A Novel Approach Using Conventional Methodologies to Scale up BNC Production Using Komagataeibacter medellinensis and Rotten Banana Waste as Alternative

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microorganisms and Seed Culture

2.2. Rotten Banana Culture Medium and Production of BNC

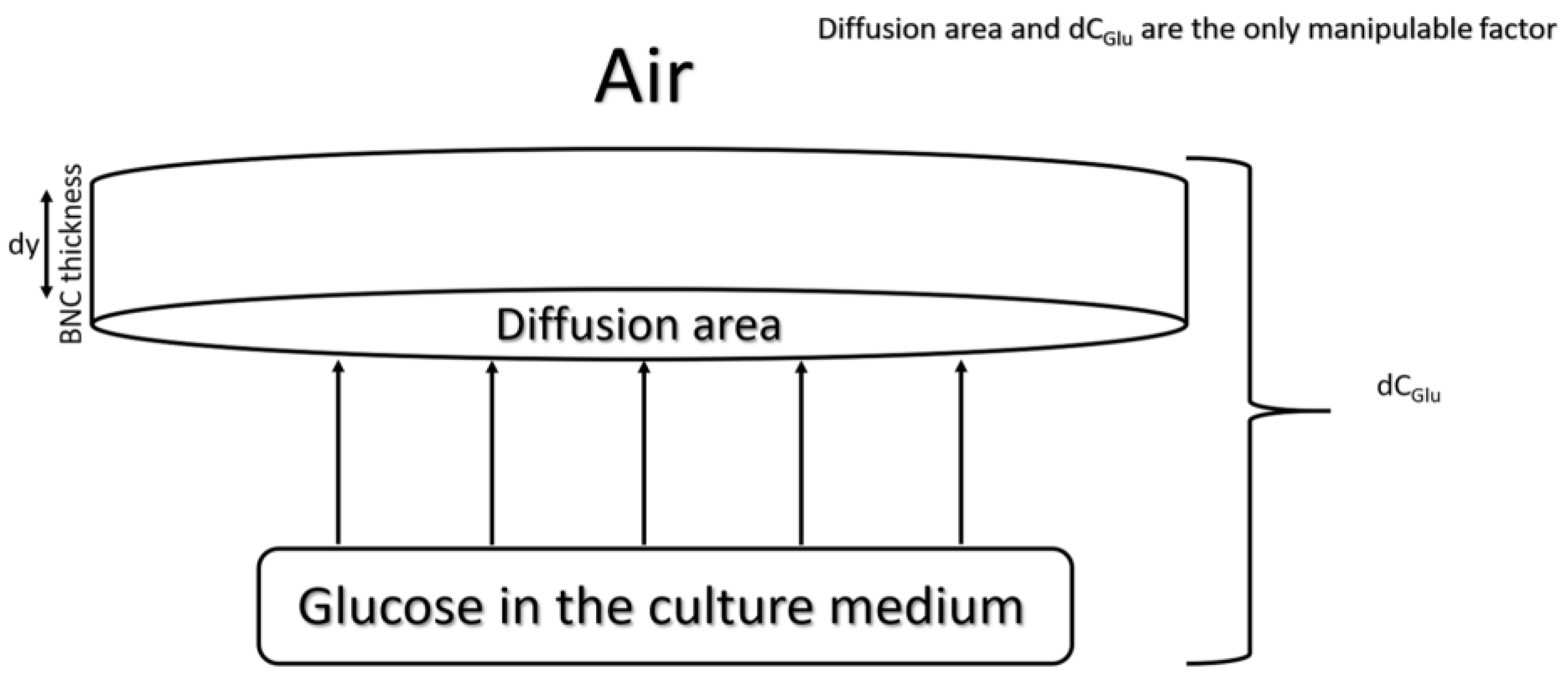

2.3. Design of Experiments

2.4. Fractional Factorial Design

2.5. Central Composite Design

2.6. Scale-up of the Bioreactor

3. Results and Discussion

3.1. Design of the Experiments and Optimization of the BNC Yield

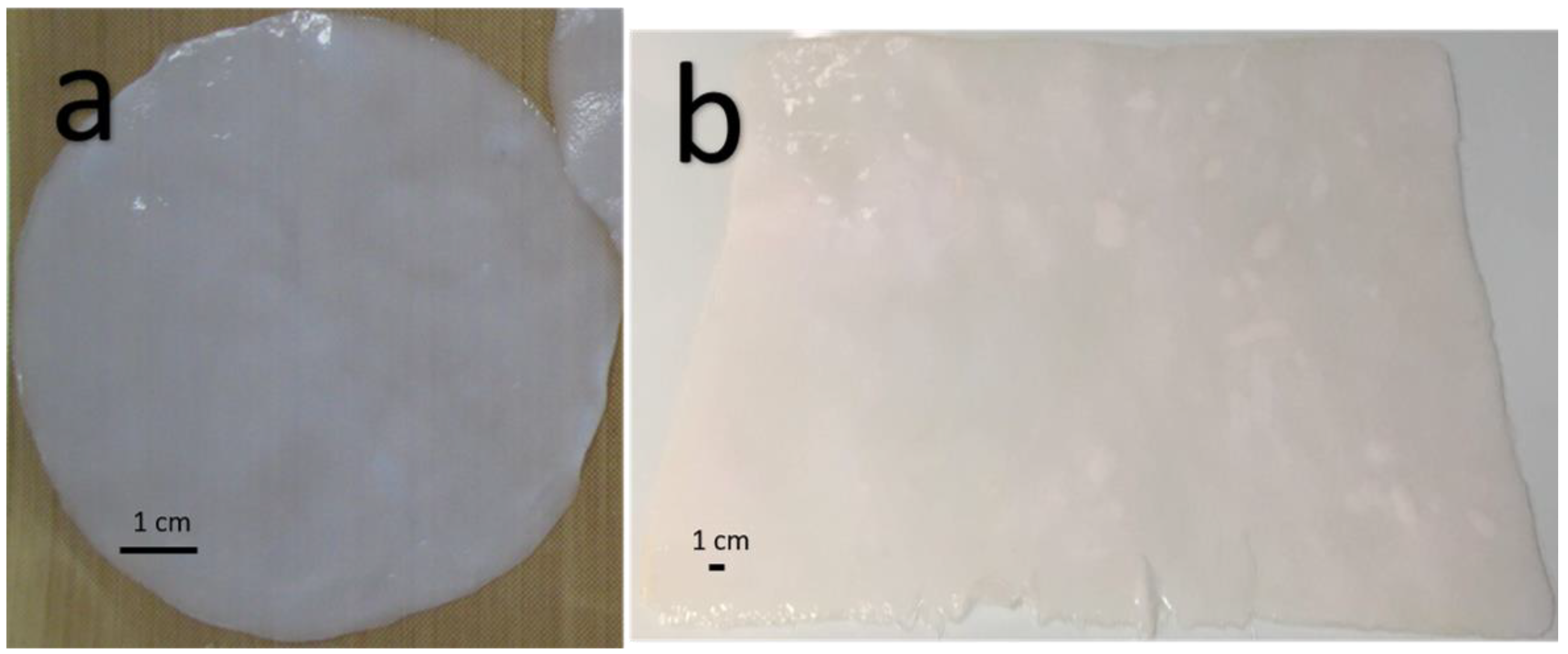

3.2. Scale-up of BNC Production under Static Conditions

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fan, X.; Gao, Y.; He, W.; Hu, H.; Tian, M.; Wang, K.; Pan, S. Production of nano bacterial cellulose from beverage industrial waste of citrus peel and pomace using Komagataeibacter xylinus. Carbohydr. Polym. 2016, 151, 1068–1072. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Zhang, Y.; Phillips, G.O.; Yang, G. Utilization of bacterial cellulose in food. Food Hydrocoll. 2014, 35, 539–545. [Google Scholar] [CrossRef]

- Santos, S.M.; Carbajo, J.M.; Gómez, N.; Quintana, E.; Ladero, M.; Sánchez, A.; Chinga-Carrasco, G.; Villar, J.C. Use of bacterial cellulose in degraded paper restoration. Part II: Application on real samples. J. Mater. Sci. 2015, 51, 1553–1561. [Google Scholar] [CrossRef]

- Gayathry, G.; Gopalaswamy, G. Production and characterisation of microbial cellulosic fibre from Acetobacter xylinum. Indian J. Fibre Text. Res. 2014, 39, 93–96. Available online: http://hdl.handle.net/123456789/27372 (accessed on 15 November 2020).

