Research on Non-Uniform Wear of Liner in SAG Mill

Abstract

1. Introduction

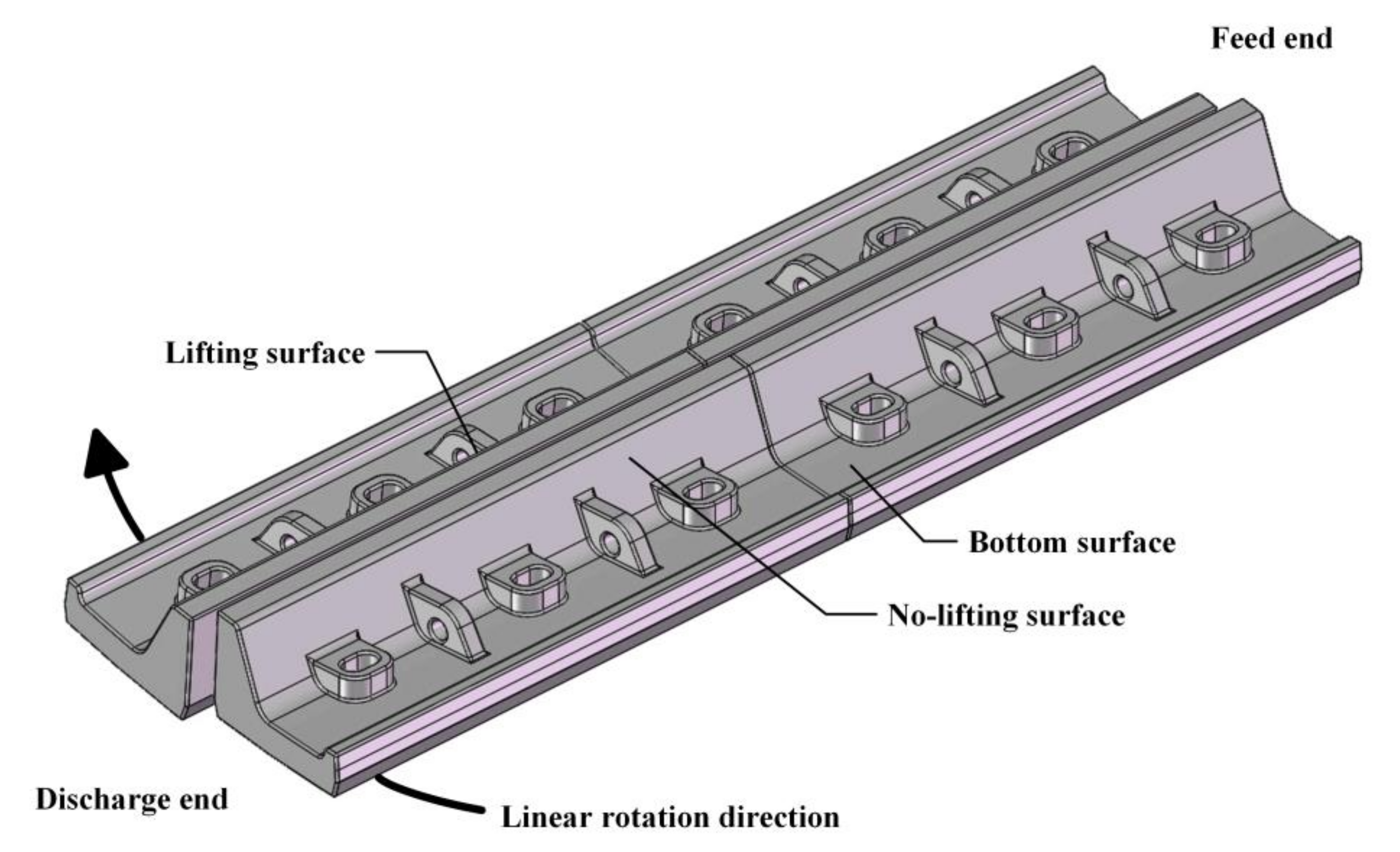

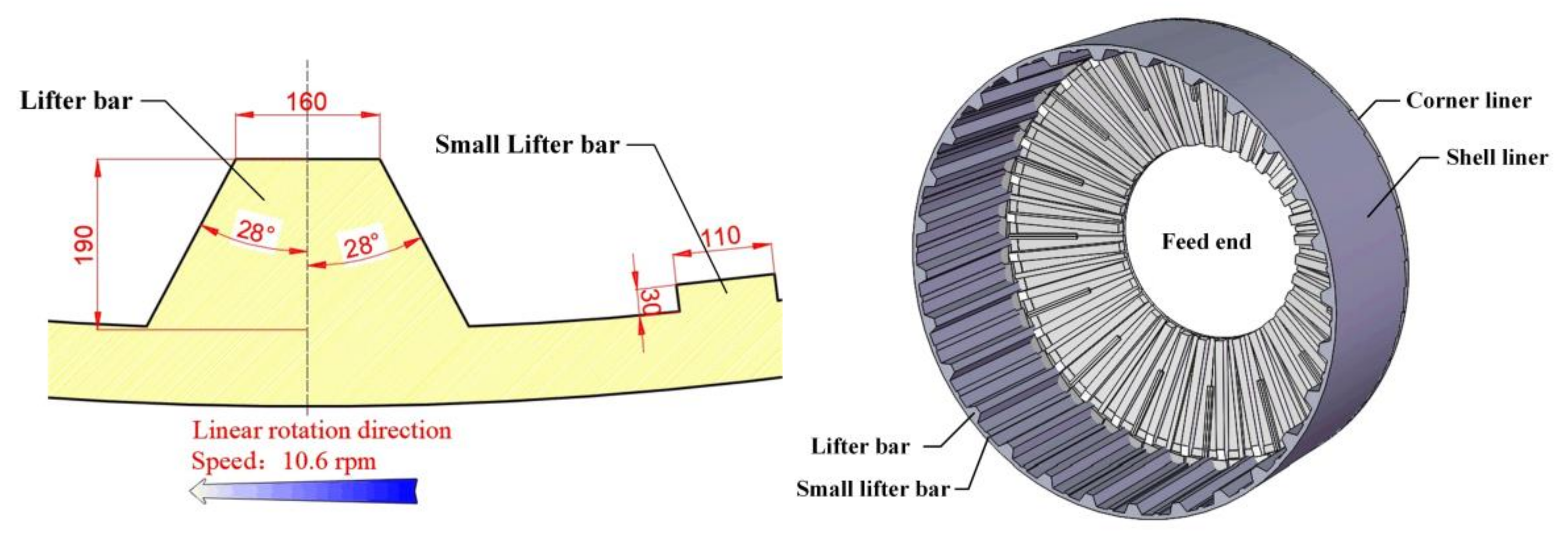

2. The Current Wear of the Cylinder Liner Structure

3. Numerical Method

3.1. Research Object

3.2. Parameter Setting

4. Results and Discussion

4.1. The Relationship between the Wear of the SAG Mill Liner and the Particle Quality

4.2. Analysis of the Influence on Liner Wear by Particles with the Same Quality

4.3. Variation of the Distribution of Particle Compositions in Each Area of the Cylinder

5. Conclusions

- The non-uniform wear along the axial direction of the cylinder liner in the large-scale SAG mill was caused by the stratification of particles during cylinder operation and the difference in the total mass of the particles in each area;

- The stratification of particles along the axial direction was the inevitable result of the conical structure of the feed end cover and the discharge end cover. With the high-speed rotation of the cylinder, the particles were thrown to the middle of the cylinder under the influence of the end cover. Large particles could only be thrown down to both sides of the cylinder, while particles with small masses were concentrated in the middle of the cylinder. As a result, the impact energy and impact density of each area of the liner along the axial direction were different, which ultimately produced the non-uniform wear of the liner along the axial direction;

