Intelligent Colored Token Petri Nets for Modeling, Control, and Validation of Dynamic Changes in Reconfigurable Manufacturing Systems

Abstract

:1. Introduction

2. Preliminary

2.1. Definition of Intelligent Colored Token Petri Nets

2.2. Design of Intelligent Colored Token Petri Nets

| Algorithm 1:Modeling operation and transportation resources |

| Initialization:Build a common load/unload place po and common transportation resource place pr, π = {Ro}, c = 0, j=0, and h = 0. |

| for (1, n, i++), choose ORi ∈ OR, do |

| while j < Fi, do |

| j = j + 1 |

| if Rij ∈ π, then |

| Build the place that corresponds to Ri(j-1), which is pa |

| Build the place that corresponds to Rij, which is pb |

| Build a transition tabhi and knowledge function Ψ(pa, cpi, dabhi) |

| Build an arc from pa to tabhi and an arc from tabhi to pb |

| if tabhi needs common place pr to transport part i from pa to pb, then |

| Update a knowledge function to Ψ(pa, pr, cpi, cti, dabhi) |

| Insert an arc from pr to tabhi and an arc from tabhi to pr. |

| end if |

| else |

| π = π ∪ {Rij} |

| c = c + 1 |

| Build a place and name it pc |

| Identify the place that corresponds to Ri(j-1), which is pa |

| Build a transition tachi and knowledge function Ψ(pa, cpi, dachi) |

| Build an arc from pa to tachi and an arc from tachi to pc |

| if tachi needs common place pr to transport part i from pa to pc, then |

| Update a knowledge function to Ψ(pa, pr, cpi, cti, dachi) |

| Insert an arc from pr to tachi and an arc from tachi to pr. |

| end if |

| end if |

| end while |

| Identify the place that corresponds to RiFi, which is pa |

| Build a transition ta0hi and knowledge function Ψ(pa, cpi, da0hi) |

| Build an arc from pa to ta0hi and an arc from ta0hi to po |

| if ta0hi needs common place pr to transport part i from pa to po, then |

| Update a knowledge function to Ψ(pa, pr, cpi, cti, da0hi) |

| Insert an arc from pr to ta0hi and an arc from ta0hi to pr. |

| end if |

| end for |

| / * Define the initial marking of the system */ |

|

| Output: The ICTPN model |

3. RMS Configuration Changes Modeling Based on ICTPN

3.1. Machine Breakdowns

- Step 1: Disable the transitions connected to the place corresponding to the breakdown machine and remove or disable this place p1.

- Step 2: Change the names of transitions based on new machine p4

- Step 3: Change the operation route from po → t011A → p1 → t130A → p3 → t300A → p0 to po → t041A → p4 → t430A → p3 → t300A → p0.

- Step 4: Connect the transitions to the new machine p4.

- Step 5: Change the names of the knowledge function of transitions based on new machine p4.

3.2. Addition of New Product

- Step 1: Add a new operation route from po → t040C → p4→ t430C → p3 → t300C → p0.

- Step 2: Add the transportation operation of part C. Transition t040C denotes loading part C to p4, and Ro2 is needed; t430C denotes transporting part C to p3 and Ro1 is needed. Transition t300C denotes unloading part C from p3 and Ro2 is needed. These operations can be done by common place pr.

- Step 3: Add the knowledge function of transitions based on a new operation route.

- Step 4: Place the token with color cp3 into place po, which denotes a part C that will be processed in the system.