- Cherian, B.M.; Leão, A.L.; de Souza, S.F.; de Olyveira, G.M.; Costa, L.M.; Brandão, C.V.; Narine, S.S. Bacterial Nanocellulose for Medical Implants. In Advances in Natural Polymers; Springer: Berlin/Heidelberg, Germany, 2013; Volume 18, pp. 337–359. [Google Scholar]

- Shah, N.; Ul-Islam, M.; Khattak, W.A.; Park, J.K. Overview of bacterial cellulose composites: A multipurpose advanced material. Carbohydr. Polym. 2013, 98, 1585–1598. [Google Scholar] [CrossRef]

- Phisalaphong, M.; Tran, T.-K.; Taokaew, S.; Budiraharjo, R.; Febriana, G.G.; Nguyen, D.-N.; Chu-Ky, S.; Dourado, F. Nata de coco Industry in Vietnam, Thailand, and Indonesia. In Bacterial Nanocellulose: From Biotechnology to Bio-Economy; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 231–236. [Google Scholar]

- Piadozo, M.E.S. Nata de Coco Industry in the Philippines. In Bacterial Nanocellulose: From Biotechnology to Bio-Economy; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 215–229. [Google Scholar]

- Hornung, M.; Ludwig, M.; Schmauder, H.P. Optimizing the Production of Bacterial Cellulose in Surface Culture: A Novel Aerosol Bioreactor Working on a Fed Batch Principle (Part 3). Eng. Life Sci. 2007, 7, 35–41. [Google Scholar] [CrossRef]

- Kralisch, D.; Hessler, N.; Klemm, D.; Erdmann, R.; Schmidt, W. White biotechnology for cellulose manufacturing—The HoLiR concept. Biotechnol. Bioeng. 2009, 105. [Google Scholar] [CrossRef]

- Chao, Y.; Ishida, T.; Sugano, Y.; Shoda, M. Bacterial cellulose production by Acetobacter xylinum in a 50-L internal-loop airlift reactor. Biotechnol. Bioeng. 2000, 68, 345–358. [Google Scholar] [CrossRef]

- Song, H.-J.; Li, H.; Seo, J.-H.; Kim, M.-J.; Kim, S.-J. Pilot-scale production of bacterial cellulose by a spherical type bubble column bioreactor using saccharified food wastes. Korean J. Chem. Eng. 2009, 26, 141–146. [Google Scholar] [CrossRef]

- Chen, G.; Wu, G.; Alriksson, B.; Chen, L.; Wang, W.; Jönsson, L.J.; Hong, F.F. Scale-up of production of bacterial nanocellulose using submerged cultivation. J. Chem. Technol. Biotechnol. 2018, 93, 3418–3427. [Google Scholar] [CrossRef]

- Kongruang, S. Bacterial cellulose production by Acetobacter xylinum strains from agricultural waste products. Appl. Biochem. Biotechnol. 2008, 148, 245–256. [Google Scholar] [CrossRef]

- Mustafa, A.; Babaeipour, V.; Roochi, M.; Kranchezar, S. Enhancement of bacterial cellulose (BC) production by optimizing of inoculation condition: RSM approach. Iran Polym. Petrochem. Inst. 2014, 11. [Google Scholar]

- Shoda, M.; Sugano, Y. Recent advances in bacterial cellulose production. Biotechnol. Bioprocess Eng. 2005, 10, 1–8. [Google Scholar] [CrossRef]

- Naritomi, T.; Kouda, T.; Yano, H.; Yoshinaga, F. Effect of ethanol on bacterial cellulose production from fructose in continuous culture. J. Ferment. Bioeng. 1998, 85, 598–603. [Google Scholar] [CrossRef]

- Molina-Ramírez, C.; Castro, C.; Zuluaga, R.; Gañán, P. Physical Characterization of Bacterial Cellulose Produced by Komagataeibacter medellinensis Using Food Supply Chain Waste and Agricultural By-Products as Alternative Low-Cost Feedstocks. J. Polym. Environ. 2017, 26, 830–837. [Google Scholar] [CrossRef]

