Numerical Investigation on the Intraphase and Interphase Mass Transfer Limitations for NH3-SCR over Cu-ZSM-5

Abstract

:1. Introduction

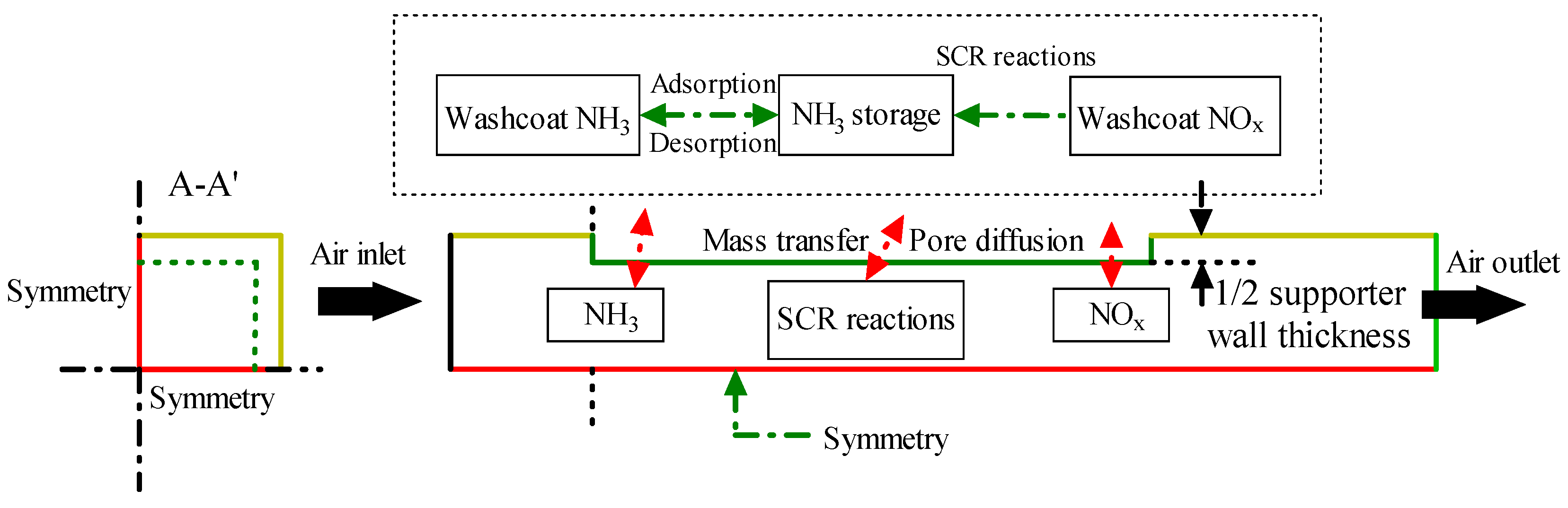

2. Methods and Model Validation

2.1. SCR Reaction Kinetic Model

- Ignore the diffusion between the whole channel, the hydrolysis of isocyanate and urea. NH3 directly enters the channel.

- Assuming that the inlet boundary condition of the channel is uniform, the Eley-Rideal mechanism is used to calculate the surface catalytic reaction of the Cu molecular sieve.

- The active catalyst is evenly coated on the coating surface, and the porous medium of the coating is evenly distributed.

