Layout Optimization Process to Minimize the Cost of Energy of an Offshore Floating Hybrid Wind–Wave Farm

Abstract

1. Introduction

2. Materials and Methods

2.1. The Costs Model

2.1.1. Levelized Cost of Energy (LCOE)

2.1.2. Capital Expenditures (CAPEX)

| estimation of concession costs per capacity unit. | |

| total capacity of the farm. | |

| FPP’s margin as a percentage of investment costs. | |

| acquisition cost of the P80. | |

| cost of components’ transportation to assembly site. | |

| P80 assembly costs. |

| is the total capacity of the farm. | |

| is the considered cost per capacity. |

| is the cost of a P80 platform. | |

| is the number of platforms. | |

| are costs associated to condition monitoring and the SCADA systems. |

| fixed cost of a platform’s mooring system (anchors, buoyancy elements, etc.). | |

| length dependent cost of the mooring lines. | |

| linear rate of mooring lines length per seafloor depth. | |

| depth under platform i. |

| is the cost of transportation of the components to the assembly site. | |

| assembly costs. | |

| mooring installation costs. | |

| costs of installation of the electrical infrastructure. | |

| costs of on-site platforms installation. | |

| commissioning or connection costs. |

| the electrical infrastructure. | |

| the platforms. | |

| the mooring system. | |

| the paperwork involved in the process. |

2.1.3. Operational Expenditures (OPEX)

| the fixed yearly O&M cost: port charges, fixed costs of vessels, etc. | |

| the O&M cost per platform in year i. | |

| hours of planned downtime in year i. |

| estimated number of failures per year for failure type i. | |

| fixed repair cost per failure for failure type i (mobilization costs, etc.). | |

| time dependent cost for failure type i (it includes personnel, vessel costs, etc.). | |

