Starting Conditions of Particle Migration in Tight Sandstone Reservoir Development

Abstract

1. Introduction

2. Motion Conditions of Particles in Non-Newtonian Fluid

2.1. Drag Force and Lift Force

2.1.1. Drag Force

2.1.2. Lift Force

2.2. Non-Newtonian Fluid

2.3. Contact Force

2.4. Particle Separation Conditions

3. Particle Transport Caused by Non-Newtonian Fluid

- (1)

- The main forces of particles in the fluid are drag and lift. Their strength and change trend determine the difficulty of particles moving in the fluid to a certain extent. When K1 = 1.2, n = 0.57 and H = 40 μm, the drag and lift increase with the increase in particle size. The difference is that the curve of drag is closer to the first-order relationship, while the curve of lift is closer to the second-order relationship, as shown in Figure 2.

- (2)

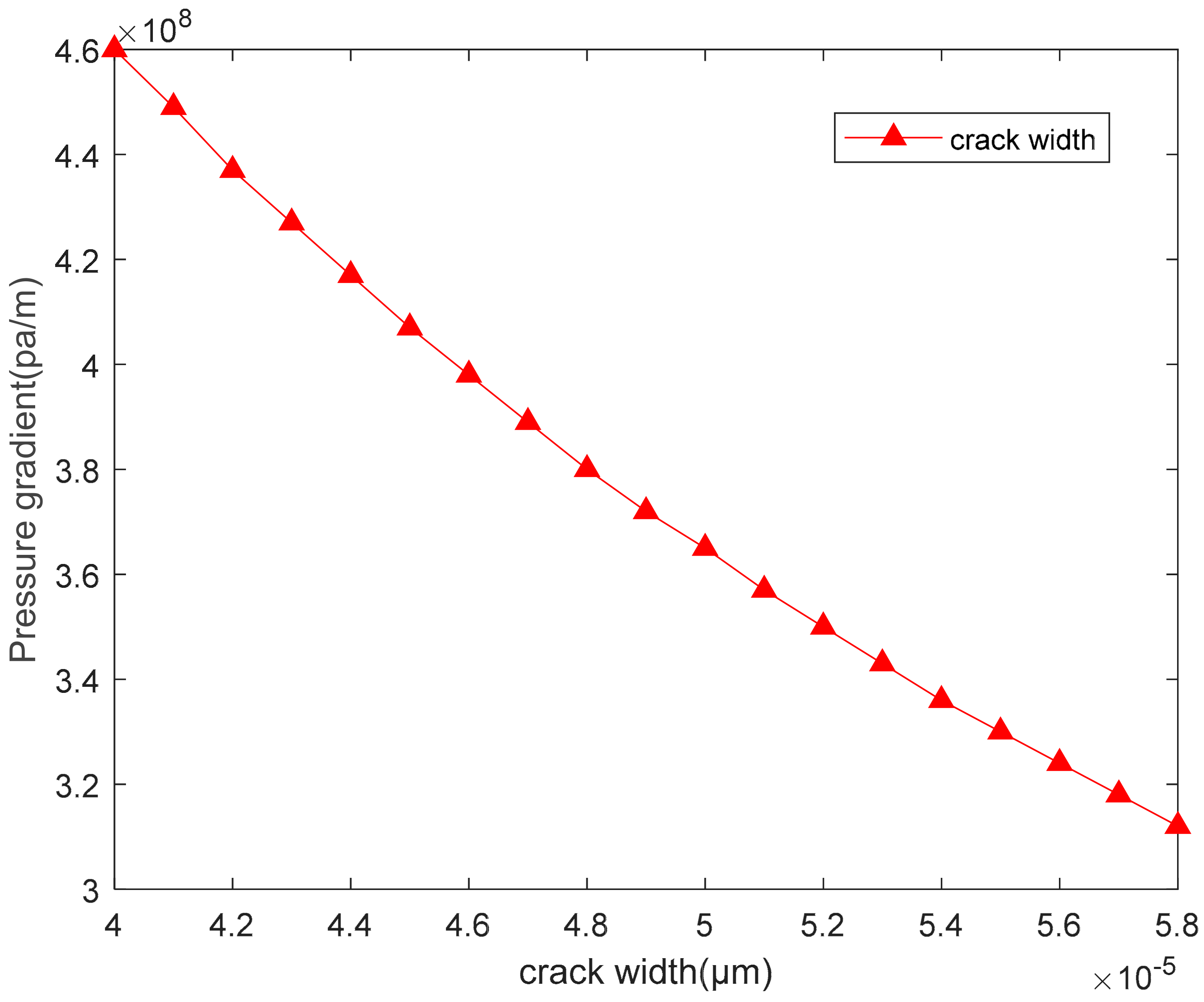

- In the process of oil production, the pressure is usually fixed, while the output is uncertain. Therefore, this paper considers that using the flow rate as the standard prediction method has little effect on the actual production, so it is better to use the pressure gradient as the variable to predict the oil production and formation damage. Secondly, in the process of oil production, the width of the passage through which the fluid passes is very different, and the fracture is very heterogeneous. Because the width of each fracture is not uniform and the velocity differs, it is difficult to make statistical comparisons for alignment, but the pressure gradient in each fracture is similar in theory and close to the overall pressure gradient. Considering the above reasons, it is more suitable to use the pressure gradient as the starting condition of particle migration, and to reasonably predict the formation damage caused by particle migration. When K1 = 1.2, n = 0.57 and r = 1 μm, the change of crack width will affect the starting conditions of particles, according to Figure 3, it is found that with the increase in the crack width, the pressure gradient decreases continuously. This indicates that in a wider environment, the particles will become easier to move, as shown in Figure 3.

- (3)