- Molina-Ramírez, C.; Cañas-Gutiérrez, A.; Castro, C.; Zuluaga, R.; Gañán, P. Effect of production process scale-up on the characteristics and properties of bacterial nanocellulose obtained from overripe Banana culture medium. Carbohydr. Polym. 2020, 240, 116341. [Google Scholar] [CrossRef]

- Kralisch, D.; Hessler, N. Large-Scale Production of BNC: State and Challenges. In Bacterial NanoCellulose: A Sophisticated Multifunctional Material; CRC Press: Boca Raton, FL, USA, 2016; pp. 76–105. [Google Scholar]

- Hestrin, S.; Schramm, M. Synthesis of cellulose by Acetobacter xylinum. 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose*. Biochem. J. 1954, 58, 345–352. Available online: http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1269899/ (accessed on 15 November 2020). [CrossRef] [Green Version]

- Cakar, F.; Özer, I.; Aytekin, A.Ö.; Şahin, F. Improvement production of bacterial cellulose by semi-continuous process in molasses medium. Carbohydr. Polym. 2014, 106, 7–13. [Google Scholar] [CrossRef]

- Jozala, A.F.; Pértile, R.A.N.; Dos Santos, C.A.; Santos-Ebinuma, V.D.C.; Seckler, M.M.; Gama, F.M.; Pessoa, A. Bacterial cellulose production by Gluconacetobacter xylinus by employing alternative culture media. Appl. Microbiol. Biotechnol. 2015, 99, 1181–1190. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.S.K.; Pfaltzgraff, L.A.; Herrero-Davila, L.; Mubofu, E.B.; Abderrahim, S.; Clark, J.H.; Koutinas, A.; Kopsahelis, N.; Stamatelatou, K.; Dickson, F.; et al. Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ. Sci. 2013, 6, 426–464. [Google Scholar] [CrossRef]

- FAO. Global Food Losses and Food Waste-Extent, Causes and Prevention; 2011; Available online: http://www.fao.org/3/mb060e/mb060e00.htm (accessed on 15 November 2020).

- Ploetz, R.C.; Evans, E.A. The Future of Global Banana Production. In Horticultural Reviews; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; Volume 43, pp. 311–352. [Google Scholar]

- Goswami, B.; Borthakur, A. Chemical and biochemical aspects of developing culinary banana (Musa ABB) ‘Kachkal’. Food Chem. 1996, 55, 169–172. [Google Scholar] [CrossRef]

- Cano, M.P.; De Ancos, B.; Matallana, M.; Cámara, M.; Reglero, G.; Tabera, J. Differences among Spanish and Latin-American banana cultivars: Morphological, chemical and sensory characteristics. Food Chem. 1997, 59, 411–419. [Google Scholar] [CrossRef] [Green Version]

- Mustaffa, R.; Osman, A.; Yusof, S.; Mohamed, S. Physico-chemical changes in Cavendish banana (Musa cavendishiiL var Montel) at different positions within a bunch during development and maturation. J. Sci. Food Agric. 1998, 78, 201–207. [Google Scholar] [CrossRef] [Green Version]

- Emaga, T.H.; Andrianaivo, R.H.; Wathelet, B.; Tchango, J.T.; Paquot, M. Effects of the stage of maturation and varieties on the chemical composition of banana and plantain peels. Food Chem. 2007, 103, 590–600. [Google Scholar] [CrossRef]

- Aurore, G.; Parfait, B.; Fahrasmane, L. Bananas, raw materials for making processed food products. Trends Food Sci. Technol. 2009, 20, 78–91. [Google Scholar] [CrossRef]

- Davey, K.; Cerf, O. Predicting Concomitant Denaturation of Vitamin as Influenced by Combined Process Temperature and pH in Batch and Continuous Flow Sterilization of Liquids. Food Bioprod. Process. 1996, 74, 200–206. [Google Scholar] [CrossRef]

- Krystynowicz, A.; Czaja, W.; Wiktorowska-Jezierska, A.; Turkiewicz, M.; Bielecki, S. Factors affecting the yield and properties of bacterial cellulose. J. Ind. Microbiol. Biotechnol. 2002, 29, 189–195. [Google Scholar] [CrossRef]