| repair time for failure type i. | |

| average distance to harbor. | |

| going speed of the vessel used in failure type i. | |

| return speed of the vessel used in failure type i. |

2.2. Optimization

2.2.1. Particle Swarm Optimization

2.2.2. Decision Variables

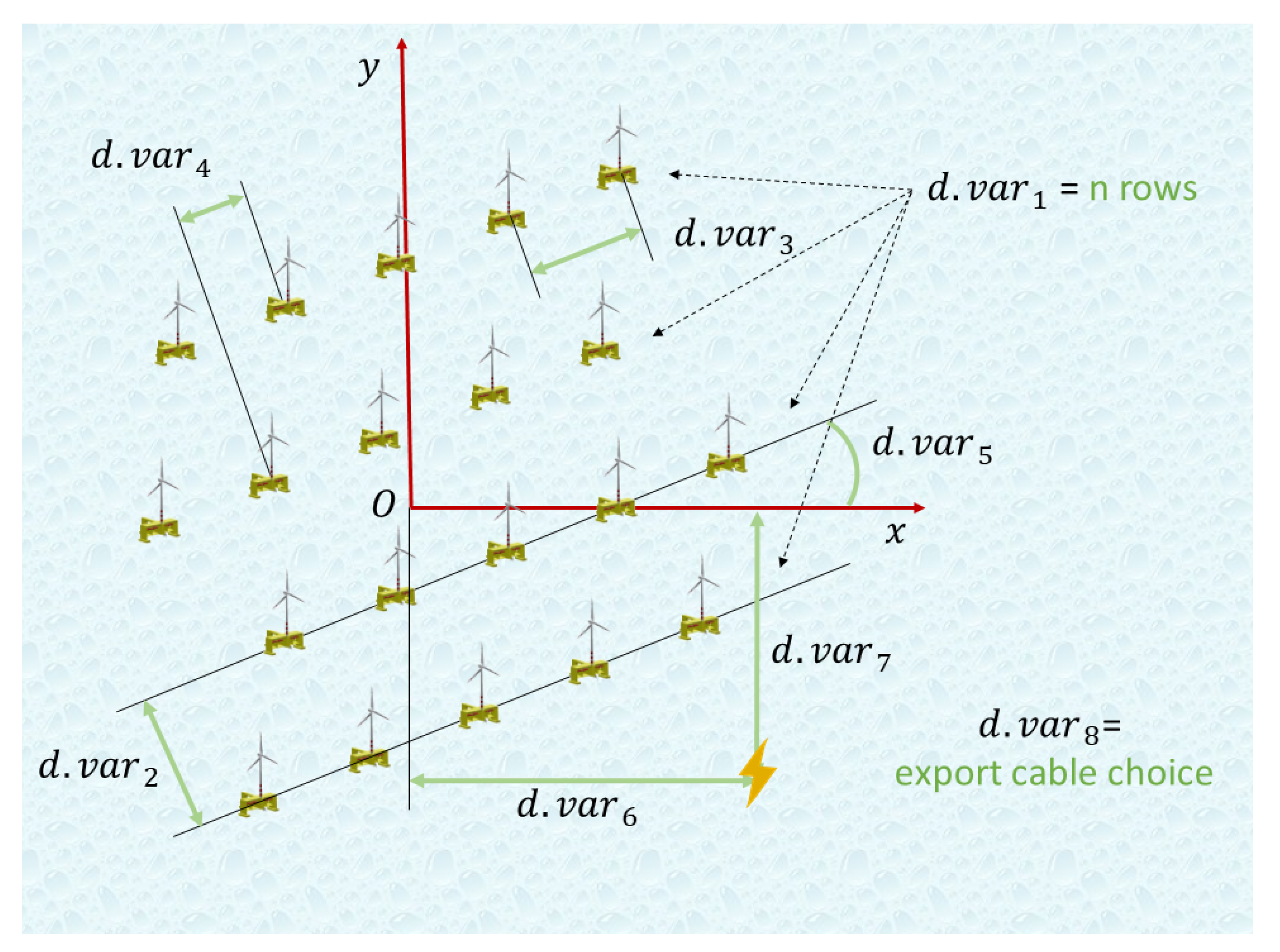

- First, the decision variables associated to the positions of the platforms: arguably, the most relevant decision variables of the model. With a set number of platforms in the farm, different ways of arranging the turbines were considered. At first, the platforms were allowed to be located independently within the limited site’s area. However, rather messy and unorganized arrangements were obtained, and this option was soon discarded due to consequent negative visual impact and the operational difficulties that this may involve (e.g., definition of boat routes and safe access areas). Moreover, this arrangement method involved having 2 decision variables per platform (x and y coordinates), which increased the computational time and decreased the efficiency of the algorithm significantly. To solve these issues, the platforms were finally arranged in rows and it was resolved that a total of five decision variables were necessary to define completely the positions of all the platforms: these are the number of rows (); the separation between rows (); the separation between platforms in each row (); the row offset (), i.e., the relative positional shift along the rows’ direction of consecutive rows; and the orientation angle of the rows (). As it can be seen in Figure 2, the platforms are located around the site’s center coordinates, so the rows are distributed equally to each side. These input parameters or decision variables are then converted into the platforms coordinates inside the function: first, the number of platforms and rows is read, and therefore the rows are created with their specified spacing ( and ); then, the uneven extra platforms are successively added from the last row towards the first one; finally, the orientation angle is applied by multiplying each platform’s coordinates by a a two-dimensional rotation matrix ().

- The second group of decision variables ( and ) are the coordinates of the offshore substation, specified as x and y distances with respect to the center of the site O.

- Finally, the last decision variable () is the farm’s export cable choice among the available ones, which has an impact in the costs and transmission losses as the chosen cable has its own specifications.

- Harbor and inland substation choice among the available ones in the area: even though the LCOE output is definitely influenced by this decision, there are many external factors that condition it as this choice highly depends on the state legislation and planning; it also depends on particular characteristics of both the harbour and substation: their size, availability, grid strength, and so on. Therefore, it would be unrealistic to model these factors so it was considered that it should be the user who makes this decision, after a site-specific study.