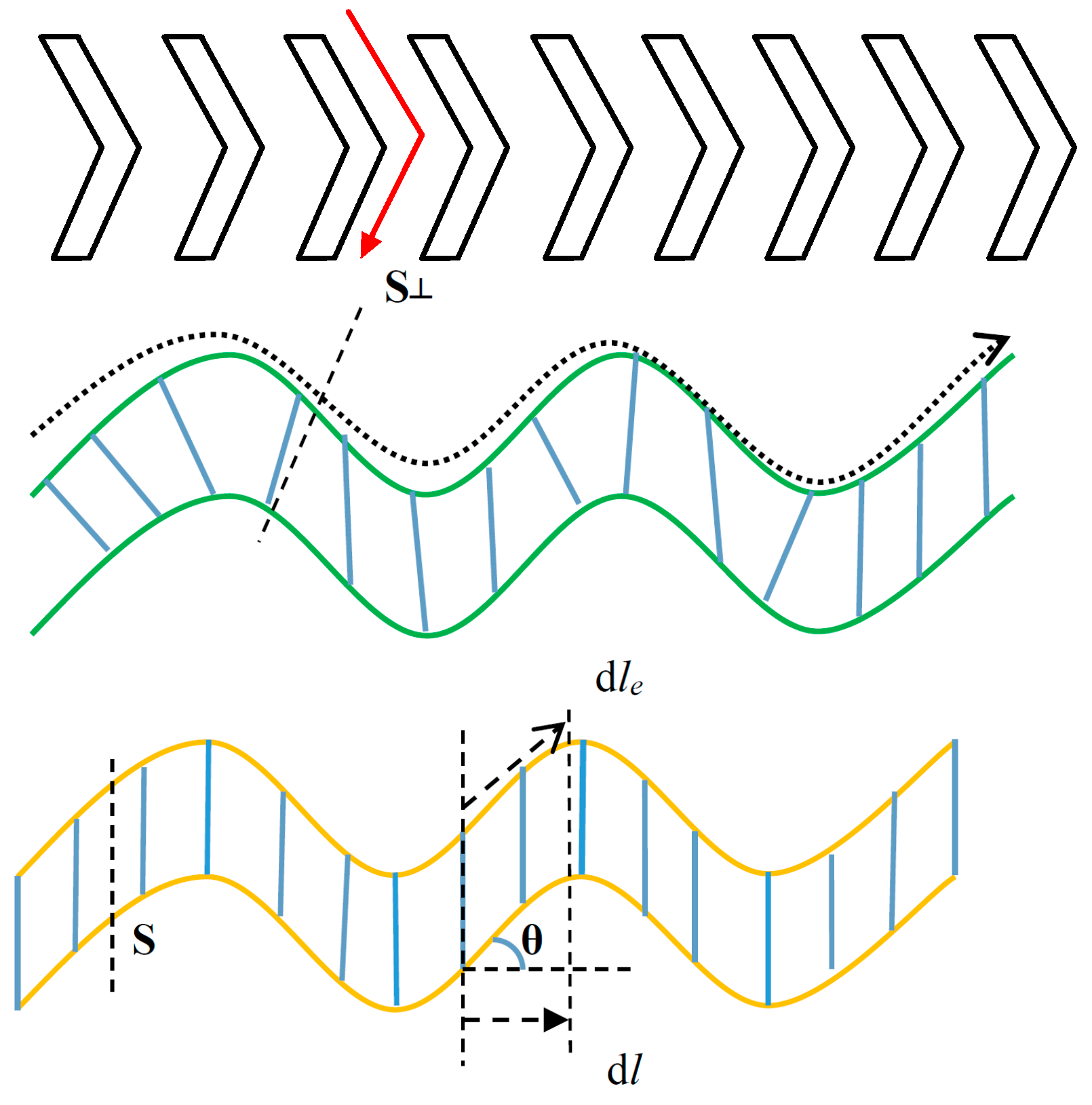

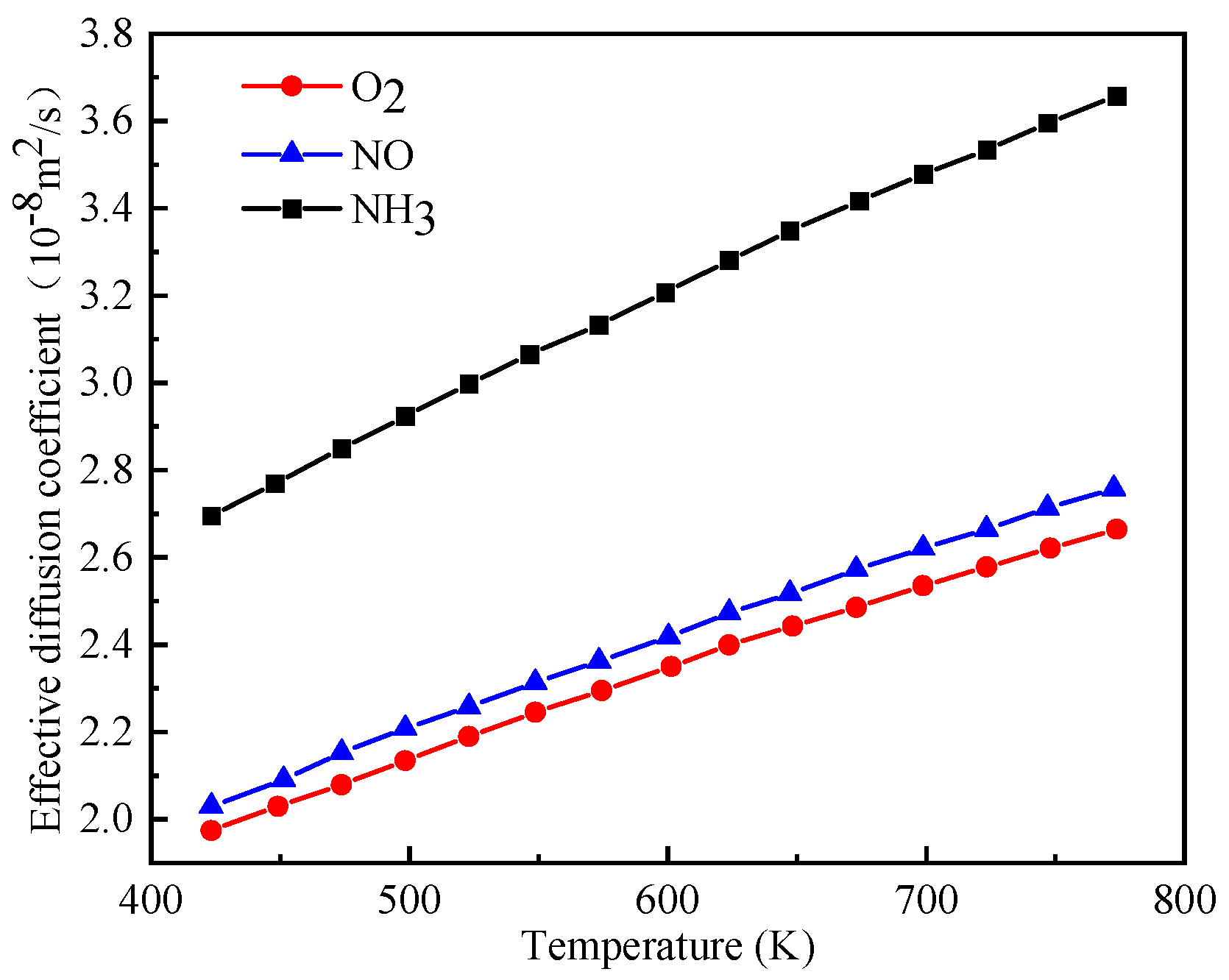

2.2. Pore Diffusion Model

2.3. Model Validation

3. Results and Discussion

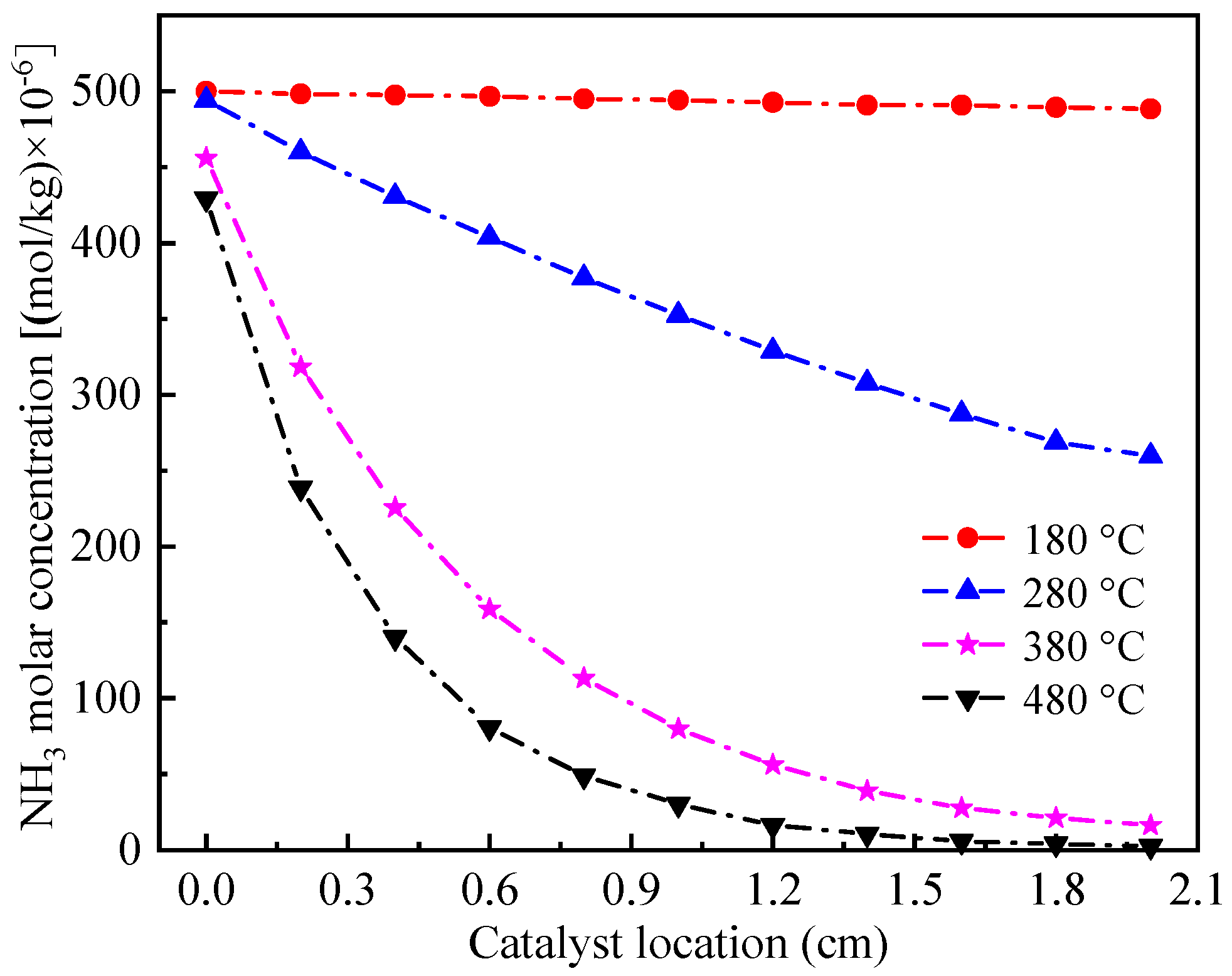