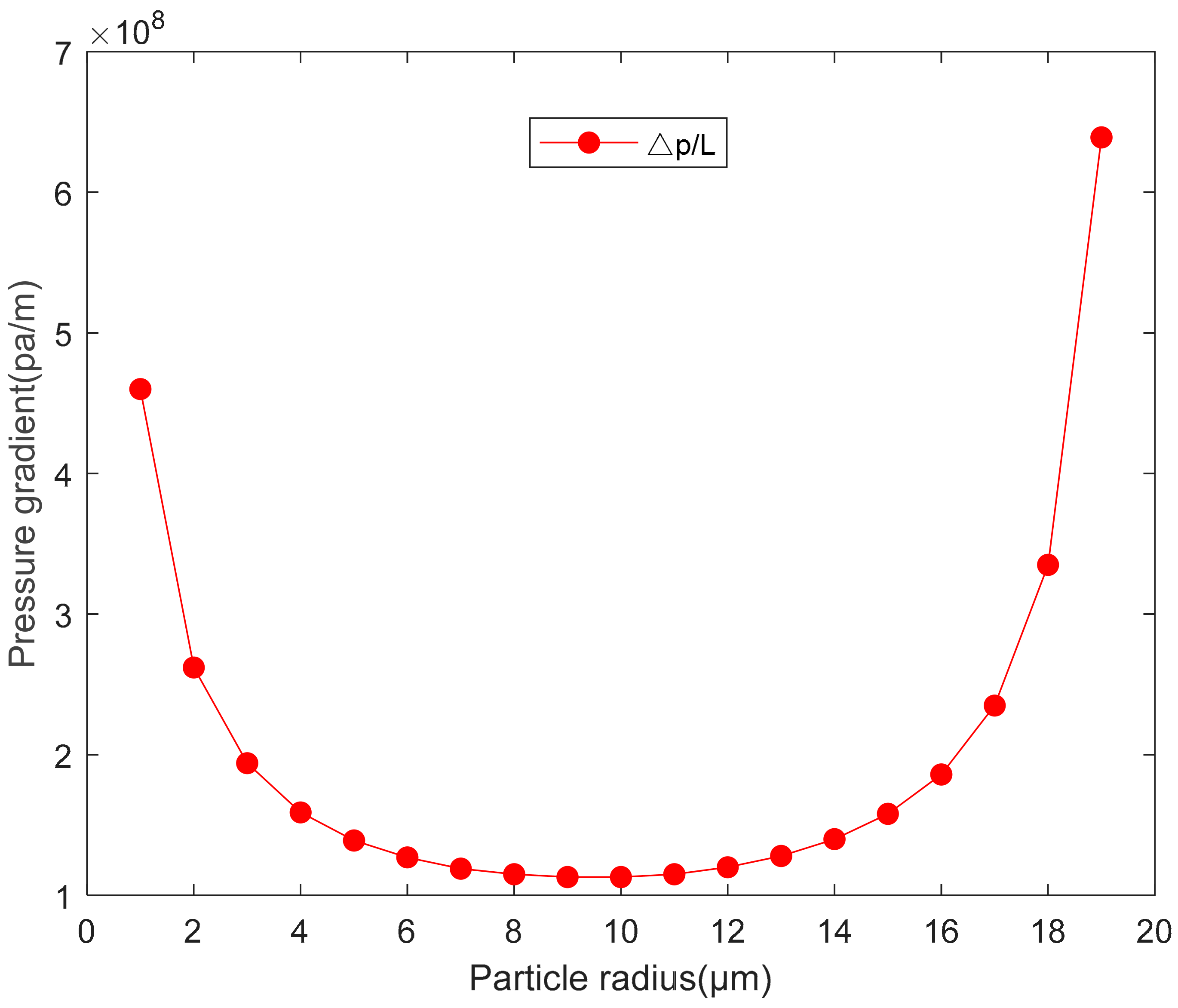

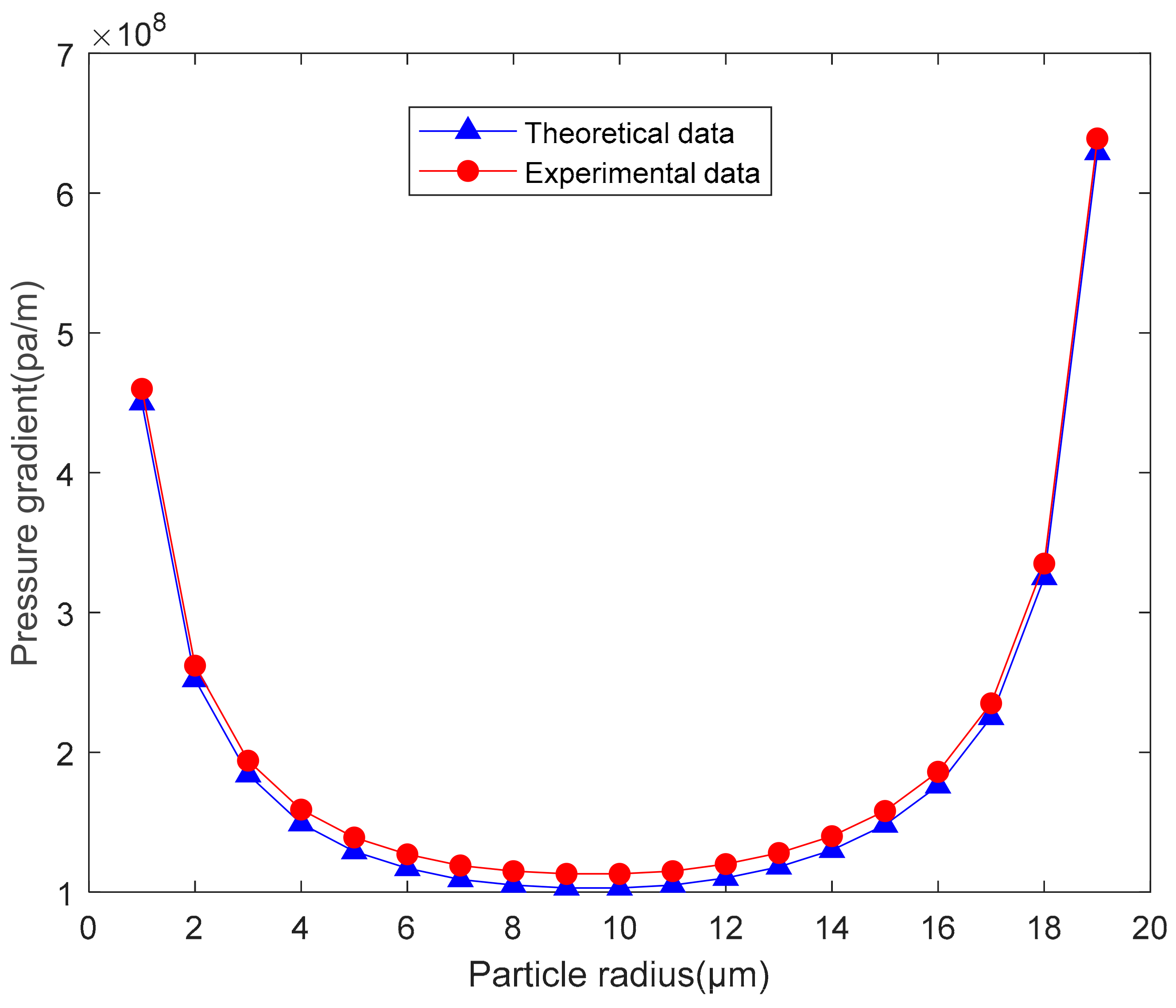

- When K1 = 1.2, n = 0.57 and H = 40 μm, as the particle size changes, the starting conditions of the particles will first increase and then decrease. The curve is U-shaped, and there are boundary conditions for particle activation. Based on the results, we can predict the minimum pressure gradient at which particles of various sizes start to migrate, as shown in Figure 4.