- Matsutani, M.; Ito, K.; Azuma, Y.; Ogino, H.; Shirai, M.; Yakushi, T.; Matsushita, K. Adaptive mutation related to cellulose producibility in Komagataeibacter medellinensis (Gluconacetobacter xylinus) NBRC 3288. Appl. Microbiol. Biotechnol. 2015, 99, 7229–7240. [Google Scholar] [CrossRef]

- Ju, L.-K.; Chase, G. Improved scale-up strategies of bioreactors. Bioprocess Biosyst. Eng. 1992, 8, 49–53. [Google Scholar] [CrossRef]

- Villadsen, J.; Nielsen, J.; Lidén, G. Scale-Up of Bioprocesses. In Bioreaction Engineering Principles; Springer US: Boston, MA, USA, 2011; pp. 497–546. [Google Scholar]

- Castro, C.; Cleenwerck, I.; Trček, J.; Zuluaga, R.; De Vos, P.; Caro, G.; Aguirre, R.; Putaux, J.-L.; Gañán, P. Gluconacetobacter medellinensis sp. nov., cellulose- and non-cellulose-producing acetic acid bacteria isolated from vinegar. Int. J. Syst. Evol. Microbiol. 2013, 63, 1119–1125. [Google Scholar] [CrossRef] [Green Version]

- Ruka, D.R.; Simon, G.P.; Dean, K. Altering the growth conditions of Gluconacetobacter xylinus to maximize the yield of bacterial cellulose. Carbohydr. Polym. 2012, 89, 613–622. [Google Scholar] [CrossRef] [PubMed]

- Mohite, B.V.; Kamalja, K.K.; Patil, S.V. Statistical optimization of culture conditions for enhanced bacterial cellulose production by Gluconoacetobacter hansenii NCIM 2529. Cellulose 2012, 19, 1655–1666. [Google Scholar] [CrossRef]

- Molina-Ramírez, C.; Zuluaga, R.; Castro, C.; Gañán, P. Statistical optimization of culture conditions to improve cell density of Komagataeibacter medellinensis NBRC 3288: The first step towards to optimize bacterial cellulose production. bioRxiv 2018, 381186. [Google Scholar] [CrossRef]

- Zwietering, M.H.; Jongenburger, I.; Rombouts, F.M.; Riet, K.V. T Modeling of the Bacterial Growth Curve. Appl. Environ. Microbiol. 1990, 56, 1875–1881. Available online: http://www.ncbi.nlm.nih.gov/pubmed/16348228 (accessed on 15 November 2020). [CrossRef] [PubMed] [Green Version]

- Díez-Sales, O.; Copoví, A.; Casabó, V.; Herraez, M. A modelistic approach showing the importance of the stagnant aqueous layers in in vitro diffusion studies, and in vitro-in vivo correlations. Int. J. Pharm. 1991, 77, 1–11. [Google Scholar] [CrossRef]

- Crooks, J.E. Measurement of diffusion coefficients. J. Chem. Educ. 1989, 66, 614. Available online: https://pubs.acs.org/sharingguidelines (accessed on 15 November 2020). [CrossRef]

- Cocinero, E.J.; Gamblin, D.P.; Davis, B.G.; Simons, J.P. The Building Blocks of Cellulose: The Intrinsic Conformational Structures of Cellobiose, Its Epimer, Lactose, and Their Singly Hydrated Complexes. J. Am. Chem. Soc. 2009, 131, 11117–11123. [Google Scholar] [CrossRef]

- Molina-Ramírez, C.; Castro, M.; Osorio, M.; Torres-Taborda, M.; Gómez, B.; Zuluaga, R.; Gómez, C.; Gañán, P.; Rojas, O.J.; Castro, C. Effect of Different Carbon Sources on Bacterial Nanocellulose Production and Structure Using the Low pH Resistant Strain Komagataeibacter Medellinensis. Materials. 2017, 10, 639. [Google Scholar] [CrossRef]

- Ito, H.; Ueno, H.; Kikuzaki, H. Free Amino Acid Compositions for Fruits. J. Nutr. Diet. Pract. 2017, 1, 1–5. [Google Scholar]