- The number of platforms: similarly, this factor depends mainly on the region and country where the farm would be installed. Factors like the strength of the grid or the need of power in the surrounding area will determine the total capacity of the farm, and thus it is something that must be chosen manually after studying these particularities.

- WTG size: One of the initial decision variables considered. However, as the P80 is currently designed to host a 8 MW WTG, it was finally decided to develop the model with it. Another type of WTG would imply different input costs, a different hub height and therefore different wind speed inputs, and probably also a different scale of the platforms and WECs.

- Lifetime: This parameter depends entirely on the design of the structures involved in the project, not on the project planning itself. As the P80 design is given for granted in the model with its consequent costs and characteristics, optimizing the lifetime is out of the scope of the model. In fact, the model would tend to increase the lifetime indefinitely in order to share the unrealistically constant investment costs with a higher amount of energy production along the years, thus reducing the LCOE as the lifetime increases. It was also considered to model an aging rate, but this was regarded as being too uncertain due to the lack of information about the real aging behavior of the P80.

2.2.3. Constraints and Penalties

- Minimum separation between platforms: they cannot be placed closer than a certain distance (because of the turbulence at the wake of the turbines, the mooring lines length, etc.).

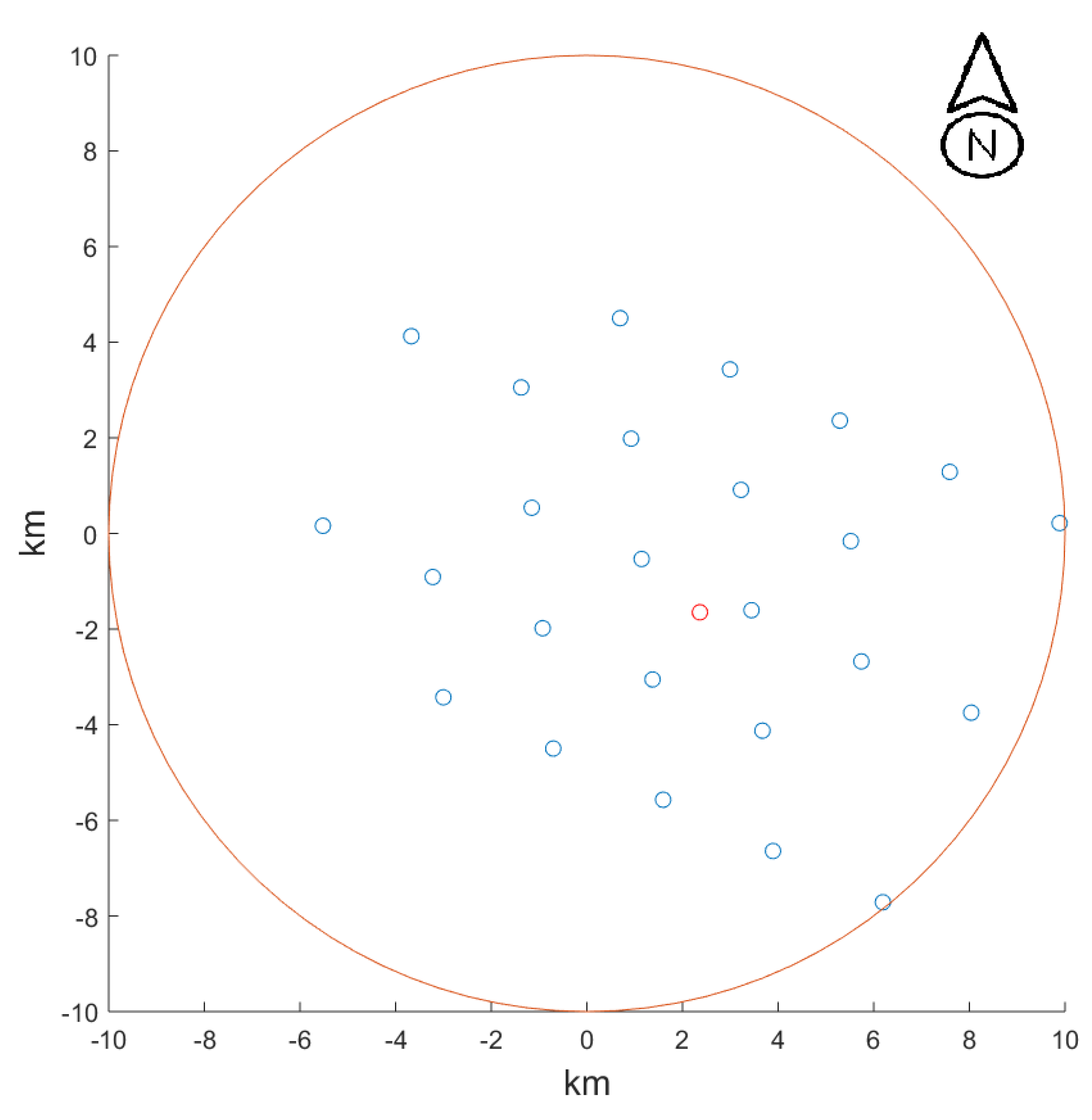

- Site delimitation: the available space cannot be infinite as the model considers a single wind and waves climate for the whole site. The site area is defined with a radius of 10 km around the center coordinates.These two first constraints affect directly the coordinates of the platforms, and indirectly the decision variables that determine their arrangement ( to ).

- Depth range: which is determined by the depth boundaries of the mooring system (from 40 to 200 m, for the case study presented later). The depth range may result in restricted areas where the seafloor is either too shallow or too deep.

- Minimum separation between platforms and substation: similarly to the first constraint, due to security and operational reasons.

- Rated power of the export cable: so the algorithm chooses an export cable that can bear the farm’s maximum output power.

2.2.4. Performance Improvement

3. Case Study and Results

3.1. General Description