- By analyzing the data of each kind of particle one by one, it was found that when the mass of a single particle was below 3 kg, the particles would have obvious accumulation in the middle, and the lighter the mass, the greater the accumulation. When the mass of a single particle was about 6 kg, the particle distribution was the most uniform. When the mass of a single particle was greater than 10 kg, this kind of particle would accumulate on both sides of the cylinder, making the wear in these areas larger than in other areas. More importantly, this effect would begin to appear in the first few laps of the SAG mill and would continue to affect work efficiency until the end of the work. Therefore, when the SAG mill is configured, the main crushed particles (that is, the rocks with a particle size of 180mm in this study) should be distributed as evenly as possible throughout the cylinder;

- The particles were affected by the conical surfaces on both sides of the cylinder, and the number of particles distributed in Areas 1 and 10 was relatively small, so the total mass and wear of the particles in Areas 1 and 10 were always the smallest;

- The accumulation of large mass particles on both sides increased the wear of the liner and also affected the discharge, which increased the possibility of jams and stubborn stone accumulation.

Author Contributions

Funding

Conflicts of Interest

References

- Jnr, W.V.; Morrell, S. The development of a dynamic model for autogenous and semi-autogenous grinding. Miner. Eng. 1995, 8, 1285–1297. [Google Scholar]

- Lakshmanan, V.I.; Ojaghi, A.; Gorain, B. Beneficiation of Gold and Silver Ores. In Innovations and Breakthroughs in the Gold and Silver Industries; Springer: Cham, Switzerland, 2019; pp. 49–77. [Google Scholar]

- Shiliang, Y.; Baodong, Y.; Longde, L.; Xiaoli, G.; Yue, W. Exploration of application of SABC process in domestic production practices. Gold 2013, 3, 19. [Google Scholar]

- Chandramohan, R.; Powell, M.S. A structured approach to modelling SAG mill liner wear–monitoring wear. In Proceedings of the International Autogenous and Semiautogenous Grinding Technology, Vancouver, Canada, 23–27 September 2006; University of British Columbia: Vancouver, BC, Canada, 2006; pp. 24–27. Available online: https://www.researchgate.net/profile/Malcolm_Powell/publication/43498056_A_structured_approach_to_modelling_SAG_mill_liner_wear_-_monitoring_wear/links/58afac92a6fdcc6f03f358c8/A-structured-approach-to-modelling-SAG-mill-liner-wear-monitoring-wear.pdf (accessed on 26 November 2020).

- Weidenbach, M.; Griffin, P. Liner optimisation to improve availability of the Ridgeway SAG mill. In Proceedings of the Ninth Mill Operators’ Conference, Fremantle, Australia, 19–21 March 2007; The Australasian Institute of Mining and Metallurgy: Carlton, Australia, 2007. [Google Scholar]

- Banisi, S.; Hadizadeh, M. 3-D liner wear profile measurement and analysis in industrial SAG mills. Miner. Eng. 2007, 20, 132–139. [Google Scholar] [CrossRef]

- Yahyaei, M.; Banisi, S. Spreadsheet-based modeling of liner wear impact on charge motion in tumbling mills. Miner. Eng. 2010, 23, 1213–1219. [Google Scholar] [CrossRef]

- Yahyaei, M.; Banisi, S.; Hadizadeh, M. Modification of SAG mill liner shape based on 3-D liner wear profile measurements. Int. J. Miner. Process. 2009, 91, 111–115. [Google Scholar] [CrossRef]

- Mishra, B.K.; Rajamani, R.K. The discrete element method for the simulation of ball mills. Appl. Math. Model. 1992, 16, 598–604. [Google Scholar] [CrossRef]

- Cleary, P.W. Charge behaviour and power consumption in ball mills: Sensitivity to mill operating conditions, liner geometry and charge composition. Int. J. Miner. Process. 2001, 63, 79–114. [Google Scholar] [CrossRef]

- Toor, P.; Bird, M.; Perkins, T.; Powell, M.; Franke, J. The influence of liner wear on milling efficiency. Proc. Metplant 2011, 2011, 193–212. [Google Scholar]