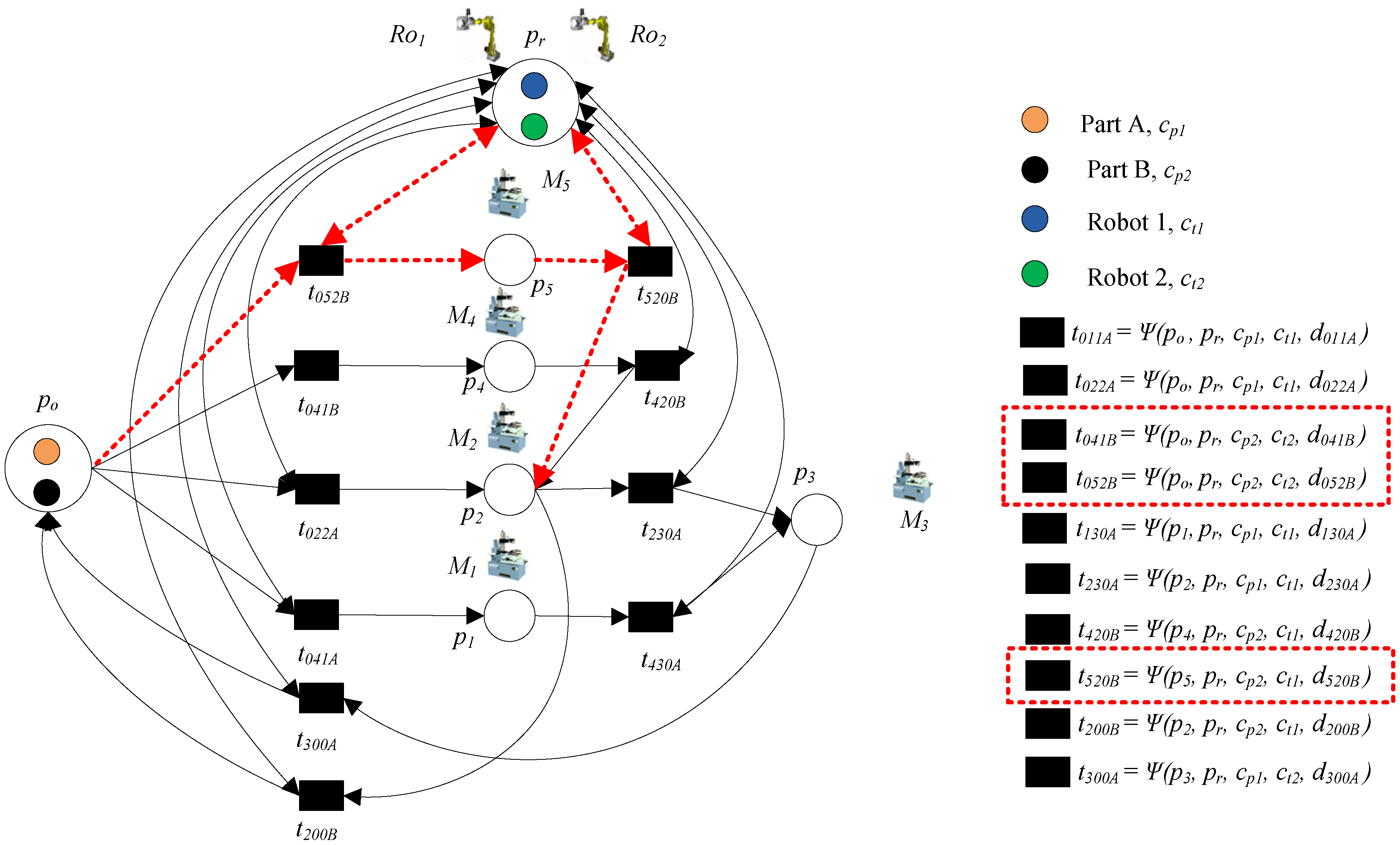

3.3. Addition of New Machine

- Step 1: Add process routes of part B as route 1: po → t041B → p4 → t420B → p2 → t200B → p0, or route 2: po → t052B → p5 → t520B → p2 → t200B → p0

- Step 2: Add the transportation operation of part B. Transitions t041B and t052B denote loading part B to p4 and p5, respectively, where Ro2 is needed; t420B and t520B denote transporting part B to p2, where Ro1 is needed; these operations can be done by common place pr.