3.2. Processes Involved in the Optimization Model

3.2.1. Definition of Constraints and Parameters

- Two main factors influence the minimum separation between the platforms: the turbulence at the wake of the wind turbines with the subsequent undesired loads in the neighboring turbines, and the horizontal length of the mooring lines which, given their dynamic nature, cannot intersect each other. Taking into account these considerations, the constraint is modeled as follows.

- It was decided to use a minimum separation between the platforms and the offshore substation of 1000 m. Given that the mooring system of the substation is considered to be much more simple and static than that of the P80s, this separation is more than enough. Furthermore, it is assumed that no further interaction between substation and generators exists in terms of wind blocking and waves shadow.

- Sixteen types of HV export cables were modeled in this case analysis, each of them with a nominal current (), section (), nominal voltage (), rated power (), and metric cost. All these cables are subject to be chosen as long as they fulfill the maximum power output constraint. The optimizer thus intends to find a balance between the total cost and transmission losses.

- The site delimitation was set to a circular area with a radius of 10 km around the site’s center coordinates, due to the fact that the wind and waves resources cannot be considered constant at higher distances. Furthermore, more extensive areas are not necessary for big farms like this one.

- Finally, the discount rate value that has been considered according to the type of technology and which has been used throughout the optimization process in this case analysis, is that of 9% [33], although this is one of the parameters with the highest level of uncertainty.

3.2.2. Optimization Process Methodology

- Step 1: finding the best sites

- Step 2: optimization and choice of the best site

- Step 3: final optimization

3.3. Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AEP | Annual Energy Production |

| ASO | Agent Swarm Optimization |

| CAPEX | Capital Expenditures |

| DTU | Technical University of Denmark |

| FPP | Floating Power Plant A/S |

| GA | Genetic Algorithm |

| HV | High Voltage |

| LCOE | Levelized Cost of Energy |

| OPEX | Operational Expenditures |

| O&M | Operation & Maintenance |

| PSO | Particle Swarm Optimization |

| WTG | Wind Turbine Generator |

| WEC | Wave Energy Converters |

References

- NASA. Global Climate Change: Scientific Consensus. Available online: https://climate.nasa.gov/scientific-consensus (accessed on 9 November 2019).