3.1. Axial Distribution of SCR Catalytic Reaction

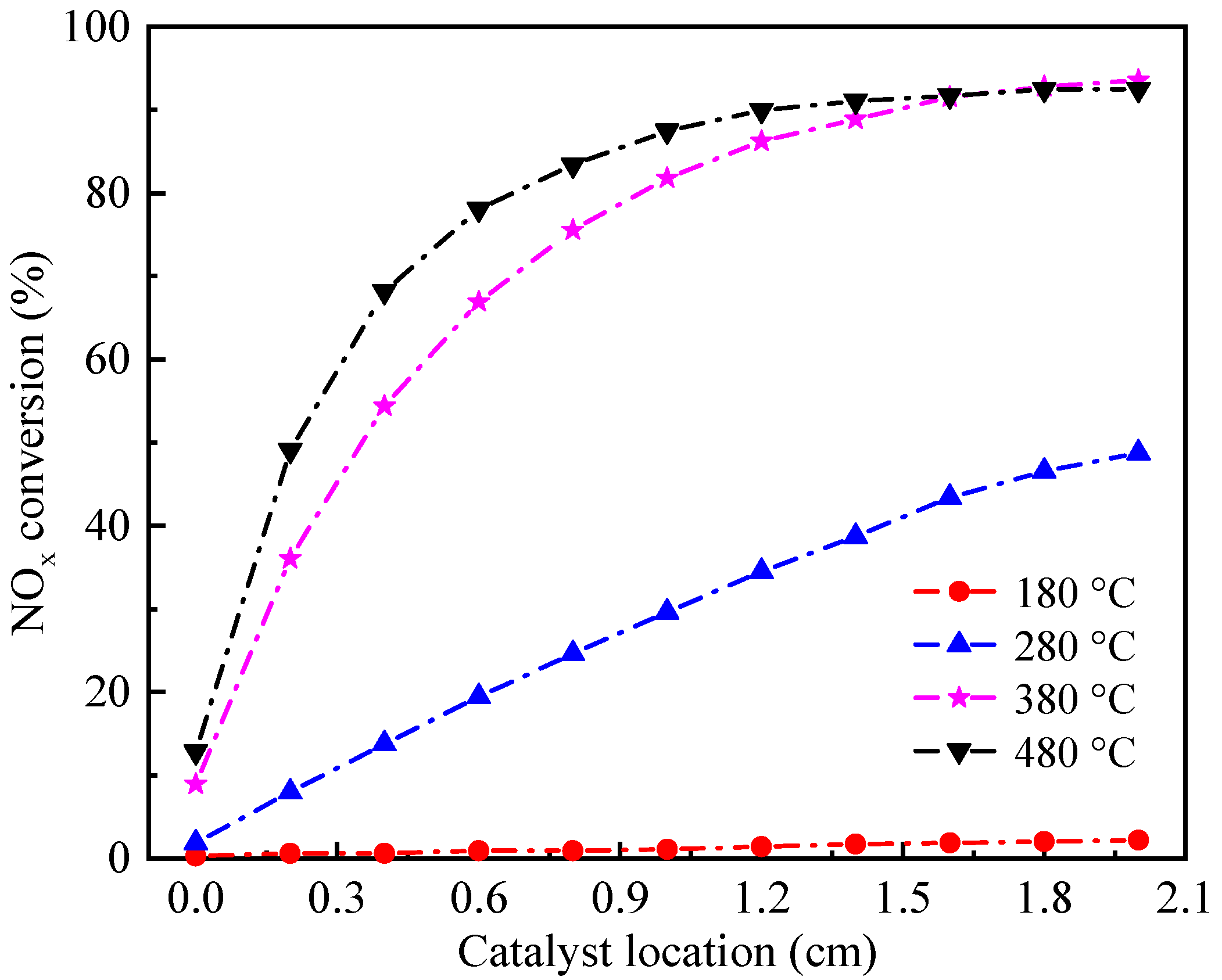

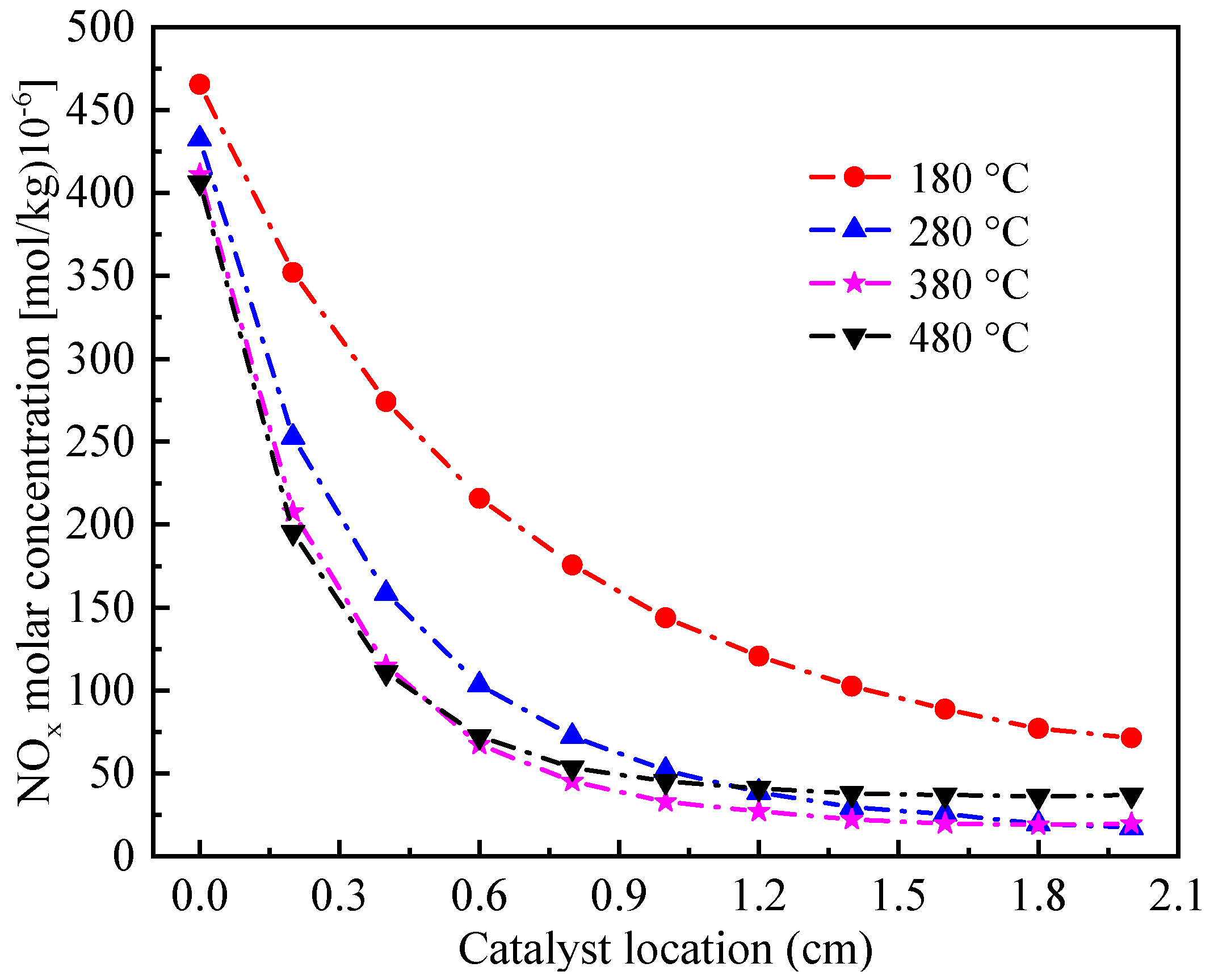

3.1.1. Standard SCR Reaction

- (1)

- NH3 concentration

- (2)

- NOx concentration

- (3)