- Step 3: Add the knowledge function of transitions based on a new machine

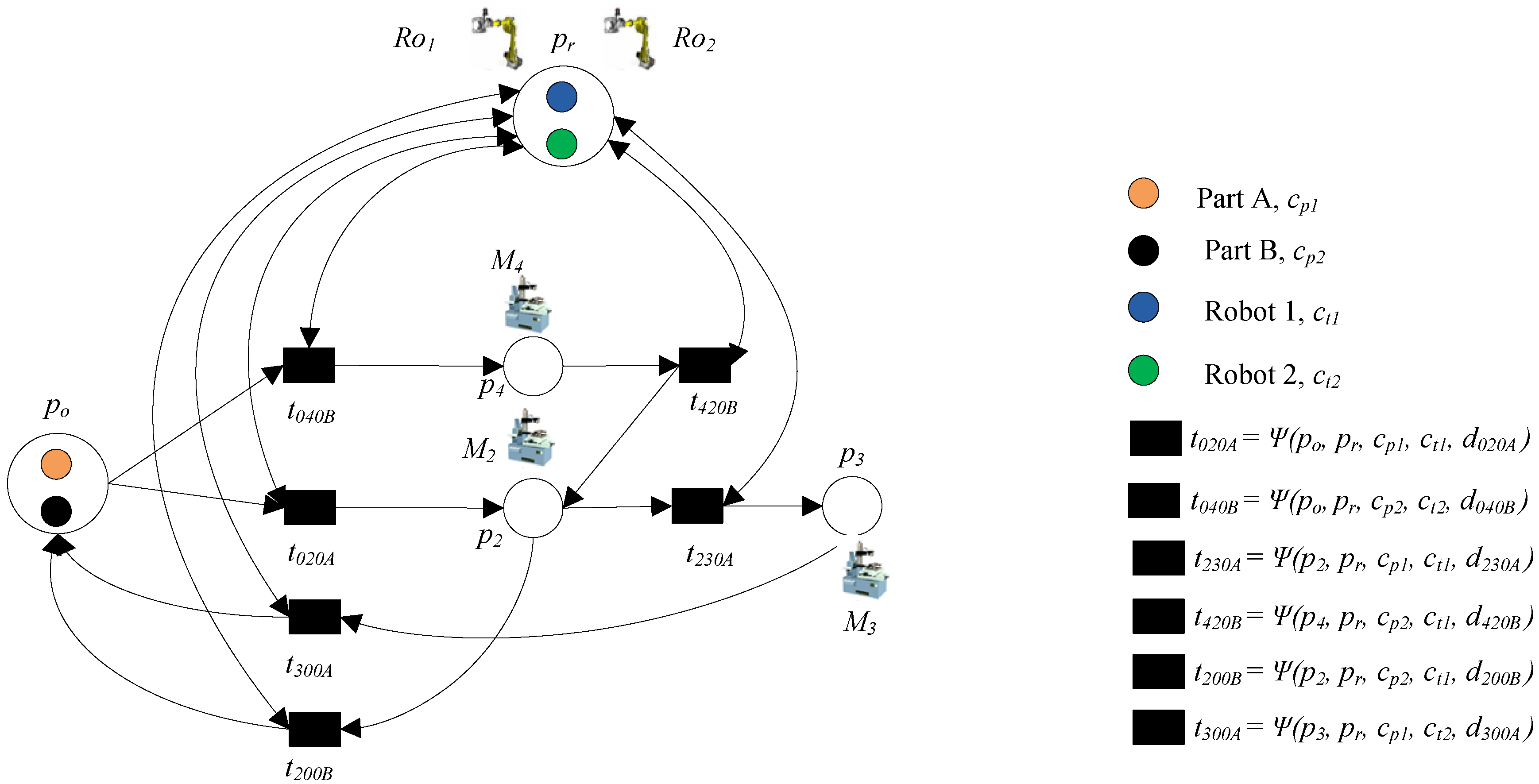

3.4. Removal of Old Machine

- Step 1: Delete all the transitions connected to the place corresponding to the removed machine p1 and remove this place p1.

- Step 2: One operation route will be considered, which is po → t020A → p2 → t230A → p3 → t300A → p0.

- Step 3: Delete the old knowledge function of transitions based on removed machine p1.

3.5. Change Processing Routes

- Step 1: Change the names of transitions based on processing routes.

- Step 2: Change the operation route of part A from po → t011A → p1 → t130A → p3 → t300A → p0 to po → t041A → p4 → t430A → p3 → t300A → p0.

- Step 3: Change the operation route of part A from po → t040B → p4 → t420B → p2 → t200B → p0 to po → t010B → p1 → t120B → p2 → t200B → p0.

- Step 4: Update the knowledge function of transitions based on removed machine p1.

3.6. Rework

- Load–unload station → M1 → inspection machine M3 → load–unload station,

- Load–unload station → M2 → inspection machine M3 → load–unload station,

- Load–unload station → M1 → inspection machine M3 → M1 → inspection machine M3 → load–unload station, or

- Load–unload station → M2→ inspection machine M3 → M1 → inspection machine M3 → load–unload station.

- Step 1: Add the process routes of part B as route 1: po → t011A → p1 → t130A → p3 → t300A → p0, route 2: po → t022A → p2 → t230A → p3 → t300A → p0, route 3: po → t011A → p1 → t130A → p3 → t310A → p1 → t130A → p3 → t300A → p0, or route 4: po → t022A → p1 → t230A → p3 → t310A → p1 → t130A → p3 → t300A → p0.