- Cleary, P.W. Axial transport in dry ball mills. Appl. Math. Model. 2006, 30, 1343–1355. [Google Scholar] [CrossRef]

- Xu, L.; Luo, K.; Zhao, Y. Numerical prediction of wear in SAG mills based on DEM simulations. Powder Technol. 2018, 329, 353–363. [Google Scholar] [CrossRef]

- Zhang, X. Performance Analysis of Ball Mill Liner Based on DEM-FEM Coupling. Adv. Manuf. Autom. 2020, 634, 3. [Google Scholar]

- Herbst, J.A.; Nordell, L. Optimization of the design of sag mill internals using high fidelity simulation. In Proceedings of the SAG Conference, Vancouver, Canada, 30 September–3 October 2001; University of British Columbia: Vancouver, BC, Canada, 2001; Volume 4, pp. 150–164. [Google Scholar]

- Cleary, P.W.; Owen, P. Effect of operating condition changes on the collisional environment in a SAG mill. Miner. Eng. 2019, 132, 297–315. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Xu, L.; Bao, S.; Zhao, Y. Multi-level DEM study on liner wear in tumbling mills for an engineering level approach. Powder Technol. 2020, 364, 332–342. [Google Scholar] [CrossRef]

- Li, T.; Peng, Y.; Zhu, Z.; Zou, S.; Yin, Z. Discrete element method simulations of the inter-particle contact parameters for the mono-sized iron ore particles. Materials 2017, 10, 520. [Google Scholar] [CrossRef] [PubMed]

- Morrell, S. Predicting the specific energy of autogenous and semi-autogenous mills from small diameter drill core samples. Miner. Eng. 2004, 17, 447–451. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Poisson’s ratio of liner material | 0.3 | |

| Liner material density | 7800 | kg/m3 |

| Length of the mill | 3.96 | m |

| Steel ball fill rate | 11 | % |

| Maximum steel ball diameter | 150 | mm |

| Total fill rate | 28 | % |

| Rotation rate | 10.6 | rpm |

| Liner length | 1618 | mm |

| Height of the lifter bar | 190 | mm |

| Number of lifter bars | 28 | - |

| Height of the small lifter bar | 30 | mm |

| Density of the rock | 3400 | kg/m3 |

| Coefficient of restitution between the rock | 0.5 | - |

| Coefficient of restitution between the rock and steel ball/cylinder | 0.41 | - |

| Coefficient of static friction between the rock | 0.49 | - |

| Coefficient of static friction between the rock and steel ball/cylinder | 0.5 | - |

| Coefficient of rolling friction between the rock | 0.15 | - |

| Coefficient of rolling friction between the rock and steel ball/cylinder | 0.25 | - |

| Kind of Particle | Particle Size (mm) | Mass (kg) | Proportion of Total Mass |

|---|---|---|---|

| Steel ball | 150 | 13.8 | 10.7% |

| Steel ball | 130 | 9 | 16% |

| Rock | 200 | 6.9 | 8.4% |

| Steel ball | 110 | 5.4 | 10.7% |

| Rock | 180 | 4 | 29.1% |

| Steel ball | 90 | 3 | 10.7% |

| Steel ball | 70 | 1.4 | 5.3% |

| Rock | 60 | 0.3 | 9.1% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Che, H.; Hao, Q. Research on Non-Uniform Wear of Liner in SAG Mill. Processes 2020, 8, 1543. https://doi.org/10.3390/pr8121543

Wu W, Che H, Hao Q. Research on Non-Uniform Wear of Liner in SAG Mill. Processes. 2020; 8(12):1543. https://doi.org/10.3390/pr8121543

Chicago/Turabian StyleWu, Wanrong, Haoran Che, and Qianhua Hao. 2020. "Research on Non-Uniform Wear of Liner in SAG Mill" Processes 8, no. 12: 1543. https://doi.org/10.3390/pr8121543

APA StyleWu, W., Che, H., & Hao, Q. (2020). Research on Non-Uniform Wear of Liner in SAG Mill. Processes, 8(12), 1543. https://doi.org/10.3390/pr8121543