4. Effect of Non-Newtonian Fluid with Different Parameters on Particle Migration

- (1)

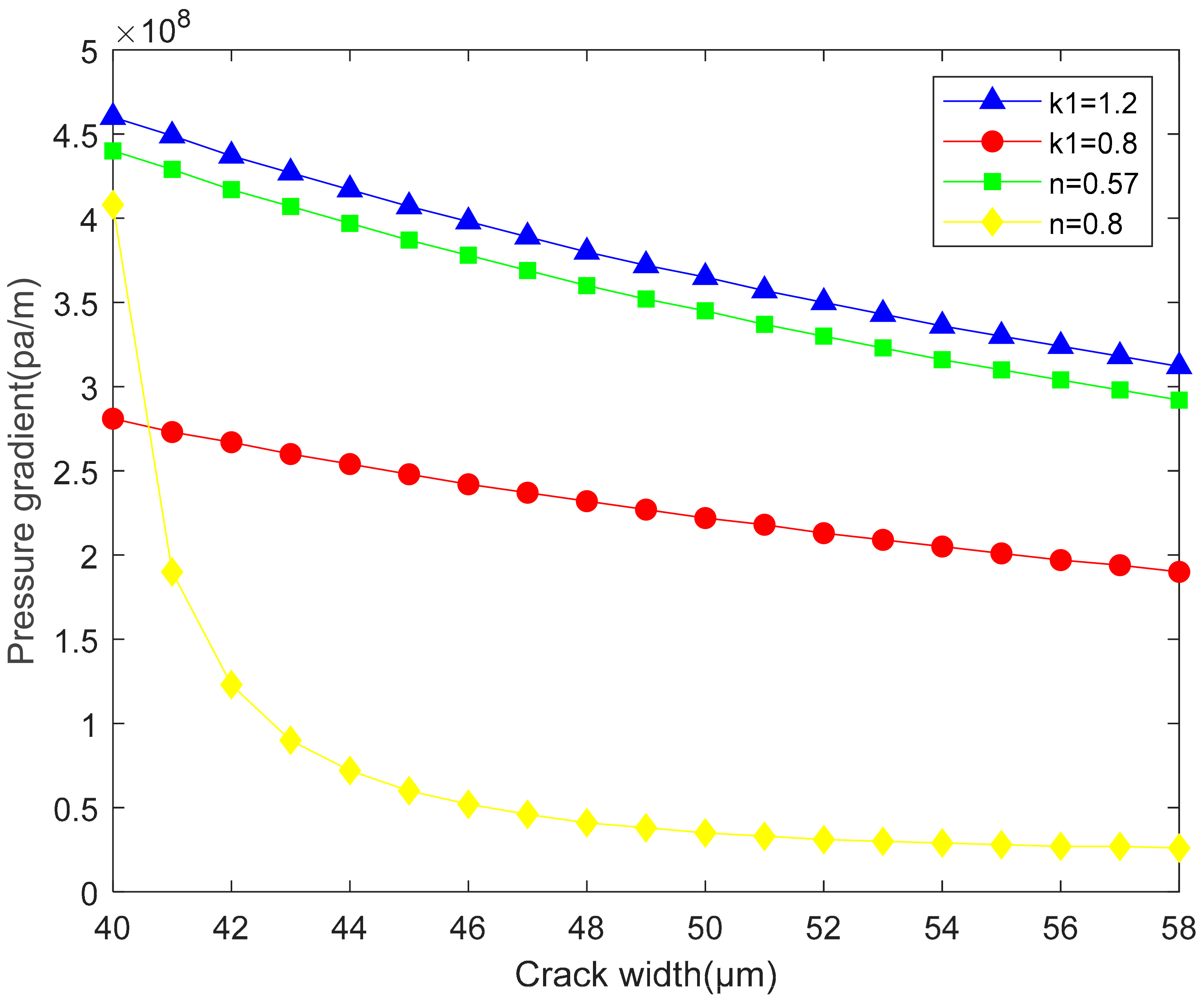

- When n = 0.57 and H = 40 μm, the increase in the consistency coefficient will accelerate the growth of resistance and lift. It can be seen that a larger consistency coefficient will lead to greater resistance and lift. When the consistency coefficient increases, the curve of the pressure gradient decreasing with the increase in particle size obviously moves up, as shown in Figure 5. When K1 is increased from 0.8 to 1.2, the drag force and lift force are almost equal from the original, and finally the drag force increases by 65% and the lift by force 39%.