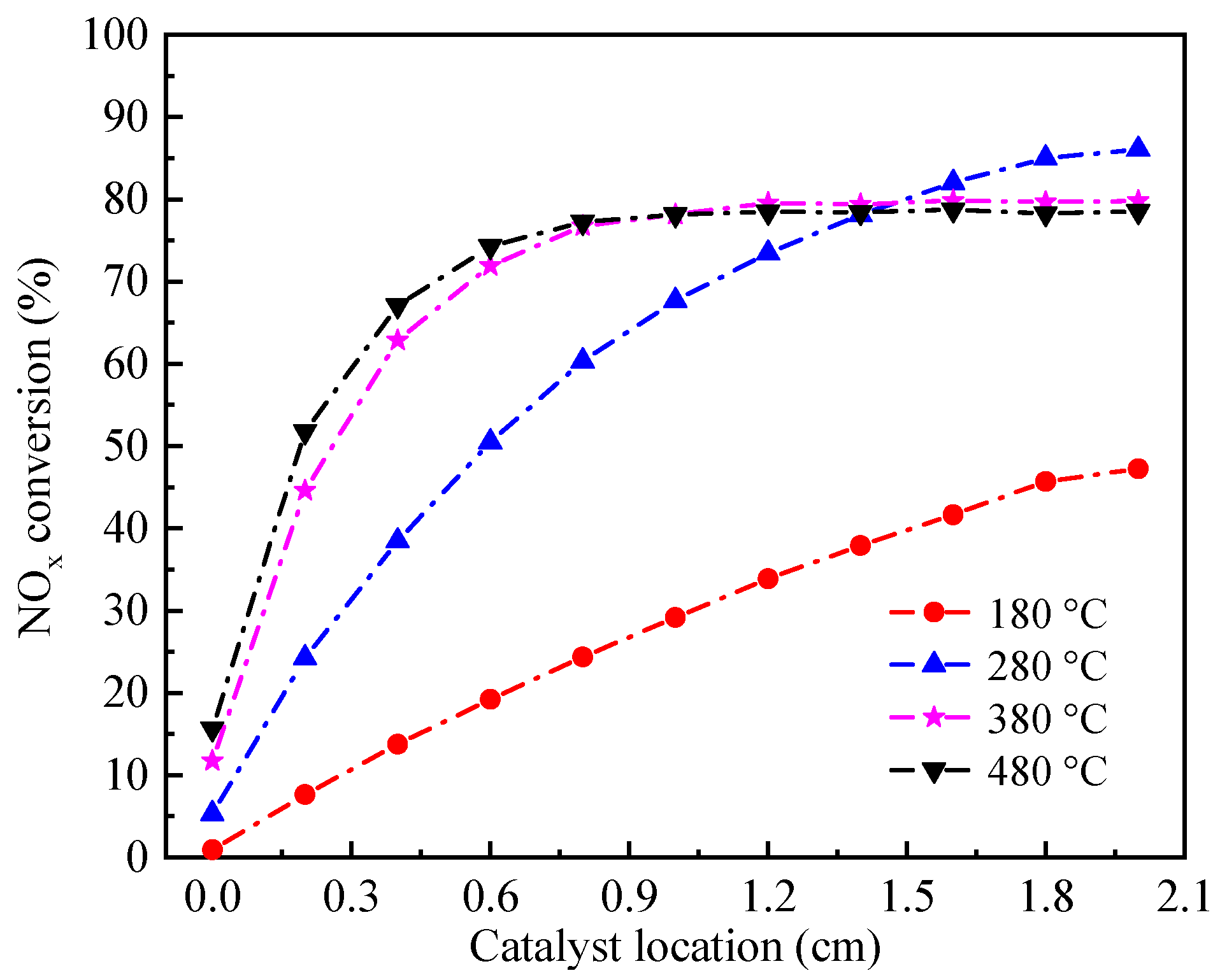

- NOx conversion

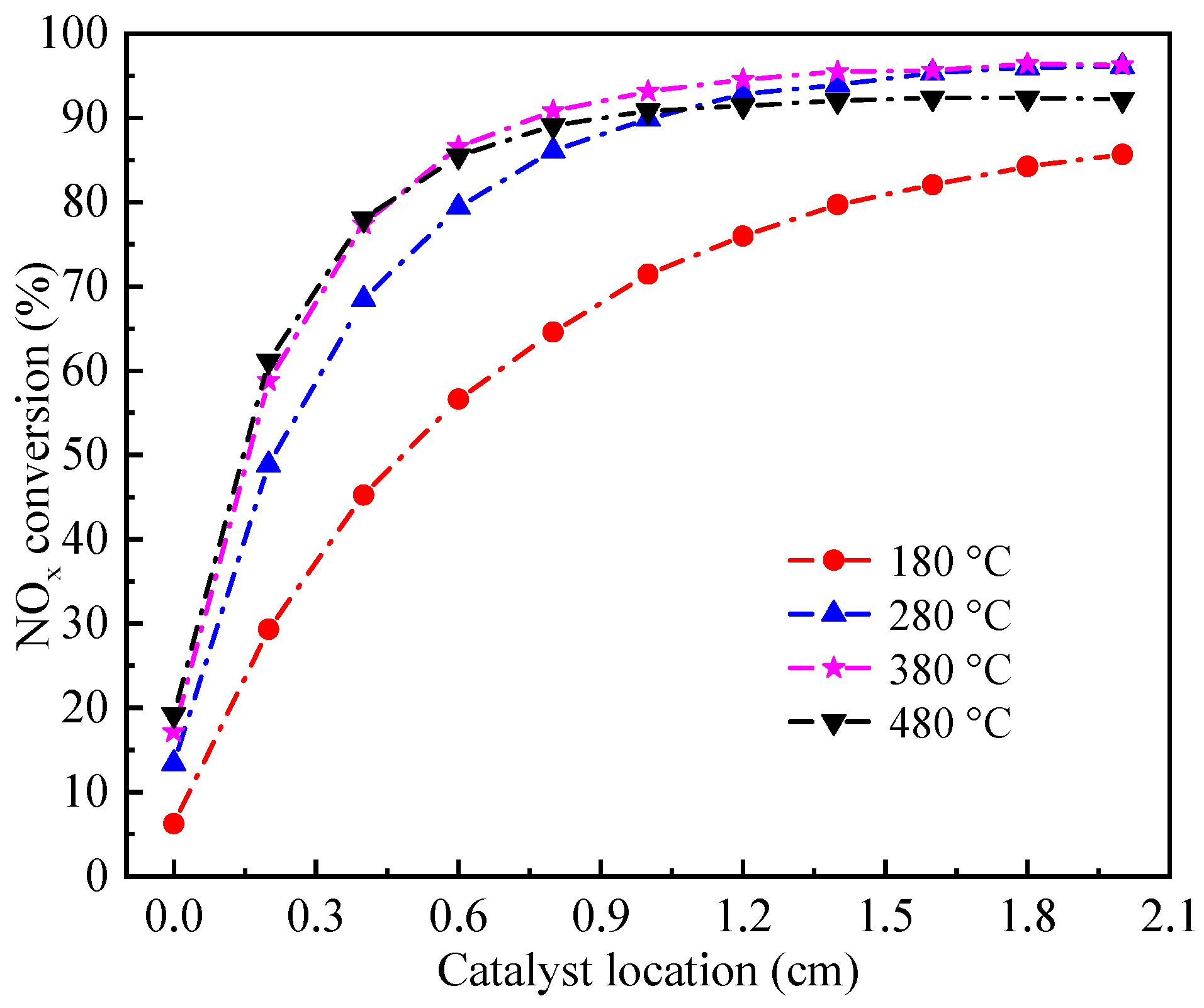

3.1.2. Fast SCR Reaction

- (1)

- NH3 concentration

- (2)

- NOx concentration

- (3)

- NOx conversion

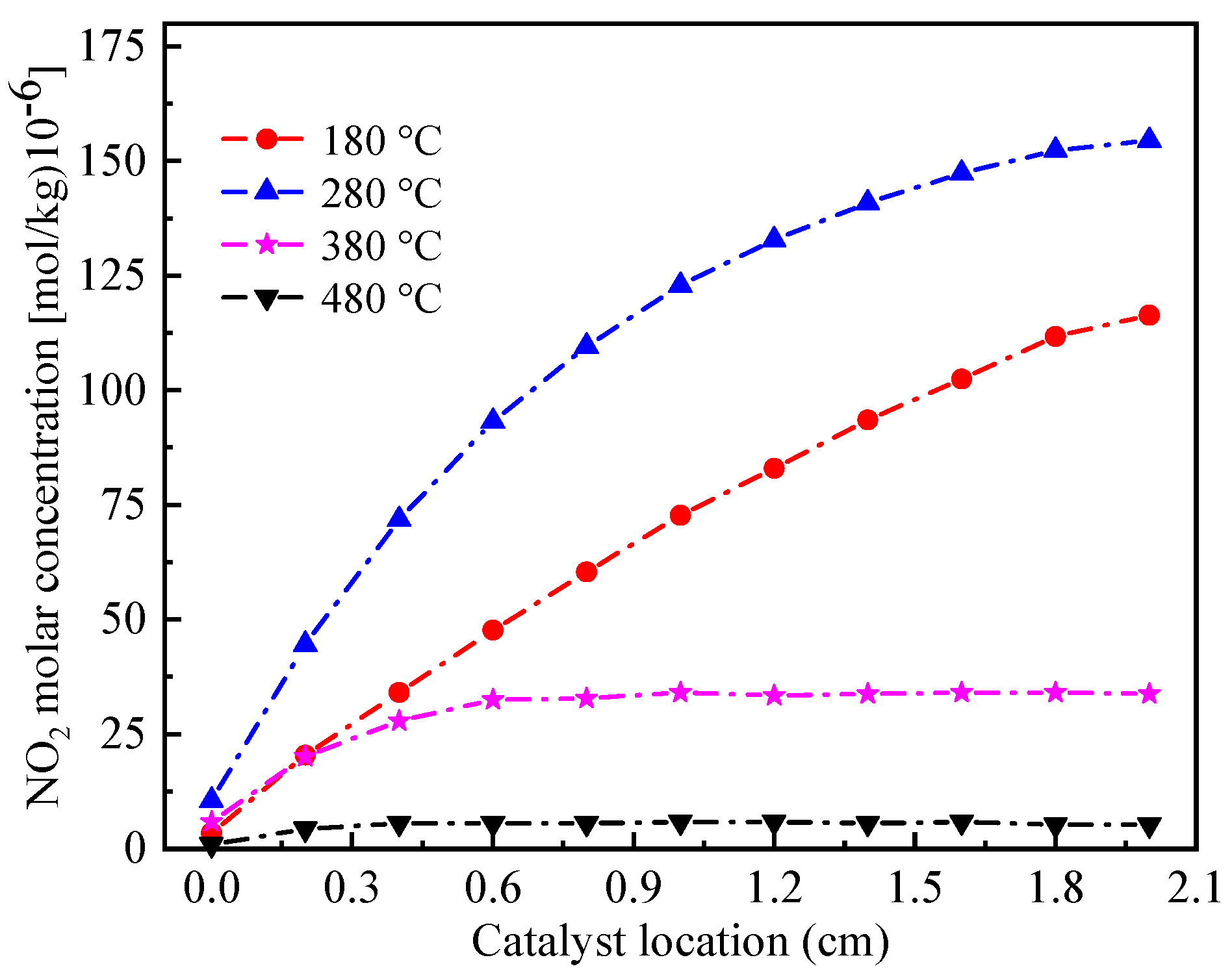

3.1.3. NO2-SCR Reaction

- (1)

