic reactions and slag formation. The high volatile matter content of biomass and it derivatives can be problematic for especially closed hearth SAF. Selected properties of biomass, charcoal and fossil fuel coke are summarized in Table 1, while minimum requirements for metallurgical processes are summarized in Chapter 4 (Table 5). The typical particle size of carbon reductants in SAF can vary from 5 to 30 mm [29,30]. It is obvious that raw biomass must be processed to fulfill the required properties in SAF. While wood has been used as the only feedstock over the millennia, herbaceous biomass waste [31,32,33,34] and algae [35] can be also considered as feedstocks nowadays. Possible steps for the charcoal production and use as a reductant in ferroalloy industries are shown in Figure 1.

Table 1.

Comparison of biomass and charcoal properties to fossil fuel reductants used in ferroalloy production [36,37,38,39].

Figure 1.

Schematic of the possible charcoal production steps.

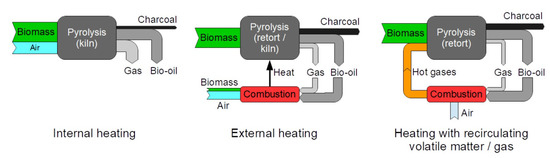

Charcoal is defined as a solid residue from wood pyrolysis. Pyrolysis is the thermochemical decomposition of organic material at elevated temperatures, most often between 350 to 700 C, in absence of oxygen. The required thermal energy is provided by the partial combustion of additional feedstock or pyrolysis by-products, i.e., gas and oil (volatile matter), which is released during pyrolysis. While charcoal kilns have been used over millenia and are still used in several countries, modern kilns and large-scale retorts are the main production processes in industrialized countries.

2.1. Biomass Composition

The most common biomass used as a renewable reductant is wood. However, due to the high price of woody biomass, alternative feedstock such as herbaceous biomass or waste have become more attractive in recent years. Biomass is a mixture of organic compounds and mineral matter. Woody biomass is mainly composed of cellulose, hemicellulose, lignin and minor amounts of extractives, in which softwood has a greater lignin content than hardwood, whereas the cellulose, hemicellulose and extractives are greater in hardwood [40]. The compositional analysis of herbaceous biomass as well as selected softwood and hardwood species is shown in Table 2. The analysis of specific feedstock can be found elsewhere [38,41], such as differences between bark and stemwood [42].

Table 2.

Composition of hardwood, softwood, wheat straw and rice husks.

The biomass constituents have a major impact on the product properties, composition and yields in thermochemical conversion. The constituents react in broad temperature ranges using different mechanisms, pathways and rates [43] and Thus, affect the primary and secondary reactions in the kiln or retort. Pyrolysis reactions of cellulose are mainly endothermic, whereas decomposition of lignin and secondary decomposition of volatiles are exothermic [43,44]. Thus, biomass composition has a strong effect on the char yield and by-product composition.

The volatile composition is based on the biomass feedstock and heating rate of the process, in which cellulose, hemicellulose and lignin (CHL) decompose to characteristic monomer and monomer-related fragments [45]. Cellulose decomposes in the temperature range between 280 to 380 C with a maximum reaction rate at 350 C [46,47]. Hemicellulose decomposes in the wider temperature range between 190 to 380 C with a maximum reaction rate at 260 and 310 C [48,49,50,51]. Lignin decomposes in the widest temperature range between 200 to 500 C with a maximum reaction rate at 360 and 400 C [48,50,52]. Thus, thermal breakdown (degradation) of hemicellulose is larger than that cellulose and larger than that of lignin [43]. The pyrolysis of cellulose results in a formation of levoglucosan and its derivatives [46] with a solid residue of 7–20% [53]. The char yield from xylan can be twice greater than that of cellulose and three times greater than that of glucomannan [54,55]. Lignin has the greatest solid yield with about 50% at 500 C, further decreasing to 40% at 900 C [55,56].

Minerals in the ash can catalyze primary and secondary pyrolysis reactions. Potassium and silica showed a greater catalytic effect on the remaining radical concentration compared to the CHL composition in the biomass [57]. In addition, charcoal forming reactions under fast heating rates were much stronger affected by the potassium content than by CHL composition [58]. Sugar and sugar derivatives were increased at the cost of carbonyls and phenolic compounds after acid leaching [59]. To evaluate the conversion performance of biomass, five grades on basis of the compositional and proximate analyses were established [60].

2.2. Pre-Treatment of Raw Feedstock and Charcoal

Ferroalloy industries require pre-treatment processes to have a low capital and operating cost and also to be effective on a wide range and loading of lignocellulosic material. To improve biomass properties for transport, storage and thermochemical conversion, biomass can be pretreated by resizing and drying. Fresh woody biomass provides a moisture content up to 60% [65] and ≈80% for fresh algae [66,67]. To reduce the energy demand in the first pyrolysis stage, biomass should be naturally dried to less than 25% [68]. The equilibrium moisture content of wood can vary from 4 to 18.1 wt.% [69], similar to that of dried herbaceous biomass such as wheat straw or rice husks. A high moisture content increases the energy demand for pyrolysis, resulting in a decreased energy conversion efficiency [70]. In addition, the amount of bio-oil would be increased by a larger water fraction, but with a decreased amount of organic compounds and heating value [71,72].

A stem wood length of 5 to 6 m is most often used for road transport in Europe. The feedstock size must be adjusted to the thermochemical conversion process, whereas a length of ≈30 cm and a thickness of 10–18 cm are required for pyrolysis retorts, respectively a length of 60–120 cm and a diameter of 12–20 mm for charcoal kilns [25,73], or milled to fines for fast pyrolysis processes [74]. Sawdust from sawmills is therefore useful for fast and flash pyrolysis units, or must be densified by pelletizing or briquetting. Herbaceous biomass must be milled and densified to be usable in classical charcoal production. However, fine biomass milling is energy-consuming, and fibrous particles with low bulk densities may cause feeding problems.

The use of a bioreductant that is more reactive in CO than fossil-based coke may increase maintenance costs of the metallurgical process [75,76]. Ash constituents such as potassium act as a catalyst for CO reactivity and should be minimized. Stem wood can be debarked to reduce the ash content of the feed material and increase the value of the woody biomass [77], in which debarking can be carried out with modified harvesting heads in the forests [78]. The removal of bark from wood logs reduces the concentration of alkali metals which can have a negative impact on the metal parts of the kiln leading to corrosion. One of the major challenges of agricultural residues is therefore related to its quality, such as a higher ash content of problematic alkali metal compounds. Washing or leaching are common methods to reduce the ash content of the parental feedstock.

Thermochemical processes such as torrefaction and hydrothermal carbonization can be used to improve physicochemical properties. However, and efficient and cost-effective biomass pre-treatment is very important for overcoming biomass limitations and hurdles in use of biocarbon-based reductants in the ferroalloy industry. Value-added compounds may be removed from the biomass prior to the pyrolysis process to improve the economics of the process chain. In contrast to classical charcoal production require extraction processes wood particles of small size for the high process efficiency. Thus, particle size of the material must be adjusted for each step in a process chain, and should target a final particle size that can vary from 5 to 30 mm for the further use as a reductant in ferroalloy industries [29,30]. Briquetting or pelletizing can be carried out after the extraction process.