- Pachauri, R.K.; Allen, M.R.; Barros, V.R.; Broome, J.; Cramer, W.; Christ, R.; Church, J.A.; Clarke, L.; Dahe, Q.; Dasgupta, P.; et al. Climate Change 2014: Synthesis Report. In The Core Writing Team; Pachauri, R.K., Meyer, L., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Komusanac, I.; Fraile, D.; Brindley, E. Wind Energy in Europe in 2018, Trends and Statistics; WindEurope: Bruxelles, Belgium, 2019; Available online: www.windeurope.org (accessed on 9 November 2019).

- World Wind Energy Association (WWEA). Wind Power Capacity Worldwide Reaches 597 GW, 50.1 GW. Available online: https://wwindea.org/blog/2019/02/25/wind-power-capacity-worldwide-reaches-600-gw-539-gw-added-in-2018/ (accessed on 9 November 2019).

- Global Offshore Wind Energy Capacity from 2008 to 2018 (in Megawatts). Available online: https://www.statista.com/statistics/476327/global-capacity-of-offshore-wind-energy/ (accessed on 9 November 2019).

- Haliade-X Offshore Wind Turbine Platform. Available online: https://www.ge.com/renewableenergy/wind-energy/offshore-wind/haliade-x-offshore-turbine (accessed on 9 November 2019).

- Pérez-Collazo, C. A Review of Combined Wave and Offshore Wind Energy. Renew. Sustain. Energy Rev. 2015, 42, 141–153. [Google Scholar] [CrossRef]

- Astariz, S. Enhancing wave energy competitiveness through co-located wind and wave energy farms. A review on the shadow effect. Energies 2015, 8, 7344–7366. [Google Scholar] [CrossRef]

- Floating Power Plant A/S. Available online: http://www.floatingpowerplant.com/ (accessed on 9 November 2019).

- Bäck, T. Evolutionary Algorithms in Theory and Practice: Evolution Strategies, Evolutionary Programming, Genetic Algorithms; Oxford University Press: Oxford, UK, 1996. [Google Scholar]

- Mosetti, P. Optimization of wind turbine positioning in large windfarms by means of a genetic algorithm. J. Wind. Eng. Ind. Aerodyn. 1994, 51, 105–116. [Google Scholar] [CrossRef]

- Serrano-González, J. Optimization of wind farm turbines layout using an evolutive algorithm. Renew. Energy 2010, 35, 1671–1681. [Google Scholar] [CrossRef]

- Grady, H. Placement of wind turbines using genetic algorithms. Renew. Energy 2005, 30, 259–270. [Google Scholar] [CrossRef]

- Emami, A. New approach on optimization in placement of wind turbines within wind farm by genetic algorithms. Renew. Energy 2010, 35, 1559–1564. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the IEEE International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; IEEE Press: Piscataway, NJ, USA, 1995; pp. 1942–1948. [Google Scholar]

- Ohlsen, G.L. Positioning of Danish Offshore Wind Farms until 2030—Using Levelized Cost of Energy (LCoE). Master’s Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2019. [Google Scholar]

- Izquierdo-Pérez, J. Sensitivity Analysis on the Levelized Cost of Energy for Floating Offshore Wind Farms. Master’s Thesis, Technical University of Denmark, Kongens Lyngby, Denmark, 2019. [Google Scholar]

- Lerch, M. Sensitivity analysis on the levelized cost of energy for floating offshore wind farms. Sustain. Energy Technol. Assess. 2018, 30, 77–90. [Google Scholar] [CrossRef]

