Influence of Gasoline Addition on Biodiesel Combustion in a Compression-Ignition Engine with Constant Settings

Abstract

1. Introduction

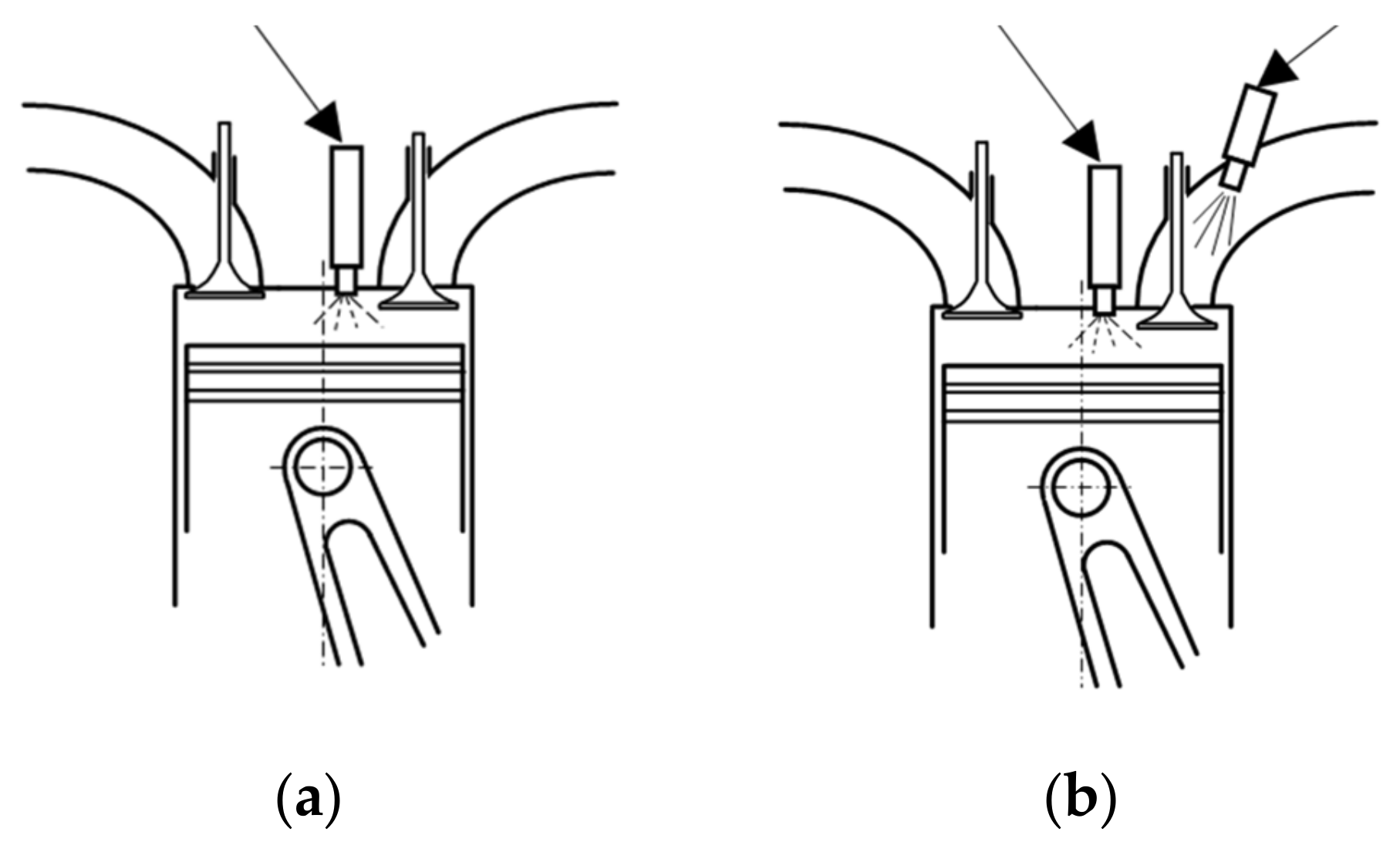

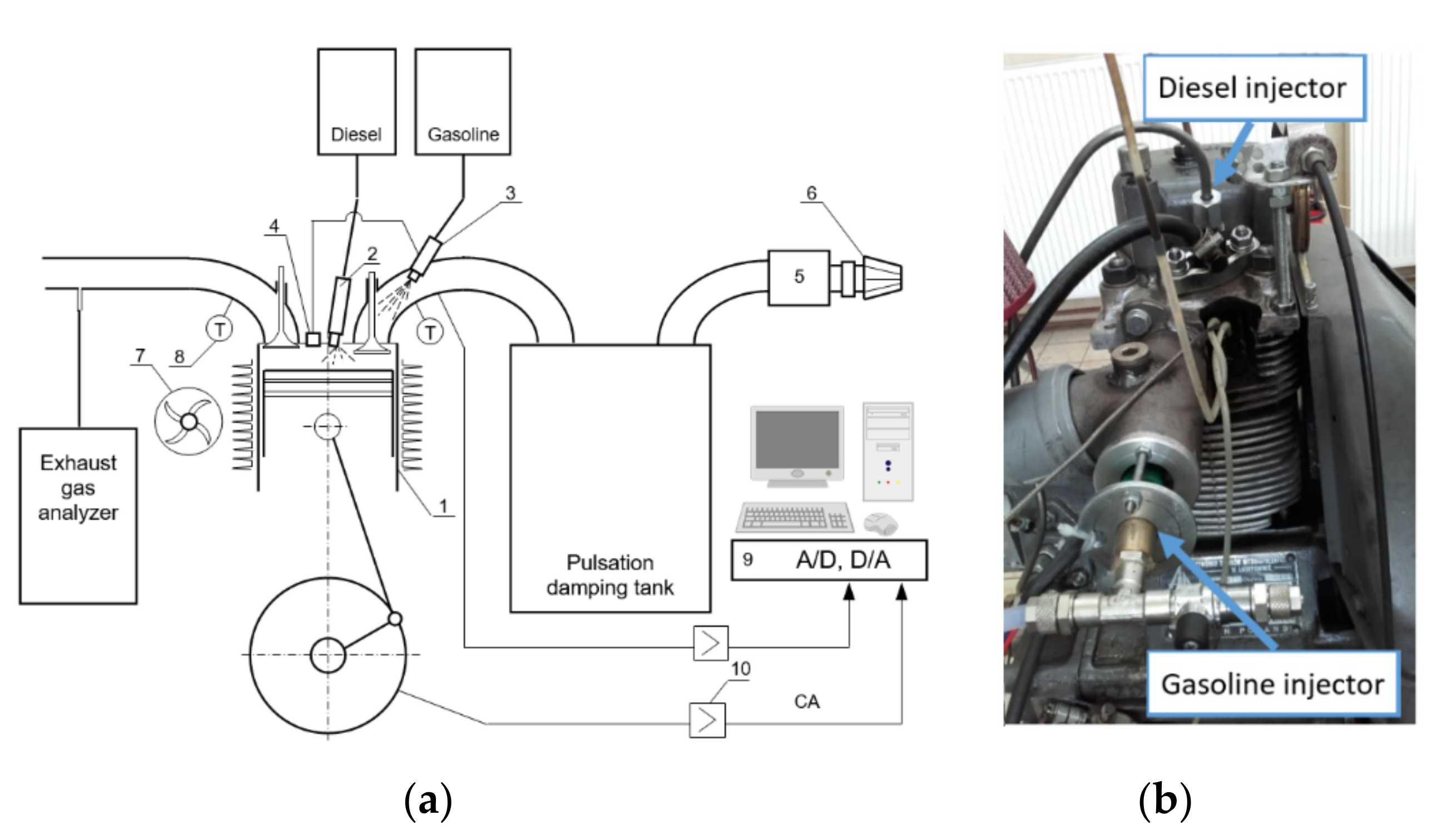

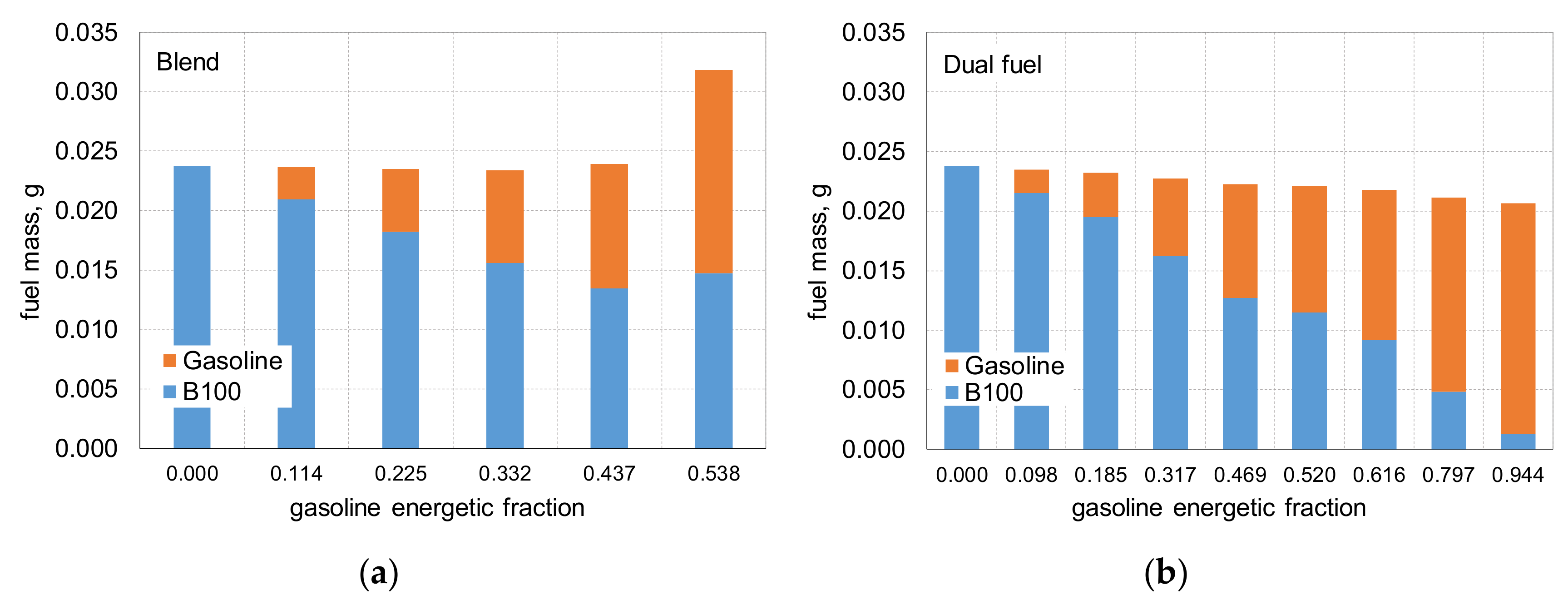

2. Experimental Setup