2.3. Milling/Grinding

The particle size of the feedstock material must be adjusted for each step in the process chain, and should target a final particle size between 5 to 30 mm for the further use as renewable reductant [29,30]. While wood is sawed and split into logs prior to charcoal production, herbaceous biomass must be milled and grinded prior to its compaction. The pre-treatment of herbaceous biomass can be adopted from biomass combustion, where the lignocellulosic materials are first decentralized milled and pelletized, and second biomass pellets are then milled using coal roller mills prior to combustion [79]. A number of studies [80,81,82,83,84,85,86,87,88] have investigated the influence of mill type on both the particle size and shape. Momeni [80] showed that comminuting woody pellets in hammer and roller mills produced significantly different sized particles. In other investigations [81,83], higher fractions of fine particles were obtained after comminution in a hammer mill compared to milling using a knife mill. In agreement with this observation, the energy consumption of the knife mill was found in all cases to be smaller than that of the hammer mill [82,83]. The feedstock type (hardwood, straw, corn cobs and corn stover) affected the energy consumption of the hammer and disk mills [84].

The energy consumption for the comminution of dry pellets was lower for the hammer mill than for the disk mill, and the particle size distribution was broader with larger particle aspect ratios after comminution in the hammer mill [86]. In addition, it was reported that a high moisture content (>20%) increased the specific energy consumption by 50% [86]. It appeared that different feedstocks (switchgrass, corn and soybean) showed differences in the particle size and shape during comminution and generated particles with various morphological properties [87,88]. Milling of the thermally treated material showed that the energy efficiency can increase twice at temperatures up to 180 C and decrease at carbonization temperatures above 270 C reduced by factor of 4 [89].

Particles should be milled to an optimal size for the consecutive processes, in which a later densification must be ensured. Biomass can be compacted by pelletization and briquetting, in which pellets showed best mechanical stability for a broad particle size distribution and a low amount (≤20%) of particles less than 0.5 mm [90]. However, pellets produced from smaller particle sizes (≤300 m) resulted in a higher yield stress and density than for larger particles (300–600 m) [91]. Particles larger 5 mm can be compacted by briquetting.

2.4. Washing/Leaching

The alkali metals, particularly potassium, calcium and sodium catalyze the thermal degradation of biomass, increasing the yield of reaction water and decreasing the yield of tar and char [92,93]. Other soluble inorganic species can also be problematic because of their effects on the charcoal properties, such as increased reactivity, electrical conductivity and purity of base metals [94,95]. Water leaching removes alkali sulfates, carbonates, and chlorides, whereas HCl leaches carbonates and sulfates of alkaline earth and other metals [96]. For example, ash content of wheat straw and rice husks were reduced by nearly 50% by acid leaching [97,98,99], in which especially alkali and alkali-earth metals were removed. In addition, ammonia removes organic compounds of Mg, Ca, K and Na. Overall, leaching with dilute acids is known to remove only soluble metals which are not physiologically bound to the matrix of lignocellulosic feedstocks, while dilute alkali or other catalysts are required to disrupt cell walls and release ash components which are physiologically bound to the feedstock matrix [33]. However, previous studies have shown that leaching of biomass can also remove the organic fraction, especially reducing the lignin amount [92,100].

Leaching can also result in a loss of cellulose and hemicelluloses through hydrolysis pre-treatment [101]. Another challenge related to the biomass leaching with the acid catalysts is the remaining acid in the charcoal matrix that requires post-processing including calcination or disposal of catalysts and additional washing of charcoal with the deionized water. Concurrently, water washing may also be desirable to reduce volatilization of sulfur and chlorine products during pyrolysis [102,103]. In addition, leaching may increase the energy density up to 25% through increased heating values and pellet density [104]. Differences in carbon structure suggest that leaching of original biomass affect the charcoal properties after heat treatment at elevated temperatures, whereas temperature is the dominant process variable at temperatures above 2000 C [62,105]. The alkali and alkali-earth metals are removed in a rapid phase, whereas other elements are removed in slow phases which can exceed several days [106]. Boiling-water leaching is inferior to acid leaching to remove ash elements, but superior on the basis of investment costs and chemical demand [98]. However, the removal of these elements is beneficial for the metallurgical industry [105], since these are catalyzing the Boudouard reaction.

2.5. Extraction

The separation of extractives (e.g., lipids/resin acids) from the biomass feedstock provides a possibility to considerably reduce off-gassing and provides valuable chemicals or biofuel for the energy sector and metallurgical industries [107]. The extracted fatty/resin acids can be utilized as primary feedstocks for chemicals and biorefinery applications [108,109,110,111], whereas the wood fraction after extraction is of high importance as a source of green carbon that could be utilized in metallurgical industries. Several methods exist for the extraction of high-value molecules from biomass including conventional organic solvent extraction, hydrodistillation, low-pressure solvent extraction and hydrothermal feedstock processing [112,113,114].

Supercritical fluids demonstrate properties between those of a liquid and a gas, with the viscosity of a supercritical fluid being an order of magnitude lower than a liquid, whereas the diffusivity is an order of magnitude higher and Thus, leading to the enhanced heat and mass transfer [115]. The properties of a solvent can be fine-tuned by varying the temperature and pressure. Conventional solvents traditionally utilized in wax extraction (such as hexane) are frequently viewed as being problematic due to the toxicological and environmental impacts [116]. Supercritical fluid extraction using CO as a solvent has an easily accessible critical point, is non-flammable, has minimal toxicity and is widely available [117]. Supercritical CO extraction (scCO) has been conducted on a commercial scale for over two decades for the extraction of high-value products from biomass [118]. Supercritical extraction process has been shown to improve the off-gassing of wood pellets, thus reducing the potential for uncontrolled auto-oxidation, while maintaining pellet properties [107,119]. Moreover, supercritical CO extraction can also improve the physicochemical properties of solid char from pyrolysis at high temperatures, leading to greater electric conductivity and low reactivity of charcoal [120]. Supercritical CO extraction increases the bending strength and stiffness of residual wood and, Thus, decreases the cost of process scaling up, wood storage and transportation [121].

The pre-treatment using scCO extraction of wood removes more than half of value-added compounds without any significant influence on the physical properties of original wood and on the yield of solid charcoal [122]. Under properly selected treatment conditions (e.g., >1100 C), charcoal samples can be produced from a mixture of different low quality wood fractions with reactivity and dielectric properties approaching that of fossil-based metallurgical coke and with the low content of liquid products, including naphthalene, PAHs, aromatic and phenolic fractions.

2.6. Torrefaction

Torrefaction is a mild pyrolysis process that converts biomass into a carbon material with increased energy density and decreased oxygen content, removing smoke-forming volatiles and result in a product yield of ≈45–70% of the initial weight [123,124]. Torrefaction contributes to dehydration, deoxygenation, partial degassing, and structural changes through breaking hemicellulose, lignin and cellulose chains at elevated temperatures [125], in which the lignin content is increased by ≈10–15% [124]. This leads to increased calorific value that improves biomass physiochemical properties during co-firing with coal [126,127]. For example, the feedstock becomes more uniform that improves pelletization and the flow properties of torrefied products [123] and the energy density is increased to more than 20 GJ m [124].

The higher heating value of torrefied olive stones (28.8 MJ kg) at 300 C can be achieved in a rotary slow pyrolysis reactor to meet the requirements of metallurgical industries [128]. In addition, the torrefaction length did not have a strong influence on the CO reactivity of olive stones, whereas the temperature and particle size had a significant influence on the composition and product yields [129]. Longer torrefaction times and greater heat treatment temperatures led to the improvement of higher heating value of olive stones leading to higher carbon and lower oxygen content. One way to improve torrefied biomass handling and combustion properties is by densification into briquettes or pellets which have many advantages over torrefied feedstock including reduction of dust, improved handling properties and higher bulk density (up to 66% greater) [130].