- (2)

- Under the condition that the r = 1 μm. When the fluidity index increases, the curve of the pressure gradient decreasing with the increase of crack width obviously moves down, and it increases the trend of bending and the speed of decline, which is closer to Type C. As the consistency coefficient increases, the curve moves up obviously, but the starting conditions of particles decrease with the increase of cracks. As shown in Figure 6. When k1 increases from 0.8 to 1.2, the final pressure gradient of the curve increases by 65%. When n increases from 0.57 to 0.8, the curve eventually drops to 9% of the original.

- (3)

- When K1 = 1.2 and H = 40 μm, according to the figure below, with the increase in the fluidity index, the curve of the pressure gradient changing with particle size moves down obviously, the lowest point of the curve decreases obviously, and particle migration becomes easier, as shown in Figure 7. When n is increased from 0.57 to 0.8, the pressure gradient at the lowest point of the curve is reduced to 49% of the original.

- (4)

- When n = 0.57 and H = 40 μm, with the increase in the consistency coefficient, the curve of the pressure gradient with the change in particle size obviously moves up, and the lowest point of the curve rises. It can be seen that with the increase in the consistency coefficient, the migration of particles becomes easier, as shown in Figure 8. When K1 increases from 0.8 to 1.2, the pressure gradient at the lowest point of the curve increases by 66%.