- NOx concentration

- (2)

- NOx conversion

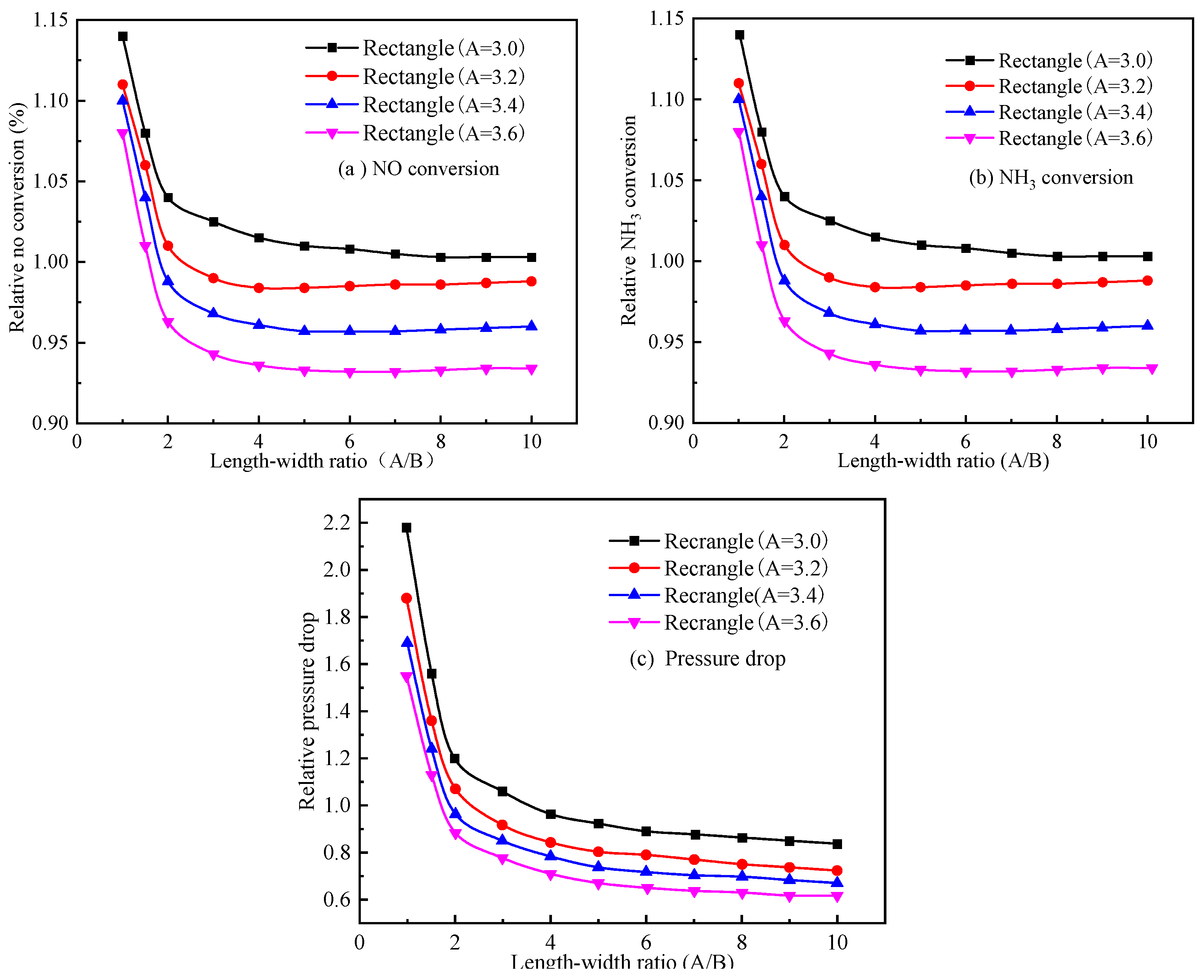

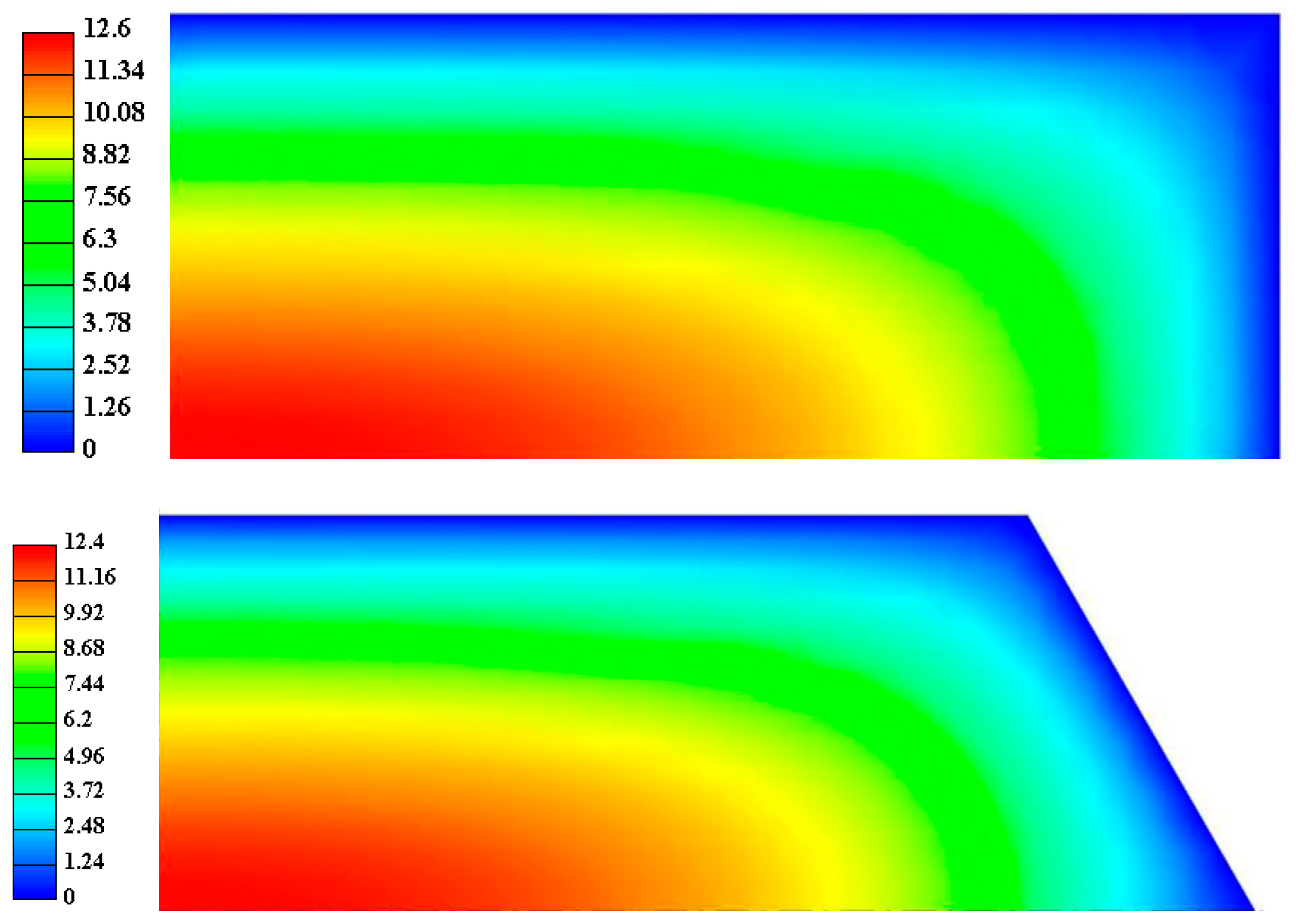

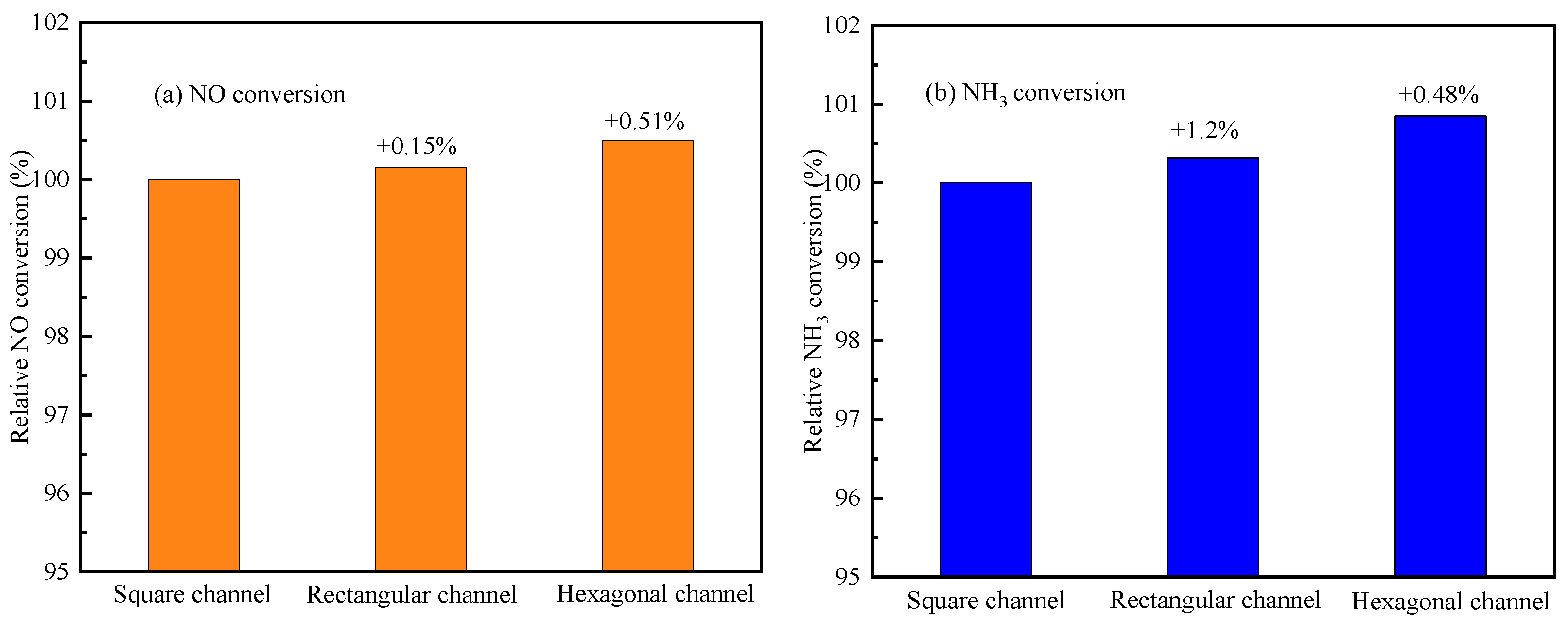

3.2. Reaction Conditions of Different SCR Channel Cross-Sections

4. Conclusions

- (1)

- The improved model can better predict the catalytic reaction of the diesel SCR system.

- (2)

- The Cu-based zeolite catalyst is of poor low-temperature characteristics and good high-temperature activity.

- (3)

- NH3-SCR catalytic reaction is mainly concentrated in the first half of the reactor, and the influence of the second half is little.

- (4)

- The hexagonal channel can effectively increase the diffusion rate of gas reactants to the catalyst wall, reduce the pressure drop and improve the catalytic conversion efficiencies of NH3 and NOx.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; E, J.; Chen, J.; Zhu, H.; Zhao, X.; Han, D.; Zuo, W.; Peng, Q.; Gong, J.; Yin, Z. Effects of low-level water addition on spray, combustion and emission characteristics of a medium speed diesel engine fueled with biodiesel fuel. Fuel 2018, 239, 245–262. [Google Scholar] [CrossRef]

- Emiroğlu, A.O. Effect of fuel injection pressure on the characteristics of single cylinder diesel engine powered by butanol-diesel blend. Fuel 2019, 256, 115928. [Google Scholar] [CrossRef]

- Zhang, Z.; E, J.; Chen, J.; Zhao, X.; Zhang, B.; Deng, Y.; Peng, Q.; Yin, Z. Effects of boiling heat transfer on the performance enhancement of a medium speed diesel engine fueled with diesel and rapeseed methyl ester. Appl. Therm. Eng. 2020, 169, 114984. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, J.; Tan, D.; Feng, Z.; Luo, J.; Tan, Y.; Huang, Y. The effects of Fe2O3 based DOC and SCR catalyst on the combustion and emission characteristics of a diesel engine fueled with biodiesel. Fuel 2021, 290, 120039. [Google Scholar] [CrossRef]

- E, J.; Zhao, X.; Liu, G.; Zhang, B.; Zuo, Q.; Wei, K.; Li, H.; Han, D.; Gong, J. Effects analysis on optimal microwave energy consumption in the heating process of composite regeneration for the diesel particulate filter. Appl. Energy 2019, 254, 113736. [Google Scholar] [CrossRef]

- Di Benedetto, A. Modeling and simulation of soot combustion dynamics in a catalytic diesel particulate filter. Chem. Eng. Sci. 2015, 137, 69–78. [Google Scholar]

- Li, W.; Ji, J.; Huang, L.; Guo, Z. Global dynamics of a controlled discontinuous diffusive SIR epidemic system. Appl. Math. Lett. 2021, 121, 107420. [Google Scholar] [CrossRef]