2.7. Hydrothermal Carbonization

In hydrothermal carbonization (HTC) feedstocks remains in contact with hot, compressed water increasing carbon and hydrogen contents and also producing hydrochar with a high stability [131]. HTC treatment generates three products: gases, liquid compounds, and hydrochar that contains 80–95% of the energy content of the raw feedstock and 55–90% of the original mass [132]. Gaseous products cover ≈10% by mass of the raw feedstock and liquid compounds, primarily hydroxymethylfurfural, furfural, phenol, pentoses, hexoses, comprise the remainder of the products [133]. HTC is carried out in a hot liquid water in the temperature range 180 to 250 C at solids loading ranging from 7 to 25%, and reaction time ranging from a few minutes to several hours [134]. Specifically, HTC removes a significant fraction of undesired inorganic elements such as Na and K that would otherwise contribute to slag [135]. Previous studies showed that the alkali content can be further reduced by increasing the heat treatment temperature or by washing the hydrochar with the deionized water after the pre-treatment [136]. In addition, hydrochar has superior mechanical properties and pelletability compared with torrefaction or pyrolysis biochar [129,137]. Besides the complexity of structure-property relationship, the use of bioreductants is hindered by the price of feedstock and hydrochar yield [138,139]. Thus, a limited number of studies using lignocellulosic biomass and waste has been conducted to investigate the hydrochar properties for the use in ferroalloy industries.

2.8. Pelletizing and Briquetting

Densification processes such as pelletizing and briquetting can significantly reduce carbon losses due to dust formation. In addition, pelletizing and briquetting provide the product with a defined uniform shape and size [133]. Combined carbonization and pelletizing can be used to increase the fuel value of feedstock by increasing its energy density and improving its handling and transport processes in the reduction furnace [140]. One of the challenges in using renewable reductants in metallurgical processes is related to its fragility with the generation of large amounts of fine particles during transportation and storage [141]. The mechanical strength of biomass pellets can be improved through pelletization or briquetting and is slightly larger than that of charcoal pellets [142]. However, recent studies have shown that pelletizing charcoal fines increase the usable carbon yield in ferroalloy production [143].

In ferroalloy industries, manganese ore pellets must be sintered at higher temperatures to provide a mechanical stability that is similar to that of iron ore pellets. The addition of wood dust and dolomite are known to increase the required sintering temperature of the ore pellets and Thus, generally used in iron and manganese alloy production [16,144]. The use of pellets from charcoal-ore blends is known to reduce the electricity demand and increase the yield of elemental manganese [145]. Current metallurgical production is based on the use of fossil-based fuels because the use of biomass-ore and charcoal-ore pellets in the reduction process can increase the overall power consumption by 72–152 kWh per tonne of FeMn and will increase the cost of the reduction process [146].

Previous studies showed that the durability of high quality pellets is required to be >97.5% to fulfill the criteria of the European Standard Committee CET/TC 335 and be used in ferroalloy production [147]. Pelletizing of HTC char prepared at 200–240 C provided mechanically stable bioreductants compared to the dried torrefied-based pellets without an additional binder [135,148,149]. An additional heat treatment improved the agglomeration of the hydrochar particles, increasing the durability of hydrochar pellets to >95% at temperatures above 300 C [129]. A maximum durability of 98.5% was measured during the heat treatment of hydrochar at 450 C showing similar properties to charcoal pellets with the pre-mixed bio-oil binder [63,150]. Torrefied biomass particles are loose and nonuniform due to decreased hemicellulose content [126]. In comparison, mechanical strength and pelletability of torrefied charcoal are less compared to that of HTC chars [135,137,151]. Therefore, the pre-treatment of biomass under the HTC conditions might be more suitable for the production of reductants for the ferroalloy industries than torrefaction.

2.9. Slow Pyrolysis

Slow pyrolysis is the thermal decomposition of organic feedstocks i.e., biomass, coal in an inert atmosphere at low heating rates (up to 20 C · min). Slow pyrolysis processes are used to produce solid products like biochar or charcoal from biomass [152,153]. The feedstock is firstly dried by driving off the moisture and pore water of the organic feedstock. The dried feedstock undergoes a thermal decomposition of the organic matrix with increasing temperature, in which volatile compounds are released. The product composition is based on the feedstock and process conditions, such as heating rate, heat treatment temperature and residence time. Biomass is heated up to about 300 to 700 C, and up to 50 wt.% of the feedstock are recovered as solid residue [56,154]. Pyrolysis at temperatures less than 1200 C is defined as carbonization process [40], in which the solid yield decreases with increasing heat treatment temperature. The volatile fraction is composed of condensates (e.g., bio-oil) and pyrolysis gases, such as CO, CO, H and CH. The solid pyrolysis product is rich in carbon [155], whereas the liquid by-products from biomass pyrolysis have a high oxygen content. The final yield and quality of the pyrolysis products are affected by the feedstock composition, pre-treatment, heat treatment temperature, heating rate, reaction gas atmosphere, particle residence time, pressure and catalysts (e.g., alkali and alkali earth metals) [152,154,156].

In general, the pyrolysis of biomass follows a three-step mechanism as described above: 1. dehydration, 2. primary pyrolysis reactions and 3. secondary pyrolysis reactions. Primary pyrolysis reactions include dehydrogenation, depolymerization, and fragmentation reactions of the organic matrix, and can be considered as homogenous reactions. Secondary (and ternary) pyrolysis reactions summarize the reactions of intermediate decomposition products and gas reactions, as well as the heterogeneous reactions with the formed char [56]. Moreover, secondary reactions of bio-oil compounds can increase the solid yield by more than 4%-points [63]. Previous studies have shown that secondary reactions can be induced by long residence times, large particles and increased pressure [157,158], and are affected by the ash yield and composition.

Charcoal yields are maximized at low heating rates, long residence times and high pressures [157,158], where increased pressure leads to an increase in a char yield (up to 50%) with the decreased residence time [159]. Classical charcoal is produced at a temperature below 700 C at low heating rates. An operation cycle can vary from 7 days to more than 30 days [160,161] and is accounted as slow pyrolysis. At temperatures of 400–450 C, about 37–50% charcoal, 34–47% bio-oil (4–11% tar, 30–36% aqueous phase), and 14–29% permanent gases are formed from wood [8,10,162]. However, due to the partial combustion of feedstock and undefined process conditions in kilns, charcoal yield is highly influenced by the skills of the operator, and is generally less than 20–25% on dry basis [160,163,164]. Industrial retorts used in Europe provide a charcoal yield of ≈35% on dry basis [153]. Char yields of 15–43 wt.% can be obtained for the slow pyrolysis of microalgae [35], similar as reported for agricultural residues [25,32].

Recent studies have shown that multi-stage pyrolysis processes can improve the solid yield and reduce its energy demand. The fixed carbon yield can be increased by 11% to 25.7% by a three-stage pyrolysis process with different heating rates, resulting in an energy saving of 20–30% [165,166]. This approach incorporates the temperature regions of endothermic and exothermic reactions and Thus, enables a better control of product yield and quality. However, the multi-stage pyrolysis requires carefully design to obtain the optimized product yield and energy savings [167] and no multi-stage process was installed on industrial scale when this review was initiated.