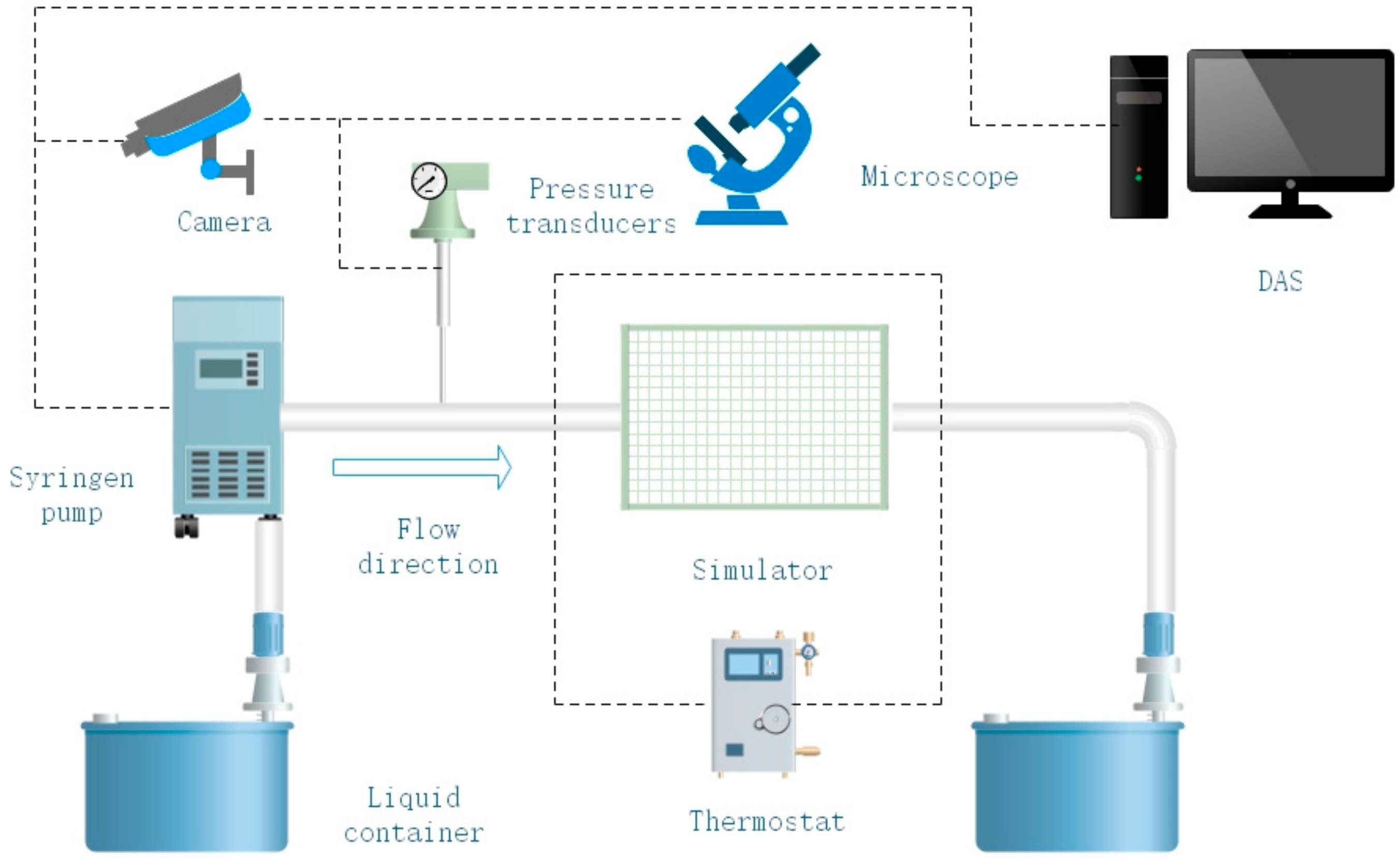

5. Experimental Demonstration

- (1)

- There is a chart showing that the experimental results are generally consistent with the theoretical results, and the theoretical calculations reasonably predict the actual situation.

- (2)

- Since there are many differences between the glass plane and the actual crack plane, the actual crack is rougher.

- (3)

- Since the particles in theory are perfectly spherical and differ from the actual particles, the actual particles have more tips and protrusions and are more likely to migrate due to the movement of the fluid. The experimental curve is also clearly above the theoretical curve. On the one hand, the error produced by the experimental design is formed.

6. Conclusions

- (1)

- The starting pressure gradient of particles in fractures decreases first and then increases with the increase in particle size, and the starting pressure gradient of particles with the same particle size in fractures with different fracture width also differs; specifically, the larger the fracture width is, the smaller the starting pressure gradient of the particles is.

- (2)

- Based on the theory of this paper, when designing a reasonable interval of oil production pressure gradient, the principle of improving the permeability of the maximum fracture width should be given priority, and the maximum pressure gradient should be controlled, so as to effectively prevent the migration of particles.

- (3)

- According to the theory of this paper, the risk of formation damage in each stage of oil well operation can be reduced, the damage of permeability caused by fine particle migration can be avoided, the damage of equipment caused by impurities can be effectively reduced, and stable production can be effectively achieved.

- (4)

- The non-Newtonian fluid coefficient has a significant effect on the particle migration curve. With the increase in the fluidity index, particle migration becomes easier, while with the increase in the consistency coefficient, particle migration becomes more difficult. It is thus very important to consider the influence of the production environment on the fluidity index and the consistency coefficient in production.

- (5)

- The objects studied in previous articles are often the state of motion and initial conditions of uniform particles under the influence of Newtonian fluid in the pore structure. However, for the gap structure, different gap size, different particle size, quantitative research in non-Newtonian fluid is insufficient. This article intends to study the starting conditions of particle migration under the influence of non-Newtonian fluid under different gap sizes and different particle sizes.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Fd | drag force (N) |

| Fl | lift force (N) |

| μ | apparent viscosity of the fluid (Pa·s) |

| r | particle radius (m) |

| ∂u/∂z | shear rate of the fluid at the center of the fine particle (s−1) |

| ρl | density of the fluid (kg/m3) |

| ∆p | pressure difference at both ends of the crack (pa) |

| L | crack length (m) |

| H | crack width (m) |

| K1 | consistency coefficient |

| n | fluidity index |

| Fa | contact force (N) |

| ϕa | total interaction energy (J) |

| h | distance between the fine particles and the contact surface (m) |

| ϕEDL | EDL force (J) |

| ϕLW | LW force (J) |

| ϕAB | AB force(J) |

| ϕBR | Born force (J) |

| ε0 | permittivity of the free space (c/(V*m)) |

| εr | relative permittivity |

| ψ1, ψ2 | surface potentials of fine particles and fracture surfaces respectively (V) |

| κ | reciprocal of the Debye length (m−1) |

| e | Electronic charge (C) |

| Nj | concentration of the J~(th) ion in solution (m−3) |

| Zj | Valence state of the J~(th) ion in solution |

| N0 | Avogadro constant |

| I | ion strength (mol/L) |

| Kb | Boltzmann constant (J/K) |

| T | temperature (K) |

| A132 | effective Hamaker constant of (1-particle)-(3-liquid medium)-(2-fracture) system (J) |