- Keshk, S.M. Vitamin C enhances bacterial cellulose production in Gluconacetobacter xylinus. Carbohydr. Polym. 2014, 99, 98–100. [Google Scholar] [CrossRef]

- Kouda, T.; Yano, H.; Yoshinaga, F. Effect of agitator configuration on bacterial cellulose productivity in aerated and agitated culture. J. Ferment. Bioeng. 1997, 83, 371–376. [Google Scholar] [CrossRef]

- Matsuoka, M.; Tsuchida, T.; Matsushita, K.; Adachi, O.; Yoshinaga, F. A Synthetic Medium for Bacterial Cellulose Production byAcetobacter xylinumsubsp.sucrofermentans. Biosci. Biotechnol. Biochem. 1996, 60, 575–579. [Google Scholar] [CrossRef]

- Laidler, K.J.; Shuler, K.E. The Kinetics of Membrane Processes. I. The Mechanism and the Kinetic Laws for Diffusion through Membranes. J. Chem. Phys. 1949, 17, 851. [Google Scholar] [CrossRef]

- Hornung, M.; Ludwig, M.; Gerrard, A.M.; Schmauder, H.-P. Optimizing the Production of Bacterial Cellulose in Surface Culture: Evaluation of Substrate Mass Transfer Influences on the Bioreaction (Part 1). Eng. Life Sci. 2006, 6, 537–545. [Google Scholar] [CrossRef]

- Sweere, A.; Luyben, K.; Kossen, N. Regime analysis and scale-down: Tools to investigate the performance of bioreactors. Enzym. Microb. Technol. 1987, 9, 386–398. [Google Scholar] [CrossRef]

- Mavituna, F. Strategies for Bioreactor Scale-Up. In Computer and Information Science Applications in Bioprocess Engineering; Springer Science and Business Media LLC: Dordrecht, The Netherlands, 1996; pp. 125–142. [Google Scholar]

- Verschuren, P.G.; Cardona, T.D.; Nout, M.; De Gooijer, K.D.; Heuvel, J.C.V.D. Location and limitation of cellulose production by Acetobacter xylinum established from oxygen profiles. J. Biosci. Bioeng. 2000, 89, 414–419. [Google Scholar] [CrossRef]

- Doran, P.M. Mass Transfer. In Bioprocess Engineering Principles; Elsevier: Amsterdam, The Netherlands, 2013; pp. 379–444. [Google Scholar]