- Step 2: Add the knowledge function of transition based on rework:

4. Qualitative and Quantitative Study of ICTPN

4.1. Deadlock

4.2. Conservativeness

| D = | −1 | 0 | 1 | 0 | 0 | 0 |

| −1 | 0 | 0 | 1 | 0 | 0 | |

| −1 | 0 | 0 | 0 | 0 | 1 | |

| 0 | 0 | −1 | 0 | 1 | 0 | |

| 0 | 0 | 0 | −1 | 1 | 0 | |

| 0 | 0 | 0 | 1 | 0 | −1 | |

| 1 | 0 | 0 | −1 | 0 | 0 | |

| 1 | 0 | 0 | 0 | −1 | 0 |

| −1 | 0 | 1 | 0 | 0 | 0 | ||||

| −1 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | ||

| −1 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | ||

| 0 | 0 | −1 | 0 | 1 | 0 | 1 | 0 | ||

| 0 | 0 | 0 | −1 | 1 | 0 | × | 1 | = | 0 |

| 0 | 0 | 0 | 1 | 0 | −1 | 1 | 0 | ||

| 1 | 0 | 0 | −1 | 0 | 0 | 1 | 0 | ||

| 1 | 0 | 0 | 0 | −1 | 0 |

4.3. Reversibility

4.4. Structural Complexity

4.5. Validation and Behavioral Permissiveness of ICTPN Model

4.6. Computational Complexity

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mehrabi, M.G.; Ulsoy, A.G.; Koren, Y. Reconfigurable manufacturing systems: Key to future manufacturing. J. Intell. Manuf. 2000, 11, 403–419. [Google Scholar] [CrossRef]

- Katz, R. Design principles of reconfigurable machines. Int. J. Adv. Manuf. Technol. 2007, 34, 430–439. [Google Scholar] [CrossRef]

- Patel, R.; Gojiya, A.; Deb, D. Failure reconfiguration of pumps in two reservoirs connected to overhead tank. In Innovations in Infrastructure; Springer: Berlin/Heidelberg, Germany, 2019; pp. 81–92. [Google Scholar]

- Lee, S.; Tilbury, D.M. Deadlock-free resource allocation control for a reconfigurable manufacturing system with serial and parallel configuration. IEEE Trans. Syst. Man Cybern. Part C (Appl. Rev.) 2007, 37, 1373–1381. [Google Scholar] [CrossRef]

- Li, J.; Dai, X.; Meng, Z. Automatic reconfiguration of petri net controllers for reconfigurable manufacturing systems with an improved net rewriting system-based approach. IEEE Trans. Autom. Sci. Eng. 2009, 6, 156–167. [Google Scholar] [CrossRef]

- Wu, N.; Zhou, M. Intelligent token petri nets for modelling and control of reconfigurable automated manufacturing systems with dynamical changes. Trans. Inst. Meas. Control 2011, 33, 9–29. [Google Scholar]

- Târnaucă, B.; Puiu, D.; Comnac, V.; Suciu, C. Modelling a flexible manufacturing system using reconfigurable finite capacity petri nets. In Proceedings of the 2012 13th International Conference on. Optimization of Electrical and Electronic Equipment (OPTIM), Brasov, Romania, 24–26 May 2012; pp. 1079–1084. [Google Scholar]

- Kahloul, L.; Bourekkache, S.; Djouani, K.; Chaoui, A.; Kazar, O. Using high level petri nets in the modelling, simulation and verification of reconfigurable manufacturing systems. Int. J. Softw. Eng. Knowl. Eng. 2014, 24, 419–443. [Google Scholar] [CrossRef]

- Berthomieu, B.; Ribet, P.-O.; Vernadat, F. The tool tina–construction of abstract state spaces for petri nets and time petri nets. Int. J. Prod. Res. 2004, 42, 2741–2756. [Google Scholar] [CrossRef]

- Bonet, P.; Catalina, M.L.; Puigjaner, R. A petri net tool for performance modeling. In Proceedings of the 23rd Latin American Conference on Informatics, San Jose, Costa Rica, 10–11 October 2007. [Google Scholar]

- Da Silva, R.M.; Benítez-Pina, I.F.; Blos, M.F.; Santos Filho, D.J.; Miyagi, P.E. Modeling of reconfigurable distributed manufacturing control systems. IFAC Pap. 2015, 48, 1284–1289. [Google Scholar] [CrossRef]

- Yu, Z.; Guo, F.; Ouyang, J.; Zhou, L. Object-oriented petri nets and π-calculus-based modeling and analysis of reconfigurable manufacturing systems. Adv. Mech. Eng. 2016, 8, 1687814016677698. [Google Scholar] [CrossRef] [Green Version]