2.10. Fast Pyrolysis

Fast and flash pyrolysis of biomass are mainly used to produce liquid biofuels (e.g., bio-oil) at high heating rates (>100 C s) and reduced to atmospheric pressure. At a heat treatment temperature of 500 C, about 24 wt.% of solid residue (including ash) can be recovered [168], whereas high yields of charcoal are formed at increased pressure [152,157]. The greater charcoal yield and the larger throughput in pressurized pyrolysis can improve the economics of the overall process, in which the fixed carbon yield can be increased to 70–85% of the theoretical value [157]. However, the fixed carbon content of the produced charcoal was less than 85% [152,157] and Thus, increases the demand for enhanced off-gas cleaning systems due to the reduced quality of the off-gases [169,170] or additional post-treatment.

Properties of flash pyrolysis char and soot differ from that of industrial charcoal and may be considered as an alternative resource in metallurgy. The solid residue is strongly affected by the feedstock composition and final temperature in the process [171]. Charcoal from fast pyrolysis exhibits a higher volatile matter content compared to slow pyrolysis char produced at same temperature [172]. The charcoal yield of wood and herbaceous biomass decreases to less than 4% on dry ash free basis at temperatures above 1000 C [173,174], whereas the formation of soot increases at temperatures larger than 900 C with a maximum yield between 1100 to 1250 C [97,175]. Biomass with a high lignin content will form larger soot yields compared to biomass which is enriched in cellulose or xylan content [171,176], in which the soot and tar formation is reduced by high concentrations of alkali metals. At temperatures larger than 1000 C, beechwood and straw samples retained their original structure, while low ash pinewood underwent a morphological transformation with a highly molten surface [100]. Cellulose pyrolysis under high heating rates produces mostly permanent gases and a limited amount of bio-oil [171].

Fast pyrolysis processes are technically complex [177] and will require a profound understanding of the primary and secondary pyrolysis reactions [164] to provide a biocarbon with the required properties for metallurgical application. A major drawback of bio-oil from fast pyrolysis is the lack of integrated biorefinery concepts into metallurgy [178]. The bio-oil is generally upgraded into a valuable biofuel or chemical feedstock [179]. In addition, bio-oil can be used in the ferroalloy industry as a binder for carbon briquettes, pellets and agglomerates [63,150,180] or as feedstock for electrode material [181]. The large fractions of small aromatics (e.g., benzene and toluene) and phenols which are found mostly in lignin bio-oil are beneficial for the use as a binder [176]. However, both process chains would require an additional post-treatment of the collected bio-oil samples.

2.11. Emissions

The charcoal fuel cycle from classical charcoal production is one of the most GHG intensive energy sources used by mankind [5]. Liquid and gaseous products from biomass pyrolysis can be accounted as value-added by-products or emissions. Charcoal is commonly produced in simple kiln technologies and small scale retorts without off-gas cleaning system or flares, releasing the unburnt by-products as emissions. These kilns generate multiple hazardous emissions by the incomplete combustion of the feedstock, such as PM, VOC, NO and CO [24,182] as summarized in Table 3. Some advanced charcoal kilns partly condense the VOC by a chimney and use these as a value-added by-product [25]. VOC can be subdivided into methane and non-methane organic compounds [182]. PM are increased from incomplete combustion of especially dried feedstock, whereas feedstock with high moisture content increases smoke formation [183]. Highest PM emissions occur in the first hours after the under-stoichiometric combustion is initiated [10]. Large PM emissions in combination with deforestation can result in a net increase in global warming potential [182] and must therefore be inhibited.

Table 3.

Possible emissions from charcoal production in kiln technologies.

About 3–3.6% of the biomass carbon is emitted as condensable liquid emissions from simple kilns [182]. Polycyclic aromatic hydrocarbons (PAH) are one class of these products which are partly considered as hazardous to health and environment [184,185], and are mainly emitted in the first hours of the wood carbonization process [10]. 5.0 to 7.6% of total PAHs or 82 to 100% of the aromatics with 5 to 6 rings are found within the PM [10,184]. The number of PAHs in pyrolysis off-gases is higher than that of complete biomass combustion [10]. The concentration of dust including PM can range from 1.77 to 38.9 mg m at highest concentration of total dust [186]. About 2.8 mg m of particle bound PAH is smaller than the total emission of gaseous PAHs, which accounted to 23.6 mg m [10]. Maximum concentration of 64–100 mg m have been detected in the initial phase of the pyrolysis process [10,186].

NO emissions are dependent on the nitrogen content of the original feedstock. 60–80% of the nitrogen involved in the pyrolysis exists as protein nitrogen in the biomass, resulting in the formation of N-containing compounds at lower heating rates [187]. A high concentration of lignin promote to formation of NO [187]. The amount of NO emissions can range between 0.016 to 11 g per kg of charcoal [24,182]. Sulfur of the parental biomass will be partly released as SO emissions. About one-third of the sulfur is released as emissions with the volatiles in carbonization of coal [16]. Sulfur content of biomass transited from mostly sulfate to organosulfur from 500 C to 850 C [188]. However, sulfur content in wood biomass is generally low.

CO and CO emissions are formed by incomplete combustion and thermal decomposition of the biomass. Carbon monoxide emissions are reported in the range of 130 to 373 g kg of charcoal [24,182]. Approximately 25% of the biomass carbon is converted to CO, resulting in an emission factor between 543–3027 g CO per kg of charcoal for the different kiln technologies [182]. The maximum of 3.03 kg of CO-equivalent per kg charcoal is produced in earthmound kilns. The 100 year global warming potential is stated to 1.144–5.685 kg of CO-equivalent per kg charcoal [189]. However, CO emissions can be accounted as CO neutral for the sustainable biomass production. On average, 28 to 61% of the CO emissions are referred to the charcoal production process, whereas 29 to 61% arise from the biomass production [189]. Thus, a sustainable biomass production and utilization of the by-products are essential to reduce anthropogenic CO emissions in metallurgy, whereas an increased carbon conversion efficiency and recirculation of volatiles are the most important improvements to reduce the pyrolysis gas emissions into the atmosphere [68].

More than 80% of the volatile emissions from simple charcoal kilns can be reduced by using a chimney and afterburner [24], which are usually installed in advanced kilns such as Brazilian Beehive kiln and Missouri kiln [25]. Industrial retort systems such as Degussa retort, Lambiotte retort etc. are closed systems that use off-gas scrubber and other gas cleaning systems in addition. Thus, modern charcoal production retorts do not pollute the environment compared to their simple predecessor [190] and generally fulfill the regulations for industrial emissions in Europe and North-America.

2.12. Post-Treatment Processes

Charcoal produced from feedstock of differing particle size showed various chemical properties. Small feedstock particles increase the rate of volatile escape, and the charcoal has an increased ash content [92,193]. The charcoal (or biocarbon) can be post-treated to adjust its properties and to utilize additional by-product streams, such as fine material or bio-oil. The ash content of charcoal is about 3 to 4 times larger than that of biomass due to the devolatilization of the organic volatile matter. Post treatment processes like water- and acid-leaching can be used to reduce the final ash content of the charcoal as described above [59,99,194]. A large extent of fine particles is produced during transport and handling of charcoal. Briquetting, pelletizing and agglomeration can be used to compact charcoal fines and to produce a renewable reductant with increased properties [124], such as mechanical strength and density [150,180,195,196]. Densification processes vary by energy consumption and can impact the chemical and physical properties of the charcoal [124].