| Factor | Coded Name | Levels | |

|---|---|---|---|

| Low | High | ||

| Glucose concentration (g/L) | X1 | 10.0 | 30.0 |

| Ethanol concentration (g/L) | X2 | 0.0 | 1.0 |

| Inoculum concentration (g/L) | X3 | 0.14 | 0.42 |

| Inoculum age (h) | X4 | 24 | 48 |

| Volume/area ratio (cm) | X5 | 2.0 | 4.0 |

| Run | Coded Factors | BNC Yield (g/L) | ||||

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | X5 | ||

| 1 | 30.0 | 0.0 | 0.14 | 24 | 2.0 | 2.34 |

| 2 | 30.0 | 0.0 | 0.42 | 48 | 2.0 | 2.29 |

| 3 | 30.0 | 1.0 | 0.14 | 24 | 4.0 | 1.89 |

| 4 | 30.0 | 1.0 | 0.14 | 48 | 2.0 | 1.75 |

| 5 | 30.0 | 1.0 | 0.42 | 48 | 4.0 | 2.03 |

| 6 | 20.0 | 0.5 | 0.28 | 36 | 3.0 | 1.94 |

| 7 | 30.0 | 1.0 | 0.42 | 24 | 2.0 | 2.88 |

| 8 | 10.0 | 0.0 | 0.14 | 24 | 4.0 | 0.71 |

| 9 | 10.0 | 1.0 | 0.14 | 24 | 2.0 | 1.35 |

| 10 | 10.0 | 1.0 | 0.42 | 48 | 2.0 | 1.04 |

| 11 | 30.0 | 0.0 | 0.42 | 24 | 4.0 | 1.81 |

| 12 | 30.0 | 0.0 | 0.14 | 48 | 4.0 | 1.92 |

| 13 | 10.0 | 0.0 | 0.42 | 24 | 2.0 | 1.12 |

| 14 | 20.0 | 0.5 | 0.28 | 36 | 3.0 | 1.92 |

| 15 | 10.0 | 1.0 | 0.42 | 24 | 4.0 | 0.82 |

| 16 | 10.0 | 0.0 | 0.42 | 48 | 4.0 | 0.76 |

| 17 | 20.0 | 0.5 | 0.28 | 36 | 3.0 | 1.88 |

| 18 | 20.0 | 0.5 | 0.28 | 36 | 3.0 | 1.81 |

| 19 | 10.0 | 1.0 | 0.14 | 48 | 4.0 | 1.01 |

| 20 | 10.0 | 0.0 | 0.14 | 48 | 2.0 | 0.48 |

| Run | Coded Factor | BNC Yield (g/L) | |

|---|---|---|---|

| X1 | X5 | ||

| 1 | 30.0 | 2.0 | 3.04 |

| 2 | 25.0 | 1.50 | 3.08 |

| 3 | 30.0 | 2.0 | 3.44 |

| 4 | 30.0 | 2.0 | 3.63 |

| 5 | 23.0 | 2.0 | 3.45 |

| 6 | 30.0 | 2.0 | 3.44 |

| 7 | 30.0 | 2.70 | 3.09 |

| 8 | 37.0 | 2.0 | 2.12 |

| 9 | 35.0 | 2.50 | 2.68 |

| 10 | 30.0 | 1.30 | 2.53 |

| 11 | 30.0 | 2.0 | 3.29 |

| 12 | 35.0 | 1.50 | 1.97 |

| 13 | 30.0 | 2.0 | 3.48 |

| 14 | 30.0 | 2.0 | 3.49 |

| 15 | 25.0 | 2.50 | 3.53 |

| 16 | 30.0 | 2.0 | 3.23 |

| Mechanism | Parameter | Characteristic Time (h) |

|---|---|---|

| Transport Phenomena | ||

| Glucose diffusion | DGlu = 1.22 × 10−13 m2/s | 675.47 |

| Conversion Phenomena | ||

| Microbial growth | µm = 0.06 h−1 | 15.62 |

| BNC production | µP = 0.02 h−1 | 44.92 |

| Glucose consumption | µGlu = 0.22 h−1 | 4.51 |

| Dry Weight (g) | Yield (in Total Volume, g/L) | Yield (by Surface Area, g/m2) | Characterization of Samples * | |||||

|---|---|---|---|---|---|---|---|---|

| Nanofibers Diameters (nm) | Porous Size Mean (nm) | Maximun Degradation Temperature Rate (°C) | Crystallinity Index (%) | Modulusof Elasticity (MPa) | ||||

| Glass vessel (small scale) | 0.46 | 5 | 109 | 110.14 | 20.69 | 357.5 | 82.93 | 1149.84 |

| Plastic bioreactor | 16 | 4 | 89 | 64.38 | 16.88 | 353.3 | 81.56 | 569.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molina-Ramírez, C.; Álvarez, J.; Zuluaga, R.; Castro, C.; Gañán, P. A Novel Approach Using Conventional Methodologies to Scale up BNC Production Using Komagataeibacter medellinensis and Rotten Banana Waste as Alternative. Processes 2020, 8, 1469. https://doi.org/10.3390/pr8111469

Molina-Ramírez C, Álvarez J, Zuluaga R, Castro C, Gañán P. A Novel Approach Using Conventional Methodologies to Scale up BNC Production Using Komagataeibacter medellinensis and Rotten Banana Waste as Alternative. Processes. 2020; 8(11):1469. https://doi.org/10.3390/pr8111469

Chicago/Turabian StyleMolina-Ramírez, Carlos, Juan Álvarez, Robin Zuluaga, Cristina Castro, and Piedad Gañán. 2020. "A Novel Approach Using Conventional Methodologies to Scale up BNC Production Using Komagataeibacter medellinensis and Rotten Banana Waste as Alternative" Processes 8, no. 11: 1469. https://doi.org/10.3390/pr8111469