- González-Rodríguez, A. Review of offshore wind farm cost components. Energy Sustain. Dev. 2017, 37, 10–19. [Google Scholar] [CrossRef]

- Manwell, J.F.; McGowan, J.G.; Rogers, A.L. Wind Energy Explain. Theory, Des. Application; John Wiley Sons: Chichester, UK, 2010. [Google Scholar]

- Montalvo, I.; Martínez-Rodríguez, J.B.; Izquierdo, J.; Pérez-García, R. Water Distribution System Design using Agent Swarm Optimization. In Proceedings of the Water Distribution System Analysis 2010—WDSA2010, Tucson, AZ, USA, 19–23 September 2010; pp. 747–763. [Google Scholar]

- Montalvo, I.; Izquierdo, J.; Herrera, M.; Pérez-García, R. Water Distribution System Computer-aided Design by Agent Swarm Optimization. Comput.-Aided Civ. Infrastruct. Eng. 2014, 29, 433–448. [Google Scholar] [CrossRef]

- Shi, Y.H.; Eberhart, R.C. A modified particle swarm optimizer. In Proceedings of the IEEE International Conference on Evolutionary Computation Proceedings. IEEE World Congress on Computational Intelligence, Anchorage, AK, USA, 4–9 May 1998; pp. 69–73. [Google Scholar]

- Pedersen, M.E.H. Good Parameters for Particle Swarm Optimization; Technical Report no. HL1001; Hvass Laboratories: Seattle, WA, USA, 2010. [Google Scholar]

- Ireland Second Highest in Europe for Wind Energy. Available online: https://www.irishexaminer.com/breakingnews/ireland/ireland-second-highest-in-europe-for-wind-energy-910442.html (accessed on 9 November 2019).

- Ireland Plans 12GW Renewables Boost. Available online: https://www.windpowermonthly.com/article/1587884/ireland-plans-12gw-renewables-boost (accessed on 9 November 2019).

- Renewable Electricity Support Scheme. Department of Communications, Climate Action & Environment of the Republic of Ireland. Available online: https://www.dccae.gov.ie/en-ie/energy/topics/Renewable-Energy/electricity/renewable-electricity-supports/ress/Pages/default.aspx (accessed on 9 November 2019).

- EirGrid, SONI. DS3 Programme Operational Capability Outlook 2016. 2016. Available online: http://www.eirgridgroup.com/site-files/library/EirGrid/DS3-Operational-Capability-Outlook-2016.pdf (accessed on 14 January 2020).

- Desmond, C.J.; Murphy, J.; Blonk, L.; Haans, W. Description of an 8 MW reference wind turbine. J. Phys. Conf. Ser. 2016, 753. [Google Scholar] [CrossRef]

- Global Wind Atlas (GWA). Available online: https://globalwindatlas.info/ (accessed on 9 November 2019).

- MIKE 21 Wave Modelling Spectral Waves FM Short Description; Danish Hydraulics Institute: Horsholm, Denmark, 2017.

- Bathymetry Viewing and Downloading Service, EMODnet. Available online: http://portal.emodnet-bathymetry.eu/?menu=19 (accessed on 9 November 2019).

- Grant Thornton. A Grant Thornton and Clean Energy Pipeline initiative. In Renewable Energy Discount Rate Survey Results; Grant Thornton: Chicago, IL, USA, 2018. [Google Scholar]