| h0 | particle separation distance (m) |

| γLW | Lifshitz-van der Waals (non-polarity) part of the surface tension (J/m2) |

| δ | Born collision parameter (m) |

| λAB | correlation length of the petroleum molecules (m) |

| ϕAB (H = H0) | interaction energy of the Lewis acid-base (AB) at H0 (J/m2) |

| γ+, γ− | surface tension components of the electron acceptor (polarity) and electron donor (polarity) (J/m2) |

| Fn | total force in the vertical direction (N) |

| Ln | lever arm of the horizontal force (m) |

| a | area radius of the deformation of the contact circle between the particles and the plane (m) |

| K2 | contact elastic modulus (Pa) |

| E1, E2 | Young’s modulus of particles and surfaces respectively (Pa) |

| ν1, ν2 | Poisson’s ratio of particles and surfaces respectively |

References

- Zou, C.; Zhu, R.; Wu, S. Types, characteristics, genesis and prospects of conventional and unconventional hydrocarbon accumulations: Taking tight oil and tight gas in China as an instance. Acta Pet. Sin. 2012, 33, 173–187. [Google Scholar]

- Miranda, R.M.; Underdown, D.R. Laboratory Measurement of Critical Rate: A Novel Approach for Quantifying Fines Migration Problems. In Proceedings of the SPE Production Operations Symposium, Oklahoma City, OK, USA, 21–23 March 1993. [Google Scholar]

- Maini, B.; Wassmuth, F.; Schramm, L.L. Fines Migration in Petroleum Reservoirs. Adv. Chem. 1996, 251, 321–375. [Google Scholar]

- Tang, G.Q.; Morrow, N.R. Influence of brine composition and fines migration on crude oil/brine/rock interactions and oil recovery. J. Pet. Sci. Eng. 1998, 24, 99–111. [Google Scholar] [CrossRef]

- Neaman, A.; Singer, A.; Stahr, K. Dispersion and migration of fine particles in two palygorskite-containing soils of the Jordan Valley. J. Plant Nutr. Soil Sci. 2000, 163, 537–547. [Google Scholar] [CrossRef]

- Bedrikovetsky, P.; Marchesin, D.; Shecaira, F.; Souza, A.; Milanez, P.; Rezende, E. Characterisation of deep bed filtration system from laboratory pressure drop measurements. J. Pet. Sci. Eng. 2001, 32, 167–177. [Google Scholar] [CrossRef]

- Hayatdavoudi, A. Formation Sand Liquefaction: A Mechanism for Explaining Fines Migration and Well Sanding. J. Energy Resour. Technol. 2005, 127, 181–190. [Google Scholar] [CrossRef]

- Civan, F. Non-isothermal Permeability Impairment by Fines Migration and Deposition in Porous Media including Dispersive Transport. Transp. Porous Media 2010, 85, 233–258. [Google Scholar] [CrossRef]

- Huang, T.; Clark, D.E. Enhancing Oil Recovery With Specialized Nanoparticles by Controlling Formation-Fines Migration at Their Sources in Waterflooding Reservoirs. SPE J. 2015, 20, 743–746. [Google Scholar] [CrossRef]

- Kanimozhi, B.; Prakash, J.; Pranesh, R.V.; Mahalingam, S. Numerical and experimental investigation on the effect of retrograde vaporization on fines migration and drift in porous oil reservoir: Roles of phase change heat transfer and saturation. J. Pet. Explor. Prod. Technol. 2019, 9, 2953–2963. [Google Scholar] [CrossRef]

- Hu, X.; Xie, J.; Cai, W.; Wang, R.; Davarpanah, A. Thermodynamic effects of cycling carbon dioxide injectivity in shale reservoirs. J. Pet. Sci. Eng. 2020, 195, 107717. [Google Scholar] [CrossRef]

- Yi, J.; Afshin, D. Using Photo-Fenton and Floatation Techniques for the Sustainable Management of Flow-Back Produced Water Reuse in Shale Reservoirs Exploration. Water Air Soil Pollut. 2020, 231. [Google Scholar] [CrossRef]

- Hu, X.; Li, M.; Peng, C.; Davarpanah, A. Hybrid Thermal-Chemical Enhanced Oil Recovery Methods; An Experimental Study for Tight Reservoirs. Symmetry 2020, 12, 947. [Google Scholar] [CrossRef]