- Rogóż, R.; Kapusta, J.; Bachanek, J.; Vankan, J.; Teodorczyk, A. Improved urea-water solution spray model for simulations of selective catalytic reduction systems. Renew. Sustain. Energy Rev. 2019, 120, 109616. [Google Scholar] [CrossRef]

- E, J.; Zhao, X.; Qiu, L.; Wei, K.; Zhang, Z.; Deng, Y.; Han, D.; Liu, G. Experimental investigation on performance and economy characteristics of a diesel engine with variable nozzle turbocharger and its application in urban bus. Energy Convers. Manag. 2019, 193, 149–161. [Google Scholar] [CrossRef]

- Zhang, Z.; E, J.; Deng, Y.; Pham, M.; Zuo, W.; Peng, Q.; Yin, Z. Effects of fatty acid methyl esters proportion on combustion and emission characteristics of a biodiesel fueled marine diesel engine. Energy Convers. Manag. 2018, 159, 244–253. [Google Scholar] [CrossRef]

- Tan, D.; Chen, Z.; Li, J.; Luo, J.; Yang, D.; Cui, S.; Zhang, Z. Effects of Swirl and Boiling Heat Transfer on the Performance Enhancement and Emission Reduction for a Medium Diesel Engine Fueled with Biodiesel. Processes 2021, 9, 568. [Google Scholar] [CrossRef]

- E, J.; Liu, G.; Zhang, Z.; Han, D.; Chen, J.; Gong, J.; Yin, Z. Effect analysis on cold starting performance of a diesel engine fueled with biodiesel fuel based on an improved thermodynamic model. Appl. Energy 2019, 243, 321–335. [Google Scholar] [CrossRef]

- Guan, B.; Zhan, R.; Lin, H.; Huang, Z. Review of state of the art technologies of selective catalytic reduction of NOx from diesel engine exhaust. Appl. Therm. Eng. 2014, 66, 395–414. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D. Effects of fuel composition and wall thermal conductivity on thermal and NOx emission performances of an ammonia/hydrogen-oxygen micro-power system. Fuel Process. Technol. 2020, 209, 106527. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Li, J.; Ji, H.; Tan, D.; Luo, J.; Jiang, Y.; Yang, D.; Cui, S. Effects of Different Mixture Ratios of Methanol-Diesel on the Performance Enhancement and Emission Reduction for a Diesel Engine. Processes 2021, 9, 1366. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Tian, J.; Xie, G.; Tan, D.; Qin, B.; Huang, Y.; Cui, S. Effects of Different Diesel-Ethanol Dual Fuel Ratio on Performance and Emission Characteristics of Diesel Engine. Processes 2021, 9, 1135. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, R.; Wang, H.; Wei, Y. Strategy on Effective Synthesis of SSZ-13 Zeolite Aiming at Outstanding Performances for NH3-SCR Process. Catal. Surv. Asia 2020, 24, 143–155. [Google Scholar] [CrossRef]