3. Results

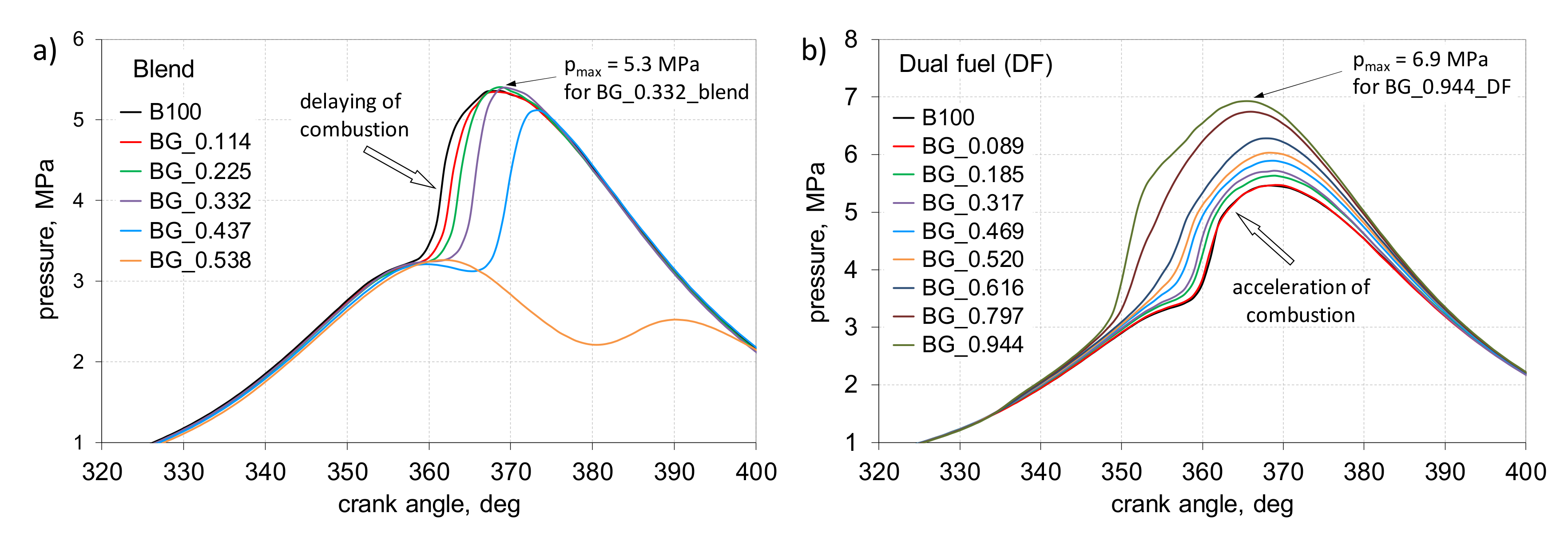

3.1. Biodiesel Combustion Process

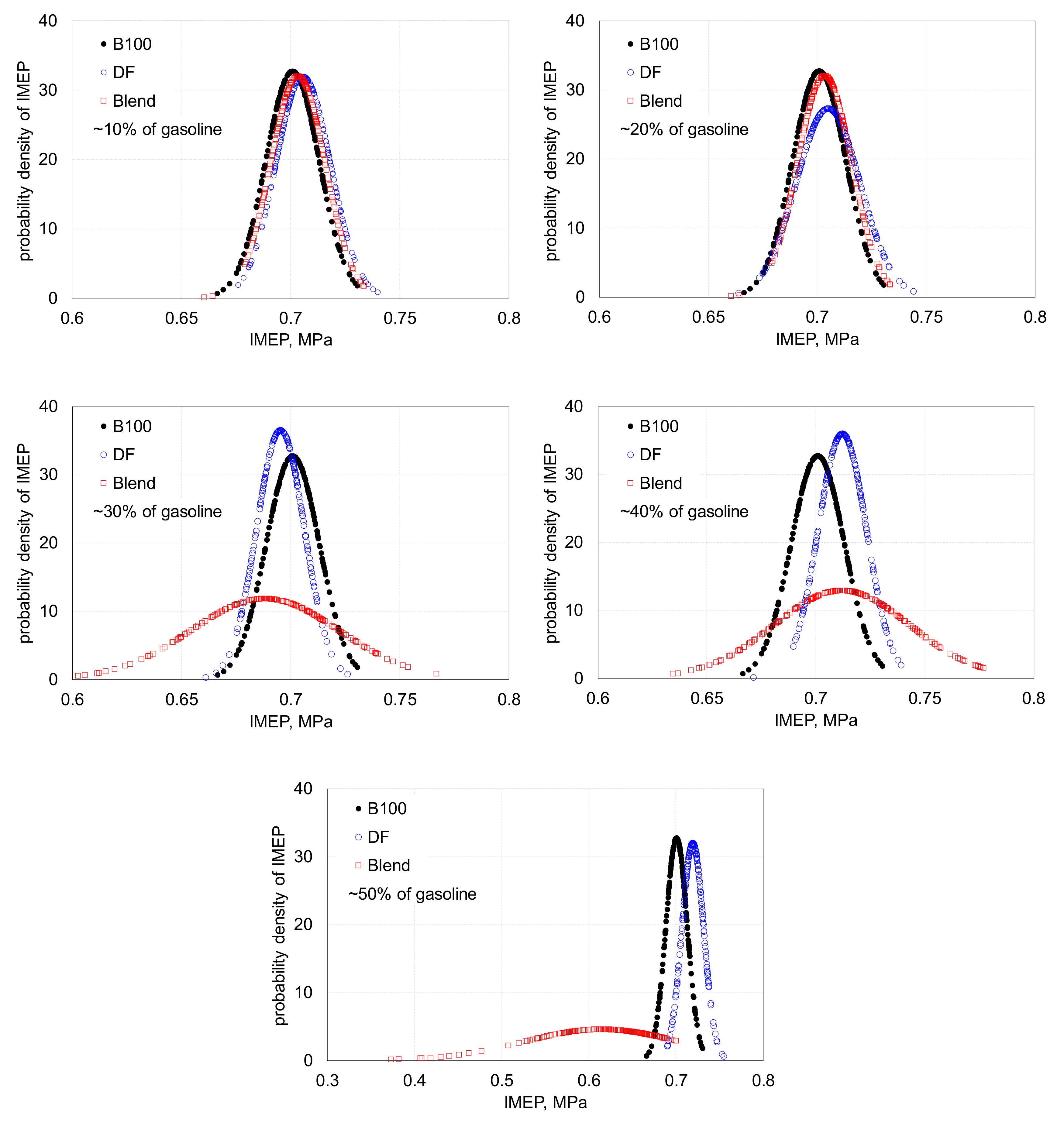

3.2. Combustion Stability

3.3. Emission Analysis

4. Conclusions

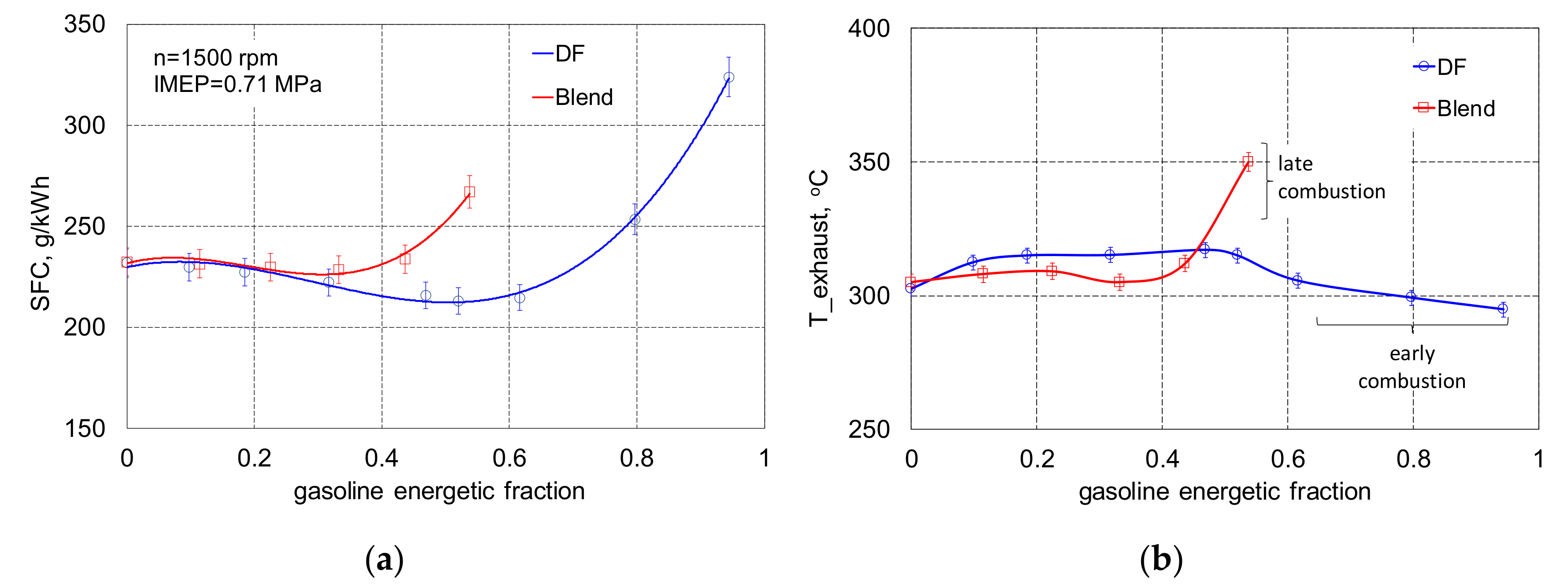

- For DF technology with an increase in the gasoline fraction, the SFC decreased up to 0.62 of gasoline fraction; in the case of blend combustion for all analyzed gasoline fractions, the SFC was higher in comparison to DF technology, up to 0.3 of gasoline in blend SFC was at the same level—equal to 230 g/kWh.