A balance between mechanical strength and porosity of charcoal has to be found for the use of bioreductants in ferroalloy industries. Charcoal is often porous (both micro- and macroporous), which is disadvantageous when carbon needs to be mechanically stable and not excessively reactive, as it is the case in manganese production. The micropores in charcoal can be closed by the deposition of carbon from methane that could ease the transition to the use of biocarbon as a means of metal ore reduction [28,197]. In addition, properties of the original feedstock such as density, moisture content, heating value, ash content, and compressive strength affect the quality of charcoal and pellets/briquettes made from charcoal. Therefore, process route of the raw feedstock and by-products is a dominating factor governing properties of charcoal and bioreductant-based pellets/briquettes in the reduction furnace.

The possible method for preparing charcoal-based reductants is to compact fine charcoal particles with the addition of a binder. The fines can be agglomerated to improve the mechanical properties of charcoal-based reductants by adding water and organic binder i.e molasse [172], starch [195], lignin [124,198] and bio-oil [63,150]. The binder is required due to the lack of plasticity of charcoal particles compared to untreated biomass. The binder forms solid bridges between particles, resulting in an improved mechanical stability of the densified product [172]. Starch in combination with water are superior to bio-oil based on its availability and low economical value [195]. Lignin softens at temperature above 140 C and forms agglomerates between charcoal particles [124,198,199], in which hardwood lignin is superior to softwood lignin due to the greater amount of methoxy content [199]. Lignin is commercially available as a by-product from second generation bio-fuels [150] and from pulping industry [199].

Mechanical properties are affected by the added binder, its content and compacting pressure. The mechanical strength of carbon briquettes can be increased by increasing the binder content to 6.5–8.6 wt.% of softwood and hardwood lignin [199]. An increased bio-oil ratio from 10 to 40% resulted in an increased compression strength by approximately 50% after a second heat treatment [150]. The second heat treatment reduced the volatile matter from the pellets and resulted in cross-linking of the bio-oil and charcoal particles and improved the mechanical strength of charcoal pellets and briquettes [105,200,201]. Lignin and bio-oil were successfully tested as binders for heat treatment temperatures up to 1100 C [150,199]. To ensure a high mechanical stability at higher temperatures, metallic silicon can be added as an additive to the binder-charcoal mixture [199]. Overall, charcoal producents strive for the use of small charcoal particles in pelletizing process without further milling to keep the cost of the overall bioreductant process low. Further heat treatments can be used to reduce the volatile matter content and to improve mechanical strength of the lump charcoal, pellets and briquettes [105,200,201].

However, charcoal pellets can reduce a self-heating risk when the operating temperature in the furnace exceeds 600 C [180]. In addition, porosity and surface area decreased after charcoal pelletizing using the pyrolysis bio-oil, whereas the use of coal tar as a binder did not affect the combustion and physicochemical properties of pellets made from fossil-based reductants [202]. Coal tar is a type of toxic, hazardous and carcenogenic solid waste generated in the process of coal gasification or coking and composed of heavy tar oil, pulverised coal and particles in gases produced in coal pyrolysis [203,204]. Therefore, renewable and carbon-neutral binders i.e., bio-oil with the addition of paraffin oil, castor oil, mineral oil and linseed oil can be an alternative to fossil-based binders due to the increased energy density of charcoal pellets with the low self-heating risk [205].

3. Charcoal

Charcoal is comprised of the unconverted organic solids, the non-volatile mineral matter and the carbonized products. Fixed carbon content of charcoal is generally greater than 70% [5,73], and it is considered greater than 85% for metallurgical grade charcoal [5,152]. The feedstock origin and the pyrolysis conditions are the main influencing parameter on the physicochemical properties [156,206]. The obtained structure of charcoal is defined by the original feedstock, particle size and heating rate, in which pyrolysis at slow heating rates and larger particles results in the similar charcoal structure compared to its feedstock [206]. Charcoal produced from dense hardwood provide a greater mechanical stability than charcoal produced from softwood, which is preferable in the ferroalloy industry [152]. The electrical properties of charcoal are also important for the use as a reductant in SAF.

The charcoal yield of classical kiln production processes is in the range of 5 to 20 wt.% on dry basis due to the limited control of process conditions (e.g., air supply) [8]. These production processes release often large quantities of unburnt hydrocarbons to the atmosphere, and provide a fixed carbon content in the range of 65 to 80% [25]. Industrial retorts on the other hand provide charcoal yields of ≈35% [207,208], whereas charcoal yields up to 62% were reported for pilot scale experiments [153,209]. Thus, the conversion efficiency of the carbonization process is one of the key issues for a sustainable process chain [7].

3.1. Yields

The charcoal yield from industrial charcoal production is summarized in Table 4. Carbon efficiency of modern retorts is about twice greater than that of earth mound kilns, and achieve a yield of about 35 wt.% on dry basis [6,43]. Well operated Brazilian kilns with tar recovery provided a similar charcoal yield with up to 36.4% and carbon yield of 69% [182]. In charcoal kilns, the required thermal energy is provided by the partial combustion of wood, its by-products and other fuels i.e., gas, oil, etc. [25]. The combustion of by-products and wood can decrease the charcoal yield to less than 20%. The modernized energy efficient kilns include the bio-oil condensation units and can obtain higher charcoal yields than it was reported for traditional kilns [6,182].

Table 4.

Charcoal yield for the pyrolysis of biomass.

Charcoal yield from pyrolysis of “dead” biomass is similar to “living” biomass, whereas the bio-oil yield is approximately 1% greater for dead biomass at the cost of pyrolysis gases [210]. Thus, charcoal yield from sapwood at short rotation forestry (≤20 years) is similar to stem wood (sapwood and heartwood) from classical forestry (50–150 years cycle). The low solid yield in fast pyrolysis indicates a limited potential of charcoal use in ferroalloy industries [74,101,177,179]. However, bio-oil utilization as a binder or an electrode material using fast pyrolysis opens new opportunities for the process upscale in ferroalloy industries.

To estimate the usable carbon fraction for metallurgical application, yield and fixed carbon content of charcoal were combined in the fixed carbon yield. The fixed carbon yield is defined as: = , where is the fixed carbon yield, is the charcoal yield, is the fixed carbon content of the charcoal and a is the ash content of the biomass [1,209,211]. The fixed carbon yield of charcoal varies from 20 to 30 wt.% on dry basis [155,208]. Bio-oil utilization can increase by 4–5%-points [63,105]. Herbaceous biomass such as sugarcane has a lower conversion efficiency than wood pyrolysis, resulting in a lower bio-oil yield and lower exergy efficiency than that of wood pyrolysis on area basis despite its greater growth rate [212].

3.2. By-Products

Volatile pyrolysis products are accounted as by-products from charcoal production. Volatiles are composed of light pyrolysis gases, such as CO, CO, CH, H and light hydrocarbons [222,223], and condensable liquids, such as organic acids, methanol, heavy hydrocarbons, oxygenates, etc. [43,61]. The liquid products are defined as bio-oil, which is composed of more than 300 compounds with an oxygen content between 35 and 40% and heating value of 11 to 26 MJ kg [223,224]. Water content of slow pyrolysis bio-oil is more than twice larger than that of fast pyrolysis oil [225] and strongly affected by the initial moisture content of the biomass feedstock. The high water content of slow pyrolysis bio-oil 50% [63,225] can lead to a phase separation, which generally occurs for bio-oils with a water content larger than 30–35% under storage [222]. This emphasizes the importance of dried biomass feedstock, since the moisture content increases the bio-oil yield and decreases the concentration of the organic fraction and its heating value. A moisture content less than 45–50% is required for an autothermal operation [226], respectively less than 20–25% for an efficient and stable operation of industrial scale retorts, such as the Lambiotte process [6,68].