- Xue, H.; Guo, X.; Meng, T.; Guo, Q.; Mao, D.; Wang, S. Cu-ZSM-5 Catalyst Impregnated with Mn–Co Oxide for the Selected Catalytic Reduction of NO: Physicochemical Property–Catalytic Activity Relationship and In Situ DRIFTS Study for the Reaction Mechanism. ACS Catal. 2021, 11, 7702–7718. [Google Scholar] [CrossRef]

- Naicker, T.; Friedrich, H.B. Hexane activation over vanadium modified zeolite ZSM-5. J. Porous Mater. 2012, 20, 763–775. [Google Scholar] [CrossRef]

- Zhong, C.; Tan, J.; Zuo, H.; Wu, X.; Wang, S.; Liu, J. Synergy effects analysis on CDPF regeneration performance enhancement and NOx concentration reduction of NH3–SCR over Cu–ZSM–5. Energy 2021, 230, 120814. [Google Scholar] [CrossRef]

- E, J.; Zhang, Z.; Chen, J.; Pham, M.; Zhao, X.; Peng, Q.; Zhang, B.; Yin, Z. Performance and emission evaluation of a marine diesel engine fueled by water biodiesel-diesel emulsion blends with a fuel additive of a cerium oxide nanoparticle. Energy Convers. Manag. 2018, 169, 194–205. [Google Scholar] [CrossRef]

- Cheng, M.; Jiang, B.; Yao, S.; Han, J.; Zhao, S.; Tang, X.; Zhang, J.; Wang, T. The Mechanism of NH3-SCR Reaction for NOx Removal from Diesel Engine Exhaust and Hydrothermal Stability of Cu-Mn/Zeolite Catalysts. J. Phys. Chem. C 2017, 122, 1–35. [Google Scholar]

- Fu, G.; Chen, J.; Liang, Y.; Li, R.; Yang, X.; Jiang, J. Cu-IM-5 as the Catalyst for Selective Catalytic Reduction of NOx with NH3: Role of Cu Species and Reaction Mechanism. Catalysts 2021, 11, 221. [Google Scholar] [CrossRef]

- Rajasekar, V.; Ashok, B. Critical interpretative review on current outlook and prospects of selective catalytic reduction system for De-NOx strategy in compression ignition engine. Fuel 2020, 276, 117996. [Google Scholar]

- Grossale, A.; Nova, I.; Tronconi, E. Study of a Fe–zeolite-based system as NH3-SCR catalyst for diesel exhaust aftertreatment. Catal. Today 2008, 136, 18–27. [Google Scholar] [CrossRef]

- Chapman, D.M. Behavior of titania-supported vanadia and tungsta SCR catalysts at high temperatures in reactant streams: Tungsten and vanadium oxide and hydroxide vapor pressure reduction by surficial stabilization. Appl. Catal. A: Gen. 2011, 392, 143–150. [Google Scholar] [CrossRef]

- Iwamoto, M.; Furukawa, H.; Mine, Y.; Uemura, F.; Mikuriya, S.-I.; Kagawa, S. Copper(II) ion-exchanged ZSM-5 zeolites as highly active catalysts for direct and continuous decomposition of nitrogen monoxide. J. Chem. Soc. Chem. Commun. 1986, 1272–1273. [Google Scholar] [CrossRef]

- Zhou, D.; Yang, W.; An, H.; Li, J.; Shu, C. A numerical study on RCCI engine fueled by biodiesel/methanol. Energy Convers. Manag. 2014, 89, 798–807. [Google Scholar] [CrossRef]

- Na, H.; Reed, D.C.; Annaswamy, A.M.; Laing, P.M.; Kolmanovsky, I. Control-Oriented Reduced-Order Models for Urea Selective Catalytic Reduction Systems Using a Physics-Based Approach. In Proceedings of the SAE 2011 World Congress & Exhibition, Warrendale, PA, USA, 12–14 April 2011. [Google Scholar] [CrossRef]

- Zhong, C.; Gong, J.; Tan, L.; Liu, W.; Liu, G.; Zhang, Z. Modeling intraphase and interphase mass transfer limitations for NH3–SCR over Cu–ZSM–5. Chem. Eng. Sci. 2019, 207, 479–489. [Google Scholar] [CrossRef]

- Colombo, M.; Nova, I.; Tronconi, E. Detailed kinetic modeling of the NH3–NO/NO2 SCR reactions over a commercial Cu-zeolite catalyst for Diesel exhausts after treatment. Catal. Today 2012, 197, 243–255. [Google Scholar] [CrossRef]

- Auvray, X.; Partridge, W.; Choi, J.-S.; Pihl, J.; Yezerets, A.; Kamasamudram, K.; Currier, N.; Olsson, L. Local ammonia storage and ammonia inhibition in a monolithic copper-beta zeolite SCR catalyst. Appl. Catal. B-Environ. 2012, 126, 144–152. [Google Scholar] [CrossRef]

- Henry, C.; Kamasamudram, K.; Currier, N.W.; Yezerets, A.; Castagnola, M.; Chen, H.-Y. Axially Resolved Performance of Cu-Zeolite SCR Catalysts. SAE Int. J. Engines 2012, 5, 975–984. [Google Scholar] [CrossRef]

- Hawthorn, R.D. Afterburner catalysts effects of heat and mass transfer between gas and catalyst surface. Recent Adv. Air Pollut. 1974, 70, 428–438. [Google Scholar]

- Kong, W.; Zhu, H.; Fei, Z.; Lin, Z. A modified dusty gas model in the form of a Fick’s model for the prediction of multicomponent mass transport in a solid oxide fuel cell anode. J. Power Sources 2012, 206, 171–178. [Google Scholar] [CrossRef]

- Hayes, R.; Kolaczkowskib, S.; Li, P.; Awdry, S. Evaluating the effective diffusivity of methane in the washcoat of a honeycomb monolith. Appl. Catal. B Environ. 2000, 25, 93–104. [Google Scholar] [CrossRef]

- Epstein, N. On tortuosity and the tortuosity factor in flow and diffusion through porous media. Chem. Eng. Sci. 1989, 44, 777–779. [Google Scholar] [CrossRef]

- Yuan, J.; Sundén, B. On mechanisms and models of multi-component gas diffusion in porous structures of fuel cell electrodes. Int. J. Heat Mass Transf. 2014, 69, 358–374. [Google Scholar] [CrossRef]

- Gommes, C.J.; Bons, A.J.; Blacher, S.; Dunsmuir, J.H.; Tsou, A.H. Practical methods for measuring the tortuosity of porous materials from binary or gray-tone tomographic reconstructions. Am. Inst. Chem. Eng. 2009, 55, 2000–2012. [Google Scholar] [CrossRef]

- Zhang, F.; Hayes, R.; Kolaczkowski, S. A New Technique to Measure the Effective Diffusivity in a Catalytic Monolith Washcoat. Chem. Eng. Res. Des. 2004, 82, 481–489. [Google Scholar] [CrossRef]

- Hu, X.; Yang, M.; Fan, D.; Qi, G.; Wang, J.; Wang, J.; Yu, T.; Li, W.; Shen, M. The role of pore diffusion in determining NH3 SCR active sites over Cu/SAPO-34 catalysts. J. Catal. 2016, 341, 55–61. [Google Scholar] [CrossRef]

- Santos, A.; Bahamonde, A.; Avila, P.; Garcia-Ochoa, F. Measurement of the effective diffusivity for a vanadia-tungsta-titania/sepiolite catalyst for SCR of NOx. Appl. Catal. B Environ. 1996, 8, 299–314. [Google Scholar] [CrossRef]

- Popovičová, J.; Brusseau, M.L. Dispersion and transport of gas-phase contaminants in dry porous media: Effect of heterogeneity and gas velocity. J. Contam. Hydrol. 1997, 28, 157–169. [Google Scholar] [CrossRef]

- Komatsu, T.; Nunokawa, M.; Moon, I.; Takahara, T.; Namba, S.; Yashima, T. Kinetic Studies of Reduction of Nitric Oxide with Ammonia on Cu2+-Exchanged Zeolites. J. Catal. 1994, 148, 427–437. [Google Scholar] [CrossRef]

- Gong, J.; Narayanaswamy, K.; Rutland, C.J. Heterogeneous Ammonia Storage Model for NH3-SCR Modeling. Ind. Eng. Chem. Res. 2016, 55, 5874–5884. [Google Scholar] [CrossRef]

- Metkar, P.S.; Balakotaiah, V.; Harold, M.P. Experimental study of mass transfer limitations in Fe- and Cu-zeolite-based NH3-SCR monolithic catalysts. Chem. Eng. Sci. 2011, 66, 5192–5203. [Google Scholar] [CrossRef]