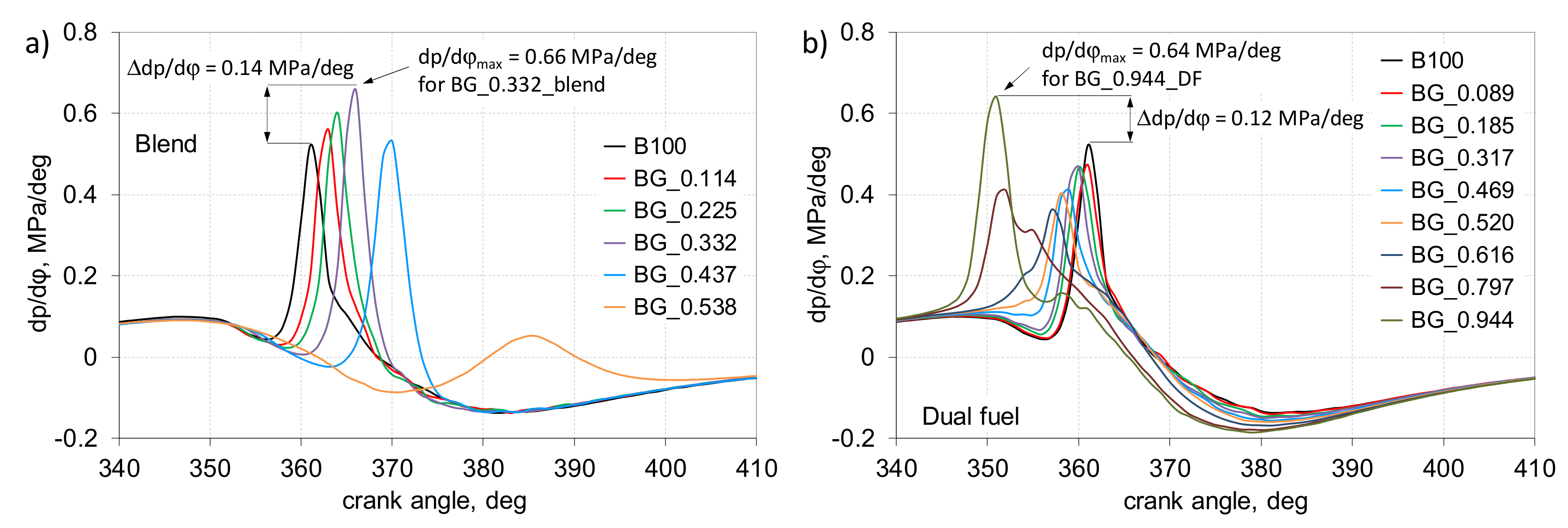

- With the increase in the gasoline share, for the blend technology the peak of HRR was shifted to the larger deg of CA after TDC, but for DF it moved in the opposite direction.

- It is possible to co-combustion biodiesel with gasoline in relatively large energetic fractions; for blend it was up to 0.54 and for dual fuel it was near to 0.95.

- The combustion process of biodiesel was characterized by a lower ignition delay in comparison to diesel fuel combustion; the difference was 2 deg of CA.

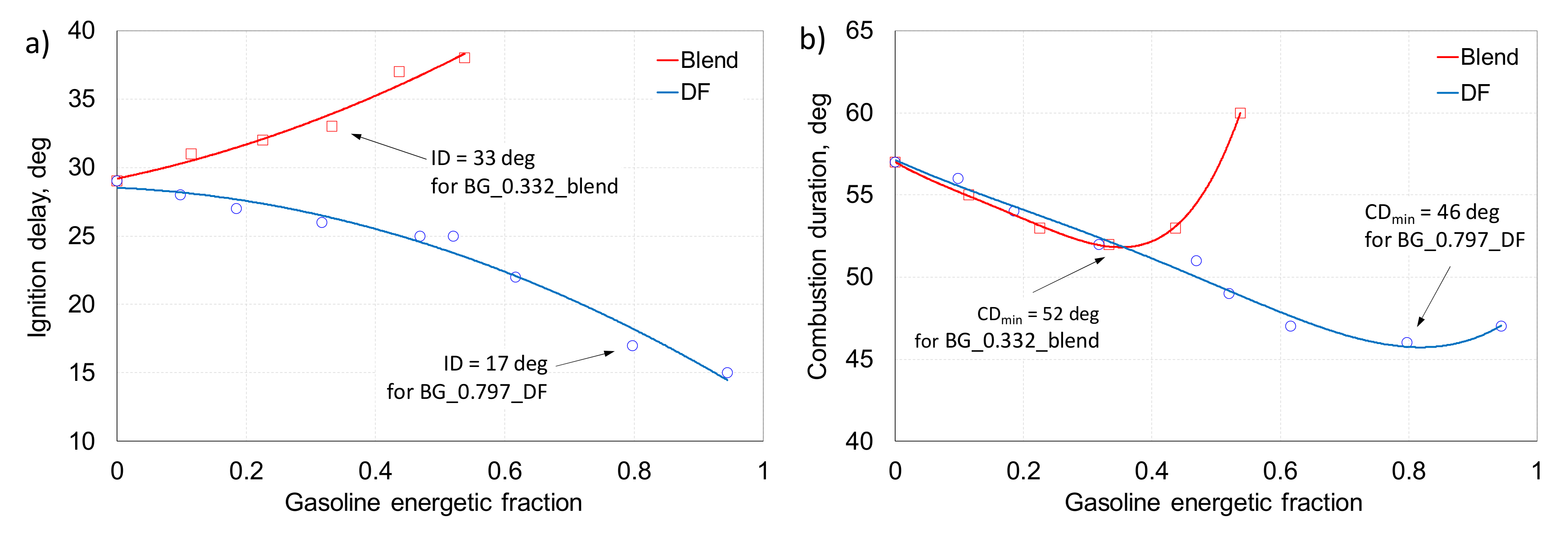

- In the case of blend combustion, the ignition delay increased from 29 to 38 deg of CA; for 0.54 of gasoline, ID increased by 31% compared to the combustion of the reference fuel, but for DF technology it was decreased from 29 to 15 deg of CA, and for 0.95 of gasolinem ID decreased by 48%.

- For blend combustion up to 0.4 of gasoline fraction, the CD decreased; for DF technology, CD decreased up to 80% of gasoline.