The major organics in bio-oil are organic acids, alcohols (e.g., methanol: 1.4–7.9%), oxygenates (e.g., acetone: 0.3–1.6%) and tars (11.8–26.6%) [61]. Most of the compounds are water soluble, while 15–35% of bio-oil is water insoluble [227,228]. Chemical composition analysis of the water insoluble fraction showed a carbon content of 50–71%, hydrogen content of 5.8–6.7% and oxygen content of 23–43% [227,229]. The high oxygen content facilitates ageing reactions in the bio-oil, leading to an increased viscosity and average molecular weight from 530 to 990 g mol [230]. In addition, the low pH-value (2–3) of bio-oil increases the maintenance cost for the condenser and storage system [224]. PAHs were found in bio-oil within a range of 10 to 50 mg kg [231], which are accounted as harmful to the environment [185]. However, only one-third to two-third of the biooil compounds can been identified by GC-MS and HPLC [227,232].

About 10–20% of pyrolysis gas is formed by pyrolysis of biomass at temperatures up to 800 C [43,225,233]. The yield of pyrolysis gas increases with increasing heat treatment temperature and can be 75% at 1200 C [154]. Its composition is strongly affected by heat treatment temperature and operation of the kiln or retort. The pyrolysis gas in charcoal production is mainly composed of H (≤ 20.1%); CH (5–22.0%); CO (30.1–58%); CO (22.5–43%) and light hydrocarbons CH (2.3%) [210,222,223]. CO and CO concentrations are increased in classical charcoal production by the partly combustion of additional feedstock, whereas H concentration would increase at high heat treatment temperature by dehydrogenation reaction and carbonization of the charcoal [234]. Unburnt pyrolysis gas can therefore be accounted as a strong pollutant based on the high CO and CH concentration [5]. However, the gas can have a heating value of 8000 kJ m [5], respectively 2.3 MJ kg [161]. Therefore, the released volatiles during pyrolysis can be combusted to provide the thermal energy for the process [5].

3.3. By Product Utilization

Pyrolysis of biomass results in the formation of 50% of liquid and 20% of gaseous by-products. In current processes, by-products can be combusted to provide the thermal energy of the process, increasing the amount of (renewable) CO emissions at the same time. Unburnt by-products reduce the process efficiency and lead to net GHG emissions. Industrial retorts on the other hand recirculate the volatile compounds and can condensate parts as value-added by-products for consecutive processes [25]. Recent studies have shown that the charcoal yield can be increased by up to 5%-points by the bio-oil recirculation [63]. Pressurized retorts decompose a large fraction of the bio-oil inside the charcoal particles [157,158], decreasing the yield of high molecular hydrocarbons in the bio-oil.

The high molecular bio-oil can be used as feedstock material for green electrodes, as a feedstock in gasification, as a binder for briquetting or pelletizing or as fuel for boilers according to EN 16900, i.e., as standardized, readily marketable product [180,181]. Briquetting and pelletizing enable a conditioning of charcoal fines at the pyrolysis plant and thus, increase the carbon yield suitable in ferroalloy industry. In addition, the homogeneity of charcoal briquettes and pellets is increased. Green electrodes have successfully been produced from fast pyrolysis bio-oil [181], but composition of bio-oil from fast pyrolysis differs from that of slow pyrolysis [225,235]. The high water content and the large fraction of organic acids, such as acetic and propionic acid, inhibit a direct usage as engine fuel [61]. Distillation of the tarry compounds will result in the formation of 35–50% of solid residues [224] and is only limited applicable for the bio-oil conditioning. Recent studies focus on the bio-oil upgrading with in-situ generation of hydrogen [236].

Gasification of bio-oil can provide a synthetic gas for fuel and chemical production [237,238]. Some bio-oil components have established markets which were supplied by coke oven batteries and other pyrolysis processes before products were synthesized by natural gas and other fossil fuels, such as acetic acid. Bio-oil conditioning may provide renewable chemicals which can directly substitute fossil fuels in the future. In short term, bio-oil as a binder can increase the charcoal yield and concurrently reduce waste streams.

4. Charcoal Properties

Properties of charcoal are crucial for the use as a reductant in metallurgical processes [16,18]. To minimize changes in a process design and optimization, charcoal properties are expected to be similar to those of fossil-based reductants, as summarized in Table 5. Fossil-based reductants show high mechanical stability and low to medium gas reactivity at a low price, whereas charcoal has a high gas reactivity and low mechanical stability. In addition, charcoal has a lower density than fossil-based reductants, that may change the mass flow and volume distribution of the raw materials in the SAF. Charcoal is produced in large proportions by kilns as a household fuel that does not require specific properties. However, the quality of charcoal produced in kilns can significantly vary from one batch to another.

Table 5.

Required properties of carbon reductants in the ferro and ferroalloy industry [29,239,240,241,242,243,244,245].

Understanding mechanical, chemical, physical and electrical properties of charcoal is a key step that affects the use of charcoal in ferroalloy industries [16,18,29,239]. Mechanical strength is required to avoid collapse of the carbon bed by the load of the burden, while abrasive strength (or durability) is required to minimize generation of fines while handling and feeding of charcoal particles into the reactor [239]. Chemical properties such as carbon content and reactivity are essential to provide the carbon in the reaction zone, while ash content and composition of the feedstock can affect the product quality and energy demand [172]. Electrical properties are crucial for the quality of carbon bed material in the SAF to provide the thermal heat by electrical energy dissipation.

4.1. Chemical Analysis

While the charcoal yield is the most important variable for its production, specific charcoal properties are compulsory for its application. The chemical analysis comprises the proximate and ultimate analyses, as well as the structural properties. The carbonization degree increases with increasing heat treatment temperature, resulting in an greater fixed carbon content of the charcoal. The carbonization results in structural changes of the carbon matrix, affecting functional group and reactivity of the sample.

4.1.1. Proximate and Ultimate Analyses

Carbon content increases with increasing heat treatment temperature and residence time. Classical charcoal production results in a carbon content greater than 70% [161]. The proximate analysis of classical charcoal production is shown in Table 6. Based on the biomass feedstock, industrial retorts provide a carbon content of 80–94% [6,37]. Charcoal with a fixed carbon content greater than 83% is considered as barbecue charcoal according to EU requirements [6] and as metallurgical grade charcoal with a fixed carbon content greater than 85% [152]. A fixed carbon content greater than 85% is therefore recommended in ferroalloy production to minimize additional slag formation by ash constituents and off-gas cleaning by volatile matter [239]. Metallurgical coke used in a closed SAF has a volatile matter content less than 3 wt.% (generally 1–1.5% [246,247]), whereas more than 10% of volatiles are released by charcoal samples. Volatile matter content of charcoal pellets is increased to more than 24% by the addition of water and binder [105,172,247]. This high volatile matter content requires an improved off-gas cleaning system and increases the risk of slag foaming in secondary steelmaking routes [248]. One possibility to reduce volatile matter content similar to metallurgical coke is to use the secondary heat treatment at temperatures of 1300 C [63].

Table 6.

Proximate analysis of industrially produced charcoal.

The ash content of charcoal is correlated to the ash content of the feedstock. Therefore, the ash content is low for stem wood charcoal and relatively high for charcoal from herbaceous biomass i.e., wheat straw, rice husks, etc. [38,155]. Ash content with more than 8–12 wt.% should be avoided in SAF to reduce the amount of impurities and generated slag [239]. Biomass ash is rich in alkali and alkali earth metals compared to fossil fuels, but low in sulfur content. An increased input of alkali metals can cause corrosion issues in the off-gas system and change reduction stages in the burden [172].