- Xue, H.; Meng, T.; Liu, F.; Guo, X.; Wang, S.; Mao, D. Enhanced resistance to calcium poisoning on Zr-modified Cu/ZSM-5 catalysts for the selective catalytic reduction of NO with NH3. RSC Adv. 2019, 9, 38477–38485. [Google Scholar] [CrossRef] [Green Version]

- Metkar, P.S.; Harold, M.P.; Balakotaiah, V. Experimental and kinetic modeling study of NH3-SCR of NOx on Fe-ZSM-5, Cu-chabazite and combined Fe- and Cu-zeolite monolithic catalysts. Chem. Eng. Sci. 2013, 87, 51–66. [Google Scholar] [CrossRef]

- Lu, Y.; Jiang, Z.; Geng, N.; Jiang, S.; Xie, X. Appointment window scheduling with wait-dependent abandonment for elective inpatient admission. Int. J. Prod. Res. 2021, 1–17. [Google Scholar] [CrossRef]

- Shi, L.; Si, Z.; Wu, X.; Weng, D.; Wu, Z. Effect of water vapor on NH3–NO/NO2 SCR performance of fresh and aged MnOx–NbOx–CeO2 catalysts. J. Environ. Sci. 2015, 31, 240–247. [Google Scholar]

- Zuo, H.; Tan, J.; Wei, K.; Huang, Z.; Zhong, D.; Xie, F. Effects of different poses and wind speeds on wind-induced vibration characteristics of a dish solar concentrator system. Renew. Energy 2021, 168, 1308–1326. [Google Scholar] [CrossRef]

- Zuo, H.; Liu, G.; Jiaqiang, E.; Zuo, W.; Wei, K.; Hu, W.; Tan, J.; Zhong, D. Catastrophic analysis on the stability of a large dish solar thermal power generation system with wind-induced vibration. Sol. Energy 2019, 183, 40–49. [Google Scholar] [CrossRef]

- Hu, L.; Hu, X.; Che, Y.; Feng, F.; Lin, X.; Zhang, Z. Reliable state of charge estimation of battery packs using fuzzy adaptive federated filtering. Appl. Energy 2020, 262, 114569. [Google Scholar] [CrossRef]

- Zhang, F.; Liao, G.; E, J.; Chen, J.; Leng, E. Comparative study on the thermodynamic and economic performance of novel absorption power cycles driven by the waste heat from a supercritical CO2 cycle. Energy Convers. Manag. 2021, 228, 113671. [Google Scholar] [CrossRef]

- Zuo, H.; Zhang, B.; Huang, Z.; Wei, K.; Tan, J. Effect analysis on SOC values of the power lithium manganate battery during discharging process and its intelligent estimation. Energy 2022, 238, 121854. [Google Scholar] [CrossRef]

- E, J.; Zhang, B.; Zeng, Y.; Wen, M.; Huang, Z.; Wei, K.; Chen, J.; Zhu, H.; Deng, Y. Effects analysis on active equalization control of lithium-ion batteries based on intelligent estimation of the state-of-charge. Energy 2022, 238, 121822. [Google Scholar] [CrossRef]

- E, J.; Luo, B.; Han, D.; Chen, J.; Liao, G.; Zhang, F.; Ding, J. A comprehensive review on performance improvement of micro energy mechanical system: Heat transfer, micro combustion and energy conversion. Energy 2022, 240, 122509. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, C.; E, J.; Mao, X.; Yu, Z. Research on modeling and parameter sensitivity of flow and heat transfer process in typical rectangular microchannels: From a data-driven perspective. Int. J. Therm. Sci. 2022, 172, 107356. [Google Scholar] [CrossRef]

- Yi, F.; E, J.; Zhang, B.; Zuo, H.; Wei, K.; Chen, J.; Zhu, H.; Zhu, H.; Deng, Y. Effects of coupling phase change material and liquid cooling on heat dissipation characteristics of Lithium-ion battery thermal management system. Renewable Energy 2022, 181, 472–489. [Google Scholar] [CrossRef]

- Cai, T.; Sun, Y.; Zhao, D. Enhancing heat transfer performance analyses of a hydrogen-fueled meso-combustor with staggered bluff-bodies. Fuel Process. Technol. 2021, 218, 106867. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D. Mitigating NOx emissions from an ammonia-fueled micro-power system with a perforated plate implemented. J. Hazard. Mater. 2021, 401, 123848. [Google Scholar] [CrossRef] [PubMed]

- Cai, T.; Zhao, D.; Wang, B.; Li, J.W.; Guan, Y.H. NOx emission and thermal performances studies on premixed ammonia-oxygen combustion in a CO2-free micro-planar combustor. Fuel 2020, 280, 118554. [Google Scholar] [CrossRef]

- E, J.; Pham, M.; Zhao, D.; Deng, Y.; Le, D.; Zuo, W.; Zhu, H.; Liu, T.; Peng, Q.; Zhang, Z. Effect of different technologies on combustion and emissions of the diesel engine fueled with biodiesel: A review. Renew. Sustain. Energy Rev. 2017, 80, 620–647. [Google Scholar] [CrossRef]

- Zhang, B.; Zuo, H.; Huang, Z.; Tan, J.; Zuo, Q. Endpoint forecast of different diesel-biodiesel soot filtration process in diesel particulate filters considering ash deposition. Fuel 2020, 272, 117678. [Google Scholar] [CrossRef]

- E, J.; Zhao, M.; Zuo, Q.; Zhang, B.; Zhang, Z.; Peng, Q.; Han, D.; Zhao, X.; Deng, Y. Effects analysis on diesel soot continuous regeneration performance of a rotary microwave-assisted regeneration diesel particulate filter. Fuel 2020, 260, 116353. [Google Scholar] [CrossRef]

- Feng, C.; Deng, Y.; Chen, L.; Han, W.; E, J.; Wei, K.; Han, D.; Zhang, B. Hydrocarbon emission control of a hydrocarbon adsorber and converter under cold start of the gasoline engine. Energy 2022, 239, 122138. [Google Scholar] [CrossRef]

- Chen, L.; Deng, Y.; Feng, C.; Han, W.; E, J.; Wang, C.; Han, D.; Zhang, B. Effects of zeolite molecular sieve on the hydrocarbon adsorbent performance of gasoline engine of during cold start. Fuel 2022, 310, 122427. [Google Scholar] [CrossRef]

- E, J.; Luo, J.; Han, D.; Tan, Y.; Feng, C.; Deng, Y. Effects of different catalysts on light-off temperature of volatile organic components in the rotary diesel particulate filter during the regeneration. Fuel 2022, 310, 122451. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D.; Sun, Y.; Ni, S.; Li, W. Evaluation of NOx Emissions Characteristics in a CO2-Free Micro-Power System by Implementing a Perforated Plate. Renew. Sustain. Energy Rev. 2021, 145, 111150. [Google Scholar] [CrossRef]

| NO. | Reactions |

|---|---|

| R1 | |

| R2 | |

| R3 | |

| R4 | |

| R5 | |

| R6 |

| Parameter/Unit | Value |

|---|---|

| Cell density/cell/in−2 | 400 |

| Coating thickness/mm | 0.025 |

| Carrier length/mm | 20 |

| Temperature/K | 373–873 |

| Cu loading/wt% | 2 |

| Washcoat porosity | 0.5 |

| Pore diameter/nm | 0.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, S.; Zhang, J. Numerical Investigation on the Intraphase and Interphase Mass Transfer Limitations for NH3-SCR over Cu-ZSM-5. Processes 2021, 9, 1966. https://doi.org/10.3390/pr9111966

Yu S, Zhang J. Numerical Investigation on the Intraphase and Interphase Mass Transfer Limitations for NH3-SCR over Cu-ZSM-5. Processes. 2021; 9(11):1966. https://doi.org/10.3390/pr9111966

Chicago/Turabian StyleYu, Shiyong, and Jichao Zhang. 2021. "Numerical Investigation on the Intraphase and Interphase Mass Transfer Limitations for NH3-SCR over Cu-ZSM-5" Processes 9, no. 11: 1966. https://doi.org/10.3390/pr9111966

APA StyleYu, S., & Zhang, J. (2021). Numerical Investigation on the Intraphase and Interphase Mass Transfer Limitations for NH3-SCR over Cu-ZSM-5. Processes, 9(11), 1966. https://doi.org/10.3390/pr9111966