| Problem Dimensions | Fitness Evaluations | PSO Parameters | |||

|---|---|---|---|---|---|

| SwarmSize | |||||

| 10 | 2000 | 63 | 0.6571 | 1.6319 | 0.6239 |

| 204 | 2.3259 | ||||

| 20,000 | 53 | 4.8976 | |||

(–) | Mean Depth (m) | (GWh) | (GWh) | |

|---|---|---|---|---|

| Site 4 | 104 | 97 | 1045.65 | 156.06 |

| Site 5 | 109.2 | 97 | 1042.64 | 171.79 |

| Site 6 | 114.2 | 120 | 1046.66 | 179.13 |

| Site 7 | 102.2 | 83 | 1034.70 | 146.79 |

| Site 8 | 105.8 | 95 | 1036.96 | 163.40 |

| Site 9 | 109.4 | 98 | 1038.64 | 171.13 |

| Site 10 | 113.7 | 119 | 1044.93 | 177.91 |

| Site 11 | 105.6 | 76 | 1032.88 | 152.41 |

| Site 12 | 109.7 | 98 | 1036.38 | 165.73 |

| Site 13 | 113.8 | 109 | 1038.71 | 174.05 |

| N. Rows | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Avg. |

|---|---|---|---|---|---|---|---|---|

| Site 4 | 102.32 | 102.13 | 102.15 | 101.81 | 101.91 | 101.85 | 101.93 | 102.02 |

| Site 7 | - | - | - | 100.34 | 100.43 | 100.39 | 100.45 | 100.41 |

| Site 8 | - | - | - | 103.68 | 103.79 | 103.73 | 103.81 | 103.76 |

| N. of Rows | Paramenters | 1st | 2nd | 3rd | 4th | 5th |

|---|---|---|---|---|---|---|

| 5 | Default | 100.12 | 100.13 | 100.13 | 100.13 | 100.13 |

| Recommended | 100 | 100.03 | 100.13 | 100.15 | 100.16 | |

| 7 | Default | 100.21 | 100.23 | 100.23 | 100.24 | 100.24 |

| Recommended | 99.93 | 99.93 | 99.94 | 99.97 | 100.12 |

| Separation between rows | 2187.12 m |

| Separations between platforms in a rows | 2535.44 m |

| Row offset | 3798.86 m |

| Angle of orientation | −24.99° |

| x-coordinate of the substation | 2364.55 m |

| y-coordinate of the substation | −1649.08 m |

| AEP wind gross | 1034.70 GWh | |

| Wake losses | 7.16 GWh | (0.69%) |

| AEP wind net | 1027.53 GWh | |

| AEP waves gross | 164.11 GWh | |

| Shadow losses | 0.08 GWh | (0.05%) |

| Vanning losses | 13.12 GWh | (8%) |

| AEP waves net | 150.90 GWh | |

| Avg. downtime losses | 123.2 GWh/year | |

| Avg. transmission losses | 1.73 GWh/year | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Izquierdo-Pérez, J.; Brentan, B.M.; Izquierdo, J.; Clausen, N.-E.; Pegalajar-Jurado, A.; Ebsen, N. Layout Optimization Process to Minimize the Cost of Energy of an Offshore Floating Hybrid Wind–Wave Farm. Processes 2020, 8, 139. https://doi.org/10.3390/pr8020139

Izquierdo-Pérez J, Brentan BM, Izquierdo J, Clausen N-E, Pegalajar-Jurado A, Ebsen N. Layout Optimization Process to Minimize the Cost of Energy of an Offshore Floating Hybrid Wind–Wave Farm. Processes. 2020; 8(2):139. https://doi.org/10.3390/pr8020139

Chicago/Turabian StyleIzquierdo-Pérez, Jorge, Bruno M. Brentan, Joaquín Izquierdo, Niels-Erik Clausen, Antonio Pegalajar-Jurado, and Nis Ebsen. 2020. "Layout Optimization Process to Minimize the Cost of Energy of an Offshore Floating Hybrid Wind–Wave Farm" Processes 8, no. 2: 139. https://doi.org/10.3390/pr8020139

APA StyleIzquierdo-Pérez, J., Brentan, B. M., Izquierdo, J., Clausen, N.-E., Pegalajar-Jurado, A., & Ebsen, N. (2020). Layout Optimization Process to Minimize the Cost of Energy of an Offshore Floating Hybrid Wind–Wave Farm. Processes, 8(2), 139. https://doi.org/10.3390/pr8020139