- Chao, D.Y. Fewer monitors and more efficient controllability for deadlock control in s3pgr2 (systems of simple sequential processes with general resource requirements). Comput. J. 2010, 53, 1783–1798. [Google Scholar] [CrossRef]

- Chao, D.Y. Improvement of suboptimal siphon-and fbm-based control model of a well-known s3pr. IEEE Trans. Autom. Sci. Eng. 2011, 8, 404–411. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, M. Elementary siphons of petri nets and their application to deadlock prevention in flexible manufacturing systems. Syst. Man Cybern. Part A Syst. Hum. IEEE Trans. 2004, 34, 38–51. [Google Scholar] [CrossRef]

- Uzam, M. An optimal deadlock prevention policy for flexible manufacturing systems using petri net models with resources and the theory of regions. Int. J. Adv. Manuf. Technol. 2002, 19, 192–208. [Google Scholar] [CrossRef]

- Uzam, M.; Zhou, M. Iterative synthesis of petri net based deadlock prevention policy for flexible manufacturing systems. In Proceedings of the 2004 IEEE International Conference on Systems, Man and Cybernetics, The Hague, The Netherlands, 10–13 October 2004; pp. 4260–4265. [Google Scholar]

- Pan, Y.-L.; Tseng, C.-Y.; Row, T.-C. Design of improved optimal and suboptimal deadlock prevention for flexible manufacturing systems based on place invariant and reachability graph analysis methods. J. Algorithms Comput. Technol. 2017, 11, 261–270. [Google Scholar] [CrossRef] [Green Version]

- Zhao, M.; Uzam, M. A suboptimal deadlock control policy for designing non-blocking supervisors in flexible manufacturing systems. Inf. Sci. 2017, 388, 135–153. [Google Scholar] [CrossRef]

- Cong, X.; Gu, C.; Uzam, M.; Chen, Y.; Al-Ahmari, A.M.; Wu, N.; Zhou, M.; Li, Z. Design of optimal petri net supervisors for flexible manufacturing systems via weighted inhibitor arcs. Asian J. Control 2018, 20, 511–530. [Google Scholar] [CrossRef]

- Abdulaziz, M.; Nasr, E.A.; Al-Ahmari, A.; Kaid, H.; Li, Z. Evaluation of deadlock control designs in automated manufacturing systems. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management, Dubai, UAE, 3–5 March 2015. [Google Scholar]

- Wang, S.; You, D.; Zhou, M. A necessary and sufficient condition for a resource subset to generate a strict minimal siphon in S 4PR. IEEE Trans. Autom. Control 2017, 62, 4173–4179. [Google Scholar] [CrossRef]

- Zhuang, Q.; Dai, W.; Wang, S.; Du, J.; Tian, Q. An mip-based deadlock prevention policy for siphon control. IEEE Access 2019, 7, 153782–153790. [Google Scholar] [CrossRef]

- Kaid, H.; Al-Ahmari, A.; El-Tamimi, A.M.; Abouel Nasr, E.; Li, Z. Design and implementation of deadlock control for automated manufacturing systems. S. Afr. J. Ind. Eng. 2019, 30, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Nasr, E.A.; El-Tamimi, A.M.; Al-Ahmari, A.; Kaid, H. Comparison and evaluation of deadlock prevention methods for different size automated manufacturing systems. Math. Probl. Eng. 2015, 501, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Sun, D.; Chen, Y.; El-Meligy, M.A.; Sharaf, M.A.F.; Wu, N.; Li, Z. On algebraic identification of critical states for deadlock control in automated manufacturing systems modeled with petri nets. IEEE Access 2019, 7, 121332–121349. [Google Scholar] [CrossRef]

- Al-Ahmari, A.; Kaid, H.; Li, Z.; Davidrajuh, R. Strict minimal siphon-based colored petri net supervisor synthesis for automated manufacturing systems with unreliable resources. IEEE Access 2020, 8, 22411–22424. [Google Scholar] [CrossRef]

- Li, L.; Basile, F.; Li, Z. An approach to improve permissiveness of supervisors for gmecs in time petri net systems. IEEE Trans. Autom. Control 2019, 65, 237–251. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, K.; Li, Z. On scalable supervisory control of multi-agent discrete-event systems. Automatica 2019, 108, 108460. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.; Yin, L.; Wu, N.; El-Meligy, M.A.; Sharaf, M.A.F.; Li, Z. Diagnosability of vector discrete-event systems using predicates. IEEE Access 2019, 7, 147143–147155. [Google Scholar] [CrossRef]