4.1.2. Structural Analysis

The carbon structure of charcoal is highly affected by the heat treatment temperature and the surrounding atmosphere, for example gasification agents or oxygen. The higher carbonization degree at higher heat treatment temperature results in a decreased CO reactivity and increased electrical conductivity [1]. Torrefaction and low pyrolysis of biomass on the other hand only slightly increase the carbonization degree. The cellulose peak can be still observed by XRD analysis after a heat treatment at ≈340 C [220].

Charcoal produced at 240 C exhibited the same FT-IR bands as biomass, whereas specific bands of cellulose, hemicellulose and aromatic ring groups from lignin disappeared after a heat treatment temperature of 400 C [250]. This change in chemical composition started at temperatures above 350 C [251]. A uniform spectra with strong aryl carbon signals indicated poly-condensation of aromatic rings at temperatures above 500 C [220], in which fast pyrolysis char showed a lower aromaticity compared to classical charcoal from slow pyrolysis. In addition, these results correspond to mass loss curves from the thermogravimetric analysis [155,172].

Charcoal structure is different from fossil fuel reductants and graphite. The charcoal structure is characterized by the greater surface area and absorptive capacity than carbon black or graphite [40]. Structural changes in coal graphitization occur mainly in four temperature ranges, 1000–1500 C, 1500–2000 C, 2000–2500 C and 2500–3000 C [252,253]. The basic structural units reorganize between 800 and 1500 C and coalesce between 1600 to 2000 C [253]. A nano-crystalline structure of charcoal was observed at heat treatment temperatures larger than 1300 C [62,200]. This temperature range is above the production temperature of industrial charcoal, but structural changes will appear in the burden and carbon bed inside SAF. Charcoal produced at temperatures above 1000 C exhibited a similar structure to petroleum coke [254]. The increased graphitization with increasing heat treatment temperatures improves the electrical properties of the charcoal.

4.2. Density and Porosity

The density and porosity are important properties for the handling, transport and storage of bulk and compacted charcoal. Density of charcoal is highly affected by the feedstock and process conditions, in which pyrolysis of softwood results in a charcoal with a lower density compared to hardwood. Density of parental wood increases with age [255], resulting in a superior charcoal from older wood. However, due to the easier and less labor-intensive handing of young growth fresh wood, secondary forestry is commonly used as a feedstock in charcoal production [11]. A greater particle density results in improved mechanical and electrical properties, which are important properties for the renewable reductant. The skeletal density of charcoal produced at temperatures up to 500 C is similar to that of the parental wood (≈1400–1550) kg m [220,256]. Above 500 C, skeletal density starts to increase with increasing heat treatment temperature [155,208,257] to ≈1750 kg m at 700 C [258] and to ≈2000 kg m at 800 C [220].

While true density increases with increasing heat treatment temperature, charcoal’s bulk density is nearly constant in the temperature range from 450 to 650 C [257,258], leading to a greater BET surface area and porosity compared to low temperature treated charcoal. Metallurgical grade charcoal has a bulk density of 180 to 350 kg m [36,37,201], about half of that for metallurgical coke (450–600 kg m) [36,37,239,246], leading to higher transport and storage costs. In addition, the lower density of charcoal increases the volume fraction of the carbon reductant in the SAF, possibly decreasing the maximum load of the furnace by its available construction height.

The porosity of charcoal increased from ≈50% at 300 C to 50–70% at temperatures above 700 C [155,259]. The porosity of spruce charcoal was about 10% points larger than that of oak charcoal [62] and similar to that of grass charcoal [258] and other woody biomass species [123]. On the other hand, total porosity of metallurgical coke ranges from 25 to 62%, increasing with larger particle size [18,62,239]. It is known from cokes that the porous structure can affect the mechanical strength of particles [260]. While a relationship between tensile strength and pore structure of coke was determined in previous studies [261], no clear correlation was found for the mechanical strength and porosity by other authors [262].

Bulk density of charcoal can be increased to 900 kg m by agglomeration and compaction [172], in which an increased particle density is achieved by blending with an organic binder and increased compaction pressure [124,150]. The addition of organic binder such as lignosulphonate and bio-oil significantly improved the density and mechanical durability of charcoal pellets [150]. A further increase in a bulk density was reported by the increased residence time of pellets and briquettes during compaction [124]. An apparent density of about 1000 kg m was reported for charcoal produced under a compressive pressure of 500 kPa, that was similar to that of metallurgical coke [259]. On the other hand, the addition of 5% sawdust to a coal blend resulted in a slightly decreased bulk density of coke, from 780 kg m for metallurgical coke to 770 kg m for bio-coke [262].

4.3. Surface Area

Operation of SAF is affected by the gas reactivity of the carbon material in the burden due to the reaction with CO and SiO. The gas reactivity depends on the accessible surface area and presence of functional groups on the surface. The morphology of charcoal is highly affected by the heat treatment temperature, residence time and gas pressure [263]. The specific surface area increased from 5 m g at 300 C to 80 m g at 500–600 C [32,264,265,266] and further to 500 m g at 800–900 C [99,213]. Above 1000 C, the specific surface area of charcoal decreased to about 10 m g [62,99]. The increase in surface area was correlated to the increase in micro- and mesoporosity and the collapse of micropores thereafter [32,263].

Charcoal produced at intermediate pyrolysis pressure (10 bar) showed a smaller surface area than charcoal generated at low pressure (5 bar), respectively high pyrolysis pressure (20 bar) [263]. Yang et al. reported that the surface area decreased with increasing heating rate [35] and was generally lower for herbaceous charcoal than for woody charcoal [32]. The results indicate that the release and secondary pyrolysis reactions of volatile matter has a high impact on the surface area of charcoal. Fossil fuel reductants, such as metallurgical coke, bio-coke and petroleum coke, exhibit a surface area of less than 3 m g [21,63,267]. Metallurgical coke and bio-cokes are produced at temperatures above 1100 C, while petroleum coke is the solidified residue from crude oil distillation. Differences in the accessibility were observed for the surface characterization in N and CO. Surface area from oak and pine charcoal increases from less than 3 m g at 400 C to 220–280 m g at 650 C for measurements in N, respectively from 250 to 530 m g for oak and 360 to 650 m g for pine in CO [268]. Thus, the accessibility of gas species into the pore volume can also affect the reactivity in different atmospheres.

4.4. Mechanical Properties

Mechanical properties of charcoal are essential to avoid generation of fine particles by transport, handling and feeding into the SAF. The furnace operation and off-gas cleaning system are significantly affected by the particle size of original feedstock and charcoal [18]. In general, charcoal is more fragile than fossil fuels samples due to its high porosity and lower carbonization degree [253]. Global charcoal transport results in the generation of 5–20% fines [159,269,270,271] due to the loading and unloading of the charcoal [271]. This material is not directly suitable for a usage in SAF, since a particle size of 5–40 mm is required for ferroalloy industry to ensure a good gas permeability [29,239]. In particular, the silicomanganese industry uses fossil fuel reductants with a particle size ranging from 5 to 20 mm [29]. Thus, particles less than 5 mm are considered as fines and should be avoided.