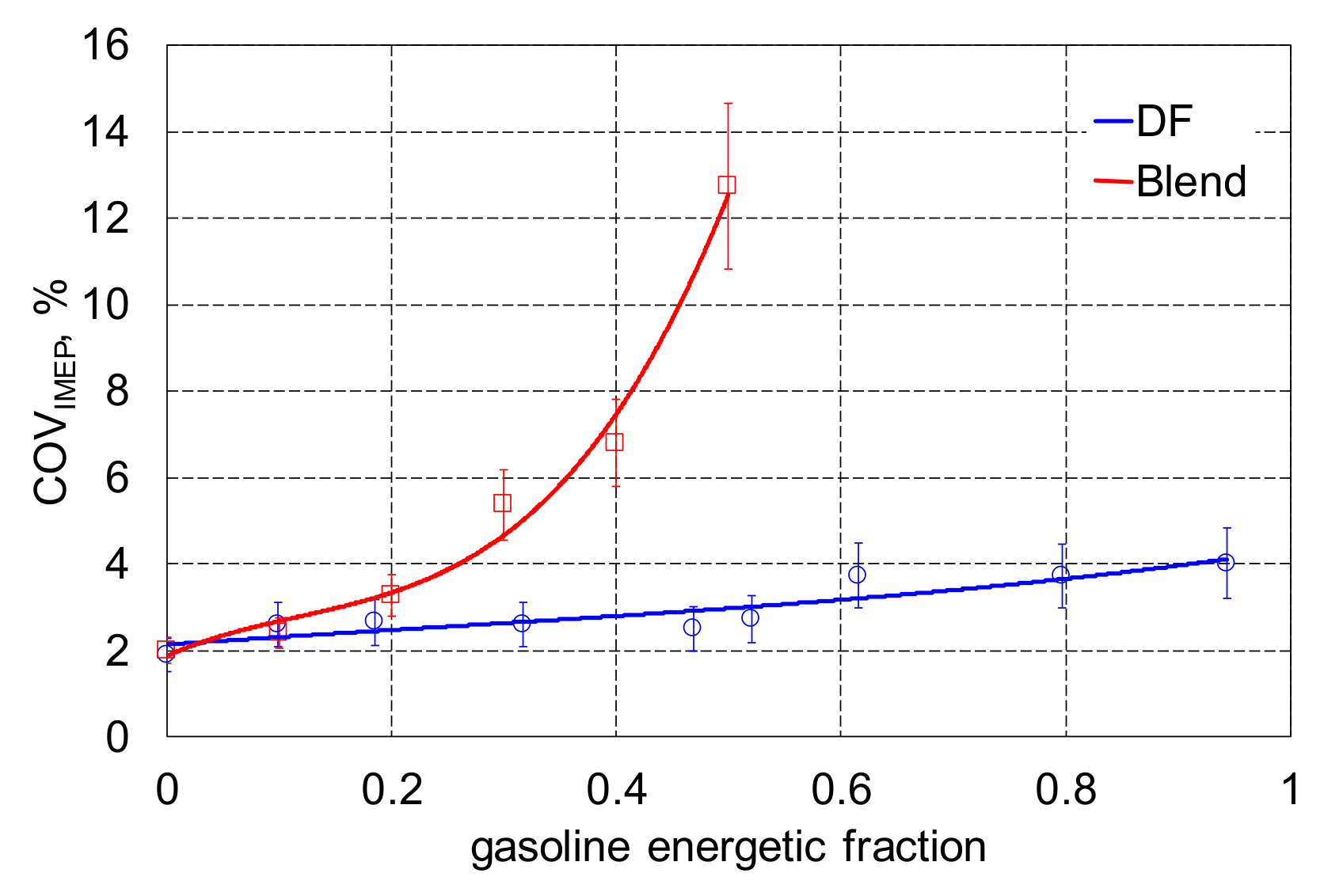

- In the case of DF mode, with the increase in gasoline fraction, COVIMEP was increased slightly up to 4%, but in the case of blend combustion, for 0.5 of gasoline fraction, the increase in COVIMEP was significant and it was near to 13%.

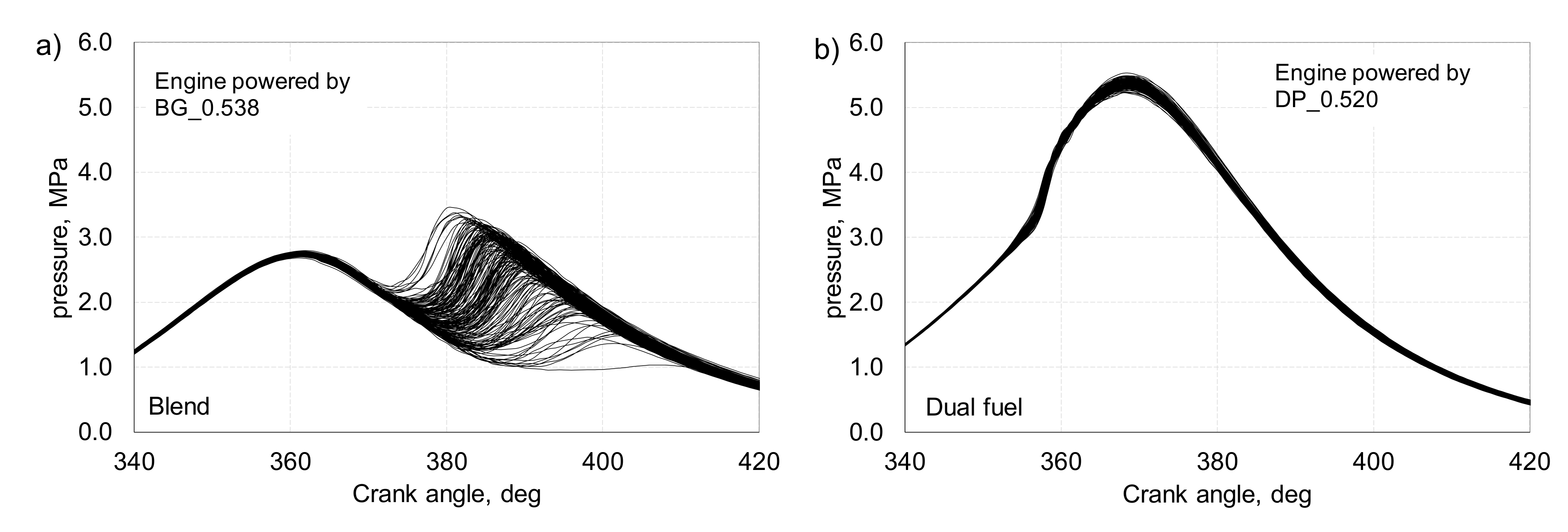

- Peak pressure vs. IMEP showed that for the DF mode, values of IMEP were in a narrow range of variation, with increased values of peak pressure; in the case of blend combustion, values of IMEP were in a larger spread area with small spread of peak pressure values.

- In the case of blend combustion, the position of peak pressure was changed in the direction of large values of CA after TDC due to an increase in the ignition delay; for 0.50 gasoline in blend, division into two areas was noticed—one with no ignition and the other in late ignition. For dual fuel technology, the peak pressure was obtained in a narrow range of the crank angle degree.

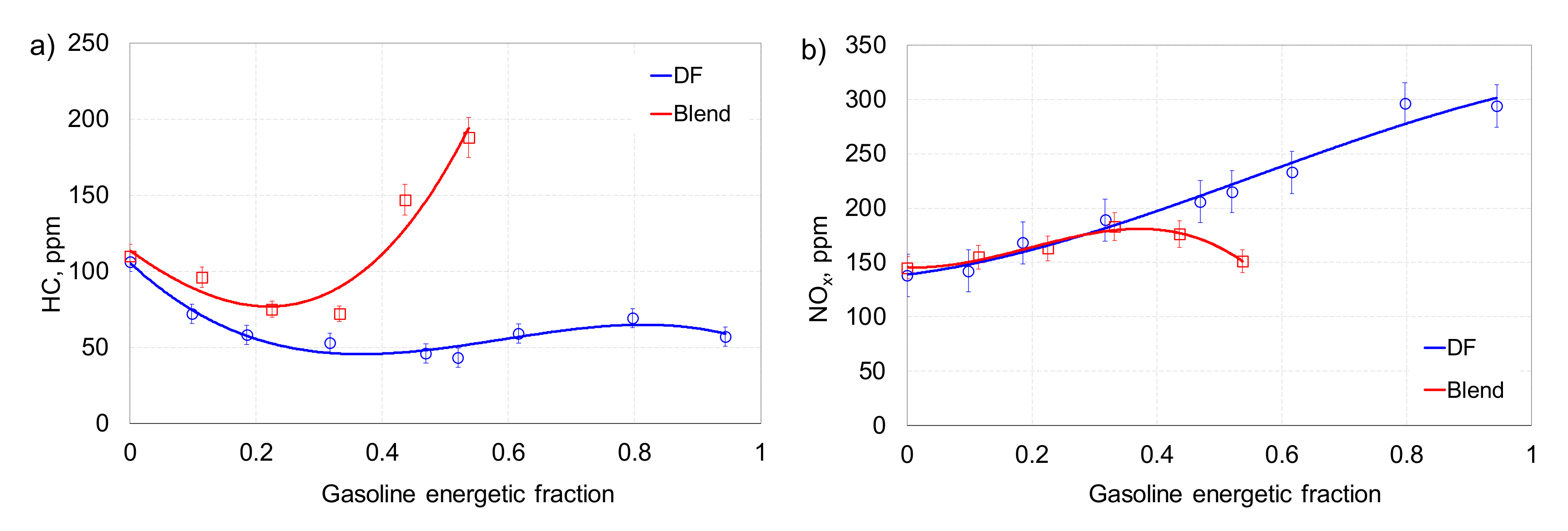

- For blend and DF combustion, up to 0.30 of energetic fraction of gasoline obtained lower HC emission.