- Afshin, D.; Behnam, M. A simulation study to control the oil production rate of oil-rim reservoir under different injectivity scenarios. Energy Rep. 2018, 4, 664–670. [Google Scholar]

- Afshin, D. Parametric Study of Polymer-Nanoparticles-Assisted Injectivity Performance for Axisymmetric Two-Phase Flow in EOR Processes. Nanomaterials 2020, 10, 1818. [Google Scholar] [CrossRef]

- Israelachvili, J.N. Intermolecular and Surface Force; Academic Press: London, UK, 1992. [Google Scholar]

- Sutera, S.P.; Skalak, R. The History of Poiseuille’s Law. Annu. Rev. Fluid Mech. 1993, 25, 1–20. [Google Scholar] [CrossRef]

- O’Neill, M.E. A sphere in contact with a plane wall in a slow linear shear flow. Chem. Eng. Sci. 1968, 23, 1293–1298. [Google Scholar] [CrossRef]

- Goldman, A.J.; Cox, R.G.; Brenner, H. Slow viscous motion of a sphere parallel to a plane wall—I motion through a quiescent fluid. Chem. Eng. Sci. 1967, 22, 637–651. [Google Scholar] [CrossRef]

- Saffman, P.G. The lift on a small sphere in a slow shear flow. J. Fluid Mech. 1965, 22, 385–400. [Google Scholar] [CrossRef]

- Ostwald, W. de Waele-Ostwald equation. Kolloid Z. 1929, 47, 176–187. [Google Scholar] [CrossRef]

- Bergendahl, J.; Grasso, D. Prediction of colloid detachment in a model porous media: Thermodynamics. AIche J. 1999, 45, 475–484. [Google Scholar] [CrossRef]

- Van Oss, C.J.; Chaudhury, M.K.; Good, R.J. Interfacial Lifshitz-van der Waals and polar interactions in macroscopic systems. Chem. Rev. 1998, 88, 921–947. [Google Scholar] [CrossRef]

- Brant, J.A.; Childress, A.E. Assessing short-range membrane-colloid interactions using surface energetics. J. Membr. Sci. 2002, 203, 257–273. [Google Scholar] [CrossRef]

- Ruckenstein, E.; Prieve, D.C. Adsorption and desorption of particles and their chromatographic separation. Alche J. 1976, 22, 276–283. [Google Scholar] [CrossRef]

- Bergendahl, J.; Grasso, D. Prediction of colloid detachment in a model porous media: Hydrodynamics. Chem. Eng. Sci. 2000, 55, 1523–1532. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and the contact of elastic solids. Proc. R. Soc. A Math. Phys. Eng. Sci. 1971, 324, 301–313. [Google Scholar]

- Jakubowski, M.; Antonowicz, A.; Janowicz, M.; Sterczyńska, M.; Piepiórka-Stepuk, J.; Poreda, A. An assessment of the potential of shadow sizing analysis and Particle Image Velocimetry (PIV) to characterise hot trub morphology. J. Food Eng. 2016, 173, 34–41. [Google Scholar] [CrossRef]

- Gercek, H. Poisson’s ratio values for rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 1–13. [Google Scholar] [CrossRef]

- Hedan, S.; Hubert, F.; Prêt, D.; Ferrage, E.; Valle, V.; Cosenza, P. Measurement of the elastic properties of swelling clay minerals using the digital image correlation method on a single macroscopic crystal. Appl. Clay Sci. 2015, 116–117, 248–256. [Google Scholar] [CrossRef]

- Schembre, J.M.; Kovscek, A.R. Mechanism of Formation Damage at Elevated Temperature. J. Energy Resour. Technol. 2005, 127, 171–180. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, J.; Zhou, X. Starting Conditions of Particle Migration in Tight Sandstone Reservoir Development. Processes 2020, 8, 1491. https://doi.org/10.3390/pr8111491

Shan J, Zhou X. Starting Conditions of Particle Migration in Tight Sandstone Reservoir Development. Processes. 2020; 8(11):1491. https://doi.org/10.3390/pr8111491

Chicago/Turabian StyleShan, Jie, and Xiaojun Zhou. 2020. "Starting Conditions of Particle Migration in Tight Sandstone Reservoir Development" Processes 8, no. 11: 1491. https://doi.org/10.3390/pr8111491

APA StyleShan, J., & Zhou, X. (2020). Starting Conditions of Particle Migration in Tight Sandstone Reservoir Development. Processes, 8(11), 1491. https://doi.org/10.3390/pr8111491