- Wang, D.; Wang, X.; Li, Z. Nonblocking supervisory control of state-tree structures with conditional-preemption matrices. IEEE Trans. Ind. Inform. 2019, 16, 3744–3756. [Google Scholar] [CrossRef]

- Hu, Y.; Ma, Z.; Li, Z. Design of supervisors for active diagnosis in discrete event systems. IEEE Trans. Autom. Control 2020. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Khalgui, M.; Mosbahi, O. Design of a maximally permissive liveness-enforcing petri net supervisor for flexible manufacturing systems. Autom. Sci. Eng. IEEE Trans. 2011, 8, 374–393. [Google Scholar] [CrossRef]

- Piroddi, L.; Cordone, R.; Fumagalli, I. Selective siphon control for deadlock prevention in petri nets. Syst. Man Cybern. Part A Syst. Hum. IEEE Trans. 2008, 38, 1337–1348. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z. Design of a maximally permissive liveness-enforcing supervisor with a compressed supervisory structure for flexible manufacturing systems. Automatica 2011, 47, 1028–1034. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Zhou, M. Behaviorally optimal and structurally simple liveness-enforcing supervisors of flexible manufacturing systems. Syst. Man Cybern. Part A Syst. Hum. IEEE Trans. 2012, 42, 615–629. [Google Scholar] [CrossRef]

- Kaid, H.; Al-Ahmari, A.; Li, Z.; Davidrajuh, R. Single controller-based colored petri nets for deadlock control in automated manufacturing systems. Processes 2020, 8, 21. [Google Scholar] [CrossRef] [Green Version]

- Davidrajuh, R. Modeling Discrete-Event Systems with Gpensim: An Introduction; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Tao, G. Adaptive Control Design and Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2003; Volume 37. [Google Scholar]

- Upadhyay, J.; Deb, D.; Rawat, A. Design of smart door closer system with image classification over WLAN. Wirel. Pers. Commun. 2019, 111, 1941–1953. [Google Scholar] [CrossRef]

- Zan, X.; Wu, Z.; Guo, C.; Yu, Z. A pareto-based genetic algorithm for multi-objective scheduling of automated manufacturing systems. Adv. Mech. Eng. 2020, 12, 1–15. [Google Scholar] [CrossRef]

- Yang, L.; Li, Z.; Giua, A. Containment of rumor spread in complex social networks. Inf. Sci. 2020, 506, 113–130. [Google Scholar] [CrossRef]