Standard tests for measuring the mechanical properties are drum tests, such as ASTM D 294-64, ISO 556 and DIN 5171 for coke, and DIN EN ISO 17831-1 for pellets and briquettes. In addition, mechanical fragmentation is investigated by the drop shatter test for coal according to ASTM D440. Hot strength of metallurgical coke is investigated by the coke strength after reaction (CSR). The combination of hot strength and CO reactivity are important parameters to evaluate the quality of reductants in the burden [37], especially for blast furnaces. However, most of the standards are not applicable for charcoal and have therefore been modified by the researchers [36,37].

While a very high compression strength is required in blast furnaces, mechanical strength is of less importance in SAF due to the low height of the burden [40,239]. Compressive strength of charcoal is 10–80 kg cm, about half of that of metallurgical coke (130–160 kg cm) [36,201]. Charcoal produced from hardwoods have generally a greater mechanical strength than charcoal from softwood or herbaceous biomass [152] and the mechanical strength is 3 to 4 times greater in the growing direction of wood fibers compared to its perpendicular direction [36]. The compression strength slightly increased after the sample was heat treated to elevated temperatures [201,272], indicating improved mechanical properties inside the SAF. Carbonized wood is about 28% stronger than its biomass precursor [273].

4.5. Charcoal Compaction

Charcoal produced at elevated temperatures has a lower tendency to agglomerate compared to raw biomass and requires the addition of a binder for compaction [123]. Charcoal fines can be compacted by pelletization and briquetting to increase bulk density and mechanical stability for the use in metallurgical industry [124,172,274]. Coal tar, coal tar pitch and bio-oil pitch have been used as binder for special purposes over decades [271]. Recent studies have confirmed that the mechanical properties can be improved for charcoal pellets and briquettes by the addition of bio-oil and bio-oil pitch and a second heat treatment [63,150,275]. The mechanical durability of the pellets increased to greater than 90% [150], similar to that of heat treated hydrochar pellets [129]. Pellets compacted at 116 MPa with an oil concentration of 34% provided optimal pelletizing conditions [180]. A slightly better mechanical durability was achieved by adding water and molasses at a compaction pressure of 100 MPa [172]. One of the major disadvantages of molasses is the addition of mineral matter (especially potassium) to charcoal pellets and briquettes. Other important parameter are particle size and moisture content, and the glass transition temperature for lignocellulosic binder [124]. Drop strength tests approved the results from mechanical durability test for charcoal pellets [172].

The compressive strength of charcoal pellets increased from less than 1 MPa to greater than 2 MPa after the secondary heat treatment [150]. A similar compressive strength was reported for charcoal briquettes using bio-oil binder [275]. The mechanical compression resistance of green pellets produced with molasses as a binder increased from 1 MPa to 2.6 MPa after storage for 12 days [172]. Similar values were found for fossil fuel briquettes compacted at 56 kPa [199], in which a higher compaction pressure resulted in improved mechanical properties and hardwood lignin developed twice the compressive strength than softwood lignin. Lignin as a binder was improved by adding tannic acid, in which the mechanical strength was also obtained as hot strength for temperatures up to 1400 C [199]. A compressive strength of 4.2 MPa was reported for briquettes using starch binder [275], which was similar to that of charcoal pellets using bio-oil binder [150]. To ensure mechanical strength at higher temperatures, silicon metal can be added to the charcoal fines, forming a network of silicon carbide nanowires between the carbon matrix [276]. The carbide nanowires improved the resistance to compaction from 1 MPa to 3–4 MPa at 1200–1400 C [199].

Pellets started to shrink after the primary heat treatment temperature was surpassed [142]. This additional size reduction must be considered if the particle size of charcoal pellets is close to the minimum particle size requirements. Pellets from fast pyrolysis and slow pyrolysis differ by its aromaticity and volatile matter content [172], leading to differences in a shrinkage at higher temperature. If lignin is selected as binder, a secondary heat treatment temperature above 450 C should be chosen to form polyaromatic structures between the particles [277]. The additional heat treatment at elevated temperature also reduces the risk of self-heating under transport and storage [274] and decreases CO reactivity [142]. In summary, the quality of pellets and briquettes is highly improved by the second heat treatment.

4.6. Electrical Properties

The electrical conductivity is one of the most important properties of carbon reductants in SAF and EAF [239,253,278]. The electrical conductivity of charcoal is affected by the heat treatment temperature (carbonization degree), density of the packed bed, particle size and volume fraction of carbon, as well as operating temperature and pressure inside the furnace [1,201,253,279,280]. Metallurgical coke used in SAF is expected to have an electrical resistivity of 7–10 m m at room temperature and 1–10 m m at 1400 C for a particle size of 5–20 mm [37,239,280]. Charcoal on the other hand has an electrical resistivity above 10 m at room temperature, decreasing to 14–23 m m at 1000 C and 9–18 m m at 1400–1600 C for 5–35 mm respectively 5–10 mm particles [37,201]. The electrical resistivity of charcoal particles from a heat treatment at 950 C was similar to that of fossil fuel coal char ranging from 1.7 to 3.4 m m [281].

The electrical resistivity of packed carbon beds is higher than that of particles due to larger contact resistance between particles [279,282]. Electrical resistivity of metallurgical coke decreased from 10–15 m m at 1000 C to 5–8 m m at 1600 C [37,201]. Packed beds of charcoal particles larger than 2 mm showed an electrical resistivity of 50 m m at 1100 C and 15–20 m m at 1600 C [37,201]. The electrical resistivity of metallurgical coke decreased by 50% when the particle size increased from 5–10 mm to 15–20 mm [280]. However, the previous results have also shown that only minimal differences were observed for small and large sizes of charcoal particles [201]. The compaction pressure of the burden has a large impact on the electrical resistivity. An increased compaction pressure decreases the air gap between particles and increases the number of contact points between the particles, resulting in a decreased electrical resistivity [18,201,279,283].

The loss in ohmic resistance can be attributed to the removal of oxygen groups by carbonization from the carbon matrix [252,284], especially at temperatures less than 950 C. The high oxygen content and disordered carbon structure act as insulators in the carbon matrix of biomass, charcoal and coal [1,285,286,287], in which a decrease in electrical resistivity of 5 orders of magnitude was observed after the release of volatile matter [1,288]. Therefore, electrical resistivity of carbon reductants can be correlated to the ordering of the carbon matrix and its reactivity [281]. The higher electrical resistivity of charcoal inhibits the conduction of current through the burden inside the SAF [288,289], where ≈5–15% of current is conducted through [18]. In addition, the higher electrical resistivity of the charcoal enables a lower electrode tip position, which improves heat distribution in the lower part of SAF [280].

4.7. Gas Reactivity

Gas reactivity of carbon reductants is an important property for the burden in SAF. About 30% of the CO emission from ferro-managnese and silicomanganese production are related to the Boudouard reaction (C(s) + CO⇌ 2 CO) [290], indicating the importance of a low gas reactivity towards CO. A high reaction rate will increase the coke and power consumption and is therefore undesirable in silicomanganese and ferromanganese production [36]. The CO reactivity of metallurgical coke is investigated according to coke reactivity index (CRI), where the mass loss is measured by difference after a 2 h heat treatment (1100 C) in pure CO. The standard can not directly be adopted for charcoal samples due to its high gas reactivity. By AC-method, charcoals reactivity can be 30 to 40 times larger compared to metallurgical coke [36]. Many researchers investigate the CO reactivity by thermogravimetric analysis at lower temperature, lower CO concentration or by non-isothermal analysis [37,63,204,291,292]. In addition, knowledge of the CO reactivity can be adopted from fixed bed biomass gasification for syngas production [293].