- The increase in the share of gasoline fraction in the combustion process causes an increase in NOx emissions; DF technology with a 0.95 share of gasoline was characterized by a 100% increase in NOx emission.

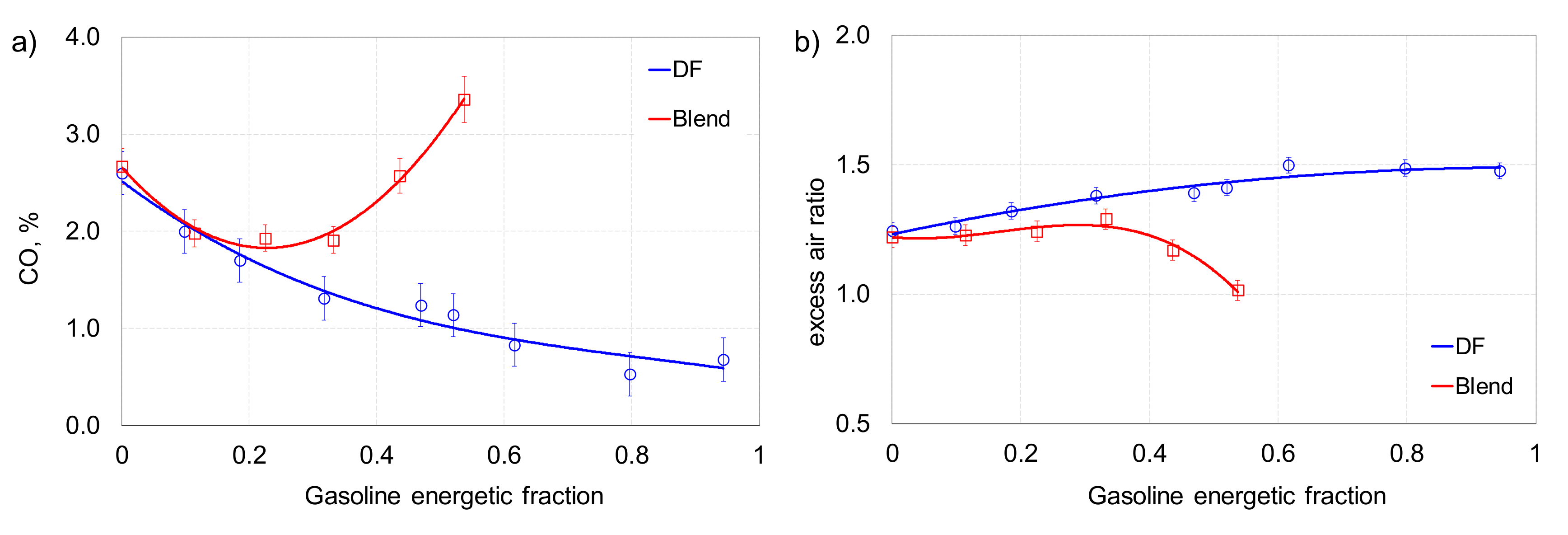

- For burning of reference fuel, the CO emission was equal to 2.7%, and for 0.95 of gasoline fraction, it decreased to 0.67%—a decrease of more than four times.

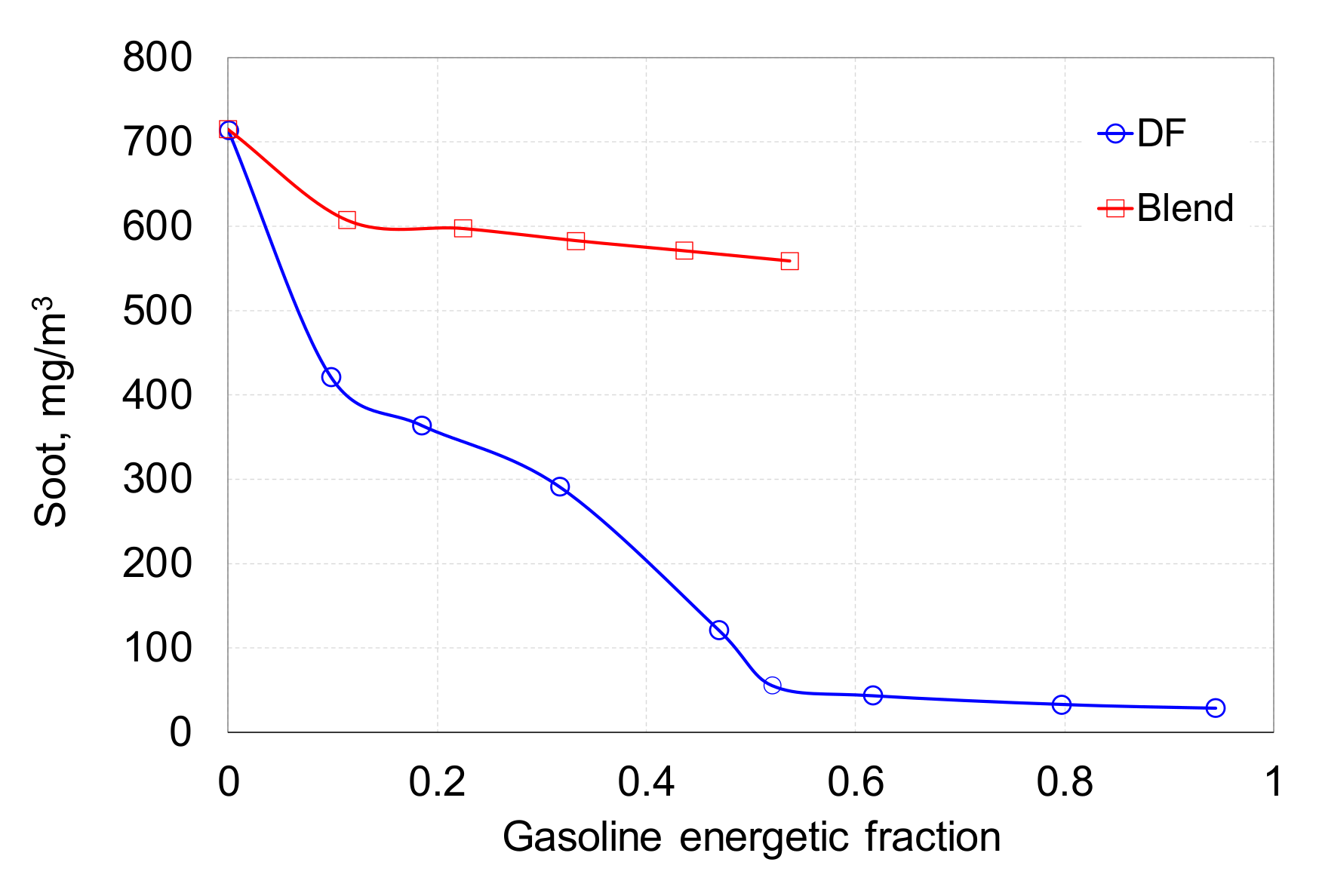

- For 10% of the energy share of gasoline, the dual fuel method reduced soot emissions by 40% and the blend method by only 15%; for blend burning, a further increase in the share of gasoline does not significantly affect soot emissions.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| BG | Biodiesel-gasoline |