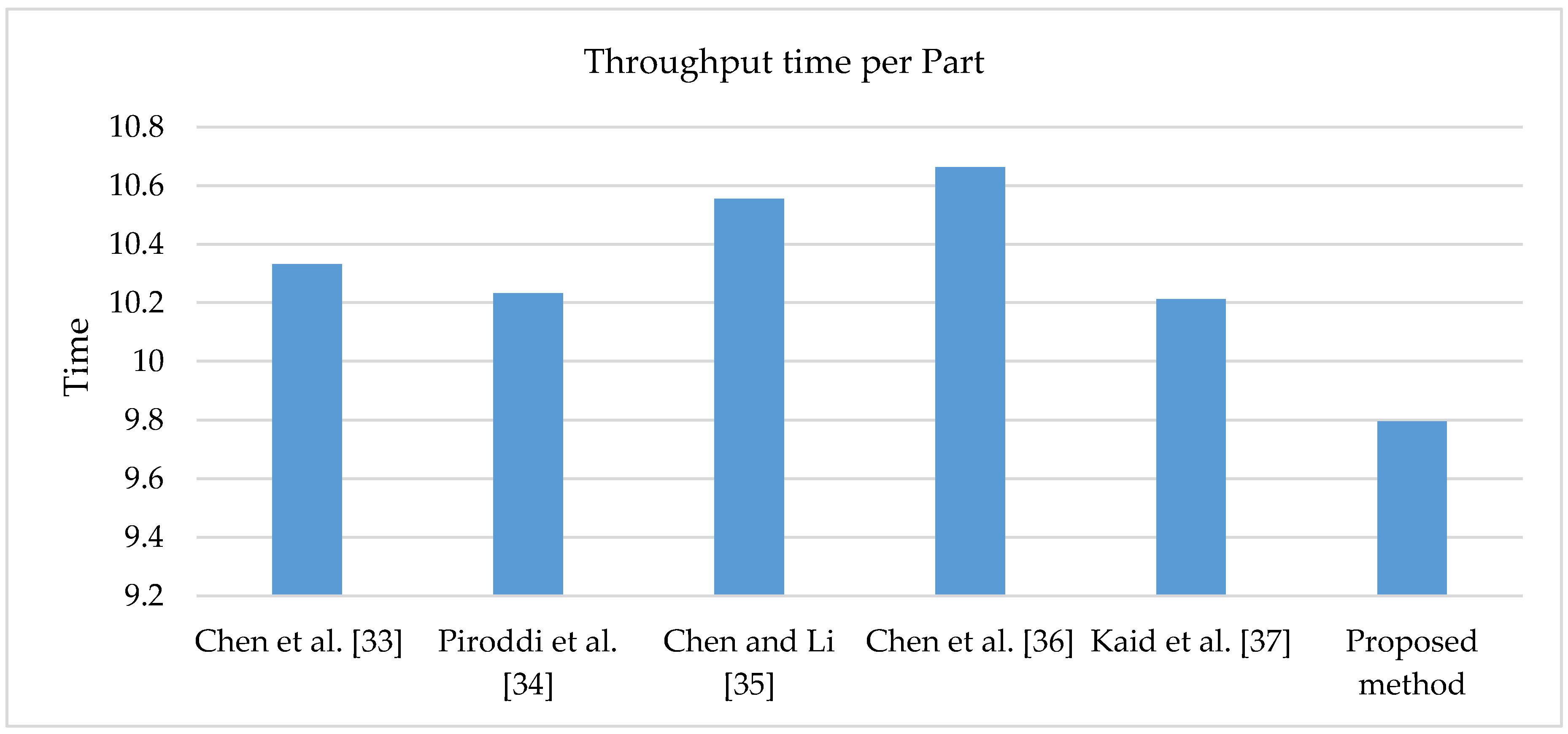

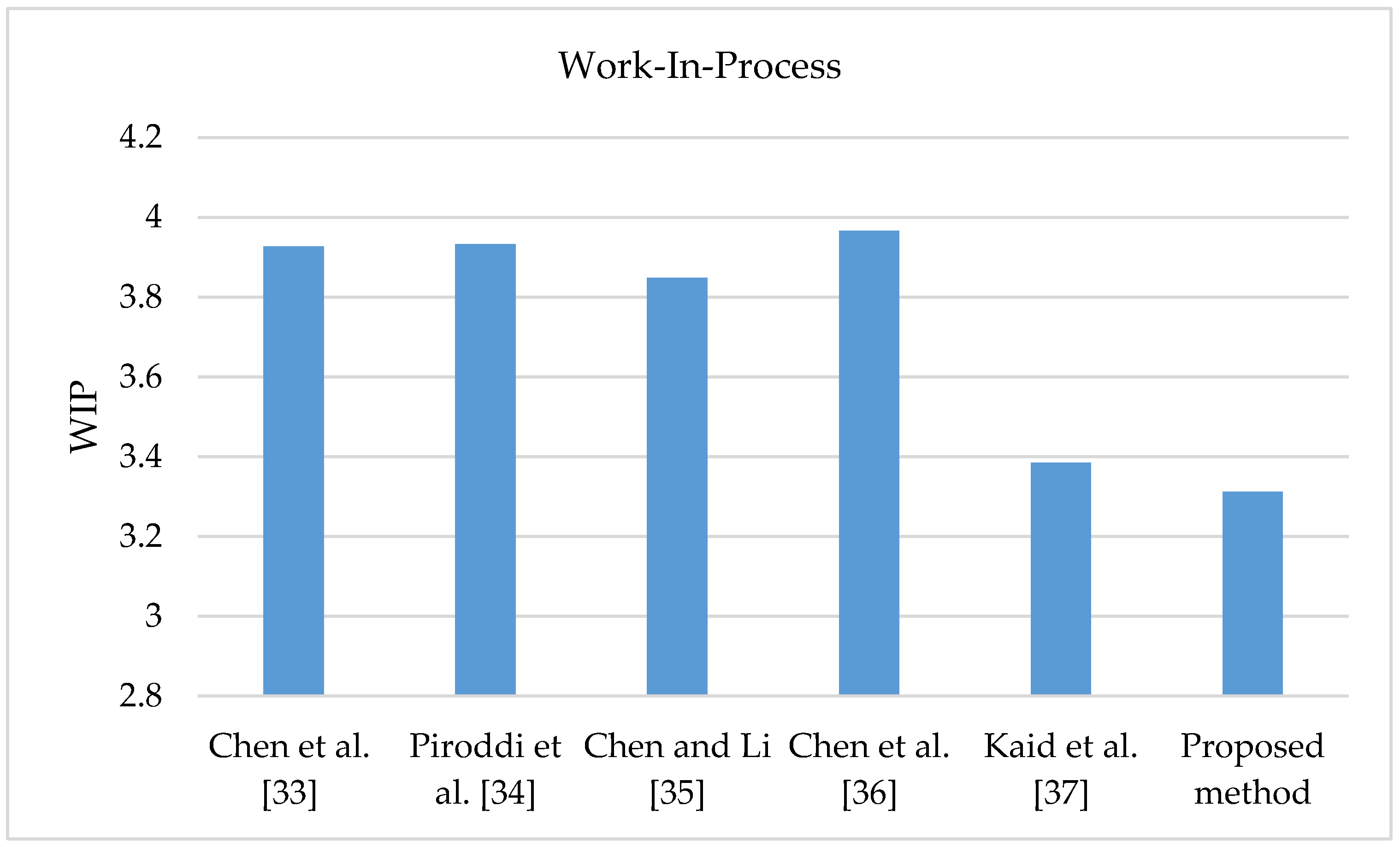

| Parameters | Chen et al. [33] | Piroddi et al. [34] | Chen and Li [35] | Chen et al. [36] | Kaid et al. [37] | Proposed ICTPN Model |

|---|---|---|---|---|---|---|

| No. idle process places | 2 | 2 | 2 | 2 | 2 | 1 |

| No. operation places | 12 | 12 | 12 | 12 | 12 | 4 |

| No. resource places | 4 | 4 | 4 | 4 | 4 | 0 |

| No. transportation places | 2 | 2 | 2 | 2 | 2 | 1 |

| No. transitions | 14 | 14 | 14 | 14 | 14 | 8 |

| Monitors | 8 | 5 | 2 | 2 | 1 | 0 |

| Arcs | 37 | 23 | 12 | 12 | 9 | 0 |

| Liveness | Live | Live | Live | Live | Live | Live |

| Reachable marking | 205 | 205 | 205 | 205 | 205 | 6 |

| Parameter | Chen et al. [33] | Piroddi et al. [34] | Chen and Li [35] | Chen et al. [36] | Kaid et al. [37] | Proposed ICTPN Model |

|---|---|---|---|---|---|---|

| M 1 utilization% | 18.75 | 17.7083 | 17.7083 | 17.7083 | 17.7083 | 30.625 |

| M 2 utilization% | 35 | 33.3333 | 33.3333 | 33.3333 | 33.9583 | 36.4583 |

| M 3 utilization% | 12.5 | 13.75 | 14.375 | 14.375 | 12.5 | 51.25 |

| M 4 utilization% | 22.5 | 21.6667 | 20.8333 | 20.8333 | 22.5 | 15 |

| R 1 utilization% | 39.5833 | 40 | 40.4167 | 40.4167 | 39.5833 | 44.583 |

| R 2 utilization% | 29.375 | 30 | 30 | 30 | 30 | 61.25 |

| Total throughput of Parts | 46 | 46 | 46 | 46 | 47 | 49 |

| Work-In-Process | 3.9271 | 3.93331 | 3.8480 | 3.9667 | 3.3854 | 3.31222 |

| Throughput time per part (min) | 10.3321 | 10.2325 | 10.5554 | 10.6635 | 10.2127 | 9.7959 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaid, H.; Al-Ahmari, A.; Li, Z.; Davidrajuh, R. Intelligent Colored Token Petri Nets for Modeling, Control, and Validation of Dynamic Changes in Reconfigurable Manufacturing Systems. Processes 2020, 8, 358. https://doi.org/10.3390/pr8030358

Kaid H, Al-Ahmari A, Li Z, Davidrajuh R. Intelligent Colored Token Petri Nets for Modeling, Control, and Validation of Dynamic Changes in Reconfigurable Manufacturing Systems. Processes. 2020; 8(3):358. https://doi.org/10.3390/pr8030358

Chicago/Turabian StyleKaid, Husam, Abdulrahman Al-Ahmari, Zhiwu Li, and Reggie Davidrajuh. 2020. "Intelligent Colored Token Petri Nets for Modeling, Control, and Validation of Dynamic Changes in Reconfigurable Manufacturing Systems" Processes 8, no. 3: 358. https://doi.org/10.3390/pr8030358

APA StyleKaid, H., Al-Ahmari, A., Li, Z., & Davidrajuh, R. (2020). Intelligent Colored Token Petri Nets for Modeling, Control, and Validation of Dynamic Changes in Reconfigurable Manufacturing Systems. Processes, 8(3), 358. https://doi.org/10.3390/pr8030358