| CA | Crank angle, deg |

| CD | Combustion duration, deg |

| CN | Cetane number |

| COV | Coefficient of variation, % |

| DF | Dual fuel |

| HCCI | Homogeneous charge compression ignition |

| RCCI | Reactivity controlled compression ignition |

| IC | Internal combustion |

| ID | Ignition delay, deg |

| IMEP | Indicated mean effective pressure, MPa |

| LHV | Lower heating value, MJ/kg |

| MFB | Mass fraction burned, % |

| PD | Probability density, % |

| SOI | Start of injection, deg |

| SFC | Specific fuel consumption, g/kWh |

| TDC | Top dead center |

| (A/F)a | Actual proportions of air and fuel, kg/kg |

| (A/F)s | Stoichiometric proportions of air and fuel, kg/kg |

| ϕ | Crank angle, deg |

| λ | Excess air ratio |

| φ | Equivalence ratio |

References

- Hoseinpour, M.; Sadrnia, H.; Tabasizadeh, M.; Ghobadian, B. Energy and exergy analyses of a diesel engine fueled with diesel, biodiesel-diesel blend and gasoline fumigation. Energy 2017, 141, 2408–2420. [Google Scholar] [CrossRef]

- Zöldy, M.; Török, Á. Road transport liquid fuel today and tomorrow: Literature overview. Period. Polytech. Transp. Eng. 2015, 43, 172–176. [Google Scholar] [CrossRef]

- Szabados, G.; Bereczky, Á.; Ajtai, T.; Bozóki, Z. Evaluation analysis of particulate relevant emission of a diesel engine running on fossil diesel and different biofuels. Energy 2018, 161, 1139–1153. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Gnatowska, R.; Nowak, Ł. Comparative analysis of the combustion stability of diesel-methanol and diesel-ethanol in a dual fuel engine. Energies 2019, 12, 971. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Grab-Rogaliński, K. An experimental study on the performance and emission of the diesel/CNG dual-fuel combustion mode in a stationary CI engine. Energies 2019, 12, 3857. [Google Scholar] [CrossRef]

- Nam, V.D.; Lim, M.T.; Lim, O. Study on auto-ignition characteristics of gasoline-biodiesel blend fuel in a rapid compression expansion machine. Energy Procedia 2017, 105, 1789–1795. [Google Scholar] [CrossRef]

- Putrasari, Y.; Lim, O. Performance and emission of gasoline compression ignition engine fueled with 5 and 20% gasoline-biodiesel blends under single injection strategy. Energy Procedia 2017, 105, 1743–1750. [Google Scholar] [CrossRef]

- Putrasari, Y.; Lim, O. A study of a GCI engine fueled with gasoline-biodiesel blends under pilot and main injection strategies. Fuel 2018, 221, 269–282. [Google Scholar] [CrossRef]

- Das, S.K.; Kim, K.; Lim, O. Experimental study on non-vaporizing spray characteristics of biodiesel blended gasoline fuel in a constant volume chamber. Fuel Process. Technol. 2018, 178, 322–335. [Google Scholar] [CrossRef]

- Adams, C.A.; Loeper, P.; Krieger, R.; Andrie, M.J.; Foster, D.E. Effects of biodiesel–gasoline blends on gasoline direct-injection compression ignition (GCI) combustion. Fuel 2013, 111, 784–790. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Gruca, M.; Pyrc, M. Performance, emission and combustion characteristics of CI dual fuel engine powered by diesel/ethanol and diesel/gasoline fuels. J. Mech. Sci. Technol. 2018, 32, 2947–2957. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Gnatowska, R. Combustion of different reactivity fuel mixture in a dual fuel engine. Therm. Sci. 2018, 22, 1191–1203. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Bereczky, Á.; Lukács, K. Effects of injection timing of diesel fuel on performance and emission of dual fuel diesel engine powered by diesel/E85 fuels. Transprt 2018, 33, 633–646. [Google Scholar] [CrossRef]

- Jamrozik, A. The effect of the alcohol content in the fuel mixture on the performance and emissions of a direct injection diesel engine fueled with diesel-methanol and diesel-ethanol blends. Energy Convers. Manag. 2017, 148, 461–476. [Google Scholar] [CrossRef]

- Park, S.H.; Yoon, S.H.; Lee, C.S. Bioethanol and gasoline premixing effect on combustion and emission characteristics in biodiesel dual-fuel combustion engine. Appl. Energy 2014, 135, 286–298. [Google Scholar] [CrossRef]

- Desantes, J.M.; Payri, R.; Salvador, F.J.; Manin, J. Influence on Diesel Injection Characteristics and Behavior Using Biodiesel Fuels; SAE Technical Paper 2009-01-0851; SAE International: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Gruca, M. Software for Acquisition of internal combustion engine data. J. Kones 2004, 11, 205–211. [Google Scholar]

- Jamrozik, A.; Tutak, W.; Pyrc, M.; Gruca, M.; Kočiško, M. Study on co-combustion of diesel fuel with oxygenated alcohols in a compression ignition dual-fuel engine. Fuel 2018, 221, 329–345. [Google Scholar] [CrossRef]

- Yusri, I.M.; Mamat, R.; Najafi, M.G.; Razman, A.; Awad, O.I.; Azmi, W.H.; Ishak, W.F.W.; Shaiful, A.I.M. Alcohol based automotive fuels from first four alcohol family in compression and spark ignition engine: A review on engine performance and exhaust emissions. Renew. Sustain. Energy Rev. 2017, 77, 169–181. [Google Scholar] [CrossRef]

- Li, Y.; Gong, J.; Deng, Y.; Yuan, W.; Fu, J.; Zhang, B. Experimental comparative study on combustion, performance and emissions characteristics of methanol, ethanol and butanol in a spark ignition engine. Appl. Therm. Eng. 2017, 115, 53–63. [Google Scholar] [CrossRef]

- Xu, Y.; Kang, H.; Gong, J.; Zhang, S.; Li, X. A study on the combustion strategy of gasoline/diesel dual-fuel engine. Fuel 2018, 225, 426–435. [Google Scholar] [CrossRef]

- Das, S.K.; Jo, H.; Jwa, K.H.; Lim, O.; Woo, Y. Combustion characteristics of biodiesel blended gasoline fuel in engine like condition using constant volume combustion (CVCC). Energy Procedia 2018, 145, 187–192. [Google Scholar] [CrossRef]

- Tutak, W.; Lukács, K.; Szwaja, S.; Bereczky, Á. Alcohol–diesel fuel combustion in the compression ignition engine. Fuel 2015, 154, 196–206. [Google Scholar] [CrossRef]

- Aldawood, A.; Mosbach, S.; Kraft, M. HCCI Combustion Control Using Dual-Fuel Approach: Experimental and Modeling Investigations; SAE Technical Paper 2012-01-1117; SAE International: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Garipov, M.D.; Rezvanov, D.R.; Zinnatullin, R.F. Experimental Study of Spark-Ignited Two-Stroke Heavy Fuel Engine. In Proceedings of the 4th International Conference on Industrial Engineering, Moscow, Russia, 15–18 May 2018; Lecture Notes in Mechanical Engineering, ICIE 2018. Springer: Cham, Switzerland, 2019; pp. 469–485. [Google Scholar]

- Kuszewski, H. Experimental study of the autoignition properties of n-butanol–diesel fuel blends at various ambient gas temperatures. Fuel 2019, 235, 1316–1326. [Google Scholar] [CrossRef]

- Kuszewski, H. Experimental investigation of the autoignition properties of ethanol–biodiesel fuel blends. Fuel 2019, 235, 1301–1308. [Google Scholar] [CrossRef]

- Kuszewski, H.; Jaworski, A.; Ustrzycki, A.; Lejda, K.; Woś, P. Use of the constant volume combustion chamber to examine the properties of autoignition and derived cetane number of mixtures of diesel fuel and ethanol. Fuel 2017, 200, 564–575. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Gnatowski, A.; Gnatowska, R.; Winczek, J.; Sosnowski, M. Modeling of Thermal Cycle CI Engine with Multi-Stage Fuel Injection. Adv. Sci. Technol. Res. J. 2017, 11, 179–186. [Google Scholar] [CrossRef]

- Merkisz, J.; Waligórski, M. Strategy of the combustion process diagnosis in direct injection engines. Procedia Eng. 2014, 96, 294–301. [Google Scholar] [CrossRef][Green Version]

- Stelmasiak, Z.; Matyjasik, M. Simulation of the combustion in a dual fuel engine with a divided pilot dose. Combust. Engines 2012, 4, 43–54. [Google Scholar]

- Merkisz, J.; Fuć, P.; Lijewski, P.; Pielecha, J. Actual emissions from urban buses powered with diesel and gas engines. Transp. Res. Procedia 2016, 14, 3070–3078. [Google Scholar] [CrossRef]

- Stelmasiak, Z.; Matyjasik, M. Exhaust emissions of dual fuel self-ignition engine with divided initial dose. Combust. Engines 2013, 154, 944–952. [Google Scholar]

- Rimkus, A.; Žaglinskis, J.; Stravinskas, S.; Rapalis, P.; Matijošius, J.; Bereczky, Á. Research on the combustion, energy and emission parameters of various concentration blends of hydrotreated vegetable oil biofuel and diesel fuel in a compression-ignition engine. Energy 2019, 12, 2978. [Google Scholar] [CrossRef]

- Rimkusa, A.; Matijošius, J.; Bogdevičius, M.; Bereczky, Á.; Török, Á. An investigation of the efficiency of using O2 and H2 (hydrooxile gas-HHO) gas additives in a ci engine operating on diesel fuel and biodiesel. Energy 2018, 152, 640–651. [Google Scholar] [CrossRef]

- Li, J.; Yang, W.M.; An, H.; Zhao, D. Effects of fuel ratio and injection timing on gasoline/biodiesel fueled RCCI engine: A modeling study. Appl. Energy 2015, 155, 59–67. [Google Scholar] [CrossRef]

- Tong, L.; Wang, H.; Zheng, Z.; Reitz, R.; Yao, M. Experimental study of RCCI combustion and load extension in a compression ignition engine fueled with gasoline and PODE. Fuel 2016, 181, 878–886. [Google Scholar] [CrossRef]

- Reitz, R.D.; Duraisamy, G. Review of high efficiency and clean reactivity controlled compression ignition (RCCI) combustion in internal combustion engines. Prog. Energy Combust. Sci. 2015, 46, 12–71. [Google Scholar] [CrossRef]

- Szwaja, S.; Ansari, E.; Rao, S.; Szwaja, M.; Pyrc, M. Influence of exhaust residuals on combustion phases, exhaust toxic emission and fuel consumption from a natural gas fueled spark-ignition engine. Energy Convers. Manag. 2018, 165, 440–446. [Google Scholar] [CrossRef]

- Kapusta, Ł.J.; Teodorczyk, A. Numerical simulations of dual fuel combustion in a heavy duty compression ignition engine. Combust. Engines 2015, 163, 47–56. [Google Scholar]

- Gad, M.S.; EL-Seesy, A.I.; Radwan, A.; He, Z. Enhancing the combustion and emission parameters of a diesel engine fueled by waste cooking oil biodiesel and gasoline additives. Fuel 2020, 269, 117466. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Book Company: New York, NY, USA, 2018. [Google Scholar]

- Bockhorn, H. Soot Formation in Combustion: Mechanisms and Models; Springer: Berlin/Heidelberg, Germany, 1994. [Google Scholar]

| Parameter | Value |

|---|---|

| Number of cylinders | 1 |

| Bore | 90 mm |

| Stroke | 90 mm |

| Displaced volume | 0.573 dm3 |

| Compression ratio | 17:1 |

| Crankshaft rotational speed | 1500 rpm |

| Biodiesel injection pressure | 21 MPa |

| Biodiesel injection timing | 23 deg bTDC |

| Maximum rated power | 7.4 kW |

| Properties | Diesel | Biodiesel | Gasoline |

|---|---|---|---|

| Molecular formula | C14H30 | CH3(CH2)nCOOH3 | CnH1.87n |

| Molecular weight | 170–198 | ~294 | 114.15 |

| Surface tension (mN/m @ 15 °C) | 26.9 | 31.1 | 21.60 |

| Cetane number | 51 | 56 | 10–15 |

| Research Octane Number | 20–30 | - | 95 |

| Lower heating value, (MJ/kg) | 41.7 | 37.1 | 42.7 |

| Density at 20 °C, kg/m3 | 856 | 855 | 745 |

| Viscosity at 25 °C, (mPa s) | 2.8 | 4.51 | 0.6 |

| Heat of evaporation, (kJ/kg) | 260 | 250 | 320 |

| Stoichiometric air fuel ratio | 14.7 | 12.5 | 14.7 |

| Autoignition temperature, (°C) | 300–340 | 363 | 420 |

| Flash point, (°C) | 78 | >101 | −43 |

| Hydrogen content, wt % | 13 | 12.1 | 14 |

| Carbon content, wt % | 87 | 77.1 | 86 |

| Oxygen content, wt % | 0 | 10.8 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tutak, W.; Jamrozik, A. Influence of Gasoline Addition on Biodiesel Combustion in a Compression-Ignition Engine with Constant Settings. Processes 2020, 8, 1499. https://doi.org/10.3390/pr8111499

Tutak W, Jamrozik A. Influence of Gasoline Addition on Biodiesel Combustion in a Compression-Ignition Engine with Constant Settings. Processes. 2020; 8(11):1499. https://doi.org/10.3390/pr8111499

Chicago/Turabian StyleTutak, Wojciech, and Arkadiusz Jamrozik. 2020. "Influence of Gasoline Addition on Biodiesel Combustion in a Compression-Ignition Engine with Constant Settings" Processes 8, no. 11: 1499. https://doi.org/10.3390/pr8111499

APA StyleTutak, W., & Jamrozik, A. (2020). Influence of Gasoline Addition on Biodiesel Combustion in a Compression-Ignition Engine with Constant Settings. Processes, 8(11), 1499. https://doi.org/10.3390/pr8111499